Biomass Waste Conversion Technologies and Its Application for Sustainable Environmental Development—A Review

Abstract

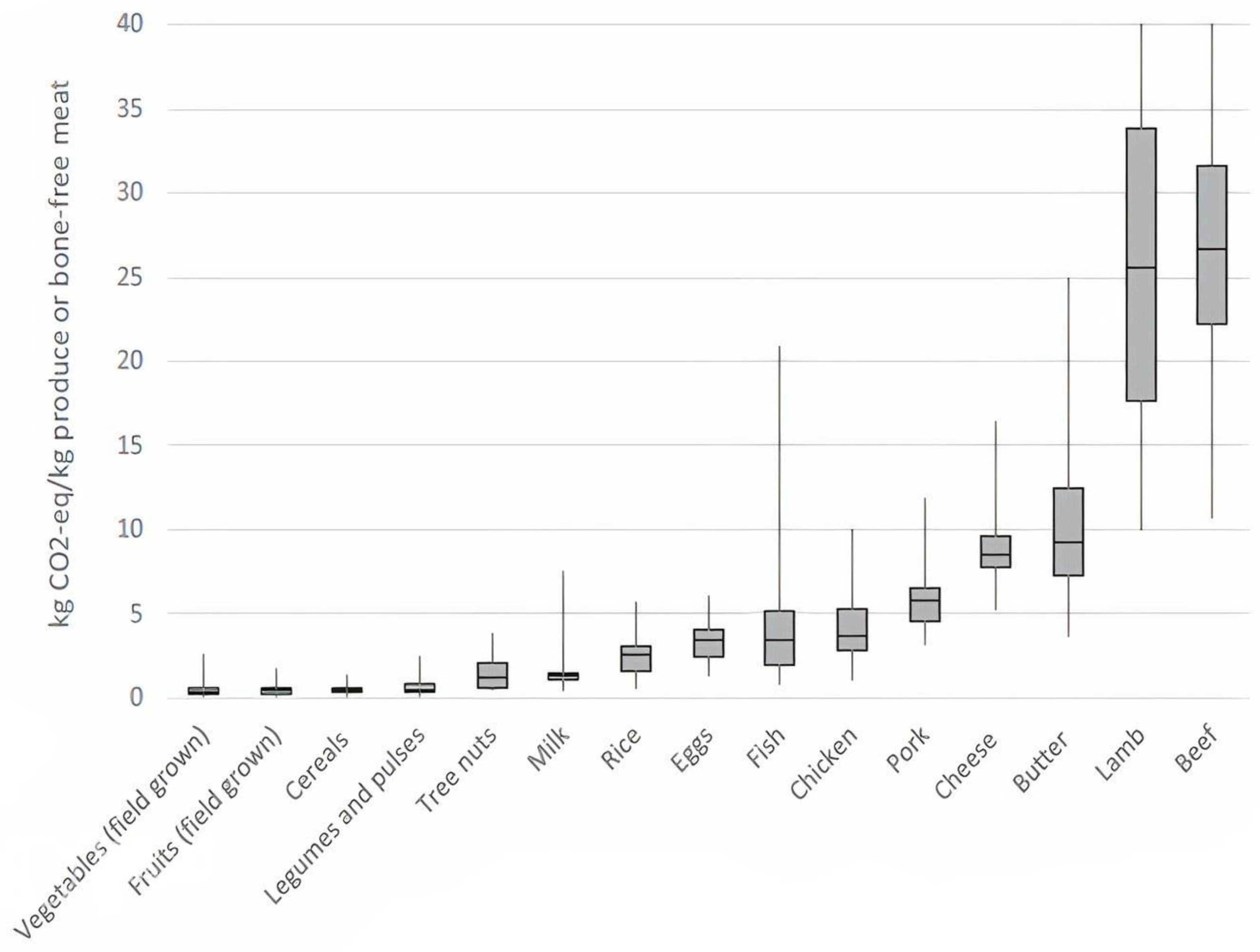

:1. Introduction

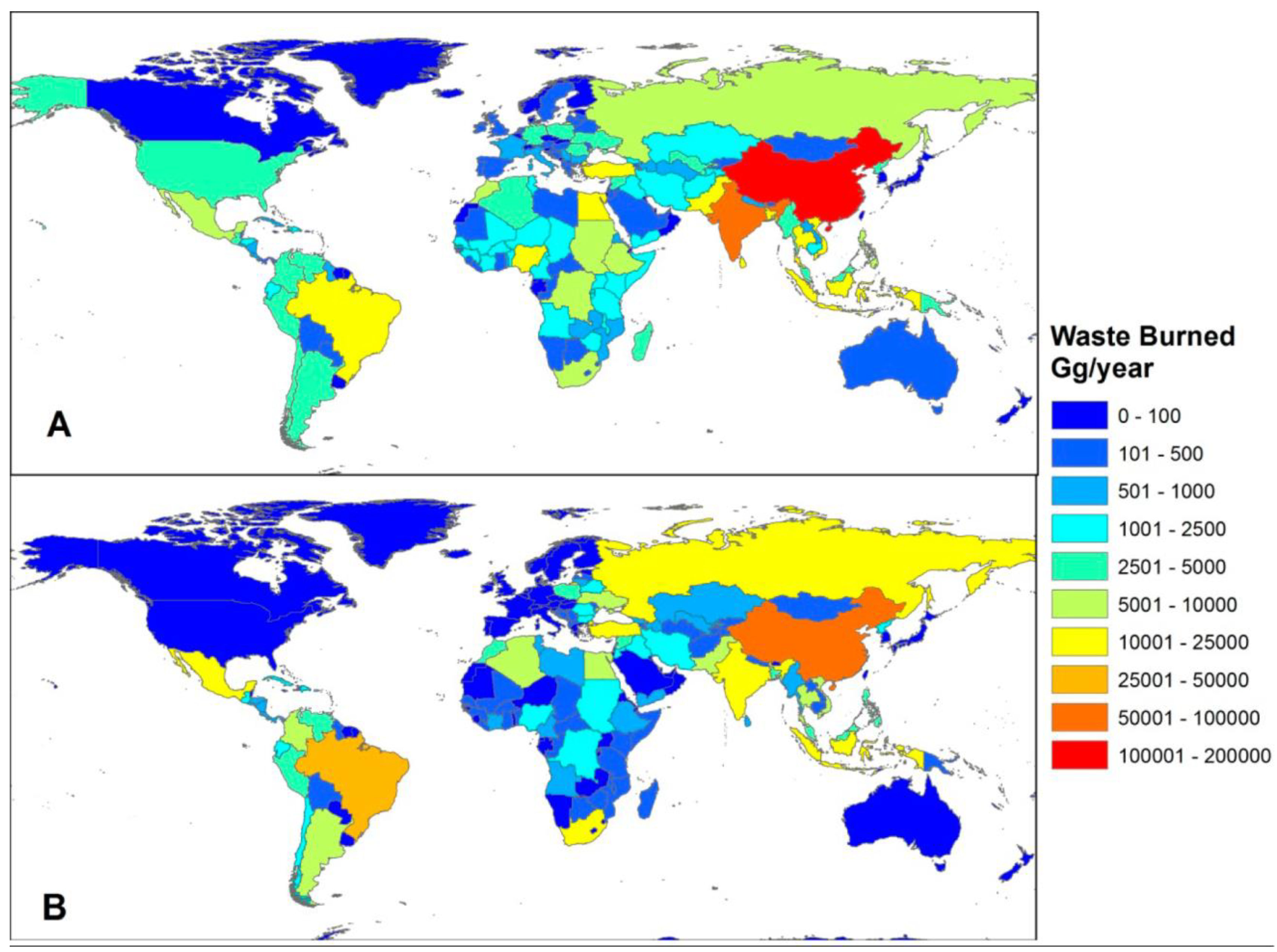

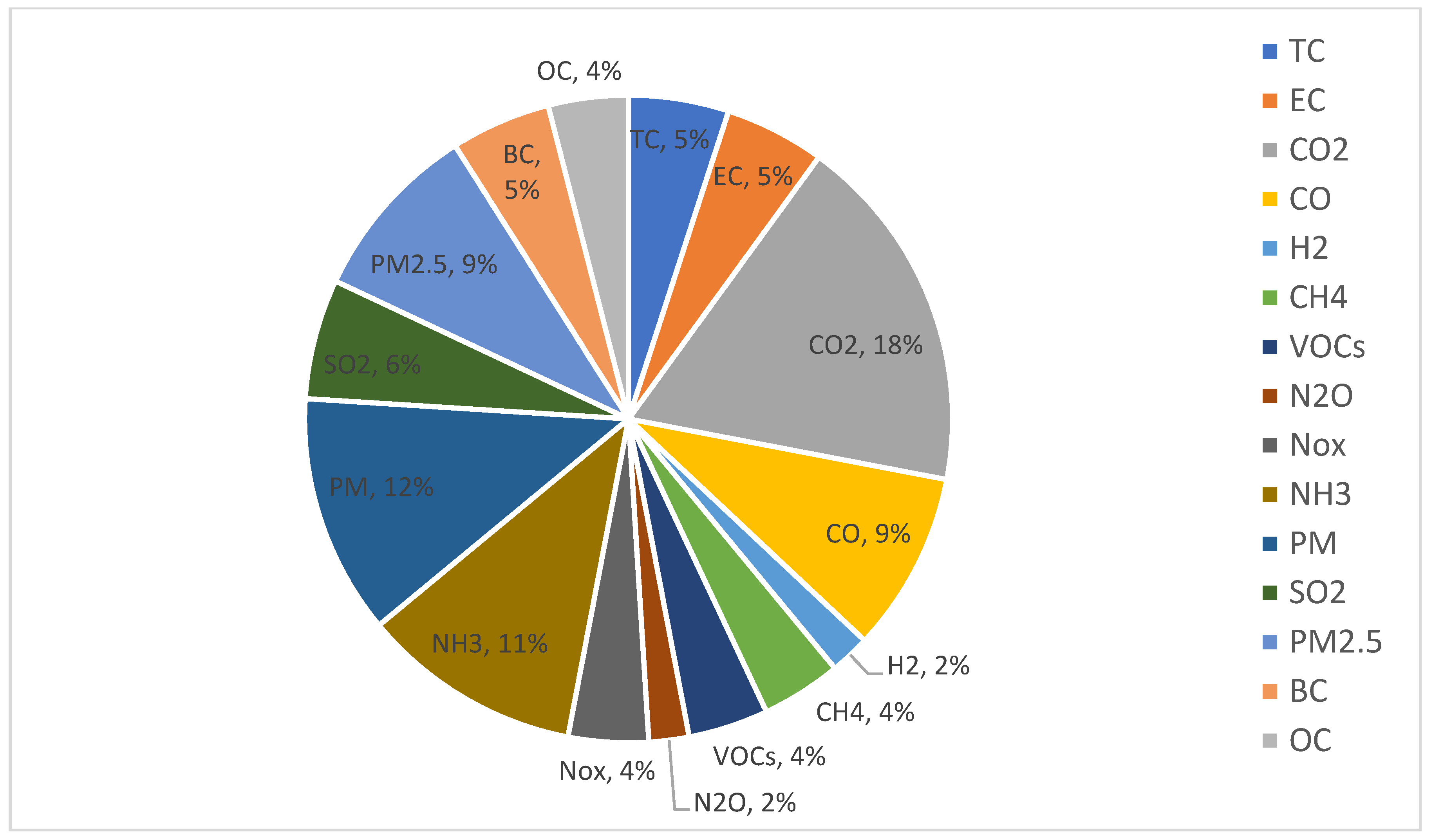

2. Biomass Waste

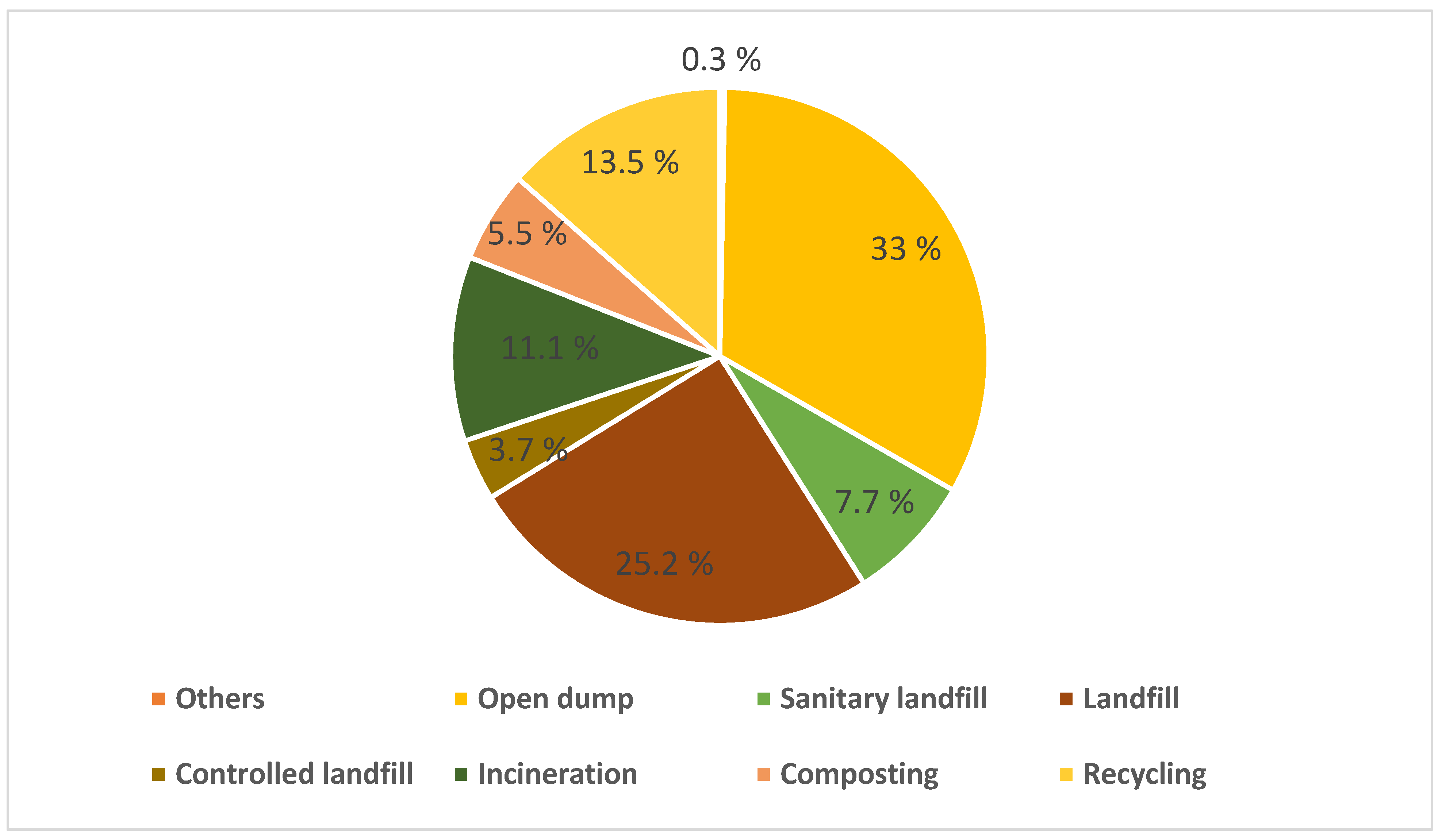

Spotlight on Lebanon

3. Biomass Conversion Technologies

3.1. Biochemical Conversion

3.1.1. Anaerobic Digestion

3.1.2. Fermentation

Fermentation Products

- Biofuels like ethanol (the most prevalent), butanol, acetone, iso-butanol, lipids, and more.

- Organic acids such as lactic acid.

- Carbon dioxide.

- Hydrogen gas (H2).

Fermentation Feedstocks

Limitations of Fermentation

- Challenges in the process of deconstructing lignocellulosic biomass into functional components like sugars and lignin.

- The need for energy-intensive pretreatment processes to separate the complex biomass into its individual components.

- A significant proportion of the cost of processing lignocellulosic biomass for energy production comes from the pretreatment step, which can be more than 40%.

