Nanometer Pore Structure Characterization of Taiyuan Formation Shale in the Lin-Xing Area Based on Nitrogen Adsorption Experiments

Abstract

:1. Introduction

2. Sample and Methods

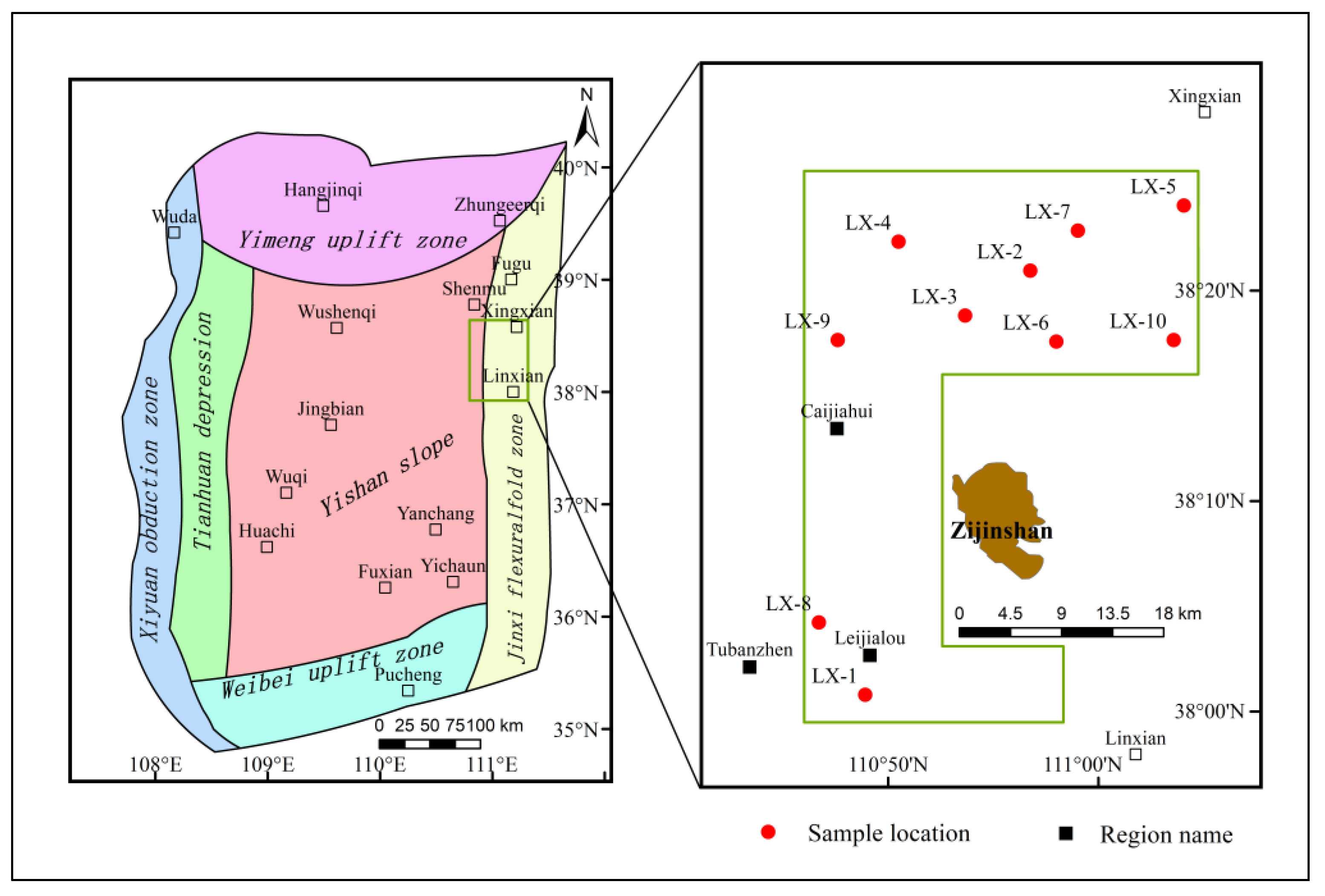

