A Review of Hologram Storage and Self-Written Waveguides Formation in Photopolymer Media

Abstract

:1. Introduction

2. Photopolymers

2.1. Photopolymer Materials Modeling and Applications

2.2. Material Composition; and Preparation of the Hologram Layer and SWW Bulk

- (a)

- Ten grams of PVA was added to 100 cm3 of deionized water and dissolved using a heater/stirrer. This solution is then allowed to cool and 70 cm3 of this solution is transferred into a beaker.

- (b)

- Triethanolamine (TEA) (8 cm3) electron donor was added to the PVA solution and stirred thoroughly.

- (c)

- Acrylamide (AA) (2.4 g) and bis-acrylamide (BA) (0.8 g) were added to the PVA solution under a fume cupboard conditions and stirred until completely dissolved.

- (d)

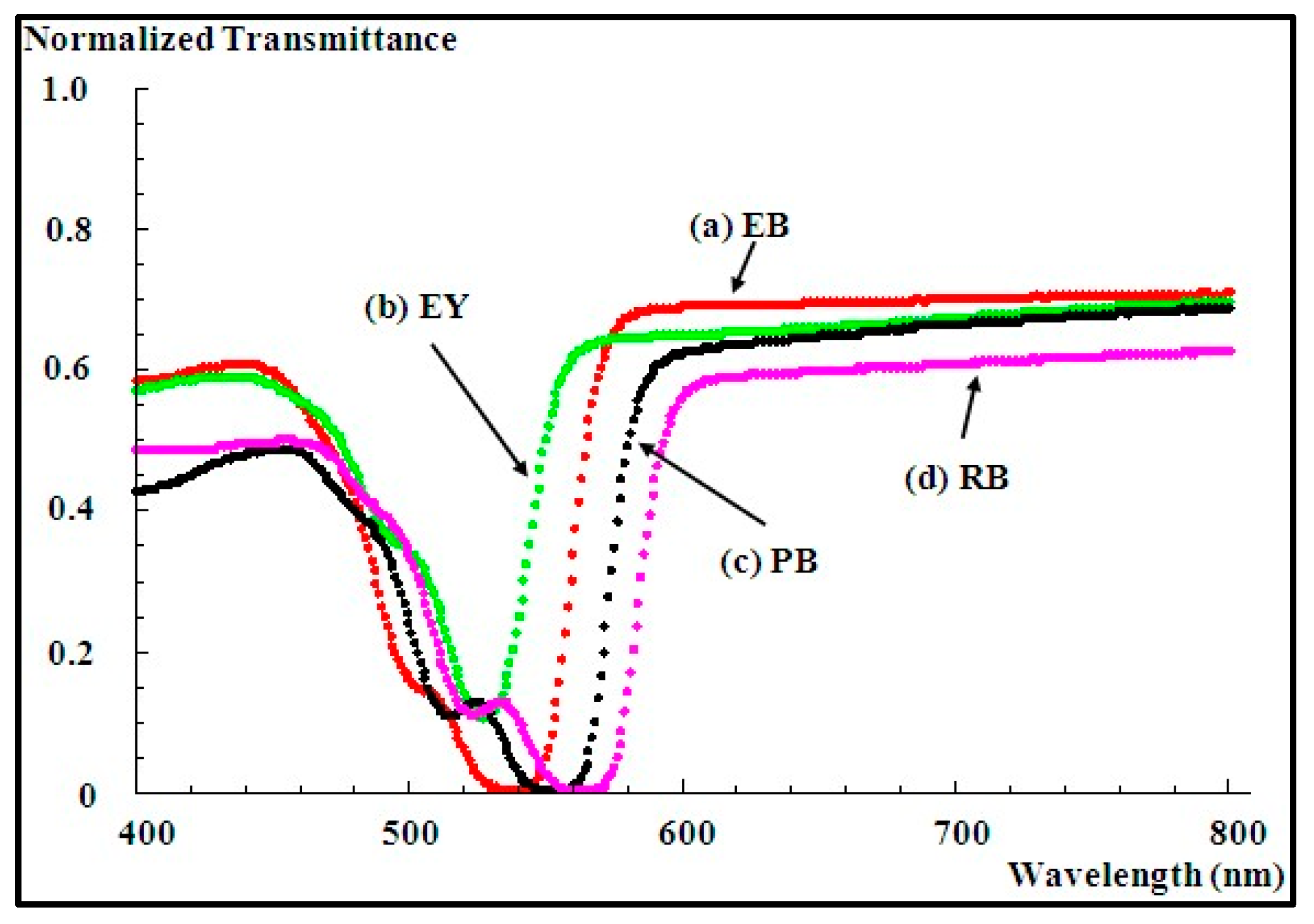

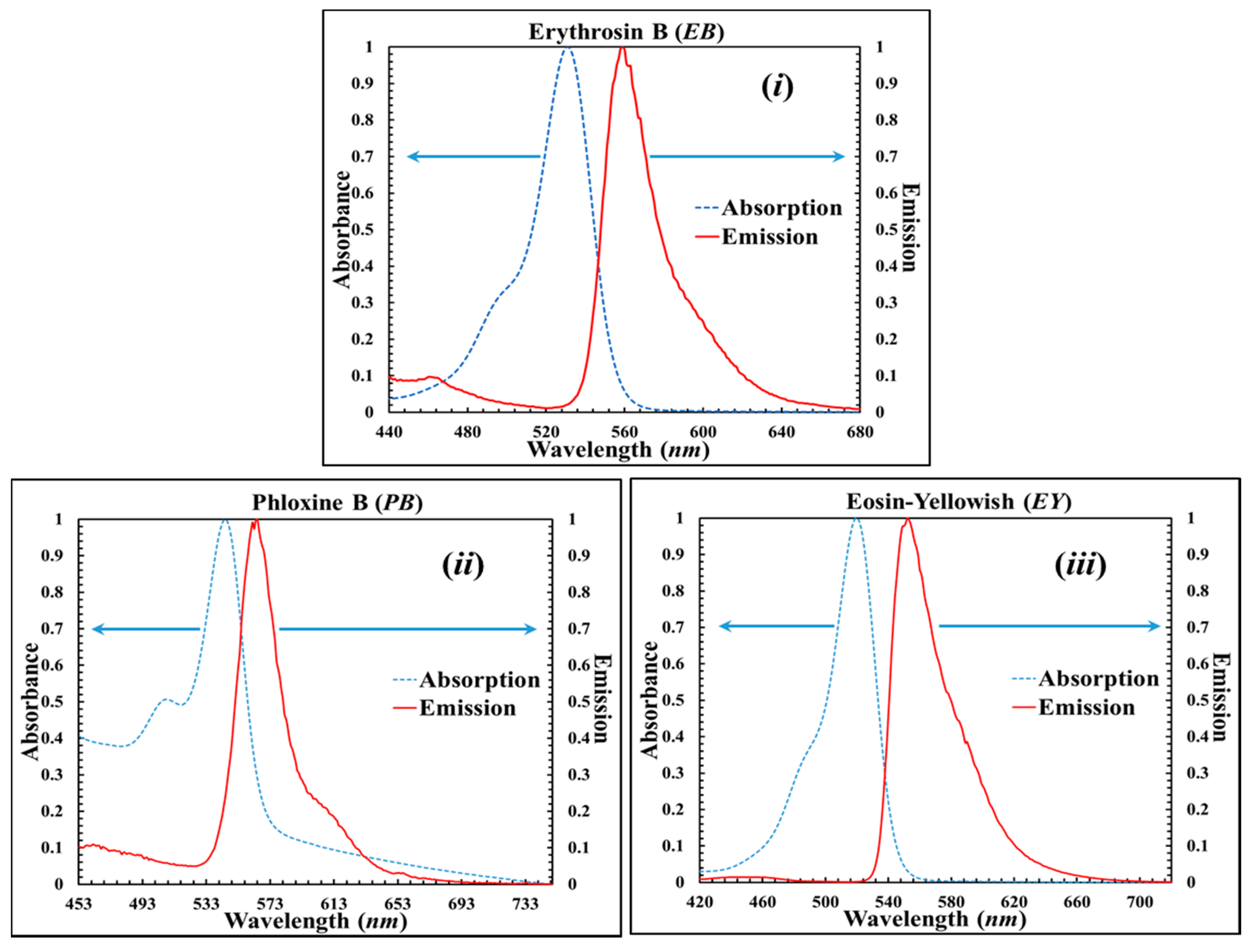

- For green photosensitive material, 16 cm3 of 1.25 × 10−3 M Xanthene dye is added to the beaker. This step and subsequent steps were carried out under a red safety light, as the material is now sensitive to green light.

- (e)

- The solution is then made up to 100 cm3 in a volumetric flask with deionized water.

- (f)

- The solution is then stored in the dark ready for plate preparation.

- (1)

- The glass substrate on which the material is to be deposited (typically 5 cm by 4 cm or a standard microscope slide) is cleaned thoroughly using deionized water and Acetone. Then, the plates are placed on a level surface so that the photopolymer layers would adhere to the glass evenly to produce a layer of uniform thickness.

- (2)

- The photopolymer solution, 2 mL, is deposited evenly over the area of the glass plate using a normal syringe.

- (3)

- This method is used to prepare a typical material thickness (100 ± 10 μm). In addition, we can obtained different thicknesses by depositing (drop casting) different quantities of material. By using a micrometer screw gauge, we can measure the thickness the thickness and uniformity of these layers.

- (4)

- The plates are then left in the dark for approximately 24 h until dry to be ready for use.

- (1)

- To evaporate the water from AA/PVA solution, we heated it while keeping it continuously agitated using a conventional magnetic stirrer. This process was performed under safe light and stable laboratory environmental conditions, with keeping AA/PVA solution at a constant temperature less than 100 °C.

- (2)

- After most of the water content evaporated, which is done for around 6 h per 100 mL, the hot solution (high viscosity liquid) is quickly poured into cuvettes (12.5 × 12.5 × 45 mm3).

- (3)

- Then, the cuvettes were rapidly transferred to a low pressure chamber to eliminate the air bubbles present in the AA/PVA, and also to allow uniform cooling of the hot material under the low temperature conditions produced under low air pressure.

- (4)

- These samples were stored in the dark for a long period (several days) to allow them to stabilize and to allow any remaining water to completely evaporate.

