Development of a Model for the Implementation of the Circular Economy in Desert Coastal Regions

Abstract

:1. Introduction

2. Environmental Characteristics of the Atacama Desert, Chile, and Sonoran Desert, Mexico

3. Circular Economy Model

3.1. Water Desalination

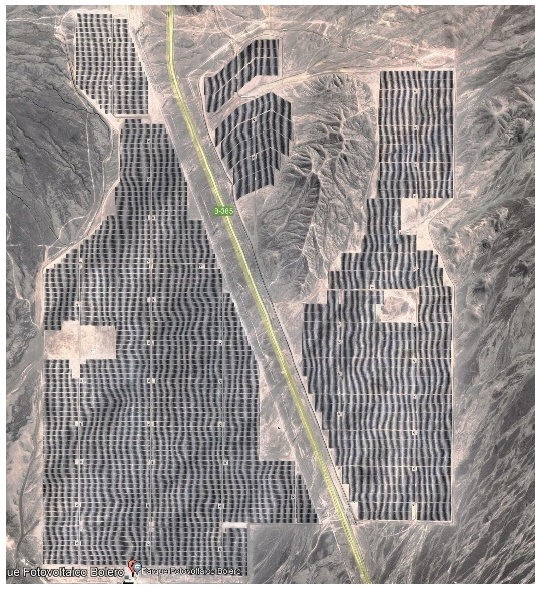

3.2. Solar Energy

3.3. Hydroponic Systems for Food Production

3.4. Water Dosing with Hydrogels for Agriculture

3.5. Microalgae Culture as a Biomass and Seaweed Farming and Processing for Food Supply and Biochemicals

3.6. Biogas Production

3.7. Nutrient Recovery from Wastewater Treatment Streams and Anaerobic Digestion

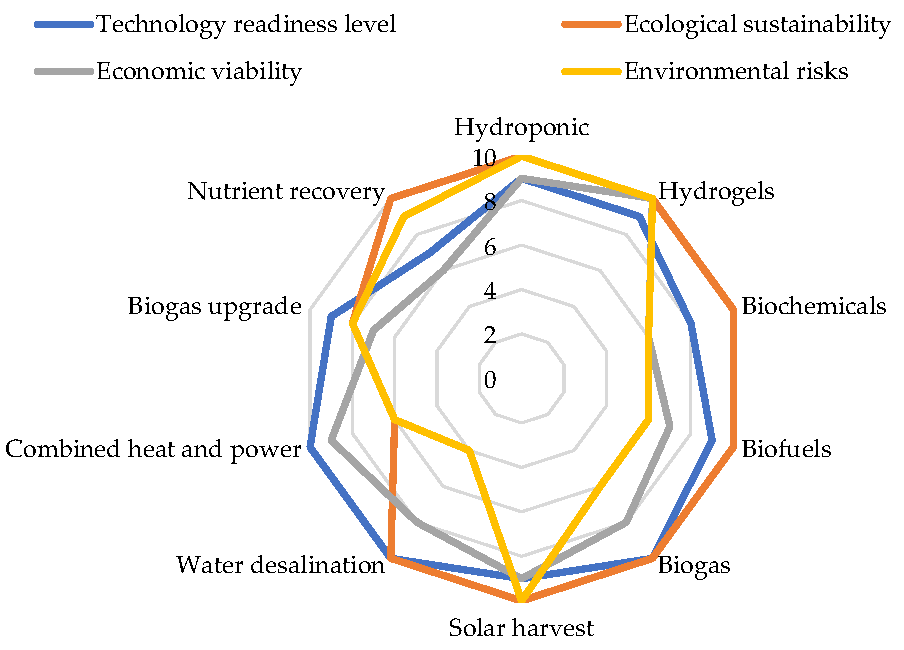

4. System’s Feasibility and Evaluation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abad-Segura, E.; de la Fuente, A.B.; González-Zamar, M.D.; Belmonte-Ureña, L.J. Effects of Circular Economy Policies on the Environment and Sustainable Growth: Worldwide Research. Sustainability 2020, 12, 5792. [Google Scholar] [CrossRef]

