Symmetric Performance Analysis for Mechanical Properties of Sustainable Asphalt Materials under Varying Temperature Conditions: An Application of DT and NDT Digital Techniques

Abstract

:1. Introduction

2. Materials and Methods

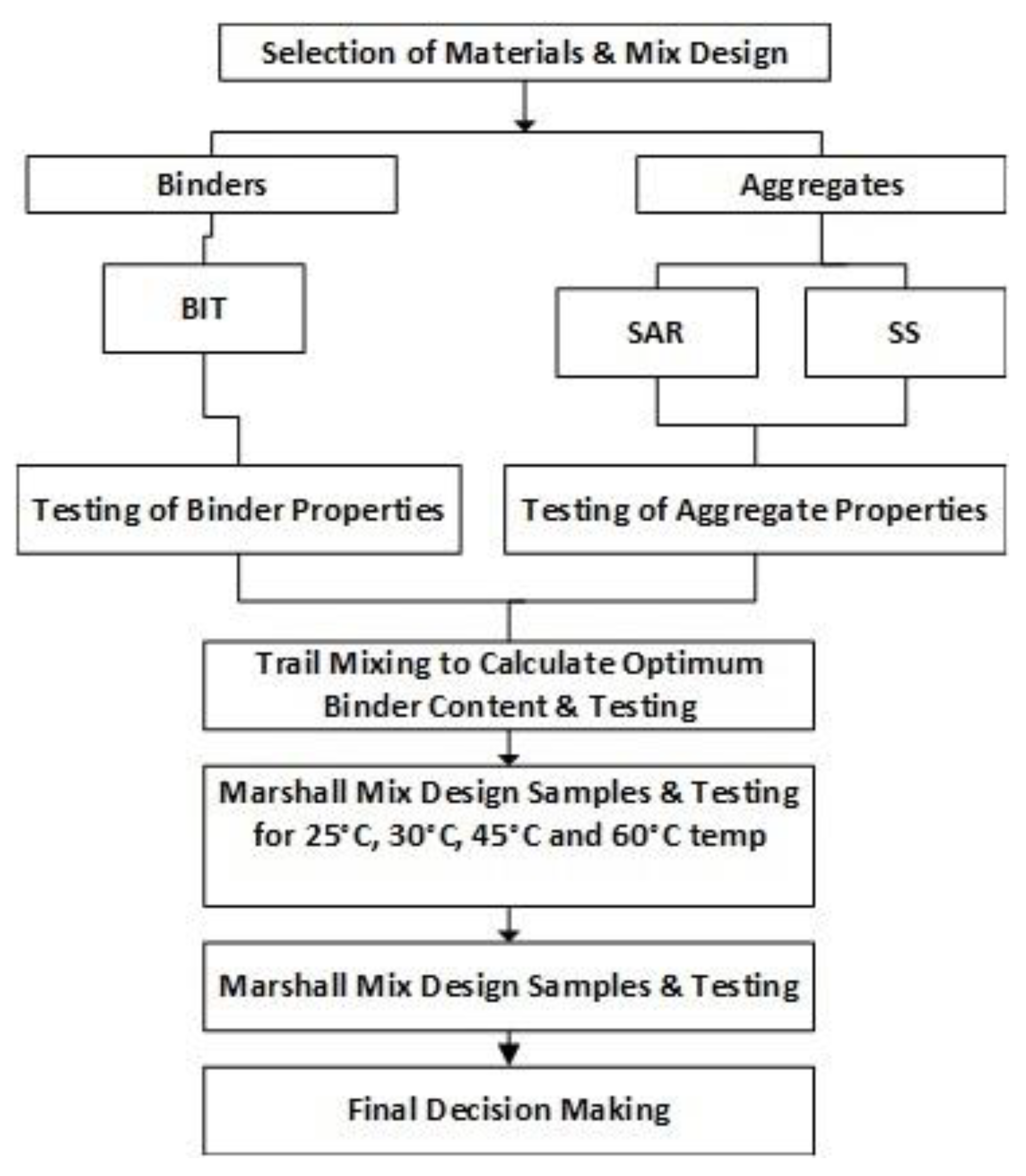

- Step 1: Selection of the basic materials and mix design.

