Characterisation and Environmental Significance of Glauconite from Mining Waste of the Egorievsk Phosphorite Deposit

Abstract

:1. Introduction

2. Geological Background

3. Materials and Methods

4. Results

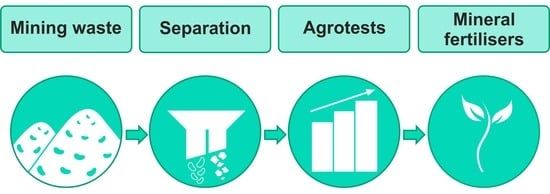

4.1. Research and Enrichment of Glauconite from Waste of the Egorievsk Deposit

4.1.1. Characteristics of Mining Waste from the Deposit and Enrichment of Glauconite Concentrate

4.1.2. Mineralogical and Geochemical Features of Glauconite

4.2. Investigation of Glauconite Application in Laboratory Conditions

5. Discussion

5.1. Mining Waste Enrichment

5.2. Morphology and Chemical Composition of Glauconite: Key Factors Determining Usefulness in the Agricultural Sector

5.3. Microinclusions in Glauconite and Their Role for Plants

5.4. Agrotests

6. Conclusions

- (1)

- Concentrating glauconite among the loose waste contributes to the economically available enrichment of the mineral concentrate by means of electromagnetic separation with the fraction of the useful component being 86%.

- (2)

- Morphological and structural–chemical features of the glauconite allow it to be referred to as a mature, rather discrete variety. The proportion of ion exchangeable potassium up to 9% and the favourable globular shape of the grains indicate the potential use of glauconite from mining waste as a mineral fertiliser.

- (3)

- The presence of apatite and pyrite inclusions in glauconite significantly increases the value of the fertiliser. Pyrite makes sulphur available to plants, while apatite releases phosphorus in acidic soils and reduces the risk of heavy metal contamination. These factors make this fertiliser more effective and environmentally safe.

- (4)

- Glauconite rocks and glauconite concentrate demonstrated a positive effect on plant growth and development in laboratory experiments. The yield of common oats (Avena sativa) increased by 3.5% and 6.3% when glauconite-containing rocks and glauconite concentrate from the mining waste of the phosphorite deposit were used, respectively.

- (5)

- Egorievsk waste fertiliser can be most beneficial when used on acidic soils and in regions with limited moisture.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Falls, J.H.; Siegel, S.A.; Industries, C.F.; City, P. Fertilisers Types of Fertilizer Materials Analytical Methods for Nitrogen; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar] [CrossRef]

- Rakesh, S.; Juttu, R.; Bairi, R. Glauconite: An Indigenous and Alternative Source of Potassium Fertilizer for Sustainable Agriculture. Int. J. Bioresour. Sci. 2020, 7, 17–19. [Google Scholar] [CrossRef]

- Zörb, C.; Senbayram, M.; Peiter, E. Potassium in agriculture—Status and perspectives. J. Plant Physiol. 2014, 171, 656–669. [Google Scholar] [CrossRef] [PubMed]

- Shekhar, S.; Sinha, S.; Mishra, D.; Agrawal, A.; Sahu, K.K. A sustainable process for recovery of potash fertilizer from glauconite through simultaneous production of pigment grade red oxide. Sustain. Mater. Technol. 2020, 23, e00129. [Google Scholar] [CrossRef]

- Manning, D.A.C. Mineral sources of potassium for plant nutrition. A review to cite this version: Mineral sources of potassium for plant nutrition. A review. Agron. Sustain. Dev. 2010, 30, 281–294. [Google Scholar] [CrossRef]

- Santos, W.O.; Mattiello, E.M.; Marciano, L.; Antônio, W.; Abrahão, P.; De Novais, R.F.; Cantarutti, R.B. Thermal and chemical solubilization of verdete for use as potassium fertilizer. Int. J. Miner. Process. 2015, 140, 72–78. [Google Scholar] [CrossRef]

- Shekhar, S.; Mishra, D.; Agrawal, A.; Sahu, K.K. Physical and chemical characterization and recovery of potash fertilizer from glauconitic clay for agricultural application. Appl. Clay Sci. 2017, 143, 50–56. [Google Scholar] [CrossRef]

- Borges, R.; Brunatto, S.F.; Leitão, A.A.; De Carvalho, G.S.G.; Wypych, F. Solid-state mechanochemical activation of clay minerals and soluble phosphate mixtures to obtain slow-release fertilisers. Clay Miner. 2015, 50, 153–162. [Google Scholar] [CrossRef]