- Mannina, G.; Badalucco, L.; Barbara, L.; Cosenza, A.; Di Trapani, D.; Gallo, G.; Laudicina, V.A.; Marino, G.; Muscarella, S.M.; Presti, D.; et al. Enhancing a Transition to a Circular Economy in the Water Sector: The EU Project WIDER UPTAKE. Water 2021, 13, 946. [Google Scholar] [CrossRef]

- Bull, A.T.; Andrews, B.A.; Dorador, C.; Goodfellow, M. Introducing the Atacama Desert. Antonie Van LeeuwenhoekInt. J. Gen. Mol. Microbiol. 2018, 111, 1269–1272. [Google Scholar] [CrossRef] [PubMed]

- Arenas-Díaz, F.; Fuentes, B.; Reyers, M.; Fiedler, S.; Böhm, C.; Campos, E.; Shao, Y.; Bol, R. Dust and Aerosols in the Atacama Desert. Earth-Sci. Rev. 2022, 226, 103925. [Google Scholar] [CrossRef]

- Jara, I.A.; Maldonado, A.; de Porras, M.E. Did Modern Precipitation Drivers Influence Centennial Trends in the Highlands of the Atacama Desert During the Most Recent Millennium? Geophys. Res. Lett. 2022, 49, e2021GL095927. [Google Scholar] [CrossRef]

- Ezcurra, E.; Mellink, E. Desert Ecosystems. Encycl. Biodivers. Second Ed. 2013, 2, 457–478. [Google Scholar] [CrossRef]

- Reyers, M.; Shao, Y. Cutoff Lows off the Coast of the Atacama Desert under Present Day Conditions and in the Last Glacial Maximum. Glob. Planet. Chang. 2019, 181, 102983. [Google Scholar] [CrossRef]

- Prieto, M.; Calderón-Seguel, M.; Fragkou, M.C.; Fuster, R. The (Not-so-Free) Chilean Water Model. The Case of the Antofagasta Region, Atacama Desert, Chile. Extr. Ind. Soc. 2022, 101081. [Google Scholar] [CrossRef]

- Cortés-Ramos, J.; Farfán, L.M.; Brito-Castillo, L. Extreme Freezing in the Sonoran Desert, Mexico: Intense and Short-Duration Events. Int. J. Climatol. 2021, 41, 4339–4358. [Google Scholar] [CrossRef]

- Zolotokrylin, A.N.; Brito-Castillo, L.; Titkova, T.B. Local Climatically-Driven Changes of Albedo and Surface Temperatures in the Sonoran Desert. J. Arid Environ. 2020, 178, 104147. [Google Scholar] [CrossRef]

- Zhao, Y.; Norouzi, H.; Azarderakhsh, M.; AghaKouchak, A. Global Patterns of Hottest, Coldest, and Extreme Diurnal Variability on Earth. Bull. Am. Meteorol. Soc. 2021, 102, E1672–E1681. [Google Scholar] [CrossRef]

- Boardman, J.; Sauser, B. Systems Thinking: Coping with 21st Century Problems, 1st ed.; CRC Press: Boca Raton, FL, USA, 2008; ISBN 9780429146404. [Google Scholar]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; The Johns Hopkins University Press: Baltimore, 1990; ISBN 0-8018-3986-6. [Google Scholar]

- Rigamonti, L.; Mancini, E. Life Cycle Assessment and Circularity Indicators. Int. J. Life Cycle Assess. 2021, 26, 1937–1942. [Google Scholar] [CrossRef]

- Ellen Macarthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition|Report; Ellen Macarthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Skawińska, E.; Zalewski, R.I. Circular Economy as a Management Model in the Paradigm of Sustainable Development. Management 2018, 22, 217–233. [Google Scholar] [CrossRef]

- Neves, S.A.; Marques, A.C. Drivers and Barriers in the Transition from a Linear Economy to a Circular Economy. J. Clean. Prod. 2022, 341, 130865. [Google Scholar] [CrossRef]

- Smol, M.; Adam, C.; Preisner, M. Circular Economy Model Framework in the European Water and Wastewater Sector. J. Mater. Cycles Waste Manag. 2020, 22, 682–697. [Google Scholar] [CrossRef]

- Ferronato, N.; Rada, E.C.; Gorritty Portillo, M.A.; Cioca, L.I.; Ragazzi, M.; Torretta, V. Introduction of the Circular Economy within Developing Regions: A Comparative Analysis of Advantages and Opportunities for Waste Valorization. J. Environ. Manag. 2019, 230, 366–378. [Google Scholar] [CrossRef]