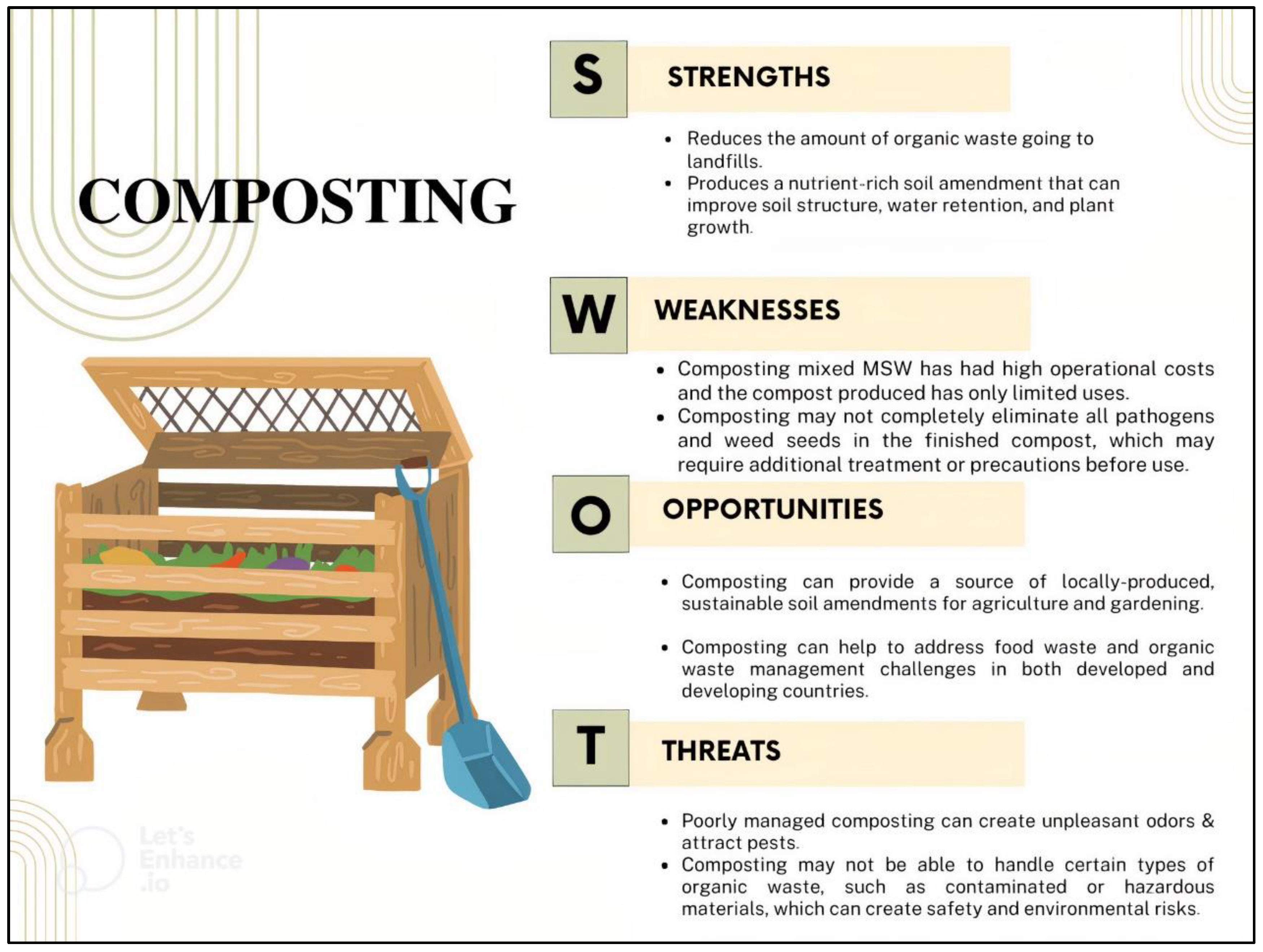

3.1.3. Composting

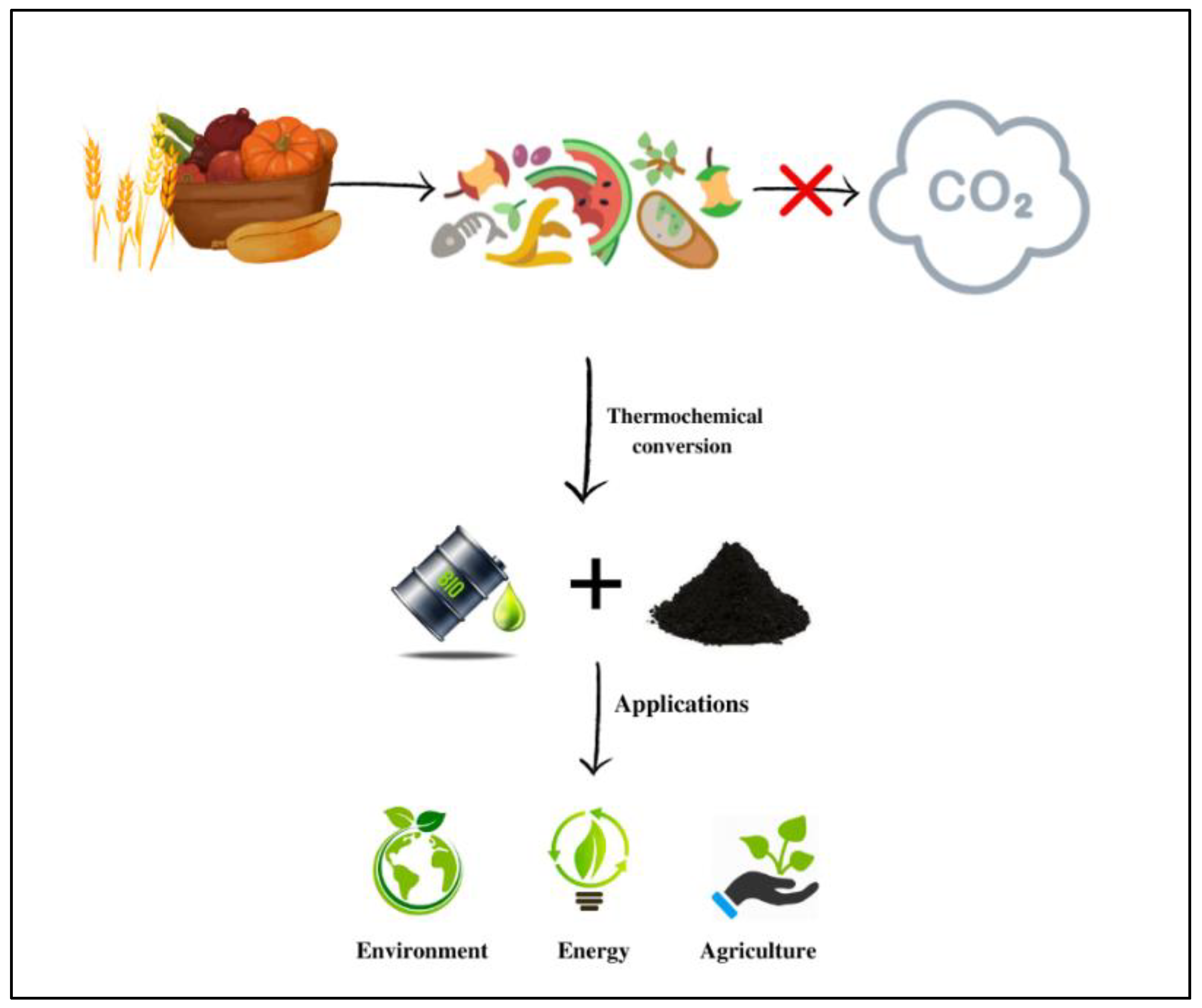

3.2. Thermochemical Conversion:

3.2.1. Direct Combustion

3.2.2. Gasification

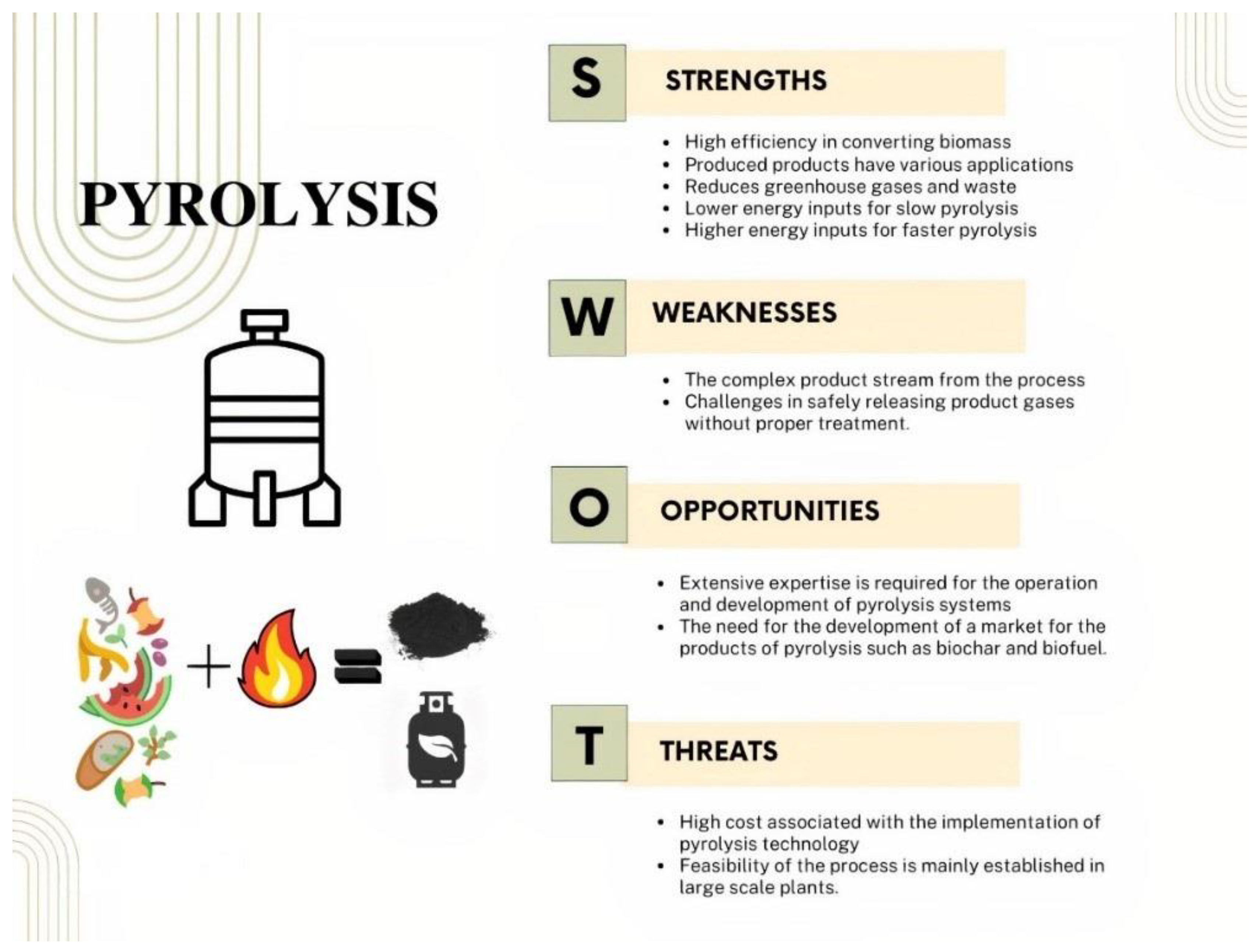

3.2.3. Pyrolysis

| Raw Material | Wood | Peat | Straw Husk | Sunflower Litter | Chicken Sludge | Sewage | |

|---|---|---|---|---|---|---|---|

| Calorific value * (MJ/kg) | Qh | 13.2 | 10.5 | 9.1 | 7.9 | 7.8 | 11.1 |

| Ql | 12.0 | 9.5 | 8.2 | 7.2 | 7.2 | 9.9 | |

| Degree of energy conversion ** | 0.18 | 0.16 | 0.14 | 0.16 | 0.14 | 0.13 | |

| Adiabatic temperature of combustion (°C) | 1860 | 1730 | 1720 | 1640 | 1710 | 1770 | |

