Evaluation of Asparagine Concentration as an Indicator of the Acrylamide Formation in Cereals Grown under Organic Farming Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Site Description

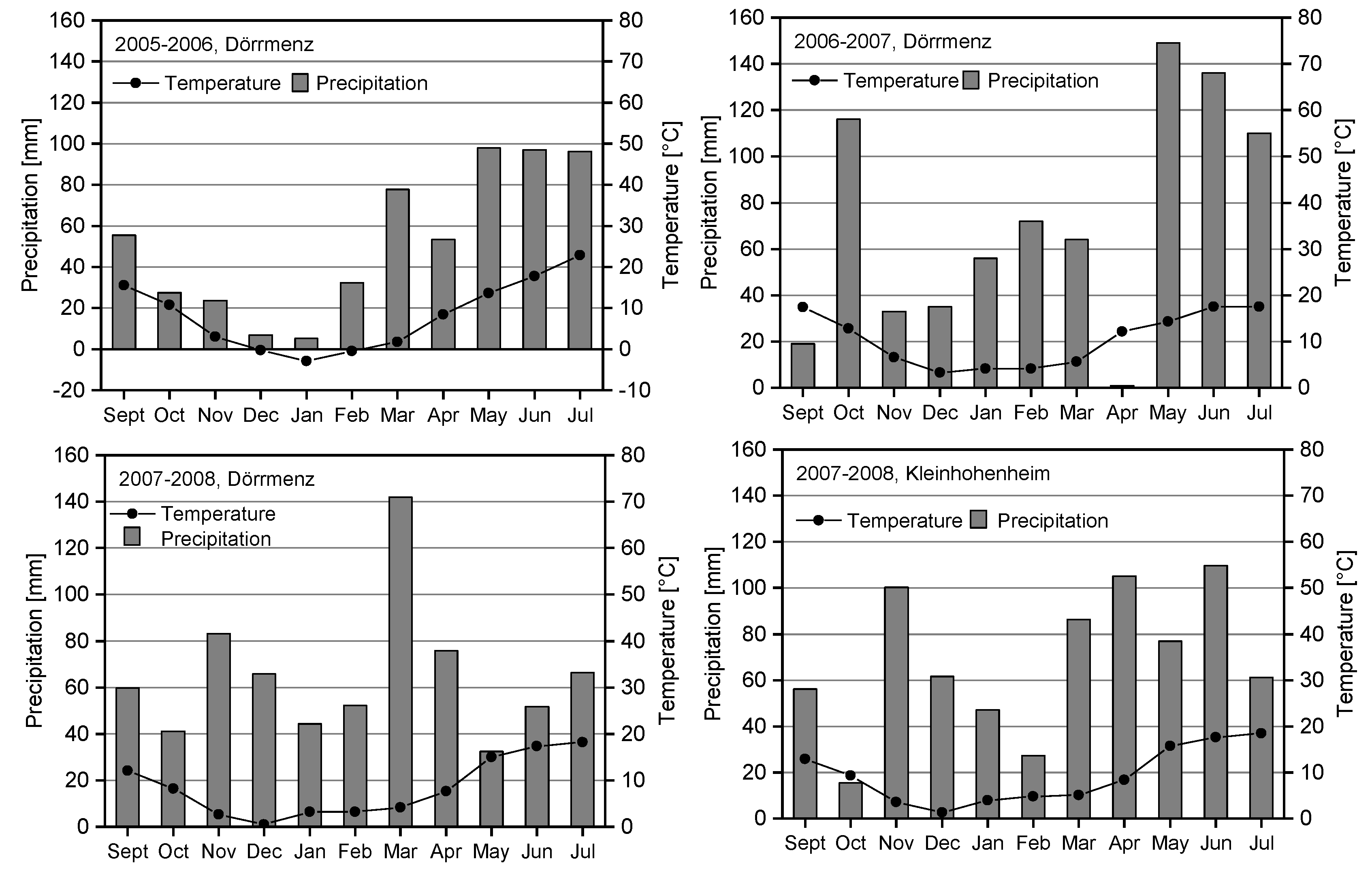

2.2. Site Conditions at the Experimental Sites

2.3. Experimental Design

2.4. Experimental Performance

2.5. Yield

2.6. Flours

2.7. Crude Protein Content

2.8. Zeleny’s Sedimentation Test