- Ahmed, Z.; Mahmud, S.; Acet, D.H. Circular Economy Model for Developing Countries: Evidence from Bangladesh. Heliyon 2022, 8, e09530. [Google Scholar] [CrossRef]

- Bermudez-Contreras, A.; Thomson, M.; Infield, D.G. Renewable Energy Powered Desalination in Baja California Sur, Mexico. Desalination 2008, 220, 431–440. [Google Scholar] [CrossRef]

- Kim, J.; Park, K.; Yang, D.R.; Hong, S. A Comprehensive Review of Energy Consumption of Seawater Reverse Osmosis Desalination Plants. Appl. Energy 2019, 254, 113652. [Google Scholar] [CrossRef]

- Mavukkandy, M.O.; Chabib, C.M.; Mustafa, I.; Al Ghaferi, A.; AlMarzooqi, F. Brine Management in Desalination Industry: From Waste to Resources Generation. Desalination 2019, 472, 114187. [Google Scholar] [CrossRef]

- European Comission Social Committee and the Committee of the Regions. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe. COM 2020, 98 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2020%3A98%3AFIN (accessed on 28 July 2022).

- Hofste, R.W.; Reig, P.; Schleifer, L. 17 Countries, Home to One-Quarter of the World’s Population, Face Extremely High Water Stress. Available online: https://www.wri.org/insights/17-countries-home-one-quarter-worlds-population-face-extremely-high-water-stress (accessed on 27 July 2022).

- Herrera-León, S.; Cruz, C.; Kraslawski, A.; Cisternas, L.A. Current Situation and Major Challenges of Desalination in Chile. Desalin. Water Treat. 2019, 171, 93–104. [Google Scholar] [CrossRef]

- Aguas Antofagasta Aguas Antofagasta Grupo EPM. Available online: www.desalar.cl (accessed on 9 June 2022).

- Shalaby, S.M.; Sharshir, S.W.; Kabeel, A.E.; Kandeal, A.W.; Abosheiasha, H.F.; Abdelgaied, M.; Hamed, M.H.; Yang, N. Reverse Osmosis Desalination Systems Powered by Solar Energy: Preheating Techniques and Brine Disposal Challenges—A Detailed Review. Energy Convers. Manag. 2022, 251, 114971. [Google Scholar] [CrossRef]

- Google. n.d. Google Earth Pro 7.3.4.8642 (64-Bit). Desalination Plant in Antofagasta, Chile. Available online: https://www.google.com/maps/place/Desaladora+Aguas+Antofagasta/@-23.5425926,-70.3991642,15z/data=!4m5!3m4!1s0x96ae2a24d07789ed:0x32a45bdc2b1c5469!8m2!3d-23.5425926!4d-70.3991642 (accessed on 29 July 2022).

- Google. n.d. Google Earth Pro 7.3.4.8642 (64-Bit). Desalination Plant in Guaymas, Mexico. Available online: https://www.google.com/maps/place/Planta+Desaladora+Guaymas/@27.9175022,-110.7425767,20z/data=!4m13!1m7!3m6!1s0x0:0xb44144b192eef538!2zMjfCsDU1JzAzLjQiTiAxMTDCsDQ0JzMyLjgiVw!3b1!8m2!3d27.9176111!4d-110.7424444!3m4!1s0x86c9730648d01d37:0x23f566817fd9ce8f!8m2!3d27.9174051!4d-110.7423246 (accessed on 29 July 2022).

- IMTA Gaceta Del Instituto Mexicano de Tecnologia Del Agua. Available online: https://www.imta.gob.mx/gaceta/anteriores/g06-10-2007/desalacion.html (accessed on 30 June 2022).

- CONAGUA CMIC. Programa para la Modernización de Organismos Operadores de agua Promagua. 2008. Available online: https://www.cmic.org.mx/comisiones/Sectoriales/infraestructurahidraulica/varios/Ejecucion_de_proyectos/Listado_proyectos_para_empresas.pdf (accessed on 30 June 2022).