| Residence Time | Heating Rate | Temperature | Main Products | |

|---|---|---|---|---|

| Slow | Days | Very show | 400 °C | Char |

| Conventional | 5–30 min | 20–100 °C/min | 450–650 °C | Liquid, gas, char |

| Fast | 0.5–5 s | 1000 °C/s | 450–650 °C | Liquid |

3.2.4. Hydrothermal Carbonization

4. Hydrochar and Biochar

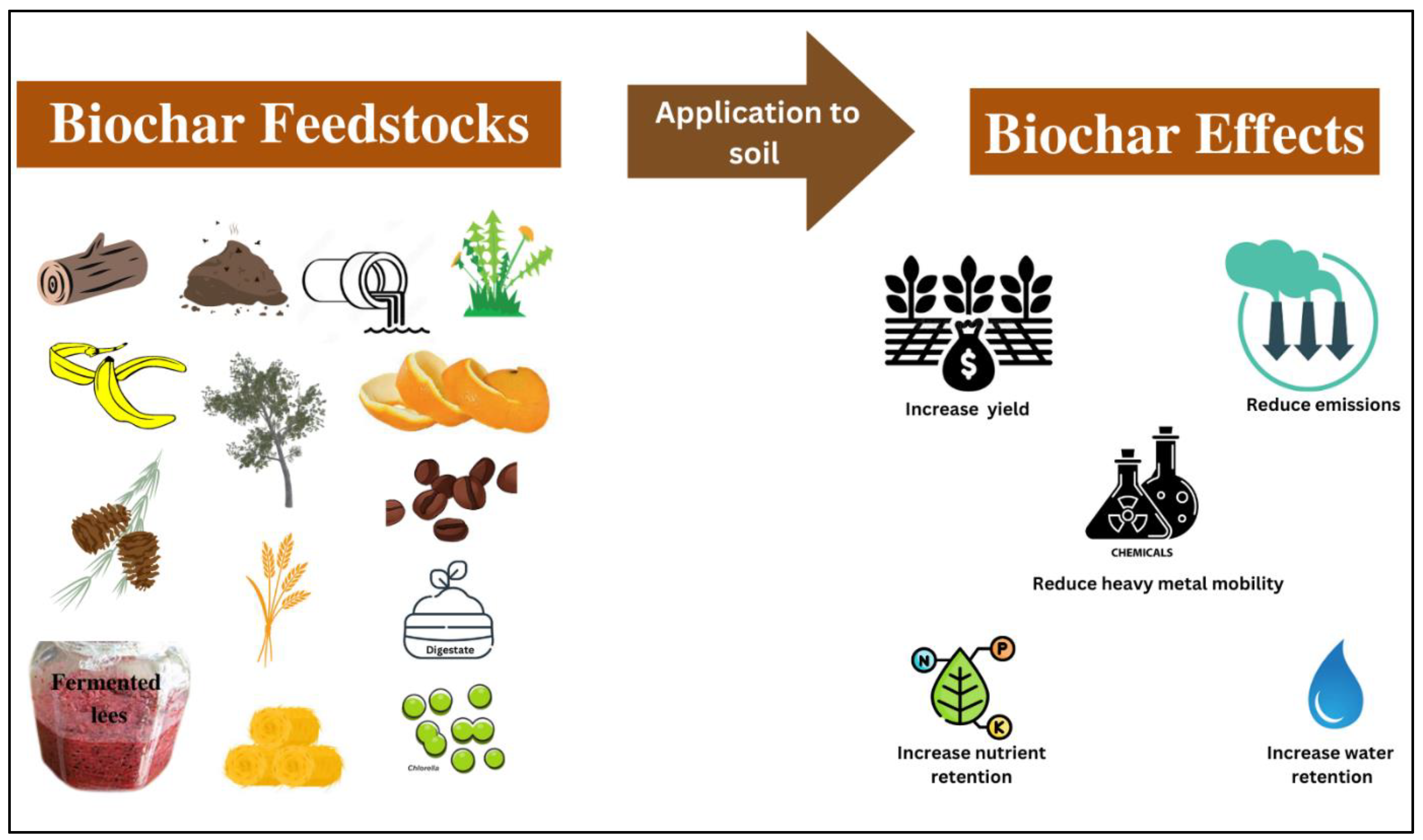

5. Application of Chars

5.1. Yield Improvement

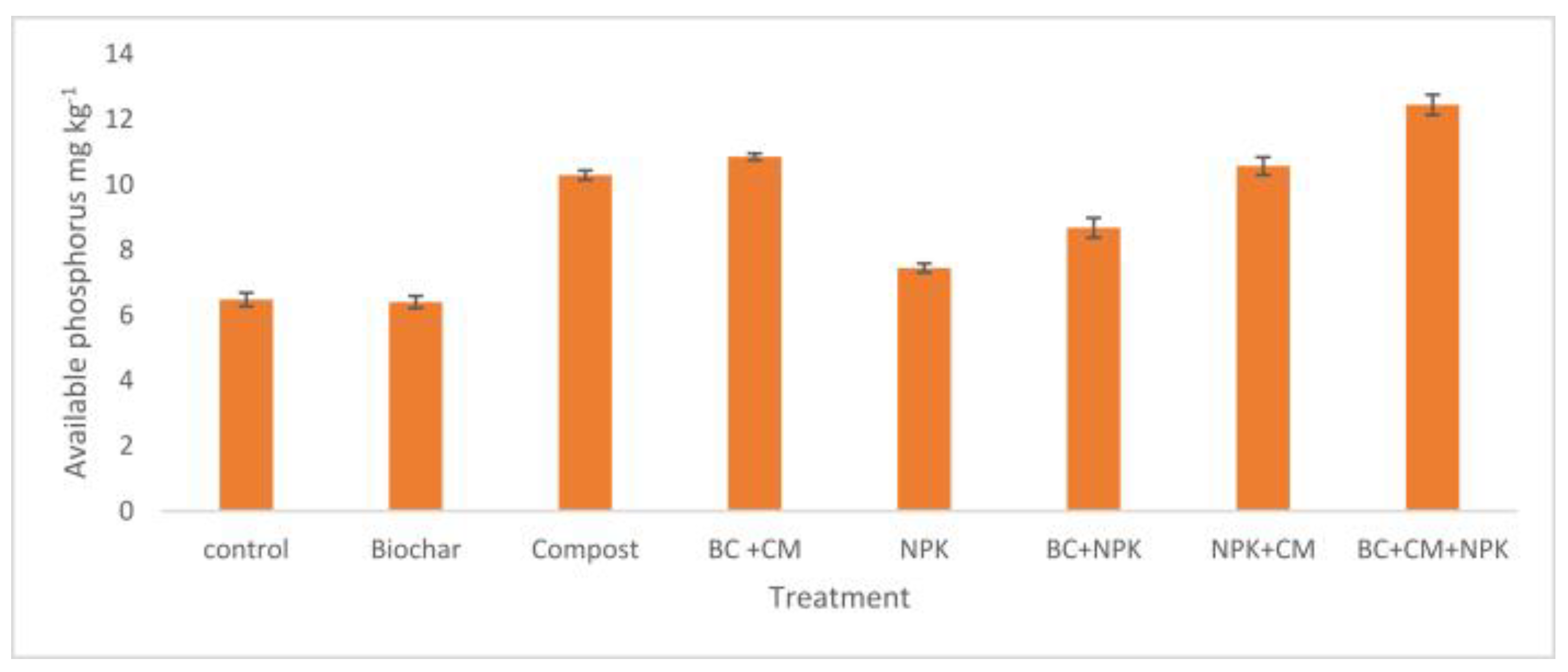

5.2. Nutrient Retention

5.3. Water Retention

5.4. Reduce Greenhouse Gases (GHG) Emissions

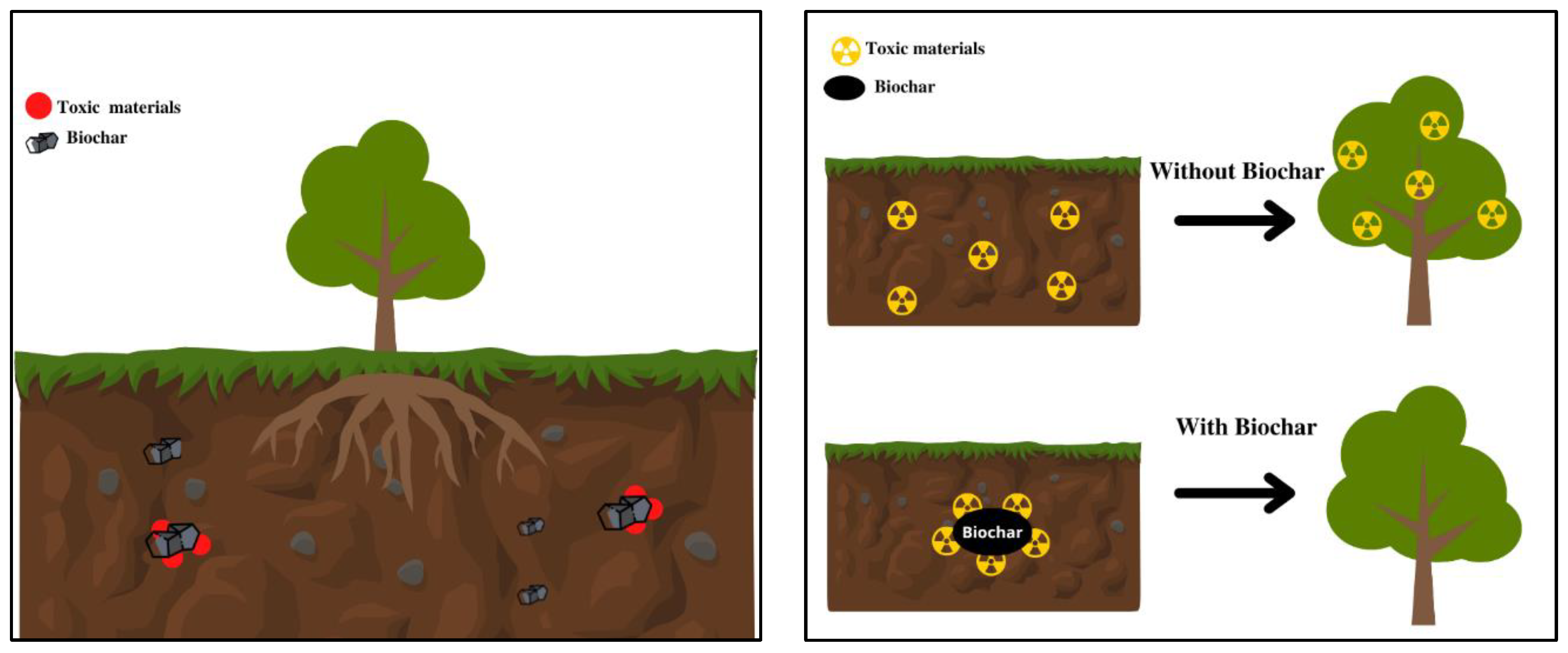

5.5. Reduce Heavy Metals Availability

5.6. Carbon Sequestration

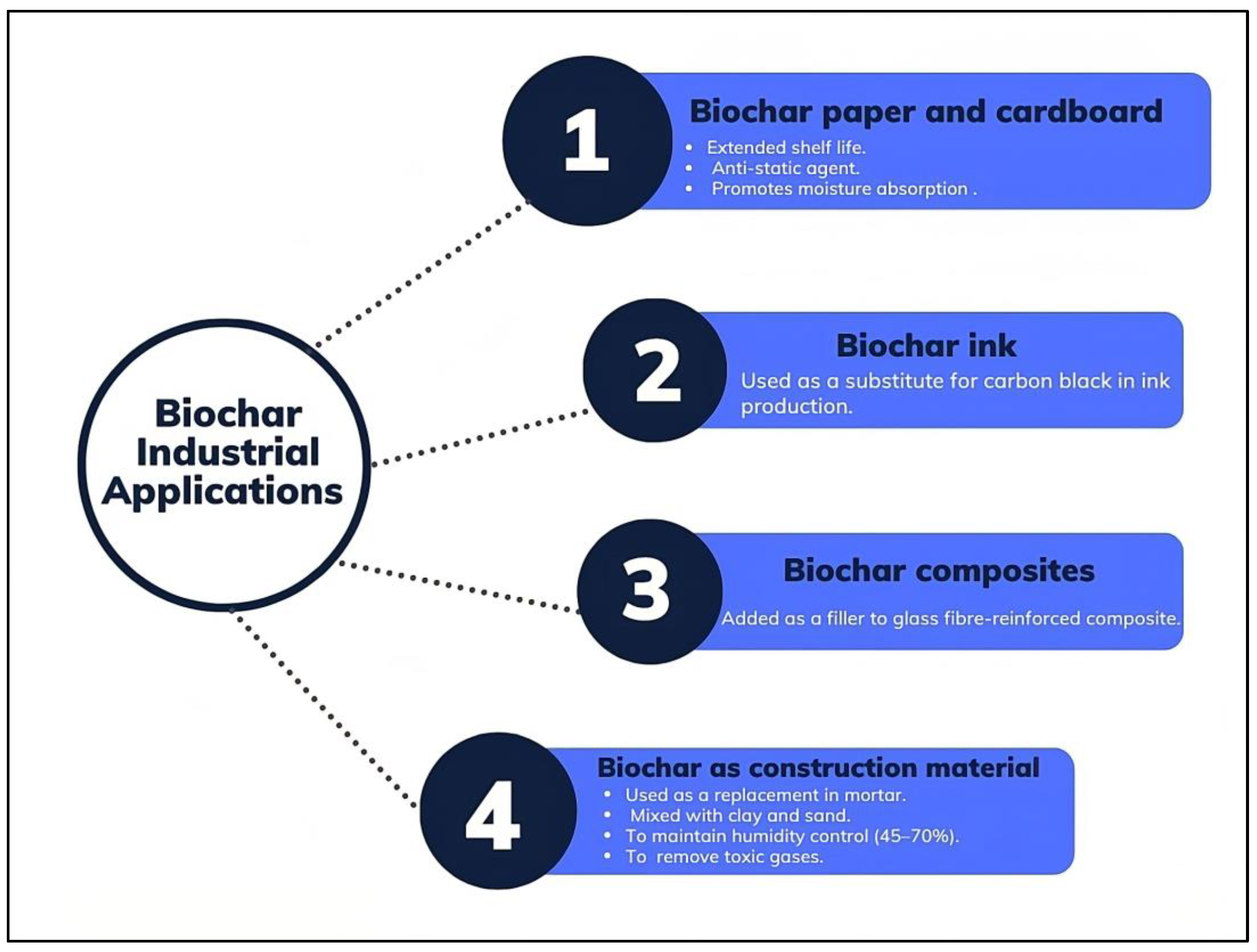

5.7. Industrial Application of Biochar

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chamie, J. Population growth diversity continuing in the twenty-first century. In Population Levels, Trends, and Differentials; Chamie, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2022; pp. 413–427. [Google Scholar] [CrossRef]

- Gu, D.; Andreev, K.; Dupre, M.E. Major trends in population growth around the world. China CDC Wkly. 2021, 3, 604–613. [Google Scholar] [CrossRef] [PubMed]

- Godfray, H.C.J.; Aveyard, P.; Garnett, T.; Hall, J.W.; Key, T.J.; Lorimer, J.; Pierrehumbert, R.T.; Scarborough, P.; Springmann, M.; Jebb, S.A. Meat consumption, health, and the environment. Science 2018, 361, eaam5324. [Google Scholar] [CrossRef] [PubMed]

- Statista. Fresh Vegetables-Worldwide: Statista Market Forecast. 2022. Available online: https://www.statista.com/outlook/cmo/food/vegetables/worldwide#revenue (accessed on 16 September 2023).

