Asymmetric Cellulosic Membranes: Current and Future Aspects

Abstract

:1. Introduction

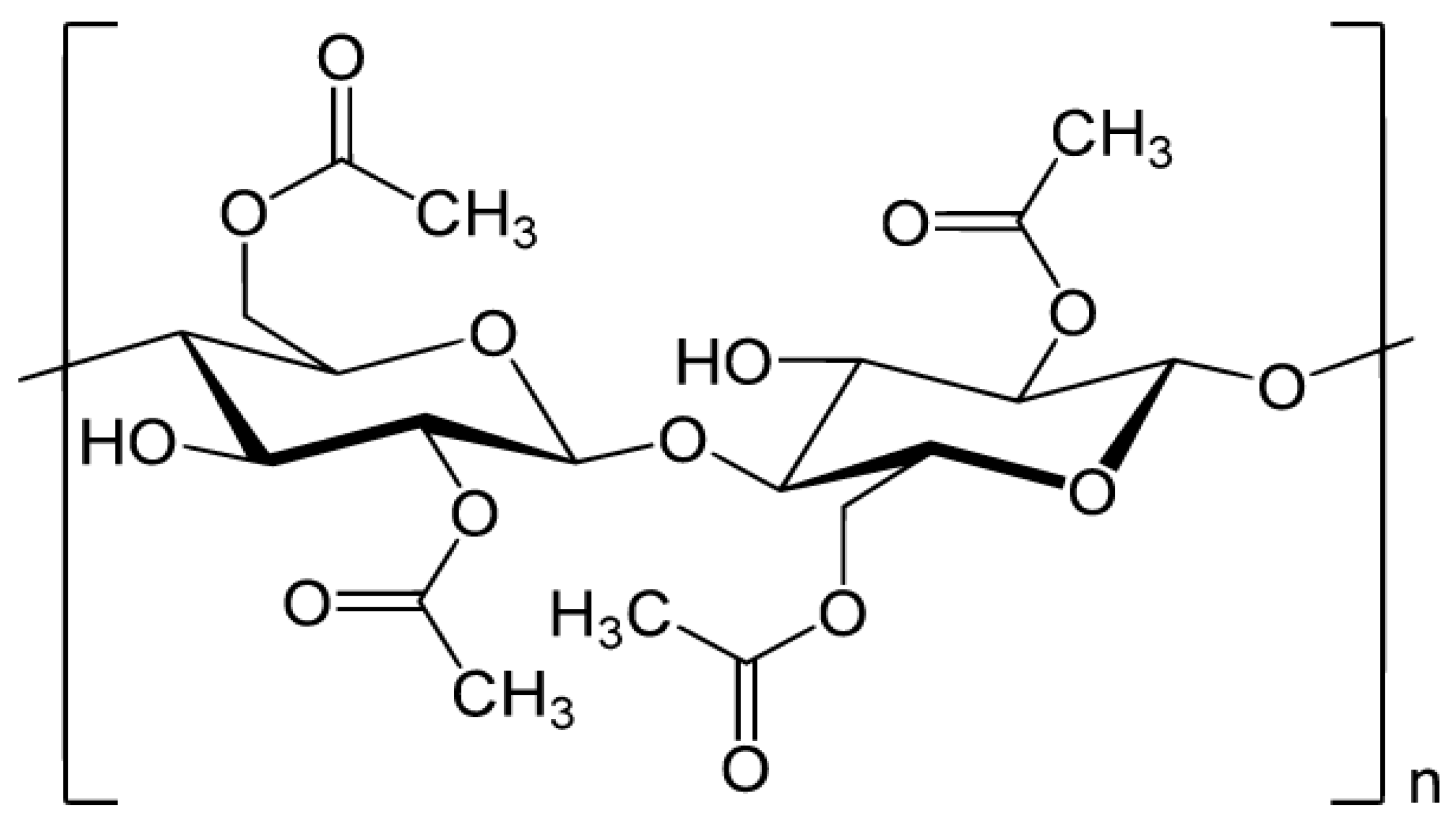

2. Cellulose

3. Cellulose Acetate

4. Cellulosic Asymmetric Membranes

- Porous skin layer integral asymmetric.