- (5)

- Following that, a dry AA/PVA was extracted from the cuvettes using a tweezers. Finally, we produced samples of size (x × y × z) 8.5 mm × 10 mm × 8.5 mm, which is suitable for use in performing self-writing experiments.

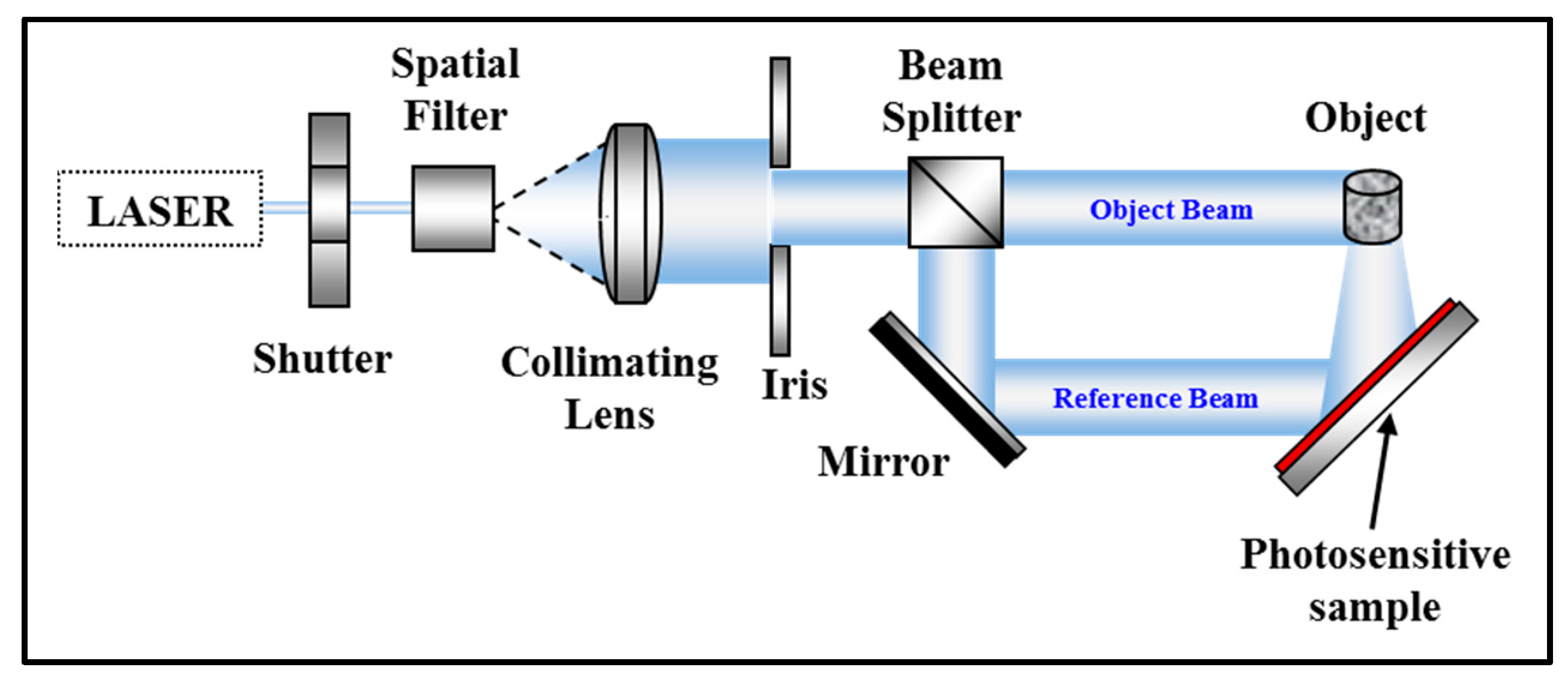

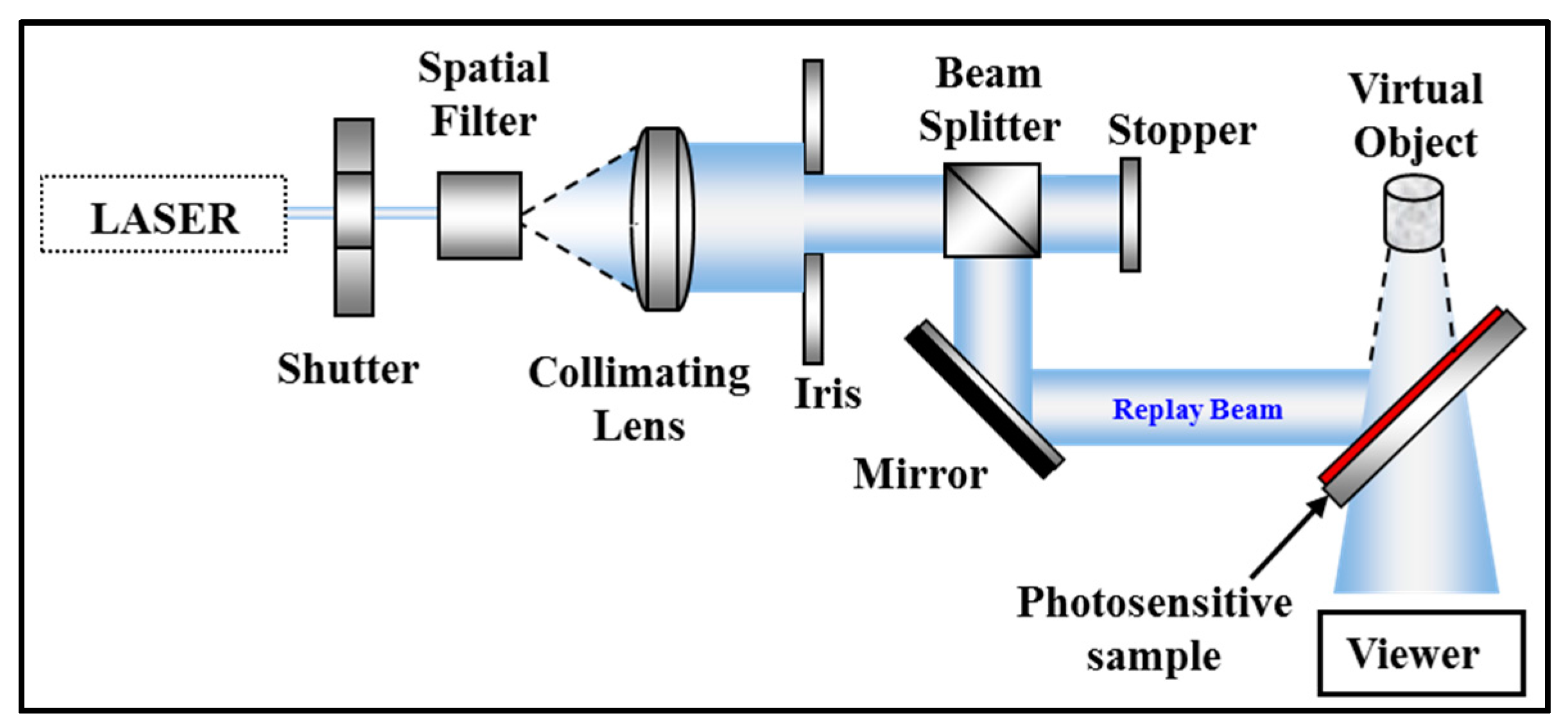

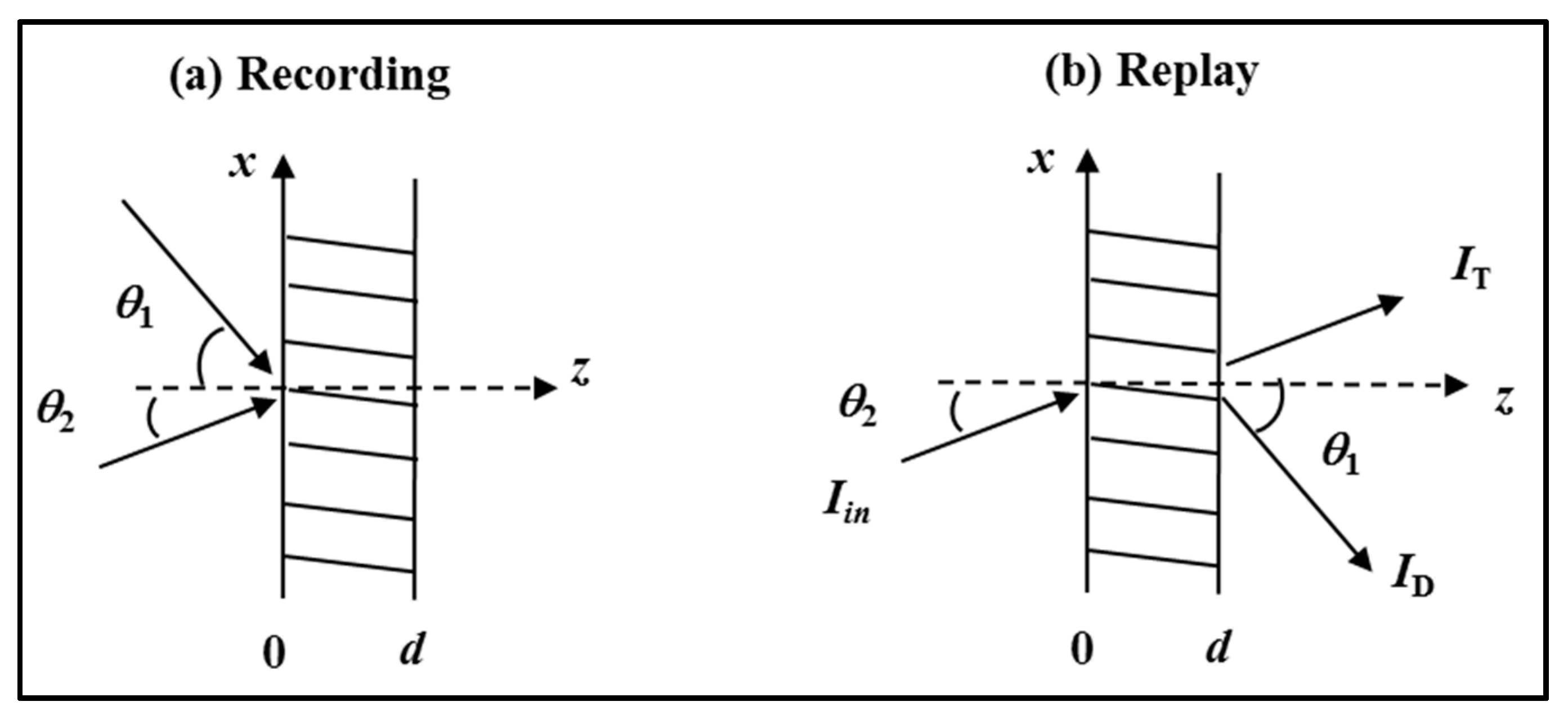

3. Holographic Gratings

3.1. Introduction to Holography

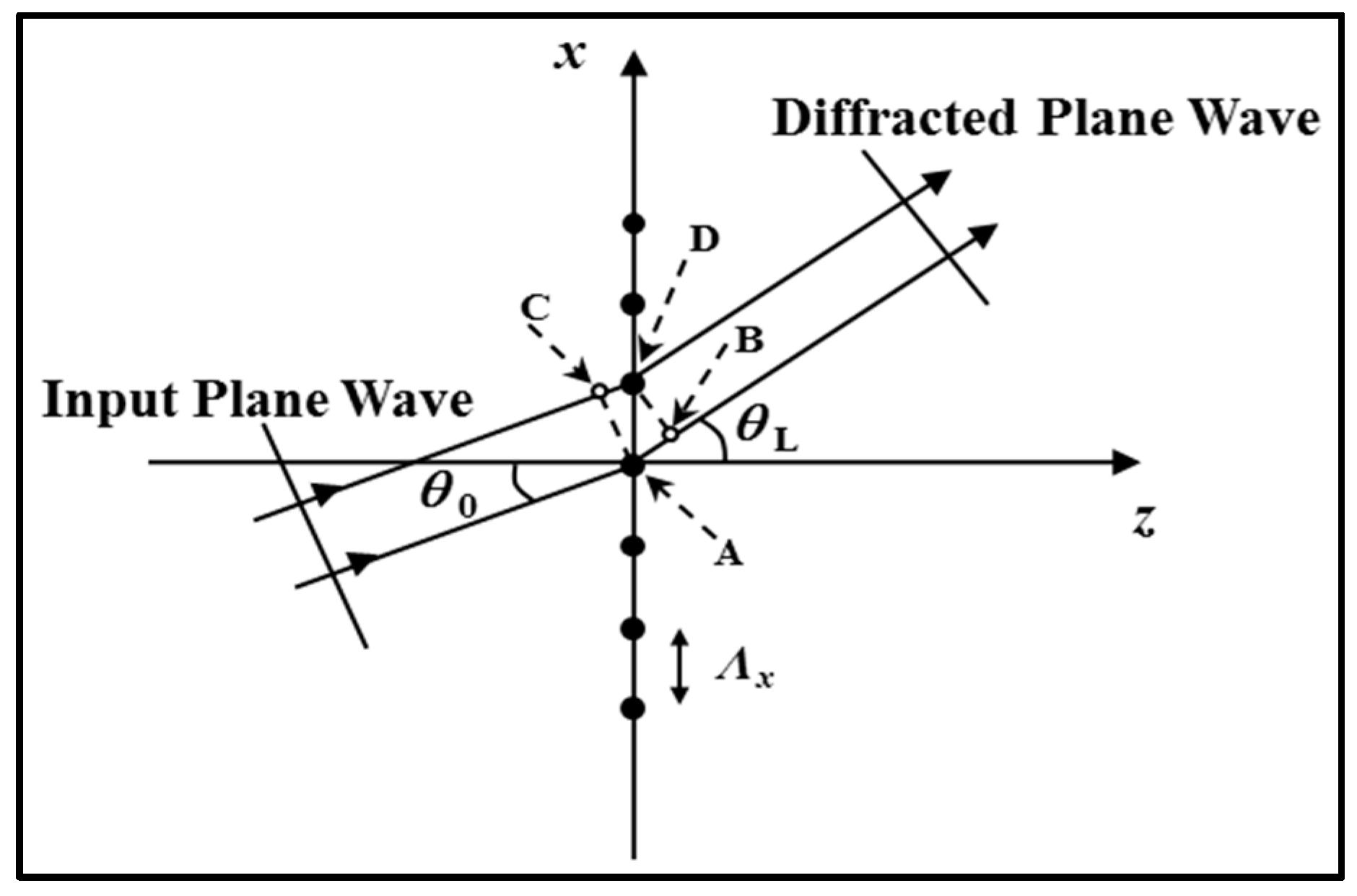

3.2. Diffraction by Thin Gratings

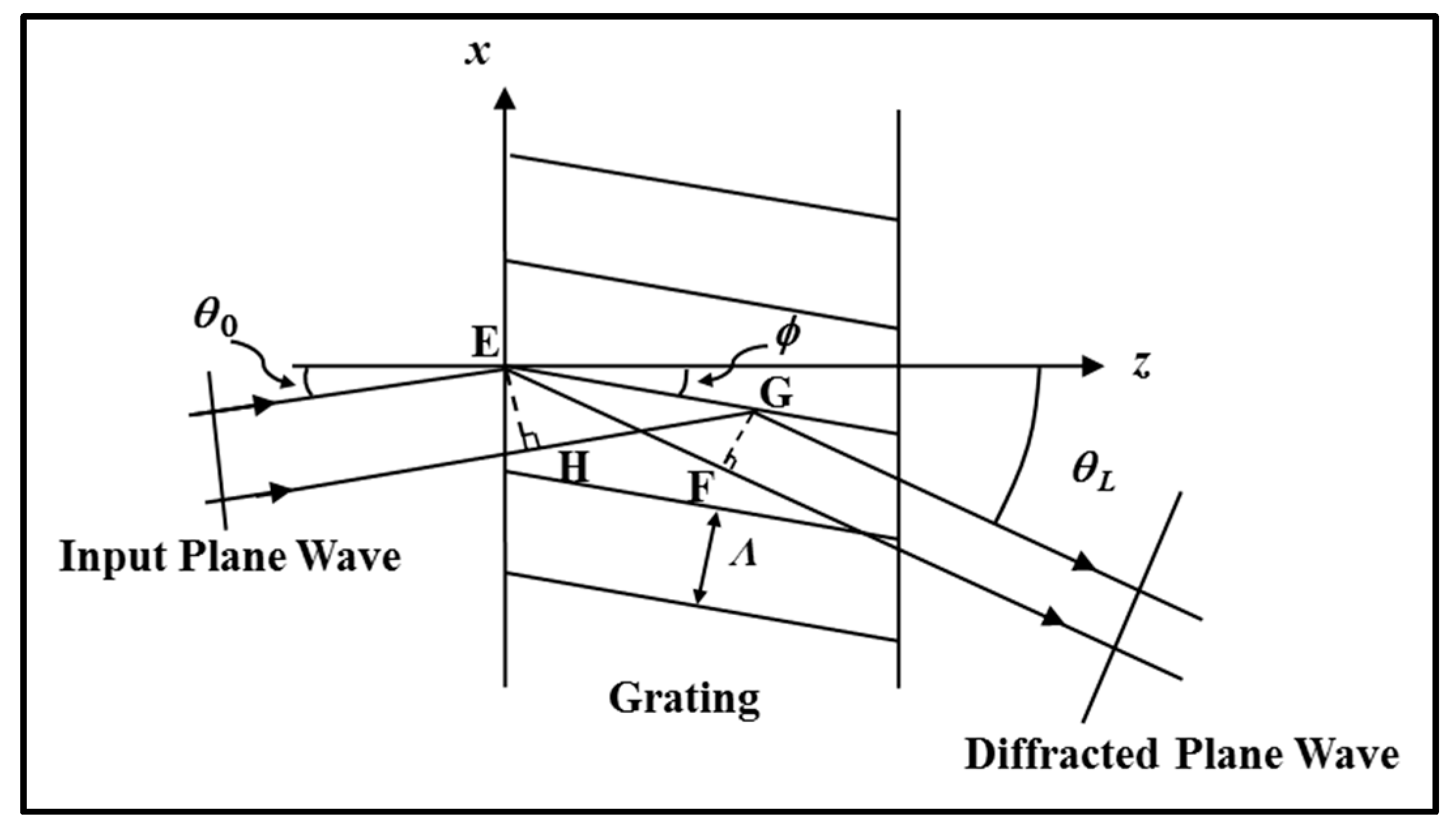

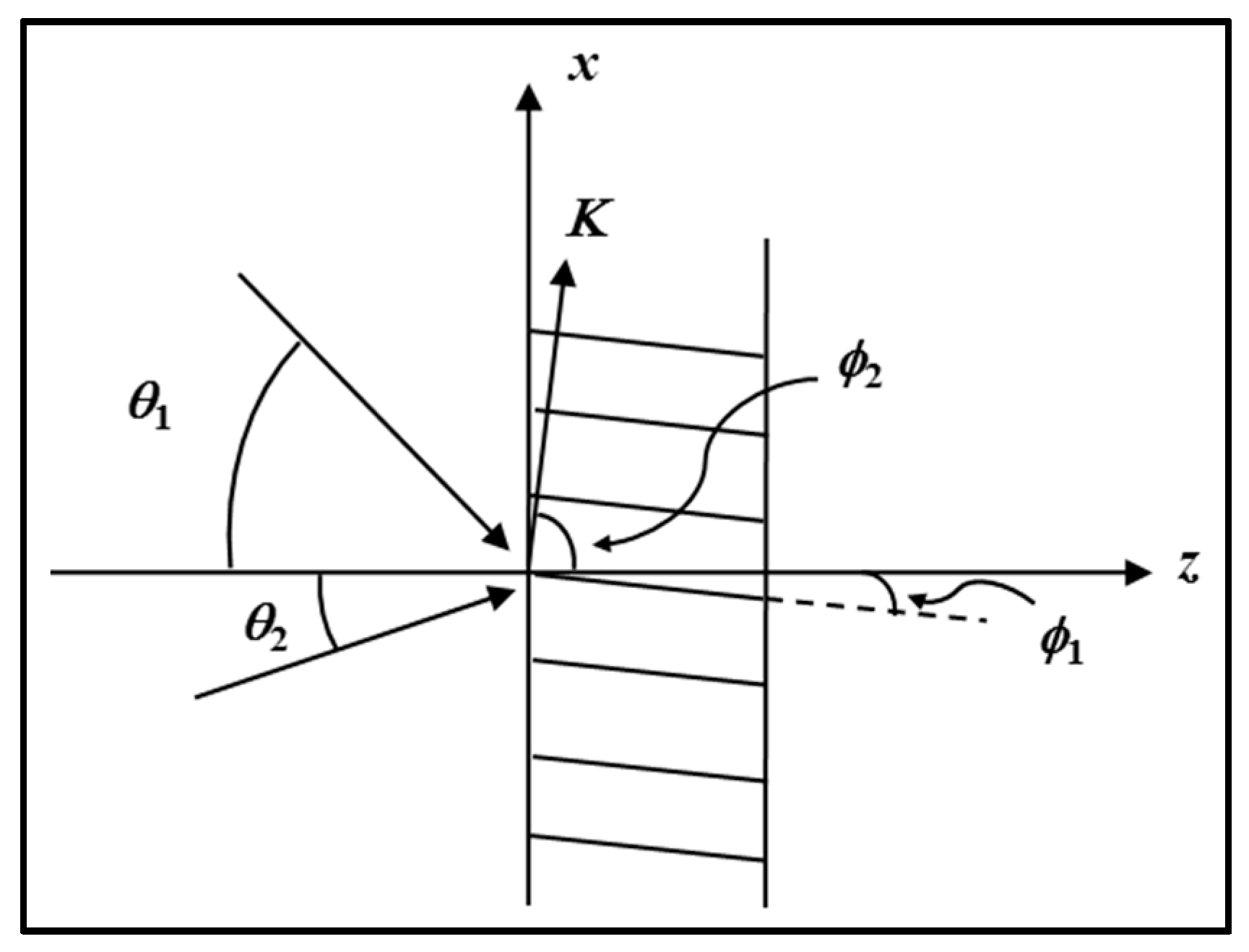

3.3. Thick Volume Gratings

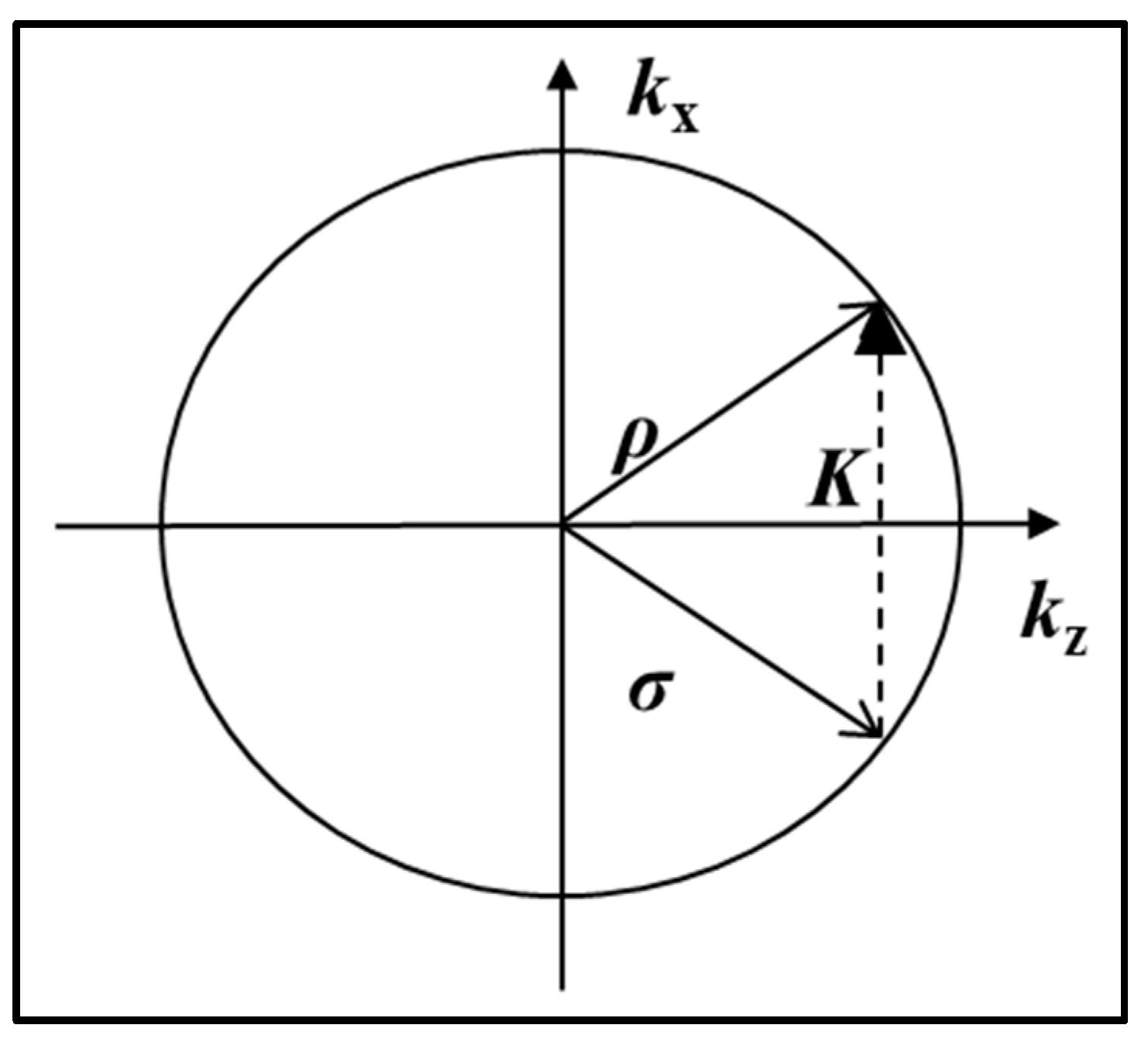

3.4. Volume Holographic Gratings

3.5. Refractive Index Modulation

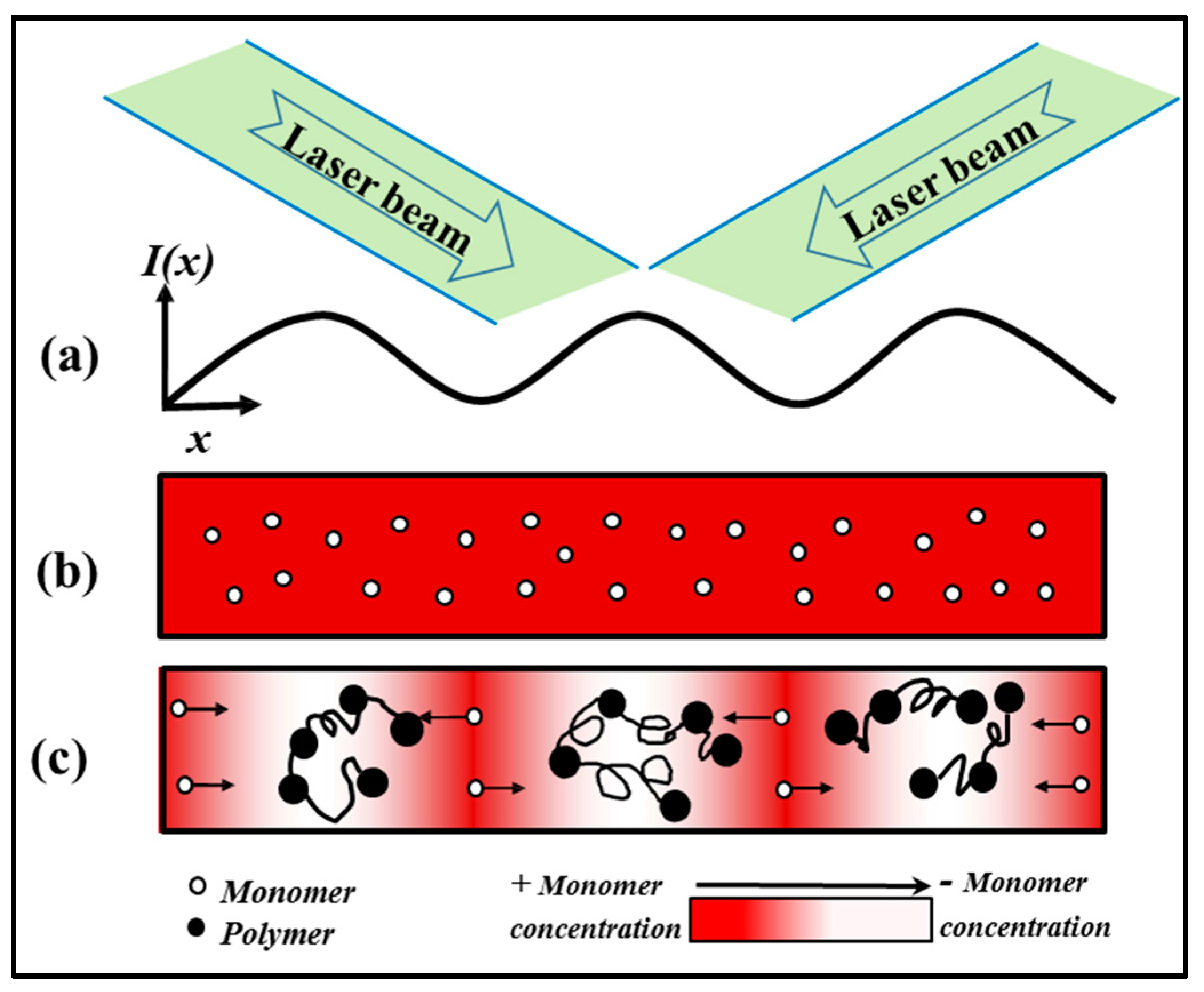

3.6. The Grating Formation Process

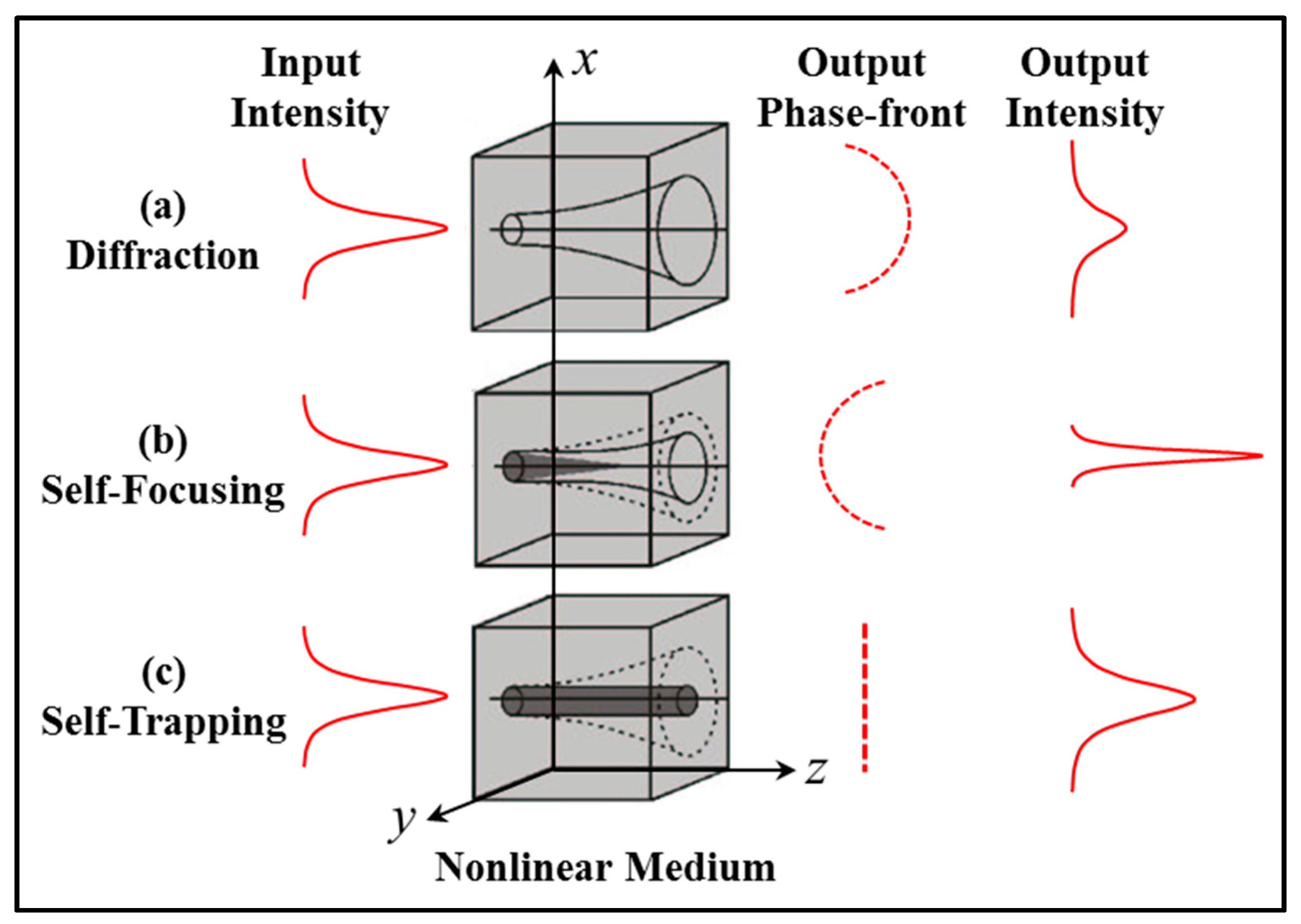

4. Self-Written Waveguides (SWWs)

4.1. Introduction to the Self-Writing Process

4.2. Previous Work on Self-Written Waveguides

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lin, S.H.; Hsu, K.Y.; Chen, W.; Whang, W.T. Phenanthrenequinone-doped poly(methyl methacrylate) photopolymer bulk for volume holographic data storage. Opt. Lett. 2000, 25, 451–453. [Google Scholar] [CrossRef] [PubMed]