2.9. Hagberg Falling Number

2.10. Free Asparagine

2.11. Acrylamide Formation Potential

2.12. Statistical Analysis

3. Results and Discussion

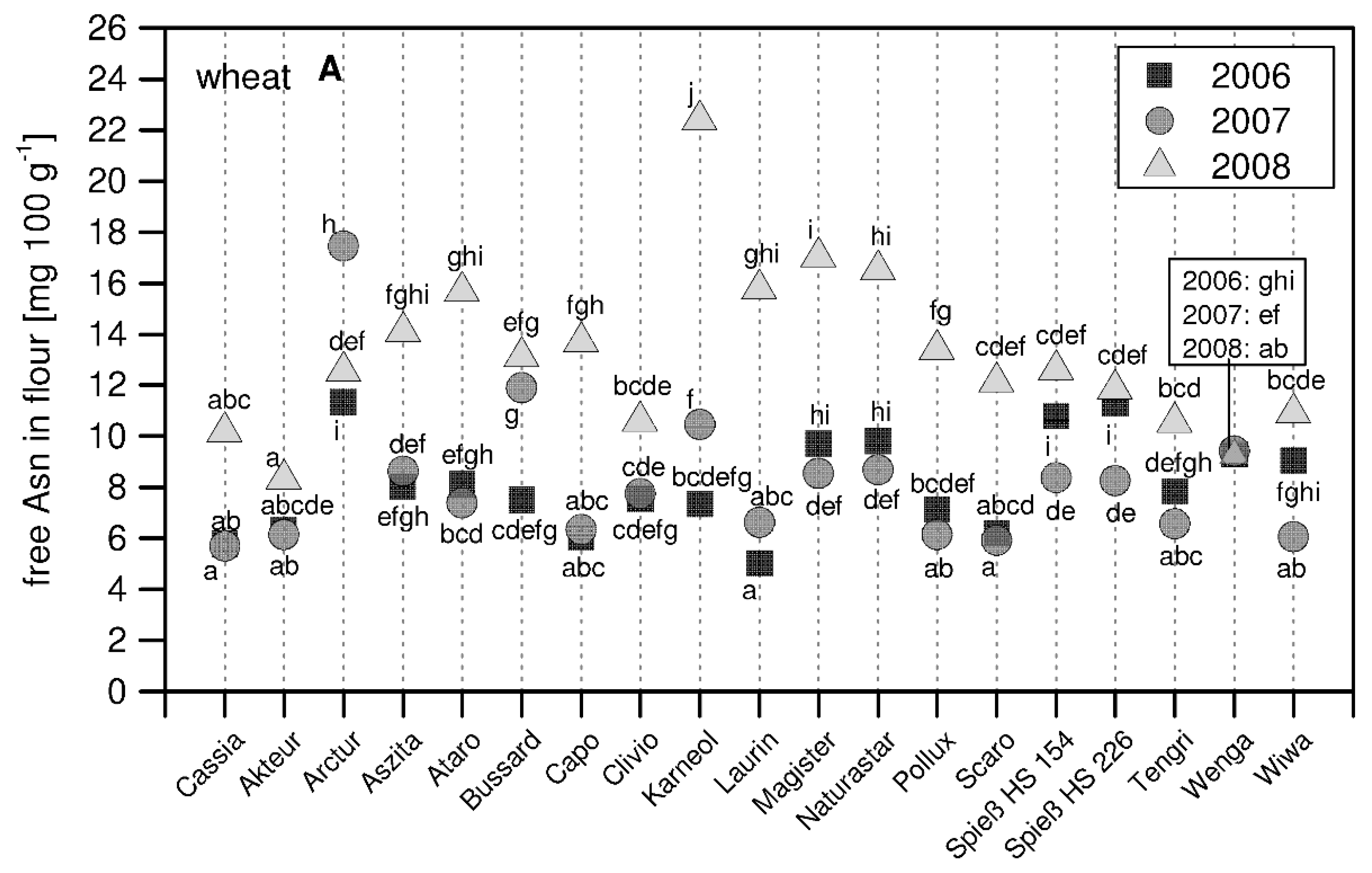

3.1. Grain Yield, Quality and Free Asn

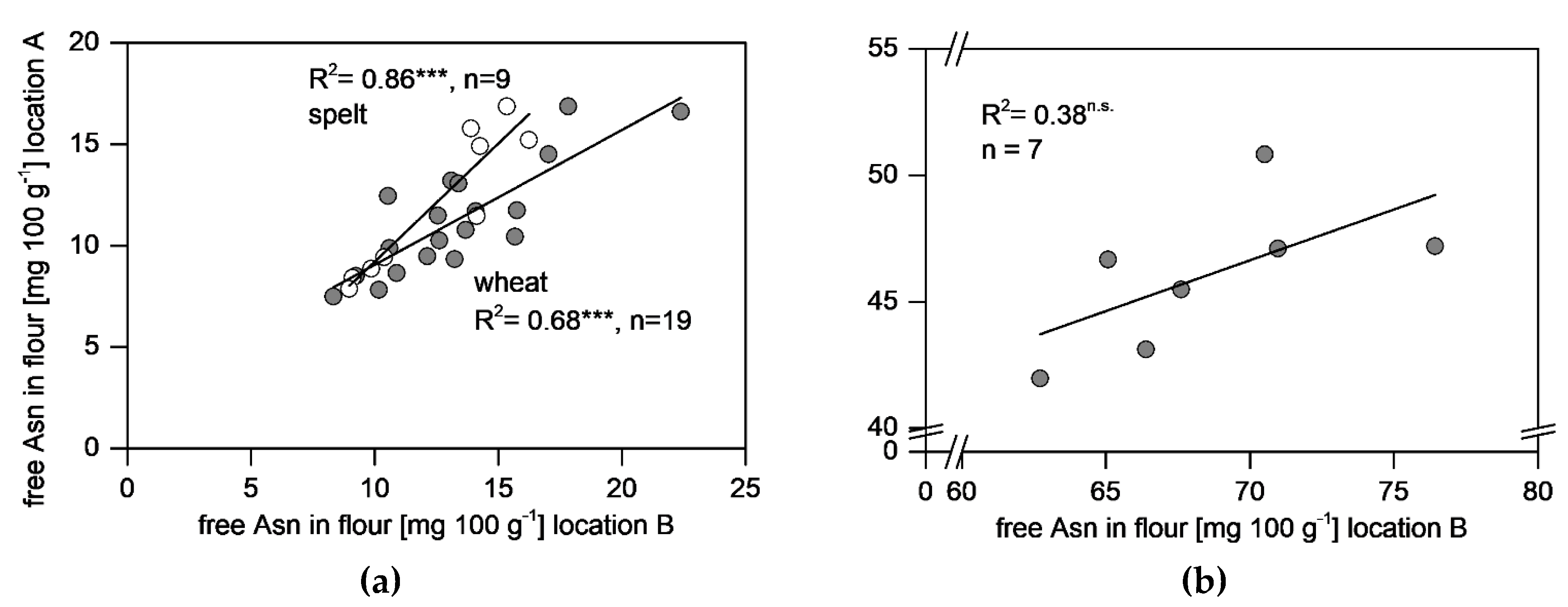

3.2. Correlation of Crude Protein, Free Asn, and AA

3.3. Impact of Location on Free Asn, Heritability

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Konings, E.J.M.; Hogervorst, J.G.F.; Van Rooij, L.; Schouten, L.J.; Sizoo, E.A.; Van Egmond, H.P.; Goldbohm, R.A.; Van Den Brandt, P.A. Validation of a database on acrylamide for use in epidemiological studies. Eur. J. Clin. Nutr. 2010, 64, 534–540. [Google Scholar] [CrossRef] [PubMed]

- Mottram, D.S.; Wedzicha, B.L.; Dodson, A.T. Acrylamide is formed in the Maillard reaction. Nature 2002, 419, 448–449. [Google Scholar] [CrossRef] [PubMed]

