Modeling and Improving the Efficiency of Crushing Equipment

Abstract

:1. Introduction

- -

- Research the modelling and automation of crushing equipment.

- -

- Develop a mathematical model of a cone crusher.

- -

- Identify the effect of plant capacity on the crusher’s current and drive power.

- -

- Find out the crushing process conditions for energy efficiency.

2. Review

2.1. Modelling the Crushing Process

- Study of the material characteristics’ relationship with laboratory-measured particle properties, considering rock texture, variability, and particle size.

- Consideration of the geometric details of loading conditions in the criteria when failure occurs and determining the size distribution and shape of fluxes.

- Continuously reducing the particle size allowances that are used so that all larger product fractions can be explicitly included in the model.

- Selective destruction and release shall be included in the calculation scheme.

- Inclusion of air flow, which for some crushers is optional.

2.2. Automation of Crushing Processes

2.3. Reducing the Wear of Crushing Equipment

3. Methods

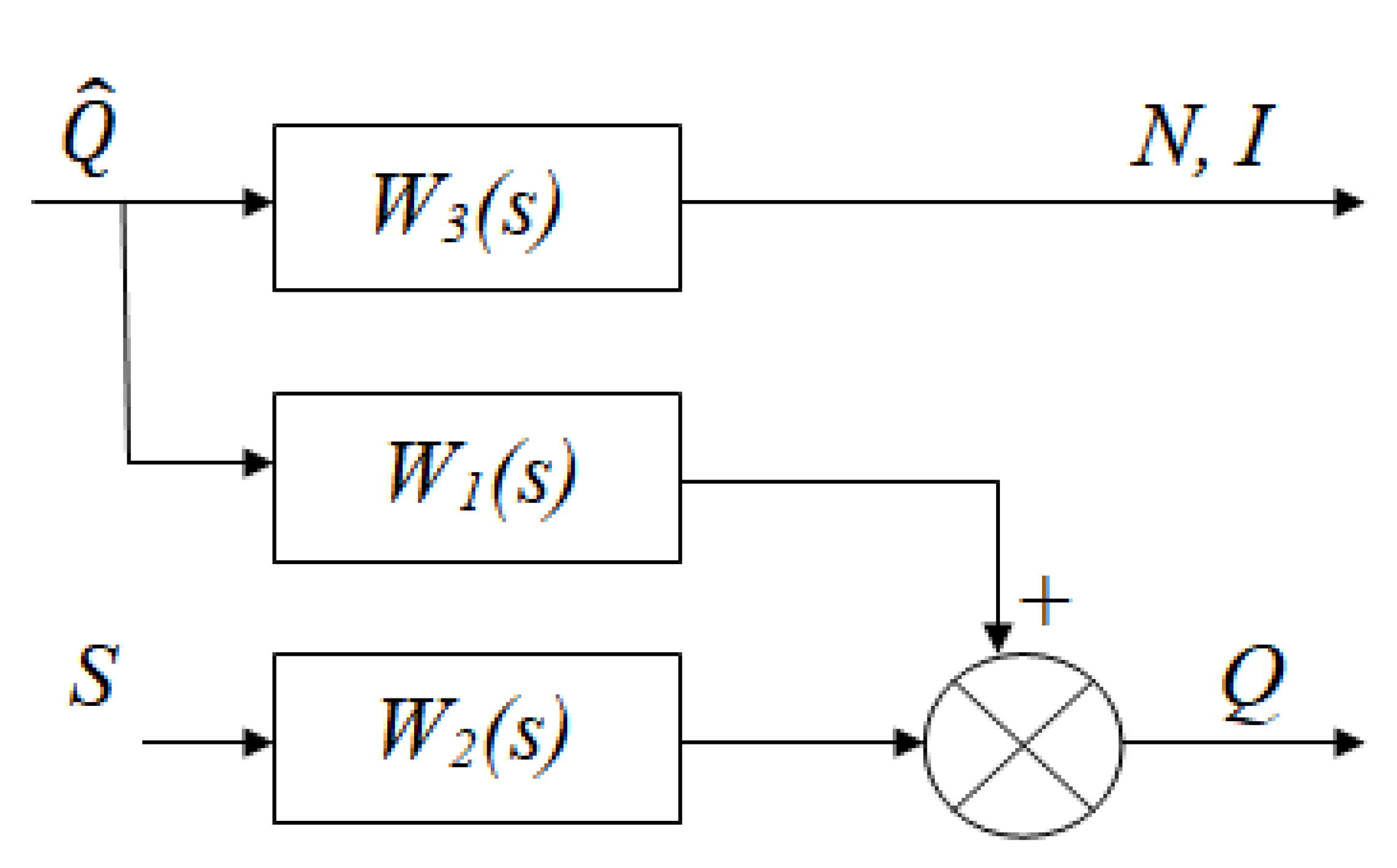

- Engine power N = 134.2 kW (deviation from the required = 1.6%).

- Engine current I = 203.8 A (deviation from the required = 1.9%).

- Capacity Q = 63.39 t/h (deviation from the required = 5.6%).

