Desilicated ZSM-5 Zeolites for the Production of Renewable p-Xylene via Diels–Alder Cycloaddition of Dimethylfuran and Ethylene

Abstract

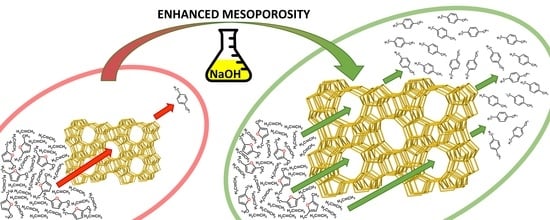

:1. Introduction

2. Results and Discussion

2.1. X-ray Diffraction

2.2. Surface Area and Porosity of the Materials

2.3. Acidity Masurements

2.4. Microscopy

2.5. 27Al MAS NMR

2.6. Catalytic Activity

2.6.1. General Considerations and Conversion

2.6.2. Products Selectivity

2.6.3. Increasing the Reaction Temperature and Catalyst Reusability

2.6.4. Mesoporosity vs Acidity

3. Materials and Methods

3.1. Materials

3.2. Catalyst Preparation

3.3. Catalytic Activity

3.4. Characterisation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lin, Z.; Ierapetritou, M.; Nikolakis, V. Aromatics from lignocellulosic biomass: Economic analysis of the production of p-xylene from 5-hydroxymethylfurfural. AIChE J. 2013, 59, 2079–2087. [Google Scholar] [CrossRef]

- Maneffa, A.; Priecel, P.; Lopez-Sanchez, J.A. Biomass-derived renewable aromatics: Selective routes and outlook for p-xylene commercialisation. ChemSusChem 2016, 9, 2736–2748. [Google Scholar] [CrossRef] [PubMed]

- Settle, A.E.; Berstis, L.; Rorrer, N.A.; Roman-Leshkov, Y.; Beckham, G.T.; Richards, R.M.; Vardon, D.R. Heterogeneous diels-alder catalysis for biomass-derived aromatic compounds. Green Chem. 2017, 19, 3468–3492. [Google Scholar] [CrossRef]

- Cheng, Y.T.; Huber, G.W. Production of targeted aromatics by using diels-alder classes of reactions with furans and olefins over zsm-5. Green Chem. 2012, 14, 3114–3125. [Google Scholar] [CrossRef]

- Brion, F. On the lewis acid catalyzed diels-alder reaction of furan. Regio- and stereospecific synthesis of substituted cyclohexenols and cyclohexadienols. Tetrahedron Lett. 1982, 23, 5299–5302. [Google Scholar] [CrossRef]

- Williams, C.L.; Chang, C.C.; Do, P.; Nikbin, N.; Caratzoulas, S.; Vlachos, D.G.; Lobo, R.F.; Fan, W.; Dauenhauer, P.J. Cycloaddition of biomass-derived furans for catalytic production of renewable p-xylene. ACS Catal. 2012, 2, 935–939. [Google Scholar] [CrossRef]

- Nikbin, N.; Do, P.T.; Caratzoulas, S.; Lobo, R.F.; Dauenhauer, P.J.; Vlachos, D.G. A dft study of the acid-catalyzed conversion of 2,5-dimethylfuran and ethylene to p-xylene. J. Catal. 2013, 297, 35–43. [Google Scholar] [CrossRef]

- Shiramizu, M.; Toste, F.D. On the diels-alder approach to solely biomass-derived polyethylene terephthalate (pet): Conversion of 2,5-dimethylfuran and acrolein into p-xylene. Chem.-Eur. J. 2011, 17, 12452–12457. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.C.; Green, S.K.; Williams, C.L.; Dauenhauer, P.J.; Fan, W. Ultra-selective cycloaddition of dimethylfuran for renewable p-xylene with h-bea. Green Chem. 2014, 16, 585–588. [Google Scholar] [CrossRef]

- Brandvold, T. Carbohydrate Route to Para-Xylene and Terephthalic Acid. U.S. Patent 8,314,267, 20 November 2012. [Google Scholar]

- Roman-Leshkov, Y.; Barrett, C.J.; Liu, Z.Y.; Dumesic, J.A. Production of dimethylfuran for liquid fuels from biomass-derived carbohydrates. Nature 2007, 447, U982–U985. [Google Scholar] [CrossRef] [PubMed]