- Thin dense skin layer integral asymmetric.

- Composites with thin-film structures [16].

5. Other Asymmetric Membranes

6. Synthesis and Processing Methods

6.1. Synthesis of Nanocellulose

6.2. Asymmetrical Membrane

- Extraction of cellulose from biomass: pure cellulose can be extracted by multistage chemical and mechanical purification methods [38].

- CA synthesis: produced via the reaction of extracted cellulose with acetic anhydride under the catalysis process (H2SO4) [40].

- Production of CAMs: asymmetric CA membranes were produced by the PI method, as discussed above [41].

7. Applications

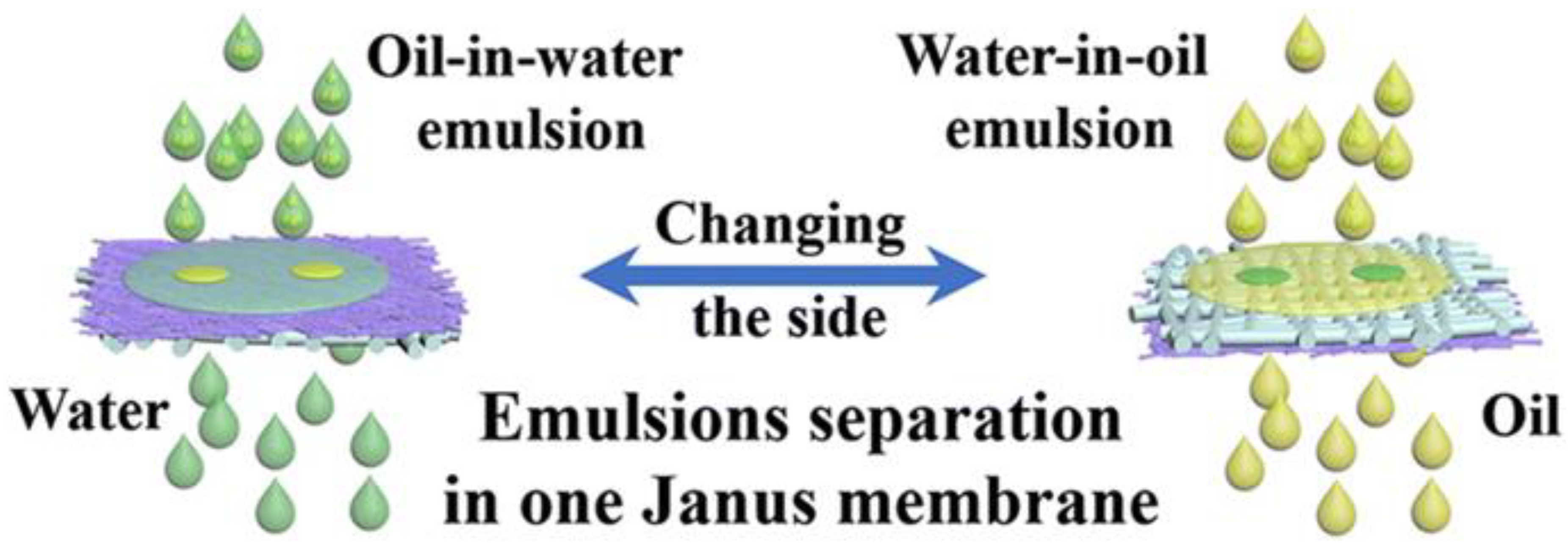