4. Results

5. Discussion

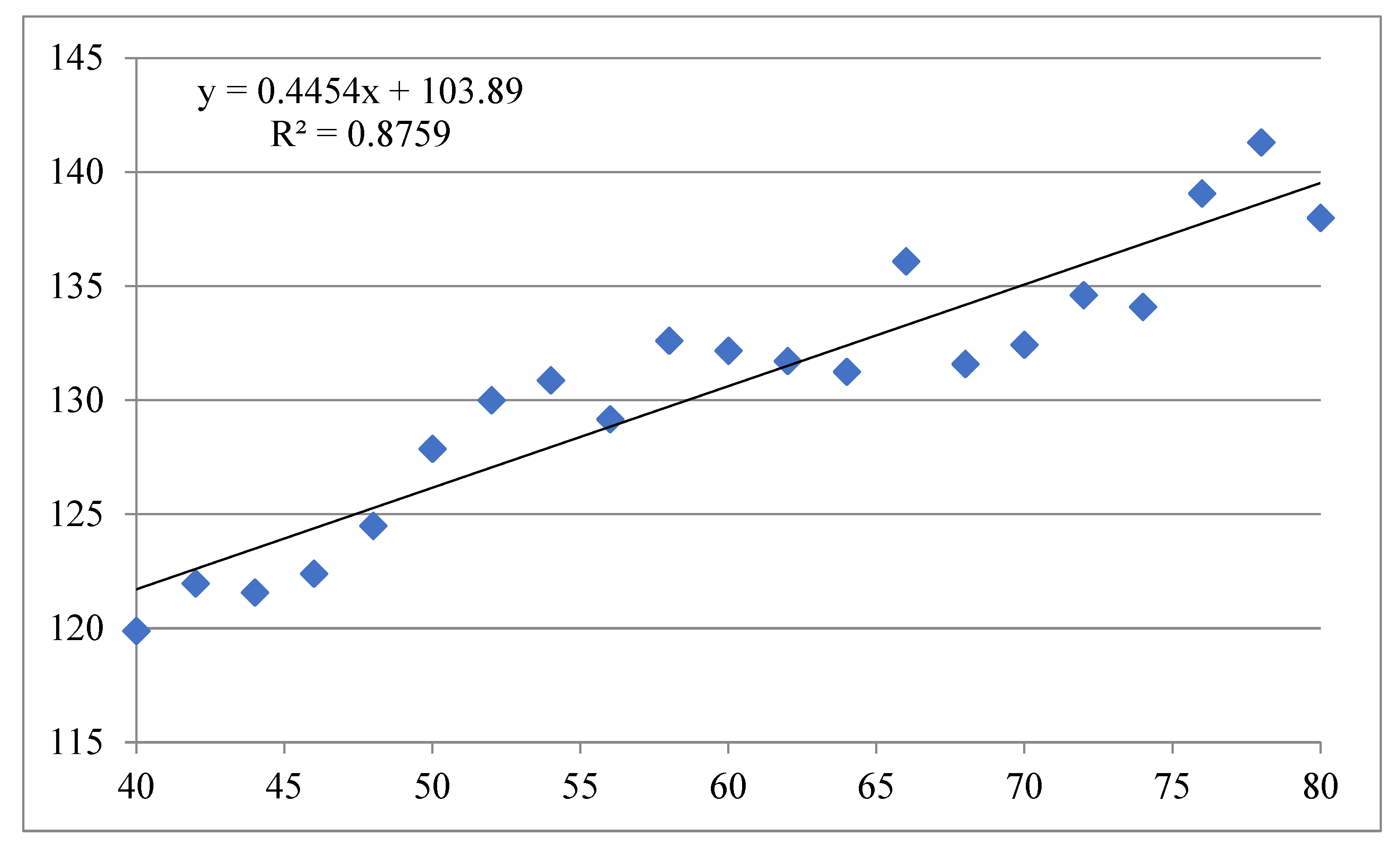

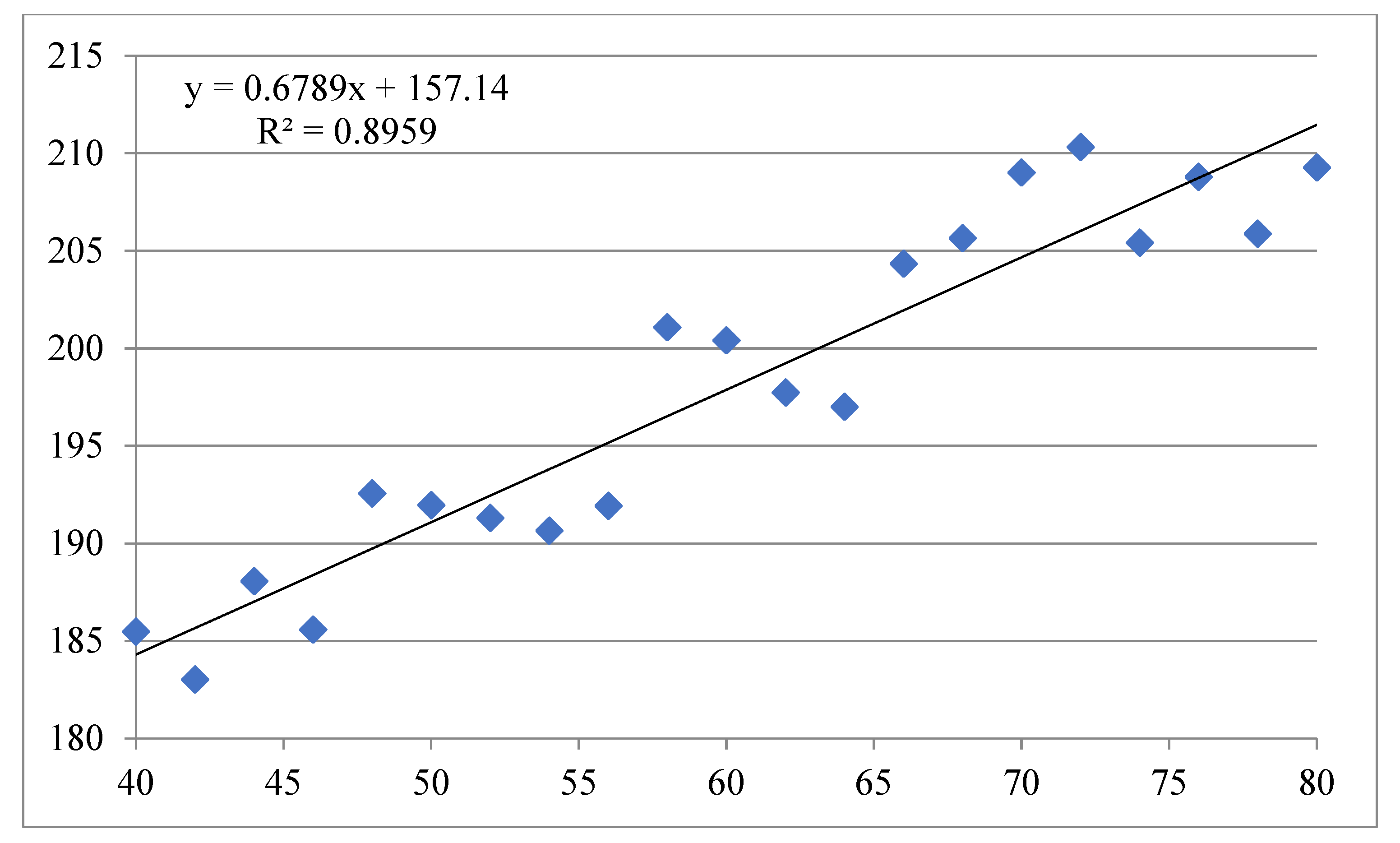

- As the feeder capacity increases, so does the crusher capacity and the crusher engine power consumed in the crushing process.

- The change in feeder capacity has an equal effect on both the crusher itself and the crusher engine capacity.

- It has been found that the unit capacity should not exceed 76.5 t/h, with a nominal value of 65 t/h.

6. Conclusions

- This article reviewed the difficulties related to the crushing process in detail, particularly those associated with increasing energy consumption and decreasing efficiency. We can say that the task of improving the energy efficiency of crushers is a pressing issue today. Scientific achievements on the research topic were divided into different aspects, with each examined in detail. In the course of the analysis, scientific research revealed unsolved tasks. The following goals can be identified, which will lead to an increase in the energy efficiency of crushers:

- ○

- Increase in the plant’s performance. This includes improving the crushing chamber, working bodies, and drive designs, increasing the conditions for removing the crushed ore from the outlet, ensuring a continuous supply of raw materials, increasing the filling ratio of the crushing chamber, reducing downtime, and reducing the number of breakdowns.

