Cooperative Exploration Model of Coal–Gallium Deposit: A Case Study of the Heidaigou Coal–Gallium Deposit in the Jungar Coalfield, Inner Mongolia, China

Abstract

:1. Introduction

2. Geological Background and Methodology

2.1. Jungar Coalfield

2.2. Heidaigou Coal–Ga Deposit

2.3. Methodology

3. Distribution Characteristics of Coal–Ga Deposits

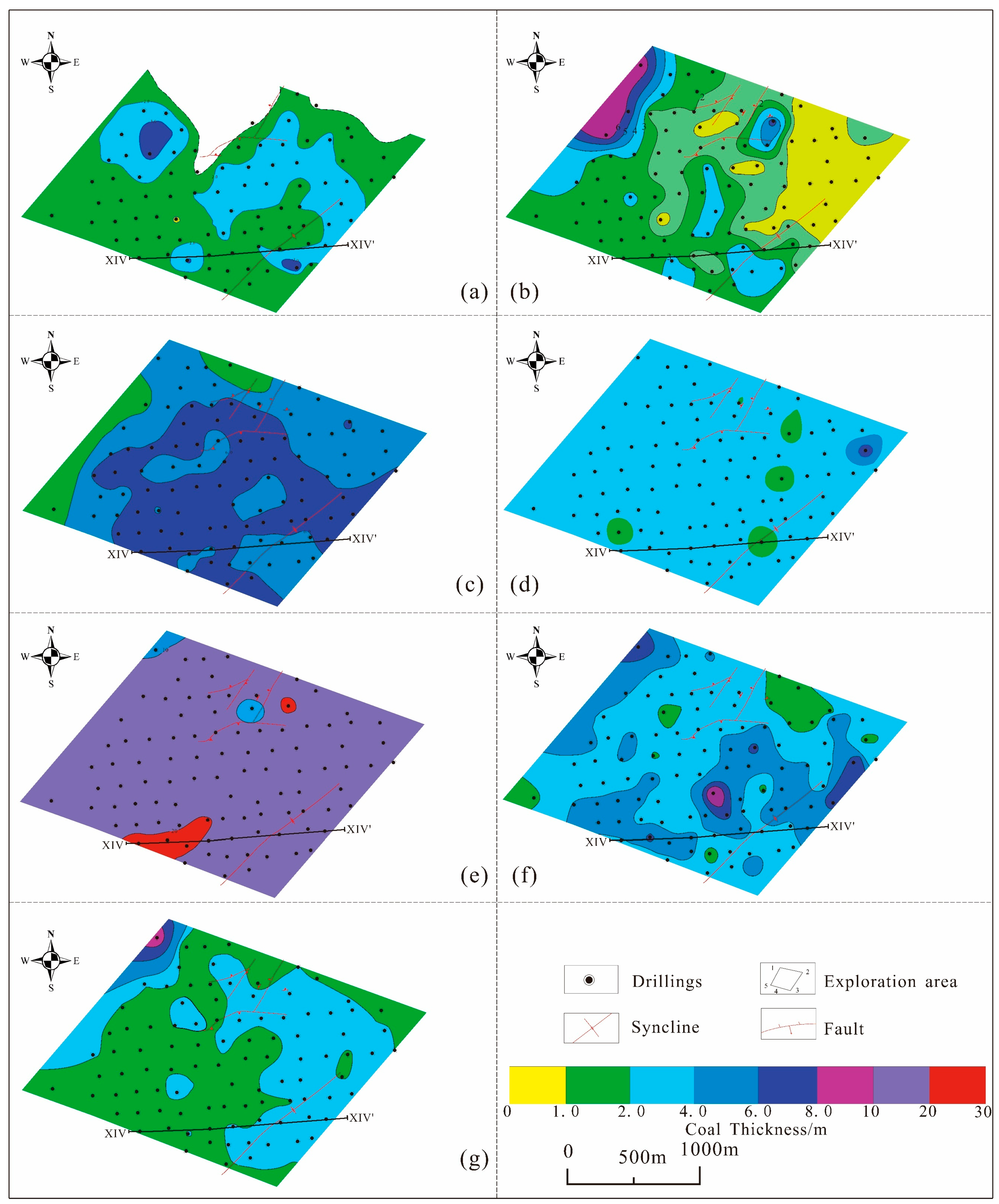

3.1. Plane of Coal Seams

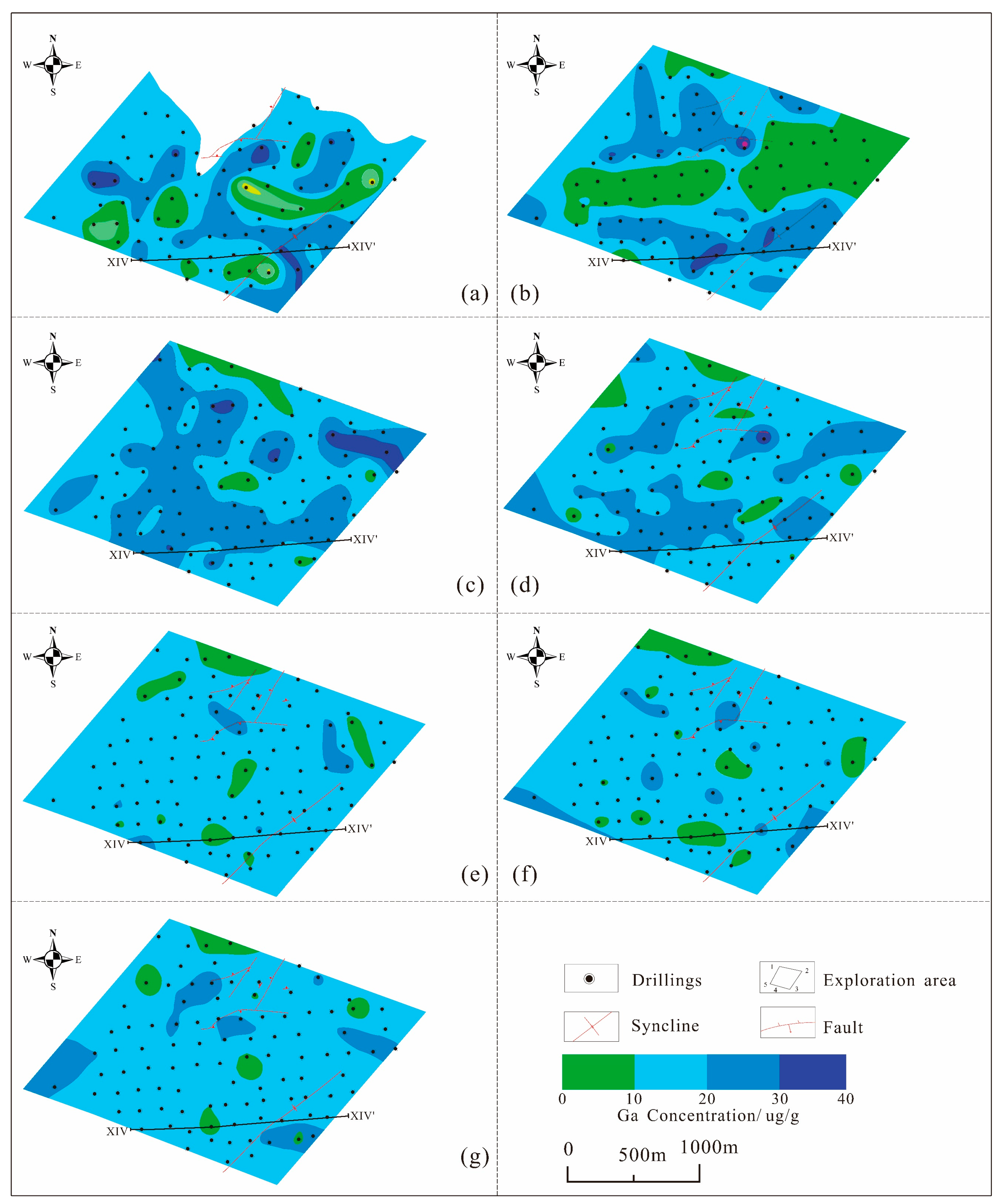

3.2. Plane of Ga Deposit

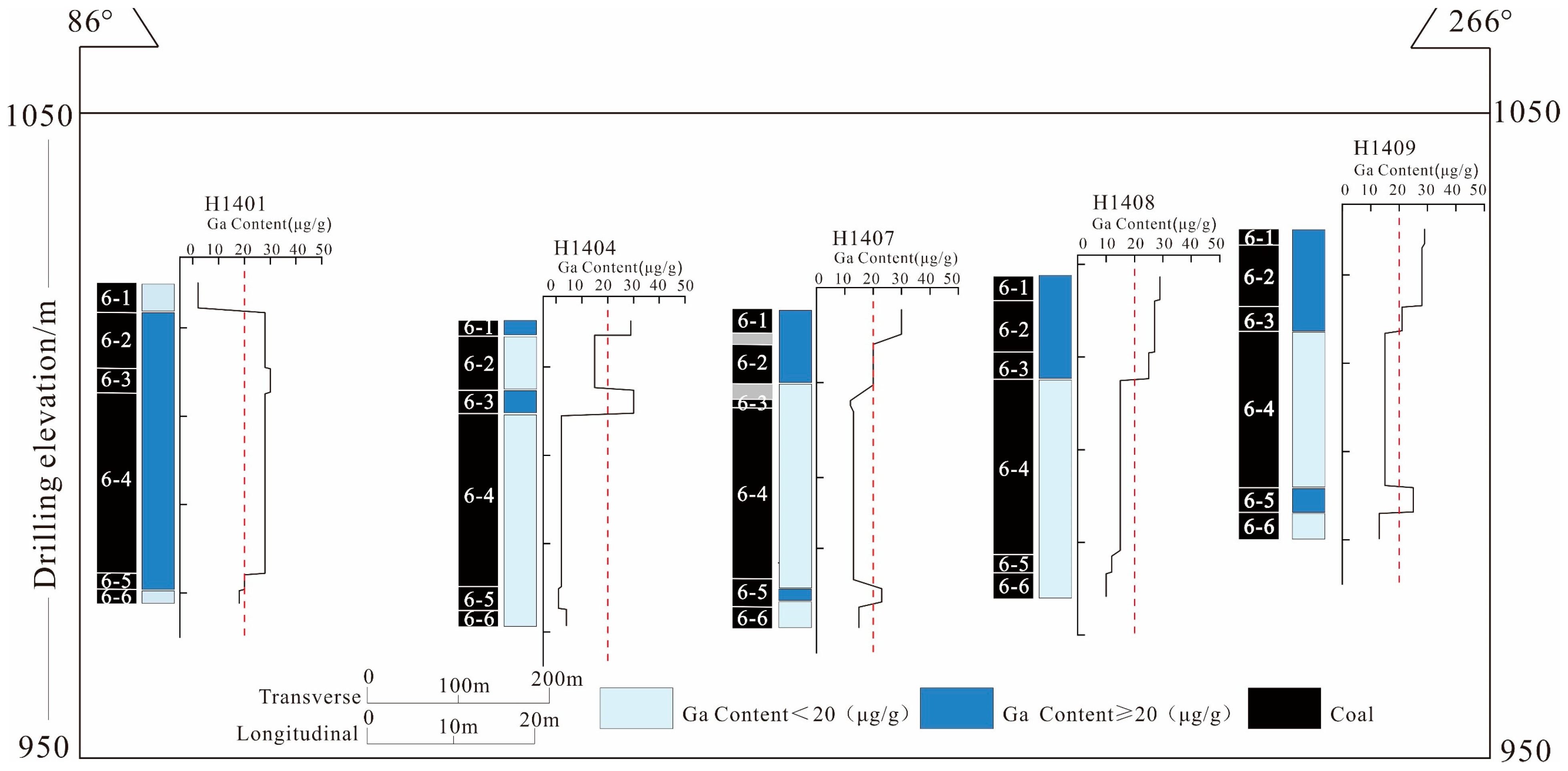

3.3. Vertical Direction of Coal–Ga Deposit

