Production, Reserves, and Processing of Feldspar and Feldspathoid Rocks in the Czech Republic from 2005 to 2019—An Overview

Abstract

:1. Introduction

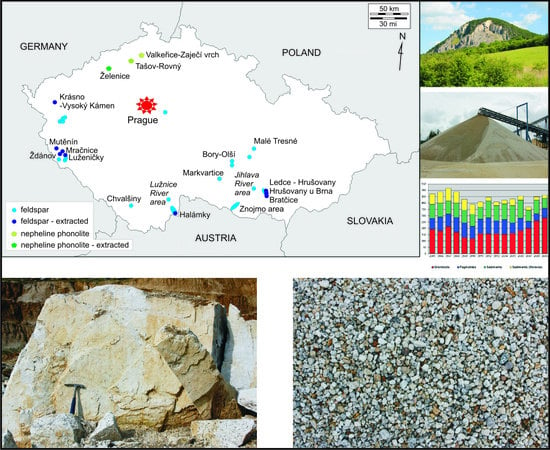

2. Classification and Quality Criteria of Czech Feldspars

3. Czech Feldspar and Feldspathoid Rock Deposits, Their Extraction, Reserves, and Resources

4. Geological Situation of Czech Feldspar and Feldspathoid Deposits.

4.1. Leucocratic Granitoids

4.2. Granitic Pegmatites

4.3. Granitic Aplite

4.4. Unconsolidated Sediments—Feldspar Gravel

4.5. Unconsolidated Sediments—Residual Kaolin

4.6. Consolidated Sediments—Arkoses

4.7. Metamorphic Rocks—Leucocratic Gneiss, Charnockite, Albitite

4.8. Feldspathoid Rocks—Nepheline Phonolites

5. Use of Czech Feldspar and Feldspathoid Rocks

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Deer, W.A.; Howie, R.A.; Zussman, J. An Introduction to The Rock-Forming Minerals, 3rd ed.; Mineralogical Society of Great Britain & Ireland: London, NY, USA, 2013; 541p. [Google Scholar] [CrossRef]

- Smith, J.V.; Brown, W.L. Feldspar Minerals. Volume 1: Crystal Structures, Physical, Chemical and Microstructural Properties, 2nd ed.; Springer: Berlin/Heidelberg, Germay, 1988; 828p. [Google Scholar] [CrossRef]

- Smith, J.V. Feldspar Minerals. Volume 2: Chemical and Textural Properties; Springer: Berlin, Germay, 1974; 691p. [Google Scholar] [CrossRef]

- Ribbe, P.H. (Ed.) Feldspar Mineralogy: Volume 2, 2nd ed.; Reviews in Mineralogy; Mineralogical Society of America: Chantilly, VA, USA, 1983; 362p. [Google Scholar]

- Van Der Plas, L. Chapter 2: The nature of feldspars. In Developments in Sedimentology; Elsevier Publishing Company: Amsterdam, The Netherland, 1966; Volume 6, pp. 19–40. [Google Scholar] [CrossRef]

- Bernasconi, A.; Marinoni, N.; Pavese, A.; Francescon, F.; Young, K. Feldspar and firing cycle effects on the evolution of sanitary-ware vitreous body. Ceram. Int. 2014, 40, 6389–6398. [Google Scholar] [CrossRef]

- Lee, W.E.; Iqbal, Y. Influence of mixing on mullite formation in porcelain. J. Eur. Ceram. Soc. 2001, 21, 2583–2586. [Google Scholar] [CrossRef]

- Martin-Marquez, J.; Rincon, J.M.; Romero, M. Mullite development on firing in porcelain stoneware bodies. J. Eur. Ceram. Soc. 2010, 30, 1599–1607. [Google Scholar] [CrossRef] [Green Version]

- Kara, A.; Özer, F.; Kağan, K.; Özer, P. Development of a multipurpose tile body: Phase and microstructural development. J. Eur. Ceram. Soc. 2006, 26, 3769–3782. [Google Scholar] [CrossRef]