- Patet, R.E.; Nikbin, N.; Williams, C.L.; Green, S.K.; Chang, C.-C.; Fan, W.; Caratzoulas, S.; Dauenhauer, P.J.; Vlachos, D.G. Kinetic regime change in the tandem dehydrative aromatization of furan diels–alder products. ACS Catal. 2015, 5, 2367–2375. [Google Scholar] [CrossRef]

- Rohling, R.Y.; Uslamin, E.; Zijlstra, B.; Tranca, I.C.; Filot, I.A.W.; Hensen, E.J.M.; Pidko, E.A. An active alkali-exchanged faujasite catalyst for p-xylene production via the one-pot diels–alder cycloaddition/dehydration reaction of 2,5-dimethylfuran with ethylene. ACS Catal. 2018, 8, 760–769. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-C.; Kim, T.-W.; Kim, Y.; Ryoo, R.; Jeong, S.-Y.; Kim, C.-U. Mesoporous mfi zeolites as high performance catalysts for diels-alder cycloaddition of bio-derived dimethylfuran and ethylene to renewable p-xylene. Appl. Catal. B Environ. 2017, 206, 490–500. [Google Scholar] [CrossRef]

- Patet, R.E.; Caratzoulas, S.; Vlachos, D.G. Tandem aromatization of oxygenated furans by framework zinc in zeolites. A computational study. J. Phys. Chem. C 2017, 121, 22178–22186. [Google Scholar] [CrossRef]

- Patet, R.E.; Fan, W.; Vlachos, D.G.; Caratzoulas, S. Tandem diels–alder reaction of dimethylfuran and ethylene and dehydration to para-xylene catalyzed by zeotypic lewis acids. ChemCatChem 2017, 9, 2523–2535. [Google Scholar] [CrossRef]

- Wijaya, Y.P.; Suh, D.J.; Jae, J. Production of renewable p-xylene from 2,5-dimethylfuran via diels-alder cycloaddition and dehydrative aromatization reactions over silica-alumina aerogel catalysts. Catal. Commun. 2015, 70, 12–16. [Google Scholar] [CrossRef]

- Nikbin, N.; Feng, S.; Caratzoulas, S.; Vlachos, D.G. P-xylene formation by dehydrative aromatization of a diels–alder product in lewis and brønsted acidic zeolites. J. Phys. Chem. C 2014, 118, 24415–24424. [Google Scholar] [CrossRef]

- Williams, C.L. Production of Sustainable Aromatics from Biorenewable Furans. Doctoral Dissertations, University of Massachusetts, Amherst, MA, USA, 2014. [Google Scholar]

- Moliner, M.; Martinez, C.; Corma, A. Multipore zeolites: Synthesis and catalytic applications. Angew. Chem. Int. Ed. 2015, 54, 3560–3579. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Choi, M.; Ryoo, R. Effect of mesoporosity against the deactivation of mfi zeolite catalyst during the methanol-to-hydrocarbon conversion process. J. Catal. 2010, 269, 219–228. [Google Scholar] [CrossRef]

- Groen, J.C.; Peffer, L.A.A.; Moulijn, J.A.; Perez-Ramirez, J. Mesoporosity development in zsm-5 zeolite upon optimized desilication conditions in alkaline medium. Colloid Surf. A 2004, 241, 53–58. [Google Scholar] [CrossRef]

- Dean, A.Y. Hydrocarbon Conversion Process and Catalyst Comprising a Crystalline Alumino-Silicate Leached with Sodium Hydroxide. US3326797 A, 20 June 1967. [Google Scholar]

- Verboekend, D.; Perez-Ramirez, J. Design of hierarchical zeolite catalysts by desilication. Catal. Sci. Technol. 2011, 1, 879–890. [Google Scholar] [CrossRef]

- Groen, J.C.; Moulijn, J.A.; Perez-Ramirez, J. Decoupling mesoporosity formation and acidity modification in zsm-5 zeolites by sequential desilication-dealumination. Microporous Mesoporous Mater. 2005, 87, 153–161. [Google Scholar] [CrossRef]