7.1. Effective Separation

7.2. Membrane Bioreactors

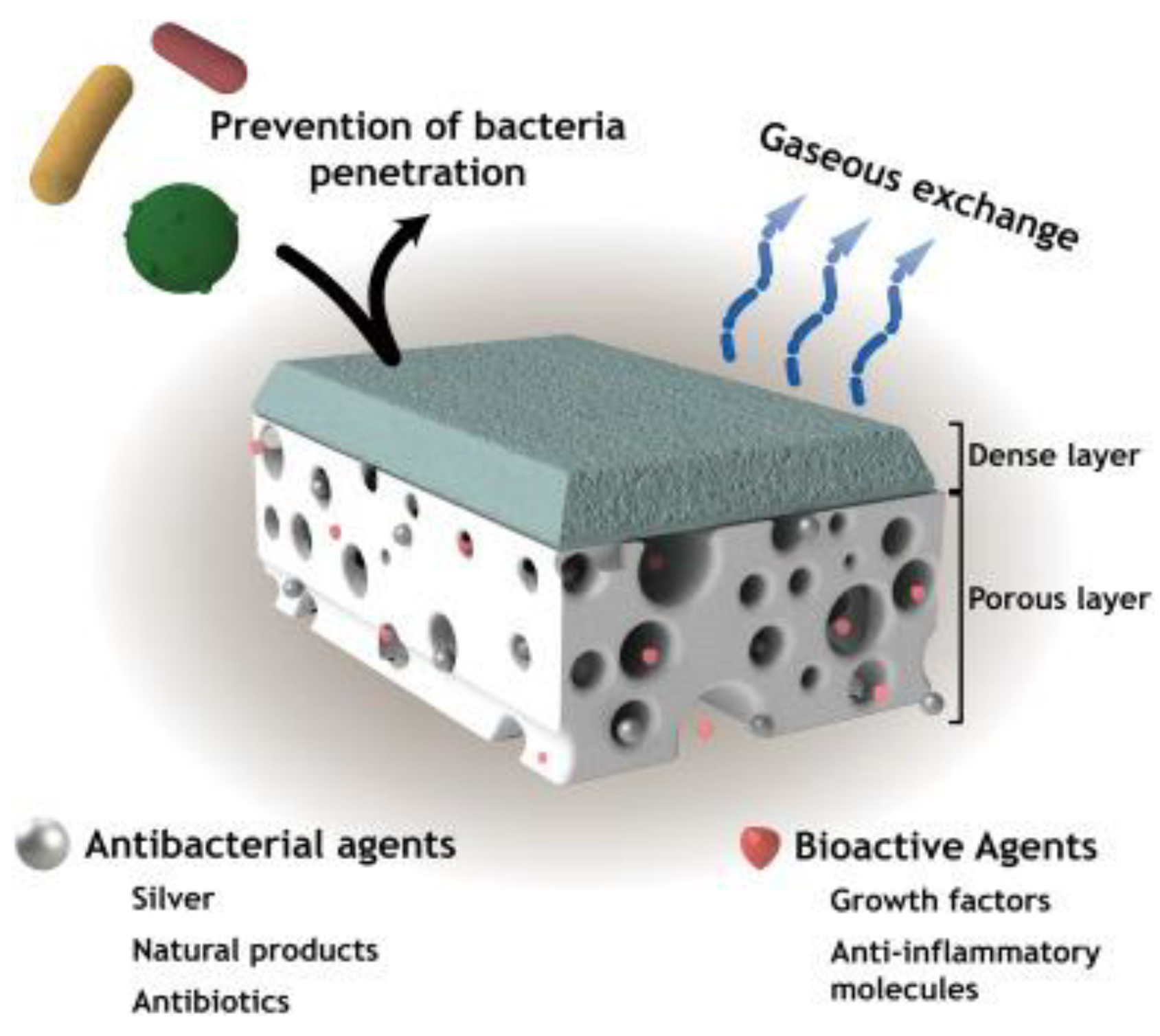

7.3. Wound Healing

7.4. Asymmetric Supercapacitors

7.5. Energy Conversion

7.6. Hemodialysis

8. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Loeb, S.; Sourirajan, S. Sea Water Demineralization by Means of an Osmotic Membrane. Adv. Chem. 1963, 38, 117–132. [Google Scholar] [CrossRef]

- Ismail, A.; Yean, L.P. Review on the development of defect-free and ultrathin-skinned asymmetric membranes for gas separation through manipulation of phase inversion and rheological factors. J. Appl. Polym. Sci. 2003, 88, 442–451. [Google Scholar] [CrossRef]

