Ductile vs. Brittle Strain Localization Induced by the Olivine–Ringwoodite Transformation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Starting Material

2.2. Deformation Experiments

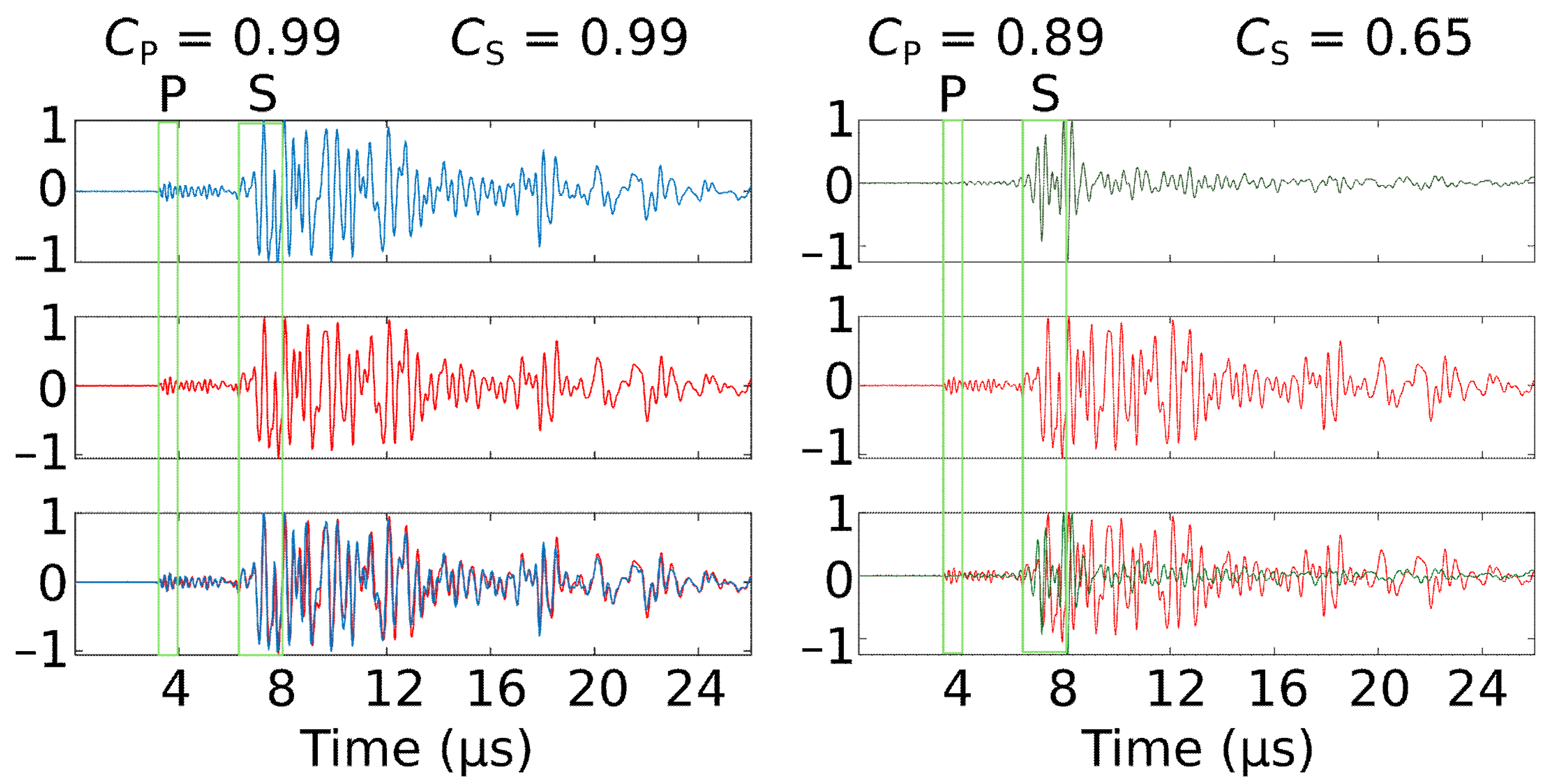

2.3. AE Analysis

2.4. SEM Imaging and Processing

3. Results

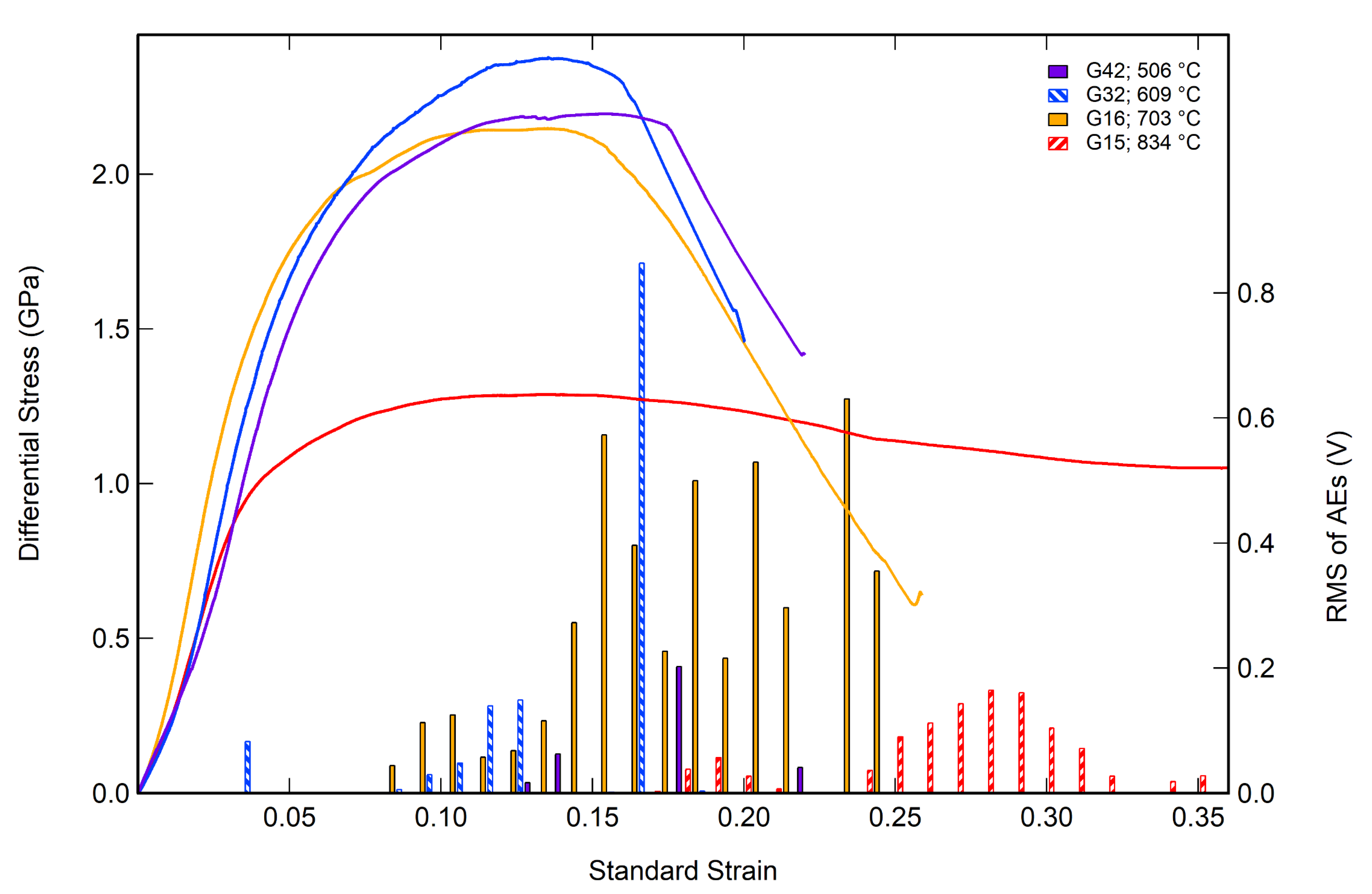

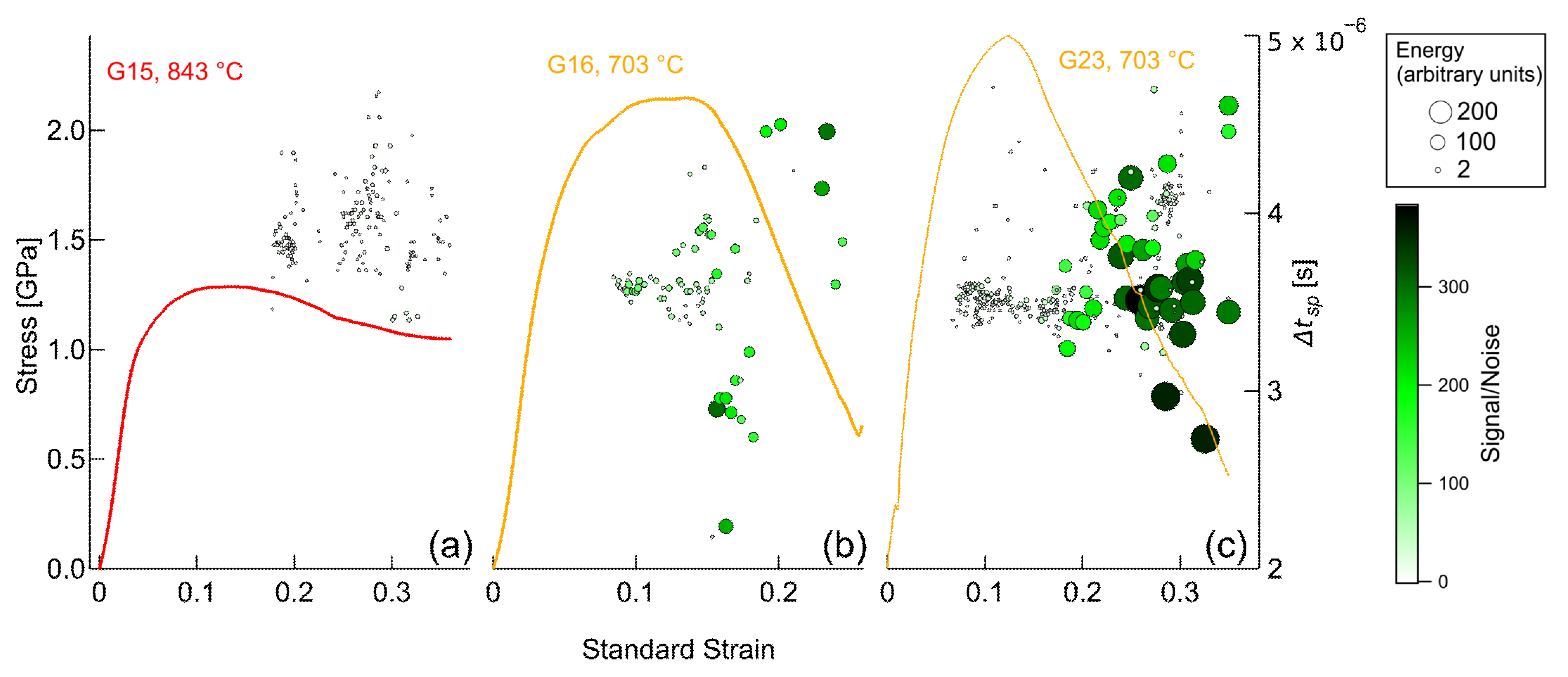

3.1. Mechanical Data and Acoustic Emissions

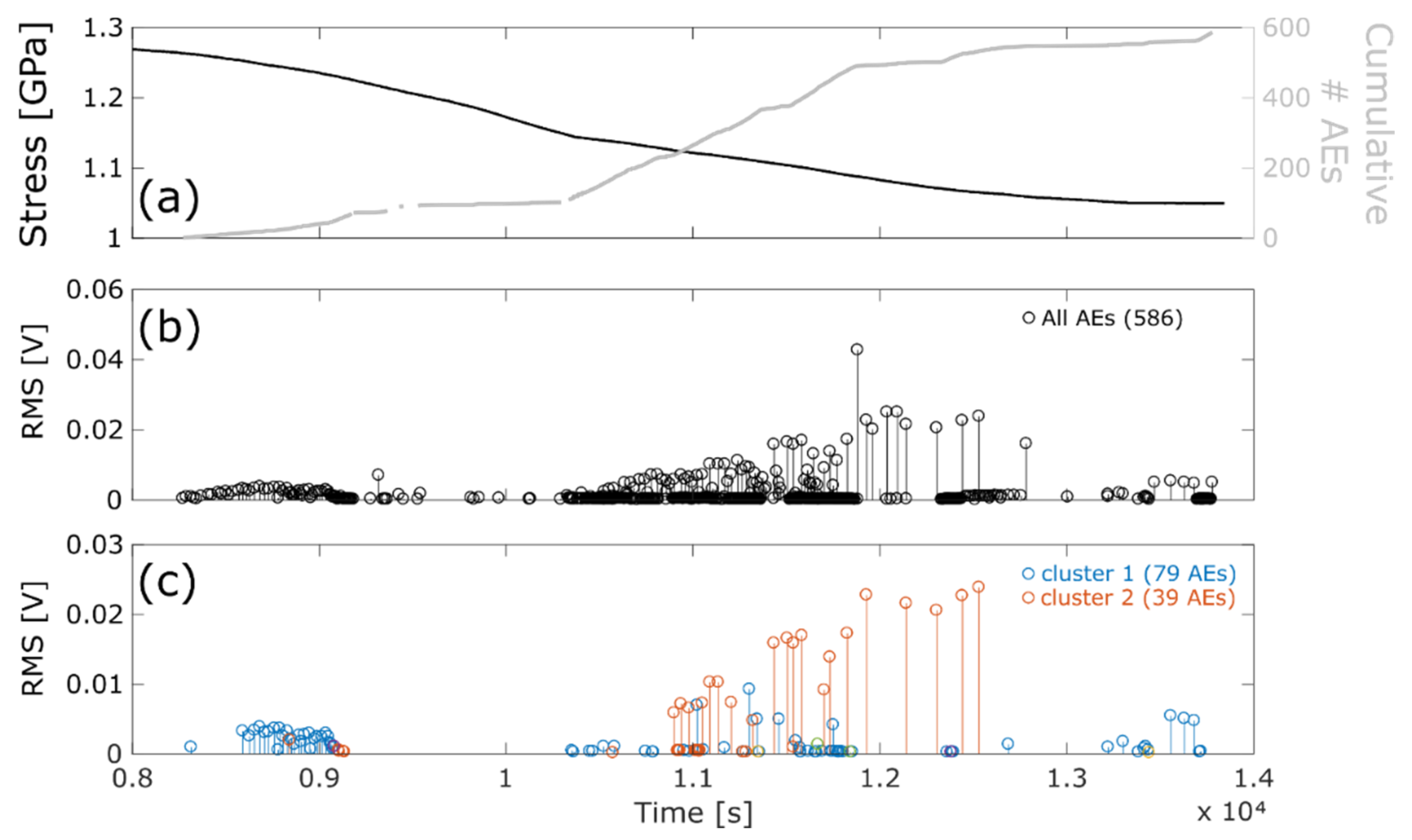

3.1.1. High-Temperature Regime

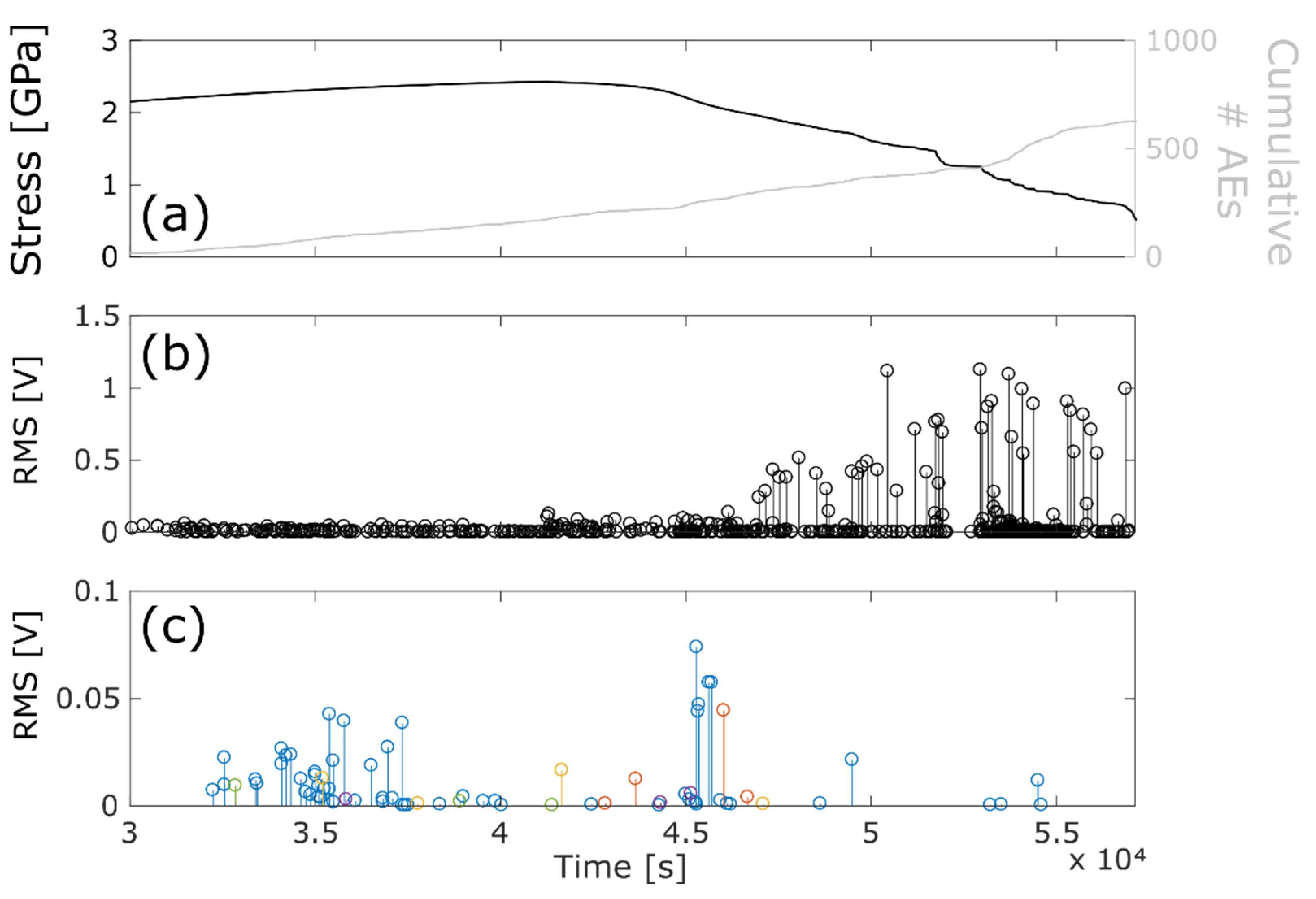

3.1.2. Intermediate Temperature Range

3.1.3. Low-Temperature Regime

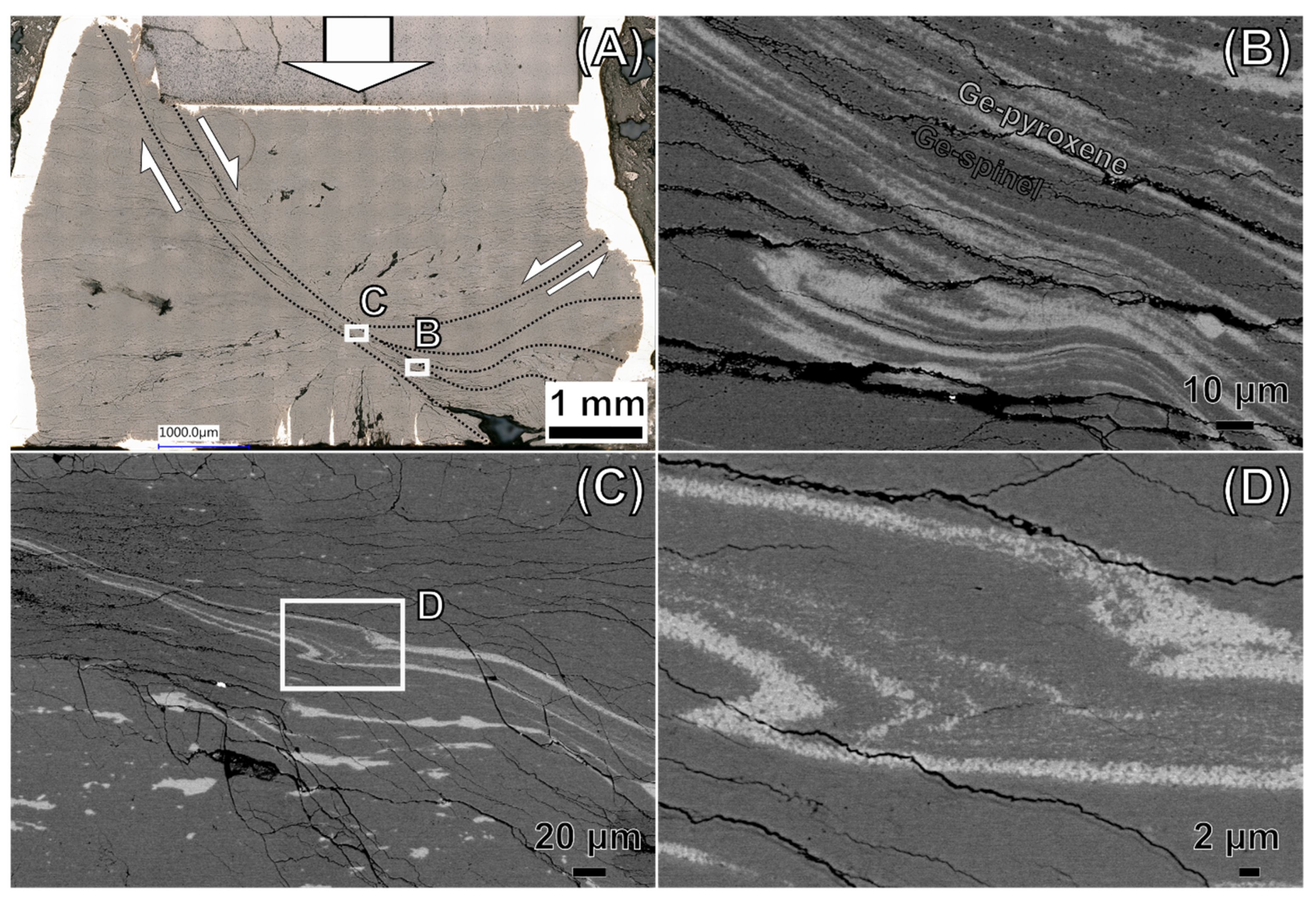

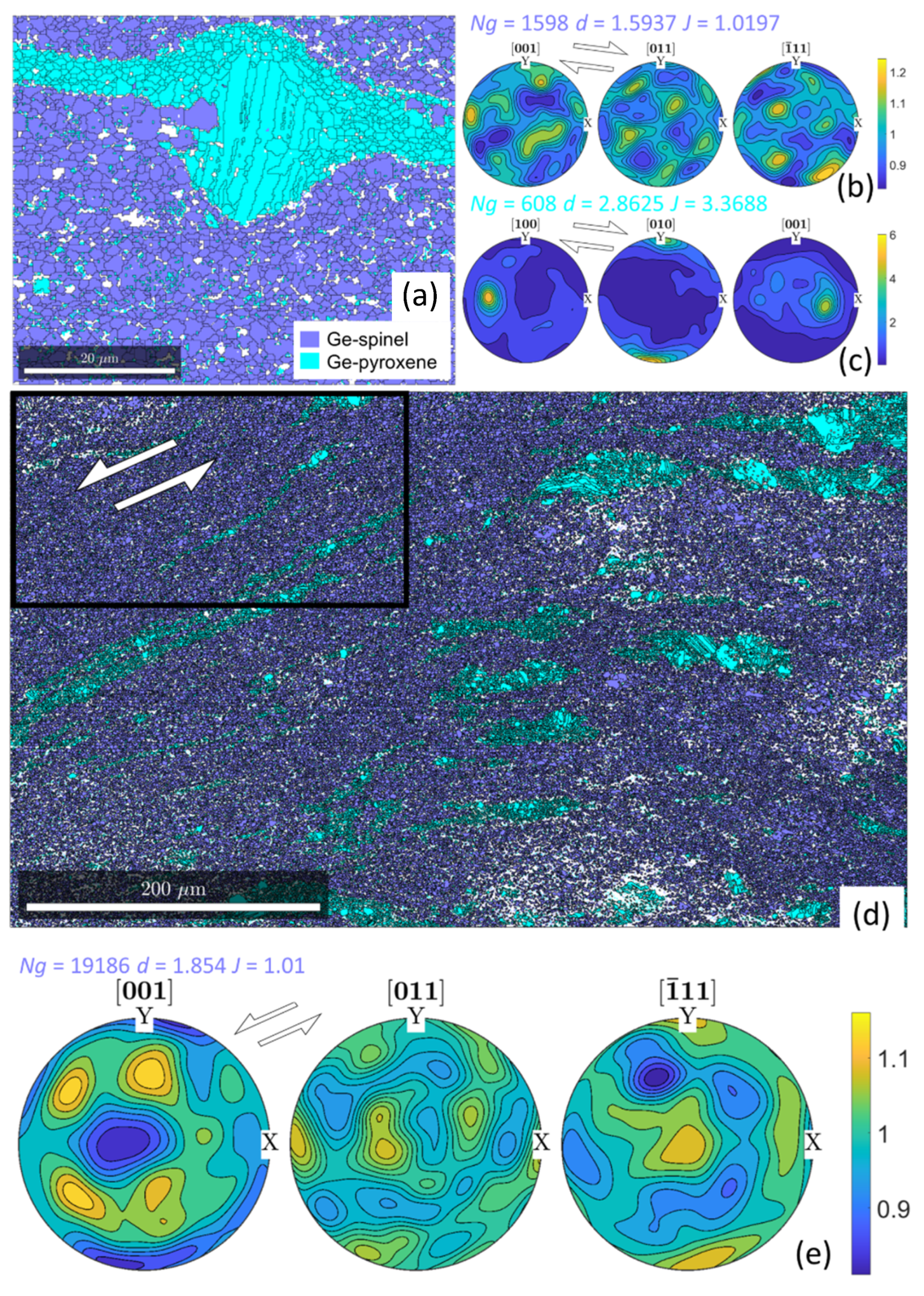

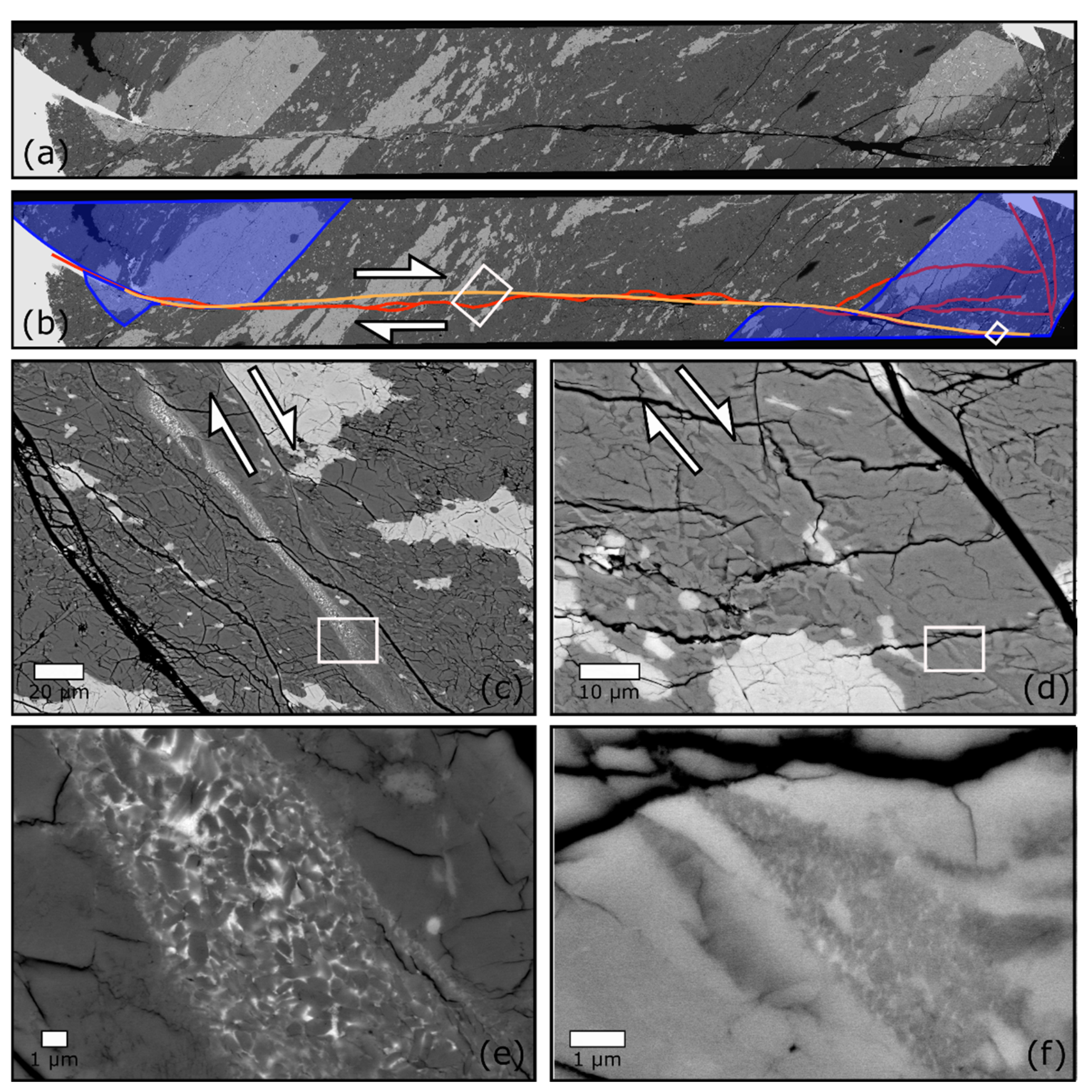

3.2. Microstructural Analysis

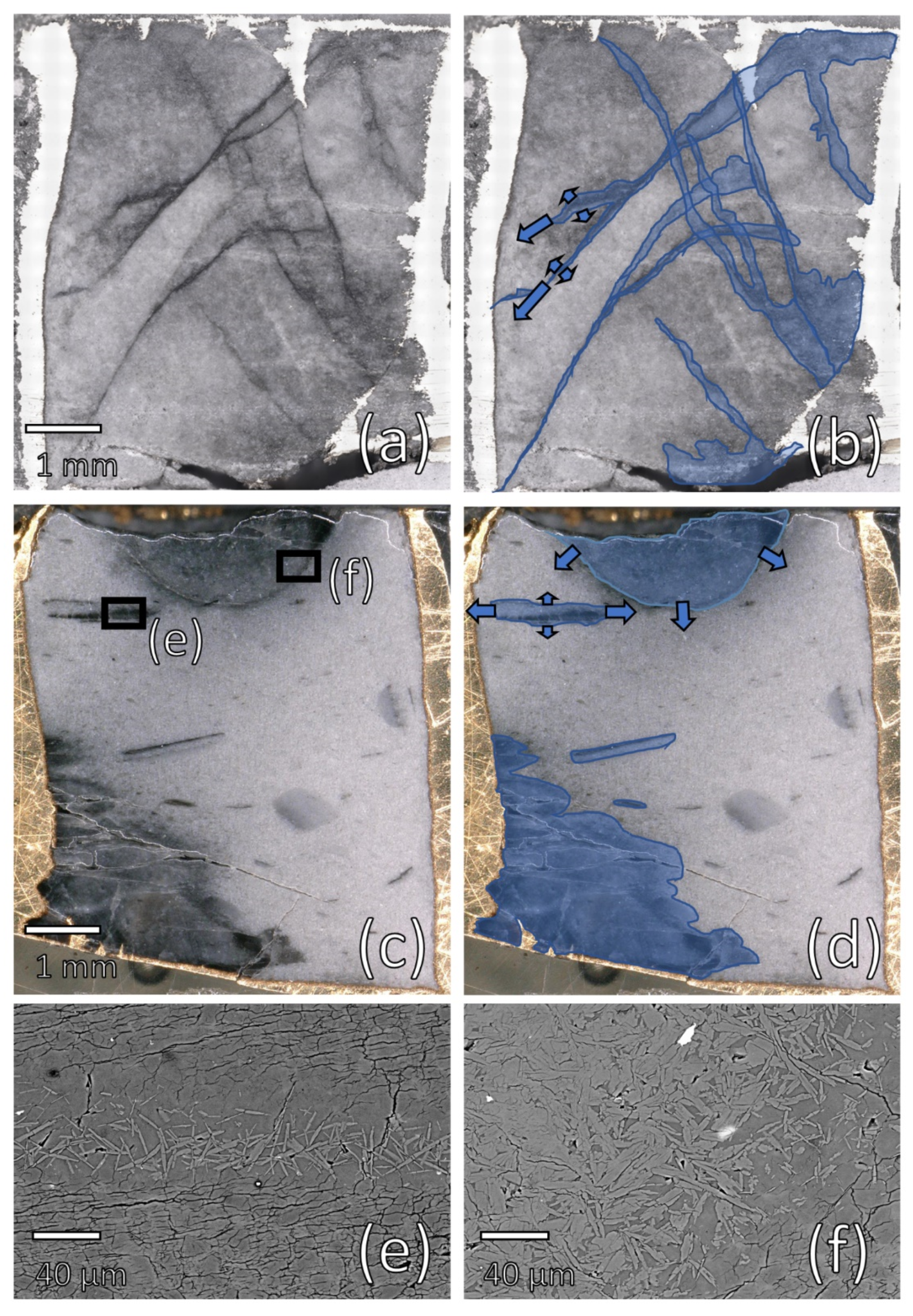

3.2.1. Ductile Localization with Rapid Ge-Spinel Growth