2.1. Samples

2.2. Nitrogen Adsorption Experiments

3. Experimental Results and Discussion

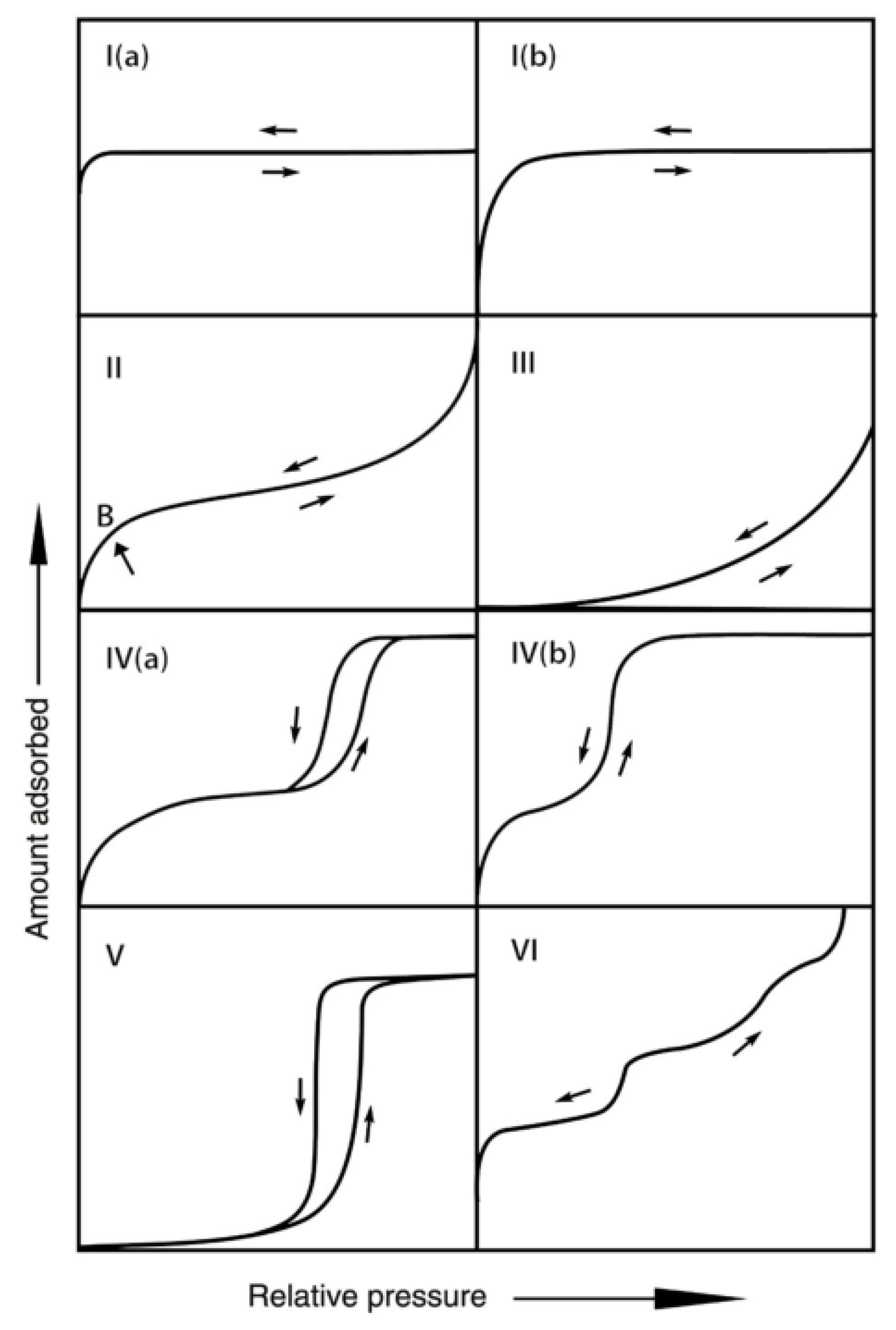

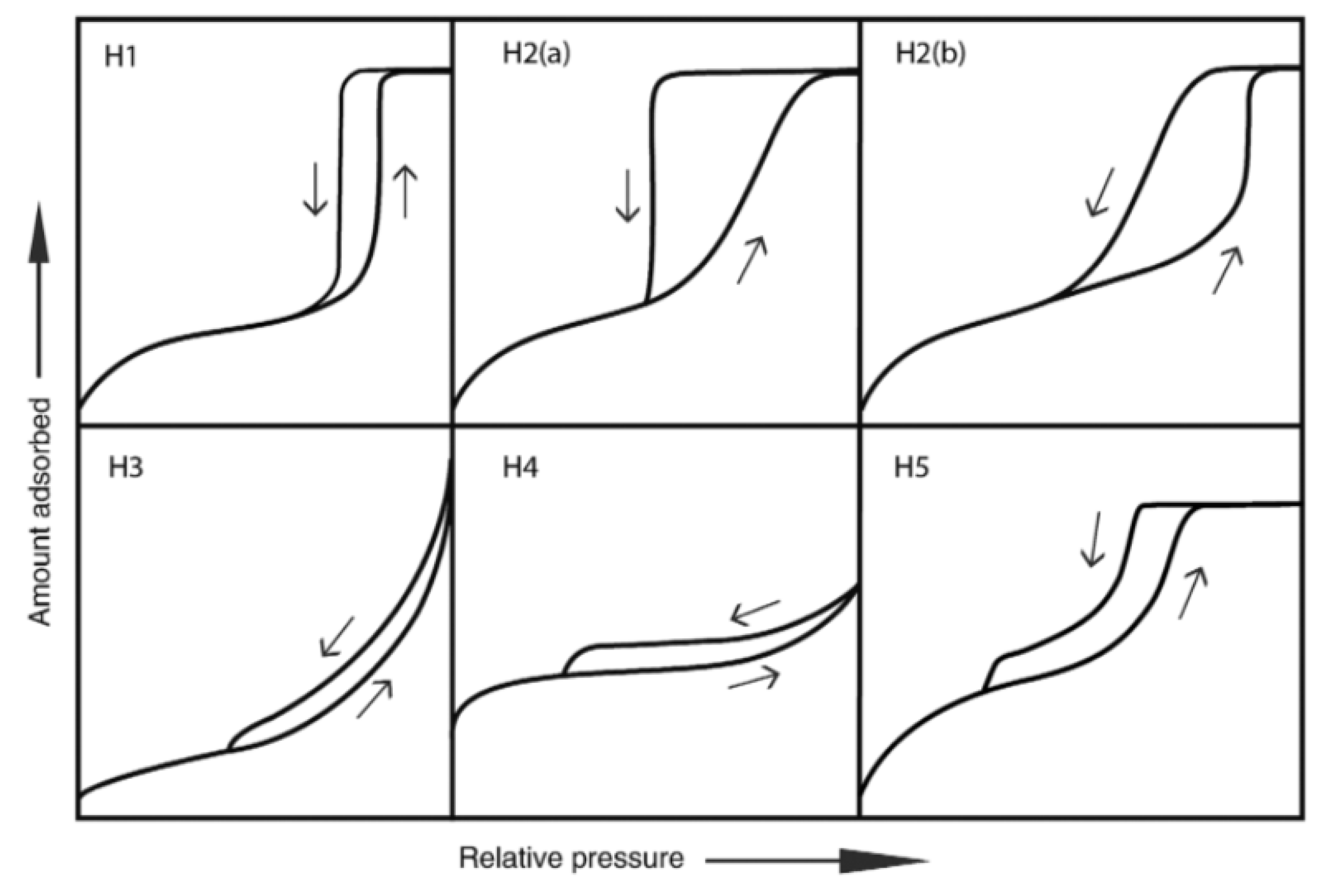

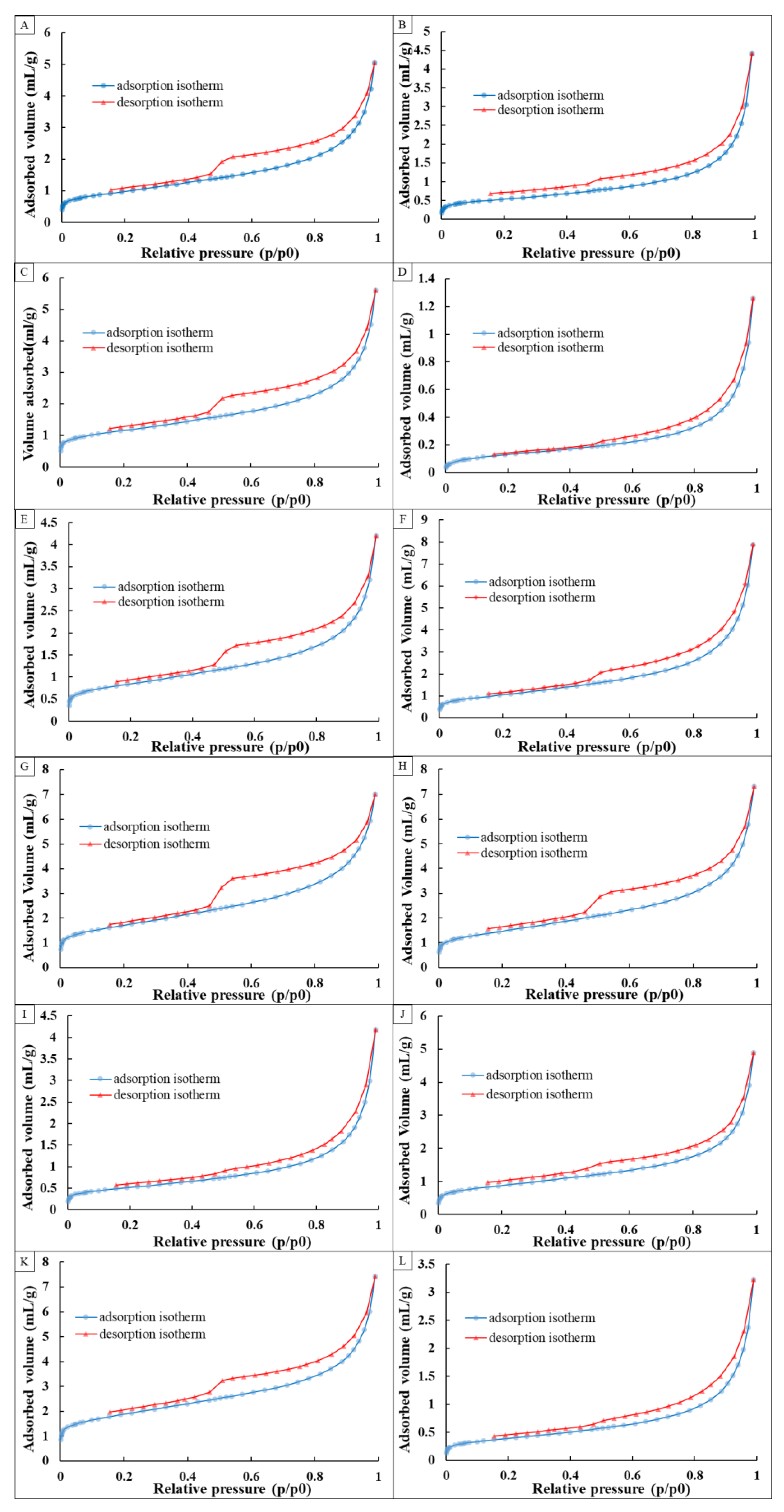