- Ghalayini, Z.T. Feldspar and nepheline syenite. In Mineral Commodity Summaries 2020; U.S. Geological Survey: Reston, VA, USA, 2020; pp. 58–59. [Google Scholar] [CrossRef] [Green Version]

- Ismail, H.; Osman, H.; Ariffin, A. A comparative study on curing characteristics, mechanical properties, swelling behavior, thermal stability, and morphology of feldspar and silica in SMR L vulcanizates. Polym. Plast. Technol. 2005, 43, 1323–1344. [Google Scholar] [CrossRef]

- Ismail, H.; Osman, H.; Ariffin, A. Curing characteristics, fatigue and hysteresis behaviour of feldspar filled natural rubber vulcanizates. Polym. Plast. Technol. 2007, 46, 579–584. [Google Scholar] [CrossRef]

- Ansari, M.N.M.; Ismail, H.; Zein, S.H.S. Effect of multi-walled carbon nanotubes on mechanical properties of feldspar filled polypropylene composites. J. Reinf. Plast. Comp. 2009, 28, 2473–2485. [Google Scholar] [CrossRef]

- Razak, J.A.; Akil, H.M.; Ong, H.L. Effect of inorganic fillers on the flamability behavior of polypropylene composites. J. Thermoplast. Compos. 2007, 20, 195–205. [Google Scholar] [CrossRef]

- Mansour, S.H.; Asaad, J.N.; Ebd-El-Messieh, S.L. Synthesis and characterization of brominated polyester composites. J. Appl. Polym. Sci. 2006, 102, 1356–1365. [Google Scholar] [CrossRef]

- Raszewski, Z.; Nowakowska-Toporowska, A.; Weżgowiec, J.; Nowakowska, D.; Więckiewicz, W. Influence of silanized silica and silanized feldspar addition on the mechanical behavior of polymethyl methacrylate resin denture teeth. J. Prosthet. Dent. 2020, 123, 647 e1–647 e7. [Google Scholar] [CrossRef]

- Zilles, J.U. Feldspar and syenites. In Fillers for Polymer Applications. Polymers and Polymerics Composites: A Reference Series; Springer: Cham, Switzerland, 2017; pp. 231–244. [Google Scholar] [CrossRef]

- Kouloumbi, N.; Ghivalos, L.G.; Pantazopoulou, P. Determination of the performance of epoxy coatings containing feldspars fillers. Pigm. Resin Technol. 2005, 34, 148–153. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Y.; Sun, N.; Liu, R.; Wang, Z.; Wang, L.; Sun, W. Systematic review of feldspar benefication and its comprehensive application. Miner. Eng. 2018, 128, 141–152. [Google Scholar] [CrossRef]

- Kangal, M.O.; Bulut, G.; Yesilyurt, Z.; Basturkcu, H.; Burat, F. Characterization and production of Turkish nepheline syenites for industrial applications. Physicochem. Probl. Mi. 2019, 55, 605–616. [Google Scholar] [CrossRef]

- Hassan, I. Feldspathoids and their relationship to zeolites. Kuwait J. Sci. Eng. 1997, 24, 163–183. [Google Scholar]

- Krivenko, P.; Petropavlovskii, O.; Vozniuk, H. Alkaline aluminosilicate-based adhesives for concrete and ceramic tiles. Rev. Rom. Mat. 2016, 46, 419–423. [Google Scholar]

- Pavlunenko, L.E. Feldspar materials in Ukraine. Glass Ceram+. 2010, 67, 216–219. [Google Scholar] [CrossRef]

- Deshkar, A.; Marcial, J.; Southern, S.A.; Kobera, L.; Bryce, D.L.; McCloy, J.S.; Goel, A. Understanding the structural origin iof crystalline phase transformations in nepheline (NaAlSiO4)-based glass-ceramics. J. Am. Ceram. Soc. 2017, 100, 2859–2878. [Google Scholar] [CrossRef]