- Step 2: Selection of two types of aggregate with reference to geology, i.e., Sargodha is composed of Dolerite-sandstone and Sakhi Sarwar is composed of mixed limestone (55%) and sandstone (45%).

- Step 3: Testing of basic properties of bitumen and aggregates.

- Step 4: Trial mixing to calculate optimum binder content and testing.

- Step 5: Development of the final mix design under varying temperature conditions, i.e., (25 °C, 30 °C, 45 °C, and 60 °C) shown in Figure 1.

- Step 6: Stability of asphalt samples and testing by Marshall stability (destructive test) and ultrasonic pulse velocity technique (non-destructive methods).

- Step 7: Comparative performance analysis with reference to standards.

- Step 8: Statistical analysis for the impact analysis of factors.

- Step 9: Final decision making.

2.1. Bitumen

2.2. Aggregate

2.3. Preparation of the Sample

2.4. Experimental Methods

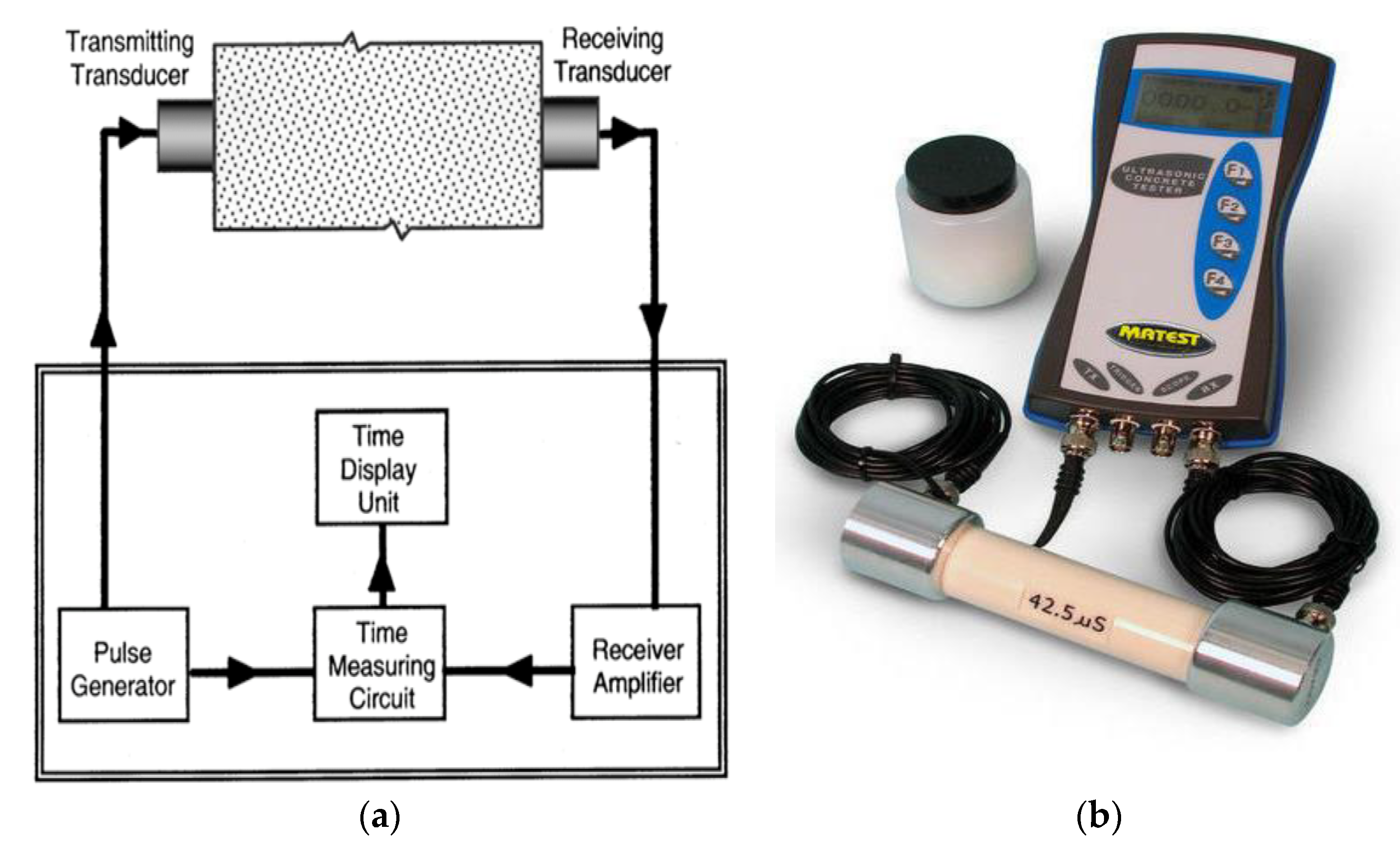

2.4.1. Ultrasonic Pulse Velocity Test

2.4.2. Stability Test

3. Results and Discussions

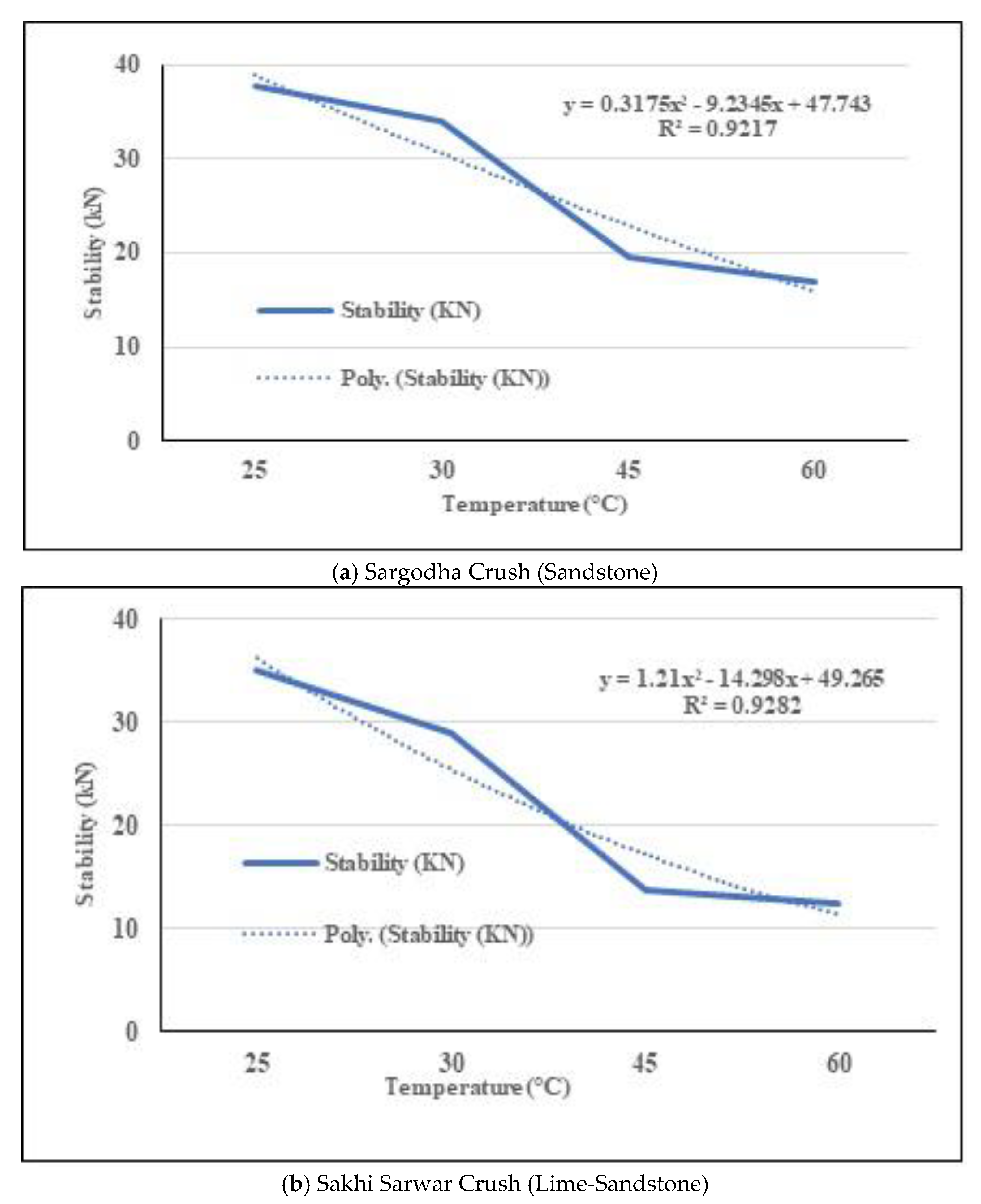