3.1. Adsorption and Desorption Isotherms

3.2. Specific Surface Area and Pore Volume of Shale

3.3. Shale Pore Size Distribution

3.4. Significance of Shale Pores for Gas Storage

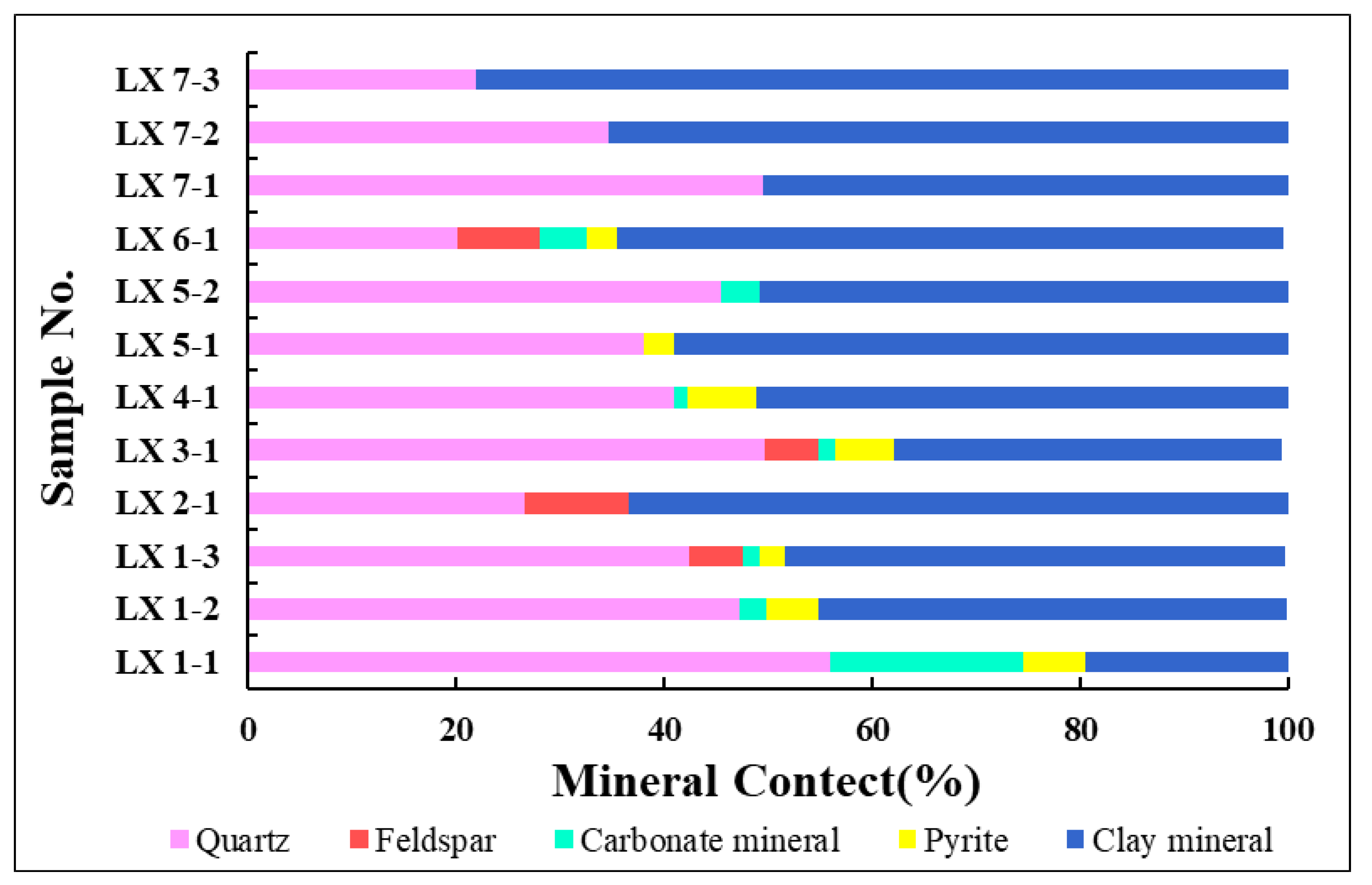