- ○

- Increase in design reliability—increase in reliability and durability of design units and improvement of protection efficiency of working bodies.

- The following conclusions can be made based on the analysis of the following information:

- ○

- Energy saving is one of the most important tasks in the management of mining enterprises.

- ○

- Crushing processes are characterized by higher specific energy consumption.

- ○

- Equipment and production, as a whole, require reconstruction.

- ○

- Development and implementation of energy-saving processes are also required.

- ○

- There is an obvious necessity to introduce automated management systems.

- ○

- Despite the large number of studies aimed at solving the task of poor energy efficiency of crushers, there is no comprehensive solution to the identified issue.

- ○

- The implementation of technologies to reduce the energy consumption of crushers is unsystematic. The developed methods are applied only locally.

- A mathematical model of the cone crusher based on material balance equations has been developed. The modelling error does not exceed 6%. A series of experiments have been carried out on the simulation model. Both dependencies of the crusher’s electric drive current and electric drive capacity on feeder performance have been found. It is shown that these dependences are linear. The determination coefficient is R2 ≈ 0.9. Analysis of the graphs (Figure 3 and Figure 4) demonstrates a symmetrical arrangement of the experimental results with respect to the approximating line. This means that the model does not have a systematic error and the results are random. It has been established that the maximum allowable capacity of the plant should not exceed 76.5 t/hour.

- The resulting mathematical model can be used to optimize control parameters in order to improve crushing efficiency and develop automated control systems for the crushing process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Matveev, A.I.; Lebedev, I.F.; Vinokurov, V.R.; Lvov, E.S. Scientific experimental bases for dry beneficiation of mineral ores. J. Min. Inst. 2022, 256, 613–622. [Google Scholar] [CrossRef]

- Koteleva, N.I.; Khokhlov, S.V.; Frenkel, I.V. Digitalization in Open-Pit Mining: A New Approach in Monitoring and Control of Rock Fragmentation. Appl. Sci. 2021, 11, 10848. [Google Scholar] [CrossRef]