- Borges, R.; Prevot, V.; Forano, C.; Wypych, F. Design and Kinetic Study of Sustainable Potential Slow-Release Fertilizer Obtained by Mechanochemical Activation of Clay Minerals and Potassium Monohydrogen Phosphate. Ind. Eng. Chem. Res. 2017, 56, 708–716. [Google Scholar] [CrossRef]

- Lei, Z.; Cagnetta, G.; Li, X.; Qu, J.; Li, Z.; Zhang, Q.; Huang, J. Enhanced adsorption of potassium nitrate with potassium cation on H3PO4 modified kaolinite and nitrate anion into Mg-Al layered double hydroxide. Appl. Clay Sci. 2018, 154, 10–16. [Google Scholar] [CrossRef]

- Rudmin, M.; Banerjee, S.; Mazurov, A.; Makarov, B.; Martemyanov, D. Economic potential of glauconitic rocks in Bakchar deposit (S-E Western Siberia) for alternate potash fertilizer. Appl. Clay Sci. 2017, 150, 225–233. [Google Scholar] [CrossRef]

- Rudmin, M.; Oskina, Y.; Banerjee, S.; Mazurov, A.; Soktoev, B.; Shaldybin, M. Roasting-leaching experiments on glauconitic rocks of Bakchar ironstone deposit (Western Siberia) for evaluation their fertilizer potential. Appl. Clay Sci. 2018, 162, 121–128. [Google Scholar] [CrossRef]

- Rudmin, M.; Banerjee, S.; Makarov, B.; Mazurov, A.; Ruban, A.; Oskina, Y.; Tolkachev, O.; Buyakov, A.; Shaldybin, M. An investigation of plant growth by the addition of glauconitic fertilizer. Appl. Clay Sci. 2019, 180, 105178. [Google Scholar] [CrossRef]

- Rudmin, M.; Banerjee, S.; Yakich, T.; Tabakaev, R.; Ibraeva, K.; Buyakov, A.; Soktoev, B.; Ruban, A. Formulation of a slow-release fertilizer by mechanical activation of smectite/glauconite and urea mixtures. Appl. Clay Sci. 2020, 196, 105775. [Google Scholar] [CrossRef]

- Odin, G.S.; Matter, A. De glauconiarum origine. Sedimentology 1981, 28, 611–641. [Google Scholar] [CrossRef]

- Dooley, J.H. Glauconite. In Industrial Minerals and Rocks: Commodities Market and Uses; Koger, J., Trivedi, N., Barrer, J., Krukowsky, N., Eds.; Society for Mining, Metallurgy and Exploration: Littleton, CO, USA, 2006; pp. 493–495. [Google Scholar]

- Banerjee, S.; Bansal, U.; Vilas Thorat, A. A review on palaeogeographic implications and temporal variation in glaucony composition. J. Palaeogeogr. 2016, 5, 43–71. [Google Scholar] [CrossRef]

- Banerjee, S.; Bansal, U.; Pande, K.; Meena, S.S. Compositional variability of glauconites within the Upper Cretaceous Karai Shale Formation, Cauvery Basin, India: Implications for evaluation of stratigraphic condensation. Sediment. Geol. 2016, 331, 12–29. [Google Scholar] [CrossRef]

- Amorosi, A. Detecting compositional, spatial, and temporal attributes of glaucony: A tool for provenance research. Sediment. Geol. 1997, 109, 135–153. [Google Scholar] [CrossRef]

- Sing, S.; Bhadauria, R.; Tomar, R. Sorption of Cd2+, Hg2+ and Pb2+ by synthetic analogue of mica mineral glauconitic. J. Appl. Chem. 2010, 6, 287–295. [Google Scholar]

- Smith, E.H.; Lu, W.; Vengris, T.; Binkiene, R. Sorption of heavy metals by Lithuanian glauconite. Water Res. 1996, 30, 2883–2892. [Google Scholar] [CrossRef]

- Terentyev, Y.N.; Syrchina, N.V.; Bogatyryova, N.N.; Ashikhmina, T.Y.; Sazanov, A.V.; Sazanova, M.L.; Pugach, V.N.; Kozvonin, V.A.; Burkov, A.A. The use of glauconite for stabilization and improvement of ammonium nitrate agrochemical properties. Theor. Appl. Ecol. 2018, 2018, 61–67. [Google Scholar] [CrossRef]

- Karimi, E.; Abdolzadeh, A.; Sadeghipour, H.R.; Aminei, A. The potential of glauconitic sandstone as a potassium fertilizer for olive plants. Arch. Agron. Soil Sci. 2012, 58, 983–993. [Google Scholar] [CrossRef]