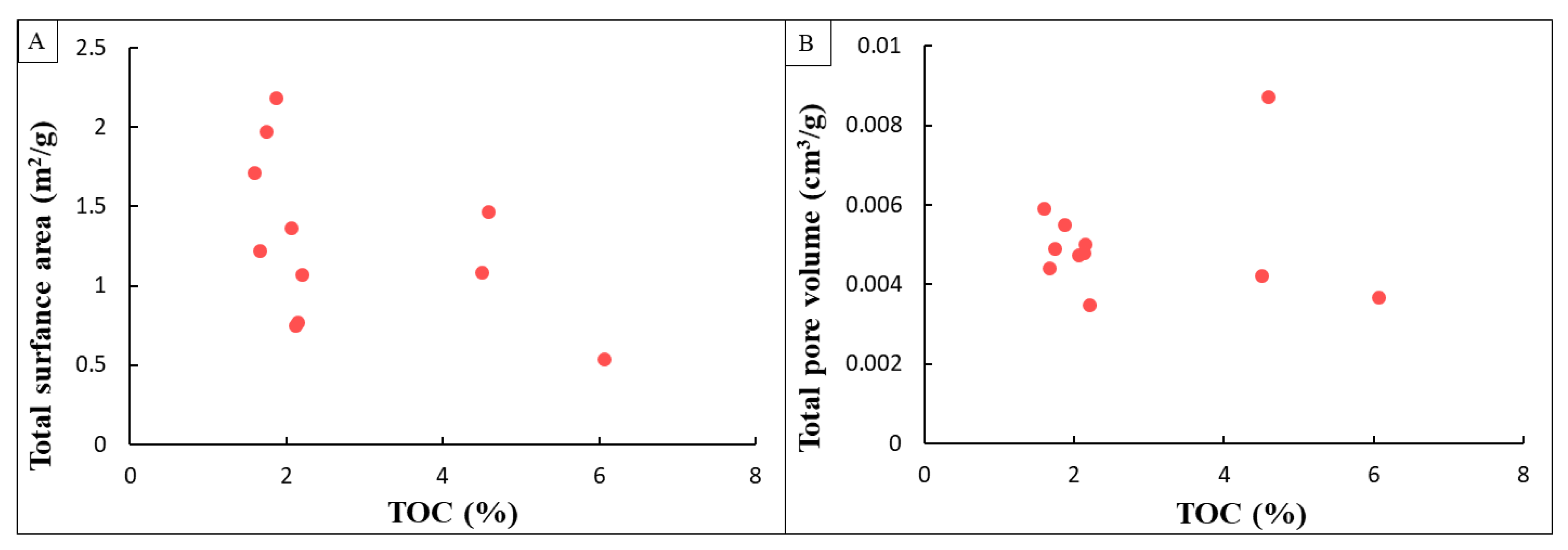

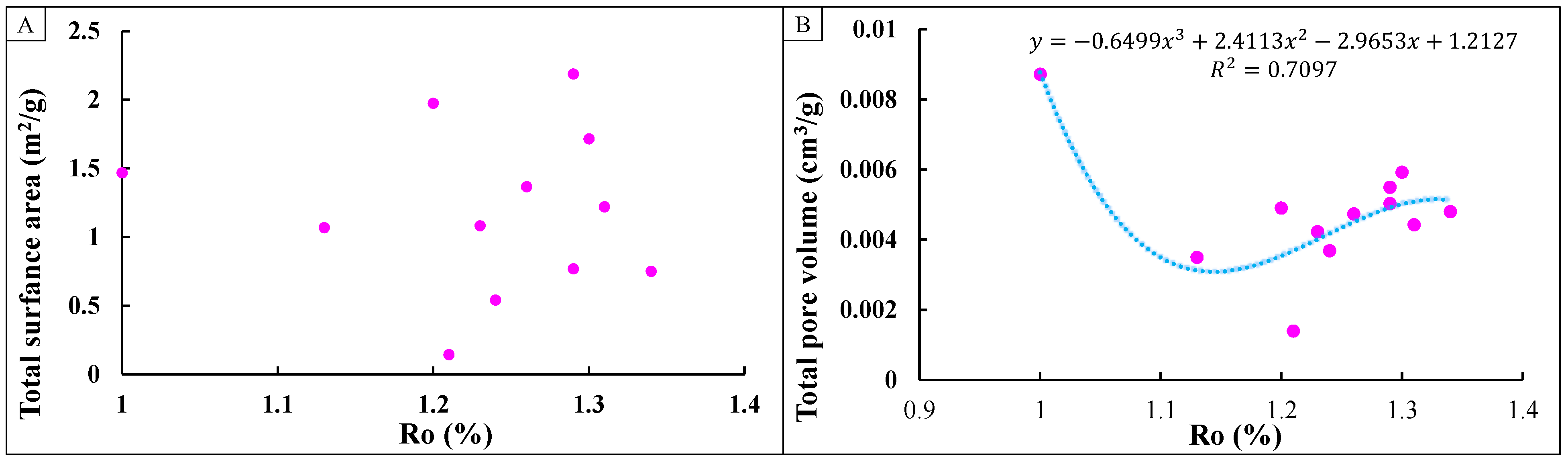

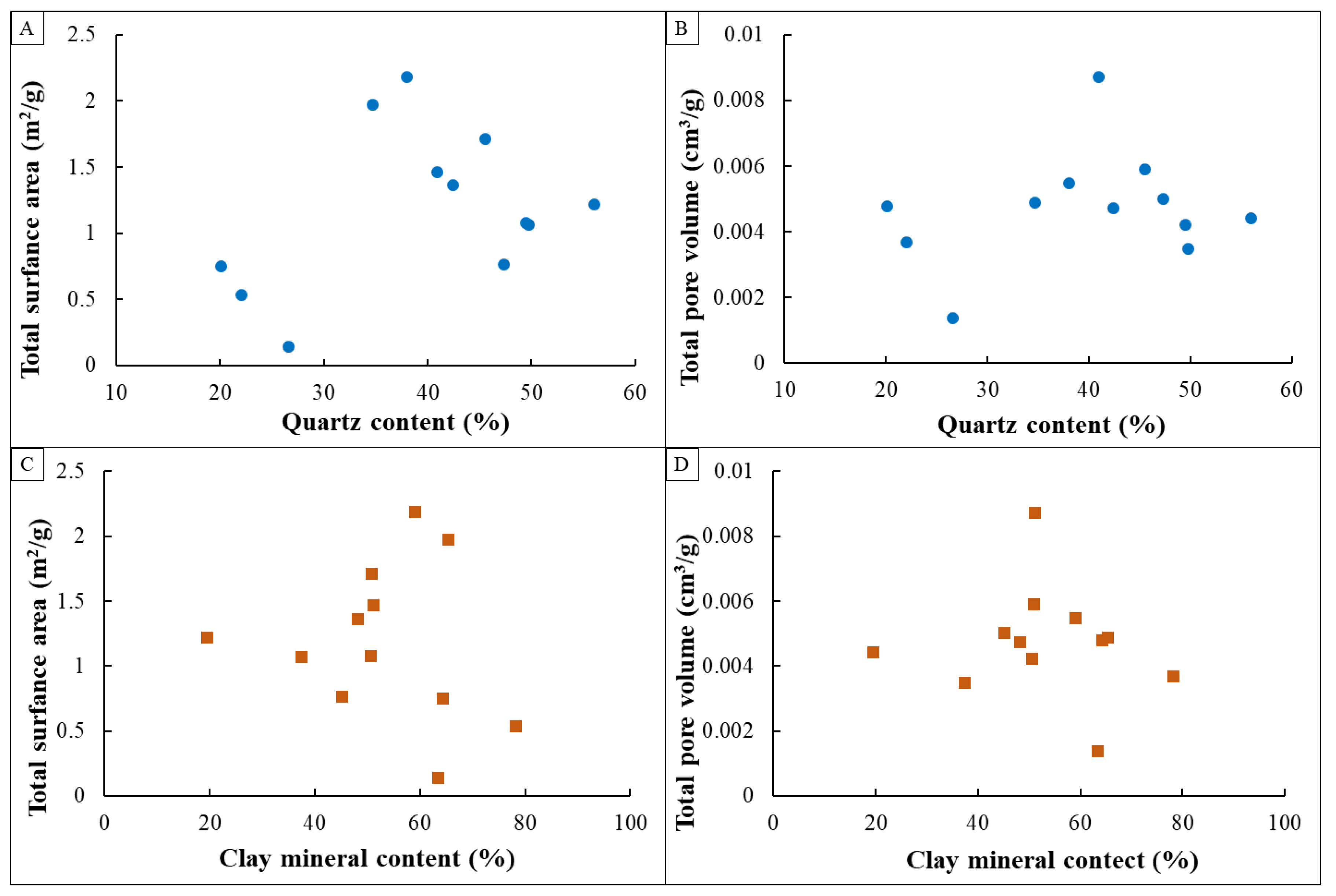

3.5. Controlling Factors of Shale Pore Development

4. Conclusions

- (1)