3.1. Marshall Stability Analysis Based on Environment Temperature

3.2. Relationship between Stability and Ultrasonic Pulse Velocity

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Brockenbrough, R.L.; Boedecker, K.J. Highway Engineering Handbook: Building and Rehabilitating the Infrastructure; McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Aodah, H.H.; Kareem, Y.N.; Chandra, S. Performance of bituminous mixes with different aggregate gradations and binders. Int. J. Eng. Technol. 2012, 2, 1802–1812. [Google Scholar]

- Celko, J.; Decky, M.; Kovac, M. An analysis of vehicle-road surface interaction for classification of IRI in the frame of Slovak PMS. Eksploat. Niezawodn. Maint. Reliab. 2009, 41, 15–21. [Google Scholar]

- Fookes, P.G. Tropical Residual Soils: A Geological Society Engineering Group working Party Revised Report; Geological Society: London, UK, 1997. [Google Scholar]

- Shashidhar, N.; Zhong, X.; Shenoy, A.V.; Bastian, E. Investigating the role of aggregate structure in asphalt pavements. In Proceedings of the International Center for Aggregates Research 8th Annual Symposium: Aggregates-Asphalt Concrete, Bases and Fines, Denver, CO, USA, 12–14 April 2000. [Google Scholar]

- Vaitkus, A.; Paliukaitė, M. Evaluation of time loading influence on asphalt pavement rutting. Procedia Eng. 2013, 57, 1205–1212. [Google Scholar] [CrossRef] [Green Version]

- Roberts, F.L.; Kandhal, P.S.; Brown, E.R.; Lee, D.-Y.; Kennedy, T.W. Hot Mix Asphalt Materials, Mixture Design and Construction; National Asphalt Pavement Association: Lanham, MA, USA, 1991. [Google Scholar]

- Ahmed, K.; Irfan, M.; Ahmed, S.; Ahmed, A.; Khattak, A. Experimental investigation of strength and stiffness characteristics of hot mix asphalt (HMA). Procedia Eng. 2014, 77, 155–160. [Google Scholar] [CrossRef] [Green Version]

- Mikolaj, J.; Remek, L.; Macula, M. Asphalt Concrete Overlay Optimization Based on Pavement Performance Models. Adv. Mater. Sci. Eng. 2017, 2017. [Google Scholar] [CrossRef] [Green Version]

- Tigdemir, M.; Karasahin, M.; Sen, Z. Investigation of fatigue behaviour of asphalt concrete pavements with fuzzy-logic approach. Int. J. Fatigue 2002, 24, 903–910. [Google Scholar] [CrossRef]