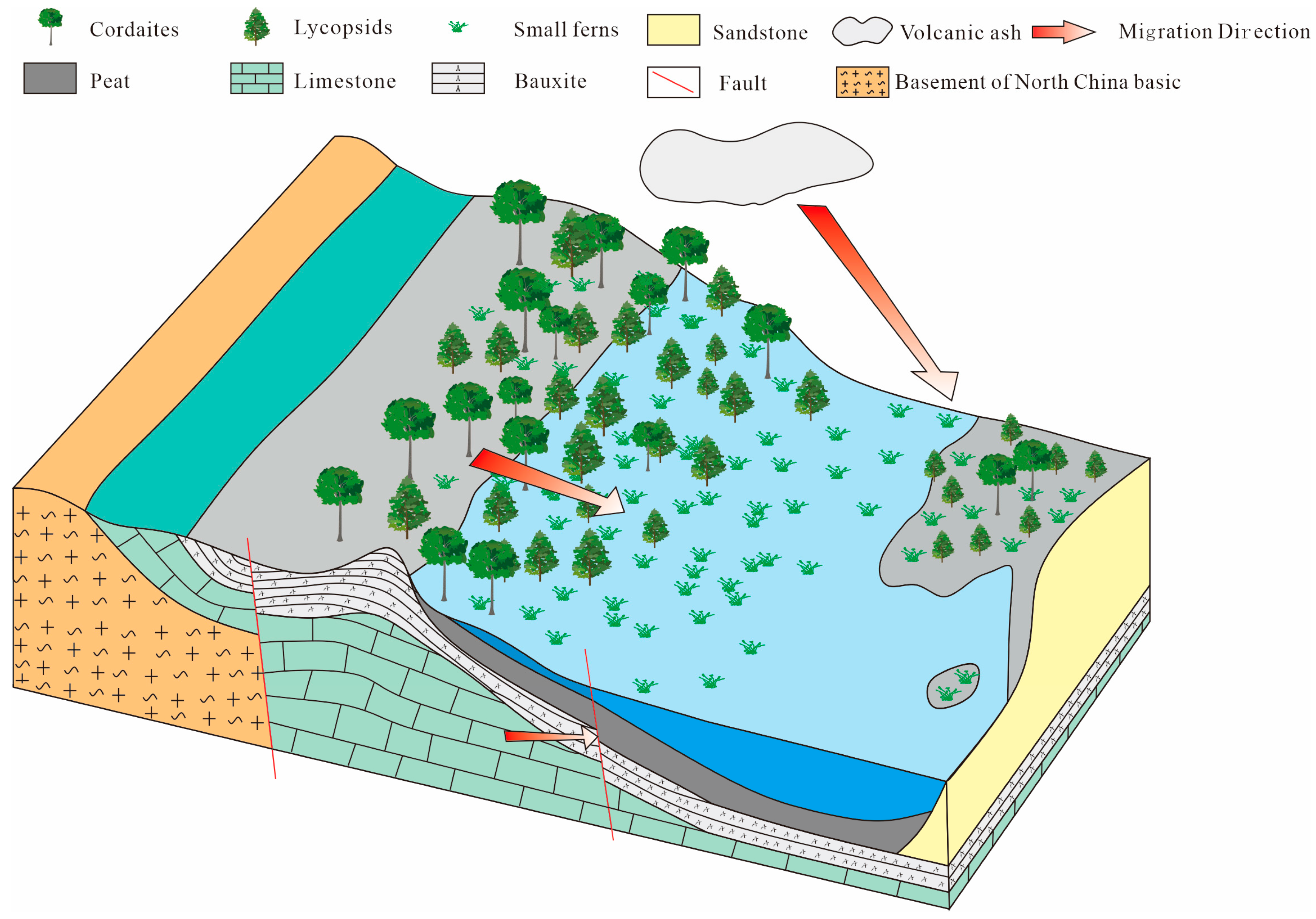

3.4. Enrichment Genesis of Heidaigou Coal–Ga Deposit

4. Cooperative Exploration Model of Coal–Ga Deposit

4.1. Original Exploration Technical Means, Exploration Project Layout, and Resource Estimation

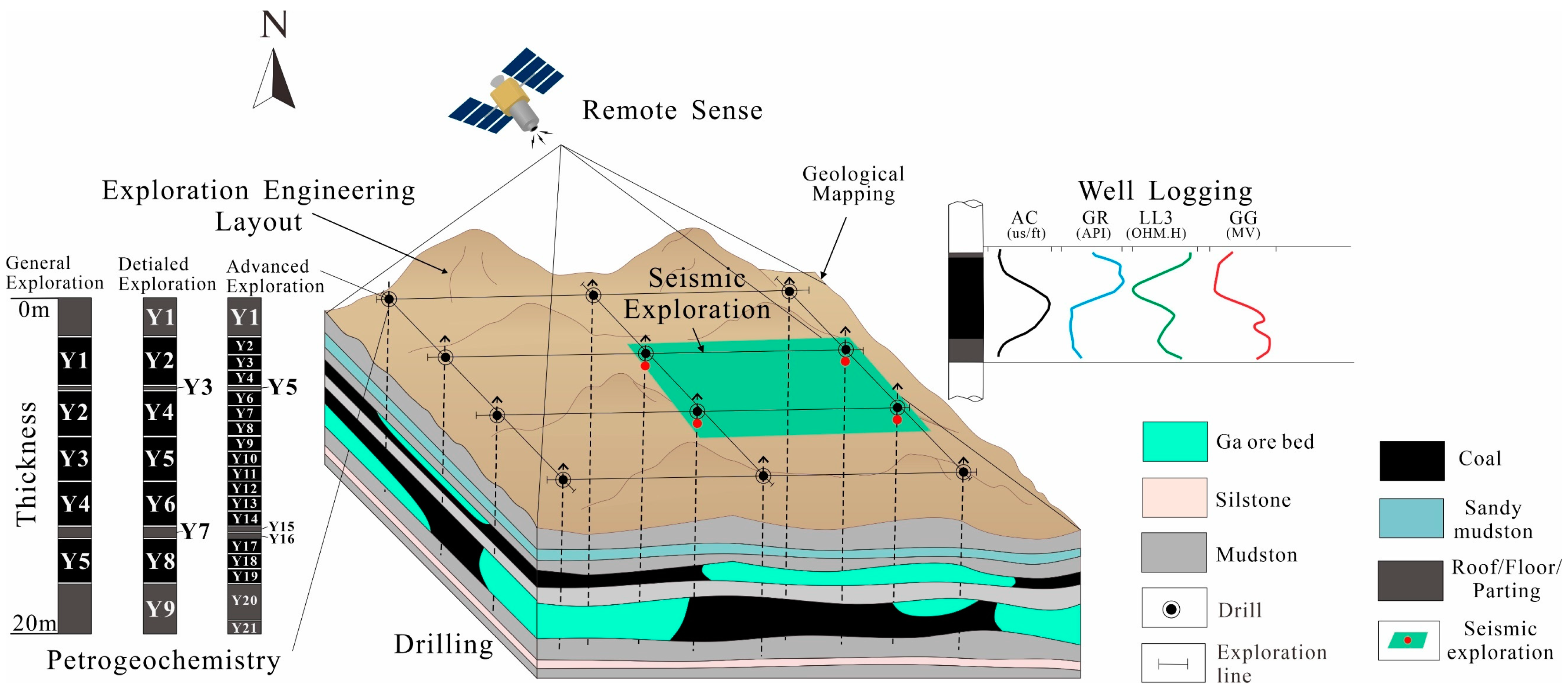

4.1.1. Exploration Technical Means

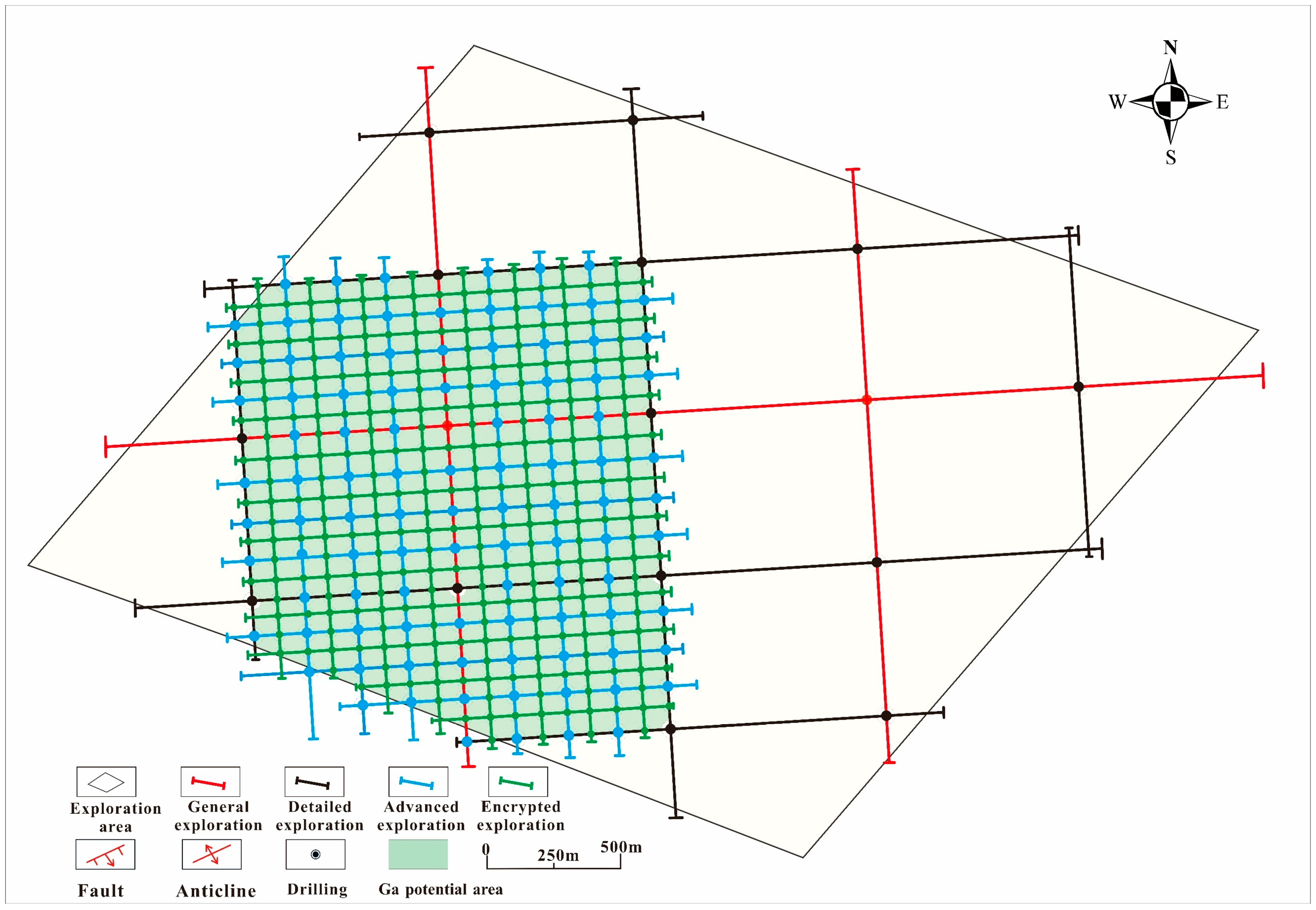

4.1.2. Layout of Exploration Engineering

4.1.3. Resource Estimation

4.2. Review of the Original Exploration Techniques, Exploration Project Layout, and Resource Estimation

4.2.1. Review of Exploration Technical Means

4.2.2. Review of the Layout of Exploration Engineering

4.2.3. Review of Resource Estimation

4.3. Optimization of Coal–Ga Deposit Cooperative Exploration Technology, Exploration Project Layout, and Resource Estimation

4.3.1. Optimization of Cooperative Exploration Technology Means

4.3.2. Optimization of Cooperative Exploration Project Layout

4.3.3. Optimizing Resource Estimation

4.4. Coal–Ga Deposit Cooperative Exploration Model

5. Conclusions

- (1)

- The Heidaigou coal–Ga deposit exhibits a distinct enrichment pattern, with the Ga concentration generally decreasing from the central–northern part of the exploration area towards the northeast and southeast. Vertically, the Ga concentration is unevenly distributed within the coal seam and adjacent boreholes show similar distribution characteristics.

- (2)

- Considering the distribution characteristics of the Heidaigou coal–Ga deposit and the efficacy of exploration techniques for coal and Ga, the exploration methodologies, project configurations, and resource estimates outlined in the original report have been thoroughly reviewed and refined.