- Hsu, K.Y.; Lin, S.H.; Hsiao, Y.N.; Whang, W.T. Experimental characterization of phenanthreneauinone-doped poly(methylmethacrylate) photopolymer for volume holographic storage. Opt. Eng. 2003, 42, 1390–1396. [Google Scholar]

- Mahilny, U.V.; Marmysh, D.N.; Stankevich, A.I.; Tolstik, A.L.; Matusevich, V.; Kowarschik, R. Holographic volume gratings in a glass-like polymer material. Appl. Phys. B 2006, 82, 299–302. [Google Scholar] [CrossRef]

- Mahilny, U.V.; Marmysh, D.N.; Tolstik, A.L.; Matusevich, V.; Kowarschik, R. Phase hologram formation in highly concentrated phenanthrenequinone-PMMA media. J. Opt. A 2008, 10, 085302. [Google Scholar] [CrossRef]

- Curtis, K.; Dhar, L.; Murphy, L.; Hill, A. Future Developments, in Holographic Data Storage: From Theory to Practical Systems; Wiley: Chichester, UK, 2010. [Google Scholar]

- Chen, Y.F.; Lin, J.H.; Lin, S.H.; Hsu, K.Y.; Whang, W.T. PQ: DMNA/PMMA photopolymer having amazing volume holographic recording at wavelength of insignificant absorption. Opt. Lett. 2013, 38, 2056–2058. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Cao, L.; He, Q.; Jin, G. Holographic kinetics for mixed volume gratings in gold nanoparticles doped photopolymer. Opt. Express 2014, 22, 5017–5028. [Google Scholar] [CrossRef] [PubMed]

- Sullivan, A.C.; Grabowski, M.W.; McLeod, R.R. Three-dimensional direct-write lithography into photopolymer. Appl. Opt. 2007, 46, 295–301. [Google Scholar] [CrossRef] [PubMed]