- Uddin, M.M.M. What are the dynamic links between agriculture and manufacturing growth and environmental degradation? Evidence from different panel income countries. Environ. Sustain. Indic. 2020, 7, 100041. [Google Scholar] [CrossRef]

- van Dijk, M.; Morley, T.; Rau, M.L.; Sulser, T.B.; Lipper, L.; Wiebe, K. A meta-analysis of projected global food demand and population at risk of hunger for the period 2010–2050. Nat. Food 2021, 2, 494–501. [Google Scholar] [CrossRef]

- Crippa, M.; Solazzo, E.; Guizzardi, D.; Monforti-Ferrario, F.; Tubiello, F.N.; Leip, A. Food systems are responsible for a third of global anthropogenic GHG emissions. Nat. Food 2021, 2, 198–209. [Google Scholar] [CrossRef] [PubMed]

- Kroyer, G. Impact of food processing on the environment—An overview. LWT Food Sci. Technol. 1995, 28, 547–552. [Google Scholar] [CrossRef]

- Giovannucci, D.; Scherr, S.J.; Nierenberg, D.; Hebebrand, C.; Shapiro, J.; Milder, J.; Wheeler, K. Food and Agriculture: The future of sustainability. SSRN Electron. J. 2012. [Google Scholar] [CrossRef]

- Everwand, G.; Cass, S.; Dauber, J.; Williams, M.; Stout, J. Legume crops and biodiversity. In Legumes in Cropping Systems, 1st ed.; Murphy-Bokern, D., Stoddard, F.L., Watson, C.A., Eds.; CABI: Oxon, UK, 2017; pp. 55–69. [Google Scholar] [CrossRef]

- Clune, S.; Crossin, E.; Verghese, K. Systematic review of greenhouse gas emissions for different fresh food categories. J. Clean. Prod. 2017, 140, 766–783. [Google Scholar] [CrossRef]

- Peoples, M.B.; Giller, K.E.; Jensen, E.S.; Herridge, D.F.; Bourion, V.; Kumar, S.; Li, L.; Mpepereki, S.; Mulholland, M.; van Kessel, C.; et al. Quantifying country-to-global scale nitrogen fixation for grain legumes: I. Reliance on nitrogen fixation of soybean, groundnut and pulses. Plant Soil 2021, 469, 1–14. [Google Scholar] [CrossRef]

- Sutton, P.; Wallinga, D.; Perron, J.; Gottlieb, M.; Sayre, L.; Woodruff, T. Reproductive Health And The Industrialized Food System: A Point Of Intervention For Health Policy. Health Aff. 2011, 30, 888–897. [Google Scholar] [CrossRef]

- Ishangulyyev, R.; Kim, S.; Lee, S.H. Understanding Food Loss and Waste—Why Are We Losing and Wasting Food? Foods 2019, 8, 297. [Google Scholar] [CrossRef]

- Kojima, R.; Ishikawa, M. Prevention and Recycling of Food Wastes in Japan. 2013. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwiQ8r-H58SCAxU6qFYBHVRECKoQFnoECBgQAQ&url=https%3A%2F%2Fs3b3b3a1c9c7aa7a9.jimcontent.com%2Fdownload%2Fversion%2F1371618475%2Fmodule%2F7050419389%2Fname%2F%25E6%2597%25A5%25E6%259C%25AC%25E3%2581%25AE%25E9%25A3%259F%25E5%2593%2581%25E3%2583%25AA%25E3%2582%25B5%25E3%2582%25A4%25E3%2582%25AF%25E3%2583%25AB%25E6%25B3%2595%25E3%2580%2580%25E3%2583%259D%25E3%2582%25B9%25E3%2582%25BF%25E3%2583%25BC%25E3%2582%25BB%25E3%2583%2583%25E3%2582%25B7%25E3%2583%25A7%25E3%2583%25B3%25EF%25BC%25882013%25E5%25B9%25B45%25E6%259C%258831%25E6%2597%25A5%25EF%25BD%259E6%25E6%259C%25881%25E6%2597%25A5%25EF%25BC%2589%25E3%2583%259C%25E3%2583%25B3.pdf&usg=AOvVaw13MRKyZxEm9xtsscZSCsog&opi=89978449 (accessed on 16 September 2023).

- Ahmad, T.; Zhang, D. A critical review of comparative global historical energy consumption and future demand: The story told so far. Energy Rep. 2020, 6, 1973–1991. [Google Scholar] [CrossRef]

- Moodley, P. Sustainable biofuels: Opportunities and challenges. Sustain. Biofuels 2021, 1–20. [Google Scholar] [CrossRef]

- Rafiee, A.; Khalilpour, K.R. Renewable Hybridization of Oil and Gas Supply Chains. In Polygeneration with Polystorage for Chemical and Energy Hubs; Academic Press: London, UK, 2019; pp. 331–372. [Google Scholar] [CrossRef]

- Esmaeili, H.; Nourafkan, E.; Nakisa, M.; Ahmed, W. Application of nanotechnology for biofuel production. In Emerging Nanotechnologies for Renewable Energy; Elsevier: Amsterdam, The Netherlands, 2021; pp. 149–172. [Google Scholar]

- Pang, S. Fuel flexible gas production: Biomass, coal and bio-solid wastes. In Fuel Flexible Energy Generation; Woodhead Publishing: Amsterdam, The Netherlands, 2016; pp. 241–269. [Google Scholar] [CrossRef]

- Kaltschmitt, M.; Janczik, S. Biomass to power is on the rise globally. Renew. Energy Focus 2015, 16, 174–176. [Google Scholar] [CrossRef]

- Tripathi, N.; Hills, C.D.; Singh, R.S.; Atkinson, C.J. Biomass waste utilisation in low-carbon products: Harnessing a major potential resource. Npj Clim. Atmos. Sci. 2019, 2, 35. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, Y. Recent progress in the conversion of biomass wastes into functional materials for value-added applications. Sci. Technol. Adv. Mater. 2020, 21, 787–804. [Google Scholar] [CrossRef] [PubMed]

- Wiedinmyer, C.; Yokelson, R.J.; Gullett, B.K. Global emissions of trace gases, particulate matter, and hazardous air pollutants from open burning of domestic waste. Environ. Sci. Technol. 2014, 48, 9523–9530. [Google Scholar] [CrossRef] [PubMed]

- Fekete, B. Biomass. In Climate Vulnerability; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; pp. 83–87. [Google Scholar] [CrossRef]

- Lou, X.F.; Nair, J. The impact of landfilling and composting on greenhouse gas emissions—A review. Bioresour. Technol. 2009, 100, 3792–3798. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H. Biomass burning emission and impacts on air pollution in China. In Asian Atmospheric Pollution; Elsevier: Amsterdam, The Netherlands, 2022; pp. 335–347. [Google Scholar] [CrossRef]

- Fajobi, M.O.; Lasode, O.A.; Adeleke, A.A.; Ikubanni, P.P.; Balogun, A.O. Investigation of physicochemical characteristics of selected lignocellulose biomass. Sci. Rep. 2022, 12, 2918. [Google Scholar] [CrossRef]

- Giglio, L.; Randerson, J.T.; van der Werf, G.R. Analysis of daily, monthly, and annual burned area using the fourth-generation global fire emissions database (Gfed4): Analysis of Burned Area. J. Geophys. Res. Biogeosci. 2013, 118, 317–328. [Google Scholar] [CrossRef]

- World Bank. The Role of Food and Agriculture for Job Creation and Poverty Reduction in Jordan and Lebanon. 2018. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwi6obv56MSCAxV7rlYBHaBjDjAQFnoECBMQAw&url=https%3A%2F%2Fdocuments1.worldbank.org%2Fcurated%2Fen%2F325551536597194695%2Fpdf%2FAgricultural-Sector-Note-Jordan-and-Lebanon.pdf&usg=AOvVaw3_pYF-uqd4JahTj6W5QmEE&opi=89978449 (accessed on 16 September 2023).

- Wehbe, N. Optimization of Lebanon’s power generation scenarios to meet the electricity demand by 2030. Electr. J. 2020, 33, 106764. [Google Scholar] [CrossRef]

- Julian, M.; Bassil, N.; Dellagi, S. Lebanon’s electricity from fuel to solar energy production. Energy Rep. 2020, 6, 420–429. [Google Scholar] [CrossRef]

- Ersoy, S.R.; Terrapon-Pfaff, J.; Ayoub, M.; Akkouch, R. Report. Sustainable Transformation of Lebanon’s Energy System. Friedrich-Ebert-Stiftung. 2021. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwitn5mH6cSCAxU8k1YBHfQfBOwQFnoECBMQAQ&url=https%3A%2F%2Flibrary.fes.de%2Fpdf-files%2Fbueros%2Fbeirut%2F19294.pdf&usg=AOvVaw3vHB8hRJE3Y5Xs5l__n6X-&opi=89978449 (accessed on 16 September 2023).

- Nobre, R.C.; Nobre, M.M. Groundwater and Health Implications of Biofuels Production. Environ. Impact Biofuels Cap 2011, 7, 123–136. [Google Scholar] [CrossRef]

- SWEEP-Net. Country Report on the Solid Waste. 2014. Available online: https://www.scirp.org/(S(lz5mqp453edsnp55rrgjct55.))/reference/referencespapers.aspx?referenceid=1754325 (accessed on 16 September 2023).

- Abbas, I.I.; Chaaban, J.K.; Al-Rabaa, A.-R.; Shaar, A.A. Solid Waste Management in Lebanon: Challenges and Recommendations. J. Environ. Manag. 2019, 248, 109302. [Google Scholar] [CrossRef]

- MOA. The Agriculture Sector-Climate Change Lebanon. 2007. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwij1qm06cSCAxXblFYBHc11D9IQFnoECBkQAQ&url=https%3A%2F%2Fclimatechange.moe.gov.lb%2Fviewfile.aspx%3Fid%3D154&usg=AOvVaw3XCNRdMdWyG4R_nasBGR12&opi=89978449 (accessed on 16 September 2023).