- Jiang, L.Y. Asymmetric Membrane. In Encyclopedia of Membranes; Drioli, E., Giorno, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Chen, X.; Gao, X.; Fu, K.; Qiu, M.; Xiong, F.; Ding, N.; Cui, Z.; Wang, Z.; Fan, Y.; Drioli, E. Tubular hydrophobic ceramic membrane with asymmetric structure for water desalination via vacuum membrane distillation process. Desalination 2018, 443, 212–220. [Google Scholar] [CrossRef]

- Tsydenov, D.; Parmon, V.; Vorontsov, A. Toward the design of asymmetric photocatalytic membranes for hydrogen production: Preparation of TiO2-based membranes and their properties. Int. J. Hydrog. Energy 2012, 37, 11046–11060. [Google Scholar] [CrossRef]

- Shan, D.; Yang, J.; Liu, W.; Yan, J.; Fan, Z. Biomass-derived three-dimensional honeycomb-like hierarchical structured carbon for ultrahigh energy density asymmetric supercapacitors. J. Mater. Chem. A 2016, 4, 13589–13602. [Google Scholar] [CrossRef]

- Jung, S.-J.; Kim, S.-H.; Chung, I.-M. Comparison of lignin, cellulose, and hemicellulose contents for biofuels utilization among 4 types of lignocellulosic crops. Biomass Bioenergy 2015, 83, 322–327. [Google Scholar] [CrossRef]

- Meng, F.; Wang, G.; Du, X.; Wang, Z.; Xu, S.; Zhang, Y. Extraction and characterization of cellulose nanofibers and nanocrystals from liquefied banana pseudo-stem residue. Compos. Part B Eng. 2019, 160, 341–347. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Dufresne, A.; Bras, J. Microfibrillated Cellulose—Its barrier properties and applications in cellulosic materials: A review. Carbohydr. Polym. 2012, 90, 735–764. [Google Scholar] [CrossRef]

- Barhoum, A.; Li, H.; Chen, M.; Cheng, L.; Yang, W.; Dufresne, A. Emerging Applications of Cellulose Nanofibers. In Handbook of Nanofibers; Springer Nature Switzerland AG: Basel, Switzerland, 2019; pp. 1131–1156. [Google Scholar]

- Rohrbach, K.; Li, Y.; Zhu, H.; Liu, Z.; Dai, J.; Andreasen, J.; Hu, L. A cellulose based hydrophilic, oleophobic hydrated filter for water/oil separation. Chem. Commun. 2014, 50, 13296–13299. [Google Scholar] [CrossRef]

- Rol, F.; Belgacem, M.N.; Gandini, A.; Bras, J. Recent advances in surface-modified cellulose nanofibrils. Prog. Polym. Sci. 2019, 88, 241–264. [Google Scholar] [CrossRef]

- Cellulose Acetate. Available online: https://en.wikipedia.org/wiki/Cellulose_acetate (accessed on 21 March 2020).

- Wu, J.; Qiu, Q.; Wang, Y.; Zhang, H.; Qin, X. Asymmetric water affinity on antibacterial electrospun sub-micro cellulose acetate Janus membrane. Mater. Lett. 2019, 256, 126607. [Google Scholar] [CrossRef]

- McKeen, L.W. Film Properties of Plastics and Elastomers; William Andrew is an imprint of Elsevier: Oxford, UK; Cambridge, MA, USA, 2017. [Google Scholar]

- Buonomenna, M.G. Design Next Generation Membranes or Rethink the “Old” Asymmetric Membranes? Symmetry 2020, 12, 270. [Google Scholar] [CrossRef] [Green Version]

- Saljoughi, E.; Mohammadi, T. Cellulose acetate (CA)/polyvinylpyrrolidone (PVP) blend asymmetric membranes: Preparation, morphology and performance. Desalination 2009, 249, 850–854. [Google Scholar] [CrossRef]

- Gu, B.; Liang, K.; Zhang, T.; Yue, X.; Qiu, F.; Yang, D.; Chen, M. Fabrication of sandwich-structured cellulose composite membranes for switchable infrared radiation. Cellulose 2019, 26, 8745–8757. [Google Scholar] [CrossRef]