- Tigdemir, M.; Kalyoncuoglu, S.F.; Kalyoncuoglu, U.Y. Application of ultrasonic method in asphalt concrete testing for fatigue life estimation. NDT E Int. 2004, 37, 597–602. [Google Scholar] [CrossRef]

- Movilla-Quesada, D.; Raposeiras, A.; Silva-Klein, L.; Lastra-González, P.; Castro-Fresno, D. Use of plastic scrap in asphalt mixtures added by dry method as a partial substitute for bitumen. Waste Manag. 2019, 87, 751–760. [Google Scholar] [CrossRef]

- Jiang, Y.; Deng, C.; Li, Q.; Liu, H. Effect of compaction methods on physical and mechanical properties of asphalt mixture. J. Mater. Civ. Eng. 2019, 31, 04019075. [Google Scholar] [CrossRef]

- Chen, W.-F.; Liew, J.R. The Civil Engineering Handbook; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Hannachi, S.; Guetteche, M. Review of the ultrasonic pulse velocity evaluating concrete compressive strength on site. In Proceedings of the Scientific Cooperation International Workshops on Engineering Branches, Istanbul, Turkey, 8–9 August 2014. [Google Scholar]

- Lytton, R.L. Determining Asphaltic Concrete Pavement Structural Properties by Nondestructive Testing; Transportation Research Board: Washington, DC, USA, 1990. [Google Scholar]

- Baldo, N.; Manthos, E.; Pasetto, M. Analysis of the Mechanical Behaviour of Asphalt Concretes Using Artificial Neural Networks. Adv. Civ. Eng. 2018, 2018, 17. [Google Scholar] [CrossRef] [Green Version]

- Sarsam, S.I.; Kadium, N.S. Feasibility of Using Pulse Velocity to Evaluate Asphalt Concrete Properties. J. Adv. Civ. Eng. Constr. Mater. 2018, 1, 51–63. [Google Scholar]

- Vila-Cortavitarte, M.; Lastra-González, P.; Calzada-Pérez, M.Á.; Indacoechea-Vega, I. Analysis of the influence of using recycled polystyrene as a substitute for bitumen in the behaviour of asphalt concrete mixtures. J. Clean. Prod. 2018, 170, 1279–1287. [Google Scholar] [CrossRef]

- Hasnain Saeed, M.; Shah, S.A.R.; Arshad, H.; Waqar, A.; Imam, M.A.H.; Sadiq, A.N.; Hafeez, S.; Mansoor, J.; Waseem, M. Sustainable Silicon Waste Material Utilization for Road Construction: An Application of Modified Binder for Marshall Stability Analysis. Appl. Sci. 2019, 9, 1803. [Google Scholar] [CrossRef] [Green Version]

- Sztukiewicz, R. Application of ultrasonic methods in asphalt concrete testing. Ultrasonics 1991, 29, 5–12. [Google Scholar] [CrossRef]

- Isacsson, U.; Zeng, H. Cracking of asphalt at low temperature as related to bitumen rheology. J. Mater. Sci. 1998, 33, 2165–2170. [Google Scholar] [CrossRef]

- Krishnan, J.M.; Rajagopal, K. Triaxial testing and stress relaxation of asphalt concrete. Mech. Mater. 2004, 36, 849–864. [Google Scholar] [CrossRef]

- Iwanski, M.; Chomicz-Kowalska, A. The effects of using foamed bitumen and bitumen emulsion in the cold recycling technology. In Proceedings of the 8th ICEE Environmental Engineering, Vilnius, Lithuania, 19–20 May; 2011; pp. 1089–1096. [Google Scholar]

- Gudimettla, J.M.; Cooley, L.A.; Brown, E. Workability of Hot Mix Asphalt. Transp. Res. Record. 2004, 1891, 229–237. [Google Scholar] [CrossRef] [Green Version]