- Manning, D.A.C. Mineral sources of potassium for plant nutrition. A review. Agron. Sustain. Dev. 2010, 30, 281–294. [Google Scholar] [CrossRef] [Green Version]

- Anthony, J.W.; Bideaux, R.A.; Bladh, K.W.; Nichols, M.C. Handbook of Mineralogy: Volume II, Part 2, 2nd ed.; Mineral Data Publishing: Tuscon, AZ, USA, 1995; pp. 1–458. [Google Scholar]

- Hålenius, U.; Hatert, F.; Pasero, M.; Mills, S.J. New minerals and nomenclature modifications approved in 2018. Mineral. Mag. 2018, 82, 445–451. [Google Scholar] [CrossRef]

- Dill, H.G. Pegmatites and aplites: Their genetic and applied ore geology. Ore Geol. Rev. 2015, 69, 417–561. [Google Scholar] [CrossRef]

- Lee, G.F.; Stitt, P.H. The Oberon alaskite deposit a source of beneficated feldspar. J. Aust. Ceram. Soc. 1982, 18, 49–52. [Google Scholar]

- Taboada, J.; Vaamonde, A.; Saavedra, A.; Ordonez, C. Geostatistical study of the feldspar content and quality of a granite deposit. Eng. Geol. 2002, 65, 285–292. [Google Scholar] [CrossRef]

- Klyachin, V.V.; Gabdulkhaev, R.L.; Voronin, L.P.; Stepanova, M.V. Use of coarse-crystalline potassium feldspar from kaolin deposits. Glass Ceram+. 1978, 35, 413–415. [Google Scholar] [CrossRef]

- Pavlunenko, L.E. Alkali kaolins of Ukraine–Complex raw materials for the ceramics industry. Glass Ceram+. 2010, 67, 190–192. [Google Scholar] [CrossRef]

- Starý, J.; Kavina, P. Czech feldspar. Ind. Miner. 2005, 10, 48–53. [Google Scholar]

- ČSN 72 1370. Czechoslovak National Standard: Feldspars and Feldspar Raw Materials; Approved in May 17, 1988, active since July 1, 1989; Úřad pro normalizaci a měření: Praha, Czechoslovak Socialist Republic, 1988; 7p. (In Czech) [Google Scholar]

- Act No. 44 of 19 April 1988 On Mineral Protection and Use (the Mining Act); Federal Assembly of the Czechoslovak Socialist Republic: Praha, Czechoslovak Socialist Republic, 1988; 14p. (In Czech)

- Starý, J.; Novák, J.; Mojžíš, J.; Novák ml., J. Bilance zásob výhradních ložisek nerostů České republiky k 1. lednu 2020 Díl III.: Výhradní Ložiska Nerudních Surovin; Ministerstvo životního prostřední České republiky & Česká geologická služba: Praha, Czech Republic, 2020; 235p. (In Czech)

- Cháb, J.; Breiter, K. Variscan and early post-Variscan intrusions. In Outline of the Geology of the Bohemian Massif: The Basement Rock and Their Carboniferous and Permian Cover; Cháb, J., Ed.; Czech Geological Survey Publishing House: Prague, Czech Republic, 2010; pp. 187–213. [Google Scholar]

- Starý, J.; Sitenský, I.; Mašek, D.; Hodková, T.; Vaněček, M.; Novák, J.; Kavina, P. Mineral commodity summaries of the Czech Republic 2019; Czech Geological Survey: Prague, Czech Republic, 2019; 394p. [Google Scholar]

- Starý, J.; Kavina, P.; Vaněček, M.; Sitenský, I.; Kotková, J.; Hodková, T. Mineral Commodity Summaries of the Czech Republic 2010; Czech Geological Survey Geofond: Prague, Czech Republic, 2010; 518p. [Google Scholar]

