Strategic Qualitative Risk Assessment of Thousands of Legacy Wells within the Area of Review (AoR) of a Potential CO2 Storage Site

Abstract

:1. Introduction

2. Materials and Methods

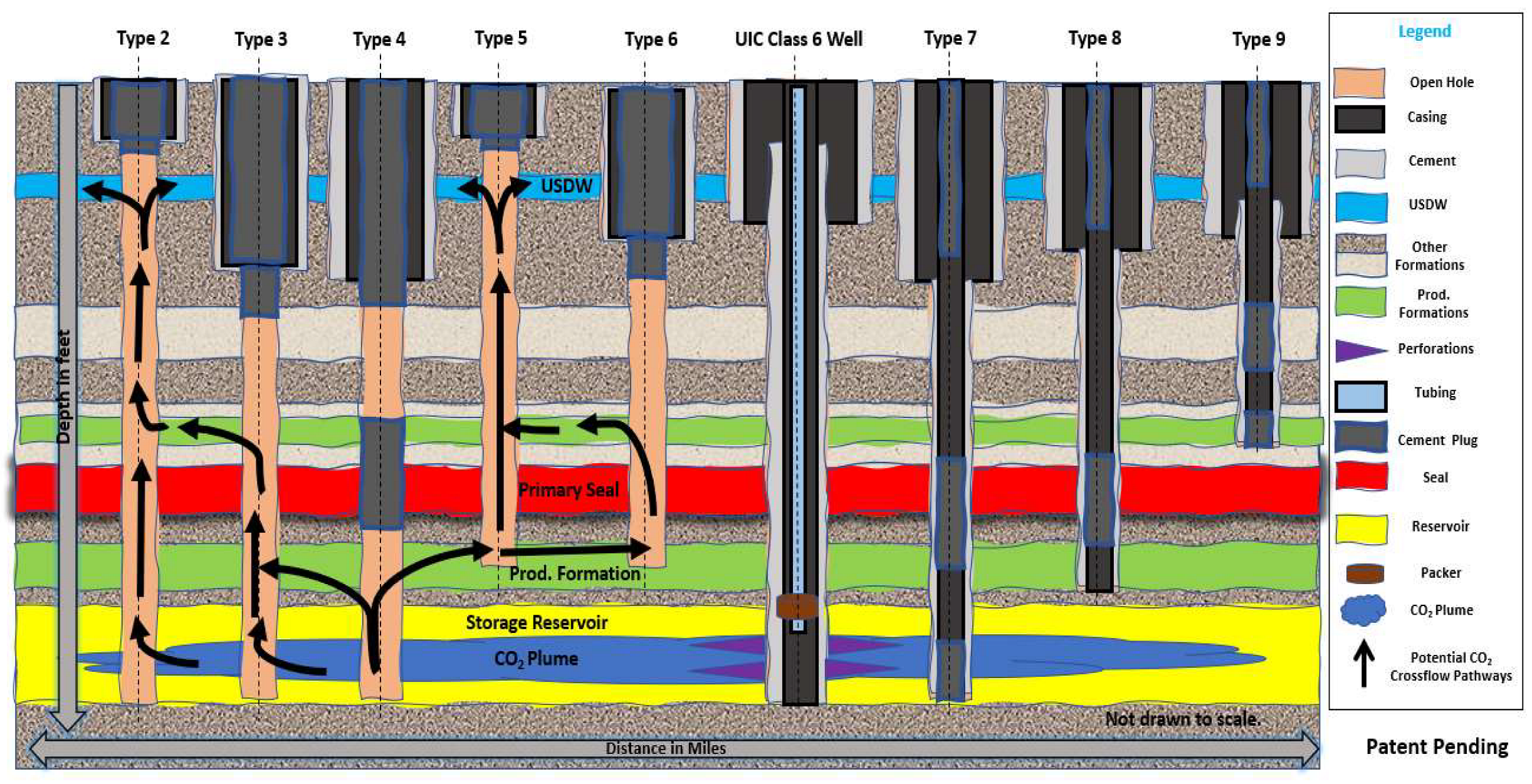

2.1. Categorization Methodology

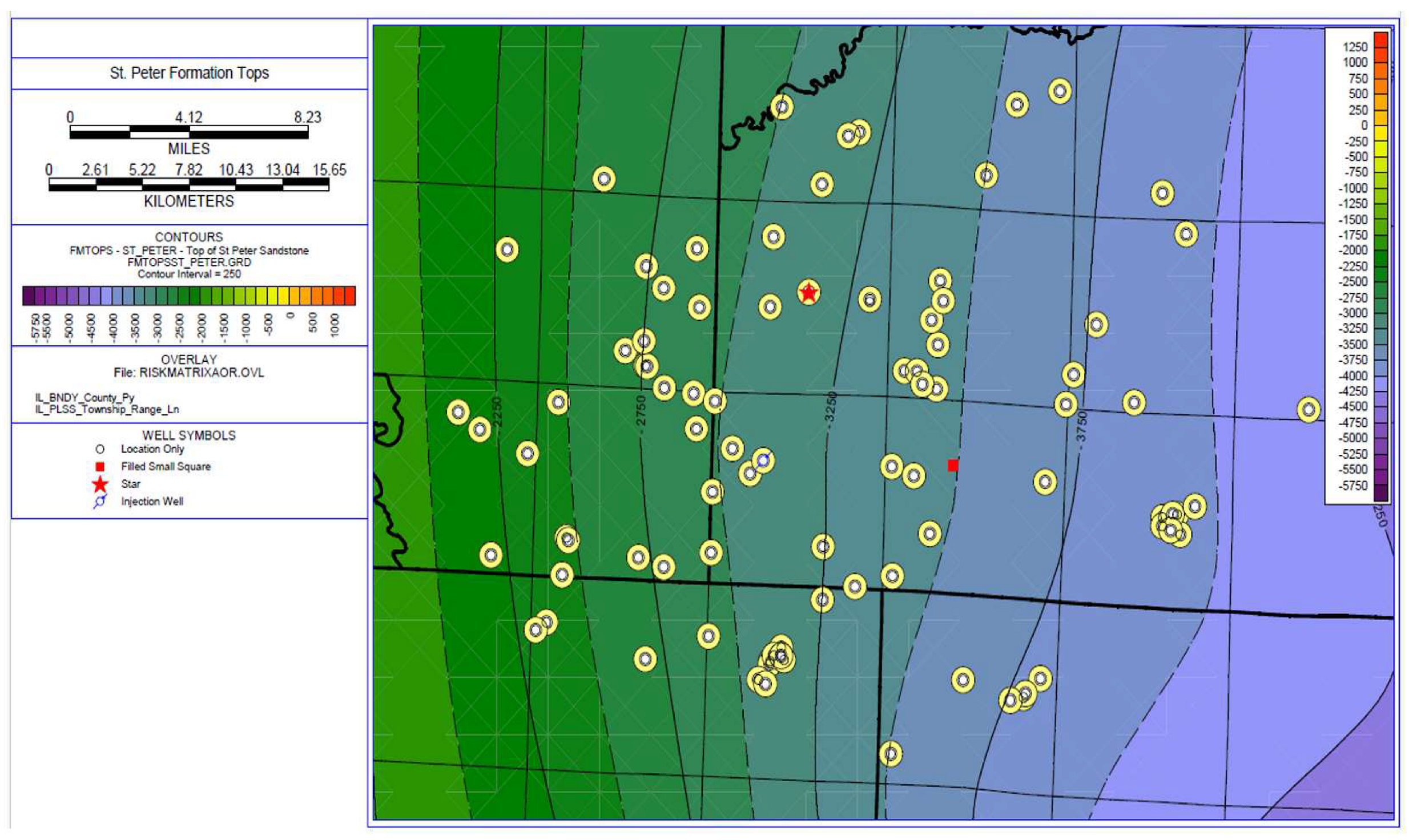

2.2. Case Study Details

2.3. Data Collection and Quality Control

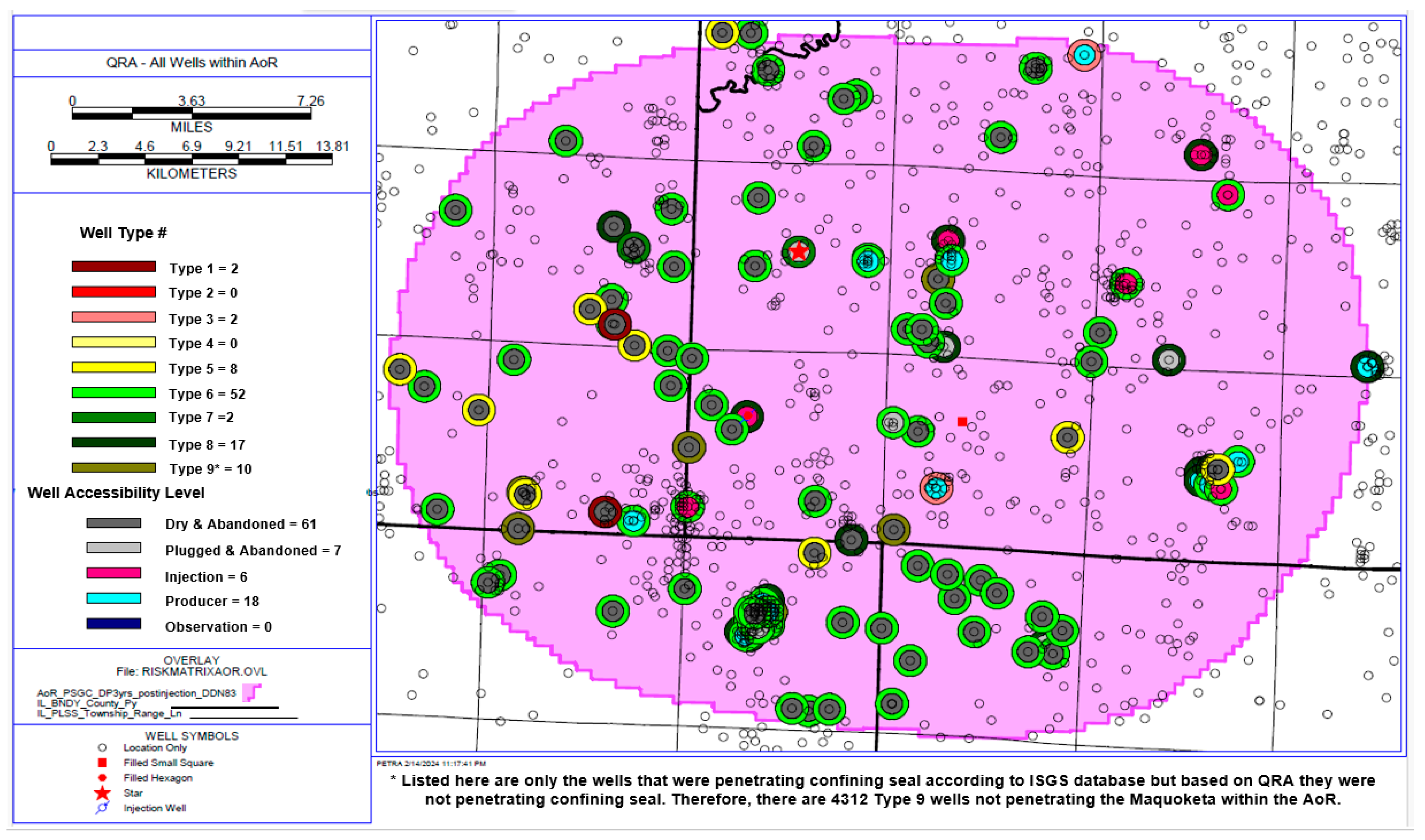

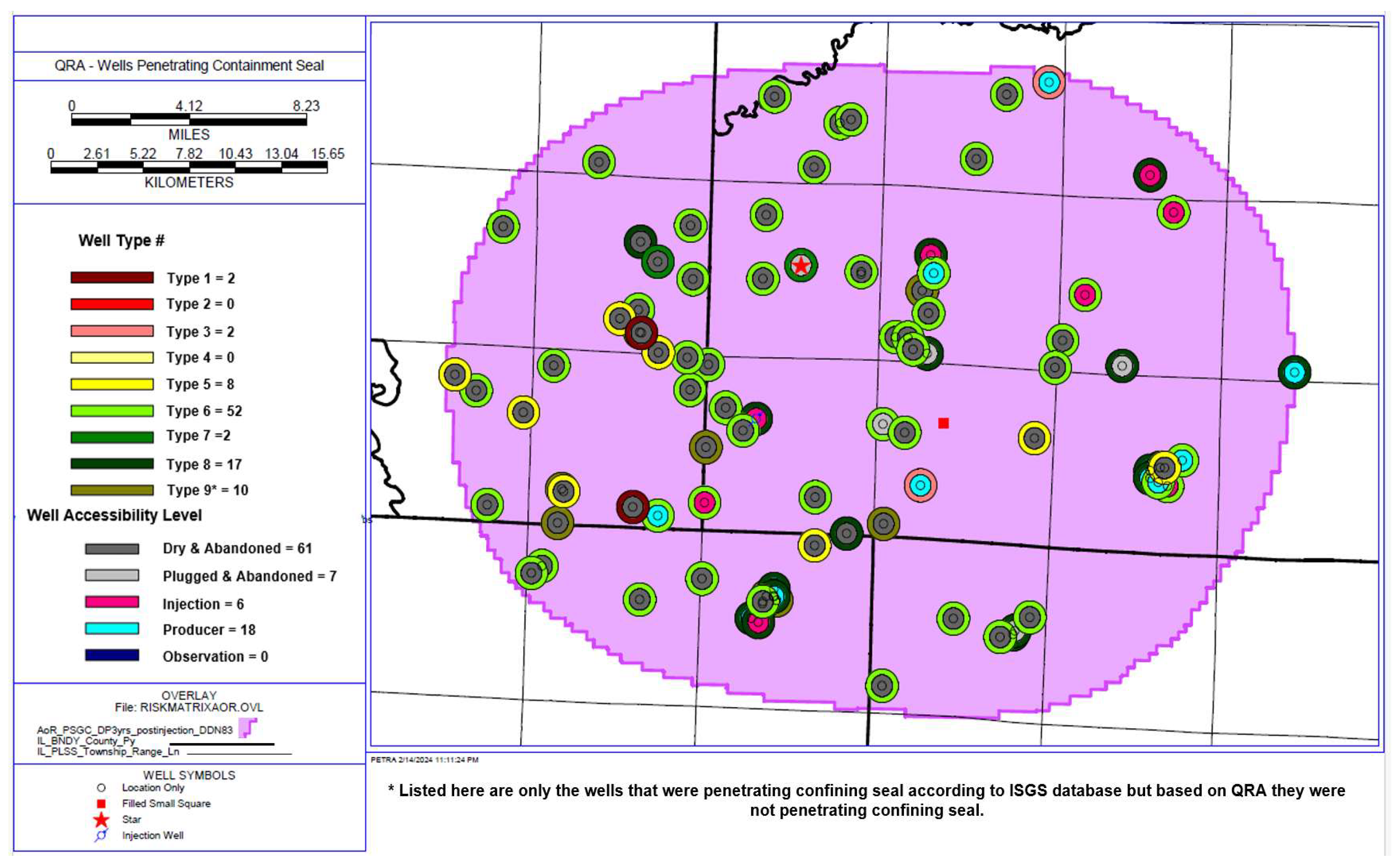

- Formation code filtering: All the 4386 wellbores in the existing database were filtered based on the formation codes, i.e., the deepest formation penetrated by the well. All the formation codes for formations below the primary confining seal were selected and all the wells penetrating those formations were shortlisted for evaluation. Table 2 provides the list of formations that are classified as primary confining seals, formations below the primary confining seals, and the storage reservoir complex for the target site.

- Depth filtering: As the approximate top of the Maquoketa seal near the LG1 is 2790 ft and its thickness is approximately 150 ft, wells with TD greater than 2470 ft were considered for preliminary risk assessment. This eliminated thousands of wells and only 521 wells with depths greater than 2470 ft were shortlisted.

