Rock Mass and Pore Fluid Response in Deep Mining: A Field Monitoring Study at Inclined Longwalls

Abstract

:1. Introduction

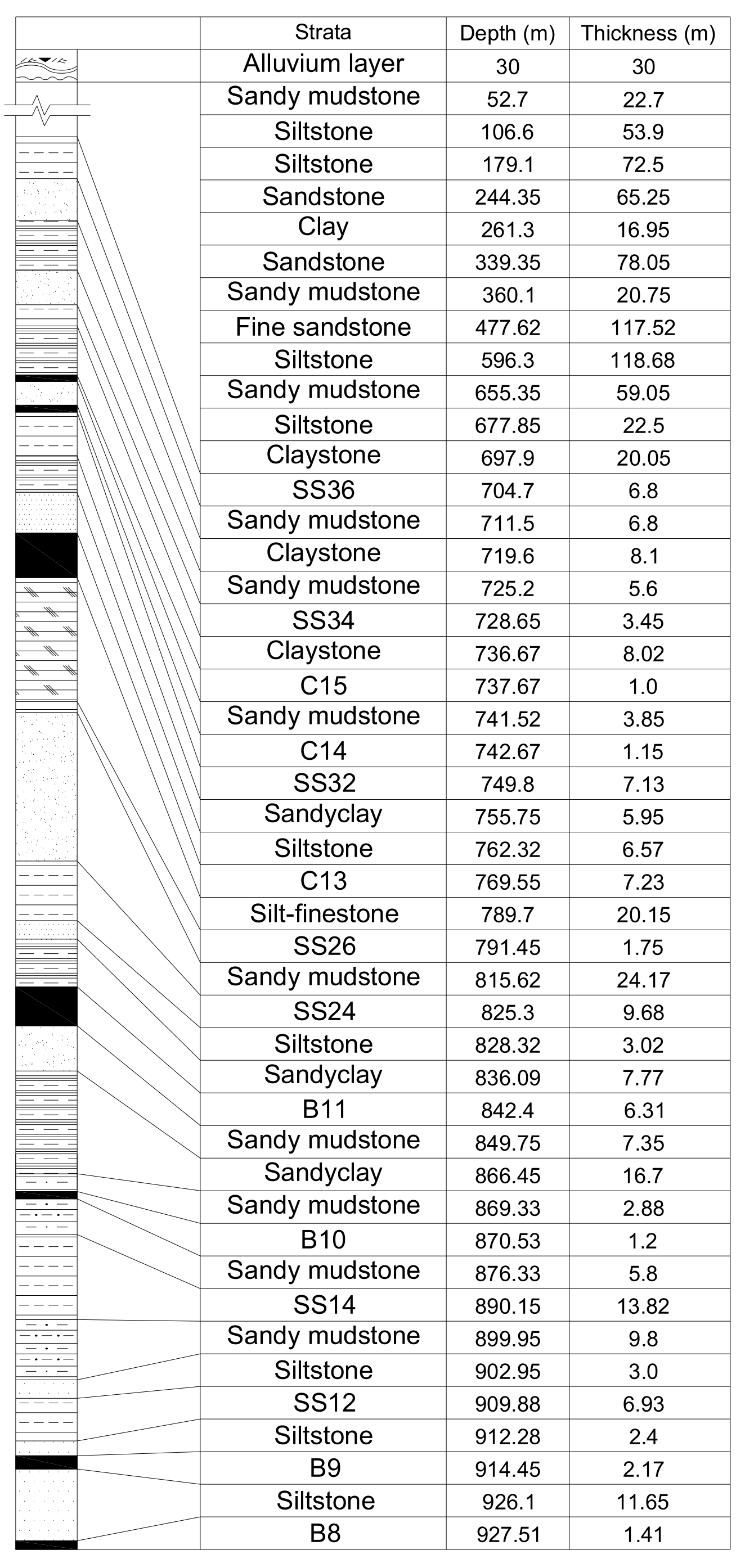

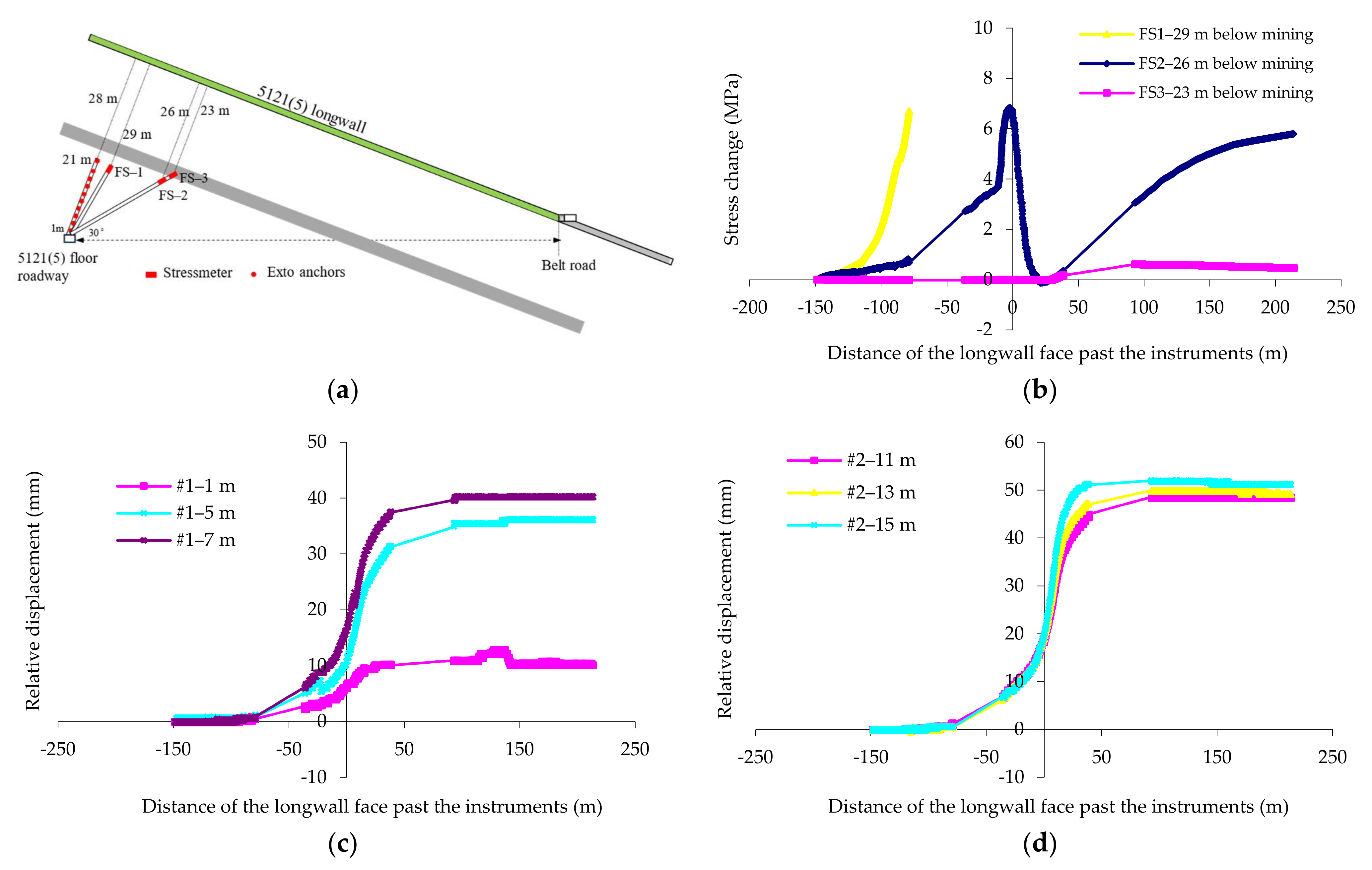

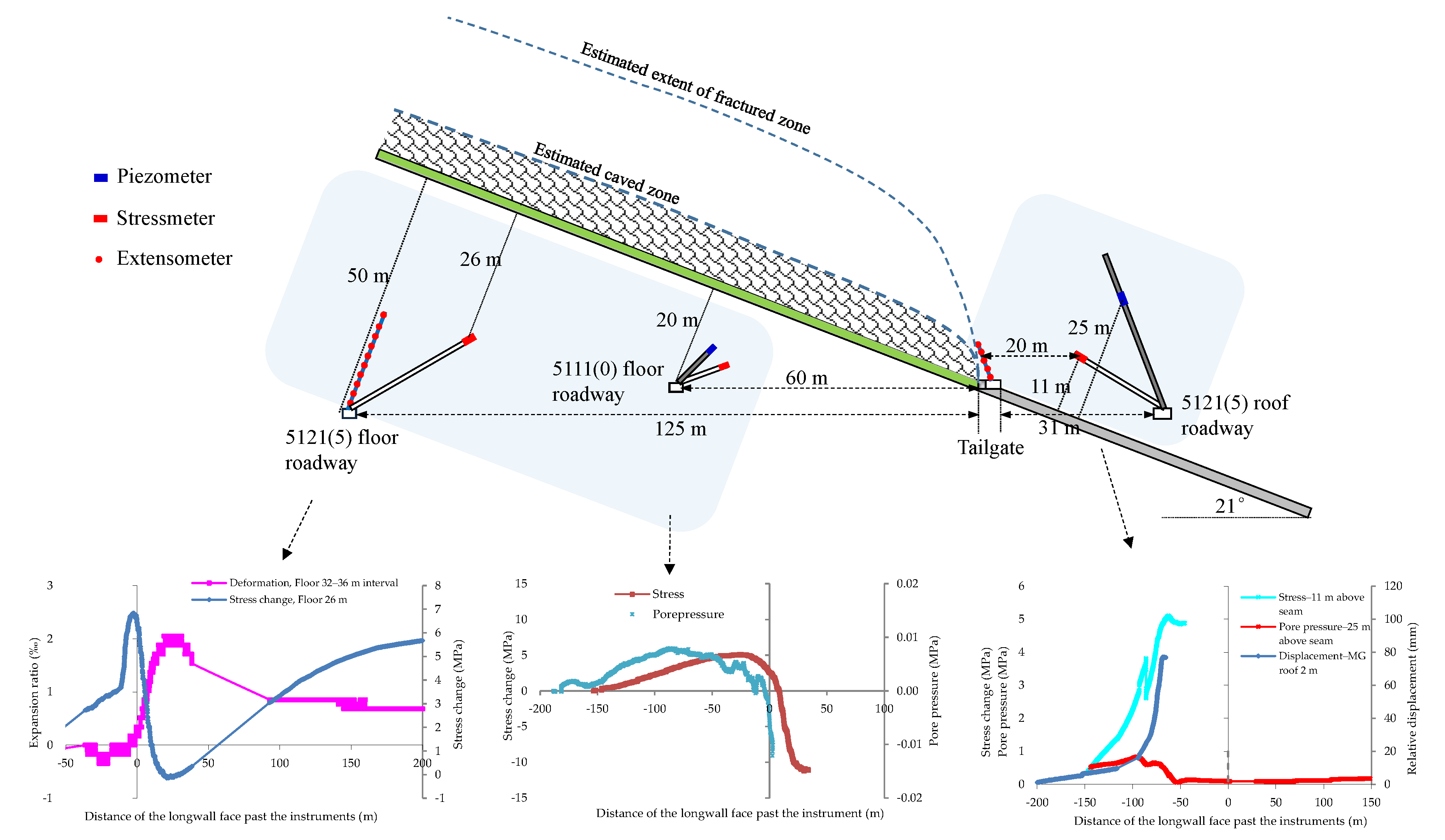

2. Mine Conditions and the Monitoring Program

3. Monitoring Results

3.1. 5121(5) Roadway Roof

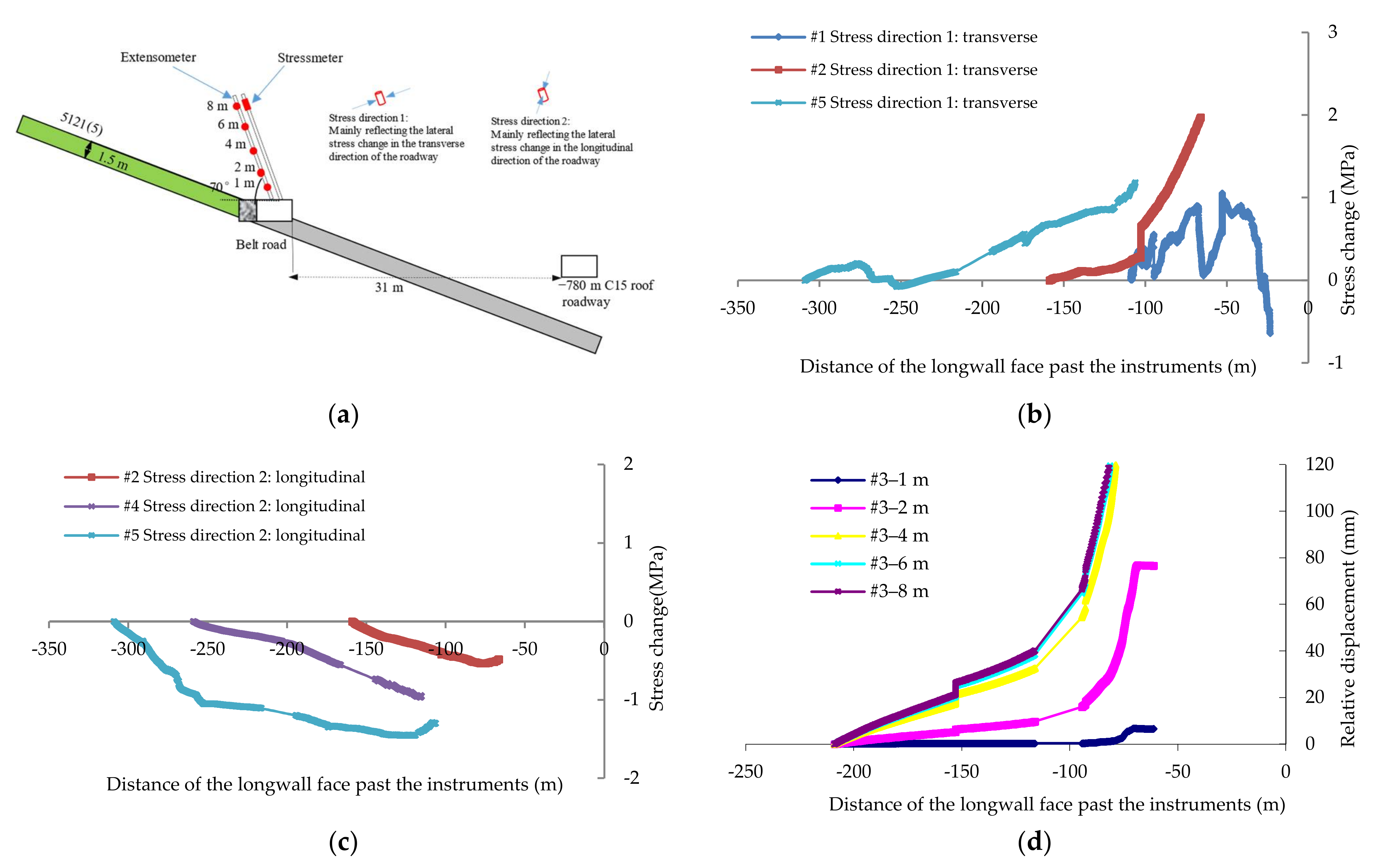