- Stadler, R.H.; Blank, I.; Varga, N.; Robert, F.; Hau, J.; Guy, P.A.; Robert, M.C.; Riediker, S. Acrylamide from Maillard reaction products. Nature 2002, 419, 449–450. [Google Scholar] [CrossRef] [PubMed]

- Commission Regulation (EU) 2017/2158. Establishing mitigation measures and benchmark levels for the reduction of the presence as acrylamide in food. J. Eur. Union 2017, 60, 24–44. [Google Scholar]

- Claus, A.; Schreiter, P.; Weber, A.; Graeff, S.; Herrmann, W.; Claupein, W.; Schieber, A.; Carle, R. Influence of Agronomic Factors and Extraction Rate on the Acrylamide Contents in Yeast-Leavened Breads. J. Agric. Food Chem. 2006, 54, 8968–8976. [Google Scholar] [CrossRef] [PubMed]

- Curtis, T.Y.; Powers, S.J.; Balagianis, D.; Elmore, J.S.; Mottram, D.; Parry, M.A.J.; Rakszegi, M.; Bedo, Z.; Shewry, P.R.; Halford, N.G. Free Amino Acids and Sugars in Rye Grain: Implications for Acrylamide Formation. J. Agric. Food Chem. 2010, 57, 1013–1021. [Google Scholar] [CrossRef] [PubMed]

- Delatour, T.; Perisset, A.; Goldmann, T. Improved sample preparation to determine acrylamide in difficult matrixes such as chocolate powder, cocoa, and coffee by liquid chromatography tandem mass spectrometry. J. Agric. Food Chem. 2004, 52, 4625–4639. [Google Scholar] [CrossRef] [PubMed]

- Surdyk, N.; Rosen, J.; Andersson, R.; Åman, P. Effects of asparagine, fructose, and baking conditions on acrylamide content in yeast-leavened wheat bread. J. Agric. Food Chem. 2004, 52, 2047–2051. [Google Scholar] [CrossRef]

- Weisshaar, R. Acrylamid in Backwaren–Ergebnisse von Modellversuchen. Dtsch. Leb. Rundsch. 2004, 100, 92–97. [Google Scholar]

- Amrein, T.M.; Schönbächler, B.; Rohner, F.; Lukac, H.; Schneider, H.; Keiser, A.; Escher, F.; Amadò, R. Potential for acrylamide formation in potatoes: Data from the 2003 harvest. Eur. Food Res. Technol. 2004, 219, 572–578. [Google Scholar] [CrossRef]

- Capuano, E.; Ferrigno, A.; Acampa, I.; Serpen, A.; Acar, Ö.C.; Gökmen, V.; Fogliano, V. Effect of flour type on Maillard reaction and acrylamide formation during toasting of bread crisp model systems and mitigation strategies. Food Res. Int. 2009, 42, 1295–1302. [Google Scholar] [CrossRef]

- Ciesarova, Z.; Kukurova, K.; Bednarikova, A.; Morales, F.J. Effect of heat treatment and dough formulation on the formation of Maillard reaction products in fine bakery products—Benefits and weak points. J. Food Nutr. Res. 2009, 48, 20–30. [Google Scholar]

- Claus, A.; Carle, R.; Schieber, A. Acrylamide in cereal products: A review. J. Cereal Sci. 2008, 47, 118–133. [Google Scholar] [CrossRef]

- Hedegaard, R.V.; Granby, K.; Frandsen, H.; Thygesen, J.; Skibsted, L.H. Acrylamide in bread. Effect of prooxidants and antioxidants. Eur. Food Res. Technol. 2008, 227, 519–525. [Google Scholar] [CrossRef]

- Kotsiou, K.; Tasioula-Margari, M.; Capuano, E.; Fogliano, V. Effect of standard phenolic compounds and olive oil phenolic extracts on acrylamide formation in an emulsion system. Food Chem. 2011, 124, 242–247. [Google Scholar] [CrossRef]

- Levine, R.A.; Ryan, S.M. Determining the Effect of Calcium Cations on Acrylamide Formation in Cooked Wheat Products Using a Model System. J. Agric. Food Chem. 2009, 57, 6823–6829. [Google Scholar] [CrossRef]