- Starý, J.; Sitenský, I.; Mašek, D.; Hodková, T.; Vaněček, M.; Novák, J.; Horáková, A.; Kavina, P. Mineral Commodity Summaries of the Czech Republic 2015; Czech Geological Survey: Prague, Czech Republic, 2015; 412p. [Google Scholar]

- Fiala, F.; Pácal, Z. Aplogranit albitowy z Krasna na tle surowców skaleniowych Czechosłowacji. Biul. Inst. Geol. 1968, 223, 119–154. (In Polish) [Google Scholar]

- Pácal, Z.; Pavlů, D. Nové poznatky o ložisku sodno-draselných živců Vysoký kámen u Krásna. Geol. průzk. 1972, 14, 357–360. (In Czech) [Google Scholar]

- Jarchovský, T. The nature and genesis of greisen stocks at Krásno, Slavkovský les area western Bohemia, Czech Republic. J. Czech Geol. Soc. 2006, 51, 201–216. [Google Scholar] [CrossRef] [Green Version]

- Punčochář, M.; Hron, M.; Kottnauer, R. Krásno Ložiskový Průzkum 2006, Závěrečná zpráva; Unpublished; GIS Geoindustry, s.r.o.: Praha, Czech Republic, 2007; 53p. (In Czech) [Google Scholar]

- Dolníček, Z.; René, M. Evidence for activity of low-temperature Ca-Na-Cl brines in feldspathitized granites of the feldspar deposit near Krásno (Krudum granite body). Geol. výzk. Mor. Slez. 2012, 19, 137–140, (In Czech with English summary). [Google Scholar] [CrossRef] [Green Version]

- Belej, C.; Bufka, J.; Duda, J.; Hájek, M.; Kužvart, M.; Mátl, V.; Nosek, P. Živec. In Ložiska nerudních surovin ČR II; Kužvart, M., Ed.; Univerzita Karlova: Praha, Czech Republic, 1992; pp. 56–83. (In Czech) [Google Scholar]

- Vejnar, Z.; Doležal, J.; Hazdrová, M.; Kříž, J.; Mrňa, F.; Pokorný, L.; Rudolský, J.; Šefrna, L.; Tásler, R.; Tomášek, M.; et al. Geology of the Domažlice Region; Academia: Praha, Czech Republic, 1984; 234p, (In Czech with English Summary). [Google Scholar]

- Zulauf, G.; Dörr, W.; Fiala, J.; Vejnar, Z. Late Cadomian crustal tilting and Cambrian transtension in the Teplá-Barrandian unit (Bohamian Massif, Central European Variscides). Geol. Rundsch. 1997, 86, 571–584. [Google Scholar] [CrossRef]

- Čtyroký, V.; Hříbal, Z.; Macourek, K.; Nosek, P. Závěrečná zpráva geologického úkolu: Mračnice, suroviny: žula; Unpublished; Geoindustria, n.p.: Praha, Czech Republic, 1963; 37p. (In Czech) [Google Scholar]

- London, D.; Kontak, D.J. Granitic pegmatites: Scientific wonders and economic bonanzas. Elements 2012, 8, 257–261. [Google Scholar] [CrossRef]

- Duda, J. Pegmatites in the Bory granulite massif (Pegmatity v borském granulitovém masívu). Sbor. Geol. Věd, Ř. LGaM 1986, 27, 157–202, (In Czech with English summary). [Google Scholar]

- Vejnar, Z. (1965): Pegmatity poběžovicko-domažlické oblasti. Sbor. Geol. Věd. Ř. LG 1965, 4, 7–84, (In Czech with German summary). [Google Scholar]

- Peikerová, S. Závěrečná zpráva geologického úkolu: Přepočet zásob na ložisku Luženičky; Unpublished; Gekon spol. s r.o.: Praha, Czech Republic, 2007; 19p. (In Czech) [Google Scholar]