- (3)

- The cooperative exploration model for coal–Ga deposits emphasizes the distribution of ore bodies, managing the impact of drilling projects on the morphology of these ore bodies, and making systematic decisions regarding the layout of exploration engineering and the concentration of Ga, providing the basis for the estimation of Ga resources.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amir, H.A.A.A.; Fakhri, M.A.; Alwahib, A.A. Review of GaN optical device characteristics, applications, and optical analysis technology. Mater. Today Proc. 2021, 42, 2815–2821. [Google Scholar] [CrossRef]

- Pearton, S.J.; Zolper, J.C.; Shul, R.J.; Ren, F. GaN: Processing, defects, and devices. Appl. Phys. Rev. 1999, 86, 1–78. [Google Scholar] [CrossRef]

- Baliga, B.J. Gallium nitride devices for power electronic applications. Semicond. Sci. Technol. 2013, 28, 074011. [Google Scholar] [CrossRef]

- Kaur, D.; Ghosh, A.; Kumar, M.A. Strategic review on gallium oxide based power electronics: Recent progress and future prospects. Mater. Today Commun. 2022, 33, 104244. [Google Scholar]

- Zhou, J.G.; Chen, H.; Fu, K.; Zhao, Y.J. Gallium oxide-based optical nonlinear effects and photonics devices. J. Mater. Res. 2021, 36, 4832–4845. [Google Scholar] [CrossRef]

- Lee, S.W.; Luna, M.L.; Berdunov, N.; Wan, W.M.; Kunze, S.; Shaikhutdinov, S. Unraveling surface structures of gallium promoted transition metal catalysts in CO2 hydrogenation. Nat. Commun. 2023, 14, 4649. [Google Scholar] [CrossRef]

- Broom, R.F.; Gooch, C.H.; Hilsum, C.; Oliver, D.J. Onset of stimulated emission from gallium arsenide semiconductor optical masers. Nature 1963, 198, 368–369. [Google Scholar] [CrossRef]

- Lu, X.F.; Wang, L.; Wang, X.D.; Niu, X.K. Research Progress in Gallium Recovery Technology. Nonferrous Met. 2008, 60, 105–108+114. (In Chinese) [Google Scholar]

- Phipps, G.; Mikolajczak, C.; Guckes, T. Indium and Gallium: Long-term supply. Renew. Energy Focus 2008, 9, 56–59. [Google Scholar] [CrossRef]

- Qin, S.J.; Sun, Y.Z.; Li, Y.H.; Wang, J.X.; Zhao, C.L.; Gao, K. Coal deposits as promising alternative sources for gallium. Earth-Sci. Rev. 2015, 150, 95–101. [Google Scholar] [CrossRef]

- Dai, S.F.; Finkelman, R.B. Coal as a promising source of critical elements: Progress and future prospects. Int. J. Coal Geol. 2018, 186, 155–164. [Google Scholar] [CrossRef]

- Seredin, V.V.; Dai, S.F.; Sun, Y.Z.; Chekryzhov, I.Y. Coal deposits as promising sources of rare metals for alternative power and energy-efficient technologies. Appl. Geochem. 2013, 31, 1–11. [Google Scholar] [CrossRef]

- Dai, S.F.; Ren, D.Y.; Li, S.S. The discovery of super-large gallium deposit in the Jungar Coalfield, Inner Mongolia, China. Chin. Sci. Bull. 2006, 2, 177–185. (In Chinese) [Google Scholar]

- Dai, S.F.; Ren, D.Y.; Li, S.S.; Chou, C.L. A Discovery of Extremely-enriched Boehmite from Coal in the Jungar Coalfield, the Northeastern Ordos Basin. Acta Geol. Sin. 2006, 2, 294–300, 315–316, (In Chinese with English Abstract). [Google Scholar]

- Dai, S.F.; Li, D.; Chou, C.L.; Zhao, L.; Zhang, Y.; Ren, D.Y.; Ma, Y.W.; Sun, Y.Y. Mineralogy and geochemistry of boehmite-rich coals: New insights from the Haerwusu Surface Mine, Jungar Coalfield, Inner Mongolia, China. Int. J. Coal Geol. 2008, 74, 185–202. [Google Scholar] [CrossRef]

- Dai, S.F.; Jiang, Y.F.; Ward, C.R.; Gu, L.D.; Seredin, V.V.; Liu, H.D.; Zhou, D.; Wang, X.B.; Sun, Y.Z.; Zou, J.H.; et al. Mineralogical and geochemical compositions of the coal in the Guanbanwusu Mine, Inner Mongolia, China: Further evidence for the existence of an Al (Ga and REE) ore deposit in the Jungar Coalfield. Int. J. Coal Geol. 2012, 98, 10–40. [Google Scholar] [CrossRef]

- Dai, S.F.; Ren, D.Y.; Chou, C.L.; Finkelman, R.B.; Seredin, V.V.; Zhou, Y. Geochemistry of trace elements in Chinese coals: A review of abundances, genetic types, impacts on human health, and industrial utilization. Int. J. Coal Geol. 2012, 94, 3–21. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, W.F.; Cheng, A.G.; Liu, X.H.; Zhao, J.L. Study of ore-forming potential of gallium in coal for the first group of state programmed mining districts. Coal Geol. China. 2009, 21, 17–21. (In Chinese) [Google Scholar]

- Yi, T.S.; Qin, Y.; Wu, Y.Y.; Li, Z.F. Gallium Accumulation and Geological Controls in Coal Seam and Its Floor from Liangshan Formation, Kaili, Eastern Guizhou, China. J. China Univ. Min. Technol. 2007, 36, 331–334, (In Chinese with English Abstract). [Google Scholar]

- Wang, W.F.; Qin, Y.; Liu, X.H.; Zhao, J.L.; Wang, J.Y.; Wu, G.D.; Liu, J.T. Distribution, occurrence and enrichment causes of gallium in coals from the Jungar Coalfield, Inner Mongolia. Sci. China, Ser. D Earth Sci. 2011, 41, 181–196. (In Chinese) [Google Scholar] [CrossRef]

- Chu, G.C.; Xiao, L.; Jin, Z.; Lin, M.Y.; Blokhin, M.G. The Relationship between Trace Element Concentrations and Coal-Forming Environments in the No. 6 Coal Seam, Haerwusu Mine, China. Energy Explor. Exploit. 2015, 33, 91–104. [Google Scholar] [CrossRef]