- Matrokhina, K.V.; Trofimets VYa Mazakov, E.B.; Makhovikov, A.B.; Khaykin, M.M. Develop-ment of methodology for scenario analysis of investment projects of enterprises of the mineral resource complex. J. Min. Inst. 2023, 259, 112–124. [Google Scholar] [CrossRef]

- Efimov, D.A.; Gospodarikov, A.P. Technical and technological aspects of the use of reuleaux triangular profile rolls in crushing units in the ore processing plant. Min. Inf. Anal. Bull. 2022, 10–12, 117–126. [Google Scholar] [CrossRef]

- Davoodi, A.; Asbjörnsson, G.; Hulthén, E.; Evertsson, M. Application of the Discrete Element Method to Study the Effects of Stream Characteristics on Screening Performance. Minerals 2019, 9, 788. [Google Scholar] [CrossRef] [Green Version]

- Zhukovskiy, Y.L.; Korolev, N.A.; Malkova, Y.M. Monitoring of grinding condition in drum mills based on resulting shaft torque. J. Min. Inst. 2022, 256, 686–700. [Google Scholar] [CrossRef]

- Gupta, A.; Yan, D. Mineral Processing Design and Operation; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar] [CrossRef]

- Evertsson, C.M. Modelling of flow in cone crushers. Miner. Eng. 1999, 12, 1479–1499. [Google Scholar] [CrossRef]

- Legendre, D.; Zevenhoven, R. Assessing the energy efficiency of a jaw crusher. Energy 2014, 74, 119–130. [Google Scholar] [CrossRef]

- Oduori, M.F.; Mutuli, S.M.; Munyasi, D.M. Analysis of the single toggle jaw crusher kinematics. J. Eng. Des. Technol. 2015, 13, 213–239. [Google Scholar] [CrossRef] [Green Version]

- Johansson, M.; Bengtsson, M.; Evertsson, M.; Hulthén, E. A fundamental model of an industrial-scale jaw crusher. Miner. Eng. 2017, 105, 69–78. [Google Scholar] [CrossRef]

- Soni, S.K.; Shukla, S.C.; Kundu, G. Modeling of particle breakage in a smooth double roll crusher. Int. J. Miner. Process. 2009, 90, 97–100. [Google Scholar] [CrossRef]

- Li, Y.-W.; Zhao, L.-L.; Hu, E.-Y.; Yang, K.-K.; He, J.-F.; Jiang, H.-S.; Hou, Q.-F. Laboratory-scale validation of a DEM model of a toothed double-roll crusher and numerical studies. Powder Technol. 2019, 356, 60–72. [Google Scholar] [CrossRef]

- Sinnott, M.D.; Cleary, P.W. Simulation of particle flows and breakage in crushers using DEM: Part 2—Impact crushers. Miner. Eng. 2015, 74, 163–177. [Google Scholar] [CrossRef]

- Yungmeyster, D.A.; Brichkin, V.N.; Isaev, A.I. Design and process parameters of an air hammer for oversize reduction. Obogashchenie Rud 2019, 2019, 3–7. [Google Scholar] [CrossRef]

- Napier-Munn, T. Is progress in energy-efficient comminution doomed? Miner. Eng. 2015, 73, 1–6. [Google Scholar] [CrossRef]

- Cleary, P.W.; Sinnott, M.D. Simulation of particle flows and breakage in crushers using DEM: Part 1—Compression crushers. Miner. Eng. 2015, 74, 178–197. [Google Scholar] [CrossRef]

- Davoodi, A.; Bengtsson, M.; Hulthén, E.; Evertsson, C.M. Effects of screen decks’ aperture shapes and materials on screening efficiency. Miner. Eng. 2019, 139, 105699. [Google Scholar] [CrossRef]

- Morrison, R.D.; Cleary, P.W. Towards a virtual comminution machine. Miner. Eng. 2008, 21, 770–781. [Google Scholar] [CrossRef] [Green Version]

- Atta, K.T.; Euzébio, T.; Ibarra, H.; Moreira, V.S.; Johansson, A. Extension, Validation, and Simulation of a Cone Crusher Model. IFAC-PapersOnLine 2019, 52, 1–6. [Google Scholar] [CrossRef]