- Raheel Shah, S.; Arshad, H.; Waqar, A.; Saeed, M.; Hafeez, S.; Mansoor, J.; Sadiq, A.; Malik, M. Saving Energy in the Transportation Sector: An Analysis of Modified Bitumen Application Based on Marshall Test. Energies 2018, 11, 3025. [Google Scholar] [CrossRef] [Green Version]

- Caniato, M.; Bettarello, F.; Marsich, L.; Ferluga, A.; Sbaizero, O.; Schmid, C. Time-depending performance of resilient layers under floating floors. Constr. Build. Mater. 2016, 102, 226–232. [Google Scholar] [CrossRef]

- Bitumen, S. The Shell Bitumen Industrial Handbook; Thomas Telford: London, UK, 1995. [Google Scholar]

- Kemalov, R.A.; Kemalov, A.F.; Nam, F.K. Comprehensive analysis of electrochemical and structural-dynamic properties of bitumnious insulating materials. Indian J. Sci. Technol. 2016, 9. [Google Scholar] [CrossRef]

- Firoozifar, S.H.; Foroutan, S.; Foroutan, S. The effect of asphaltene on thermal properties of bitumen. Chem. Eng. Res. Des. 2011, 89, 2044–2048. [Google Scholar] [CrossRef]

- Radziszewski, P.; Kowalski, K.J.; Krol, J.B.; Sarnowski, M.; Piłat, J. Quality assessment of bituminous binders based on the viscoelastic properties: Polish experience. J. Civ. Eng. Manag. 2014, 20, 111–120. [Google Scholar] [CrossRef]

- ASTM C136-06. Standard test method for sieve analysis of fine and coarse aggregates; Annual Book of ASTM Standard: West Conshohocken, PA, USA, 2006. [Google Scholar] [CrossRef]

- Caniato, M.; Bettarello, F.; Marsich, L.; Ferluga, A.; Sbaizero, O.; Schmid, C. Impulse response method for defect detection in polymers: Description of the method and preliminary results. Polym. Test. 2016, 55, 78–87. [Google Scholar] [CrossRef]

- Pan, W.-H.; Sun, X.-D.; Wu, L.-M.; Yang, K.-K.; Tang, N. Damage Detection of Asphalt Concrete Using Piezo-Ultrasonic Wave Technology. Materials 2019, 12, 443. [Google Scholar] [CrossRef] [Green Version]

- Rao, S.K.; Sravana, P.; Rao, T.C. Experimental studies in Ultrasonic Pulse Velocity of roller compacted concrete pavement containing fly ash and M-sand. Int. J. Pavement Res. Technol. 2016, 9, 289–301. [Google Scholar] [CrossRef] [Green Version]

- Mounier, D.; Di Benedetto, H.; Sauzéat, C. Determination of bituminous mixtures linear properties using ultrasonic wave propagation. Constr. Build. Mater. 2012, 36, 638–647. [Google Scholar] [CrossRef]

- Hoła, J.; Bień, J.; Schabowicz, K. Non-destructive and semi-destructive diagnostics of concrete structures in assessment of their durability. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 87–96. [Google Scholar] [CrossRef]

- abd WJ Cheesman, J.L. An Ultrasonic Method of Deterioration and Cracking in Concrete Structures. ACI J. Proc. 1949, 46. [Google Scholar] [CrossRef]

- Jones, R. Testing of concrete by ultrasonic-pulse technique. In Proceedings of the Highway Research Board Proceedings, Washington, DC, USA, 13–16 January 1953. [Google Scholar]

- Malhotra, V. Testing Hardened Concrete: Non-Destructive Methods, ACI Monograph No. 9, ACI; Iowa State University Press: Ames, IA, USA, 1976. [Google Scholar]