- Wakaizumi, M.; Yamamoto, H.; Fujimoto, N.; Ozeki, K. Acrylamide degradation by filamentous fungi used in food and beverage industries. J. Biosci. Bioeng. 2009, 108, 391–393. [Google Scholar] [CrossRef]

- Curtis, T.Y.; Muttucumaru, N.; Shewry, P.R.; Parry, M.A.J.; Powers, S.J.; Elmore, J.S.; Mottram, D.S.; Hook, S.; Halford, N.G. Effects of Genotype and Environment on Free Amino Acid Levels in Wheat Grain: Implications for Acrylamide Formation during Processing. J. Agric. Food Chem. 2009, 57, 1013–1021. [Google Scholar] [CrossRef]

- Granvogl, M.; Wiesner, H.; Koehler, P.; Von Tucher, S.; Schieberle, P. Influence of Sulfur Fertilization on the Amounts of Free Amino Acids in Wheat. Correlation with Baking Properties as well as with 3-Aminopropionamide and Acrylamide Generation during Baking. J. Agric. Food Chem. 2007, 55, 4271–4277. [Google Scholar] [CrossRef]

- Martinek, P.; Klem, K.; Váňová, M.; Bartáčková, V.; Večerková, L.; Bucher, P.; Hajšlová, J. Effects of nitrogen nutrition, fungicide treatment and wheat genotype on free asparagine and reducing sugars content as precursors of acrylamide formation in bread. Plant Soil Environ. 2009, 55, 187–195. [Google Scholar] [CrossRef]

- Muttucumaru, N.; Halford, N.G.; Elmore, J.S.; Dodson, A.T.; Parry, M.; Shewry, P.R.; Mottram, D.S. Formation of High Levels of Acrylamide during the Processing of Flour Derived from Sulfate-Deprived Wheat. J. Agric. Food Chem. 2006, 54, 8951–8955. [Google Scholar] [CrossRef] [PubMed]

- Taeymans, D.; Wood, J.; Ashby, P.; Blank, I.; Studer, A.; Stadler, R.H.; Gondé, P.; Van Eijck, P.; Lalljie, S.; Lingnert, H.; Lindblom, M.; et al. A Review of acrylamide: An industry perspective on research, analysis, formation, and control. Crit. Rev. Food Sci. Nutr. 2004, 44, 323–347. [Google Scholar] [CrossRef] [PubMed]

- Weber, E.A.; Graeff, S.; Koller, W.D.; Hermann, W.; Merkt, N.; Claupein, W. Impact of nitrogen amount and timing on the potential of acrlyamide formation in winter wheat (Triticum aestivum L.). Field Crop Res. 2008, 106, 44–52. [Google Scholar] [CrossRef]

- Weber, E.A.; Koller, W.D.; Graeff, S.; Hermann, W.; Merkt, N.; Claupein, W. Impact of different nitrogen fertilizers and an additional sulfur supply on grain yield, quality, and the potential of acrylamide formation in winter wheat. J. Plant Nutr. Soil Sci. 2008, 171, 643–655. [Google Scholar] [CrossRef]

- Corol, D.I.; Ravel, C.; Rakszegi, M.; Charmet, G.; Bedo, Z.; Beale, M.H.; Shewry, P.R.; Ward, J.L. 1H-NMR screening for the high-throughput determination of genotype and environmental effects on the content of asparagine in wheat grain. Plant Biotechnol. J. 2016, 14, 128–139. [Google Scholar] [CrossRef] [PubMed]

- Postles, J.; Powers, S.J.; Elmore, J.S.; Mottram, D.S.; Halford, N.G. Effects of variety and nutrient availability on the acramamide-forming potential of rye grain. J. Cereal Sci. 2013, 57, 463–470. [Google Scholar] [CrossRef] [PubMed]

- Shewry, P.R.; Zhao, F.J.; Gowa, G.B.; Hawkins, N.D.; Ward, J.L.; Beale, M.H.; Halford, N.G.; Parry, M.A.; Abécassis, J. Sulfur nutrition differentially affects the distribution of asparagine in wheat grain. J. Cereal Sci. 2009, 50, 407–409. [Google Scholar] [CrossRef]