- Boikov, A.; Savelev, R.; Payor, V.; Potapov, A. Universal Approach for DEM Parameters Calibration of Bulk Materials. Symmetry 2021, 13, 1088. [Google Scholar] [CrossRef]

- Cleary, P.W. Large scale industrial DEM modelling. Eng. Comput. 2004, 21, 169–204. [Google Scholar] [CrossRef]

- Cleary, P.W.; Delaney, G.W.; Sinnott, M.D.; Cummins, S.J.; Morrison, R.D. Advanced comminution modelling: Part 1—Crushers. Appl. Math. Model. 2020, 88, 238–265. [Google Scholar] [CrossRef]

- Abuhasel, K.A. Optimization and Simulation of Operation Performance in Crushing Plants Using Fuzzy Modelling. J. Syst. Sci. Syst. Eng. 2019, 28, 766–780. [Google Scholar] [CrossRef]

- Abuhasel, K.A. Machine learning approach to handle data driven model for simulation and forecasting of the cone crusher output in the stone crushing plant. Comput. Intell. 2020, 37, 1098–1110. [Google Scholar] [CrossRef]

- Azizi, A.; Rooki, R.; Mollayi, N. Modeling and prediction of wear rate of grinding media in mineral processing industry using multiple kernel support vector machine. SN Appl. Sci. 2020, 2, 1469. [Google Scholar] [CrossRef]

- Bhadani, K.; Asbjörnsson, G.; Hulthén, E.; Evertsson, M. Application of multi-disciplinary optimization architectures in mineral processing simulations. Miner. Eng. 2018, 128, 27–35. [Google Scholar] [CrossRef]

- Asbjörnsson, G.; Tavares, L.M.; Mainza, A.; Yahyaei, M. Different perspectives of dynamics in comminution processes. Miner. Eng. 2021, 176, 107326. [Google Scholar] [CrossRef]

- Leiva, C.; Arcos, K.; Poblete, D.; Serey, E.; Torres, C.; Ghorbani, Y. Design and Evaluation of an Expert System in a Crushing Plant. Minerals 2018, 8, 469. [Google Scholar] [CrossRef] [Green Version]

- Bouffard, S.C. Benefits of process control systems in mineral processing grinding circuits. Miner. Eng. 2015, 79, 139–142. [Google Scholar] [CrossRef]

- Bashaleishvili, D.I. An optimal crusher control: Its design. Autom. Remote Control 2006, 67, 54–64. [Google Scholar] [CrossRef]

- Ostroukh, A.; Kuftinova, N.; Pronin, C.; Vasiliev, Y.E.; Barinov, K.A. Crushing and screening digital system. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1159, 012090. [Google Scholar] [CrossRef]

- Shestakov, A.K.; Petrov, P.A.; Nikolaev, M.Y. Automatic System for Detecting Visible Emissions in a Potroom of Aluminum Plant Based on Technical Vision and a Neural Network. Metallurgist 2023, 66, 1308–1319. [Google Scholar] [CrossRef]

- Ostroukh, A.; Surkova, N.; Varlamov, O.O.; Chernenky, V.; Baldin, A. Automated process control system of mobile crushing and screening plant. J. Appl. Eng. Sci. 2018, 16, 343–348. [Google Scholar] [CrossRef]

- Liao, Y.; Ragai, I.; Huang, Z.; Kerner, S. Manufacturing process monitoring using time-frequency representation and transfer learning of deep neural networks. J. Manuf. Process. 2021, 68, 231–248. [Google Scholar] [CrossRef]

- Wodecki, J.; Kruczek, P.; Bartkowiak, A.; Zimroz, R.; Wyłomańska, A. Novel method of informative frequency band selection for vibration signal using Nonnegative Matrix Factorization of spectrogram matrix. Mech. Syst. Signal Process. 2019, 130, 585–596. [Google Scholar] [CrossRef]

- Itävuo, P.; Hulthén, E.; Vilkko, M. Feed-hopper level estimation and control in cone crushers. Miner. Eng. 2017, 110, 82–95. [Google Scholar] [CrossRef]