3.2. 5121(5) Roof Strata in the Side Abutment Zone

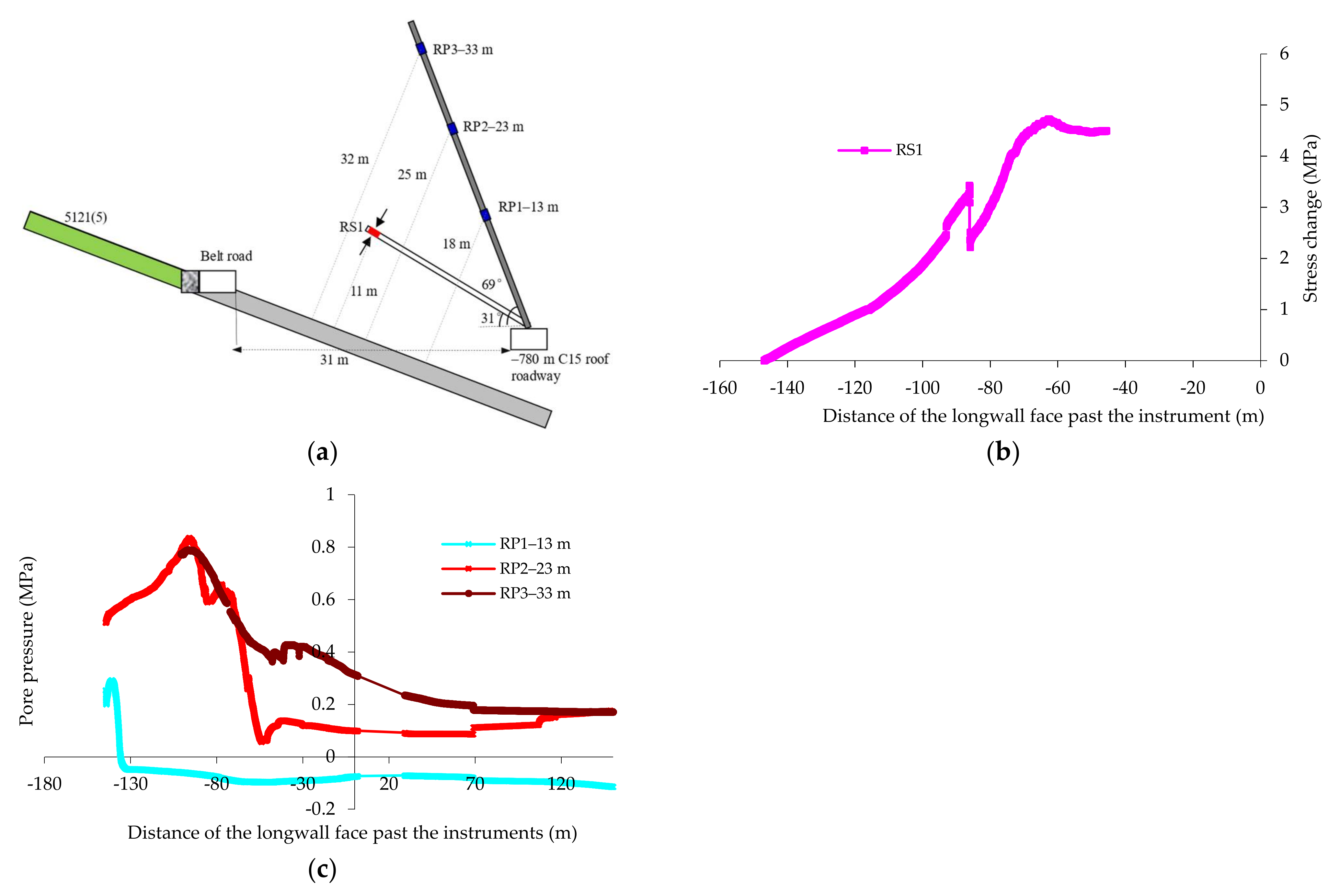

3.3. 5121(5) Floor Strata

3.4. 5111(0) Floor Strata

4. Integrated Analysis and Characterisation

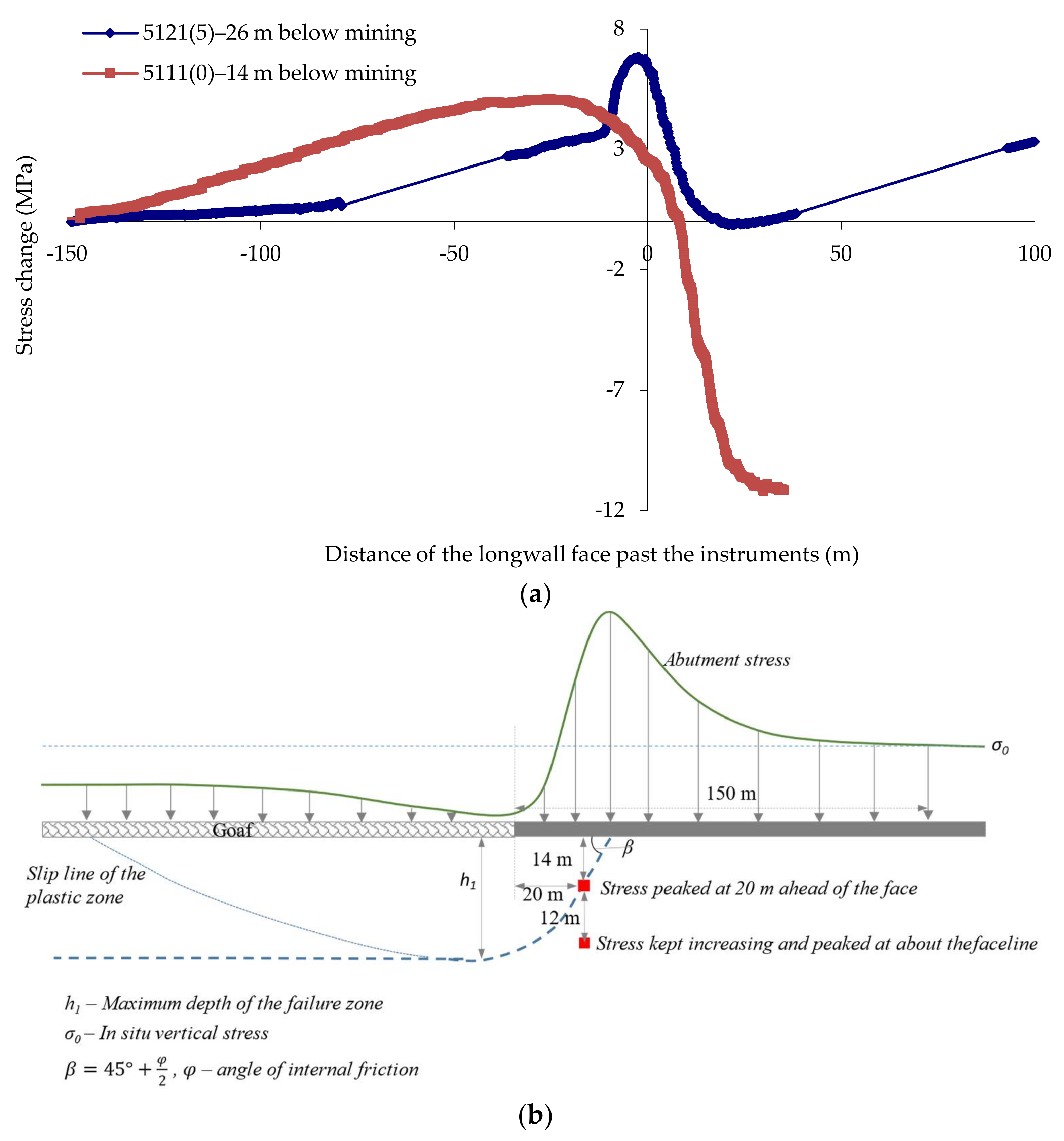

4.1. Characteristics of Stress Change and Deformation in the Floor Strata

4.2. Monitoring Results vs. Predictive Methods