- The shale nitrogen adsorption curves of the Taiyuan Formation in the Lin-Xing area are similar to those of type IV(a) isotherms based on the IUPAC standard. The hysteresis loop type is mainly similar to types H3 and H4. The main pores are mesopores and macropores with a certain amount of micropores. The shale pores are mainly wedge-shaped and plate-shaped pores with good connectivity, which are conducive to the seepage and migration of shale gas.

- (2)

- The specific surface area of the shale samples ranged from 0.143 to 2.188 m2/g, and the pore volume ranged from 0.001398 to 0.008718 cm3/g. The correlation between the specific surface area and pore volume is good, which indicates that larger pore spaces result in a stronger ability to provide a specific surface area. Micropores and mesopores, especially micropores, provide most of the specific surface area of the pores, which are the main sites for gas adsorption in shale. Mesopores and macropores, especially mesopores, provide the main pore volume and are the main locations for gas storage in the shale pores.

- (3)

- The TOC has no notable linear relationship with the total pore volume, and also has no correlation with the specific surface area. There is no correlation between the total specific surface area and vitreous reflectance, whereas there is a low correlation between the total pore volume and vitreous reflectance with a “U” curve, perhaps due to the relatively small proportion of organic pores in the shale. The influence of organic matter and maturity on the pores of the shale samples is small; the role of organic matter is to generate hydrocarbons, not reservoirs. The quartz content has no relationship with the specific surface area or the total pore volume. We presumed that quartz plays a major role in building a mineral framework. There was no significant correlation between the clay mineral content and total specific surface area and total pore volume. The specific surface area and total pore volume of the shale may be influenced by both the clay minerals and quartz. The more complex relationship between the specific surface area and total pore volume of the shale due to quartz indirectly affects the role of clay minerals on the specific surface area and total pore volume of the shale, which renders the relationship more complex and unclear.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li:, S.; Qiao, D.; Feng, Z.; Liu, L.; Wang, Q.; Nie, H. The status of worldwide shale gas exploration and its suggestion for China. Geol. Bull. China 2010, 29, 918–924. [Google Scholar]

- Dusseault, M.; McLennan, J.; Jiang, S. Massive Multi-Stage Hydraulic Fracturing for Oil and Gas Recovery from Low Mobility Reservoirs in China. Pet. Drill. Tech. 2011, 39, 6–16. [Google Scholar]

- Ross, D.J.K.; Bustin, R.M. Shale gas potential of the Lower Jurassic Gordondale Member northeastern British Columbia, Canada. Bull. Can. Pet. Geol. 2007, 55, 51–75. [Google Scholar] [CrossRef]

- Ross, D.J.K.; Bustin, R.M. Characterizing the shale gas resource potential of Devonian-Mississippian strata in the Western Canada sedimentary basin: Application of an integrated formation evaluation. AAPG Bull. 2008, 92, 87–125. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, J.; Cao, J. A preliminary discussion on evaluation of continental shale gas resources: A case study of Chang 7 of Mesozoic Yanchang Formation in Zhiluo—Xiasiwan area of Yanchang. Earth Sci. Front. 2012, 19, 192–197. [Google Scholar]

- Ambrose, R.J.; Hartman, R.C.; Diaz-Campos, M. New pore-scale considerations for shale gas in place calculations. Soc. Petroleum Eng. 2010. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, B.; Nie, H. Exploration potential of shale gas resources in China. Nat. Gas Ind. 2008, 28, 136–140. [Google Scholar]

- Curtis, J.B. Fractured shale-gas systems. AAPG Bull. 2002, 86, 1921–1938. [Google Scholar] [CrossRef]

- Javadpour, F. Nanopores and apparent permeability of gasflow in mudrocks (shales and siltstone). J. Cana Dian Pet. Technol. 2009, 48, 16–21. [Google Scholar] [CrossRef]

- Curtis, M.E.; Ambrose, R.J.; Sondergeld, C.H. Structural Characterization of Gas Shales on the Micro- and Nano-Scales. In Proceedings of the Canadian Unconventional Resources an International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar]

- Ross, D.J.; Bustin, R.M. The importance of shale composition and pore structure upon gas storage potential of shale gas reservoirs. Mar. Pet. Geol. 2009, 26, 916–927. [Google Scholar] [CrossRef]

- Curtis, M.E.; Cardott, B.J.; Sondergeld, C.H.; Rai, C.S. Development of organic porosity in the Woodford Shale with increasing thermal maturity. Int. J. Coal Geol. 2012, 103, 26–31. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, D.; Li, J.; Wang, S.; Li, X.; Wang, L.; Cheng, K.; Huang, J. Reservoir characteristics of shale gas in Longmaxi Formation of the Lower Silurian, southern Sichuan. Acta Pet. Sin. 2012, 33, 551–561. [Google Scholar]

- Tian, H.; Zhang, S.; Liu, S.; Zhang, H. Determination of organic-rich shale pore features by mercury injection and gas adsorption methods. Acta Pet. Sin. 2012, 33, 419–427. [Google Scholar]

- Wang, P.; Jiang, Z.; Chen, L.; Yin, L.; Li, Z.; Zhang, C.; Tang, X.; Wang, G. Pore structure characterization for the Longmaxi and Niutitang shales in the Upper Yangtze Platform, South China: Evidence from focused ion beam–He ion microscopy, nano-computerized tomography and gas adsorption analysis. Mar. Pet. Geol. 2016, 77, 1323–1337. [Google Scholar] [CrossRef]

- Gou, Q.; Xu, S.; Hao, F.; Lu, Y.; Zhang, A.; Wang, Y.; Cheng, X.; Qing, J. Characterization method of shale pore structure based on nano-CT: A case study of Well JY-1. Acta Pet. Sin. 2018, 39, 1253–1261. [Google Scholar]

- Sondergeld, C.H.; Ambrose, R.J.; Rai, C.S. Micro-structural studies of gas shales; In Proceedings of the SPE Unconventional Gas Conference, Pittsburgh, PA, USA, 23–25 February 2010.