- Kamarullah, K.; Susanto, H. Analysis of Vibration and Noise on Vibrating Screen at Pt. Mifa Bersaudara. Int. J. Mater. 2022, 9, 12–16. [Google Scholar] [CrossRef]

- Elgendi, E.O.; Shawki, K. Automated process control system of Jaw crusher production. J. Phys. Conf. Ser. 2021, 2128, 012034. [Google Scholar] [CrossRef]

- Terva, J.; Kuokkala, V.-T.; Valtonen, K.; Siitonen, P. Effects of compression and sliding on the wear and energy consumption in mineral crushing. Wear 2018, 398–399, 116–126. [Google Scholar] [CrossRef]

- Wang, P.; Arson, C. Energy distribution during the quasi-static confined comminution of granular materials. Acta Geotech. 2018, 13, 1075–1083. [Google Scholar] [CrossRef]

- Turysheva, A.; Voytyuk, I.; Guerra, D. Estimation of electricity generation by an electro-technical complex with photoelectric panels using statistical methods. Symmetry 2021, 13, 1278. [Google Scholar] [CrossRef]

- Kochnev, A.A.; Kozyrev, N.D.; Kochneva, O.E.; Galkin, S.V. Development of a comprehensive methodology for the forecast of effectiveness of geological and technical measures based on machine learning algorithms. Georesursy 2020, 22, 79–86. [Google Scholar] [CrossRef]

- Shishkin, E.V.; Kazakov, S.V. Energy-efficient equipment for disintegration of extremely strong materials. Gorn. Zhurnal 2021, 11, 53–59. [Google Scholar] [CrossRef]

- Machado, P.; Pereira, J.; Sinatora, A. Abrasion wear of austenitic manganese steels via jaw crusher test. Wear 2021, 476, 203726. [Google Scholar] [CrossRef]

- Teixeira, M.F.; Pacheco, J.T.; da Silva, L.J.; Rabelo, A.; Pereira, M.; Niño, C.E. Wear resistance of a Metco 1030A hard coating deposited on Hadfield steel by laser cladding for ore comminution application. Int. J. Adv. Manuf. Technol. 2021, 112, 1873–1884. [Google Scholar] [CrossRef]

- Dalai, R.; Das, S.; Das, K. Effect of thermo-mechanical processing on the low impact abrasion and low stress sliding wear resistance of austenitic high manganese steels. Wear 2018, 420–421, 176–183. [Google Scholar] [CrossRef]

- Machado, P.; Pereira, J.; Sinatora, A. Subsurface microstructural dynamic recrystallization in multiscale abrasive wear. Wear 2021, 486–487, 204111. [Google Scholar] [CrossRef]

- Ballantyne, G.R.; Powell, M.S. Benchmarking comminution energy consumption for the processing of copper and gold ores. Miner. Eng. 2014, 65, 109–114. [Google Scholar] [CrossRef] [Green Version]

- Kamani, M.; Ajalloeian, R. The effect of rock crusher and rock type on the aggregate shape. Constr. Build. Mater. 2019, 230, 117016. [Google Scholar] [CrossRef]

- Mehdizadeh, E.; Niaki, S.T.A.; Hemati, M. A bi-objective aggregate production planning problem with learning effect and machine deterioration: Modeling and solution. Comput. Oper. Res. 2018, 91, 21–36. [Google Scholar] [CrossRef]

- Sinha, R.S.; Mukhopadhyay, A.K. Failure rate analysis of Jaw Crusher: A case study. Sādhanā 2019, 44, 17. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Cichon, A.; Królczyk, G.; Li, Z. Technology development and commercial applications of industrial fault diagnosis system: A review. Int. J. Adv. Manuf. Technol. 2021, 118, 3497–3529. [Google Scholar] [CrossRef]

- Aleksandrova, T.N. Complex and deep processing of mineral raw materials of natural and technogenic origin: State and prospects. J. Min. Inst. 2022, 256, 503–504. [Google Scholar]