- Ye, C.; McLeod, R.R. GRIN lens and lens array fabrication with diffusion-driven photopolymer. Opt. Lett. 2008, 33, 2575–2577. [Google Scholar] [CrossRef] [PubMed]

- Hocine, M.; Fressengeas, N.; Kugel, G.; Carré, C.; Lougnot, D.J.; Bachelot, R.; Royer, P. Modeling the growth of a polymer microtip on an optical fiber end. J. Opt. Soc. Am. B 2006, 23, 611–620. [Google Scholar] [CrossRef] [Green Version]

- Jisha, C.P.; Kishore, V.C.; John, B.M.; Kuriakose, V.C.; Porsezian, K.; Kartha, C.S. Self-written waveguide in methylene blue sensitized poly(vinyl alcohol)/acrylamide photopolymer material. Appl. Opt. 2008, 47, 6502–6507. [Google Scholar] [CrossRef] [PubMed]

- Soppera, O.; Jradi, S.; Lougnot, D.J. Photopolymerization with microscale resolution: Influence of the physic-chemical and photonic parameters. J. Polym. Sci. Part A 2008, 46, 3783–3794. [Google Scholar] [CrossRef]

- Soppera, O.; Turck, C.; Lougnot, D.J. Fabrication of micro-optical devices by self-guiding photopolymerization in the near IR. Opt. Lett. 2009, 34, 461–463. [Google Scholar] [CrossRef] [PubMed]

- Tolstik, E.; Kashin, O.; Matusevich, V.; Kowarschik, R. Broadening of the light self-trapping due to thermal defocusing in PQ-PMMA polymeric layers. Opt. Express 2011, 19, 2739–2747. [Google Scholar] [CrossRef] [PubMed]