3.2.2. Slow Spinel Growth and Transformational Faulting

3.2.3. Transformational Faulting and Frictional Melt Production

3.2.4. Low-Temperature Plasticity

3.3. AE 1D Locations and Clustering

4. Discussion

4.1. Transformational Faulting as a Function of Strain-Rate and Reaction Kinetic

4.2. Mechanisms behind Transformational Faulting

4.2.1. A Conceptual Model for Unstable Anti-Crack Propagation

4.2.2. The Role of Latent Heat Release

4.3. High Temperature Ductile Transformation

4.4. Implications for Seismic Versus Ductile Strain Localization in the Transition Zone

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kirby, S.H.; Stein, S.; Okal, E.A.; Rubie, D.C. Metastable mantle phase transformations and deep earthquakes in subducting oceanic lithosphere. Rev. Geophys. 1996, 34, 261–306. [Google Scholar] [CrossRef]

- Rubie, D.C. The olivine→Spinel transformation and the rheology of subducting lithosphere. Nature 1984, 308, 505–508. [Google Scholar] [CrossRef]

- Rubie, C.D.; Ross, C.R. Kinetics of the olivine-spinel transformation in subducting lithosphere—Experimental constraints and implications for deep slab processes. Phys. Earth Planet. Inter. 1994, 86, 223–241. [Google Scholar] [CrossRef]

- Ritterbex, S.; Carrez, P.; Cordier, P. Deformation across the mantle transition zone: A theoretical mineral physics view. Earth Planet. Sci. Lett. 2020, 547, 116438. [Google Scholar] [CrossRef]

- Mohiuddin, A.; Karato, S.-I.; Girard, J. Slab weakening during the olivine to ringwoodite transition in the mantle. Nat. Geosci. 2020, 13, 170–174. [Google Scholar] [CrossRef]

- Panasyuk, V.S.; Hager, B.H. A model of transformational superplasticity in the upper mantle. Geophys. J. Int. 1998, 133, 741–755. [Google Scholar] [CrossRef] [Green Version]