- dos Santos Torqueti, S.T.; Boldrin, K.V.F.; do Nascimento, Â.M.P.; de Oliveira Paiva, P.D.; Furtini Neto, A.E.; Luz, I.C.A. Fonte alternativa de potássio no cultivo do girassol ornamental. Agric. Sci. 2016, 40, 257–264. [Google Scholar] [CrossRef]

- Chafetz, H.S.; Reid, A. Syndepositional shallow-water precipitation of glauconitic minerals. Sediment. Geol. 2000, 136, 29–42. [Google Scholar] [CrossRef]

- Banerjee, S.; Farouk, S.; Nagm, E.; Choudhury, T.R.; Meena, S.S. High Mg-glauconite in the Campanian Duwi Formation of Abu Tartur Plateau, Egypt and its implications. J. Afr. Earth Sci. 2019, 156, 12–25. [Google Scholar] [CrossRef]

- Kechiched, R.; Laouar, R.; Bruguier, O.; Salmi-Laouar, S.; Kocsis, L.; Bosch, D.; Foufou, A.; Ameur-Zaimeche, O.; Larit, H. Glauconite-bearing sedimentary phosphorites from the Tébessa region (eastern Algeria): Evidence of REE enrichment and geochemical constraints on their origin. J. Afr. Earth Sci. 2018, 145, 190–200. [Google Scholar] [CrossRef]

- Wigley, R.; Compton, J.S. Oligocene to Holocene glauconite-phosphorite grains from the Head of the Cape Canyon on the western margin of South Africa. Deep-Sea Res. Part II Top. Stud. Oceanogr. 2007, 54, 1375–1395. [Google Scholar] [CrossRef]

- Banerjee, S.; Choudhury, T.R.; Saraswati, P.K.; Khanolkar, S. The formation of authigenic deposits during Paleogene warm climatic intervals: A review. J. Palaeogeogr. 2020, 9, 27. [Google Scholar] [CrossRef]

- Bezdeneznych, L.; Kharlamova, O.; Shmandiy, V.; Rigas, T. Research of adsorption properties of glauconite-based composite adsorbents. J. Ecol. Eng. 2020, 21, 147–154. [Google Scholar] [CrossRef]

- Chayka, O.; Petrushka, I.; Ruda, M.; Paranyak, N.; Matskiv, O. The minimization of impact of oil pollution on soils in the area of railways using glauconite. J. Water Land Dev. 2021, 49, 79–84. [Google Scholar] [CrossRef]

- Syrchina, N.V.; Pilip, L.V.; Ashikhmina, T.Y.; Kantor, G.Y. Effect of glauconite-containing wastes obtained during phosphorite enrichment on lead mobility in soils. Biol. Bull. 2022, 3, 350–360. [Google Scholar]

- Sobeih, M.M.; El-Shahat, M.F.; Osman, A.; Zaid, M.A.; Nassar, M.Y. Glauconite clay-functionalized chitosan nanocomposites for efficient adsorptive removal of fluoride ions from polluted aqueous solutions. RSC Adv. 2020, 10, 25567–25585. [Google Scholar] [CrossRef] [PubMed]

- El-mahllawy, M.S. An Investigation on the Effect of Cement Kiln Dust and Glauconite on the Properties of Acid Resisting Brick. International Journalof Science and Technology Volume. 2013, 2, 30–43. [Google Scholar]

- Peregudov, Y.S.; Mezhri, R.; Gorbunova, E.M.; Niftaliev, S.I. Glauconite-based sorbents for oil and oil products collection. Condens. Matter Interphases 2020, 22, 257–265. [Google Scholar] [CrossRef]

- Bushinsky, G.I. Petrography and some questions of genesis of Egorievsk phosphorites of Moscow Region. Bulletin of the Moscow Society of Nature Testers. Dep. Geol. 1937, 15, 438–471. (In Russian) [Google Scholar]

- Salman, M.I.; Yashina, A.V. Geostatistical analysis of geological and industrial parameters of the Egorievsk field of gallstone phosphorites. Min. Inf.-Anal. Bull. 2006, 7, 110–115. (In Russian) [Google Scholar]