- Curtis, T.Y.; Powers, S.J.; Halford, N.G. Effects of fungicide treatment on free amino acid concentration and acrylamide-forming potential in wheat. J. Agric. Food Chem. 2016, 64, 9689–9696. [Google Scholar] [CrossRef]

- Murphy, K.M.; Campbell, K.G.; Lyon, S.R.; Jones, S.S. Evidence of varietal adaptation to organic farming systems. Field Crops Res. 2007, 102, 172–177. [Google Scholar] [CrossRef]

- Wolfe, M.S.; Baresel, J.P.; Desclaux, D.; Goldringer, I.; Hoad, S.; Kovacs, G.; Löschenberger, F.; Miedaner, T.; Østergård, H.; van Bueren Lammerts, E.T. Developments in breeding cereals for organic agriculture. Euphytica 2008, 163, 323–346. [Google Scholar] [CrossRef]

- Kunz, P.; Becker, K.; Buchmann, M.; Cuendet, C.; Müller, J.; Müller, U. Bio-Getreidezüchtung in der Schweiz. Tagungsband 2006, 2, 31–35. [Google Scholar]

- Dumas, A. Stickstoffbestimmung nach Dumas. Die Praxis des org. Chemikers, 41st ed.; Schrag: Nürnberg, Germany, 1962. [Google Scholar]

- Teller, G.L. Non-protein nitrogen compounds in cereals and their relation to the nitrogen factor for protein in cereals and bread. Cereal Chem. 1932, 9, 261–274. [Google Scholar]

- Lüpke, M. Entwicklung und Anwendung von Reagenzien und Verfahren zur Achiralen und Chiralen Analytik von Aminosäuren Mittels GC und HPLC. Ph.D. Thesis, Universität Hohenheim, Stuttgart, Germany, 1996. [Google Scholar]

- Weisshaar, R. Bestimmung von Acrylamid in Lebensmitteln, Aufarbeitungsverfahren für Die LC-MS-MS; Prüfverfahren: 200L05401; Chemisches und Veterinäruntersuchungsamt Stuttgart: Fellbach, Germany, 2003.

- Weisshaar, R. Bestimmung von Acrylamid in Lebensmitteln; Prüfverfahren: 201L01301; Chemisches und Veterinäruntersuchungsamt Stuttgart: Fellbach, Germany, 2003.

- Miedaner, T. Grundlagen der Pflanzenzüchtung; DLG-Verlag: Frankfurt am Main, Germany, 2010; ISBN 978-3769007527. [Google Scholar]

- Brunner, B. Qualität von Ökobrotgetreide weiter verbessern. Ökologie Landbau 2001, 121, 35–37. [Google Scholar]

- Baeckstrom, G.; Hanell, U.; Svensson, G. Baking quality of winter wheat grown in different cultivating systems 1992–2001—A holistic approach. J. Sustain. Agric. 2004, 3, 63–83. [Google Scholar] [CrossRef]

- Haglund, A.; Johansson, L.; Dahlstedt, L. Sensory evaluation of wholemeal bread from ecologically and conventionally grown wheat. J. Cereal Sci. 1998, 27, 199–207. [Google Scholar] [CrossRef]

- Simsek, S.; Ohm, J.B.; Lu, H.; Rugg, M.; Berzonsky, W.; Alamri, M.S.; Mergoum, M. Effect of pre-harvest sprouting on physicochemical changes of proteins in wheat. Sci. Food Agric. 2014, 94, 205–212. [Google Scholar] [CrossRef] [PubMed]

- Fredriksson, H.; Tallving, J.; Rosen, J.; Aman, P. Fermentation Reduces free Asparagines in Dough and Acrylamide Content in Bread. Cereal Chem. 2004, 81, 650–653. [Google Scholar] [CrossRef]

- Elmore, J.S.; Koutsidis, G.; Dodson, A.T.; Mottram, D.S.; Wedzicha, B.L. Measurement of acrylamide and its precursors in potato, wheat, and rye model systems. J. Agric. Food Chem. 2005, 53, 1286–1293. [Google Scholar] [CrossRef] [PubMed]