- Wancura, J.H.; Brondani, M.; Vezaro, F.D.; Martins-Vieira, J.C.; Moreira, B.P.; Dos Santos, M.S.; Abaide, E.R.; De Castilhos, F.; Mayer, F.D. Motivations to produce biofuels from rice bran: An overview involving a recent panorama. Ind. Crops Prod. 2023, 203, 117170. [Google Scholar] [CrossRef]

- Martín, M.; Taifouris, M.; Galán, G. Lignocellulosic biorefineries: A multiscale approach for resource exploitation. Bioresour. Technol. 2023, 385, 129397. [Google Scholar] [CrossRef]

- Vickram, A.; Saravanan, A.; Senthil Kumar, P.; Thamarai, P.; Yasodha, S.; Jamuna, G.; Rangasamy, G. An integrated approach to the sustainable development and production of biofuel from biopolymers and algal biomass derived from wastewater. Fuel 2023, 349, 128691. [Google Scholar] [CrossRef]

- Adams, P.; Bridgwater, T.; Lea-Langton, A.; Ross, A.; Watson, I. Biomass Conversion Technologies. In Greenhouse Gas Balances of Bioenergy Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 107–139. [Google Scholar] [CrossRef]

- Velvizhi, G.; Jacqueline, P.J.; Shetti, N.P.K.L.; Mohanakrishna, G.; Aminabhavi, T.M. Emerging trends and advances in valorization of lignocellulosic biomass to biofuels. J. Environ. Manag. 2023, 345, 118527. [Google Scholar] [CrossRef]

- Garba, A. Biomass conversion technologies for bioenergy generation: An introduction. In Biotechnological Applications of Biomass; Basso, T.P., Basso, T.O., Basso, L.C., Eds.; IntechOpen: London, UK, 2020; pp. 1–18. [Google Scholar] [CrossRef]

- Rosendahl, L. Biomass resources, fuel preparation and utilization for improving the fuel flexibility of advanced power plants. In Advanced Power Plant Materials, Design and Technology; Elsevier: Amsterdam, The Netherlands, 2010; pp. 312–331. [Google Scholar] [CrossRef]

- Williams, C.L.; Dahiya, A.; Porter, P. Introduction to bioenergy and waste to energy. In Bioenergy, 2nd ed.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2020; pp. 5–44. [Google Scholar] [CrossRef]

- Chen, H.; Wang, L. Technologies for Biochemical Conversion of Biomass; Academic Press: London, UK, 2016. [Google Scholar]

- Chen, H.; Qiu, W. Key technologies for bioethanol production from lignocellulose. Biotechnol. Adv. 2010, 28, 556–562. [Google Scholar] [CrossRef]

- Kumar, S.; Ankaram, S. Waste-to-Energy Model/Tool Presentation. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 239–258. [Google Scholar] [CrossRef]

- Sangeetha, T.; Rajneesh, C.P.; Yan, W. Integration of microbial electrolysis cells with anaerobic digestion to treat beer industry wastewater. In Integrated Microbial Fuel Cells for Wastewater Treatment; Butterworth-Heinemann: Oxford, UK; Cambridge, MA, USA, 2020; pp. 313–346. [Google Scholar] [CrossRef]

- Ghosh, P.; Sengupta, S.; Singh, L.; Sahay, A. Life cycle assessment of waste-to-bioenergy processes: A review. Bioreactors 2020, 105–122. [Google Scholar]

- Wang, W.; Lee, D. Valorization of anaerobic digestion digestate: A prospect review. Bioresour. Technol. 2021, 323, 124626. [Google Scholar] [CrossRef]

- Ge, X.; Yang, L.; Sheets, J.P.; Yu, Z.; Li, Y. Biological conversion of methane to liquid fuels: Status and opportunities. Biotechnol. Adv. 2014, 32, 1460–1475. [Google Scholar] [CrossRef]

- Xu, F.; Khalaf, A.; Sheets, J.; Ge, X.; Keener, H.; Li, Y. Phosphorus Removal and Recovery From Anaerobic Digestion Residues. Adv. Bioenergy 2018, 3, 77–136. [Google Scholar]

- Patra, D.; Patra, B.R.; Pattnaik, F.; Hans, N.; Kushwaha, A. Recent evolution in green technologies for effective valorization of food and agricultural wastes. In Emerging Trends to Approaching Zero Waste; Elsevier: Amsterdam, The Netherlands, 2022; pp. 103–132. [Google Scholar] [CrossRef]

- Galbe, M.; Wallberg, O.; Zacchi, G. Techno-economic aspects of ethanol production from lignocellulosic agricultural crops and residues. In Comprehensive Biotechnology, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2011; pp. 519–531. [Google Scholar] [CrossRef]

- Chandel, A.K.; Garlapati, V.K.; Singh, A.K.; Antunes, F.A.F.; da Silva, S.S. The path forward for lignocellulose biorefineries: Bottlenecks, solutions, and perspective on commercialization. Bioresour. Technol. 2018, 264, 370–381. [Google Scholar] [CrossRef]

- Khan, Z.; Dwivedi, A.K. Fermentation of Biomass for Production of Ethanol: A Review. Univers. J. Environ. Res. Technol. 2013, 3, 1–13. [Google Scholar]

- Rodionova, M.V.; Bozieva, A.M.; Zharmukhamedov, S.K.; Leong, Y.K.; Chi-Wei Lan, J.; Veziroglu, A.; Veziroglu, T.N.; Tomo, T.; Chang, J.; Allakhverdiev, S.I. A comprehensive review on lignocellulosic biomass biorefinery for sustainable biofuel production. Int. J. Hydrogen Energy 2022, 47, 1481–1498. [Google Scholar] [CrossRef]

- Tse, T.J.; Wiens, D.J.; Reaney, M.J.T. Production of Bioethanol—A Review of Factors Affecting Ethanol Yield. Fermentation 2021, 7, 268. [Google Scholar] [CrossRef]

- Wu, X.; Luo, N.; Xie, S.; Zhang, H.; Zhang, Q.; Wang, F.; Wang, Y. Photocatalytic transformations of lignocellulosic biomass into chemicals. Chem. Soc. Rev. 2020, 49, 6198–6223. [Google Scholar] [CrossRef]

- Kumar, M.; Goyal, Y.; Sarkar, A.; Gayen, K. Comparative economic assessment of ABE fermentation based on cellulosic and non-cellulosic feedstocks. Appl. Energy 2012, 93, 193–204. [Google Scholar] [CrossRef]

- Youngs, H.; Somerville, C. Development of feedstocks for cellulosic biofuels. F1000 Biol. Rep. 2012, 4, 10. [Google Scholar] [CrossRef]

- Sindhu, R.; Binod, P.; Pandey, A. Biological pretreatment of lignocellulosic biomass–An overview. Bioresour. Technol. 2016, 199, 76–82. [Google Scholar] [CrossRef]

- Broda, M.; Yelle, D.J.; Serwa’nska, K. Bioethanol production from lignocellulosic biomass—Challenges and solutions. Molecules 2022, 27, 8717. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Tsai, M.-L.; Sharma, V.; Sun, P.-P.; Nargotra, P.; Bajaj, B.K.; Chen, C.-W.; Dong, C.-D. Environment Friendly Pretreatment Approaches for the Bioconversion of Lignocellulosic Biomass into Biofuels and Value-Added Products. Environments 2022, 10, 6. [Google Scholar] [CrossRef]

- Gautam, P.; Kumar, S.; Lokhandwala, S. Energy-Aware Intelligence in Megacities. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 211–238. [Google Scholar] [CrossRef]

- Ghisellini, P.; Santagata, R.; Zucaro, A.; Ulgiati, S. Circular patterns of waste prevention and recovery. E3S Web Conf. 2019, 119, 00003. [Google Scholar] [CrossRef]

- Mazzà, G.; Malek, R.; Raguzzoni, K.; Ragazzi, M.; Ciolli, M. The Usage of Compost-Like Outputs in Lebanon: Regulatory Framework, Opportunities and Threats. A Survey. 2020. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwiIh9r26sSCAxV9glYBHeVNC8oQFnoECBYQAQ&url=https%3A%2F%2Fwww.microfinanzaesviluppo.it%2Fwp-content%2Fuploads%2F2021%2F02%2FCompost_Survey_Lebanon.pdf&usg=AOvVaw3wkZbrLlxfj0F38KB-xja2&opi=89978449 (accessed on 16 September 2023).

- Keener, H.M. Challenges and Opportunities in Composting Organic Waste. In Climate Change and Food Security in South Asia; Lal, R., Sivakumar, M., Faiz, S., Mustafizur Rahman, A., Islam, K., Eds.; Springer: Dordrecht, The Netherlands, 2010. [Google Scholar] [CrossRef]

- Mahinpey, N.; Gomez, A. Review of gasification fundamentals and new findings: Reactors, feedstock, and kinetic studies. Chem. Eng. Sci. 2016, 148, 14–31. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Motta, I.L.; Filho, R.M.; van der Wielen, L.; Capaz, R.; Seabra, J.; Osseweijer, P.; Posada, J.; de Freitas Gonçalves, M.; Scorza, P.R.; et al. Sustainable Aviation Fuels: Production, Use and Impact on Decarbonization. In Comprehensive Renewable Energy, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 348–371. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X. The thermochemical conversion of biomass into biofuels. In Biomass, Biopolymer-Based Materials, and Bioenergy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 327–368. [Google Scholar]

- Sadhwani, N.; Liu, Z.; Eden, M.R.; Adhikari, S. Simulation, Analysis, and Assessment of CO2 Enhanced Biomass Gasification. Comput. Aided Chem. Eng. 2013, 32, 421–426. [Google Scholar]

- Zhang, W.; Chen, Q.; Chen, J.; Xu, D.; Zhan, H.; Peng, H.; Pan, J.; Vlaskin, M.; Leng, L.; Li, H. Machine learning for hydrothermal treatment of biomass: A review. Bioresour. Technol. 2022, 370, 128547. [Google Scholar] [CrossRef]

- Yang, W.; Pudasainee, D.; Gupta, R.; Li, W.; Wang, B.; Sun, L. An overview of inorganic particulate matter emission from coal/biomass/MSW combustion: Sampling and measurement, formation, distribution, inorganic composition and influencing factors. Fuel Process. Technol. 2021, 213, 106657. [Google Scholar] [CrossRef]

- Hupa, M.; Karlström, O.; Vainio, E. Biomass combustion technology development–It is all about chemical details. Proc. Combust. Inst. 2017, 36, 113–134. [Google Scholar] [CrossRef]