- Comakli, R.; Cayirli, S. A correlative study on textural properties and crushability of rocks. Bull. Eng. Geol. Environ. 2018, 78, 3541–3557. [Google Scholar] [CrossRef]

- Kahraman, S.; Toraman, O.Y.; Cayirli, S. Predicting the strength and brittleness of rocks from a crushability index. Bull. Eng. Geol. Environ. 2017, 77, 1639–1645. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Ouchterlony, F. Energy Requirement for Rock Breakage in Laboratory Experiments and Engineering Operations: A Review. Rock Mech. Rock Eng. 2022, 55, 629–667. [Google Scholar] [CrossRef]

- Singh, V.; Dixit, P.; Venugopal, R.; Venkatesh, K.B. Ore pretreatment methods for grinding: Journey and prospects. Miner. Process. Extr. Metall. Rev. 2018, 40, 1–15. [Google Scholar] [CrossRef]

- Boikov, A.V.; Payor, V.A. The Present Issues of Control Automation for Levitation Metal Melting. Symmetry 2022, 14, 1968. [Google Scholar] [CrossRef]

- Valtonen, K.; Ojala, N.; Haiko, O.; Kuokkala, V.-T. Comparison of various high-stress wear conditions and wear performance of martensitic steels. Wear 2019, 426–427, 3–13. [Google Scholar] [CrossRef]

- Garmeh, B.; Kasiri-Asgarani, M.; Amini, K.; Ghayour, H. Analysis of Hadfield Scrap Shredder Hammer Fracture and replacing it with Carbide-free Nano-Bainitic Steel. Eng. Fail. Anal. 2019, 109, 104230. [Google Scholar] [CrossRef]

- Varela, L.B.; Tressia, G.; Masoumi, M.; Bortoleto, E.M.; Regattieri, C.; Sinatora, A. Roller crushers in iron mining, how does the degradation of Hadfield steel components occur? Eng. Fail. Anal. 2021, 122, 105295. [Google Scholar] [CrossRef]

| No. | Crusher Capacity, t/h | Engine Current, A | Engine Power, kW |

|---|---|---|---|

| 1 | 40 | 119.9 | 185.5 |

| 2 | 42 | 122.0 | 183.0 |

| 3 | 44 | 121.6 | 188.1 |

| 4 | 46 | 122.4 | 185.6 |

| 5 | 48 | 124.5 | 192.6 |

| 6 | 50 | 127.9 | 192.0 |

| 7 | 52 | 130.0 | 191.3 |

| 8 | 54 | 130.9 | 190.6 |

| 9 | 56 | 129.2 | 191.9 |

| 10 | 58 | 132.6 | 201.1 |

| 11 | 60 | 132.2 | 200.4 |

| 12 | 62 | 131.7 | 197.7 |

| 13 | 64 | 131.2 | 197.0 |

| 14 | 66 | 136.1 | 204.3 |

| 15 | 68 | 131.6 | 205.6 |

| 16 | 70 | 132.4 | 209.0 |

| 17 | 72 | 134.6 | 210.3 |

| 18 | 74 | 134.1 | 205.4 |

| 19 | 76 | 139.1 | 208.8 |

| 20 | 78 | 141.3 | 205.9 |

| 21 | 80 | 138.0 | 209.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasilyeva, N.; Golyshevskaia, U.; Sniatkova, A. Modeling and Improving the Efficiency of Crushing Equipment. Symmetry 2023, 15, 1343. https://doi.org/10.3390/sym15071343

Vasilyeva N, Golyshevskaia U, Sniatkova A. Modeling and Improving the Efficiency of Crushing Equipment. Symmetry. 2023; 15(7):1343. https://doi.org/10.3390/sym15071343

Chicago/Turabian StyleVasilyeva, Natalia, Uliana Golyshevskaia, and Aleksandra Sniatkova. 2023. "Modeling and Improving the Efficiency of Crushing Equipment" Symmetry 15, no. 7: 1343. https://doi.org/10.3390/sym15071343