- Farshi, M.M.; Javadpour, F. Uncovering nanoscale issues in shale gas systems. Geol. Soc. Am. 2011, 43, 48. [Google Scholar]

- Gregg, S.J.; Sing, K.S.W.; Salzberg, H.W. Adsorption Surface Area and Porosity. J. Electrochem. Soc. 1967, 114, 279C. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.; Kong, D.; Liu, H. Pore Structure of Shales from High Pressure Mercury Injection and Nitrogen Adsorption Method. Nat. Gas Geosci. 2013, 24, 450–455. [Google Scholar]

- Zhang, X.; Wu, C.; He, J.; Ren, Z.; Zhou, T. The Controlling Effects of Compositions on Nanopore Structure of Over-Mature Shale from the Longtan Formation in the Laochang Area, Eastern Yunnan, China. Minerals 2019, 9, 403. [Google Scholar] [CrossRef] [Green Version]

- Xue, H.; Wang, H.; Liu, H.; Yan, G.; Guo, W.; Li, X. Adsorption capability and aperture distribution characteristics of shales:taking the Longmaxi Formation shale of Sichuan Basin as an example. Acta Pet. Sin. 2013, 34, 826–832. [Google Scholar]

- Yang, W.; Chen, G.; Lv, C.; Zhong, J.; Xu, Y.; Yang, S.; Xue, L. Micropore Characteristics of the Organic-rich Shale in the 7th Member of the Yanchang Formation in the Southeast of Ordos Basin. Nat. Gas Geosci. 2015, 26, 418–426, 591. [Google Scholar]

- Giesche, H. Mercury Porosimetry: A General (Practical) Overview. Part. Part. Syst. Charact. 2006, 23, 9–19. [Google Scholar] [CrossRef]

- Bustin, A.M.M.; Bustin, R.M.; Cui, X. Importance of fabric on the production of gas shales. In Proceedings of the SPE Unconventional Reservoirs Conference, Keystone, CO, USA, 10–12 February 2008. [Google Scholar]

- Clarkson, C.R.; Freeman, M.; He, L.; Agamalian, M.; Melnichenko, Y.B.; Mastalerz, M.; Bustin, R.M.; Radlinski, A.P.; Blach, T.P. Characterization of tight gas reservoir pore structure using USANS /SANS and gas adsorption analysis. Fuel 2012, 95, 371–385. [Google Scholar] [CrossRef]

- Ruppert, L.F.; Sakurovs, R.; Blach, T.P.; He, L.; Melnichenko, Y.B.; Mildner, D.F.R.; Alcantar-Lopez, L. A USANS /SANS study of the accessibility of pores in the Barnett Shale to methane and water. Energy Fuels 2013, 27, 772–779. [Google Scholar] [CrossRef]

- Bustin, R.M.; Bustin, A.; Ross, D.; Chalmers, G.; Cui, X. Shale gas opportunities and challenges. In Proceedings of the AAPG Annual Convention, San Antonio, TX, USA, 20–23 April 2008. [Google Scholar]

- Barrett, E.P.; Joyner, L.G.; Halenda, P.P. The Determination of Pore Volume and Area Distributions in Porous Substances. I. Computations from Nitrogen Isotherms. J. Am. Chem. Soc. 1951, 73, 373. [Google Scholar] [CrossRef]

- Qin, Y.; Shen, J.; Shen, Y. Joint mining compatibility of superposed gas-bearing systems: A general geological problem for extraction of three natural gases and deep CBM in coal series. J. China Coal Soc. 2016, 41, 14–23. [Google Scholar]

- Burnaman, M.; Xia, W.; Shelton, J. Shale Gas Play Screening and Evaluation Criteria. China Pet. Explor. 2009, 14, 51–64. [Google Scholar]

- Kuuskraa, V.A.; Stevens, S.H. Worldwide gas shales and unconventional gas: A status report. In Proceedings of the United Nations Climate Change Conference, Copenhagen, Denmark, 7–19 December 2009. [Google Scholar]

- Chalmers, G.R.; Bustin, R.M.; Power, I.M. Characterization of gas shale pore systems by porosimetry, pycnometry, surface area, and field emission scanning electron microscopy/transmission electron microscopy image analyses: Examples from the Barnett, Woodford, Haynesville, Marcellus, and Doigunits. AAPG Bull. 2012, 96, 1099–1119. [Google Scholar] [CrossRef]

- Bowker, K.A. Barnett shale gas production, Fort Worth Basin: Issues and discussion. AAPG Bull. 2007, 91, 523–533. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.; Hu, C.; Wang, B.; Peng, K.; Liu, H. Characterization of microscopic pore structures in shale reservoirs. Acta Pet. Sin. 2013, 34, 301–311. [Google Scholar]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef] [Green Version]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Burgess, C.G.V.; Everett, D.H.; Nuttall, S. Adsorption hysteresis in porous materials. Pure Appl. Chem. 1989, 61, 1845–1852. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Qin, Y.; Wei, C.; Huang, L.; Shi, Q.; Wu, C.; Zhang, X. Porosity changes in progressively pulverized anthracite subsamples: Implications for the study of closed pore distribution in coals. Fuel 2018, 225, 612–622. [Google Scholar] [CrossRef]

- Chen, S.; Zhu, Y.; Wang, H.; Liu, H.; Wei, W.; Fang, J. Structure characteristics and accumulation significance of nanopores in Longmaxi shale gas reservoir in the southern Sichuan Basin. J. China Coal Soc. 2012, 37, 438–444. [Google Scholar]

- Chalmers, G.R.L.; Bustin, R.M. Lower Cretaceous gas shales in northeastern British Columbia, Part II: Evaluation of regional potential gas resource. Bull. Can. Pet. Geol. 2008, 56, 22–61. [Google Scholar] [CrossRef]

- Chatfield, C. Statistics for Technology: A Course in Applied Statistics, 3rd ed.; Chapman and Hall: Boca Raton, FL, USA, 1983; pp. 166–171. [Google Scholar]

- Zhong, L.; Zhang, H.; Yuan, Z. Influence of specific pore area and pore volume of coal on adsorption capacity. Coal Geol. Explor. 2002, 30, 26–28. [Google Scholar]

- Bowker, K.A. Recent development of the Barnett Shale play, FortWorth Basin. West Tex. Geol. Soc. Bull. 2003, 42, 1–11. [Google Scholar]

- Cao, T.; Song, Z.; Liu, G.; Yin, Q.; Luo, H. Characteristics of shale pores, fractal dimension and their controlling factors determined by nitrogen adsorption and mercury injection methods. Pet. Geol. Recovery Effic. 2016, 23, 1–8. [Google Scholar]

- Nuttall, B.C.; Drahovzal, J.A.; Eble, C.F.; Bustin, R.M. Analysis of the Devonian black shale in Kentucky for potential carbon dioxide sequestration and enhanced natural gas production. Greenhouse Gas Control Technol. 2005, 7, 2225–2228. [Google Scholar]

- Martin, J.P.; Hill, D.G.; Lombardi, T.E. Fractured shale gas potential in New York. Northeastern Geology and Environmental. Sciences 2004, 26, 57–78. [Google Scholar]

- Chalmers, G.R.L.; Bustin, R.M. Lower Cretaceous gas shales in northeastern British Columbia, Part I: Geological controls on methane sorption capacity. Bull. Can. Pet. Geol. 2008, 56, 1–21. [Google Scholar] [CrossRef]