- Robles-Lizárraga, A.; Del Rosario Martínez-Macías, M.; Encinas-Guzmán, I.; De, O.; Larraguibel-Aganza, J.; Rodríguez-López, J.; Dévora-Isiordia, G.E. Design of Reverse Osmosis Desalination Plant in Puerto Peñasco, Sonora, México. Desalin. Water Treat. 2019, 175, 1–10. [Google Scholar] [CrossRef]

- Proyectos Mexico Planta Desalinizadora de Guaymas y Empalme, Sonora—Proyectos México. Available online: https://www.proyectosmexico.gob.mx/proyecto_inversion/010-planta-desalinizadora-de-guaymas-y-empalme-sonora/ (accessed on 30 June 2022).

- Black & Veatch; LIBRA. Binational Study of Water Desalination Opportunities in the Sea of Cortez; Black & Veatch: Burnaby, BC, Canada, 2020. [Google Scholar]

- Correa-Puerta, J.; Ferrada, P.; Häberle, P.; Díaz-Almeida, D.; Sanz, A.; Zubillaga, O.; Marzo, A.; Portillo, C.; del Campo, V. Comparing the Effects of Ultraviolet Radiation on Four Different Encapsulants for Photovoltaic Applications in the Atacama Desert. Sol. Energy 2021, 228, 625–635. [Google Scholar] [CrossRef]

- INE. Generacion y Distribucion de Energia; Electrica: Region de Antofagasta, Chile, 2022. [Google Scholar]

- Google. n.d. Google Earth Pro 7.3.4.8642 (64-Bit). Bolero Photovoltaic Park, Sierra Gorda, Chile. Available online: https://www.google.com/maps/place/23%C2%B029’37.5%22S+69%C2%B025’06.7%22W/@-23.4937602,-69.4207054,17z/data=!3m1!4b1!4m5!3m4!1s0x0:0x919c1ecd05e01541!8m2!3d-23.4937602!4d-69.4185167 (accessed on 29 July 2022).

- Fronteradesk Sonora Moves Forward with Massive Solar Plant near Rocky Point|Fronteras. Available online: https://fronterasdesk.org/content/1748961/sonora-moves-forward-massive-solar-plant-near-rocky-point (accessed on 30 June 2022).

- Arancibia-Bulnes, C.A.; Peón-Anaya, R.; Riveros-Rosas, D.; Quiñones, J.J.; Cabanillas, R.E.; Estrada, C.A. Beam Solar Irradiation Assessment for Sonora, Mexico. Energy Procedia 2014, 49, 2290–2296. [Google Scholar] [CrossRef]

- Swain, A.; Chatterjee, S.; Viswanath, M.; Roy, A.; Biswas, A. Hydroponics in Vegetable Crops: A Review. Pharma Innov. J. 2021, 10, 629–634. [Google Scholar]

- Martinez-Cordova, L.R.; Lopez-Elias, J.; Martinez-Porchas, M.; Bringas-Burgos, B.; Naranjo-Paramo, J. A Preliminary Evaluation of an Integrated Aquaculture-Agriculture Systems (Tilapia and Peppers) at Mesocosm Scale. J. Aquac. Mar. Biol. 2020, 9, 19–22. [Google Scholar] [CrossRef]

- de Anda, J.; Shear, H. Potential of Vertical Hydroponic Agriculture in Mexico. Sustainability 2017, 9, 140. [Google Scholar] [CrossRef]

- Shrivastava, A.; Nayak, C.K.; Dilip, R.; Samal, S.R.; Rout, S.; Ashfaque, S.M. Automatic Robotic System Design and Development for Vertical Hydroponic Farming Using IoT and Big Data Analysis. Mater. Today: Proc. 2021; in press. [Google Scholar] [CrossRef]

- 2000Agro Hidroponia. Available online: http://www.2000agro.com.mx/hidroponia/fracasa-60-de-invernaderos-de-hidroponia-por-falta-de-capacitacion-uach/ (accessed on 30 June 2022).

- Promueve Hidroponia Hidroponia. Available online: http://hidroponia.mx/agricultura-protegida-en-mexico/ (accessed on 30 June 2022).