- Brunner, E.; Pfeifer, H.; Auroux, A.; Lercher, J.; Jentys, A.; Brait, A.; Garrone, E.; Fajula, F. Acidity and Basicity; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Rodriguez-Gonzalez, L.; Hermes, F.; Bertmer, M.; Rodriguez-Castellon, E.; Jimenez-Lopez, A.; Simon, U. The acid properties of h-zsm-5 as studied by nh3-tpd and al-27-mas-nmr spectroscopy. Appl. Catal. A Gen. 2007, 328, 174–182. [Google Scholar] [CrossRef]

- Rac, V.; Rakic, V.; Miladinovic, Z.; Stosic, D.; Auroux, A. Influence of the desilication process on the acidity of hzsm-5 zeolite. Thermochim. Acta 2013, 567, 73–78. [Google Scholar] [CrossRef]

- Sadowska, K.; Wach, A.; Olejniczak, Z.; Kustrowski, P.; Datka, J. Hierarchic zeolites: Zeolite zsm-5 desilicated with naoh and naoh/tetrabutylamine hydroxide. Microporous Mesoporous Mater. 2013, 167, 82–88. [Google Scholar] [CrossRef]

- Jiang, Y.J.; Huang, J.; Dai, W.L.; Hunger, M. Solid-state nuclear magnetic resonance investigations of the nature, property, and activity of acid sites on solid catalysts. Solid State Nucl. Mag. 2011, 39, 116–141. [Google Scholar] [CrossRef] [PubMed]

- Sklenak, S.; Dedecek, J.; Li, C.; Wichterlova, B.; Gabova, V.; Sierka, M.; Sauer, J. Aluminium siting in the zsm-5 framework by combination of high resolution al-27 nmr and dft/mm calculations. Phys. Chem. Chem. Phys. 2009, 11, 1237–1247. [Google Scholar] [CrossRef] [PubMed]

- Do, P.T.M.; McAtee, J.R.; Watson, D.A.; Lobo, R.F. Elucidation of diels-alder reaction network of 2,5-dimethylfuran and ethylene on hy zeolite catalyst. ACS Catal. 2013, 3, 41–46. [Google Scholar] [CrossRef] [PubMed]

- Salavati-fard, T.; Caratzoulas, S.; Doren, D.J. Solvent effects in acid-catalyzed dehydration of the diels-alder cycloadduct between 2,5-dimethylfuran and maleic anhydride. Chem. Phys. 2017, 485–486, 118–124. [Google Scholar] [CrossRef]

- Chang, C.-C.; Je Cho, H.; Yu, J.; Gorte, R.J.; Gulbinski, J.; Dauenhauer, P.; Fan, W. Lewis acid zeolites for tandem diels-alder cycloaddition and dehydration of biomass-derived dimethylfuran and ethylene to renewable p-xylene. Green Chem. 2016, 18, 1368–1376. [Google Scholar] [CrossRef]

- Li, Y.-P.; Head-Gordon, M.; Bell, A.T. Computational study of p-xylene synthesis from ethylene and 2,5-dimethylfuran catalyzed by h-bea. J. Phys. Chem. C 2014, 118, 22090–22095. [Google Scholar] [CrossRef]

- Wijaya, Y.P.; Kristianto, I.; Lee, H.; Jae, J. Production of renewable toluene from biomass-derived furans via diels-alder and dehydration reactions: A comparative study of lewis acid catalysts. Fuel 2016, 182, 588–596. [Google Scholar] [CrossRef]

- Fan, W.; Cho, H.J.; Ren, L.; Vattipailli, V.; Yeh, Y.-H.; Gould, N.G.; Xu, B.; Gorte, R.J.; Lobo, R.; Dauenhauer, P.J.; et al. Renewable p-xylene from 2,5-dimethylfuran and ethylene using phosphorus-containing zeolite catalysts. ChemCatChem 2016. [Google Scholar] [CrossRef]

- Yu, Z.; Li, S.; Wang, Q.; Zheng, A.; Jun, X.; Chen, L.; Deng, F. Brønsted/lewis acid synergy in h–zsm-5 and h–mor zeolites studied by 1h and 27al dq-mas solid-state nmr spectroscopy. J. Phys. Chem. C 2011, 115, 22320–22327. [Google Scholar] [CrossRef]

- Zheng, A.; Li, S.; Liu, S.-B.; Deng, F. Acidic properties and structure–activity correlations of solid acid catalysts revealed by solid-state nmr spectroscopy. Acc. Chem. Res. 2016, 49, 655–663. [Google Scholar] [CrossRef] [PubMed]