- Beira, M.J.; Da Silva, M.P.; Condesso, M.; Cosme, P.; Almeida, P.L.; Corvo, M.C.; Sebastião, P.J.; Figueirinhas, J.; De Pinho, M.N. Molecular order and dynamics of water in hybrid cellulose acetate–silica asymmetric membranes. Mol. Phys. 2018, 117, 975–982. [Google Scholar] [CrossRef]

- Lv, Y.; Li, Q.; Hou, Y.; Wang, B.; Zhang, T. Facile Preparation of an Asymmetric Wettability Janus Cellulose Membrane for Switchable Emulsions’ Separation and Antibacterial Property. ACS Sustain. Chem. Eng. 2019, 7, 15002–15011. [Google Scholar] [CrossRef]

- Yang, X.; Ma, J.; Ling, J.; Li, N.; Wang, D.; Yue, F.; Xu, S. Cellulose acetate-based SiO2/TiO2 hybrid microsphere composite aerogel films for water-in-oil emulsion separation. Appl. Surf. Sci. 2018, 435, 609–616. [Google Scholar] [CrossRef]

- Lv, J.; Zhang, G.; Zhang, H.; Yang, F. Graphene oxide-cellulose nanocrystal (GO-CNC) composite functionalized PVDF membrane with improved antifouling performance in MBR: Behavior and mechanism. Chem. Eng. J. 2018, 352, 765–773. [Google Scholar] [CrossRef]

- Asim, S.; Wasim, M.; Sabir, A.; Shafiq, M.; Andlib, H.; Khuram, S.; Ahmad, A.; Jamil, T. The effect of Nanocrystalline cellulose/Gum Arabic conjugates in crosslinked membrane for antibacterial, chlorine resistance and boron removal performance. J. Hazard. Mater. 2018, 343, 68–77. [Google Scholar] [CrossRef]

- Lv, J.; Zhang, G.; Zhang, H.; Zhao, C.; Yang, F. Improvement of antifouling performances for modified PVDF ultrafiltration membrane with hydrophilic cellulose nanocrystal. Appl. Surf. Sci. 2018, 440, 1091–1100. [Google Scholar] [CrossRef]

- Abdellah, M.H.; Pérez-Manríquez, L.; Puspasari, T.; Scholes, C.A.; Kentish, S.; Peinemann, K.-V. A catechin/cellulose composite membrane for organic solvent nanofiltration. J. Membr. Sci. 2018, 567, 139–145. [Google Scholar] [CrossRef] [Green Version]

- Sprick, C.; Chede, S.; Oyanedel-Craver, V.; Escobar, I.C. Bio-inspired immobilization of casein-coated silver nanoparticles on cellulose acetate membranes for biofouling control. J. Environ. Chem. Eng. 2018, 6, 2480–2491. [Google Scholar] [CrossRef]

- Durthi, C.P.; Rajulapati, S.B.; Palliparambi, A.A.; Kola, A.K.; Sonawane, S.H. Studies on removal of arsenic using cellulose acetate–zinc oxide nanoparticle mixed matrix membrane. Int. Nano Lett. 2018, 8, 201–211. [Google Scholar] [CrossRef] [Green Version]

- Fei, P.; Liao, L.; Meng, J.; Cheng, B.; Hu, X.; Song, J. Synthesis, characterization and antibacterial properties of reverse osmosis membranes from cellulose bromoacetate. Cellulose 2018, 25, 5967–5984. [Google Scholar] [CrossRef]

- Hayder, A.; Hussain, A.; Khan, A.N.; Waheed, H. Fabrication and characterization of cellulose acetate/hydroxyapatite composite membranes for the solute separations in Hemodialysis. Polym. Bull. 2017, 75, 1197–1210. [Google Scholar] [CrossRef]

- Wang, B.; Kang, H.; Yang, H.; Xie, J.; Liu, R. Preparation and dielectric properties of porous cyanoethyl cellulose membranes. Cellulose 2018, 26, 1261–1275. [Google Scholar] [CrossRef]