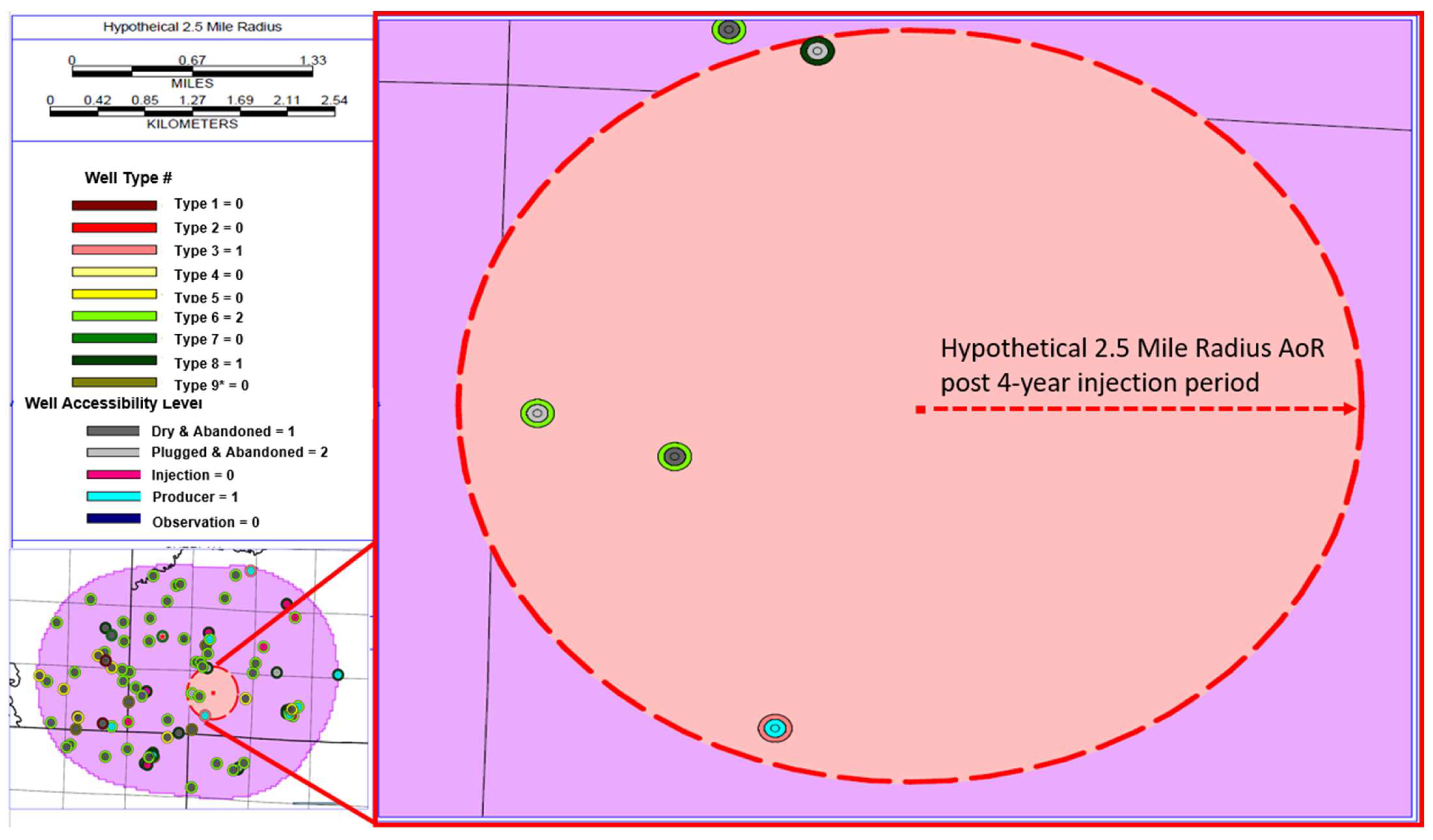

- AoR filtering: Once the AoR was predicted for a 3-year post-injection differential pressure based on a 20-year injection period using ISGS, the shapefiles of AoR were imported into Petra to identify the wells within the predicted AoR. Once the above-mentioned filters were applied, 94 wells that were penetrating the primary confining seal (i.e., Maquoketa formation) were evaluated using the qualitative risk assessment (QRA) methodology developed by Arbad et al. [45,46].