- Jarková, S. Závěrečná zpráva geologického úkolu: Luženičky severovýchod; Unpublished; Gekon s.r.o.: Praha, Czech Republic, 2012; 20p. (In Czech) [Google Scholar]

- Jarková, S.; Pachl, V.; Zahradník, J. Závěrečná zpráva geologického úkolu: Přepočet zásob v DP Luženičky, surovina: živec, živcová surovina; Unpublished; Gekon, s.r.o.: Plzen, Czech Republic, 2019; 32p. (In Czech) [Google Scholar]

- Ševčík, J.; Buriánek, D.; Jarková, S.; Pachl, V.; Ševčík, J.; Vybíral, J.; Wintrová, V. Závěrečná zpráva geologického úkolu Mutěnín, surovina: živec; Unpublished; Gekon, s.r.o.: Plzen, Czech Republic, 2009; 15p. (In Czech) [Google Scholar]

- Hora, Z.; Morysek, A.; Čtyroký, V.; Milický, V.; Jindřich, J. Závěrečná zpráva geologického úkolu: Dvorec 513 317 010; Unpublished; Geologický průzkum, n.p.: Praha, Czech Republic, 1965; 37p. (In Czech) [Google Scholar]

- Jarková, S.; Zahradník, J. Závěrečná zpráva geologického úkolu: Halámky Přepočet zásob 2017; Unpublished; Gekon s.r.o.: Plzen, Czech Republic, 2018; 32p. (In Czech) [Google Scholar]

- Opekar, L.; Brož, B.; Jaček, M.; Vrána, O. Závěrečná zpráva geologického úkolu: Přepočet zásob živcové suroviny a štěrkopísku na výhradním ložisku Ledce Hrušovany u Brna (B 3 220 300) dle nových podmínek využitelnosti z prosince 2011; Unpublished; GET, s.r.o.: Praha, Czech Republic, 2015; 74p. (In Czech) [Google Scholar]

- Zeman, A. Současný stav výzkumů pleistocenních fluviálních sedimentů v Dyjskosvrateckém úvalu a jejich problematika. Stud. Geogr. (Brno) 1974, 36, 41–60. (In Czech) [Google Scholar]

- Starý, J.; Pticen, F.; Jirásek, J.; Sivek, M. Development of kaolin production, reserves and processing in the Czech Republic in 1999–2015. Gospod. Surowcami Min. 2017, 33, 121–142. [Google Scholar] [CrossRef] [Green Version]

- Wild, J.; Pecka, I.; Knapp, R.; Stanislav, J.; Mašek, J. Závěrečná zpráva geologického úkolu: Průzkum živcových arkos. Tymákov; Unpublished; Geologický průzkum, n.p.: Praha, Czech Republic, 1962; 37p. (In Czech) [Google Scholar]

- Hranáč, P. Závěrečná zpráva: Netradiční suroviny v metalurgii; Unpublished; GEOMIN: Jihlava, Czech Republic, 2000; 11p. (In Czech) [Google Scholar]

- Houzar, S. The alkali-feldspar syenite from Markvartice near Třebíč. Acta Mus. Moraviae, Sci. nat. 1986, 71, 221–222. [Google Scholar]

- Houzar, S.; Šrein, V. Calcite-andradite microclinite from Markvartice near Třebíč, Western Moravia. Acta Mus. Moraviae Sci. nat. 1990, 75, 29–40. [Google Scholar]

- Němec, D. Identification of rocks of leptite formation in Western Moravia. Acta Mus. Moraviae, Sci. Nat. 1992, 77, 41–47. [Google Scholar]

- Dosbaba, M.; Hájek, J.; Hranáč, P. Závěrečná zpráva: Draselné živce západní Moravy; Unpublished; GEOMIN: Jihlava, Czech Republic, 2010; 42p. (In Czech) [Google Scholar]