- Perrillat, J.P.; Chollet, M.; Durand, S.; van de Moortèle, B.; Chambat, F.; Mezouar, M.; Daniel, I. Kinetics of the olivine—Ringwoodite transformation and seismic attenuation in the Earth’s mantle transition zone. Earth Planet. Sci. Lett. 2016, 433, 360–369. [Google Scholar] [CrossRef]

- Mosenfelder, J.L.; Marton, F.C.; Ross, C.R., II; Kerschhofer, L.; Rubie, D.C. Experimental constraints on the depth of olivine metastability in subducting lithosphere. Phys. Earth Planet. Inter. 2001, 127, 165–180. [Google Scholar] [CrossRef]

- Du Frane, W.L.; Sharp, T.G.; Mosenfelder, J.L.; Leinenweber, K. Ringwoodite growth rates from olivine with similar to 75 ppmw H2O: Metastable olivine must be nearly anhydrous to exist in the mantle transition zone. Phys. Earth Planet. Inter. 2013, 219, 1–10. [Google Scholar] [CrossRef]

- Ishii, T.; Ohtani, E. Dry metastable olivine and slab deformation in a wet subducting slab. Nat. Geosci. 2021, 14, 526–530. [Google Scholar] [CrossRef]

- Shen, C.Z.; Zhan, Z.W. Metastable olivine wedge beneath the Japan sea imaged by seismic interferometry. Geophys. Res. Lett. 2020, 47, e2019GL085665. [Google Scholar] [CrossRef]

- Jiang, G.; Zhao, D.; Zhang, G. Detection of metastable olivine wedge in the western Pacific slab and its geodynamic implications. Phys. Earth Planet. Inter. 2015, 238, 1–7. [Google Scholar] [CrossRef]

- Kawakatsu, H.; Yoshioka, S. Metastable olivine wedge and deep dry cold slab beneath southwest Japan. Earth Planet. Sci. Lett. 2011, 303, 1–10. [Google Scholar] [CrossRef]

- Zhan, Z. Mechanisms and implications of deep earthquakes. Annu. Rev. Earth Planet. Sci. 2020, 48, 147–174. [Google Scholar] [CrossRef]

- Burnley, P.C.; Green, H.W.; Prior, D.J. Faulting associated with the olivine to spinel transformation in Mg2GeO4and its implications for deep-focus earthquakes. J. Geophys. Res. Earth Surf. 1991, 96, 425–443. [Google Scholar] [CrossRef]

- Green, W.H.; Burnley, P.C. A new self-organizing mechanism for deep-focus earthquakes. Nature 1989, 341, 733–737. [Google Scholar] [CrossRef]

- Wiens, A.D. Seismological constraints on the mechanism of deep earthquakes: Temperature dependence of deep earthquake source properties. Phys. Earth Planet. Inter. 2001, 127, 145–163. [Google Scholar] [CrossRef]

- Wiens, A.D.; Snider, N.O. Repeating deep earthquakes: Evidence for fault reactivation at great depth. Science 2001, 293, 1463–1466. [Google Scholar] [CrossRef] [Green Version]

- McGuire, J.J.; Wiens, D.A.; Shore, P.J.; Bevis, M.G. The March 9, 1994 (Mw7.6), deep Tonga earthquake: Rupture outside the seismically active slab. J. Geophys. Res. Earth Surf. 1997, 102, 15163–15182. [Google Scholar] [CrossRef]