- Figueiredo, A.S.; Garcia, A.R.; Minhalma, M.; Ilharco, L.; de Pinho, M. The ultrafiltration performance of cellulose acetate asymmetric membranes: A new perspective on the correlation with the infrared spectra. J. Membr. Sci. Res. 2019, 6, 70–80. [Google Scholar]

- El-Gendi, A.; Favre, E.; Roizard, D. Asymmetric polyetherimide membranes (PEI) for nanofiltration treatment. Eur. Polym. J. 2018, 105, 204–216. [Google Scholar] [CrossRef]

- Nascimento, D.M.d.; Almeida, J.S.; Vale, M.d.S.; Leitão, R.C.; Muniz, C.R.; Figueirêdo, M.C.B.d.; Morais, J.P.S.; Rosa, M.d.F. A comprehensive approach for obtaining cellulose nanocrystal fromcoconut fiber. Part I: Proposition of technological pathways. Ind. Crops Prod. 2016, 93, 66–75. [Google Scholar] [CrossRef]

- Cranston, E.D.; Gray, D.G. Morphological and Optical Characterization of Polyelectrolyte Multilayers Incorporating Nanocrystalline Cellulose. Biomacromolecules 2006, 7, 2522–2530. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Ahmad, I.; Abdullah, I.; Dufresne, A.; Zainudin, S.Y.; Sheltami, R.M. Effects of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenaf bast fibers. Cellulose 2012, 19, 855–866. [Google Scholar] [CrossRef]

- do Nascimento, D.M.; Dias, A.F.; de Araújo Junior, C.P.; de Freitas Rosa, M.; Morais, J.P.S.; de Figueirêdo, M.C.B. A comprehensive approach for obtaining cellulose nanocrystal fromcoconut fiber. Part II: Environmental assessment of technologicalpathways. Ind. Crops Prod. 2016, 93, 58–65. [Google Scholar] [CrossRef]

- Yasim-Anuar, T.A.T.; Ariffin, H.; Norrrahim, M.N.F.; Hassan, M.A. Factors Affecting Spinnability of Oil Palm Mesocarp Fiber Cellulose Solution for the Production of Microfiber. Bioresources 2016, 12, 715–734. [Google Scholar] [CrossRef] [Green Version]

- Tuerxun, D.; Pulingam, T.; Nordin, N.I.; Chen, Y.W.; Bin Kamaldin, J.; Julkapli, N.B.M.; Lee, H.V.; Leo, B.F.; Johan, M.R.; Duolikun, T.; et al. Synthesis, characterization and cytotoxicity studies of nanocrystalline cellulose from the production waste of rubber-wood and kenaf-bast fibers. Eur. Polym. J. 2019, 116, 352–360. [Google Scholar] [CrossRef]

- Nu, D.T.T.; Hung, N.P.; Van Hoang, C.; Van Der Bruggen, B. Preparation of an Asymmetric Membrane from Sugarcane Bagasse Using DMSO as Green Solvent. Appl. Sci. 2019, 9, 3347. [Google Scholar] [CrossRef] [Green Version]

- Meireles, C.D.S.; Filho, G.R.; Ferreira, M.F., Jr.; Cerqueira, D.; Assunção, R.M.N.; Ribeiro, E.A.M.; Poletto, P.; Zeni, M. Characterization of asymmetric membranes of cellulose acetate from biomass: Newspaper and mango seed. Carbohydr. Polym. 2010, 80, 954–961. [Google Scholar] [CrossRef]

- Durmaz, E.N.; Culfaz-Emecen, P.Z. Cellulose-based membranes via phase inversion using [EMIM]OAc-DMSO mixtures as solvent. Chem. Eng. Sci. 2018, 178, 93–103. [Google Scholar] [CrossRef]

- Zhang, D.; Karkooti, A.; Liu, L.; Sadrzadeh, M.; Thundat, T.; Liu, Y.; Narain, R. Fabrication of antifouling and antibacterial polyethersulfone (PES)/cellulose nanocrystals (CNC) nanocomposite membranes. J. Membr. Sci. 2018, 549, 350–356. [Google Scholar] [CrossRef]