- Franěk, J.; Schulmann, K.; Lexa, O. Kinematic and rheological model of exhumation of high pressure granulites in the Variscan orogenic root: Example of the Blanský les granulite, Bohemian Massif, Czech Republic. Mineral. Petrol. 2006, 86, 253–276. [Google Scholar] [CrossRef]

- Janoušek, V.; Krenn, E.; Finger, F.; Míková, J.; Frýda, J. Hyperpotassic granulites from the Blanský les Massif (Moldanubian Zone, Bohemian Massif) revisited. J. Geosci. 2007, 52, 73–112. [Google Scholar] [CrossRef]

- Šourek, J.; Hájek, J.; Grym, V.; Štrouf, R.; Pekárek, L.; Zápalka, D. Závěrečná zpráva úkolu Chvalšiny živec; Unpublished; Geoindustria GMS, s.p.: Jihlava, Czech Republic, 1992; 31p. (In Czech) [Google Scholar]

- Hranáč, P. Závěrečná zpráva Netradiční suroviny v metalurgii, dílčí úkol Malé Tresné, číslo úkolu 74812311, surovina: Na-živec, stav ke dni 31.5.1996; Unpublished; GEOMIN s.r.o.: Jihlava, Czech Republic, 1996; 15p. (In Czech) [Google Scholar]

- Hranáč, P.; Pticen, F. Závěrečná Zpráva: Ověření Technologických Vlastností Na-živců v tělesech Albititů Olešnické Skupiny Moravika; Unpublished; GEOMIN s.r.o.: Jihlava, Czech Republic, 2012; 30p. (In Czech) [Google Scholar]

- Čada, M.; Franče, J.; Knapp, R. Závěrečná zpráva úkolu Nebauxitové hliníkové suroviny; Unpublished; Geoindustria: Praha, Czech Republic, 1980; 39p. (In Czech) [Google Scholar]

- Jiránek, J. Možnosti použití fonolitů a trachytů Českého masívu. In Ložiska Nerudních Surovin ČR II.; Kužvart, M., Ed.; Univerzita Karlova: Praha, Czech Republic, 1992; pp. 450–455. (In Czech) [Google Scholar]

- Krutský, N.; Mag, M.; Radimský, V.; Krones, J.; Cholava, J.; Hubáček, J. Závěrečná Zpráva úkolu Výzkum a Prognózní Zhodnocení Netradičních Nerudních Surovin, Fonolity, 01 86 1080; Unpublished; Geoindustria st.p.: Dolby, Czech Republic, 1989; 191p. (In Czech) [Google Scholar]

- Ackerman, L.; Ulrych, J.; Řanda, Z.; Erban, V.; Hegner, E.; Magna, T.; Balogh, K.; Frána, J.; Lang, M.; Novák, J.K. Geochemical characteristics and petrogenesis of phonolites and trachytic rocks from the České Středohoří Volcanic Complex, the Ohře Rift, Bohemian Massif. Lithos 2015, 224, 256–271. [Google Scholar] [CrossRef]

- Kolář, Z. Průzkum kamene 1961 Želenice 51 331 067; Unpublished; Geologický průzkum, n.p.: Praha, Czech Republic, 1961; 22p. (In Czech) [Google Scholar]

- Pazdernik, P. Compositional variations in the sodalite-bearing nephelinite phonolite from Želenický vrch Hill, North Bohemia. Acta Univ. Carol. Geol. 1997, 42, 65–79. [Google Scholar]

- Sivek, M.; Kavina, P.; Jirásek, J. New mineral policy of the Czech Republic of June 2017. Resour. Policy 2019, 60, 246–254. [Google Scholar] [CrossRef]

- Elsner, H.; Homberg-Heumann, D.; Huy, D.; Lutz, R.; Moldenhauer, K.; Pein, M.; Schauer, M.; Schmidt, S.; Schmitz, M.; Sievers, H.; et al. Deutschland Rohstoffsituation 2018; Bundesanstalt für Geowissenschaften und Rohstoffe: Hannover, Germany, 2019; 144p. (In German) [Google Scholar]