- Johansson, E.; Svensson, G. Variation in bread-making quality: Effects of weather parameters on protein concentration and quality in some Swedish wheat cultivars grown during the period 1975–1996. J. Sci. Food Agric. 1998, 78, 109–118. [Google Scholar] [CrossRef]

- Stockmann, F.; Weber, E.A.; Graeff, S.; Claupein, W. Influence of cropping systems on the potential formation of acrylamide in different cultivars of wheat. In Proceedings of the 16th IFOAM Organic World Congress, Modena, Italy, 16–20 June 2008. [Google Scholar]

- Springer, M.; Fischer, T.; Lehrack, A.; Freund, W. Acrylamidbildung in Backwaren. Getreide Mehl Brot 2003, 57, 274–278. [Google Scholar]

- Lea, P.J.; Sodek, L.; Parry, M.A.J.; Shewry, P.R.; Halford, N.G. Asparagine in Plants. Ann. Appl. Biol. 2006, 150, 1–26. [Google Scholar] [CrossRef]

- Ohm, J.B.; Simsek, S.; Mergoum, M. Variation of protein MWD parameters and their associations with free asparagine concentration and quality characteristics in hard red spring wheat. J. Cereal Sci. 2018, 79, 154–159. [Google Scholar] [CrossRef]

| Species | Cultivar | Quality Grade * | Cultivation Year | Cultivated in 2008 | |

|---|---|---|---|---|---|

| Dörrmenz | Kleinhohenheim | ||||

| Winter wheat | Akteur | E | 2006, 2007, 2008 | yes | yes |

| Arctur | - | ′′ | yes | yes | |

| Aszita | B | ′′ | yes | yes | |

| Ataro | 1 | ′′ | yes | yes | |

| Bussard | E | ′′ | yes | yes | |

| Capo | E | ′′ | yes | yes | |

| Cassia | TOP | ′′ | yes | yes | |

| Clivio | 1 | ′′ | yes | yes | |

| Karneol | - | ′′ | yes | yes | |

| Laurin | TOP | ′′ | yes | yes | |

| Magister | E | ′′ | yes | yes | |

| Naturastar | A | ′′ | yes | yes | |

| Pollux | 1 | ′′ | yes | yes | |

| Scaro | TOP | ′′ | yes | yes | |

| SpießHS154 | - | ′′ | yes | yes | |

| SpießHS226 | - | ′′ | yes | yes | |

| Tengi | TOP | ′′ | yes | yes | |

| Wenga | TOP | ′′ | yes | yes | |

| Wiwa | TOP | ′′ | yes | yes | |

| Winter spelt | Franckenkorn | 2006, 2007, 2008 | yes | yes | |

| O. Rotkorn | ′′ | yes | yes | ||

| Alkor | ′′ | yes | yes | ||

| Sirino | ′′ | yes | yes | ||

| Badengold | ′′ | yes | yes | ||

| Tauro | ′′ | yes | yes | ||

| Titan | ′′ | yes | yes | ||

| Samir | 2008 | yes | yes | ||

| Zollernspelz | 2008 | yes | yes | ||

| Winter rye | Recrut | 2006, 2007, 2008 | yes | yes | |

| Lichtkornroggen | ′′ | yes | yes | ||

| Amilo | 2008 | yes | yes | ||

| Carotop | 2006, 2007 | no | no | ||

| Conduct | 2008 | yes | yes | ||

| Crona | 2006 | no | no | ||

| Hacada | 2006 | no | no | ||

| Harca | 2006, 2008 | yes | yes | ||

| HS Aman | 2008 | yes | no | ||

| Firmament | 2007, 2008 | yes | no | ||

| Lauropa | 2008 | yes | yes | ||

| Rolipa | 2008 | yes | yes | ||

| Winter einkorn | Saffra | 2006 | no | no | |

| Albini | 2007 | no | no | ||

| Terzino | 2008 | yes | no | ||

| Winter emmer | EM07 | 2007 | no | no | |

| EM08 | 2008 | yes | no | ||

| Grain Yield | Crude Protein | Free Asn | |||||

|---|---|---|---|---|---|---|---|

| DF | F | p1 | F | p | F | p | |

| Species (S) | 7.69 | *** | 62.08 | *** | 134.83 | *** | |

| Year (Y) | 16.22 | *** | 12.89 | *** | 48.89 | *** | |

| S × Y | 25.49 | *** | 9.36 | *** | 16.78 | *** | |

| Winter Wheat | Winter Spelt | Winter Rye | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GY | CP | SV | Asn | GY | CP | Asn | GY | FN | Asn | |||||||||||