- Jiu, B.; Huang, W.H.; Spiro, B.; Hao, R.; Mu, N.N.; Wen, L.; Hao, H.D. Distribution of Li, Ga, Nb, and REEs in coal as determined by LA-ICP-MS imaging: A case study from Jungar coalfield, Ordos Basin, China. Int. J. Coal Geol. 2023, 267, 104184. [Google Scholar] [CrossRef]

- Jiu, B.; Jin, Z.J.; Wang, Z.G. Multiscale in-situ elemental characterization of critical elements in low rank coal, implications for modes of occurrence. Fuel 2023, 349, 128632. [Google Scholar] [CrossRef]

- Sun, Y.Z.; Zhao, C.L.; Li, Y.H.; Wang, J.X.; Zhang, J.Y.; Jin, Z.; Lin, M.Y.; Wolfgang, K. Further Information of the Associated Li Deposits in the No.6 Coal Seam at Jungar Coalfield, Inner Mongolia, Northern China. Acta Geol. Sin. (Engl. Ed.) 2013, 87, 1097–1108. [Google Scholar]

- Sun, Y.Z.; Zhao, C.L.; Qin, S.J.; Lin, B.; Li, Z.S.; Lin, M.Y. Occurrence of some valuable elements in the unique ‘high-aluminium coals’ from the Jungar coalfield, China. Ore Geol. Rev. 2015, 72, 659–668. [Google Scholar] [CrossRef]

- Xiao, L.; Zhao, B.; Duan, P.P.; Shi, Z.X.; Ma, J.L.; Lin, M.Y. Geochemical Characteristics of Trace Elements in the No. 6 Coal Seam from the Chuancaogedan Mine, Jungar Coalfield, Inner Mongolia, China. Minerals 2016, 6, 28. [Google Scholar] [CrossRef]

- Zhao, C.L.; Qin, S.J.; Yang, Y.C.; Li, Y.H.; Lin, M.Y. Concentration of gallium in the Permo-carboniferuos coal of China. Energy Explor. Exploit. 2009, 27, 333. [Google Scholar] [CrossRef]

- Wei, Y.C.; He, W.B.; Qin, G.H.; Fan, M.H.; Cao, D.Y. Lithium Enrichment in the No. 21 Coal of the Hebi No. 6 Mine, Anhe Coalfield, Henan Province, China. Minerals 2020, 10, 521. [Google Scholar] [CrossRef]

- Wei, Y.C.; He, W.B.; Qin, G.H.; Wang, A.M.; Cao, D.Y. Mineralogy and Geochemistry of the Lower Cretaceous Coals in the Junde Mine, Hegang Coalfield, Northeastern China. Energies 2022, 15, 5078. [Google Scholar] [CrossRef]

- Sun, S.L.; Wu, G.Q.; Cao, D.Y.; Ning, S.Z.; Qiao, J.W.; Zhu, H.X.; Han, L.; Zhu, S.F.; Miao, Q.; Zhou, J.; et al. Coal measure mineral resources and their development trend. Coal Geol. China. 2014, 26, 1–11. (In Chinese) [Google Scholar]

- Ren, D.Y.; Zhao, F.H.; Dai, S.F.; Zhang, J.Y.; Luo, K.L. Geochemistry of Trace Elements in Coal; Science Press: Beijing, China, 2006. (In Chinese) [Google Scholar]

- DZ/T 0400-2022; Standard of Mineral Resources and Reserves Scale. Geological Publishing House: Beijing, China, 2022. (In Chinese)

- GB/T 41042-2021; Guidance for Utilization and Classification of Concentration of Valuable Elements in Coal. Standards Press of China: Beijing, China, 2021. (In Chinese)

- Ning, S.Z.; Cao, D.Y.; Zhu, S.F.; Qiao, J.W.; Wei, Y.C.; Deng, X.L.; Zhang, J.Q.; Li, C.C. Discussion on comprehensive evaluation technical method of coal resources. China Min. Mag. 2019, 28, 73–79. [Google Scholar]

- Tang, X.Y.; Huang, W.H. Trace Elements in Chinese Coal; The Mercial Press: Beijing, China, 2004. (In Chinese) [Google Scholar]

- Liu, G.J.; Yang, P.Y.; Peng, Z.C.; Wang, G.L.; Cao, Z.H. Occurrence of trace elements in coal of Yanzhou mining district. Geochimica 2002, 31, 85–90. (In Chinese) [Google Scholar]

- Mukherjee, K.N.; Dutta, N.R.; Chandra, D.; Pandalai, H.S.; Singh, M.P. A statistical approach to the study of the distribution of trace elements and their organic/ inorganic affinity in lower Gondwana coals of India. Int. J. Coal Geol. 1988, 10, 99–108. [Google Scholar] [CrossRef]

- Dai, S.F.; Finkelman, R.B.; French, D.; Hower, J.C.; Graham, I.T.; Zhao, F.H. Modes of occurrence of elements in coal: A critical evaluation. Earth-Sci. Rev. 2021, 222, 103815. [Google Scholar] [CrossRef]

- Seredin, V.V.; Finkelman, R.B. Metalliferous coals: A review of the main genetic and geochemical types. Int. J. Coal Geol. 2008, 76, 253–289. [Google Scholar] [CrossRef]

- Bennett, R.; Czechowski, F. Gallium porphyrins in bituminous coal. Nature 1980, 283, 465–467. [Google Scholar] [CrossRef]

- Bonnett, R.; Cousins, R.P.C. On the metal concentration and metal ion uptake of botanically specific peats and the derived humic acids. Org. Geochem. 1987, 11, 497–503. [Google Scholar] [CrossRef]

- Bonnett, R. Porphyrins in coal. Int. J. Coal Geol. 1996, 32, 137–149. [Google Scholar] [CrossRef]

- Dai, S.F.; Ren, D.Y.; Chou, C.L.; Li, S.S.; Jiang, Y.F. Mineralogy and geochemistry of the No. 6 Coal (Pennsylvanian) in the Jungar Coalfield, Ordos Basin, China. Int. J. Coal Geol. 2006, 66, 253–270. [Google Scholar] [CrossRef]

- Swaine, D.J. Trace Elements in Coals; Butterworth: London, UK, 1990. [Google Scholar]

- Eskenazy, G. Adsorption of gallium on peat and humic acids. Fuel 1967, 46, 187. [Google Scholar]