- Malon, A. Surowce skaleniowe. In Bilans zasobów złóż kopalin w Polsce wg stanu na 31 XII 2018 r.; Szuflicki, M., Malon, A., Tymiński, M., Eds.; Państwowy Instytut Geologiczny Państwowy Instytut Badawczy: Warszawa, Poland, 2019; pp. 447–448. (In Polish) [Google Scholar]

- Lewicka, E. Rational use of selected mining by-products in the ceramic industry in Poland. Gospod. Surowcami Min. 2020, 36, 59–76. [Google Scholar] [CrossRef]

- Lewicka, E. Conditions of the feldspathic raw materials supply from domestic and foreign sources in Poland. Gospod. Surowcami Min. 2010, 26, 5–19. [Google Scholar]

- Lewicka, E.; Wyszomirski, P. Polish feldspar raw materials for the domestic ceramic tile industry Current state and prospects. Mat. Ceram. 2010, 62, 582–585. [Google Scholar]

- Panna, W.; Wyszomirski, P.; Gajek, M. Characteristics of the fine-grained fractions of the crushed Strzegom granites as possible materials in manufacture of ceramic tiles. Gospod. Surowcami Min. 2015, 31, 59–76. [Google Scholar] [CrossRef] [Green Version]

- Mayer-Jauck, H.; Schatz, M. Österreichisches Montan-Handbuch 2019; Bundesministerium für Nachhaltigkeit und Tourismus: Wien, Austria, 2019; 345p. (In German) [Google Scholar]

- Kúšik, D.; Mižák, J.; Šoltés, S. Slovak Minerals Yearbook 2017; State Geological Institute of Dionyz Stur: Bratislava, Slovakia, 2018; 141p. [Google Scholar]

| Mineral | Mineral Formula | K2O | Na2O | CaO | Al2O3 | SiO2 |

|---|---|---|---|---|---|---|

| Alkali Feldspars | ||||||

| Orthoclase | KAlSi3O8 | 16.92 | 0 | 0 | 18.32 | 64.76 |

| Microcline | KAlSi3O8 | 16.92 | 0 | 0 | 18.32 | 64.76 |

| Albite | NaAlSi3O8 | 0 | 11.82 | 0 | 19.44 | 68.74 |

| Plagioclase Series | ||||||

| Albite (endmember) | NaAlSi3O8 | 0 | 11.82 | 0 | 19.44 | 68.74 |

| Oligoclase 1 | (Na,Ca)[Al(Si,Al)Si2O8] | 0 | 9.34 | 4.23 | 23.05 | 63.38 |

| Andesine 1,2 | (Na,Ca)[Al(Si,Al)Si2O8] | 0 | 6.92 | 8.35 | 26.57 | 58.16 |

| Labradorite 1,2 | (Ca,Na)[Al(Al,Si)Si2O8] | 0 | 4.56 | 12.38 | 30.01 | 53.05 |

| Bytownite 1,2 | (Ca,Na)[Al(Al,Si)Si2O8] | 0 | 2.25 | 16.31 | 33.37 | 48.07 |

| Anorthite (endmember) 2 | CaAl2Si2O8 | 0 | 0 | 19.20 | 35.84 | 44.40 |

| Feldspathoids | ||||||

| Nepheline | Na3K(Al4Si4O16) | 8.06 | 15.91 | 0 | 34.90 | 41.13 |

| Feldspar | Label | K2O/(K2O + Na2O) | CaO/(CaO + Na2O − K2O) |

|---|---|---|---|

| potassium | K | 0.75–1.00 | |

| potassium-sodium | KNa | 0.60–0.75 | |

| sodium-potassium | NaK | 0.40–0.60 | |

| sodium | Na | 0.00–0.40 | |

| sodium-calcium | NaCa | 0.16–0.63 | |

| calcium-sodium | CaNa | 0.63–1.00 |

| Label | Feldspar Content (%) | K2O/(K2O + Na2O) Ratio | Fe2O3 max. (%) | TiO2 max. (%) | Fused Material Color |