- World Economic Forum. System Initiative on Shaping the Future of Food Security and Agriculture; Summary Report; World Economic Forum: Cologny, Switzerland, 2017. [Google Scholar]

- Michalik, R.; Wandzik, I. A Mini-Review on Chitosan-Based Hydrogels with Potential for Sustainable Agricultural Applications. Polymers 2020, 12, 2425. [Google Scholar] [CrossRef] [PubMed]

- Kalhapure, A.; Kumar, R.; Singh, V.P.; Pandey, D.S. Hydrogels: A Boon for Increasing Agricultural Productivity in Water-Stressed Environment on JSTOR. Curr. Sci. 2016, 111, 1773–1779. [Google Scholar]

- Freitas-Azevedo, L.; Tédson, D.; Bertonha, A.; Andrade-Gonçalves, A.C. USO DE HIDROGEL NA AGRICULTURA. Rev. Do Programa De Cienc. Ago-Ambient. 2002, 1, 23–31. [Google Scholar]

- López-Elías, J.; Garza, S.; Jiménez, J.L.; Huez, M.A.; Garrido, O.D. Uso De Un Polímero Hidrófilo A Base De Poliacrilamida Para Mejorar La Eficiencia En El Uso Del Agua. Eur. Sci. J. Esj 2016, 12, 160. [Google Scholar] [CrossRef]

- Ramli, R.A. Slow Release Fertilizer Hydrogels: A Review. Polym. Chem. 2019, 10, 6073–6090. [Google Scholar] [CrossRef]

- Macías-Duarte, R.; Grijalva-Contreras, R.L.; Robles-Contreras, F.; López-Carvajal, A.; Núñez-Ramírez, F. Irrigation Deficit and Hydrogel Application in Olive Productivity in Desert Regions. Rev. Mex. De Cienc. Agrícolas 2019, 10, 393–404. [Google Scholar] [CrossRef]

- Alam, M.A.; Xu, J.L.; Wang, Z. Microalgae Biotechnology for Food, Health and High Value Products; Springer: Singapore, 2020; ISBN 9789811501692. [Google Scholar]

- Das, P.; Thaher, M.I.; Khan, S.; AbdulQuadir, M.; Chaudhary, A.K.; Alghasal, G.; Al-Jabri, H. Comparison of Biocrude Oil Production from Self-Settling and Non-Settling Microalgae Biomass Produced in the Qatari Desert Environment. Int. J. Environ. Sci. Technol. 2019, 16, 7443–7454. [Google Scholar] [CrossRef]

- Rasheed, R.; Thaher, M.; Younes, N.; Bounnit, T.; Schipper, K.; Nasrallah, G.K.; Al Jabri, H.; Gifuni, I.; Goncalves, O.; Pruvost, J. Solar Cultivation of Microalgae in a Desert Environment for the Development of Techno-Functional Feed Ingredients for Aquaculture in Qatar. Sci. Total Environ. 2022, 835, 155538. [Google Scholar] [CrossRef]

- Schipper, K.; Al Muraikhi, M.; Alghasal, G.S.H.S.; Saadaoui, I.; Bounnit, T.; Rasheed, R.; Dalgamouni, T.; Al Jabri, H.M.S.J.; Wijffels, R.H.; Barbosa, M.J. Potential of Novel Desert Microalgae and Cyanobacteria for Commercial Applications and CO2 Sequestration. J. Appl. Phycol. 2019, 31, 2231–2243. [Google Scholar] [CrossRef]

- Gao, F.; Zhang, X.L.; Zhu, C.J.; Huang, K.H.; Liu, Q. High-Efficiency Biofuel Production by Mixing Seawater and Domestic Sewage to Culture Freshwater Microalgae. Chem. Eng. J. 2022, 443, 136361. [Google Scholar] [CrossRef]

- Sosa-Hernández, J.E.; Romero-Castillo, K.D.; Parra-Arroyo, L.; Aguilar-Aguila-Isaías, M.A.; García-Reyes, I.E.; Ahmed, I.; Parra-Saldivar, R.; Bilal, M.; Iqbal, H.M.N. Mexican Microalgae Biodiversity and State-Of-The-Art Extraction Strategies to Meet Sustainable Circular Economy Challenges: High-Value Compounds and Their Applied Perspectives. Mar. Drugs 2019, 17, 174. [Google Scholar] [CrossRef]