- Ward, C.R.; Gurba, L.W. Chemical composition of macerals in bituminous coals of the Gunnedah Basin, Australia, using electron microprobe analysis techniques. Int. J. Coal Geol. 1999, 39, 279–300. [Google Scholar] [CrossRef]

- Mukherjee, K.N.; Dutta, N.R.; Chandra, D.; Singh, M.P. Geochemistry of trace elements of Tertiary coals of India. Int. J. Coal Geol. 1992, 20, 99113. [Google Scholar] [CrossRef]

- Mastalerz, M.; Drobniak, A. Gallium and germanium in selected Indiana coals. Int. J. Coal Geol. 2012, 94, 302–313. [Google Scholar] [CrossRef]

- Li, J.; Zhuang, X.G.; Yuan, W.; Liu, B.; Querol, X.; Font, O.; Moreno, N.; Li, J.F.; Gang, T.; Liang, G.K. Mineral composition and geochemical characteristics of the Li-Ga-rich coals in the Buertaohai-Tianjiashipan mining district, Jungar Coalfield, Inner Mongolia. Int. J. Coal Geol. 2016, 167, 157–175. [Google Scholar] [CrossRef]

- Xu, S.S.; Wang, T.; Sun, S.L.; Cao, D.Y.; Li, Z.X. New Architecture of Integrated Coal Resource Exploration Technology in China. Coal Geol. China 2009, 21, 1–5. (In Chinese) [Google Scholar]

- Cao, D.Y.; Wei, Y.C. Coal Geological Exploration and Evaluation; China University of Mining and Technology Press: Xuzhou, China, 2021. (In Chinese) [Google Scholar]

- Cao, D.Y.; Lin, Z.Y.; Wei, Y.C.; Li, X.M.; Zhang, J.K.; Zheng, Z.H. Types and models of coal-deposit exploration in China. Energy Explor. Exploit. 2011, 29, 495–515. [Google Scholar] [CrossRef]

- Wei, Y.C.; Cao, D.Y.; Xia, Y.X.; Zhang, Q.; Li, Y.F.; Wei, Z.D.; Zhu, W.W. Discussion on Exploration Methods of Coal Resources in Areas with Complex Geologic Conditions. Coal Eng. 2014, 46, 115–117. (In Chinese) [Google Scholar]

- Wang, H.H.; Wang, Y.J.; Zhu, Y.Z.; Shen, L.J.; Li, H.K.; Li, X.Z.; Zhou, M.L.; Zhang, X.B.; Shao, Y.B.; Zhang, W.Y.; et al. Theoretical Research on “Coal-iron Co-basin”and“Iron Finding under Coal”Engineering Practice in the Coal-producing Region of North China—A Case Study of Iron-rich Ore Finding in the Yellow River North Coalfield in Shandong. Coal Geol. China 2023, 35, 7–11. (in Chinese). [Google Scholar]

- Wang, H.H.; Shen, L.J.; Wang, D.D.; Zhu, Y.Z.; Li, Z.X.; Wang, Y.J.; Mao, Q. Study on Mesozoic magmatic intrusion and Paleozoic multi-mineral genesis mechanism in Huanghebei Coalfield, Shandong Province. Coal Geol. Explor. 2021, 49, 83–92. (In Chinese) [Google Scholar]

- Wang, H.H.; Zhang, X.B.; Wang, Y.J.; Zhu, Y.Z.; Shen, L.J. Progress in Research on Multi-mineral Co-exploration Theory and Technology System in Mega Thick Overburden Area to the North of Yellow River. Coal Geol. China. 2020, 32, 150–154+166. (In Chinese) [Google Scholar]

- Li, Z.X.; Wang, D.D.; Lyu, D.W.; Li, Y.; Liu, H.Y.; Wang, H.H.; Wang, P.L. Study progress on coal measure mineral type and coordinated exploration: Discussion on conception standardized issues of coal geology. Coal Sci. Technol. 2018, 46, 164–176+201, (In Chinese with English Abstract). [Google Scholar]

- Li, Z.X.; Wang, T.; Wang, H.H.; Lyu, D.W.; Liu, H.Y. Theory and Technical System Study on Multiple Energy Mineral Resources Exploration in Coordination. Coal Geol. China 2011, 23, 68–72. (In Chinese) [Google Scholar]

- Duan, Z.K.; Xu, G.Z.; He, X.L. On Basic Principles in Integrated Coal Exploration in Company with Uranium and Evaluation Technology. Coal Geol. China 2015, 27, 1–4+17. (In Chinese) [Google Scholar]

- Wang, T.; Sun, J.; Jiang, T.; Lin, Z.Y.; Zhang, F.; Zhao, X.; Xie, Z.Q. Basic configuration and scientific problems of coal eco-geological survey. J. China Coal Soc. 2020, 45, 276–284. (In Chinese) [Google Scholar]

- Wang, T.; Han, X.Z.; Deng, J.; Sun, Y.J.; Li, Z.X.; Tang, S.H.; Mao, S.J. Orientation and major research problems of coal geological exploration in China under new conditions. Coal Geol. Explor. 2023, 51, 27–44. (In Chinese) [Google Scholar]

- Wei, Y.C.; Li, X.; Cao, D.Y.; Zhang, Y.; Wei, J.H.; Xu, L.X.; Wang, A.M. Cooperative exploration methods of coal and strategic metal resources in coal-bearing strata in China. Coal Sci. Technol. 2023, 51, 27–41. (In Chinese) [Google Scholar]

- Cao, D.Y.; Wei, Y.C.; Li, X.; Zhang, Y.; Xu, L.X.; Wei, J.H.; Dong, B. Discussion on the theory and technical framework of cooperative exploration of coal andstrategic metal resources in coal-bearing strata. J. China Coal Soc. 2024, 49, 1–16. (In Chinese) [Google Scholar]

- Zhao, G.R.; Ma, L.J.; Yang, F.T.; Lu, Z.S. Geological Report of Exploration in Heidaigou Mining Area, Jungar Coalfield, Inner Mongolia; Mongolia Coalfield Geological Company: Hohhot, China, 1982. (In Chinese) [Google Scholar]

- DZ/T 0215-2020; Specifications for Coal Exploration. Geological Publishing House: Beijing, China, 2020. (In Chinese)

- DZ/T 0203-2020; Specifications for Rare Metal Mineral Exploration. Geological Publishing House: Beijing, China, 2020. (In Chinese)