- Houk, K.N.; Strozier, R.W. Lewis acid catalysis of diels-alder reactions. J. Am. Chem. Soc. 1973, 95, 4094–4096. [Google Scholar] [CrossRef]

- Birney, D.M.; Houk, K.N. Transition structures of the lewis acid-catalyzed diels-alder reaction of butadiene with acrolein—The origins of selectivity. J. Am. Chem. Soc. 1990, 112, 4127–4133. [Google Scholar] [CrossRef]

| Catalyst | SBet (m2 g−1) a | Vtotal b (cm3 g−1) | Vmicro c (cm3 g−1) | Smeso c (m2 g−1) | Crystallinity (%) d | SiO2/Al2O3 Ratio e | Total Acid Sites, μmol g−1 f | Weak Acid Sites, μmol g−1 f | Strong Acid Sites, μmol g−1 f | Brønsted Acid Sites, μmol g−1 g | Lewis Acid Sites, μmol g−1 g |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PZ30 | 344 | 0.250 | 0.147 | 142 | 100 | 28 | 581 | 165 | 416 | 295 | 286 |

| Z30.2 | 340 | 0.315 | 0.147 | 181 | 92 | 24 | 655 | 205 | 450 | 163 | 492 |

| Z30.4 | 340 | 0.397 | 0.148 | 216 | 87 | 21 | 692 | 266 | 426 | 337 | 355 |

| PZ80 | 376 | 0.253 | 0.165 | 131 | 100 | 72 | 333 | 55 | 278 | 166 | 167 |

| Z80.2 | 327 | 0.454 | 0.143 | 224 | 84 | 50 | 369 | 109 | 260 | 24 | 345 |

| Z80.4 | 312 | 0.734 | 0.122 | 260 | 31 | 31 | 504 | 260 | 244 | 368 | 136 |

| SAMPLE | Ratio of Peaks at 54 to 0 ppm | Normalised Areas at Peak Positions | |

|---|---|---|---|

| 54 ppm | 0 ppm | ||

| PZ30 | 17.8 | 0.947 | 0.053 |

| Z30.2 | 11.9 | 0.923 | 0.077 |

| Z30.4 | 11.1 | 0.917 | 0.083 |

| PZ80 | 63.7 | 0.985 | 0.015 |

| Z80.2 | 42.5 | 0.977 | 0.023 |

| Z80.4 | 4.7 | 0.823 | 0.177 |

| Test Description | X | S(p-Xylene) | S(HDO) | S(MCP) | S(AP) | S(HA) | Carbon Mass Balance |

|---|---|---|---|---|---|---|---|

| fresh | 42.9 | 50.1 | 13.9 | 0.8 | 16.0 | 19.2 | 93.2 |

| reuse 1 * | 41.4 | 51.6 | 13.7 | 0.5 | 17.9 | 16.3 | 95.5 |

| reuse 2 | 42.4 | 48.8 | 14.5 | 0.6 | 16.0 | 20.2 | 92.6 |

| reuse 3 | 41.7 | 48.9 | 14.7 | 0.5 | 14.8 | 21.2 | 94.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

McGlone, J.; Priecel, P.; Da Vià, L.; Majdal, L.; Lopez-Sanchez, J.A. Desilicated ZSM-5 Zeolites for the Production of Renewable p-Xylene via Diels–Alder Cycloaddition of Dimethylfuran and Ethylene. Catalysts 2018, 8, 253. https://doi.org/10.3390/catal8060253

McGlone J, Priecel P, Da Vià L, Majdal L, Lopez-Sanchez JA. Desilicated ZSM-5 Zeolites for the Production of Renewable p-Xylene via Diels–Alder Cycloaddition of Dimethylfuran and Ethylene. Catalysts. 2018; 8(6):253. https://doi.org/10.3390/catal8060253

Chicago/Turabian StyleMcGlone, Joel, Peter Priecel, Luigi Da Vià, Liqaa Majdal, and Jose A. Lopez-Sanchez. 2018. "Desilicated ZSM-5 Zeolites for the Production of Renewable p-Xylene via Diels–Alder Cycloaddition of Dimethylfuran and Ethylene" Catalysts 8, no. 6: 253. https://doi.org/10.3390/catal8060253