- Kuzmin, A.N.N.; Kirikov, V.P.; Lukyanova, N.V.; Maksimov, A.V.; Kossovaya, I.O.; Evdokimova, N.R.; Gorbatsevich, V.V.; Savanin, G.V.; Kotlyar, A.V.; Samsonov. Savanin, G.V.; et al. State Geological Map of the Russian Federation. Scale 1:1,000,000, 3rd ed.; Central European Series. Sheet N-37—Moscow. Explanatory note.—St. Petersburg; Cartographic Factory VSEGEI: Saint Petersburg, Russia, 2015. (In Russian) [Google Scholar]

- Lygach, A.V. State-of-the-art and prospects of using Egorievsk nodular phosphorite in the Voskresensky district, Moscow region. Min. Inf. Anal. Bull. 2018, 2018, 29–37. [Google Scholar] [CrossRef]

- Lygach, A.V.; Ignatkina, V.A. Flotation properties of base minerals in Egorievsk nodular phosphorite. Min. Inf. Anal. Bull. 2018, 2018, 163–175. [Google Scholar] [CrossRef]

- Moore, D.M.; Reynolds, R.C. X-ray Diffraction and the Identification and Analysis of Clay Minerals; Illinois: State Geologycal Survey; Oxford University Press: Oxford, UK, 1989; p. 332. [Google Scholar]

- Bish, D.L.; Post, J.E. Quantitative mineralogical analysis using the Rietveld full-pattern fitting method. Am. Mineral. 1993, 78, 932–940. [Google Scholar]

- Rudmin, M.; Banerjee, S.; Makarov, B.; Belousov, P.; Kurovsky, A.; Ibraeva, K.; Buyakov, A. Glauconite-Urea Nanocomposites As Polyfunctional Controlled-Release Fertilisers. J. Soil Sci. Plant Nutr. 2022, 22, 4035–4046. [Google Scholar] [CrossRef]

- Paula De Souza, M.E.; Cardoso, I.M.; De Carvalho, A.M.X.; Lopes, A.P.; Jucksch, I.; Janssen, A. Rock Powder Can Improve Vermicompost Chemical Properties and Plant Nutrition: An On-farm Experiment. Commun. Soil Sci. Plant Anal. 2018, 49, 1–12. [Google Scholar] [CrossRef]

- Westfall, D.G.; Mortvedt, J.J.; Peterson, G.A.; Gangloff, W.J. Efficient and Environmentally Safe Use of Micronutrients in Agriculture. Commun. Soil Sci. Plant Anal. 2005, 36, 169–182. [Google Scholar] [CrossRef]

- GOST R 58658-2019; Products and Food with Improved Characteristics. Mineral Fertilisers. General Technical Conditions (with Amendments). Federal Agency for Technical Regulation and Metrology: Moscow, Russia, 2022. (In Russian)

- Cakmak, I.; Yazici, A.M. Magnesium: A forgotten element in crop production. Better Crops 2010, 94, 23–25. Available online: https://www.ksminerals-and-agriculture.com/en/pdf-articles/article-201006-better-crops-magnesium.pdf (accessed on 27 August 2023).

- Ishfaq, M.; Wang, Y.; Yan, M.; Wang, Z.; Wu, L.; Li, C.; Li, X. Physiological Essence of Magnesium in Plants and Its Widespread Deficiency in the Farming System of China. Front. Plant Sci. 2022, 13, 802274. [Google Scholar] [CrossRef]

- Eskandari, H. The Importance of Iron (Fe) in Plant Products and Mechanism of Its Uptake by Plants. J. Appl. Environ. Biol. Sci. 2011, 1, 448–452. [Google Scholar]

- Rout, G.R.; Sahoo, S. Role of iron in plant growth and metabolism. Rev. Agric. Sci. 2015, 3, 1–24. [Google Scholar] [CrossRef]

- Shatagin, N.N.; Iranmanesh, M.; Fazlavi, A. An Estimation of Heavy Metals Environmental Impact from Phosphorites of Egorievsk Deposit (Moskow Region, Russia). In Proceedings of the 4th International Iran and Russia Conference “Agriculture and Natural Resources”, Shahrekord, Iran, 8–10 September 2004; pp. 205–206. [Google Scholar]

- Iranmanesh, M. Assessment of Environmental Impact of Toxic Metals from Phosphorites of Egorievsk Deposit (Moscow region, Russia). In Proceedings of the X International Environmental Conference of Students and Young Scientists “Environmental Safety as a Key Factor of Sustainable Development”, Moscow, Russia, 25–27 April 2006. (In Russian). [Google Scholar]