2.4. Well Record Evaluation

3. Results

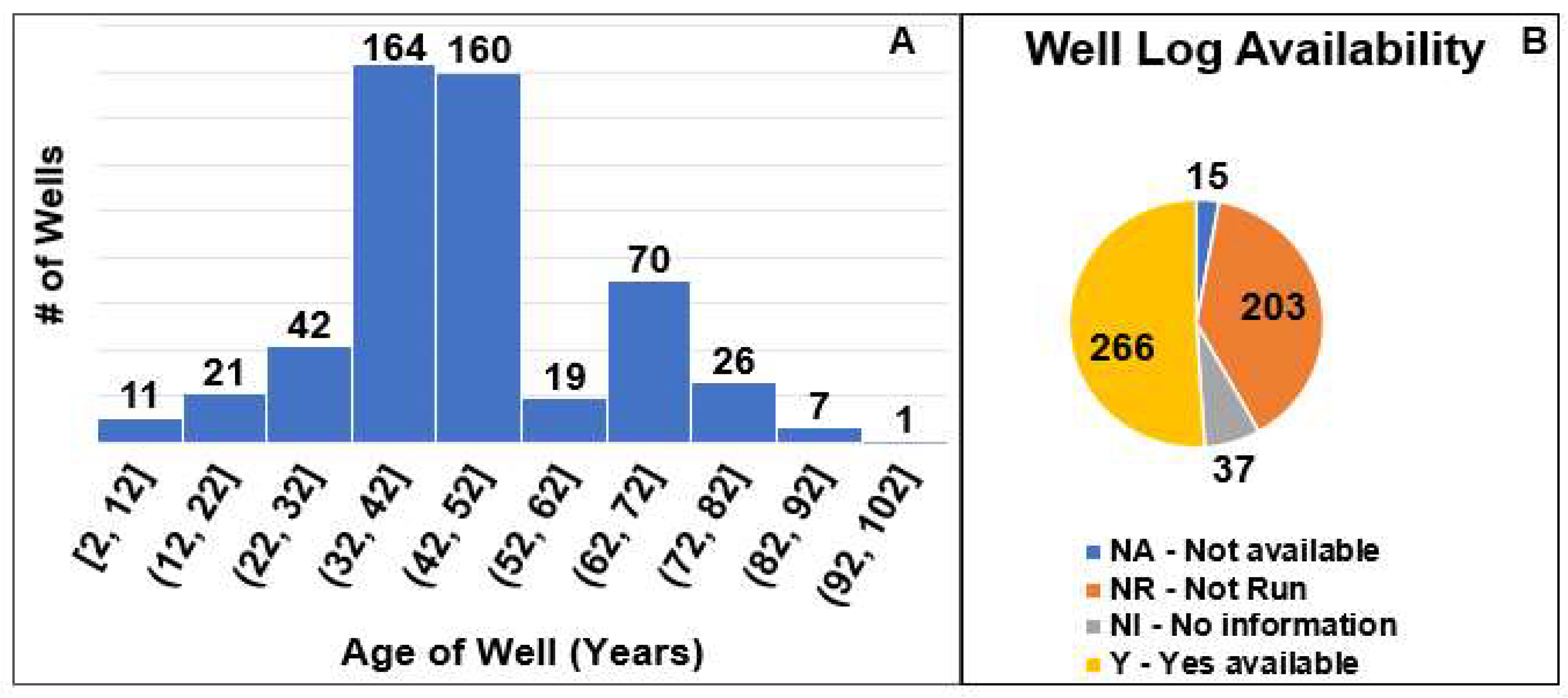

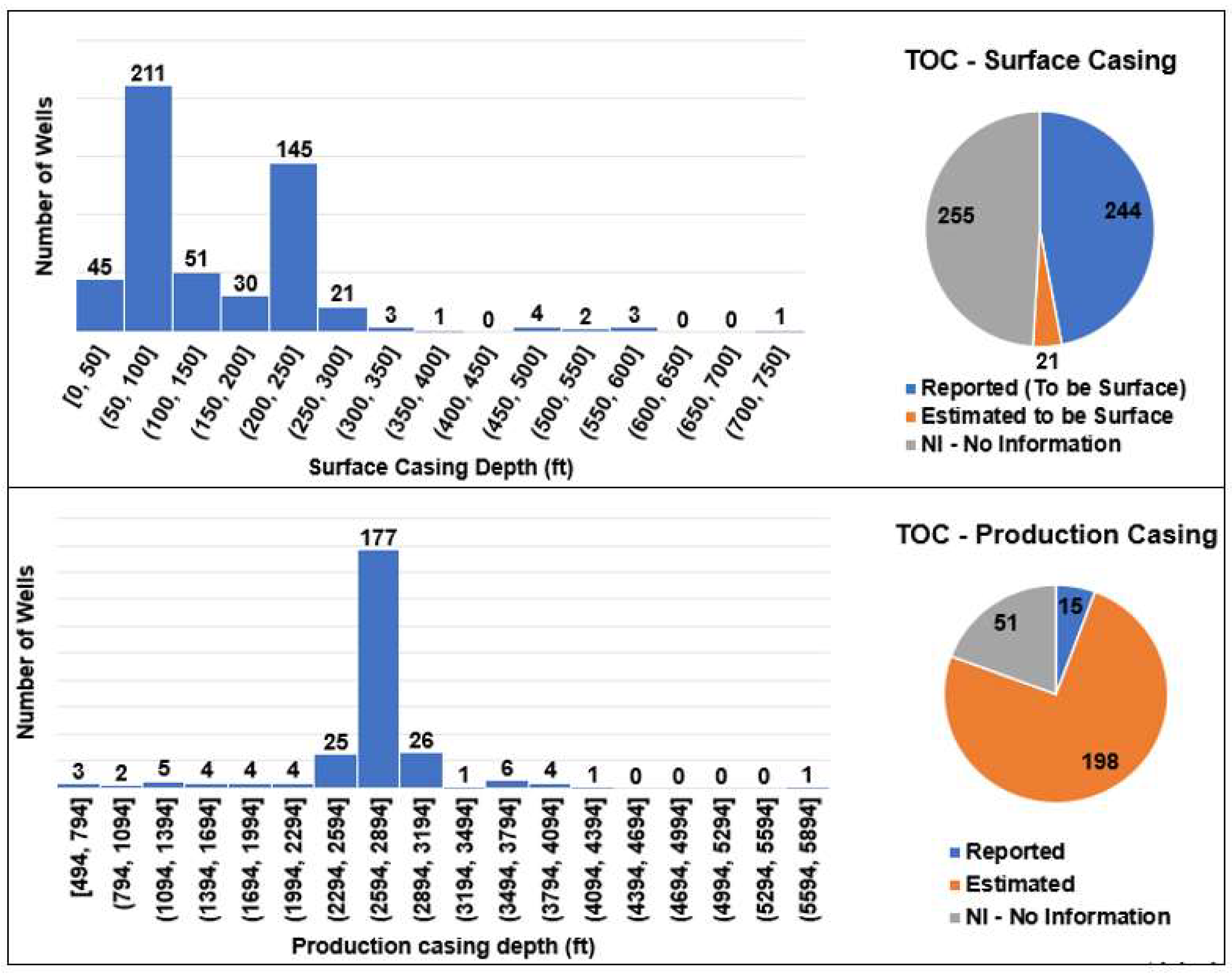

3.1. Summary of Wells Evaluated

3.2. Qualitative Risk Assessment Summary

4. Discussion

4.1. Salient Features of Wells within AoR

4.2. Wells with Target Depth (TD) Formation Code as 203MQKT

4.3. Phased Corrective Action Plan

- Type 6 with D&A status: This well just has surface casings and shallow plugs as barriers but no cement plugs across the confining seals.

- Type 6 with P&A status: This well has a cast iron bridge plug set at a shallower depth within the production casing that is cut and retrieved above the TOC.