- Zhan, Z. Gutenberg–Richter law for deep earthquakes revisited: A dual-mechanism hypothesis. Earth Planet. Sci. Lett. 2017, 461, 1–7. [Google Scholar] [CrossRef]

- Green, H.W.; Young, T.E.; Walker, D.; Scholz, C.H. Erratum: Anticrack-associated faulting at very high pressure in natural olivine. Nature 1991, 349, 264. [Google Scholar] [CrossRef] [Green Version]

- Schubnel, A.; Brunet, F.; Hilairet, N.; Gasc, J.; Wang, Y.; Green, H.W. Deep-Focus earthquake analogs recorded at high pressure and temperature in the laboratory. Science 2013, 341, 1377–1380. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhu, L.; Shi, F.; Schubnel, A.; Hilairet, N.; Yu, T.; Rivers, M.; Gasc, J.; Addad, A.; Deldicque, D.; et al. A laboratory nanoseismological study on deep-focus earthquake micromechanics. Sci. Adv. 2017, 3, e1601896. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moarefvand, A.; Gasc, J.; Fauconnier, J.; Baïsset, M.; Burdette, E.; Labrousse, L.; Schubnel, A. A new generation Griggs apparatus with active acoustic monitoring. Tectonophysics 2021, 816, 229032. [Google Scholar] [CrossRef]

- Ross, L.N.; Navrotsky, A. The Mg2GeO4 olivine-spinel phase-transition. Phys. Chem. Miner. 1987, 14, 473–481. [Google Scholar] [CrossRef]

- Précigout, J.; Stünitz, H.; Pinquier, Y.; Champallier, R.; Schubnel, A. High-pressure, high-temperature deformation experiment using the new generation griggs-type apparatus. J. Vis. Exp. 2018, 134, e56841. [Google Scholar] [CrossRef] [Green Version]

- Dachille, F.; Roy, R. Spinel-olivine inversion in Mg2GeO4. Nature 1959, 183, 1257. [Google Scholar] [CrossRef]

- Weidner, J.D.; Hamaya, N. Elastic properties of the olivine and spinel polymorphs of Mg2GeO4, and evaluation of elastic analogs. Phys. Earth Planet. Inter. 1983, 33, 275–283. [Google Scholar] [CrossRef]

- Meredith, G.P.; Main, I.G.; Jones, C. Temporal variations in seismicity during quasi-static and dynamic rock failure. Tectonophysics 1990, 175, 249–268. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture analysis with MTEX—Free and open source software toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar]

- Ohuchi, T.; Fujino, K.; Kawazoe, T.; Irifune, T. Crystallographic preferred orientation of wadsleyite and ringwoodite: Effects of phase transformation and water on seismic anisotropy in the mantle transition zone. Earth Planet. Sci. Lett. 2014, 397, 133–144. [Google Scholar] [CrossRef]

- Gasc, J.; Demouchy, S.; Barou, F.; Koizumi, S.; Cordier, P. Creep mechanisms in the lithospheric mantle inferred from deformation of iron-free forsterite aggregates at 900–1200 °C. Tectonophysics 2019, 761, 16–30. [Google Scholar] [CrossRef]

- Ohuchi, T.; Nishihara, Y.; Seto, Y.; Kawazoe, T.; Nishi, M.; Maruyama, G.; Hashimoto, M.; Higo, Y.; Funakoshi, K.-I.; Suzuki, A.; et al. In Situ observation of crystallographic preferred orientation of deforming olivine at high pressure and high temperature. Phys. Earth Planet. Inter. 2015, 243, 1–21. [Google Scholar] [CrossRef]

- Gasc, J.; Daigre, C.; Moarefvand, A.; Deldicque, D.; Fauconnier, J.; Gardonio, B.; Madonna, C.; Burnley, P.C.; Schubnel, A. Deep-focus earthquakes: From high-temperature experiments to cold slabs. Geology 2022, in press. [Google Scholar] [CrossRef]

- Burnley, C.P.; Green, H.W. Stress dependence of the mechanism of the olivine spinel transformation. Nature 1989, 338, 753–756. [Google Scholar] [CrossRef]

- Burnley, P.C. The fate of olivine in subducting slabs; a reconnaissance study. Am. Miner. 1995, 80, 1293–1301. [Google Scholar] [CrossRef]

- Incel, S.; Labrousse, L.; Hilairet, N.; John, T.; Gasc, J.; Shi, F.; Wang, Y.; Andersen, T.B.; Renard, F.; Jamtveit, B.; et al. Reaction-induced embrittlement of the lower continental crust. Geology 2019, 47, 235–238. [Google Scholar] [CrossRef]

- Rutter, H.E.; Brodie, K.H. Experimental syntectonic dehydration of serpentinite under conditions of controlled pore water-pressure. J. Geophys. Res.-Solid Earth Planets 1988, 93, 4907–4932. [Google Scholar] [CrossRef]

- Miyamoto, Y.; Takubo, H.; Kume, S.; Koizumi, M. Melting of Mg2GeO4 under pressure. Bull. Volcanol. 1978, 41, 664–669. [Google Scholar] [CrossRef]

- Kirby, S.H. Localized polymorphic phase-transformations in high-pressure faults and applications to the physical-mechanism of deep earthquakes. J. Geophys. Res.-Solid Earth Planets 1987, 92, 13789–13800. [Google Scholar] [CrossRef]

- Green, W.H.; Zhou, Y. Transformation-induced faulting requires an exothermic reaction and explains the cessation of earthquakes at the base of the mantle transition zone. Tectonophysics 1996, 256, 39–56. [Google Scholar] [CrossRef]

- Faul, U.H.; Fitz Gerald, J.D.; Farla, R.J.M.; Ahlefeldt, R.; Jackson, I. Dislocation creep of fine-grained olivine. J. Geophys. Res.-Solid Earth 2011, 116. [Google Scholar] [CrossRef] [Green Version]

- Hirth, G.; Kohlstedt, D. The stress dependence of olivine creep rate: Implications for extrapolation of lab data and interpretation of recrystallized grain size. Earth Planet. Sci. Lett. 2015, 418, 20–26. [Google Scholar] [CrossRef]

- Kerschhofer, L.; Rubie, D.; Sharp, T.; McConnell, J.; Dupas-Bruzek, C. Kinetics of intracrystalline olivine—Ringwoodite transformation. Phys. Earth Planet. Inter. 2000, 121, 59–76. [Google Scholar] [CrossRef]

- Officer, T.; Secco, R.A. Detection of high P,T transformational faulting in Fe2SiO4 via In Situ acoustic emission: Relevance to deep-focus earthquakes. Phys. Earth Planet. Inter. 2020, 300, 106429. [Google Scholar] [CrossRef]