- Lam, M.K.; Loy AC, M.; Yusup, S.; Lee, K.T. Biohydrogen Production from Algae. In Biohydrogen, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 219–245. [Google Scholar] [CrossRef]

- Alnouss, A.; McKay, G.; Al-Ansari, T. Superstructure Optimization for the Production of Fuels, Fertilizers and Power using Biomass Gasification. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; Volume 46, pp. 301–306. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, M.; Raheem, A.; Wang, F.; Wei, J.; Xu, D.; Song, X.; Bao, W.; Huang, A.; Zhang, S.; et al. Syngas Production from Biomass Gasification: Influences of Feedstock Properties, Reactor Type, and Reaction Parameters. ACS Omega 2023, 8, 31620–31631. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M. Biomass Gasification. In Encyclopedia of Sustainable Technologies; Elsevier: Amsterdam, The Netherlands, 2019; pp. 205–216. [Google Scholar] [CrossRef]

- Tasaka, K.; Furusawa, T.; Ujimine, K.; Tsutsumi, A. Surface Analyses of Cobalt Catalysts for the Steam Reforming of Tar derived from Biomass Gasification. Stud. Surf. Sci. Catal. 2006, 159, 517–520. [Google Scholar] [CrossRef]

- Walling, E.; Babin, A.; Vaneeckhaute, C. Nutrient and Carbon Recovery from Organic Wastes. In Biorefinery; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Palmer, R. Identification and Comparison. In Encyclopedia of Forensic Sciences; Academic Press: San Diego, CA, USA, 2013; pp. 129–137. [Google Scholar] [CrossRef]

- Rasul, M.G.; Jahirul, M.I. Recent developments in biomass pyrolysis for bio-fuel production: Its potential for commercial applications. In Proceedings of the Recent Research in Environmental and Geological Sciences, 7th WSEAS International Conference on Energy & Environment (EE’12), Kos Island, Greece, 14–17 July 2012; pp. 256–264, ISBN 978-1-61804-110-4. [Google Scholar]

- Saravanan, A.; Senthil Kumar, P.; Khoo, K.S.; Show, P.; Femina Carolin, C.; Fetcia Jackulin, C.; Jeevanantham, S.; Karishma, S.; Show, K.; Lee, D.; et al. Biohydrogen from organic wastes as a clean and environment-friendly energy source: Production pathways, feedstock types, and future prospects. Bioresour. Technol. 2021, 342, 126021. [Google Scholar] [CrossRef]

- Angin, D.; Şensöz, S. Effect of pyrolysis temperature on chemical and surface properties of biochar of rapeseed (Brassica napus L.). Int. J. Phytoremediat. 2014, 16, 684–693. [Google Scholar] [CrossRef]

- Egbosiuba, T.C. Biochar and bio-oil fuel properties from nickel nanoparticles assisted pyrolysis of cassava peel. Heliyon 2022, 8, e10114. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Zhou, T.; Tian, H.; Feng, L.; Yao, C.; Yin, Y.; Chen, D. Effects of pyrolysis parameters on the distribution of pyrolysis products of Miscanthus. Prog. React. Kinet. Mech. 2021, 46, 146867832110109. [Google Scholar] [CrossRef]

- Lee, Y.; Eum, P.; Ryu, C.; Park, Y.; Jung, J.; Hyun, S. Characteristics of biochar produced from slow pyrolysis of Geodae-Uksae 1. Bioresour. Technol. 2013, 130, 345–350. [Google Scholar] [CrossRef]

- Mašek, O. Biochar in thermal and thermochemical biorefineries—Production of biochar as a coproduct. In Handbook of Biofuels Production, 2nd ed.; Woodhead Publishing: Amsterdam, The Netherlands, 2016; pp. 655–671. [Google Scholar] [CrossRef]

- Larina, O.M.; Markin, A.V.; Borshchevskaya, E.A.; Shrednik, V.N.; Shabalin, E.V. Study of the Electron-Density Distribution of Composite Films by the Method of High-Energy X-ray Diffraction. J. Phys. Conf. Ser. 2016, 774, 012137. [Google Scholar] [CrossRef]

- Bertero, M.; Sedran, U. Coprocessing of Bio-oil in Fluid Catalytic Cracking. In Recent Advances in Thermo-Chemical Conversion of Biomass; Elsevier: Amsterdam, The Netherlands, 2014; pp. 355–381. [Google Scholar] [CrossRef]

- Charis, G.; Danha, G.; Muzenda, E. Optimizing Yield and Quality of Bio-Oil: A Comparative Study of Acacia tortilis and Pine Dust. Processes 2020, 8, 551. [Google Scholar] [CrossRef]

- Jha, S.; Nanda, S.; Acharya, B.; Dalai, A.K. A Review of Thermochemical Conversion of Waste Biomass to Biofuels. Energies 2022, 15, 6352. [Google Scholar] [CrossRef]

- Arellano, O.; Flores, M.; Guerra, J.; Hidalgo, A.; Rojas, D.; Strubinger, A. Hydrothermal carbonization of corncob and characterization of the obtained hydrochar. Chem. Eng. Trans. 2016, 50, 235–240. [Google Scholar] [CrossRef]

- Nasrollahzadeh, M.; Nezafat, Z.; Shafiei, N. Lignin chemistry and valorization. In Biopolymer-Based Metal Nanoparticle Chemistry for Sustainable Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 145–183. [Google Scholar] [CrossRef]

- Singh, R.; Prakash, A.; Balagurumurthy, B.; Bhaskar, T. Hydrothermal Liquefaction of Biomass. In Recent Advances in Thermo-Chemical Conversion of Biomass; Elsevier: Amsterdam, The Netherlands, 2015; pp. 269–291. [Google Scholar] [CrossRef]

- Basu, P. Hydrothermal Conversion of Biomass. In Biomass Gasification, Pyrolysis and Torrefaction, 3rd ed.; Demirbas, A., Ed.; Academic Press: London, UK, 2018; pp. 331–371. [Google Scholar] [CrossRef]

- Sharma, H.B.; Venna, S.; Dubey, B.K. Resource recovery and circular economy approach in organic waste management using hydrothermal carbonization. Clean Energy Resour. Recovery 2021, 1, 313–326. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, P.; Bolan, N.S.; Wang, H. The potential agronomic and environmental applications of biochar: Prospects and challenges. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Kumar, A.; Saini, K.; Bhaskar, T. Hydochar and biochar: Production, physicochemical properties and techno-economic analysis. Bioresour. Technol. 2020, 310, 123442. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liu, J.; Liu, R. Effects of pyrolysis temperature and heating time on biochar obtained from the pyrolysis of straw and lignosulfonate. Bioresour. Technol. 2015, 176, 288–291. [Google Scholar] [CrossRef]

- Masoumi, S.; Borugadda, V.B.; Nanda, S.; Dalai, A.K. Hydrochar: A Review on Its Production Technologies and Applications. Catalysts 2021, 11, 939. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, Z.; Shen, B.; Liu, L. Insights into biochar and hydrochar production and applications: A review. Energy 2019, 171, 581–598. [Google Scholar] [CrossRef]

- Armah, E.K.; Chetty, M.; Adedeji, J.A.; Estrice, D.E.; Mutsvene, B.; Singh, N.; Tshemese, Z. Biochar: Production, Application and the Future. In Biochar—Productive Technologies, Properties and Applications; IntechOpen: London, UK, 2022; pp. 1–22. [Google Scholar] [CrossRef]

- Islam, M.; Halder, M.; Siddique, M.A.B.; Razir, S.A.A.; Sikder, S.; Joardar, J.C. Banana peel biochar as alternative source of potassium for plant productivity and sustainable agriculture. Int. J. Recycl. Org. Waste Agricult. 2019, 8 (Suppl. S1), 407–413. [Google Scholar] [CrossRef]

- Choudhary, P.; Prasad, M.; Choudhary, M.; Kumar, A.; Kumar, S.; Srinivasan, R.; Mahawer, S.K. Exploring invasive weed biochar as soil amendment: A study on fodder oats productivity and soil biological properties. Environ. Res. 2023, 216, 114527. [Google Scholar] [CrossRef]

- Ye, L.; Camps-Arbestain, M.; Shen, Q.; Lehmann, J.; Singh, B.; Sabir, M. Biochar effects on crop yields with and without fertilizer: A meta-analysis of field studies using separate controls. Soil Use Manag. 2019, 36, 2–18. [Google Scholar] [CrossRef]

- Frimpong, K.A.; Phares, C.A.; Boateng, I.; Abban-Baidoo, E.; Apuri, L. One-time application of biochar influenced crop yield across three cropping cycles on tropical sandy loam soil in Ghana. Heliyon 2021, 7, e06267. [Google Scholar] [CrossRef]

- Knoblauch, C.; Renuka Priyadarshani, S.H.; Haefele, S.M.; Schröder, N.; Pfeiffer, M. Impact of biochar on nutrient supply, crop yield and microbial respiration on sandy soils of northern Germany. Eur. J. Soil Sci. 2021, 72, 1885–1901. [Google Scholar] [CrossRef]

- Christou, A.; Stylianou, M.; Georgiadou, E.C.; Gedeon, S.; Ioannou, A.; Michael, C.; Papanastasiou, P.; Fotopoulos, V.; Fatta-Kassinos, D. Effects of biochar derived from the pyrolysis of either biosolids, manure or spent coffee grounds on the growth, physiology and quality attributes of field-grown lettuce plants. Environ. Technol. Innov. 2022, 26, 102263. [Google Scholar] [CrossRef]

- Joseph, S. Biochar increases soil organic carbon, avocado yields and economic return over 4 years of cultivation. Sci. Total Environ. 2020, 724, 138153. [Google Scholar] [CrossRef]

- Kalu, S.; Simojoki, A.; Karhu, K.; Tammeorg, P. Long-Term Effects of Softwood Biochar on Soil Physical Properties, Greenhouse Gas Emissions and Crop Nutrient Uptake in Two Contrasting Boreal Soils. Agric. Ecosyst. Environ. 2021, 316, 107454. [Google Scholar] [CrossRef]

- Soinne, H.; Keskinen, R.; Heikkinen, J.; Hyväluoma, J.; Uusitalo, R.; Peltoniemi, K.; Velmala, S.; Pennanen, T.; Fritze, H.; Kaseva, J.; et al. Are There Environmental or Agricultural Benefits in Using Forest Residue Biochar in Boreal Agricultural Clay Soil? Sci. Total Environ. 2020, 731, 138955. [Google Scholar] [CrossRef] [PubMed]

- Romero, C.M.; Hao, X.; Li, C.; Owens, J.; Schwinghamer, T.; McAllister, T.A.; Okine, E. Nutrient retention, availability and greenhouse gas emissions from biochar-fertilized Chernozems. Catena 2021, 198, 105046. [Google Scholar] [CrossRef]