- Type 3 with producer status: As this well is accessible due to its producer status, priority should be given to abandoned wells since locating them and re-entering would be challenging.

4.4. Uncertainty Reduction and Future Work

5. Conclusions

- Utilizing publicly available data, including reports and well logs submitted to state regulatory agencies, potential risky wells were identified based on criteria such as the proximity to the injection well location, depth, and mechanical integrity of well barriers.

- Among the 4386 wells assessed, 54 were identified as having high priority for corrective action, while 10 had medium priority, and the remaining were of low priority.

- Case study results from the Illinois basin demonstrated the effectiveness and applicability of this approach, showcasing its potential to enhance the safety and success of carbon capture and storage (CCS) projects globally.

6. Patent

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

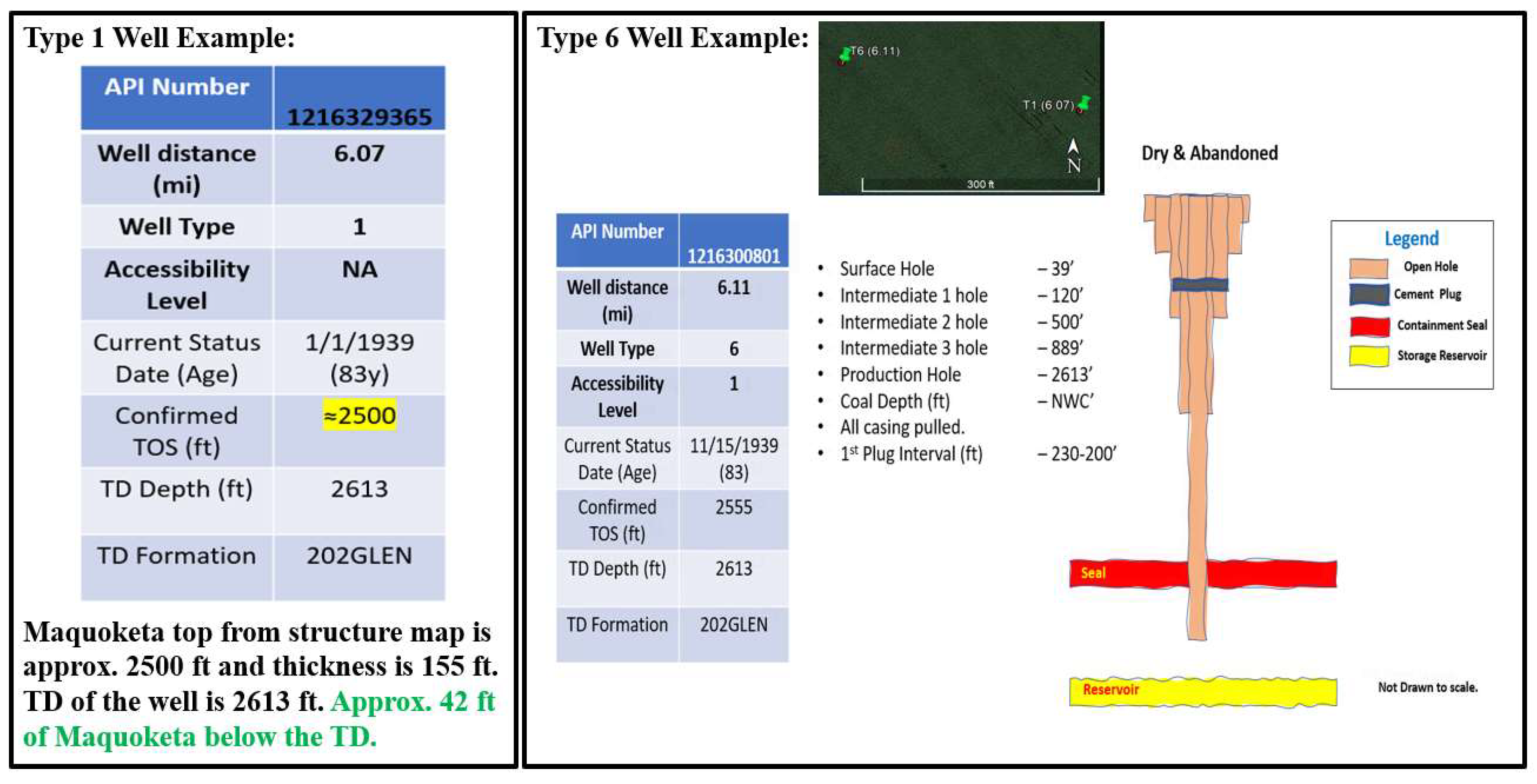

- Type 1 and Type 6 Well examples: There were no well reports available for this Type 1 well (API#1216329365), but an offset well (Type 6 well—API#1216300801) that was drilled by the same operator and abandoned in the same year was located just 300 ft away from this Type 1 well. Figure A1 shows the well schematic of the offset well. Based on a detailed evaluation of both wells, the authors estimated approximately 42 ft of Maquoketa shale was not penetrated by the Type 1 well. As seen in Figure A1, the offset well had all casing pulled out of the hole (POOH) and was plugged with only one 30-foot cement plug. It was still difficult to speculate if a similar plugging strategy was applied by the operator for the Type 1 well in discussion. It is interesting to note that all Type 6 wells have USDW protection, but there are no barriers across the primary confining seals.