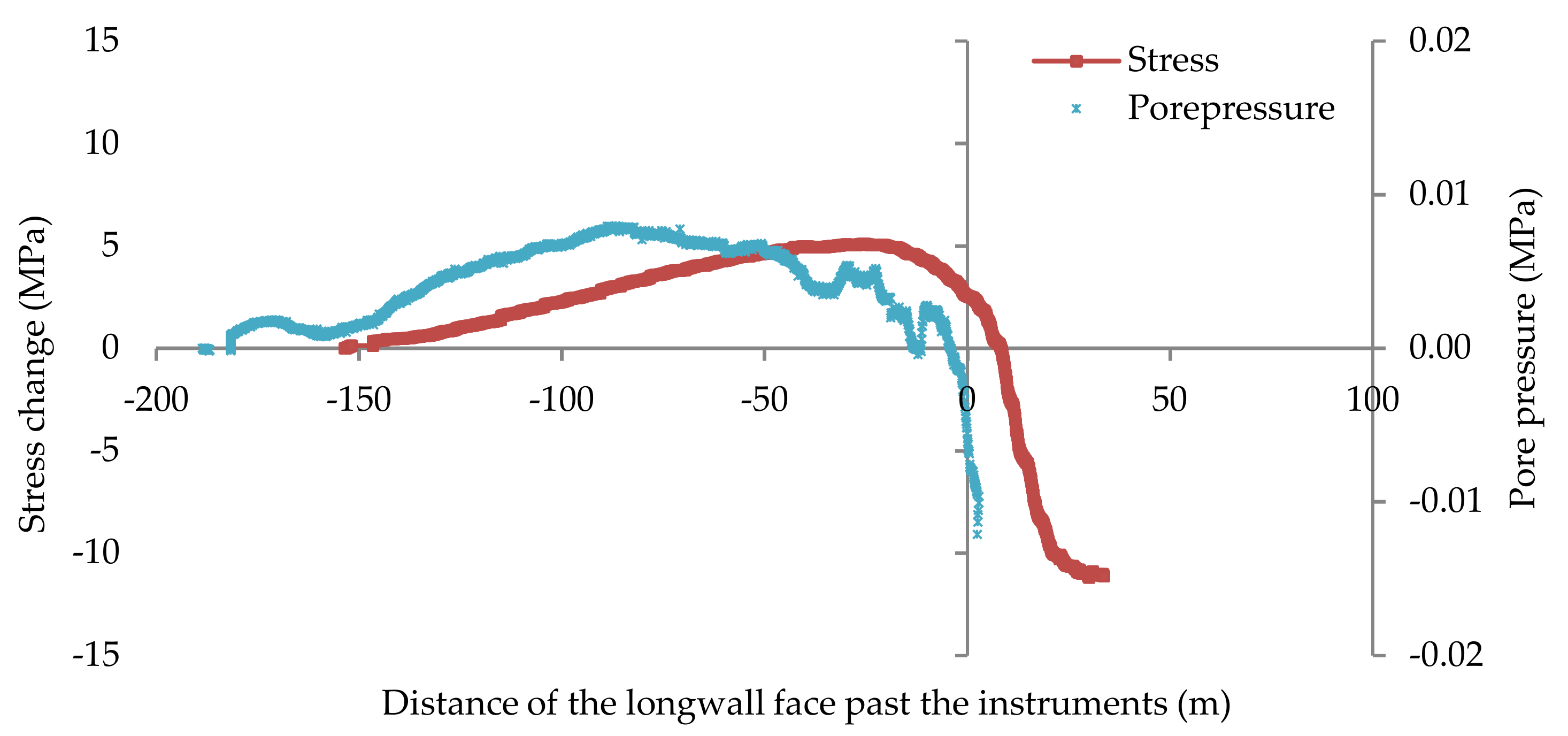

4.3. Coupled Response of Strata Stress, Deformation and Pore Pressure

4.4. Strata Behaviour in Different Regions along the Face Direction

5. Summary and Conclusions

- The mining-induced stress change in the floor strata exhibited a three-stage variation as the longwall advanced: increase, decrease and recovery. The stress started to increase at about 150 m away from the longwall face, peaked at about 0–20 m away and began to decline afterwards. The stress started to recover at about 35 m behind the longwall face and became almost stable at around 200 m.

- Mining-induced strata deformation and pore pressure change occurred correspondingly with stress change. Stress concentration in the front abutment zone caused roadways to deform and the pore pressure to rise. Stress relief in the initial goafing stage led to strata expansion and pore pressure reduction. Stress recovery was correlated with strata re-compaction and pore pressure recovery.

- Stress relief and strata expansion occurred primarily in the region 0–35 m behind the face and vertically to at least 42 m below the mining seam. This zone marks the optimal zone of gas extraction. At 34 m below the mining seam, the maximum expansion ratio of strata was about 2 mm/m in this mining condition.

- The two predictive methods for estimating the depth of the floor failure zone in shallow mines, proposed by Zhang [35], could still predict approximate results for mining at a depth of about 800 m.