|---|---|---|---|---|---|

| Ž85K15 | 85 | 0.75–1.0 | 0.15 | 0.1 | white |

| Ž85KNa25 | 85 | 0.6–0.75 | 0.25 | 0.1 | white |

| Ž65NaK40 | 65 | 0.4–0.6 | 0.40 | 0.2 | with shade |

| Ž55K60 | 55 | 0.75–1.0 | 0.60 | 0.2 | with shade |

| Ž55KNa40 | 55 | 0.6–0.75 | 0.40 | 0.2 | with shade |

| Ž40Na100 | 40 | 0.0–0.4 | 1.00 | 0.2 | with shade |

| Feldspar deposits | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 |

| Total number of deposits | 34 | 33 | 33 | 34 | 34 | 35 | 35 | 37 |

| Active deposits | 10 | 10 | 10 | 8 | 8 | 8 | 9 | 9 |

| Total mineral resources (kt) | 67,610 | 65,497 | 71,092 | 69,234 | 68,788 | 68,696 | 68,276 | 70,191 |

| Economic proved reserves (kt) | 24,979 | 24,518 | 30,126 | 28,594 | 28,176 | 27,784 | 27,392 | 26,574 |

| Economic probable reserves (kt) | 35,590 | 27,566 | 27,220 | 26,829 | 26,804 | 27,107 | 27,079 | 29,621 |

| Potentially economic resources (kt) | 7041 | 13,413 | 13,746 | 13,811 | 13,808 | 13,805 | 13,805 | 13,996 |

| Mineable reserves (kt) | 10,890 | 10,447 | 15,213 | 14,625 | 16,666 | 15,960 | 24,940 | 24,444 |

| Mine production (kt) | 472 | 487 | 514 | 488 | 431 | 388 | 407 | 445 |

| Feldspar deposits | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | |

| Total number of deposits | 37 | 36 | 36 | 39 | 39 | 40 | 41 | |

| Active deposits | 9 | 9 | 9 | 9 | 9 | 9 | 10 | |

| Total mineral resources (kt) | 70,184 | 69,729 | 69,271 | 76,476 | 76,063 | 91,722 | 101,487 | |

| Economic proved reserves (kt) | 25,889 | 25,456 | 25,048 | 24,593 | 24,415 | 28,709 | 29,742 | |

| Economic probable reserves (kt) | 30,815 | 30,793 | 31,052 | 36,185 | 36,162 | 47,157 | 55,889 | |

| Potentially economic resources (kt) | 13,480 | 13,480 | 13,171 | 15,698 | 15,698 | 15,856 | 15,856 | |

| Mineable reserves (kt) | 24,299 | 23,887 | 28,041 | 22,981 | 22,872 | 22,596 | 22,126 | |

| Mine production (kt) | 411 | 412 | 433 | 454 | 368 | 449 | 460 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zahradník, J.; Jirásek, J.; Starý, J.; Sivek, M. Production, Reserves, and Processing of Feldspar and Feldspathoid Rocks in the Czech Republic from 2005 to 2019—An Overview. Minerals 2020, 10, 722. https://doi.org/10.3390/min10080722

Zahradník J, Jirásek J, Starý J, Sivek M. Production, Reserves, and Processing of Feldspar and Feldspathoid Rocks in the Czech Republic from 2005 to 2019—An Overview. Minerals. 2020; 10(8):722. https://doi.org/10.3390/min10080722

Chicago/Turabian StyleZahradník, Jan, Jakub Jirásek, Jaromír Starý, and Martin Sivek. 2020. "Production, Reserves, and Processing of Feldspar and Feldspathoid Rocks in the Czech Republic from 2005 to 2019—An Overview" Minerals 10, no. 8: 722. https://doi.org/10.3390/min10080722