A Porous Cobalt (II) Metal–Organic Framework with Highly Efficient Electrocatalytic Activity for the Oxygen Evolution Reaction

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Methods

2.2. Synthesis of [Co1.5(tib)(dcpna)]·6H2O (1)

2.3. X-ray Crystallography

2.4. Experiment for Electrochemical Measurements

2.5. Calculation Method of the Turnover Frequency (TOF)

3. Results and Discussion

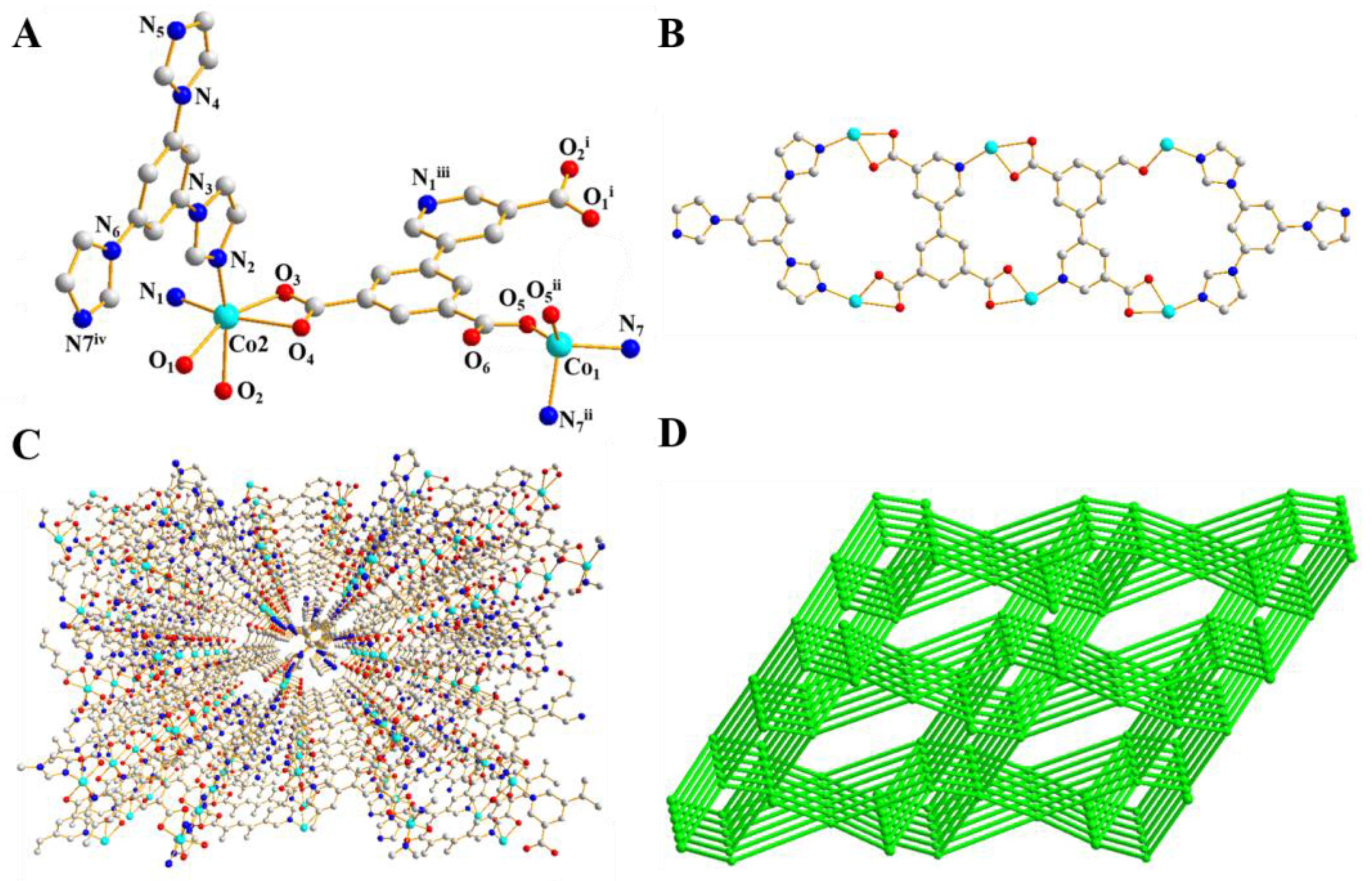

3.1. X-ray Single Crystal Structure

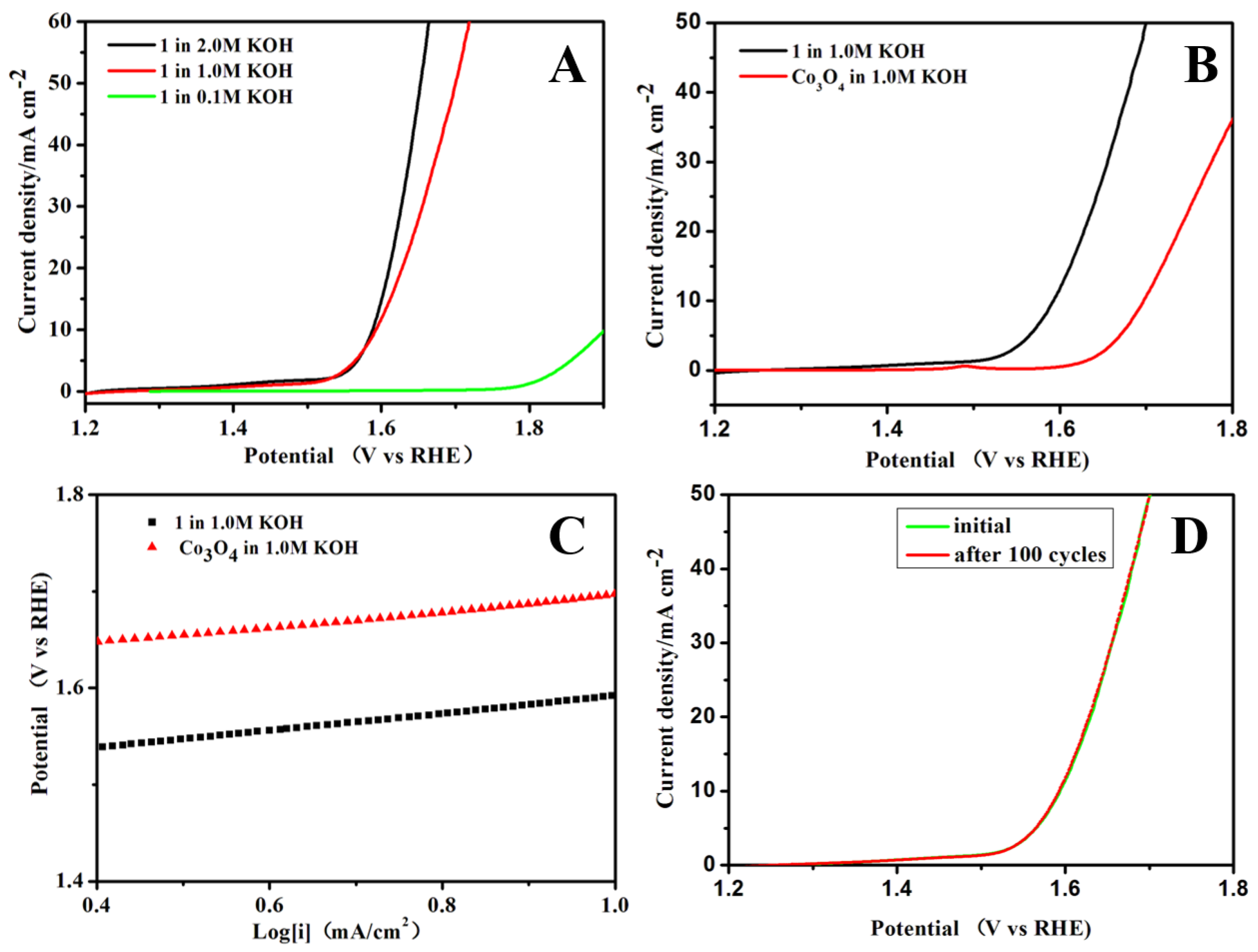

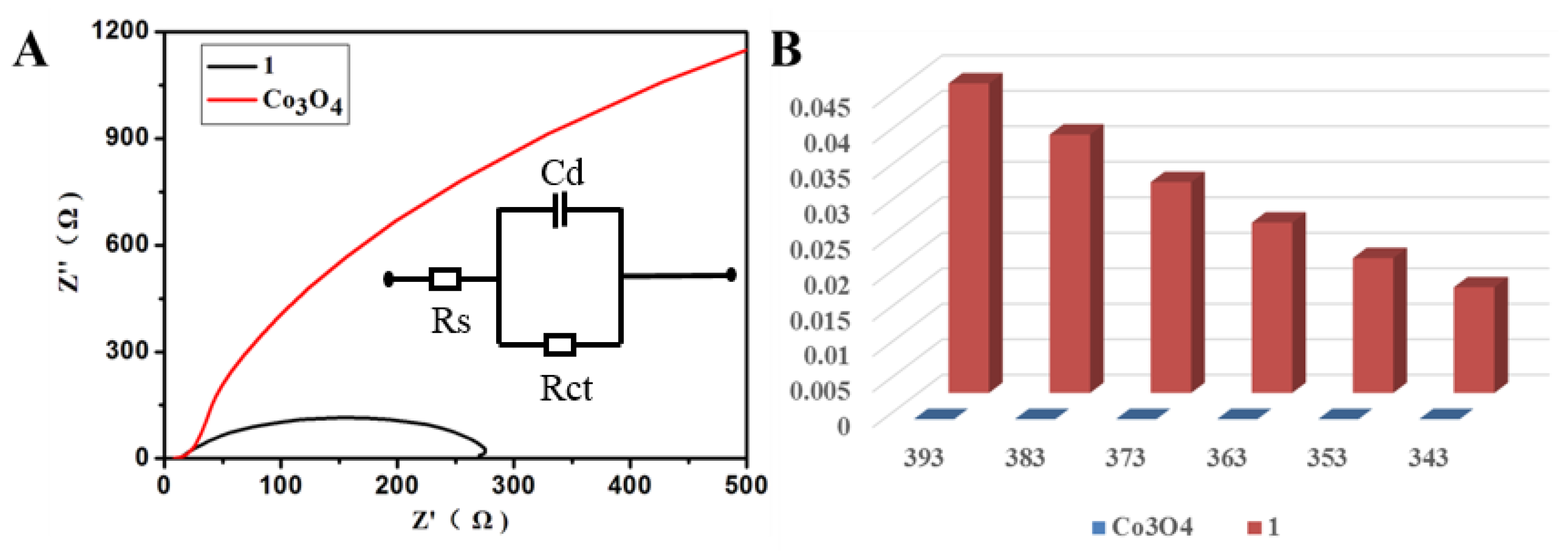

3.2. Electrocatalytic Activity

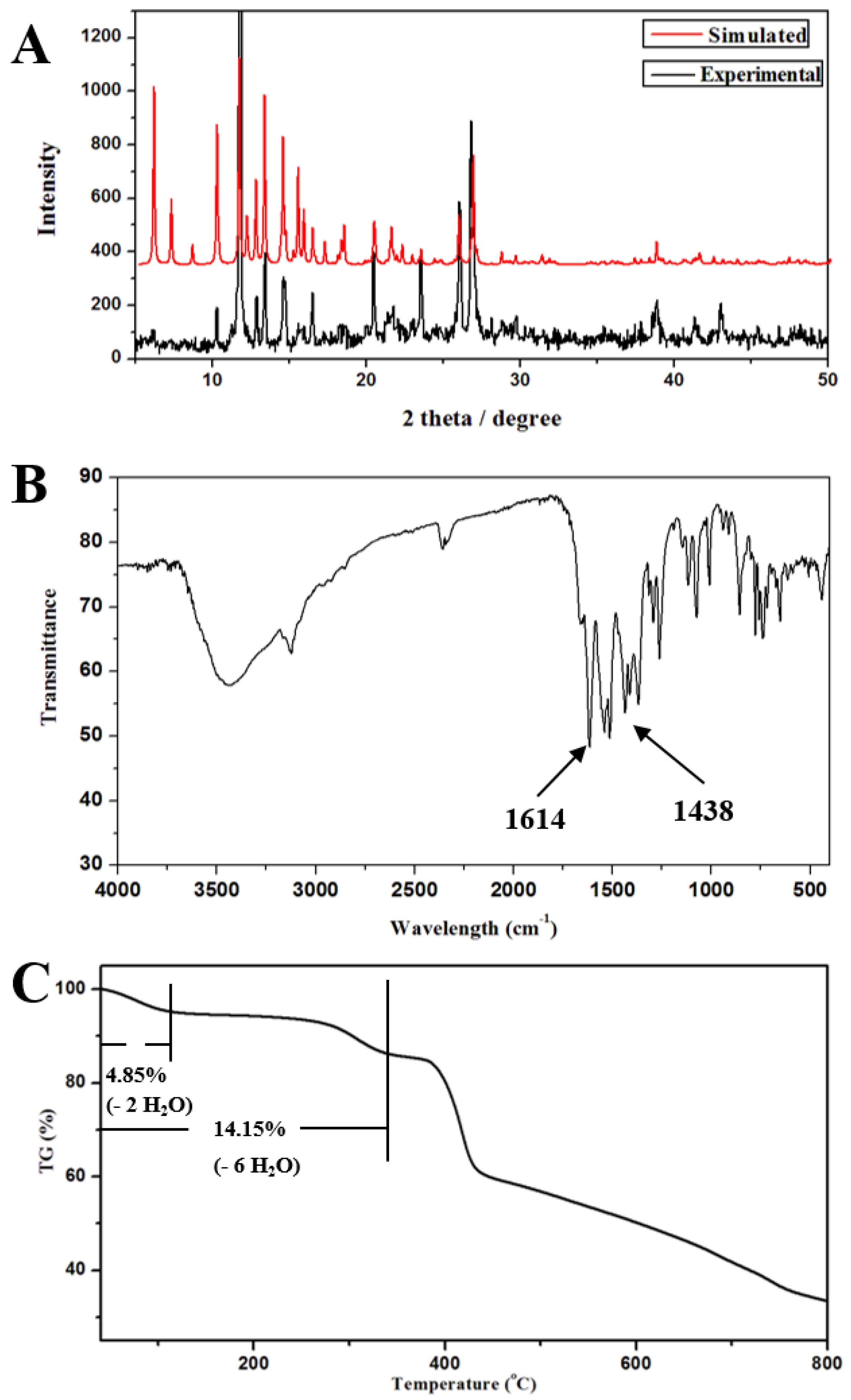

3.3. X-ray Powder Diffraction Analyses, IR Spectra and Thermal Analyses

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, J.; Zhou, P.; Li, F.; Ren, R.; Liu, Y.; Niu, J.; Ma, J.; Zhang, X.; Tian, M.; Jin, J.; et al. Ni@Pd/PEI-rGO stack structures with controllable Pd shell thickness as advanced electrodes for efficient hydrogen evolution. J. Mater. Chem. A 2015, 3, 11261–11268. [Google Scholar] [CrossRef]