- Zhang, Z.H.; Lyu, D.W.; Hower, J.C.; Wang, L.J.; Shen, Y.Y.; Zhang, A.C.; Xu, J.C.; Gao, J. Geochronology, mineralogy, and geochemistry of tonsteins from the Pennsylvanian Taiyuan Formation of the Jungar Coalfield, Ordos Basin, North China. Int. J. Coal Geol. 2023, 267, 104183. [Google Scholar] [CrossRef]

- Wang, L.J.; Lyu, D.W.; Hower, J.C.; Zhang, Z.H.; Raji, M.; Tang, J.G.; Liu, Y.M.; Gao, J. Geochemical characteristics and paleoclimate implication of Middle Jurassic coal in the Ordos Basin, China. Ore Geol. Rev. 2022, 144, 104848. [Google Scholar] [CrossRef]

- Gao, J.; Lyu, D.W.; Loon, T.; Hower, J.C.; Raji, M.; Yang, Y.; Ren, Z.H.; Wang, Y.J.; Zhang, Z.H. Reconstruction of provenance and tectonic setting of the Middle Jurrasic Yan’an Formation (Ordos Basin, North China) by analysis of major, trace and rare earth elements in the coals. Ore Geol. Rev. 2022, 151, 105218. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Xiao, L. Petrographic characteristics and depositional environment of No. 6 coal from Xiaoyμgou Mine, Jungar Coalfield, China. Int. J. Coal Sci. Technol. 2014, 1, 395–401. [Google Scholar] [CrossRef]

- Liu, C.; Chang, X.D.; Sun, B.L.; Zeng, F.G. New Insight into the Depositional Age of No. 6 Coal in Heidaigou Mine, Late Paleozoic Jungar Coalfield, Inner Mongolia, China. Sustainability 2021, 14, 6297. [Google Scholar] [CrossRef]

- Hao, R.W.; Li, X.L.; Xu, P.J.; Liu, Q.F. Thermal activation and structural transformation mechanism of kaolinitic coal gangue from Jungar coalfield, Inner Mongolia, China. Appl. Clay Sci. 2022, 223, 106508. [Google Scholar] [CrossRef]

- Liu, D.N.; Lin, J.W.; Zhou, A.C.; Zhao, F.H.; Zhou, R.; Zou, Y. Tectono-Thermal Events of Coal-Bearing Basin in the Northern North China Craton: Evidence from Zircon–Apatite Fission Tracks and Vitrinite Reflectance. Minerals 2022, 12, 942. [Google Scholar] [CrossRef]

- Liu, Z.F.; Wei, Y.C.; Ning, S.Z.; Jia, X.; Qin, R.F.; Cao, D.Y. The differences of element geochemical characteristics of the main coal seams in the Ningdong coalfield, Ordos Basin. J. Geochem. Explor. 2019, 202, 77–91. [Google Scholar]

- Qin, G.H.; Cao, D.Y.; Wei, Y.C.; Wang, A.M.; Liu, J.C. Geochemical characteristics of the Permian coals in the Junger-Hebaopian mining district, northeastern Ordos Basin, China: Key role of paleopeat-forming environments in Ga-Li-REY enrichment. J. Geochem. Explor. 2020, 213, 106494. [Google Scholar] [CrossRef]

- Wang, S.M. Coal Aggregation Pattern and Coal Resource Evaluation in Ordos Basin; China Coal Industry Publishing House: Beijing, China, 1996; (In Chinese with English Abstract). [Google Scholar]

- Zhang, S.; Xiu, W.; Sun, B.; Liu, Q.F. Provenance of multi-stage volcanic ash recorded in the Late Carboniferous coal in the Jungar Coalfield, North China, and their contribution to the enrichment of critical metals in the coal. Int. J. Coal Geol. 2023, 273, 104265. [Google Scholar] [CrossRef]

- Zhang, S.; Yuan, T.C.; Sun, B.; Li, L.; Ma, X.J.; Shi, S.L.; Liu, Q.F. Formation of boehmite throμgh desilication of volcanic-ash-altered kaolinite and its retention for gallium: Contribution to enrichment of aluminum and gallium in coal. Int. J. Coal Geol. 2024, 281, 104404. [Google Scholar] [CrossRef]

- Wang, L.J.; Lyu, D.W.; Zhang, Z.H.; Hower, J.C.; Raji, M.; Zhang, Y.S.; Shen, Y.Y.; Gao, J. Geochronology, Mineralogy, and Geochemistry of the Tonsteins from the Permo–Carboniferous Benxi Formation, Ordos Basin, North China Craton. Acta Geol. Sin. (Engl. Ed.) 2023, 97, 1355–1371. [Google Scholar] [CrossRef]

- Zhou, A.C. The Evolution of Late Paleozoic Basins in North Margin of North China Block and the Coupling Relationship between Basin and Range; China Coal Industry Publishing House: Beijing, China, 2002; (In Chinese with English Abstract). [Google Scholar]

- GB/T 23561.1-2009; Methods for Determining the Physical and Mechanical Properties of Coal and Rock—Part 1: General Requirements for Sampling. Standards Press of China: Beijing, China, 2009. (In Chinese)

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wei, Y.; Cao, D.; Li, X.; Wei, J.; Xu, L.; Dong, B.; Xu, T. Cooperative Exploration Model of Coal–Gallium Deposit: A Case Study of the Heidaigou Coal–Gallium Deposit in the Jungar Coalfield, Inner Mongolia, China. Minerals 2024, 14, 156. https://doi.org/10.3390/min14020156

Zhang Y, Wei Y, Cao D, Li X, Wei J, Xu L, Dong B, Xu T. Cooperative Exploration Model of Coal–Gallium Deposit: A Case Study of the Heidaigou Coal–Gallium Deposit in the Jungar Coalfield, Inner Mongolia, China. Minerals. 2024; 14(2):156. https://doi.org/10.3390/min14020156

Chicago/Turabian StyleZhang, Yun, Yingchun Wei, Daiyong Cao, Xin Li, Jinhao Wei, Laixin Xu, Bo Dong, and Tengyue Xu. 2024. "Cooperative Exploration Model of Coal–Gallium Deposit: A Case Study of the Heidaigou Coal–Gallium Deposit in the Jungar Coalfield, Inner Mongolia, China" Minerals 14, no. 2: 156. https://doi.org/10.3390/min14020156