- Yue, X.; Zhang, T.; Yang, D.; Qiu, F.; Li, Z. Janus ZnO-cellulose/MnO2 hybrid membranes with asymmetric wettability for highly-efficient emulsion separations. Cellulose 2018, 25, 5951–5965. [Google Scholar] [CrossRef]

- Kusworo, T.D.; Soetrisnanto, D.; Santoso, C.; Payanti, T.D.; Utomo, D.P. Hydrophylicity enhancement of modified cellulose acetate membrane to improve the membrane performance in produced water treatment. MATEC Web Conf. 2018, 156, 08003. [Google Scholar] [CrossRef] [Green Version]

- Morgado, P.I.; Aguiar-Ricardo, A.; Correia, I.J. Asymmetric membranes as ideal wound dressings: An overview on production methods, structure, properties and performance relationship. J. Membr. Sci. 2015, 490, 139–151. [Google Scholar] [CrossRef]

- Miguel, S.P.; Moreira, A.F.; Correia, I.J. Chitosan based-asymmetric membranes for wound healing: A review. Int. J. Boil. Macromol. 2019, 127, 460–475. [Google Scholar] [CrossRef]

- Poonguzhali, R.; Basha, S.K.; Kumari, V.S. Novel asymmetric chitosan/PVP/nanocellulose wound dressing: In vitro and in vivo evaluation. Int. J. Boil. Macromol. 2018, 112, 1300–1309. [Google Scholar] [CrossRef]

- Xia, L.Y.; Li, X.; Wu, X.; Huang, L.; Liao, Y.; Qing, Y.; Wu, Y.; Lu, X.; Yu, L. Fe3O4 nanoparticles embedded in cellulose nanofibre/graphite carbon hybrid aerogels as advanced negative electrodes for flexible asymmetric supercapacitors. J. Mater. Chem. A 2018, 6, 17378–17388. [Google Scholar] [CrossRef]

- Gingerich, D.; Mauter, M.S. Quantity, Quality, and Availability of Waste Heat from United States Thermal Power Generation. Environ. Sci. Technol. 2015, 49, 8297–8306. [Google Scholar] [CrossRef]

- Swaminathan, J.; Chung, H.W.; Warsinger, D.M.; Lienhard V, J.H. Membrane distillation model based on heat exchanger theory and configuration comparison. Appl. Energy 2016, 184, 491–505. [Google Scholar] [CrossRef] [Green Version]

- Straub, A.P.; Yip, N.Y.; Lin, S.; Lee, J.; Elimelech, M. Harvesting low-grade heat energy using thermo-osmotic vapour transport through nanoporous membranes. Nat. Energy 2016, 1, 16090. [Google Scholar] [CrossRef]

- Phillip, W.A. Under Pressure; Nature Publishing Group Macmillan Building: London, UK, 2016. [Google Scholar]

- Shaulsky, E.; Karanikola, V.; Straub, A.P.; Deshmukh, A.; Zucker, I.; Elimelech, M. Asymmetric membranes for membrane distillation and thermo-osmotic energy conversion. Desalination 2019, 452, 141–148. [Google Scholar] [CrossRef]

- Ronci, M.; Leporini, L.; Felaco, P.; Sirolli, V.; Pieroni, L.; Greco, V.; Aceto, A.; Urbani, A.; Bonomini, M. Proteomic Characterization of a New asymmetric Cellulose Triacetate Membrane for Hemodialysis. Proteom.-Clin. Appl. 2018, 12, e1700140. [Google Scholar] [CrossRef]

- Togo, K.; Yamamoto, M.; Imai, M.; Akiyama, K.; Yamashita, A.C. Comparison of biocompatibility in cellulose triacetate dialysis membranes with homogeneous and asymmetric structures. Ren. Replace. Ther. 2018, 4, 29. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.R.; Hadidi, M.; Motevalian, S.P.; Sunohara, T.; Zydney, A.L. Effects of Plasma Proteins on the Transport and Surface Characteristics of Polysulfone/Polyethersulfone and Asymmetric Cellulose Triacetate High Flux Dialyzers. Artif. Organs 2018, 42, 1070–1077. [Google Scholar] [CrossRef]