- Li, F.; Zhang, L.; Li, J.; Lin, X.; Li, X.; Fang, Y.; Huang, J.; Li, W.; Tian, M.; Jin, J.; et al. Synthesis of Cu-MoS2/rGO hybrid as non-noble metal electrocatalysts for the hydrogen evolution reaction. J. Power Sources 2015, 292, 15–22. [Google Scholar] [CrossRef]

- Suen, N.T.; Hung, S.F.; Quan, Q.; Zhang, N.; Xu, Y.J.; Chen, H.M. Electrocatalysis for the oxygen evolution reaction: Recent development and future perspectives. Chem. Soc. Rev. 2017, 46, 337–365. [Google Scholar] [CrossRef] [PubMed]

- Gong, M.; Dai, H. A mini review of NiFe-based materials as highly active oxygen evolution reaction electrocatalysts. Nano Res. 2015, 8, 23–39. [Google Scholar] [CrossRef]

- Meng, Y.; Song, W.; Huang, H.; Ren, Z.; Chen, S.; Suib, S. Structure-Property Relationship of Bifunctional MnO2 Nanostructures: Highly Efficient, Ultra-Stable Electrochemical Water Oxidation and Oxygen Reduction Reaction Catalysts Identified in Alkaline Media. J. Am. Chem. Soc. 2014, 136, 11452–11464. [Google Scholar] [CrossRef] [PubMed]

- Gong, M.; Zhou, W.; Tsai, M.C.; Zhou, J.; Guan, M.; Lin, M.C.; Zhang, B.; Hu, Y.; Wang, D.Y.; Yang, J.; et al. Nanoscale nickel oxide/nickel heterostructures for active hydrogen evolution electrocatalysis. Nat. Commun. 2014, 5, 4695–4701. [Google Scholar] [CrossRef] [PubMed]

- Morales-Guio, C.G.; Stern, L.A.; Hu, X. Nanostructured hydrotreating catalysts for electrochemical hydrogen evolution. Chem. Soc. Rev. 2014, 43, 6555–6569. [Google Scholar] [CrossRef] [PubMed]

- Cook, T.R.; Dogutan, D.K.; Reece, S.Y.; Surendranath, Y.; Teets, T.S.; Nocera, D.G. Solar Energy Supply and Storage for the Legacy and Nonlegacy Worlds. Chem. Rev. 2010, 110, 6474–6502. [Google Scholar] [CrossRef] [PubMed]

- Suntivich, J.; May, K.J.; Gasteiger, H.A.; Goodenough, J.B.; Shao-Horn, Y. A Perovskite Oxide Optimized for Oxygen Evolution Catalysis from Molecular Orbital Principles. Science 2011, 334, 1383–1385. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Nakamura, R.; Kamiya, K.; Nakanishi, S.; Hashimoto, K. Nitrogen-doped carbon nanomaterials as non-metal electrocatalysts for water oxidation. Nat. Commun. 2013, 4, 2390. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.Y.; Dai, S.; Jaroniec, M.; Qiao, S.Z. Graphitic Carbon Nitride Nanosheet-Carbon Nanotube Three-Dimensional Porous Composites as High-Performance Oxygen Evolution Electrocatalysts. Angew. Chem. Int. Ed. 2014, 53, 7281–7285. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.; Wen, Z.; Cui, S.; Ci, S.; Mao, S.; Chen, J. An Advanced Nitrogen-Doped Graphene/Cobalt-Embedded Porous Carbon Polyhedron Hybrid for Efficient Catalysis of Oxygen Reduction and Water Splitting. Adv. Funct. Mater. 2015, 25, 872–882. [Google Scholar] [CrossRef]

- Blakemore, J.D.; Crabtree, R.H.; Brudvig, G.W. Molecular Catalysts for Water Oxidation. Chem. Rev. 2015, 115, 12974–13005. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.; Dai, S.; Jaroniec, M.; Qiao, S. Metal-Organic Framework Derived Hybrid Co3O4-Carbon Porous Nanowire Arrays as Reversible Oxygen Evolution Electrodes. J. Am. Chem. Soc. 2014, 136, 13925–13931. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Xu, K.; Tong, Y.; Li, X.; Tao, S.; Fang, Z.; Chu, W.; Wua, X.; Wu, C. Cobalt nitrides as a class of metallic electrocatalysts for the oxygen evolution reaction. Inorg. Chem. Front. 2016, 3, 236–242. [Google Scholar] [CrossRef]