- Burnley, P.C. Investigation of the martensitic-like transformation from Mg2GeO4 olivine to its spinel structure polymorph. Am. Miner. 2005, 90, 1315–1324. [Google Scholar] [CrossRef]

- Green, H.W. Shearing instabilities accompanying high-pressure phase transformations and the mechanics of deep earthquakes. Proc. Natl. Acad. Sci. USA 2007, 104, 9133–9138. [Google Scholar] [CrossRef] [Green Version]

- Kerschhofer, L.; Dupas, C.; Liu, M.; Sharp, T.G.; Durham, W.B.; Rubie, D.C. Polymorphic transformations between olivine, wadsleyite and ringwoodite: Mechanisms of intracrystalline nucleation and the role of elastic strain. Miner. Mag. 1998, 62, 617–638. [Google Scholar] [CrossRef]

- Liu, M.; Kerschhofer, L.; Mosenfelder, J.L.; Rubie, D.C. The effect of strain energy on growth rates during the olivine-spinel transformation and implications for olivine metastability in subducting slabs. J. Geophys. Res. Earth Surf. 1998, 103, 23897–23909. [Google Scholar] [CrossRef]

- Kirby, H.S.; Durham, W.B.; Stern, L.A. Mantle phase-changes and deep-earthquake faulting in subducting lithosphere. Science 1991, 252, 216–225. [Google Scholar] [CrossRef] [Green Version]

- Green, W.H.; Houston, H. The mechanics of deep earthquakes. Annu. Rev. Earth Planet. Sci. 1995, 23, 169–213. [Google Scholar] [CrossRef]

- Yamazaki, D.; Inoue, T.; Okamoto, M.; Irifune, T. Grain growth kinetics of ringwoodite and its implication for rheology of the subducting slab. Earth Planet. Sci. Lett. 2005, 236, 871–881. [Google Scholar] [CrossRef]

- Leydier, T.; Goncalves, P.; Lanari, P.; Oliot, E. On the petrology of brittle precursors of shear zones—An expression of concomitant brittle deformation and fluid-rock interactions in the ‘ductile’ continental crust? J. Metamorph. Geol. 2019, 37, 1129–1149. [Google Scholar] [CrossRef]

- Menegon, L.; Pennacchioni, G.; Malaspina, N.; Harris, K.; Wood, E. Earthquakes as precursors of ductile shear zones in the dry and strong lower crust. Geochem. Geophys. Geosystems 2017, 18, 4356–4374. [Google Scholar] [CrossRef] [Green Version]

- Wiens, D.A.; McGuire, J.J.; Shore, P.J. Evidence for transformational faulting from a deep double seismic zone in Tonga. Nature 1993, 364, 790–793. [Google Scholar] [CrossRef]

- Wiens, A.D.; Gilbert, H.J. Effect of slab temperature on deep-earthquake aftershock productivity and magnitude-frequency relations. Nature 1996, 384, 153–156. [Google Scholar] [CrossRef]

- Yoshioka, S.; Torii, Y.; Riedel, M.R. Impact of phase change kinetics on the Mariana slab within the framework of 2-D mantle convection. Phys. Earth Planet. Inter. 2015, 240, 70–81. [Google Scholar] [CrossRef] [Green Version]

- Warren, L.M.; Hughes, A.N.; Silver, P.G. Earthquake mechanics and deformation in the Tonga-Kermadec subduction zone from fault plane orientations of intermediate- and deep-focus earthquakes. J. Geophys. Res. Earth Surf. 2007, 112. [Google Scholar] [CrossRef] [Green Version]

- Yu, C.W.; Wen, L.X. Deep-focus repeating earthquakes in the Tonga-Fiji subduction zone. Bull. Seismol. Soc. Am. 2012, 102, 1829–1849. [Google Scholar] [CrossRef]

- Myhill, R.; McKenzie, D.; Priestley, K. The distribution of earthquake multiplets beneath the southwest Pacific. Earth Planet. Sci. Lett. 2010, 301, 87–97. [Google Scholar] [CrossRef]

- Gardonio, B.; Schubnel, A.; Das, S.; Lyon-Caen, H.; Marsan, D.; Bouchon, M.; Kato, A. The preseismic and postseismic phases of the similar to 700 km deep M(w)7.9 Bonin Islands earthquake, Japan. Geophys. Res. Lett. 2020, 47. [Google Scholar] [CrossRef]

| Experiment # | T (°C) | Duration (s) | Final Volume Fraction of Ge-Spinel | Peak Stress (GPa) | Strain Rate at Peak Stress (× 10–5 s–1) | Mechanical Behaviour | Number of AEs | AEs Cumulated RMS (V) | b-Value |

|---|---|---|---|---|---|---|---|---|---|

| G15 | 843 | 13,844 | 0.8 | 1.29 | 2.79 | Ductile | 586 | 1.12 | 1.5 (0.070) |

| G43 | 834 | 54,953 | 0.95 | 1.31 | 0.495 | Ductile | 0 | 0 | - |

| G16 | 703 | 9592 | 0.2 | 2.15 | 2.69 | Faulting | 147 | 4.55 | 0.52 (0.042) |

| G22 | 703 | 6230 | 0.05 | 2.23 | 4.31 | Faulting | 64 | 2.00 | 0.77 (0.095) |

| G23 | 703 | 57,462 | 0.2 | 2.43 | 0.602 | Faulting | 633 | 1.01 | 0.62 (0.024) |

| G32 | 609 | 25,449 | 0.1 | 2.37 | 0.998 | Faulting | 32 | 1.33 | 1.1 (0.18) |

| G42 | 506 | 7777 | 0.01 | 2.19 | 3.54 | Faulting | 7 | 0.33 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gasc, J.; Gardonio, B.; Deldicque, D.; Daigre, C.; Moarefvand, A.; Petit, L.; Burnley, P.; Schubnel, A. Ductile vs. Brittle Strain Localization Induced by the Olivine–Ringwoodite Transformation. Minerals 2022, 12, 719. https://doi.org/10.3390/min12060719

Gasc J, Gardonio B, Deldicque D, Daigre C, Moarefvand A, Petit L, Burnley P, Schubnel A. Ductile vs. Brittle Strain Localization Induced by the Olivine–Ringwoodite Transformation. Minerals. 2022; 12(6):719. https://doi.org/10.3390/min12060719

Chicago/Turabian StyleGasc, Julien, Blandine Gardonio, Damien Deldicque, Clémence Daigre, Arefeh Moarefvand, Léo Petit, Pamela Burnley, and Alexandre Schubnel. 2022. "Ductile vs. Brittle Strain Localization Induced by the Olivine–Ringwoodite Transformation" Minerals 12, no. 6: 719. https://doi.org/10.3390/min12060719