- Cao, T.; Deng, M.; Luo, H.; Liu, H.; Liu, G.; Hursthouse, A.S. Characteristics of organic pores in Middle and Upper Permian shale in the Lower Yangtze region. Pet. Geol. Exp. 2018, 40, 315–322, 396. [Google Scholar]

- Xue, C.; Wu, J.; Zhong, J.; Liu, Q.; Zhang, S.; Hou, M.; Li, F.; Peng, C. Characteristics of reservoir variability of transitional and continental shale, Shanxi Formation, Linxing and Shenfu area, Northeastern Ordos Basin. J. Cent. South Univ. 2020, 51, 998–1011. [Google Scholar]

- Cheng, P.; Xiao, X. Gas content of organic-rich shales with very high maturities. J. China Coal Soc. 2013, 38, 737–741. [Google Scholar]

- Baskin, D.K.; Liu, Q. Evaluation of Thermal Maturity and Hydrocarbon Generation Potential of Source Rocks Using kerogen H/C Ratio. Nat. Gas Geosci. 2002, Z3, 41–49. [Google Scholar]

- Zhang, J.; He, S.; Yan, X.; Hou, Y.; Chen, X. Structural characteristics and thermal evolution of nanoporosity in shales. J. China Univ. Pet. 2017, 41, 11–24. [Google Scholar]

- Jacob, H. Disperse solid bitumens as an indicator for migration and maturity in prospecting for oil and gas. Erdoel Kohle Erd Gas Petrochem. 1985, 38, 365. [Google Scholar]

- Jarvie, D.M.; Hill, R.J.; Ruble, T.E.; Pollastro, R.M. Unconventional shale-gas systems: The Mississippian Barnett shale of north-central Texas as one model for thermogenic shale-gas assessment. AAPG Bull. 2007, 91, 475–499. [Google Scholar] [CrossRef]

- Martineau, D.F. History of the Newark East field and the Barnett shale as a gas reservoir. AAPG Bull. 2007, 91, 399–403. [Google Scholar] [CrossRef]

- Milici, R.C.; Swezey, C.S. Assessment of Appalachian Basin Oil and Gas Resources: Devonian Shale Middle and Upper Paleozoic Total Petroleum System, 1st ed.; Geological Survey: Reston, VA, USA, 2006; pp. 1–70. [Google Scholar]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef] [Green Version]

- Wei, X.; Liu, R.; Zhang, T.; Liang, X. Micro-pores Structure Characteristics and Development Control Factors of Shale Gas Reservoir: A Case of Longmaxi Formation in XX Area of Southern Sichuan and Northern Guizhou. Nat. Gas Geosci. 2013, 24, 1048–1059. [Google Scholar]

- Li, Y.; Cai, J. Effect of smectite illitization on shale gas occurrence in argillaceous source rocks. Pet. Geol. Exp. 2014, 36, 352–358. [Google Scholar]

- Zhang, C.; Zhu, Y.; Liu, Y.; Chen, J.; Li, Z. Pore and fractal characteristics of shale in different maturity. Fault Block Oil Gas Field 2016, 23, 583–588. [Google Scholar]

- Liu, G.; Huang, Z.; Jiang, Z.; Chen, J.; Chen, F.; Xing, J. Effect of liquid hydrocarbons on gas adsorption in alacustrine shale: A case study of the Yanchang Formation, Ordos Basin. Pet. Geol. Exp. 2015, 37, 648–653+659. [Google Scholar]

- Nie, H.; Zhang, J. Shale Gas Accumulation Conditions and Gas Content Calculation: A Case Study of Sichuan Basin and Its Periphery in the Lower Paleozoic. Acta Geol. Sin. 2012, 86, 349–361. [Google Scholar]

- Zeng, W.; Zhang, J.; Ding, W.; Wang, X.; Zhu, D.; Liu, Z. The Gas Content of Continental Yanchang Shale and Its Main Controlling Factors: A Case Study of Liuping-171 Well in Ordos Basin. Nat. Gas Geosci. 2014, 25, 291–301. [Google Scholar]

- Zhao, P.; Li, X.; Tian, X.; Su, G.; Zhang, M.; Guo, M.; Dong, Z.; Sun, M.; Wang, F. Study on Micropore Structure Characteristics of Longmaxi Formation Shale Gas Reservoirs in the Southern Sichuan Basin. Nat. Gas Geosci. 2014, 25, 947–956. [Google Scholar]

- He, J.; Zhang, X.; Zhao, Y.; Wu, H.; Chen, J. Nanometer Pore Structure Characterization of Chang 7 Member Continental Shale in Northern Shaanxi Area, Ordos Basin Based on the Nitrogen Adsorption Experiment. J. Nanosci. Nanotechnol. 2017, 17, 6386–6394. [Google Scholar] [CrossRef]

- Guo, X.; Li, Y.; Liu, R.; Wang, Q. Characteristics and controlling factors of micro-pore structures of Longmaxi Shale Play in the Jiaoshiba area, Sichuan Basin. Nat. Gas Ind. 2014, 34, 9–16. [Google Scholar]

| Sample No. | Depth (m) | TOC (%) | Sapropelinite (%) | Vitrinite (%) | Inertinite (%) | Kerogen Type | Ro (%) |

|---|---|---|---|---|---|---|---|

| LX1-1 | 1991 | 1.66 | 54 | 8 | 38 | II2 | 1.31 |

| LX1-2 | 2037 | 2.14 | 55 | 5 | 40 | II2 | 1.29 |

| LX1-3 | 2067 | 2.06 | 71 | 5 | 25 | II1 | 1.26 |

| LX2-1 | 1736 | 22.58 | 45 | 29 | 26 | III | 1.21 |

| LX3-1 | 1722 | 2.2 | 56 | 9 | 35 | II2 | 1.13 |

| LX4-1 | 1659 | 4.58 | 56 | 12 | 32 | II2 | 1.00 |

| LX5-1 | 1952 | 1.87 | 66 | 5 | 29 | II2 | 1.29 |

| LX5-2 | 1993 | 1.59 | 71 | 6 | 23 | II1 | 1.30 |

| LX6-1 | 1947 | 2.12 | 72 | 7 | 21 | II1 | 1.34 |

| LX7-1 | 1714 | 4.5 | 72 | 4 | 24 | II1 | 1.23 |

| LX7-2 | 1716 | 1.74 | 75 | 5 | 20 | II1 | 1.20 |

| LX7-3 | 1717 | 6.06 | 65 | 8 | 27 | II2 | 1.24 |

| Sample No. | Mineral Content (%) | |||||

|---|---|---|---|---|---|---|

| Quartz | Feldspar | Carbonate Minerals | Pyrite | Clay Minerals | Brittle Minerals | |