- Frydendal, R.; Paoli, E.A.; Knudsen, B.P.; Wickman, B.; Malacrida, P.; Stephens, I.E.L.; Chorkendorff, I. Benchmarking the Stability of Oxygen Evolution Reaction Catalysts: The Importance of Monitoring Mass Losses. ChemElectroChem 2014, 1, 2075–2081. [Google Scholar] [CrossRef]

- Lee, Y.; Suntivich, J.; May, K.J.; Perry, E.E.; Shao-Horn, Y. Synthesis and Activities of Rutile IrO2 and RuO2 Nanoparticles for Oxygen Evolution in Acid and Alkaline Solutions. J. Phys. Chem. Lett. 2012, 3, 399–404. [Google Scholar] [CrossRef] [PubMed]

- Reier, T.; Oezaslan, M.; Strasser, P. Electrocatalytic Oxygen Evolution Reaction (OER) on Ru, Ir, and Pt Catalysts: A Comparative Study of Nanoparticles and Bulk Materials. ACS Catal. 2012, 2, 1765–1772. [Google Scholar] [CrossRef]

- Vuković, M. Oxygen evolution reaction on thermally treated iridium oxide films. J. Appl. Electrochem. 1987, 17, 737–745. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, H.; Kong, D.; Yan, K.; Hsu, P.C.; Zheng, G.; Yao, H.; Liang, Z.; Sun, X.; Cui, Y. Electrochemical tuning of layered lithium transition metal oxides for improvement of oxygen evolution reaction. Nat. Commun. 2014, 5, 4345. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Gao, S.; Lei, F.; Liu, J.; Liang, L.; Xie, Y. Atomically-thin non-layered cobalt oxide porous sheets for highly efficient oxygen-evolving electrocatalysts. Chem. Sci. 2014, 5, 3976–3982. [Google Scholar] [CrossRef]

- Gao, M.; Sheng, W.; Zhuang, Z.; Fang, Q.; Gu, S.; Jiang, J.; Yan, Y. Efficient Water Oxidation Using Nanostructured α-Nickel-Hydroxide as an Electrocatalyst. J. Am. Chem. Soc. 2014, 136, 7077. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.I.; Jeong, H.Y.; Lee, J.S.; Kim, M.G.; Cho, J. A Bifunctional Perovskite Catalyst for Oxygen Reduction and Evolution. Angew. Chem. Int. Ed. 2014, 53, 4582–4586. [Google Scholar] [CrossRef] [PubMed]

- Delgado, D.; Minakshi, M.; McGinnity, J.; Kim, D. Co/Mo bimetallic addition to electrolytic manganese dioxide for oxygen generation in acid medium. Sci. Rep. 2015, 5, 15208. [Google Scholar] [CrossRef] [PubMed]

- Delgado, D.; Minakshi, M.; Senanayake, G.; Kim, D. Modified electrolytic manganese dioxide (MEMD) for oxygen generation in alkaline medium. J. Solid State Electr. 2015, 19, 1133–1142. [Google Scholar] [CrossRef]

- Qu, K.; Zheng, Y.; Dai, S.; Qiao, S. Graphene oxide-polydopamine derived N, S-codoped carbon nanosheets as superior bifunctional electrocatalysts for oxygen reduction and evolution. Nano Energy 2016, 19, 373–381. [Google Scholar] [CrossRef]

- Long, X.; Li, J.; Xiao, S.; Yan, K.; Wang, Z.; Chen, H.; Yang, S. A Strongly Coupled Graphene and FeNi Double Hydroxide Hybrid as an Excellent Electrocatalyst for the Oxygen Evolution Reaction. Angew. Chem. Int. Ed. 2014, 53, 7584–7588. [Google Scholar] [CrossRef] [PubMed]

- Suntivich, J.; Gasteiger, H.A.; Yabuuchi, N.; Nakanishi, H.; Goodenough, J.B.; Shao-Horn, Y. Design principles for oxygen-reduction activity on perovskite oxide catalysts for fuel cells and metal-air batteries. Nat. Chem. 2011, 3, 546–550. [Google Scholar] [CrossRef] [PubMed]

- Deria, P.; Gomez-Gualdróń, D.A.; Hod, I.; Snurr, R.Q.; Hupp, J.T.; Farha, O.K. Framework-Topology-Dependent Catalytic Activity of Zirconium-Based (Porphinato) zinc(II) MOFs. J. Am. Chem. Soc. 2016, 138, 14449–14457. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Feng, D.; Liu, T.; Su, J.; Yuan, S.; Chen, Y.; Bosch, M.; Zou, X.; Zhou, H. A Series of Highly Stable Mesoporous Metalloporphyrin Fe-MOFs. J. Am. Chem. Soc. 2014, 136, 13983–13986. [Google Scholar] [CrossRef] [PubMed]

- Shen, K.; Chen, L.; Long, J.; Zhong, W.; Li, Y. MOFs-Templated Co@Pd Core-Shell NPs Embedded in N-Doped Carbon Matrix with Superior Hydrogenation Activities. ACS Catal. 2015, 5, 5264–5271. [Google Scholar] [CrossRef]