- Tolstik, E.; Romanov, O.; Matusevich, V.; Tolstik, A.; Kowarschik, R. Formation of self-trapping waveguides in bulk PMMA media doped with Phenanthrenequinone. Opt. Express 2014, 22, 3228–3233. [Google Scholar] [CrossRef] [PubMed]

- Manivannan, G.; Lessard, R.A. Trends in holographic recording materials. Trends Polym. Sci. 1994, 2, 282–290. [Google Scholar]

- Lawrence, J.R.; O’Neill, F.T.; Sheridan, J.T. Photopolymer holographic recording material. Optik 2001, 112, 449–463. [Google Scholar] [CrossRef]

- Kashin, A.M.; Monro, T.M. Exploration of self-writing and photosensitivity inion-exchanged waveguides. J. Opt. Soc. Am. B 2003, 20, 1317–1325. [Google Scholar]

- Syms, R.R.A. Practical Volume Holography; Clarendon Press: Oxford, UK, 1990. [Google Scholar]

- Kogelnik, H. Coupled wave theory for thick hologram gratings. Bell Syst. Tech. J. 1969, 48, 2909–2947. [Google Scholar] [CrossRef]

- Close, D.H.; Jacobson, A.D.; Magerum, R.C.; Brault, R.G.; McClung, F.J. Hologram recording on photopolymer materials. Appl. Phys. Lett. 1969, 14, 159–160. [Google Scholar] [CrossRef]

- Aprilis. HMC Media. 2006. Available online: www.aprilisinc.com/datastorage_media.htm (accessed on 2 August 2017).