- Iranmanesh, M.; Shatagin, N.N.; Baraboshkina, T.A. Ecogeology of Phosphorite Deposits of the Moskovskaya Syneclise. In Proceedings of the V International Scientific and Practical Conference “Science and the Latest Technologies in the Search, Exploration and Development of Mineral Deposits”, Dushanbe, Tajikistan, 12–15 June 2006; p. 011001. (In Russian). [Google Scholar]

- Das, C.K.; Srivastava, G.; Dubey, A.; Roy, M.; Jain, S.; Sethy, N.K.; Saxena, M.; Harke, S.; Sarkar, S.; Misra, K.; et al. Nano-iron pyrite seed dressing: A sustainable intervention to reduce fertilizer consumption in vegetable (beetroot, carrot), spice (fenugreek), fodder (alfalfa), and oilseed (mustard, sesamum) crops. Nanotechnol. Environ. Eng. 2016, 1, 2. [Google Scholar] [CrossRef]

- Ortas, I.; Kaya, Z.; Ercan, S. Effect of Pyrite Application on Wheat-Maize Growth and Nutrient Uptake Under Diverse Soil Conditions. J. Plant Nutr. 2015, 38, 295–309. [Google Scholar] [CrossRef]

- Tiwari, K.N.; Dwivedi, B.S.; Pathak, A.N. Evaluation of iron pyrites as sulphur fertilizer. Fertil. Res. 1984, 5, 235–243. [Google Scholar] [CrossRef]

- Guidry, M.W.; Mackenzie, F.T. Experimental study of igneous and sedimentary apatite dissolution. Geochim. Cosmochim. Acta 2003, 67, 2949–2963. [Google Scholar] [CrossRef]

- Valsami-Jones, E.; Ragnarsdottir, K.V.; Putnis, A.; Bosbach, D.; Kemp, A.J.; Cressey, G. The dissolution of apatite in the presence of aqueous metal cations at pH 2–7. Chem. Geol. 1998, 151, 215–233. [Google Scholar] [CrossRef]

- Zhenghua, W.; Xiaorong, W.; Yufeng, Z.; Lemei, D.; Yijun, C. Effects of apatite and calcium oxyphosphate on speciation and bioavailability of exogenous rare earth elements in the soil-plant system. Chem. Speciat. Bioavailab. 2001, 13, 49–56. [Google Scholar] [CrossRef]

| Na2O | MgO | Al2O3 | SiO2 | P2O5 | K2O | CaO | TiO2 | MnO | Fe2O3 | SUMM | LOI | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BS | 0.8 | 1.3 | 11.1 | 43.6 | 6.2 | 2.9 | 6.9 | 0.2 | 0.1 | 11.1 | 84.2 | 15.8 |

| GC | 0.4 | 1.3 | 9.5 | 41.5 | 2.0 | 5.0 | 2.7 | 0.3 | 0.1 | 28.9 | 91.4 | 8.6 |

| BS | GC | Texas [44] | Brazil [45] | Europe [45] | USA [45] | Russia [46] | |

|---|---|---|---|---|---|---|---|

| Cr | 26.9 | 45.0 | 200 | 56 | 55 | ||

| Ni | 32.7 | 66.8 | 420 | 70 | 44 | 100 | |

| Cu | 5.3 | 60 | 172 | 600 | |||

| Zn | 131.8 | 227.5 | 370 | 347 | 556 | 1500 | |

| As | 11.9 | 15.7 | 41 | 20 | |||

| Se | 6.4 | 8.4 | 100 | ||||

| Mo | 0.8 | 1.1 | 18 | ||||

| Cd | 0.1 | 0.2 | 39 | 3 | 0.7 | 0.8 | 20 |

| Pb | 8.5 | 7.9 | 300 | 150 | 18 | 27 | 120 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalinina, N.; Maximov, P.; Makarov, B.; Dasi, E.; Rudmin, M. Characterisation and Environmental Significance of Glauconite from Mining Waste of the Egorievsk Phosphorite Deposit. Minerals 2023, 13, 1228. https://doi.org/10.3390/min13091228

Kalinina N, Maximov P, Makarov B, Dasi E, Rudmin M. Characterisation and Environmental Significance of Glauconite from Mining Waste of the Egorievsk Phosphorite Deposit. Minerals. 2023; 13(9):1228. https://doi.org/10.3390/min13091228

Chicago/Turabian StyleKalinina, Natalia, Prokopiy Maximov, Boris Makarov, Evan Dasi, and Maxim Rudmin. 2023. "Characterisation and Environmental Significance of Glauconite from Mining Waste of the Egorievsk Phosphorite Deposit" Minerals 13, no. 9: 1228. https://doi.org/10.3390/min13091228