- Cavieres, L.; Bazaes, J.; Marticorena, P.; Riveros, K.; Medina, P.; Sepúlveda, C.; Riquelme, C. Pilot-Scale Phycoremediation Using Muriellopsis Sp. For Wastewater Reclamation in the Atacama Desert: Microalgae Biomass Production and Pigment Recovery. Water Sci. Technol. 2021, 83, 331–343. [Google Scholar] [CrossRef] [PubMed]

- Pardilhó, S.; Cotas, J.; Pereira, L.; Oliveira, M.B.; Dias, J.M. Marine Macroalgae in a Circular Economy Context: A Comprehensive Analysis Focused on Residual Biomass. Biotechnol. Adv. 2022, 60. [Google Scholar] [CrossRef] [PubMed]

- Filote, C.; Santos, S.C.R.; Popa, V.I.; Botelho, C.M.S.; Volf, I. Biorefinery of Marine Macroalgae into High-Tech Bioproducts: A Review; Springer International Publishing: Berlin/Heidelberg, Germany, 2021; Volume 19, ISBN 0123456789. [Google Scholar]

- Alemañ, A.E.; Robledo, D.; Hayashi, L. Development of Seaweed Cultivation in Latin America: Current Trends and Future Prospects. Phycologia 2019, 58, 462–471. [Google Scholar] [CrossRef] [Green Version]

- AlgaHealth AlgaHealth Project Ocean Farming in the Desert Commission. Available online: https://cordis.europa.eu/article/id/415806-ocean-farming-in-the-desert (accessed on 30 June 2022).

- Angelidaki, I.; Ellegaard, L.; Ahring, B.K. Applications of the Anaerobic Digestion Process. Adv. Biochem. Eng./Biotechnol. 2003, 82, 1–33. [Google Scholar] [CrossRef]

- Kougias, P.G.; Angelidaki, I. Biogas and Its Opportunities—A Review. Front. Environ. Sci. Eng. 2018, 12, 14. [Google Scholar] [CrossRef]

- Casiano Flores, C.; Bressers, H.; Gutierrez, C.; de Boer, C. Towards Circular Economy—A Wastewater Treatment Perspective, the Presa Guadalupe Case. Manag. Res. Rev. 2018, 41, 554–571. [Google Scholar] [CrossRef]

- Danish Energy Agency; Ea Energy Analyses. In IBTech Pre-Feasibility Studies for Biogas in Sonora; Ea Energianalyse: København, Denmark, 2019.

- Kim, Y.H.; Lee, J.C.; An, H.J. Developing Renewable Energy in Mesoamerica with Special Focus on Biogas from Food Waste in Hermosillo, Sonora (Mexico); Commission for Ecology and Sustainable Development of the State of Sonora: Sonora, CA, USA, 2020. [Google Scholar]

- Noyola, A.; Morgan-Sagastume, J.; Harder, B.; Ramirez-Higareda, B.L.; Lopez, J.; Castro, M.; Lindboe, H.H. Biogas in Mexico: Lessons Learned from Partnership Projects 2018–2019; Wiley Online Library: New York, NY, USA, 2019. [Google Scholar]

- Saliu, T.D.; Oladoja, N.A. Nutrient Recovery from Wastewater and Reuse in Agriculture: A Review. Environ. Chem. Lett. 2021, 19, 2299–2316. [Google Scholar] [CrossRef]

- Batstone, D.J.; Hülsen, T.; Mehta, C.M.; Keller, J. Platforms for Energy and Nutrient Recovery from Domestic Wastewater: A Review. Chemosphere 2015, 140, 2–11. [Google Scholar] [CrossRef] [PubMed]

- Shi, L.; Simplicio, W.S.; Wu, G.; Hu, Z.; Hu, H.; Zhan, X. Nutrient Recovery from Digestate of Anaerobic Digestion of Livestock Manure: A Review. Curr. Pollut. Rep. 2018, 4, 74–83. [Google Scholar] [CrossRef]

- Navarro, C. Officials Inaugurate Solar-Powered System for Wastewater Treatment Plant in Sonora. Lat. Am. Digit. Beat 2016. [Google Scholar]

- Google. n.d. Google Earth Pro 7.3.4.8642 (64-Bit). Solar-Powered Wastewater Treatment Plant, Nogales, Mexico. Available online: https://www.google.com/maps/place/31%C2%B007’33.0%22N+110%C2%B056’27.8%22W/@31.1258357,-110.9432304,17z/data=!4m5!3m4!1s0x0:0xcfda7759a4bf549!8m2!3d31.1258357!4d-110.9410417!5m1!1e1 (accessed on 29 July 2022).