- Gleeson, M.R.; Sheridan, J.T.; Bruder, F.K.; Rolle, T.; Berneth, H.; Weiser, M.S.; Facke, T. Comparison of a new self-developing photopolymer with AA/PVA based photopolymer utilizing the NPDD model. Opt. Express 2011, 19, 26325–26342. [Google Scholar] [CrossRef] [PubMed]

- Maruo, S.; Nakamura, O.; Kawata, S. Three-dimensional microfabrication with two-photon-absorbed photopolymerization. Opt. Lett. 1997, 22, 132–134. [Google Scholar] [CrossRef] [PubMed]

- Saravanamuttu, K.; Blanford, C.F.; Sharp, D.N.; Dedman, E.R.; Turberfield, A.J.; Denning, R.G. Sol-gel organic-inorganic composites for 3-D holographic lithography of photonic crystals with submicron periodicity. Chem. Mater. 2003, 15, 2301–2304. [Google Scholar] [CrossRef]

- Gu, M.; Straub, M.; Nguyen, L.H. Complex-shaped 3-D microstructures and photonic crystals generated in a polysiloxane polymer by two-photon microstereolithography. Opt. Mater. 2004, 27, 359–364. [Google Scholar]

- Sullivan, A.C.; McLeod, R.R. Tomographic reconstruction of weak, replicated index structures embedded in a volume. Opt. Express 2007, 15, 14202–14212. [Google Scholar] [CrossRef] [PubMed]

- Dhar, L.; Hale, A.; Katz, H.E.; Schilling, M.L.; Schnoes, M.G.; Schilling, F.C. Recording media that exhibit high dynamic range for digital holographic data storage. Opt. Lett. 1999, 24, 487–489. [Google Scholar] [CrossRef] [PubMed]

- Dhar, L.; Hale, A.; Kurtis, K.; Schnoes, M.; Tackitt, M.; Wilson, W.; Hill, A.; Schilling, M.; Katz, H.; Olsen, A. Photopolymer recording media for high density data storage. In Proceedings of the Optical Data Storage Conference Digest, Whisler, BC, Canada, 14–17 May 2000; pp. 158–160. [Google Scholar]

- Schultz, S.; Glytsis, E.; Gaylord, T. Design, fabrication, and performance of preferential-order volume grating waveguide couplers. Appl. Opt. 2000, 39, 1223–1232. [Google Scholar] [CrossRef] [PubMed]

- Sato, A.; Scepanovic, M.; Kostuk, R. Holographic edge-illuminated polymer Bragg gratings for dense wavelength division optical filters at 1550 nm. Appl. Opt. 2003, 42, 778–784. [Google Scholar] [CrossRef] [PubMed]

- Sheridan, J.T.; Kelly, J.V.; O’Brien, G.; Gleeson, M.R.; O’Neill, F.T. Generalized non-local responses and higher harmonic retention in non-local polymerization driven diffusion model based simulations. J. Opt. A 2004, 6, 1089–1096. [Google Scholar] [CrossRef]

- McLeod, R.R.; Daiber, A.J.; McDonald, M.E.; Robertson, T.L.; Slagle, T.; Sochava, S.L.; Hesselink, L. Microholographic multilayer optical disk data storage. Appl. Opt. 2005, 44, 3197–3207. [Google Scholar] [CrossRef] [PubMed]

- Milster, T.D. Horizons for optical storage. Opt. Photonics News 2005, 16, 28–33. [Google Scholar] [CrossRef]

- Sheridan, J.T.; Kelly, J.V.; Close, C.E.; O’Neill, F.T. Optimized holographic data storage: Diffusion and randomization. J. Opt. A 2006, 8, 236–243. [Google Scholar] [CrossRef]

- Toishi, M.; Tanaka, T.; Watanabe, K.; Betsuyaku, K. Analysis of photopolymer media of holographic data storage using non-local polymerization driven diffusion model. Jpn. J. Appl. Phys. 2007, 46, 3438–3447. [Google Scholar] [CrossRef]

- Toishi, M.; Tanaka, T.; Watanabe, K. Analysis of temperature change effects on hologram recording and a compensation method. Opt. Rev. 2008, 15, 11–18. [Google Scholar] [CrossRef]

- Nagy, Z.; Koppa, P.; Ujhelyi, F.; Dietz, E.; Frohmann, S.; Orlic, S. Modeling material saturation effects in microholographic recording. Opt. Express 2007, 15, 1732–1737. [Google Scholar] [CrossRef] [PubMed]

- Jenney, J.A. Holographic recording in photopolymers. J. Opt. Soc. Am. 1970, 60, 1155–1161. [Google Scholar] [CrossRef]

- Jenney, J.A. Nonlinearities of photopolymer holographic recording materials. Appl. Opt. 1971, 11, 1371–1381. [Google Scholar] [CrossRef] [PubMed]

- Sugawara, S.; Murase, K.; Kitayama, T. Holographic recording by dye-sensitized photopolymerisation of acrylamide. Appl. Opt. 1975, 14, 378–382. [Google Scholar] [CrossRef] [PubMed]

- Sukegawa, K.; Sugawara, S.; Murase, K. Holographic recording by FE3+ sensitized photopolymerization. Electron. Commun. Jpn. 1975, 58, 132–138. [Google Scholar]

- Sadlej, N.; Smolinska, B. Stable photo-sensitive polymer layers for holography. Opt. Laser Technol. 1975, 7, 175–179. [Google Scholar] [CrossRef]

- Jeudy, M.J.; Robillard, J.J. Spectral photosensitisation of a variable index material for recording phase holograms with high efficiency. Opt. Commun. 1975, 13, 25–28. [Google Scholar] [CrossRef]

- Calixto, S. Dry polymer for holographic recording. Appl. Opt. 1987, 26, 3904–3909. [Google Scholar] [CrossRef] [PubMed]

- Fimia, A.; Lopez, N.; Mateos, F. Acrylamide photopolymers for use in real time holography: Improving energetic sensitivity. Proc. SPIE 1992, 1732, 105–109. [Google Scholar]

- Fimia, A.; Lopez, N.; Mateos, F.; Sastre, R.; Pineda, J.; Amatguerri, F. Elimination of oxygen inhibition in photopolymer system used as holographic recording materials. J. Mod. Opt. 1993, 40, 699–706. [Google Scholar] [CrossRef]

- Martin, S.; Leclere, P.; Renotte, Y.; Toal, V.; Lion, Y. Characterisation of an acrylamide-based dry photopolymer holographic recording material. Opt. Eng. 1994, 33, 3942–3946. [Google Scholar]

- Weiss, V.; Millul, E.; Friesem, A.A. Photpolymeric holographic recording media: In-situ and real-time characterisation. Proc. SPIE 1996, 2688, 11–21. [Google Scholar]

- Blaya, S.; Mallavia, R.; Carretero, L.; Fimia, A.; Madrigal, R.F. Highly sensitive photopolymerisable dry film for use in real time holography. Appl. Phys. Lett. 1998, 73, 1628–1630. [Google Scholar] [CrossRef]

- Blaya, S.; Carretero, L.; Fimia, A.; Mallavia, R.; Madrigal, R.F.; Sastre, R.; Amat-Guerri, F. Optimal composition of an acrylamide and N,N’-methylenebisacrylamide holographic recording material. J. Mod. Opt. 1998, 45, 2573–2584. [Google Scholar] [CrossRef]

- Blaya, S.; Carretero, L.; Mallavia, R.; Fimia, A.; Madrigal, R.F.; Ulibarrena, M.; Levy, D. Optimization of an acrylamide-based dry film used for holographic recording. Appl. Opt. 1998, 37, 7604–7610. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Frietmann, E.E.; Li, X. Novel type of red sensitive photopolymer system for optical storage. Proc. SPIE 1998, 3468, 317–321. [Google Scholar]

- Mallavia, R.; Fimia, A.; Blaya, S.; Carretero, L.; Madrigal, R.F.; Amat-Guerri, F.; Sastre, R. A mixture of mono-, bi- and trifunctional acrylates with eosine O-benzoyl-a-oxooxime: Advances in holographic copolymerizable composition. J. Mod. Opt. 1999, 46, 559–566. [Google Scholar]

- Fimia, A.; Mateos, F.; Mallavia, R.; Blaya, S.; Belendez, A.; Sastre, R.; Amat-Guerri, F. High-energy sensitivity enhancement in panchromatic photopolymers for holography using a mixture of visible light photoinitiators. J. Mod. Opt. 1999, 46, 1091–1098. [Google Scholar] [CrossRef]

- O’Neill, F.T.; Lawrence, J.R.; Sheridan, J.T. Improvement of holographic recording material using aerosol sealant. J. Opt. A 2001, 3, 20–25. [Google Scholar] [CrossRef]

- Yao, H.; Huang, M.; Chen, Z.; Hou, L.; Gan, F. Optimization of two-monomer-based photopolymer used for holographic recording. Mater. Lett. 2002, 56, 3–8. [Google Scholar] [CrossRef]

- Suzuki, N.; Tomita, Y.; Kojima, T. Holographic recording in TiO2 nanoparticle-dispersed methacrylate photopolymer films. Appl. Phys. Lett. 2002, 81, 4121–4123. [Google Scholar] [CrossRef]

- Tomita, Y.; Nishibiraki, H. Improvement of holographic recording sensitivities in the green in SiO2 nanoparticle-dispersed methacrylate photopolymers doped with pyrromethene dyes. Appl. Phys. Lett. 2003, 83, 410–412. [Google Scholar] [CrossRef]

- Blaya, S.; Acebal, P.; Carretero, L.; Fimia, A. Pyrromethene-HEMA-based photopolymerizable holographic recording material. Opt. Commun. 2003, 228, 55–61. [Google Scholar] [CrossRef]

- Kelly, J.V.; Gleeson, M.R.; Close, C.E.; Neill, F.T.O.; Sheridan, J.T.; Gallego, S.; Neipp, C. Temporal analysis of grating formation in photopolymer using the nonlocal polymerization-driven diffusion model. Opt. Express 2005, 13, 6690–7004. [Google Scholar] [CrossRef]

- Sheridan, J.T.; Lawrence, J.R. Nonlocal-response diffusion model of holographic recording in photopolymer. J. Opt. Soc. Am. A 2000, 17, 1108–1114. [Google Scholar] [CrossRef]

- Lawrence, J.R.; O’Neill, F.T.; Sheridan, J.T. Adjusted intensity nonlocal diffusion model of photopolymer grating formation. J. Opt. Soc. Am. B 2002, 19, 621–629. [Google Scholar] [CrossRef]

- Moharam, M.G.; Gaylord, T.K. Rigorous coupled-wave analysis of planar-grating diffraction. J. Opt. Soc. Am. 1981, 71, 811–818. [Google Scholar] [CrossRef]

- O’Neill, F.T.; Carr, A.J.; Daniels, S.M.; Gleeson, M.R.; Kelly, J.V.; Lawrence, J.R.; Sheridan, J.T. Refractive elements produced in photopolymer layers. J. Mater. Sci. 2005, 40, 4129–4132. [Google Scholar] [CrossRef]

- Gleeson, M.R.; Sabol, D.; Liu, S.; Close, C.E.; Kelly, J.V.; Sheridan, J.T. Improvement of the spatial frequency response of photopolymer materials by modifying polymer chain length. J. Opt. Soc. Am. B 2008, 25, 396–406. [Google Scholar] [CrossRef]