- Wu, W.; Yang, M.; Feng, Q.; McGrouther, K.; Wang, H.; Lu, H.; Chen, Y. Chemical characterization of rice straw-derived biochar for soil amendment. Biomass Bioenergy 2012, 47, 268–276. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Wei, Q.; Gou, J. Biochar enhances the retention capacity of nitrogen fertilizer and affects the diversity of nitrifying functional microbial communities in karst soil of southwest China. Ecotoxicol. Environ. Saf. 2021, 226, 112819. [Google Scholar] [CrossRef]

- Tangmankongworakoon, N. An approach to produce biochar from coffee residue for fuel and soil amendment purpose. Int. J. Recycl. Org. Waste Agric. 2019, 8, 37–44. [Google Scholar] [CrossRef]

- Razzaghi, F.; BilsonObour, P.; Arthur, E. Does biochar improve soil water retention? A systematic review and meta-analysis. Geoderma 2020, 361, 114055. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiao, J.; Xue, J.; Zhang, L. Quantifying the effects of biochar application on greenhouse gas emissions from agricultural soils: A global meta-analysis. Sustainability 2020, 12, 3436. [Google Scholar] [CrossRef]

- Sial, T.A.; Lan, Z.; Khan, M.N.; Zhao, Y.; Kumbhar, F.; Liu, J.; Zhang, A.; Hill, R.L.; Lahori, A.H.; Memon, M. Evaluation of orange peel waste and its biochar on greenhouse gas emissions and soil biochemical properties within a loess soil. Waste Manag. 2019, 87, 125–134. [Google Scholar] [CrossRef] [PubMed]

- Joseph, S.; Pan, G. Effects of biochar on availability and plant uptake of heavy metals–A meta-analysis. J. Environ. Manag. 2018, 222, 76–85. [Google Scholar] [CrossRef]

- Ogura, A.P.; Lima, J.Z.; Marques, J.P.; Massaro Sousa, L.; Rodrigues, V.G.S.; Espíndola, E.L.G. A review of pesticides sorption in biochar from maize, rice, and wheat residues: Current status and challenges for soil application. J. Environ. Manag. 2021, 300, 113753. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.B.; Ying, G.G.; Peng, P.A.; Wang, L.; Zhao, J.L.; Zhang, L.J.; Yuan, P.; He, H.P. Influence of biochars on plant uptake and dissipation of two pesticides in an agricultural soil. J. Agric. Food Chem. 2010, 58, 7915–7921. [Google Scholar] [CrossRef]

- Yang, S.; Chen, X.; Jiang, Z.; Ding, J.; Sun, X.; Xu, J. Effects of Biochar Application on Soil Organic Carbon Composition and Enzyme Activity in Paddy Soil under Water-Saving Irrigation. Int. J. Environ. Res. Public Health 2019, 17, 333. [Google Scholar] [CrossRef]

- Fawzy, S.; Osman, A.I.; Mehta, N.; Moran, D.; Al-Muhtaseb, A.H.; Rooney, D.W. Atmospheric carbon removal via industrial biochar systems: A techno-economic-environmental study. J. Clean. Prod. 2022, 371, 133660. [Google Scholar] [CrossRef]

- Chu, Q.; Xue, L.; Cheng, Y.; Liu, Y.; Feng, Y.; Yu, S.; Meng, L.; Pan, G.; Hou, P.; Duan, J.; et al. Microalgae-derived hydrochar application on rice paddy soil: Higher rice yield but increased gaseous nitrogen loss. Sci. Total Environ. 2020, 717, 137127. [Google Scholar] [CrossRef]

- Zhang, A.; Cui, L.; Pan, G.; Li, L.; Hussain, Q.; Zhang, X.; Zheng, J.; Crowley, D. Effect of biochar amendment on yield and methane and nitrous oxide emissions from a rice paddy from Tai Lake plain, China. Agric. Ecosyst. Environ. 2010, 139, 469–475. [Google Scholar] [CrossRef]

- Mau, V.; Arye, G.; Gross, A. Poultry litter hydrochar as an amendment for sandy soils. J. Environ. Manag. 2020, 271, 110959. [Google Scholar] [CrossRef]

- Chan, K.Y.; Van Zwieten, L.; Meszaros, I.; Downie, A.; Joseph, S. Using poultry litter biochars as soil amendments. Aust. J. Soil Res. 2008, 46, 437–444. [Google Scholar] [CrossRef]

- Ren, J.; Wang, F.; Zhai, Y.; Zhu, Y.; Peng, C.; Wang, T.; Li, C.; Zeng, G. Effect of sewage sludge hydrochar on soil properties and Cd immobilization in a contaminated soil. Chemosphere 2017, 189, 627–633. [Google Scholar] [CrossRef]

- Al-Wabel, M.I.; Usman, A.R.; El-Naggar, A.H.; Aly, A.A.; Ibrahim, H.M.; Elmaghraby, S.; Al-Omran, A. Conocarpus biochar as a soil amendment for reducing heavy metal availability and uptake by maize plants. Saudi J. Biol. Sci. 2015, 22, 503–511. [Google Scholar] [CrossRef]

- Patel, A.; Agrawal, B.; Rawal, B.R. Pyrolysis of biomass for efficient extraction of biofuel. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 1649–1661. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Low, C.Y. Use of biochar as carbon sequestering additive in cement mortar. Cem. Concr. Compos. 2018, 87, 110–129. [Google Scholar] [CrossRef]

- De Jager, M.; Schröter, F.; Wark, M.; Giani, L. The stability of carbon from a maize-derived hydrochar as a function of fractionation and hydrothermal carbonization temperature in a Podzol. Biochar 2022, 4, 52. [Google Scholar] [CrossRef]

- Glaser, B.; Parr, M.; Braun, C.; Kopolo, G. Biochar is carbon negative. Nat. Geosci. 2009, 2, 2. [Google Scholar] [CrossRef]

- Gąsior, D.; Tic, W. Application of the biochar-based technologies as the way of realization of the sustainable development strategy. Econ. Environ. Stud. 2017, 17, 597–611. [Google Scholar] [CrossRef]

- Garcia, B.; Alves, O.; Rijo, B.; Lourinho, G.; Nobre, C. Biochar: Production, applications, and market prospects in Portugal. Environments 2022, 9, 95. [Google Scholar] [CrossRef]

| Anaerobic Digestion | Fermentation |

|---|---|

| Organic MSW and agricultural waste are the most suitable as feedstock | Organic MSW and agricultural waste are the most suitable as feedstock |

| Process occurs in the absence of oxygen | Process occurs in the absence of oxygen |

| Final products: methane and digestate | Final products: acid or alcohol (ethanol, lactic acid, etc.) and a nutrient-rich residue |

| The biogas can be used to produce heat or electricity | Bioethanol can be used as clean fuel for transportation |

| Thermochemical | Biochemical |

|---|---|

| Effectively applied to almost any biomass feedstock | Involves the use of microbes, enzymes, and/or chemicals |

| No pretreatment | Pretreatment is essential |

| Relatively higher productivity due to completely chemical nature of reaction | Productivity is limited due to biological conversion |

| Multiple high-value products possible using fractional separation of products | Normally limited to one or few products and would require additional microbes, enzymes for more products |

| Independent of climatic conditions | Mostly susceptible to ambient temperature, anaerobic digester |

| Complete utilization of waste/biomass | Production of secondary wastes such as biomass sludge |

| Less reaction time | High reaction time |

| Hydrochar | Biochar | |

|---|---|---|

| Temperature | Low: 180–260 °C [98] | High: between 300 °C and 1000 °C [102] |

| Residence time | Short | Long |

| Pressure | High: 10–25 MPa [103] | Low |

| Moisture content | >10% | <10% |

| Characteristics | Non porous—core shell, alkali rich surface | Porous and aromatic rich surface |

| Low in fixed and total carbon content Energy efficient process | High in fixed and total carbon content High ash content | |

| High HHV | Low HHV |

| Feedstock | Percentage (in 174 Publications) |

|---|---|

| Wood | 43.4 |

| Straw | 45.7 |

| Others | 10.9 |

| Pyrolysis speed | |

| Slow | 79.2 |

| Fast | 20.8 |

| Application | Hydrochar | Biochar | References |

|---|---|---|---|

| Soil amendment | The use of Hydrochar made from Chlorella vulgaris microalgae in a soil column system for growing rice resulted in a 13.5–26.8% increase in grain yield | Adding 10 or 40 tons of wheat straw biochar per hectare to unfertilized soil led to a 12% and 14% increase in rice yields, respectively. In soil that received nitrogen fertilization, the same additions resulted in an 8.8% and 12.1% yield increase. | [127,128] |

| Introducing 0.5% or 1% hydrochar to the soil led to enhanced plant growth, although there was an initial lag. The enhancement was attributed to the increased soil moisture retention capacity of the soil. | The use of poultry litter biochars at a rate of 10 tons per hectare resulted in a 42% increase in the dry matter yield of radish. | [129,130] | |

| Removal of pollutants | Applying 5% of sewage sludge hydrochar to the soil reduced the amount of Cd that was available to plants by 52.29%, preventing cabbage from absorbing the metal from the soil. | The addition of Concarpus biochar greatly decreased the concentration of heavy metals in the shoots of maize plants, with the highest reduction of 60.5% for manganese. | [131,132] |

| Energy production | - | The yield of high-grade biofuels produced through the pyrolysis process can range from 21.9% to 75%, depending on the temperature of the process, the type of biomass used, and the type of reactor used. | [133] |

| Carbon sequestration | Because hydrochar contains more easily decomposable carbon, it is less efficient as a carbon sequestering agent in soil than biochar made by pyrolysis. | Biochar can sequester up to 1.67 mmol/g of CO2 when prepared at 300 °C and used as an additive in mortar mixtures. | [134,135] |

| - | It was estimated that the implementation of biochar has the potential to decrease 9% of Europe’s total emissions. | [136] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kataya, G.; Cornu, D.; Bechelany, M.; Hijazi, A.; Issa, M. Biomass Waste Conversion Technologies and Its Application for Sustainable Environmental Development—A Review. Agronomy 2023, 13, 2833. https://doi.org/10.3390/agronomy13112833

Kataya G, Cornu D, Bechelany M, Hijazi A, Issa M. Biomass Waste Conversion Technologies and Its Application for Sustainable Environmental Development—A Review. Agronomy. 2023; 13(11):2833. https://doi.org/10.3390/agronomy13112833

Chicago/Turabian StyleKataya, Ghenwa, David Cornu, Mikhael Bechelany, Akram Hijazi, and May Issa. 2023. "Biomass Waste Conversion Technologies and Its Application for Sustainable Environmental Development—A Review" Agronomy 13, no. 11: 2833. https://doi.org/10.3390/agronomy13112833