| LX1-1 | 55.99 | 0 | 18.46 | 6.12 | 19.43 | 74.45 |

| LX1-2 | 47.30 | 0 | 2.56 | 4.96 | 45.12 | 49.86 |

| LX1-3 | 42.36 | 5.26 | 1.54 | 2.42 | 48.17 | 49.16 |

| LX2-1 | 26.55 | 10.11 | 0 | 0 | 63.34 | 36.66 |

| LX3-1 | 49.72 | 5.16 | 1.61 | 5.54 | 37.32 | 56.49 |

| LX4-1 | 40.92 | 0 | 1.30 | 6.69 | 51.07 | 42.22 |

| LX5-1 | 37.98 | 0 | 0 | 3.04 | 58.98 | 37.98 |

| LX5-2 | 45.50 | 0 | 3.73 | 0 | 50.77 | 49.23 |

| LX6-1 | 20.07 | 8.05 | 4.46 | 2.86 | 64.18 | 32.58 |

| LX7-1 | 49.45 | 0 | 0 | 0 | 50.55 | 49.45 |

| LX7-2 | 34.62 | 0 | 0 | 0 | 65.38 | 34.62 |

| LX7-3 | 21.992 | 0 | 0 | 0 | 78.08 | 21.92 |

| Sample No. | Relative Percentage (%) | Proportion of Illite Smectite Mixed Layer (%) | |||

|---|---|---|---|---|---|

| Illite Smectite Mixed Layer | Illite | Kaolinite | Chlorite | ||

| LX1-1 | 43 | 18 | 28 | 11 | 23 |

| LX1-2 | 31 | 23 | 36 | 10 | 22 |

| LX1-3 | 39 | 18 | 31 | 12 | 15 |

| LX2-1 | 20 | 15 | 49 | 16 | 31 |

| LX3-1 | 34 | 25 | 28 | 13 | 26 |

| LX4-1 | 32 | 19 | 35 | 14 | 26 |

| LX5-1 | 36 | 22 | 29 | 12 | 18 |

| LX5-2 | 46 | 16 | 26 | 12 | 18 |

| LX6-1 | 37 | 13 | 36 | 14 | 12 |

| LX7-1 | 48 | 18 | 21 | 13 | 26 |

| LX7-2 | 24 | 12 | 46 | 18 | 25 |

| LX7-3 | 12 | 9 | 58 | 21 | 25 |

| Sample No. | Total Surface Area (m2/g) | Proportion of Respective Surface Area (%) | Respective Surface Area (m2/g) | ||||

|---|---|---|---|---|---|---|---|

| Micropore | Mesopore | Macropore | Micropore | Mesopore | Macropore | ||

| LX1-1 | 1.221 | 52.93 | 44.19 | 2.88 | 0.646 | 0.539 | 0.035 |

| LX1-2 | 0.769 | 39.76 | 53.11 | 7.13 | 0.306 | 0.409 | 0.055 |

| LX1-3 | 1.368 | 58.90 | 38.22 | 2.88 | 0.805 | 0.523 | 0.039 |

| LX2-1 | 0.143 | 11.62 | 77.55 | 10.84 | 0.017 | 0.111 | 0.016 |

| LX3-1 | 1.070 | 60.18 | 37.03 | 2.78 | 0.644 | 0.396 | 0.030 |

| LX4-1 | 1.469 | 30.54 | 64.36 | 5.10 | 0.448 | 0.944 | 0.075 |

| LX5-1 | 2.188 | 61.62 | 36.97 | 1.40 | 1.348 | 0.809 | 0.031 |

| LX5-2 | 1.716 | 55.62 | 41.57 | 2.81 | 0.954 | 0.713 | 0.048 |

| LX6-1 | 0.750 | 38.88 | 54.40 | 6.71 | 0.292 | 0.408 | 0.050 |

| LX7-1 | 1.083 | 63.60 | 32.46 | 3.94 | 0.689 | 0.351 | 0.043 |

| LX7-2 | 1.975 | 71.11 | 27.08 | 1.81 | 1.404 | 0.535 | 0.036 |

| LX7-3 | 0.540 | 33.06 | 60.22 | 6.72 | 0.179 | 0.325 | 0.036 |

| Average | 1.191 | 48.15 | 47.26 | 4.59 | 0.644 | 0.505 | 0.041 |

| Sample No. | Total Pore Volume (cm3/g) | Proportion of the Respective Pore Volume (%) | Respective Pore Volume (cm3/g) | ||||

|---|---|---|---|---|---|---|---|

| Micropore | Mesopore | Macropore | Micropore | Mesopore | Macropore | ||

| LX1-1 | 0.004430 | 9.85 | 63.35 | 26.80 | 0.000436 | 0.002807 | 0.001187 |

| LX1-2 | 0.005029 | 4.00 | 58.18 | 37.82 | 0.000201 | 0.002926 | 0.001902 |

| LX1-3 | 0.004738 | 13.12 | 58.14 | 28.74 | 0.000622 | 0.002754 | 0.001362 |

| LX2-1 | 0.001398 | 0.93 | 62.09 | 36.98 | 0.000013 | 0.000868 | 0.000517 |

| LX3-1 | 0.003495 | 12.50 | 59.41 | 28.09 | 0.000437 | 0.002077 | 0.000982 |

| LX4-1 | 0.008718 | 3.31 | 68.64 | 28.05 | 0.000286 | 0.005917 | 0.002418 |

| LX5-1 | 0.005499 | 17.13 | 65.12 | 17.75 | 0.000942 | 0.003581 | 0.000976 |

| LX5-2 | 0.005926 | 11.46 | 61.77 | 26.77 | 0.000679 | 0.003661 | 0.001586 |

| LX6-1 | 0.004800 | 3.82 | 60.26 | 35.92 | 0.000183 | 0.002893 | 0.001724 |

| LX7-1 | 0.004228 | 10.06 | 54.13 | 35.81 | 0.000425 | 0.002289 | 0.001514 |

| LX7-2 | 0.004904 | 22.43 | 54.76 | 22.80 | 0.001100 | 0.002686 | 0.001118 |

| LX7-3 | 0.003682 | 3.17 | 62.86 | 33.98 | 0.000117 | 0.002314 | 0.001251 |

| Average | 0.004737 | 9.32 | 60.73 | 29.96 | 0.000453 | 0.002898 | 0.001378 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, C.; He, J.; Wu, H.; Zhang, X. Nanometer Pore Structure Characterization of Taiyuan Formation Shale in the Lin-Xing Area Based on Nitrogen Adsorption Experiments. Minerals 2021, 11, 298. https://doi.org/10.3390/min11030298

Ding C, He J, Wu H, Zhang X. Nanometer Pore Structure Characterization of Taiyuan Formation Shale in the Lin-Xing Area Based on Nitrogen Adsorption Experiments. Minerals. 2021; 11(3):298. https://doi.org/10.3390/min11030298

Chicago/Turabian StyleDing, Chenlong, Jinxian He, Hongchen Wu, and Xiaoli Zhang. 2021. "Nanometer Pore Structure Characterization of Taiyuan Formation Shale in the Lin-Xing Area Based on Nitrogen Adsorption Experiments" Minerals 11, no. 3: 298. https://doi.org/10.3390/min11030298