- In the roof strata of the longwall roadway, the lateral stress parallel to the roadway decreased as the longwall advanced, whereas the lateral stress perpendicular to the roadway increased. Roof strata in the side abutment zone within 20 m of the goaf edge and 11 m above the mining seam showed a similar trend in stress change and pore pressure to that in the floor strata.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peng, S.S. Longwall Mining, 2nd ed.; West Virginia University: Morgantown, WV, USA, 2006. [Google Scholar]

- Qian, M.; Shi, P.; Xu, J. Mine Pressure and Ground Control; China University of Mining and Technology Press: Xuzhou, China, 2010. [Google Scholar]

- Guo, H.; Qu, Q.; Adhikary, D. Overburden response to longwall mining. In Advances in Coal Mine Ground Control; Peng, S.S., Ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 111–155. [Google Scholar]

- Guo, H.; Yuan, L.; Shen, B.; Qu, Q.; Xue, J. Mining-induced strata stress changes, fractures and gas flow dynamics in multi-seam longwall mining. Int. J. Rock Mech. Min. Sci. 2012, 54, 129–139. [Google Scholar] [CrossRef]

- Yavuz, H. An estimation method for cover pressure re-establishment distance and pressure distribution in the goaf of longwall coal mines. Int. J. Rock Mech. Min. Sci. 2004, 41, 193–205. [Google Scholar] [CrossRef]

- Qu, Q.; Guo, H.; Khanal, M. Monitoring and analysis of ground movement from multi-seam mining. Int. J. Rock Mech. Min. Sci. 2021, 148, 104949. [Google Scholar] [CrossRef]

- Cheng, G.; Ma, T.; Tang, C.; Liu, H.; Wang, S. A zoning model for coal mining-induced strata movement based on microseismic monitoring. Int. J. Rock Mech. Min. Sci. 2017, 94, 123–138. [Google Scholar] [CrossRef]

- Zhu, W.; Qi, X.; Ju, J.; Xu, J. Mechanisms behind strong strata behaviour in high longwall mining face-ends under shallow covers. J. Geophys. Eng. 2019, 16, 559–570. [Google Scholar] [CrossRef] [Green Version]

- Zhu, W.; Chen, L.; Zhou, Z.; Shen, B.; Xu, Y. Failure Propagation of Pillars and Roof in a Room and Pillar Mine Induced by Longwall Mining in the Lower Seam. Rock Mech. Rock Eng. 2019, 52, 1193–1209. [Google Scholar] [CrossRef]

- Majdi, A.; Hassani, F.P.; Nasiri, M.Y. Prediction of the height of distressed zone above the mined panel roof in longwall coal mining. Int. J. Coal Geol. 2012, 98, 62–72. [Google Scholar] [CrossRef]

- Booth, C.J. Groundwater as an environmental constraint of longwall coal mining. Environ. Geol. 2006, 49, 796–803. [Google Scholar] [CrossRef]

- Newman, C.; Agioutantis, Z.; Leon, G. Assessment of potential impacts to surface and subsurface water bodies due to longwall mining. Int. J. Min. Sci. Technol. 2017, 27, 57–64. [Google Scholar] [CrossRef]

- Zhang, D.; Fan, G.; Ma, L.; Wang, X. Aquifer protection during longwall mining of shallow coal seams: A case study in the Shendong Coalfield of China. Int. J. Coal Geol. 2011, 86, 190–196. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, W.; Wang, X. New method to predict the height of fractured water-conducting zone by location of key strata. J. China Coal Soc. 2012, 37, 762–769. [Google Scholar]

- Karacan, C.Ö.; Esterhuizen, G.S.; Schatzel, S.J.; Diamond, W.P. Reservoir simulation-based modelling for characterising longwall methane emissions and gob gas venthole production. Int. J. Coal Geol. 2007, 71, 225–245. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Goodman, G. Probabilistic modelling using bivariate normal distributions for identification of flow and displacement intervals in longwall overburden. Int. J. Rock Mech. Min. Sci. 2011, 48, 27–41. [Google Scholar] [CrossRef]

- Schatzel, S.J.; Karacan, C.Ö.; Dougherty, H.; Goodman, G.V.R. An analysis of reservoir conditions and responses in longwall panel overburdenduring mining and its effect on gob gas well performance. Eng. Geol. 2012, 127, 65–74. [Google Scholar] [CrossRef]

- Qu, Q.; Xu, J.; Qian, M. Study of the influence of key strata movement on gas emission from overlying coal seams. Chin. J. Rock Mech. Eng. 2007, 26, 1479–1484. [Google Scholar]

- Qu, Q.; Xu, J.; Wu, R.; Qin, W.; Hu, G. Three-zone characterisation of coupled strata and gas behaviour in multi-seam mining. Int. J. Rock Mech. Min. Sci. 2015, 78, 91–98. [Google Scholar] [CrossRef]

- Palchik, V. Localization of mining-induced horizontal fractures along rock layer interfaces in overburden: Field measurements and prediction. Environ. Geol. 2005, 48, 68–80. [Google Scholar] [CrossRef]

- Yuan, L. The technique of integrated coal and methane extraction with retaining roadway and drainage boreholes. J. China Coal Soc. 2008, 33, 898–902. [Google Scholar]

- Yuan, L. Theory and practice of integrated pillarless coal production and methane extraction in multi-seams of low permeability. Eng. Sci. 2009, 11, 72–80. [Google Scholar]

- Zhang, J.; Shen, B. Coal mining under aquifers in China: A case study. Int. J. Rock Mech. Min. Sci. 2004, 41, 629–639. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.; Wang, Z.; Hou, H.; Shen, Y. Determining areas in an inclined coal seam floor prone to water-inrush by micro-seismic monitoring. Min. Sci. Technol. 2011, 21, 165–168. [Google Scholar]