- Qurashi, M.A.; Shah, S.A.R.; Farhan, M.; Taufiq, M.; Khalid, W.; Arshad, H.; Tayyab, M.; Shahzadi, G.; Waseem, M. Sustainable Design and Engineering: A Relationship Analysis between Digital Destructive and Non-Destructive Testing Process for Lightweight Concrete. Processes 2019, 7, 791. [Google Scholar] [CrossRef] [Green Version]

- Davis, A.; Ansari, F.; Gaynor, R.; Lozen, K.; Rowe, T.; Caratin, H.; Heidbrink, F.; Malhotra, V.; Simons, B.; Carino, N. Nondestructive test methods for evaluation of concrete in structures. Am. Concr. Inst. Aci 1998, 228. [Google Scholar]

- Dumoulin, J.; Ibos, L.; Marchetti, M.; Mazioud, A. Detection of non emergent defects in asphalt pavement samples by long pulse and pulse phase infrared thermography. Eur. J. Environ. Civ. Eng. 2011, 15, 557–574. [Google Scholar] [CrossRef]

- Özgan, E. Determining the stability of asphalt concrete at varying temperature and exposure times using destructive and non-destructive methods. J. Appl. Sci. 2007, 7, 3870–3879. [Google Scholar]

| Type of Test | Test Method | Units | Results | Standard |

|---|---|---|---|---|

| Penetration at 25 °C | ASTM D5-97 | mm | 66 | 60–70 |

| Softening point | ASTM D36 | °C | 55 | 40–55 |

| Flash Point | ASTM D92-16b | °C | 302 | 232 min |

| Ductility 25 °C | ASTM D113 | cm | 99 | >75 |

| Type of Test | Test Methods | Result | Specifications | |

|---|---|---|---|---|

| SAR * | SS * | |||

| Aggregate Impact Test | BS812:Part3 | 16.55% | 21.33% | Less than 27% |

| Los Angeles Abrasion Test | ASTM: C131 | 21.67% | 27% | Less than 35% |

| Aggregate Crushing Test | BS812: Part3 | 24.86% | 23.21% | Less than 30% |

| Water Absorption Test | ASTM:C127 | 2.50% | 1.90% | Less than 2% |

| Specific Gravity (Aggregate) | ASTM:C127 | 2.3 | 2.33 | 2–3 |

| Geology | SAR-Sand | SS-Lime and sandstone | ||

| Sieve Size (mm) | 19 | 12.5 | 9.5 | 4.75 | 2 | 0.475 | 0.177 | 0.075 |

| Passing (%) by Weight | 5 | 20 | 25 | 15 | 10 | 10 | 8 | 7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anwar, M.K.; Shah, S.A.R.; Sadiq, A.N.; Siddiq, M.U.; Ahmad, H.; Nawaz, S.; Javead, A.; Saeed, M.H.; Khan, A.R. Symmetric Performance Analysis for Mechanical Properties of Sustainable Asphalt Materials under Varying Temperature Conditions: An Application of DT and NDT Digital Techniques. Symmetry 2020, 12, 433. https://doi.org/10.3390/sym12030433

Anwar MK, Shah SAR, Sadiq AN, Siddiq MU, Ahmad H, Nawaz S, Javead A, Saeed MH, Khan AR. Symmetric Performance Analysis for Mechanical Properties of Sustainable Asphalt Materials under Varying Temperature Conditions: An Application of DT and NDT Digital Techniques. Symmetry. 2020; 12(3):433. https://doi.org/10.3390/sym12030433

Chicago/Turabian StyleAnwar, Muhammad Kashif, Syyed Adnan Raheel Shah, Abdullah Naveed Sadiq, Muhammad Usman Siddiq, Hassam Ahmad, Saqib Nawaz, Asif Javead, Muhammad Hasnain Saeed, and Ahsan Rehman Khan. 2020. "Symmetric Performance Analysis for Mechanical Properties of Sustainable Asphalt Materials under Varying Temperature Conditions: An Application of DT and NDT Digital Techniques" Symmetry 12, no. 3: 433. https://doi.org/10.3390/sym12030433