| F | p1 | F | p | F | p | F | p | F | p | F | p | F | p | F | p | F | p | F | p | |

| Cultivar | 6.1 | *** | 42.0 | *** | 27.5 | *** | 16.7 | *** | 19.1 | *** | 446.0 | *** | 57.0 | *** | 80.5 | *** | 1.2 | n.s. | 0.1 | n.s. |

| Year | 1616.6 | *** | 273.2 | *** | 41.9 | *** | 264.1 | *** | 540.7 | *** | 469.7 | *** | 204.4 | *** | 28.2 | *** | 1.3 | n.s. | 143.2 | *** |

| Cultivar × Year | 1.5 | n.s. | 6.5 | *** | 3.0 | *** | 7.3 | *** | 2.5 | * | 17.67 | *** | 7.1 | *** | 0.9 | n.s. | 0.5 | n.s. | 0.2 | n.s. |

| Winter Wheat | Winter Spelt | Winter Rye | Winter Einkorn | Winter Emmer * | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2006 | 2007 | 2008 | 2006 | 2007 | 2008 | 2006 | 2007 | 2008 | 2006 | 2007 | 2008 | 2007 | 2008 | |

| GY [t ha−1] | 4.2 ef | 2.1 a | 4.2 ef | 4.2 ef | 2.4 ab | 4.7 f | 4.1 de | 3.3 cd | 3.4 cd | 2.7 abc | 1.8 a | 3.1 bcd | 1.9 | 4.2 |

| CP [%] | 11.6 e | 9.9 c | 10.4 d | 13.4 fg | 11.6 e | 12.9 f | 6.8 a | 6.6 a | 8.8 b | 15.6 g | 11.9 ef | 14.8 fg | 10.6 | 11.8 |

| Asn [mg 100 g−1] | 8.1 b | 8.2 b | 13.2 c | 6.6 ab | 5.5 a | 12 c | 32.3 de | 28.6 d | 67.0 f | 25.5 d | 30.7 de | 40.0 e | 13.4 | 18.1 |

| SV [ml] | 31.8 b | 30.6 a | 34.7 c | |||||||||||

| FN [s] | 217 a | 224 a | 245 a | |||||||||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stockmann, F.; Weber, E.A.; Mast, B.; Schreiter, P.; Merkt, N.; Claupein, W.; Graeff-Hönninger, S. Evaluation of Asparagine Concentration as an Indicator of the Acrylamide Formation in Cereals Grown under Organic Farming Conditions. Agronomy 2018, 8, 294. https://doi.org/10.3390/agronomy8120294

Stockmann F, Weber EA, Mast B, Schreiter P, Merkt N, Claupein W, Graeff-Hönninger S. Evaluation of Asparagine Concentration as an Indicator of the Acrylamide Formation in Cereals Grown under Organic Farming Conditions. Agronomy. 2018; 8(12):294. https://doi.org/10.3390/agronomy8120294

Chicago/Turabian StyleStockmann, Falko, Ernst Albrecht Weber, Benjamin Mast, Pat Schreiter, Nikolaus Merkt, Wilhelm Claupein, and Simone Graeff-Hönninger. 2018. "Evaluation of Asparagine Concentration as an Indicator of the Acrylamide Formation in Cereals Grown under Organic Farming Conditions" Agronomy 8, no. 12: 294. https://doi.org/10.3390/agronomy8120294

APA StyleStockmann, F., Weber, E. A., Mast, B., Schreiter, P., Merkt, N., Claupein, W., & Graeff-Hönninger, S. (2018). Evaluation of Asparagine Concentration as an Indicator of the Acrylamide Formation in Cereals Grown under Organic Farming Conditions. Agronomy, 8(12), 294. https://doi.org/10.3390/agronomy8120294