- Kim, T.R.; Hadidi, M.; Motevalian, S.P.; Zydney, A.L.; Sunohara, T. Transport Characteristics of Asymmetric Cellulose Triacetate Hemodialysis Membranes. Blood Purif. 2017, 45, 46–52. [Google Scholar] [CrossRef]

- Martin, C.R.; Wu, X.; Martin, C.R. From Ion Current to Electroosmotic Flow Rectification in Asymmetric Nanopore Membranes. Nanomaterials 2017, 7, 445. [Google Scholar] [CrossRef] [Green Version]

| Cellulosic Membrane | Specifications | Advantages | Ref |

|---|---|---|---|

| Janus cellulose membrane | Switchable separation | Remarkably impactful for human health and eco-remediation | [20] |

| CA/polyvinylpyrrolidone | Increasing macrovoids formation | Reduction of the membrane hydrophilicity | [17] |

| CA Janus membrane | Directional water transportation | Functional surface for protection from recontamination. | [14] |

| CA-SiO2/TiO2 composite | Water/oil separation | Good stability, durability, photocatalytic ability, facile preparation, and potential biodegradation | [21] |

| GO/CNC-PVDF functionalized membrane | A novel additive for hydrophilic and antifouling | Acceptable wettability, distinguished porosity, water permeability, long cleaning cycle, low irreversible fouling | [22] |

| CNC based crosslinked membrane | Hazardous salt removal | Antibacterial, chlorine resistance, and boron removal | [23] |

| CNC/PVDF ultrafiltration membrane | Improvement of antifouling performances | Hydrophilicity, permeability, and antifouling property | [24] |

| Cellulosic catechin membrane | Nanofiltration for food and pharmaceutical industries | Stability above a month | [25] |

| Casein-coated Ag-CA Membranes | Biofouling control | Higher average flux values, better antimicrobial properties | [26] |

| CA–ZnO mixed matrix membrane | Removal of arsenic | Higher removal efficiency, flux and permeation rate | [27] |

| Bromoacetyl/CA reverse osmosis membrane | Long-term and efficiency running in complex situations | Antibacterial and antifouling capability | [28] |

| CA/hydroxyapatite composite membrane | Solute separations in hemodialysis | Better surface roughness, good uremic toxin permeabilities, and hydrophilicity | [29] |

| Porous cyanoethyl cellulose (CEC) membranes | Miniature capacitors, high-temperature capacitors, and electroluminescent materials | Low porosity and high permittivity | [30] |

| Hybrid CA/silica asymmetric membranes | Water ordering in the porous structure | Controllable diffusion direction | [19] |

| Integral asymmetric CA membrane | Ultrafiltration performance | Capable of differentiating anionic species is enabled, but with the advantage of having higher permeation fluxes. | [31] |

| Cellulosic sandwich structured composite membrane | Switchable infrared radiation, thermal controlled application | Exhibits Janus infrared radiation properties, excellent controllable thermal management properties, and good antimicrobial activity | [18] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duolikun, T.; Ghazali, N.; Leo, B.F.; Lee, H.V.; Lai, C.W.; Johan, M.R.B. Asymmetric Cellulosic Membranes: Current and Future Aspects. Symmetry 2020, 12, 1160. https://doi.org/10.3390/sym12071160

Duolikun T, Ghazali N, Leo BF, Lee HV, Lai CW, Johan MRB. Asymmetric Cellulosic Membranes: Current and Future Aspects. Symmetry. 2020; 12(7):1160. https://doi.org/10.3390/sym12071160

Chicago/Turabian StyleDuolikun, Tuerxun, Nadiah Ghazali, Bey Fen Leo, Hwei Voon Lee, Chin Wei Lai, and Mohd Rafie Bin Johan. 2020. "Asymmetric Cellulosic Membranes: Current and Future Aspects" Symmetry 12, no. 7: 1160. https://doi.org/10.3390/sym12071160