- Cámara De Diputados, C.D.L.U. Ley General del Equilibrio Ecológico y la Protección al Ambient; Mexican Environmental Management Agency: Mexico, Mexico, 1988; pp. 1–142. [Google Scholar]

- ProyectoPuente Operan En Hermosillo 44 Empresas Con Plantas Tratadoras de Agua; Son Para Áreas Verdes y Actividades Industriales. Available online: https://proyectopuente.com.mx/2020/12/03/empresas-que-utilizan-plantas-tratadoras-tienen-ahorro-importante-en-recibo-hay-44-en-hermosillo-que-la-usan-para-areas-verdes-y-actividades-industriales/ (accessed on 3 August 2022).

- Google. n.d. Google Earth Pro 7.3.4.8642 (64-Bit). The Wastewater Treatment Plant, Hermosillo, Sonora, Mexico. Available online: https://www.google.com/maps/place/29%C2%B002’07.8%22N+111%C2%B003’54.8%22W/@29.0355,-111.0674109,17z/data=!3m1!4b1!4m2!3m1!1s0x0:0xa7698df249f8e324!5m1!1e1 (accessed on 29 July 2022).

- Corvellec, H.; Stowell, A.F.; Johansson, N. Critiques of the Circular Economy. J. Ind. Ecol. 2022, 26, 421–432. [Google Scholar] [CrossRef]

- Erixno, O.; Rahim, N.A.; Ramadhani, F.; Adzman, N.N. Energy Management of Renewable Energy-Based Combined Heat and Power Systems: A Review. Sustain. Energy Technol. Assess. 2022, 51, 101944. [Google Scholar] [CrossRef]

- Ministerio del Medioambiente Ley 20920. D. Of. 2016, pp. 17–20. Available online: https://www.bcn.cl/leychile/navegar?idNorma=1090894&idParte=9705129&idVersion=2016-06-01 (accessed on 3 August 2022).

- Propuesta Constitución Política de la República de Chile; Editorial Jurídica de Chile: Santiago, Chile, 2022.

- Ministerio de Medio Ambiente Hoja de Ruta Nacional a La Economía Circular Al 2040. 2020. Available online: https://economiacircular.mma.gob.cl/hoja-de-ruta/ (accessed on 1 August 2022).

- Munoz-Melendez, G.; Delgado-Ramos, G.C.; Diaz-Chavez, R. Circular Economy in Mexico. In Circular Economy: Recent Trends in Global Perspective 2021; Springer: Singapore, 2021; pp. 497–523. [Google Scholar] [CrossRef]

- Valenzuela-Corral, L.; Hinojosa-Rodriguez, C. Teoria Fundamentada Sobre Los Elementos de Implementacion de Economia Circular En El Sur Del Estado de Sonora. Rev. Entorno Acad. 2018, 20, 23–28. [Google Scholar]

- Cansino-Loeza, B.; del Munguía-López, A.C.; Ponce-Ortega, J.M. A Water-Energy-Food Security Nexus Framework Based on Optimal Resource Allocation. Environ. Sci. Policy 2022, 133, 1–16. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation Climate and a Circular Economy|Ellen MacArthur Foundation. Available online: https://ellenmacarthurfoundation.org/topics/climate/overview (accessed on 25 July 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabrera-González, M.; Ramonet, F.; Harasek, M. Development of a Model for the Implementation of the Circular Economy in Desert Coastal Regions. Land 2022, 11, 1506. https://doi.org/10.3390/land11091506

Cabrera-González M, Ramonet F, Harasek M. Development of a Model for the Implementation of the Circular Economy in Desert Coastal Regions. Land. 2022; 11(9):1506. https://doi.org/10.3390/land11091506

Chicago/Turabian StyleCabrera-González, Mayuki, Fernando Ramonet, and Michael Harasek. 2022. "Development of a Model for the Implementation of the Circular Economy in Desert Coastal Regions" Land 11, no. 9: 1506. https://doi.org/10.3390/land11091506