- Vilhelmsen, L.B.; Walton, K.S.; Sholl, D.S. Structure and Mobility of Metal Clusters in MOFs: Au, Pd, and AuPd Clusters in MOF-74. J. Am. Chem. Soc. 2012, 134, 12807–12816. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Wang, Z.; Xu, Y.; Dai, F.; Zhang, L.; Sun, D. Porous Zirconium Metal-Organic Framework Constructed from 2D→3D Interpenetration Based on a 3,6-Connected kgd Net. Inorg. Chem. 2014, 53, 7086–7088. [Google Scholar] [CrossRef] [PubMed]

- Qin, J.S.; Du, D.Y.; Guan, W.; Bo, X.J.; Li, Y.F.; Guo, L.P.; Su, Z.M.; Wang, Y.Y.; Lan, Y.Q.; Zhou, H.C. Ultrastable Polymolybdate-Based Metal-Organic Frameworks as Highly Active Electrocatalysts for Hydrogen Generation from Water. J. Am. Chem. Soc. 2015, 137, 7169–7177. [Google Scholar] [CrossRef] [PubMed]

- Dai, F.; Fan, W.; Bi, J.; Jiang, P.; Liu, D.; Zhang, X.; Lin, H.; Gong, C.; Wang, R.; Zhang, L.; et al. A lead-porphyrin metal–organic framework: Gas adsorption properties and electrocatalytic activity for water oxidation. Dalton Trans. 2016, 45, 61–65. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wu, Y.; Cao, R.; Ren, L.; Chen, M.; Feng, X.; Zhou, J.; Wang, B. Fe/Ni Metal-Organic Frameworks and Their Binder-Free Thin Films for Efficient Oxygen Evolution with Low Overpotential. ACS Appl. Mater. Interfaces 2016, 8, 16736–16743. [Google Scholar] [CrossRef] [PubMed]

- Bruker. SMART, SAINT and SADABS; Bruker AXS Inc.: Madison, WI, USA, 1998. [Google Scholar]

- Sheldrick, G.M. SHELXS-97, Program for X-ray Crystal Structure Determination; University of Gottingen: Gottingen, Germany, 1997. [Google Scholar]

- Sheldrick, G.M. SHELXL-97, Program for X-ray Crystal Structure Refinement; University of Gottingen: Gottingen, Germany, 1997. [Google Scholar]

- Spek, A.L. PLATON, A Multipurpose Crystallographic Tool; Utrecht University: Utrecht, The Netherlands, 2002. [Google Scholar]

- Zhang, L.; Liu, F.; Guo, Y.; Wang, X.; Guo, J.; Wei, Y.; Chen, Z.; Sun, D. Crystal Structure Diversities Based on 4,4′-(2,3,6,7-Tetramethoxyanthracene-9,10-diyl)dibenzoic Acid: From 2D Layer to 3D Net Framework. Cryst. Growth Des. 2012, 12, 6215–6222. [Google Scholar] [CrossRef]

- Zou, K.; Liu, Y.; Jiang, Y.; Yu, C.; Yue, M.; Li, Z. Benzoate Acid-Dependent Lattice Dimension of Co-MOFs and MOF-Derived CoS2@CNTs with Tunable Pore Diameters for Supercapacitors. Inorg. Chem. 2017, 56, 6184–6196. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Huang, L.; Liu, X.; Ai, L. Bioinspired Cobalt-Citrate Metal-Organic Framework as an Efficient Electrocatalyst for Water Oxidation. ACS Appl. Mater. Interfaces 2017, 9, 7193–7201. [Google Scholar] [CrossRef] [PubMed]

- Cheng, N.; Liu, Q.; Asiri, A.M.; Xing, W.; Sun, X. A Fe-doped Ni3S2 particle film as a high-efficiency robust oxygen evolution electrode with very high current density. J. Mater. Chem. A 2015, 3, 23207–23212. [Google Scholar] [CrossRef]

- Lu, X.F.; Liao, P.Q.; Wang, J.W.; Wu, J.X.; Chen, X.W.; He, C.T.; Zhang, J.P.; Li, G.R.; Chen, X.M. An Alkaline-Stable, Metal Hydroxide Mimicking Metal-Organic Framework for Efficient Electrocatalytic Oxygen Evolution. J. Am. Chem. Soc. 2016, 138, 8336–8339. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Hou, Y.; Lin, S.; Wang, X. Water Oxidation Electrocatalysis by a Zeolitic Imidazolate Framework. Nanoscale 2014, 6, 9930–9934. [Google Scholar] [CrossRef] [PubMed]

- Aiyappa, H.B.; Thote, J.; Shinde, D.B.; Banerjee, R.; Kurungot, S. Cobalt-Modified Covalent Organic Framework as a Robust Water Oxidation Electrocatalyst. Chem. Mater. 2016, 28, 4375–4379. [Google Scholar] [CrossRef]