- Kelly, J.V.; Gleeson, M.R.; Close, C.E.; Sheridan, J.T. Optimized scheduling for holographic data storage. J. Opt. A 2008, 10, 115203. [Google Scholar] [CrossRef]

- Gleeson, M.R.; Liu, S.; Guo, J.; Sheridan, J.T. Non-Local photo-polymerization kinetics including multiple termination mechanisms and dark reactions: Part III. Primary radical generation and inhibition. J. Opt. Soc. Am. B 2010, 27, 1804–1812. [Google Scholar] [CrossRef]

- Guo, J.; Liu, S.; Gleeson, M.R.; Sheridan, J.T. Study of photosensitizer diffusion in a photopolymer material for holographic applications. Opt. Eng. 2011, 50, 015801. [Google Scholar] [CrossRef]

- Lougnot, D.J.; Jost, P.; Lavielle, L. Polymers for holographic recording: VI. Some basic ideas for modelling the kinetics of the recording process. Pure Appl. Opt. 1997, 6, 225–245. [Google Scholar] [CrossRef]

- Close, C.E.; Gleeson, M.R.; Sheridan, J.T. Monomer diffusion rates in photopolymer material. Part I. Low spatial frequency holographic gratings. J. Opt. Soc. Am. B 2011, 28, 658–666. [Google Scholar] [CrossRef]

- Close, C.E.; Gleeson, M.R.; Mooney, D.A.; Sheridan, J.T. Monomer diffusion rates in photopolymer material. Part II. High-frequency gratings and bulk diffusion. J. Opt. Soc. Am. B 2011, 28, 842–850. [Google Scholar] [CrossRef]

- Sabol, D.; Gleeson, M.R.; Liu, S.; Sheridan, J.T. Photoinitiation study of Irgacure 784 in an epoxy resin photopolymer. J. Appl. Phys. 2010, 107, 053113. [Google Scholar] [CrossRef]

- Trentler, T.; Boyd, J.; Colvin, V. Epoxy resin photopolymer composites for volume holography. Chem. Mater. 2000, 12, 1431–1438. [Google Scholar] [CrossRef]

- Gleeson, M.R.; Guo, J.; Sheridan, J.T. Optimisation of photopolymers for holographic applications using the Non-local Photo-polymerization Driven Diffusion model. Opt. Express 2011, 19, 22423–22436. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Gleeson, M.R.; Guo, J.; Sheridan, J.T.; Tolstik, E.; Matusevich, V.; Kowarschik, R. Modeling the photochemical kinetics induced by holographic exposures in PQ/PMMA photopolymer material. J. Opt. Soc. Am. B 2011, 28, 2833–2843. [Google Scholar] [CrossRef]

- Rölle, T.; Bruder, F.K.; Fäcke, T.; Weiser, M.S.; Hönel, D.; Stoeckel, N. Photopolymerzusammensetzungen für Optische Elemente und Visuelle Darstellungen. Patent EP 2,172,505 A1, 7 April 2010. [Google Scholar]

- Guo, J.; Gleeson, M.R.; Liu, S.; Sheridan, J.T. Non-local spatial frequency response of photopolymer materials containing chain transfer agents: Part I. Theoretical modeling. J. Opt. 2011, 13, 095601. [Google Scholar] [CrossRef]

- Guo, J.; Gleeson, M.R.; Liu, S.; Sheridan, J.T. Non-local spatial frequency response of photopolymer materials containing chain transfer agents: Part II. Experimental results. J. Opt. 2011, 13, 095602. [Google Scholar] [CrossRef]

- Cody, D.; Naydenova, I.; Mihaylova, E. New non-toxic holographic photopolymer material. J. Opt. 2012, 14, 015601. [Google Scholar] [CrossRef]

- Ortuño, M.; Gallego, S.; Márquez, A.; Neipp, C.; Pascual, I.; Beléndez, A. Biophotopol: A Sustainable Photopolymer for Holographic Data Storage Applications. Materials 2012, 5, 772–783. [Google Scholar] [CrossRef]

- Navarro-Fuster, V.; Ortuño, M.; Gallego, S.; Márquez, A.; Beléndez, A.; Pascual, I. Biophotopol’s energetic sensitivity improved in 300 μm layers by tuning the recording wavelength. Opt. Mater. 2016, 52, 111–115. [Google Scholar] [CrossRef]

- Sabel, T.; Zschocher, M. Transition of refractive index contrast in course of grating growth. Sci. Rep. 2013, 3, 2552. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Fujii, R.; Ono, T.; Klepp, J.; Pruner, C.; Fally, M.; Tomita, Y. Effects of chain-transferring thiol functionalities on the performance of nanoparticle-polymer composite volume gratings. Opt. Lett. 2014, 39, 6743–6746. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Fujii, R.; Tomita, Y. Volume holographic recording in nanoparticle-polymer composites doped with multifunctional chain transfer agents. Opt. Rev. 2015, 22, 832–836. [Google Scholar] [CrossRef]

- Kawana, M.; Takahashi, J.; Guo, J.; Tomita, Y. Measurement of polymerization shrinkage evolution during curing in photopolymer with a white-light Fabry-Perot interferometer. Opt. Express 2015, 23, 15356–15364. [Google Scholar] [CrossRef] [PubMed]

- Shelkovnikov, V.; Vasiljev, E.; Russkih, V.; Berezhnaya, V. Photopolymer material sensitized by xanthene dyes for holographic recording using forbidden singlet-triplet electronic transitions. J. Opt. 2016, 18, 075402. [Google Scholar] [CrossRef]

- Gore, M.G. Spectrophotometry & Spectrofluorimetry; Oxford University Press: New York, NY, USA, 2000. [Google Scholar]

- Qi, Y.; Gleeson, M.R.; Guo, J.; Gallego, S.; Sheridan, J.T. Quantitative comparison of five different photosensitizers for use in a photopolymer. Phys. Res. Int. 2012, 2012, 975948. [Google Scholar] [CrossRef]

- Gómez, A.R.; Sánchez-Hernández, C.M.; Fleitman-Levin, I.; Arenas-Alatorre, J.; Alonso-Huitrón, J.C.; Vergara, M.E.S. Optical Absorption and Visible Photoluminescence from Thin Films of Silicon Phthalocyanine Derivatives. Materials 2014, 7, 6585–6603. [Google Scholar] [CrossRef]

- Gabor, D. A new microscopic principle. Nature 1948, 161, 777–778. [Google Scholar] [CrossRef] [PubMed]

- Leith, E.; Upatnieks, J. Reconstructed wavefronts and communication theory. J. Opt. Soc. Am. 1962, 52, 1123–1130. [Google Scholar] [CrossRef]

- Solymar, L.; Cooke, D.J. Volume Holography and Volume Gratings; Academic Press: London, UK, 1981. [Google Scholar]

- O’Neill, F.T.; Lawrence, J.R.; Sheridan, J.T. Thickness variation of self-processing acrylamide-based photopolymer and reflection holography. Opt. Eng. 2001, 40, 533–539. [Google Scholar]

- Kelly, J.V. Analysis of Holographic Grating Formation in Photopolymer with Application to Data Storage. Ph.D. Thesis, University College Dublin, Dublin, Ireland, 2007. [Google Scholar]

- Uchida, N. Calculation of diffraction efficiency in hologram gratings attenuated along the direction perpendicular to the grating vector. J. Opt. Soc. Am. A 1973, 63, 280–287. [Google Scholar] [CrossRef]

- Sheridan, J.T. A comparison of diffraction theories for off-Bragg replay. J. Mod. Opt. 1992, 39, 1709–1718. [Google Scholar] [CrossRef]

- Fally, M.; Klepp, J.; Tomita, Y. An experimental study on the validity of diffraction theories for off-Bragg replay volume holographic gratings. Appl. Phys. B 2012, 108, 89–96. [Google Scholar] [CrossRef]

- Kewitsch, A.S.; Yariv, A. Self-focusing and self-trapping of optical beams upon photopolymerization. Opt. Lett. 1996, 21, 24–26. [Google Scholar] [CrossRef] [PubMed]

- Kewitsch, A.S.; Yariv, A. Nonlinear optical properties of photoresists for projection lithography. Appl. Phys. Lett. 1996, 68, 455–457. [Google Scholar] [CrossRef]

- Aitchison, J.S.; Weiner, A.M.; Silberberg, Y.; Leaird, D.E.; Oliver, M.K.; Jackel, J.L.; Smith, P.W.E. Experimental observation of spatial soliton interactions. Opt. Lett. 1991, 16, 15–17. [Google Scholar] [CrossRef] [PubMed]

- Monro, T.M.; Moss, D.; Bazylenko, M.; Sterke, C.M.; Poladian, L. Observation of self-trapping of light in a self-written channel in a photosensitive glass. Phys. Rev. Lett. 1998, 80, 4072–4075. [Google Scholar] [CrossRef]

- Chiao, R.Y.; Garmire, E.; Townes, C.H. Self-trapping of optical beams. Phys. Rev. Lett. 1964, 13, 479–482. [Google Scholar] [CrossRef]

- Bjorkholm, J.E.; Ashkin, A. CW self-focusing and self-trapping of light in sodium vapor. Phys. Rev. Lett. 1974, 32, 129–132. [Google Scholar] [CrossRef]

- Mitchell, M.; Chen, Z.; Shih, M.; Segev, M. Self-trapping of partially incoherent light. Phys. Rev. Lett. 1996, 77, 490–493. [Google Scholar] [CrossRef] [PubMed]

- Dorkenoo, K.; Crégut, O.; Mager, L.; Gillot, F.; Carre, C.; Fort, A. Quasi-solitonic behaviour of self-written waveguides created by photopolymerization. Opt. Lett. 2002, 27, 1782–1784. [Google Scholar] [CrossRef] [PubMed]

- Lawrence, J.R.; O’Neil, F.T.; Sheridan, J.T. Photopolymer holographic recording material parameter estimation using a nonlocal diffusion based model. J. Appl. Phys. 2001, 90, 3142–3148. [Google Scholar] [CrossRef]

- Gleeson, M.R.; Sheridan, J.T. Non-local photo-polymerization kinetics including multiple termination mechanisms and dark reactions: Part I. Modelling. J. Opt. Soc. Am. B 2009, 26, 1736–1745. [Google Scholar] [CrossRef]