- Wei, X.; Gao, M.; Lv, Y.; Shi, X.; Gao, H.; Zhou, H. Evolution of a mining-induced fracture network in the overburden strata of an inclined coal seam. Int. J. Min. Sci. Technol. 2012, 22, 779–783. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, K.; Yun, D.; Jie, P.; Wang, G. Research progress on the safe and efficient mining technology of steeply dipping seam. J. China Coal Soc. 2014, 39, 1611–1618. [Google Scholar]

- Yao, Q.; Li, X.; Sun, B.; Ju, M.; Chen, T.; Zhou, J.; Liang, S.; Qu, Q. Numerical investigation of the effects of coal seam dip angle on coal wall stability. Int. J. Rock Mech. Min. Sci. 2017, 100, 298–309. [Google Scholar] [CrossRef]

- Rak, Z.; Stasica, J.; Burtan, Z.; Chlebowski, D. Technical Aspects of Mining Rate Improvement in Steeply Inclined Coal Seams: A Case Study. Resources 2020, 9, 138. [Google Scholar] [CrossRef]

- Mikkelsen, P.E.; Green, G.E. Piezometers in Fully Grouted Boreholes. In Proceedings of the 6th International Symposium on Field Measurements in Geomechanics, Oslo, Norway, 15–18 September 2013. [Google Scholar]

- Zhang, J.; Liu, T. On depth of fissured zone in seam floor resulted from coal extraction and its distribution characteristics. J. China Coal Soc. 1990, 15, 46–55. [Google Scholar]

- Cao, M.; Yin, S.; Xu, B. Water inrush and failure characteristics of coal seam floor over a confined aquifer. Energy Rep. 2021, 7, 8298–8311. [Google Scholar] [CrossRef]

- Islavath, S.A.; Deb, D.; Kumar, H. Numerical analysis of a longwall mining cycle and development of a composite longwall index. Int. J. Rock Mech. Min. Sci. 2016, 89, 43–54. [Google Scholar] [CrossRef]

- Xie, J.; Xu, J.; Wang, F. Mining-induced stress distribution of the working face in a kilometer-deep coal mine—A case study in Tangshan coal mine. J. Geophys. Eng. 2018, 15, 2060–2070. [Google Scholar] [CrossRef] [Green Version]

- State Administration of Work Safety of China (SAWSC). Regulations for Prevention and Control of Outbursts of Coal and Gas; China Coal Industry Publishing House: Beijing, China, 2009. [Google Scholar]

- Zhang, J. Investigations of water inrushes from aquifers under coal seams. Int. J. Rock Mech. Min. Sci. 2005, 42, 350–360. [Google Scholar] [CrossRef]

- Qu, Q.; Guo, H.; Wilkins, A. Using stress relief ratio to delineate optimal methane drainage zone in longwall goaf. In Proceedings of the 11th International Mine Ventilation Congress, Xi’an, China, 14–20 September 2018; Chang, X., Ed.; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

| Longwall | Installation Roadway | Installed Instruments | Instruments Depths or Depth Range |

|---|---|---|---|

| LW 5121(5) | Longwall belt roadway | 5 extensometers | 1–8 m |

| 9 stressmeters | 1–8 m | ||

| C13 floor roadway (−780 m) | 2 extensometers | 1–21 m | |

| 3 stressmeters | 20 m, 28 m, 30 m | ||

| 10 piezometers | 3–16 m | ||

| C15 roof roadway (−780 m) | 2 stressmeters | 20 m, 21 m | |

| 3 piezometers | 13 m, 23 m, 33 m | ||

| LW 5111(0) | Longwall intake roadway | 5 extensometers | 2–25 m |

| 4 stressmeters | 19–35 m | ||

| B10 floor roadway (−720 m) | 3 extensometers | 2–25 m | |

| 2 stressmeters | 9 m, 10 m | ||

| 2 piezometers | 4–16 m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, Q.; Guo, H.; Yuan, L.; Shen, B.; Yu, G.; Qin, J. Rock Mass and Pore Fluid Response in Deep Mining: A Field Monitoring Study at Inclined Longwalls. Minerals 2022, 12, 463. https://doi.org/10.3390/min12040463

Qu Q, Guo H, Yuan L, Shen B, Yu G, Qin J. Rock Mass and Pore Fluid Response in Deep Mining: A Field Monitoring Study at Inclined Longwalls. Minerals. 2022; 12(4):463. https://doi.org/10.3390/min12040463

Chicago/Turabian StyleQu, Qingdong, Hua Guo, Liang Yuan, Baotang Shen, Guofeng Yu, and Johnny Qin. 2022. "Rock Mass and Pore Fluid Response in Deep Mining: A Field Monitoring Study at Inclined Longwalls" Minerals 12, no. 4: 463. https://doi.org/10.3390/min12040463