- Wurster, B.; Grumelli, D.; Hotger, D.; Gutzler, R.; Kern, K. Driving the Oxygen Evolution Reaction by Nonlinear Cooperativity in Bimetallic Coordination Catalysts. J. Am. Chem. Soc. 2016, 138, 3623–3626. [Google Scholar] [CrossRef] [PubMed]

- Manna, P.; Debgupta, J.; Bose, S.; Das, S.K. A Mononuclear CoII Coordination Complex Locked in a Confined Space and Acting as an Electrochemical Water-Oxidation Catalyst: A “Ship-in-a-Bottle” Approach. Angew. Chem. Int. Ed. 2016, 55, 2425–2430. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.; Canaff, C.; Rousseau, J.; Arrii-Clacens, S.; Napporn, T.W.; Habrioux, A.; Kokoh, K.B. Effect of the Oxide-Carbon Heterointerface on the Activity of Co3O4/NRGO Nanocomposites toward ORR and OER. J. Phys. Chem. C 2016, 120, 7949–7958. [Google Scholar] [CrossRef]

- Zhu, Y.P.; Ma, T.Y.; Jaroniec, M.; Qiao, S.Z. Self-Templating Synthesis of Hollow Co3O4 Microtube Arrays for Highly Efficient Water Electrolysis. Angew. Chem. Int. Ed. 2017, 56, 1324–1328. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Jiang, Q.; Xiao, Z.; Li, X.; Huo, J.; Wang, S.; Dai, L. Plasma-Engraved Co3O4 Nanosheets with Oxygen Vacancies and High Surface Area for the Oxygen Evolution Reaction. Angew. Chem. Int. Ed. 2016, 55, 5277–5281. [Google Scholar] [CrossRef] [PubMed]

- Ge, R.; Du, H.; Tao, K.; Zhang, Q.; Chen, L. Cobalt-Borate Nanoarray: An Efficient and Durable Electrocatalyst for Water Oxidation under Benign Conditions. ACS Appl. Mater. Interfaces 2017, 9, 15383–15387. [Google Scholar] [CrossRef] [PubMed]

- Dutta, A.; Samantara, A.K.; Dutta, S.K.; Jena, B.; Pradhan, N. Surface-Oxidized Dicobalt Phosphide Nanoneedles as a Nonprecious, Durable, and Efficient OER Catalyst. ACS Energy Lett. 2016, 1, 169–174. [Google Scholar] [CrossRef]

- Liang, H.; Meng, F.; Cabán-Acevedo, M.; Li, L.; Forticaux, A.; Xiu, L.; Wang, Z.; Jin, S. Hydrothermal Continuous Flow Synthesis and Exfoliation of NiCo Layered Double Hydroxide Nanosheets for Enhanced Oxygen Evolution Catalysis. Nano Lett. 2015, 15, 1421–1427. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Li, J. Cobalt Phosphide Hollow Polyhedron as Efficient Bifunctional Electrocatalysts for the Evolution Reaction of Hydrogen and Oxygen. ACS Appl. Mater. Interfaces 2016, 8, 2158–2165. [Google Scholar] [CrossRef] [PubMed]

- Delgado, D.; Minakshi1, M.; Kim, D. Electrochemical Impedance Spectroscopy Studies on Hydrogen Evolution from Porous Raney Cobalt in Alkaline Solution. Int. J. Electrochem. Sci. 2015, 10, 9379–9394. [Google Scholar]

- Wang, H.; Yin, F.; Li, G.; Chen, B.; Wang, Z. Preparation, Characterization and Bifunctional Catalytic Properties of MOF(Fe/Co) Catalyst for Oxygen Reduction/Evolution Reactions in Alkaline Electrolyte. Int. J. Hydrogen Energy 2014, 39, 16179–16186. [Google Scholar] [CrossRef]

- Ramkumar, R.; Minakshi, M. Fabrication of ultrathin CoMoO4 nanosheets modified with chitosan and their improved performance in energy storage device. Dalton Trans. 2015, 44, 6158–6168. [Google Scholar] [CrossRef] [PubMed]