- Qi, Y.; Li, H.; Fouassier, J.P.; Lalevée, J.; Sheridan, J.T. Comparison of a new photosensitizer with Erythrosin B in an AA/PVA based photopolymer material. Appl. Opt. 2014, 53, 1052–1062. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.; Li, H.; Guo, J.; Gleeson, M.R.; Sheridan, J.T. Material response of photopolymer containing four different photosensitizers. Opt. Commun. 2014, 320, 114–124. [Google Scholar] [CrossRef]

- Shoji, S.; Kawata, S.; Sukhorukov, A.A.; Kivshar, Y. Self-written waveguides in photopolymerizable regins. Opt. Lett. 2002, 27, 185–187. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Sheridan, J.T.; Saravanamuttu, K. Collective dynamics of populations of weakly correlated filaments of incoherent white light. J. Opt. 2013, 14, 035201. [Google Scholar] [CrossRef]

- Mizrahi, V.; Lemaire, P.J.; Erdogan, T.; Reed, W.A.; DiGiovanni, D.J.; Atkins, R.M. Ultraviolet laser fabrication of ultra-strong optical fiber gratings and of Germania-doped channel waveguides. Appl. Phys. Lett. 1993, 63, 1727–1729. [Google Scholar] [CrossRef]

- Ruan, Y.; Li, W.; Jarvis, R.; Madsen, N.; Rode, A.; Davies, B.L. Fabrication and characterization of low loss rib chalcogenide waveguides made by dry etching. Opt. Express 2004, 12, 5140–5145. [Google Scholar] [CrossRef] [PubMed]

- Kagami, M.; Yamashita, T.; Ito, H. Light-induced self-written three-dimensional optical waveguide. Appl. Phys. Lett. 2001, 79, 1079–1081. [Google Scholar] [CrossRef]

- Jradi, S.; Soppera, O.; Lougnot, D.J. Fabrication of polymer waveguides between two optical fibers using spatially controlled light-induced polymerization. Appl. Opt. 2008, 47, 3987–3993. [Google Scholar] [CrossRef] [PubMed]

- Jradi, S.; Soppera, O.; Lougnot, D.J.; Bachelot, R.; Royer, P. Tailoring the geometry of polymer tips on the end of optical fibers via control of physico-chemical parameters. Opt. Mater. 2009, 31, 640–646. [Google Scholar] [CrossRef]

- Missinne, J.; Beri, S.; Dash, M.; Samal, S.K.; Dubruel, P.; Watté, J.; Steenberge, G.V. Curing kinetics of step-index and graded-index single mode polymer self-written waveguides. Opt. Mater. Express 2014, 4, 1324–1335. [Google Scholar] [CrossRef]

- Zhang, J.; Kasala, K.; Rewari, A.; Saravanamuttu, K. Self-trapping of spatially and temporally incoherent white light in a photochemical medium. J. Am. Chem. Soc. 2006, 128, 406–407. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Saravanamuttu, K. The dynamics of self-trapped beams of incoherent white light in a free-radical photopolymerizable medium. J. Am. Chem. Soc. 2006, 128, 14913–14923. [Google Scholar] [CrossRef] [PubMed]

- Qiu, L.; Saravanamuttu, K. Optical self-trapping in a photopolymer doped with Ag nanoparticles: A singlestep route to metallodielectric cylindrical waveguides. J. Opt. Soc. Am. B 2012, 29, 1085–1093. [Google Scholar] [CrossRef]

- Bachelot, R.; Ecoffet, C.; Deloeil, D.; Royer, P.; Lougnot, D.J. Integration of micrometer-sized polymer elements at the end of optical fibers by free-radical photopolymerization. Appl. Opt. 2001, 40, 5860–5871. [Google Scholar] [CrossRef] [PubMed]

- Kashin, O.; Tolstik, E.; Matusevich, V.; Kowarschik, R. Numerical investigation of the (1 + 1)D self-trapping of laser beams in polymeric films based on polymethylmethacrylate and phenanthrenequinone. J. Opt. Soc. Am. B 2009, 26, 2152–2156. [Google Scholar] [CrossRef]

- Li, H.; Qi, Y.; Ryle, J.P.; Sheridan, J.T. Self-written waveguides in a dry acrylamide/polyvinyl alcohol photopolymer material. Appl. Opt. 2014, 53, 8086–8094. [Google Scholar] [CrossRef] [PubMed]

- Monro, T.M.; Poladian, L.; Sterke, C.M. Analysis of self-written waveguides in photopolymers and photosensitive materials. Phys. Rev. E 1998, 57, 1104–1113. [Google Scholar] [CrossRef]

- Engin, D.; Kewitsch, A.S.; Yariv, A. Holographic characterization of chain photopolymerization. J. Opt. Soc. Am. B 1999, 16, 1213–1219. [Google Scholar] [CrossRef]

- Shoji, S.; Kawata, S. Optically-induced growth of fiber patterns into a photopolymerizable resin. Appl. Phys. Lett. 1999, 75, 737–739. [Google Scholar] [CrossRef]

- Eldada, L.; Lawrence, L.W. Advances in polymer integrated optics. IEEE J. Sel. Top. Quantum Electron. 2000, 6, 54–68. [Google Scholar] [CrossRef]

- Hirose, N.; Yoshimura, T.; Ibaragi, O. Optical component coupling using self-written waveguides. Proc. SPIE 2002, 4640, 64–71. [Google Scholar]

- Hirose, N.; Ibaragi, O. Optical solder effects in self-written waveguides in optical circuit devices coupling. In Proceedings of the Electronic Components and Technology Conference, San Diego, CA, USA, 28–31 May 2002; Volume 52, pp. 268–275. [Google Scholar]

- Bachelot, R.; Fares, A.; Fikri, R.; Barchiesi, D.; Lerondel, G.; Royer, P. Coupling semiconductor lasers into single-mode optical fibers by use of tips grown by photopolymerization. Opt. Lett. 2004, 29, 1971–1973. [Google Scholar] [CrossRef] [PubMed]

- Yonemura, M.; Kawasaki, A.; Kato, S.; Kagami, M.; Inui, Y. Polymer waveguide module for visible wavelength division multiplexing plastic optical fiber communication. Opt. Lett. 2005, 30, 2206–2208. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.; Jin, W.; Demokan, M.S.; Ho, H.L.; Tam, H.Y.; Ju, J.; Yu, J. Photopolymer microtips for efficient light coupling between single-mode fibers and photonic crystal fibers. Opt. Lett. 2006, 31, 1791–1793. [Google Scholar] [CrossRef] [PubMed]

- Gleeson, M.R.; Liu, S.; O’Duill, S.; Sheridan, J.T. Examination of the photoinitiation processes in photopolymer materials. J. Appl. Phys. 2008, 104, 064917. [Google Scholar] [CrossRef]

- Gleeson, M.R.; Sheridan, J.T. A review of the modeling of free-radical photopolymerization in the formation of holographic gratings. J. Opt. A 2008, 11, 024008. [Google Scholar] [CrossRef]

- Gleeson, M.R.; Liu, S.; McLeod, R.R.; Sheridan, J.T. Non-local photo-polymerization kinetics including multiple termination mechanisms and dark reactions: Part II. Experimental validation. J. Opt. Soc. Am. B 2009, 26, 1746–1754. [Google Scholar] [CrossRef]

- Gleeson, M.R.; Liu, S.; Sheridan, J.T. The production of primary radicals in photopolymers during holographic exposure. Optik 2010, 121, 2273–2275. [Google Scholar] [CrossRef]

- Qi, Y.; Li, H.; Tolstik, E.; Guo, J.; Gleeson, M.R.; Matusevich, V.; Kowarschik, R.; Sheridan, J.T. Study of PQ/PMMA photopolymer. Part 1: Theoretical. J. Opt. Soc. Am. B 2013, 30, 3298–3307. [Google Scholar] [CrossRef]

- Qi, Y.; Tolstik, E.; Li, H.; Guo, J.; Gleeson, M.R.; Matusevich, V.; Kowarschik, R.; Sheridan, J.T. Study of PQ/PMMA photopolymer. Part 2: Experimental results. J. Opt. Soc. Am. B 2013, 30, 3308–3315. [Google Scholar] [CrossRef]

- Pang, C.; Gesuele, F.; Bruyant, A.; Blaize, S.; Lérondel, G.; Royer, P. Enhanced light coupling in sub-wavelength single-mode silicon on insulator waveguides. Opt. Express 2009, 17, 6939–6945. [Google Scholar] [CrossRef] [PubMed]

- Belgacem, M.B.; Kamoun, S.; Gargouri, M.; Dorkenoo, K.D.; Barsella, A.; Mager, L. Light induced self-written waveguides interactions in photopolymer media. Opt. Express 2015, 23, 20841–20848. [Google Scholar] [CrossRef] [PubMed]

- Burrell, D.; Middlebrook, C. Comparison of self-written waveguide techniques and bulk index matching for low-loss polymer waveguide interconnects. Proc. SPIE 2016, 9753, 975306. [Google Scholar]

| Component | Function | Per 100 cm3 |

|---|---|---|

| Polyvinyl Alcohol (PVA) | Binder | 70 cm3 of 10% sol. |

| Acrlyamide (AA) | Monomer | 2.4 g |

| Bis-acrylamide (BA) | Cross-linker | 0.8 g |

| Xanthene dye | Dye | 16 cm3 of 1.25 × 10−3 M |

| Triethanolamine (TEA) | Electron Donor (ED) | 8 cm3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malallah, R.; Li, H.; Kelly, D.P.; Healy, J.J.; Sheridan, J.T. A Review of Hologram Storage and Self-Written Waveguides Formation in Photopolymer Media. Polymers 2017, 9, 337. https://doi.org/10.3390/polym9080337

Malallah R, Li H, Kelly DP, Healy JJ, Sheridan JT. A Review of Hologram Storage and Self-Written Waveguides Formation in Photopolymer Media. Polymers. 2017; 9(8):337. https://doi.org/10.3390/polym9080337

Chicago/Turabian StyleMalallah, Ra’ed, Haoyu Li, Damien P. Kelly, John J. Healy, and John T. Sheridan. 2017. "A Review of Hologram Storage and Self-Written Waveguides Formation in Photopolymer Media" Polymers 9, no. 8: 337. https://doi.org/10.3390/polym9080337