| Complex | 1 |

|---|---|

| Empirical formula | C29H18Co1.5N7O6 |

| Formula weight | 648.90 |

| Temperature/K | 293(2) |

| Crystal system | monoclinic |

| Space group | C2/c |

| a/Å | 35.366(7) |

| b/Å | 9.2025(18) |

| c/Å | 25.003(5) |

| α/° | 90.00 |

| β/° | 124.34(3) |

| γ/° | 90.00 |

| Volume/Å3 | 6719(2) |

| Z | 8 |

| ρcalcg/cm3 | 1.283 |

| μ/mm−1 | 0.797 |

| F(000) | 2636.0 |

| Crystal size/mm3 | 0.29 × 0.25 × 0.18 |

| Radiation | MoKα (λ = 0.71000) |

| 2Θ range for data collection/° | 6.08 to 54.9 |

| Index ranges | −45 ≤ h ≤ 45, −11 ≤ k ≤ 9, −32 ≤ l ≤ 31 |

| Reflections collected | 31073 |

| Independent reflections | 7671 [Rint = 0.0698, Rsigma = 0.0717] |

| Data/restraints/parameters | 7671/0/393 |

| Goodness-of-fit on F2 | 1.012 |

| Final R indexes [I ≥ 2σ (I)] | R1 = 0.0547, wR2 = 0.1418 |

| Final R indexes [all data] | R1 = 0.0959, wR2 = 0.1685 |

| Largest diff. peak/hole/e Å−3 | 0.53/−0.58 |

| Co1-O5 | 1.993(3) | Co1-N7 | 2.047(3) | Co2-O3 | 2.059(2) |

| Co2-O1 | 2.128(2) | Co2-O4 | 2.296(3) | Co2-O2 | 2.194(3) |

| Co2-N1 | 2.092(3) | O5 1-Co1-O5 | 126.18(17) | O5-Co1-N7 1 | 108.31(12) |

| O5 1-Co1-N7 1 | 106.78(12) | N7 1-Co1-N7 | 96.47(17) | O3-Co2-O1 | 157.03(12) |

| O3-Co2-O4 | 60.35(9) | O3-Co2-O2 | 101.56(11) | O3-Co2-N1 | 96.76(11) |

| O1-Co2-O4 | 103.00(10) | O1-Co2-O2 | 60.64(10) | O2-Co2-O4 | 90.64(11) |

| N1-Co2-O1 | 98.04(11) | N1-Co2-O4 | 156.94(10) | N1-Co2-O2 | 91.53(12) |

| N2-Co2-O3 | 97.93(11) | N2-Co2-O1 | 97.79(11) | N2-Co2-O4 | 90.13(11) |

| N2-Co2-O2 | 157.97(11) | N2-Co2-N1 | 96.31(12) |

| Catalysts | Overpotential@10 mA mA·cm−2 (mV) | Tafel slope (mV·dec−1) | Electrolyte | Substrate | References |

|---|---|---|---|---|---|

| MAFX27-OH | 387 | 60 | 1 M KOH | Glassy Carbon | [45] |

| UTSA-16 | 410 | 40 | 1 M KOH | Glassy Carbon | [43] |

| Co-ZIF | 510@1 mA·cm−2 | 193 | pH = 13.4 | FTO | [46] |

| Co-TpBpy | 400@1 mA mA·cm−2 | / | pH = 7.0 | Glassy Carbon | [47] |

| CoTPyP | 400@1 mA mA·cm−2 | / | 0.1 M NaOH | FTO | [48] |

| Co-WOC-1 | 390@1 mA mA·cm−2 | 128 | 0.1 M KOH | Au(111) single-crystal | [49] |

| Co3O4/NRGO | 420 | 83 | 1 M KOH | Glassy Carbon | [50] |

| hollow Co3O4 microtubes | 290 | 84 | 1 M KOH | Ni foam | [51] |

| Co3O4 nanosheets | 300 | 68 | 0.1 M KOH | Ti foil | [52] |

| Co-Bi nanoarray | 411 | 166 | 0.1 M K-Bi | Carbon cloth | [53] |

| Co2P nanoneedles | 310 | 50 | 1 M KOH | Glassy Carbon | [54] |

| NiCo LDH | 367 | 40 | 1 M KOH | Carbon paper | [55] |

| CoP | 400 | 57 | 1 M KOH | Glassy Carbon | [56] |

| Pb-TCPP | 470 | 106 | 1 M KOH | Glassy Carbon | [35] |

| Fe/Ni-BTC@NF | 270 | 47 | 0.1 M KOH | Nickel foam | [36] |

| Co-MOF | 360 | 89 | 1 M KOH | Glassy Carbon | Present work |

| Material | Rs (Ω) | Rct (Ω) | Cdl (mF) |

|---|---|---|---|

| 1 | 13.4 | 247.0 | 118 |

| Co3O4 | 14.1 | 408.6 | 0.56 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Q.; Yang, J.; Ma, S.; Zhai, M.; Lu, J. A Porous Cobalt (II) Metal–Organic Framework with Highly Efficient Electrocatalytic Activity for the Oxygen Evolution Reaction. Polymers 2017, 9, 676. https://doi.org/10.3390/polym9120676

Meng Q, Yang J, Ma S, Zhai M, Lu J. A Porous Cobalt (II) Metal–Organic Framework with Highly Efficient Electrocatalytic Activity for the Oxygen Evolution Reaction. Polymers. 2017; 9(12):676. https://doi.org/10.3390/polym9120676

Chicago/Turabian StyleMeng, Qingguo, Jianjian Yang, Shixuan Ma, Mujun Zhai, and Jitao Lu. 2017. "A Porous Cobalt (II) Metal–Organic Framework with Highly Efficient Electrocatalytic Activity for the Oxygen Evolution Reaction" Polymers 9, no. 12: 676. https://doi.org/10.3390/polym9120676