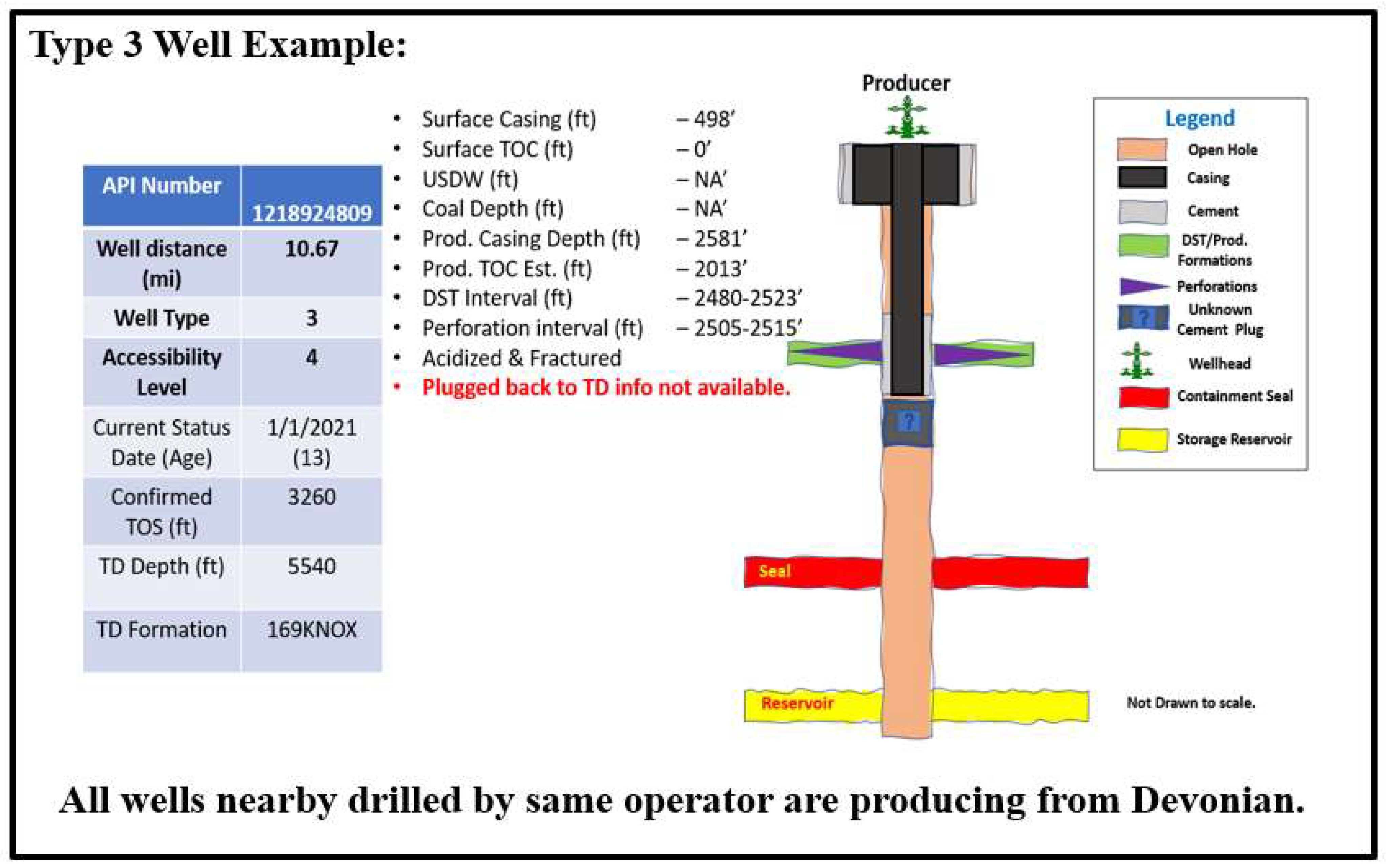

- Type 3 well example: Figure A2 shows the well schematic of the Type 3 well (API#1218924809). The plugback information was missing for this well, and all the nearby wells drilled by the same operator were completed and produced from the Devonian formation. This makes it difficult to understand the plugback strategy used by the operator and the uncertainty regarding the status of well barriers protecting the storage reservoir and primary confining seal remains for this Type 3 well.

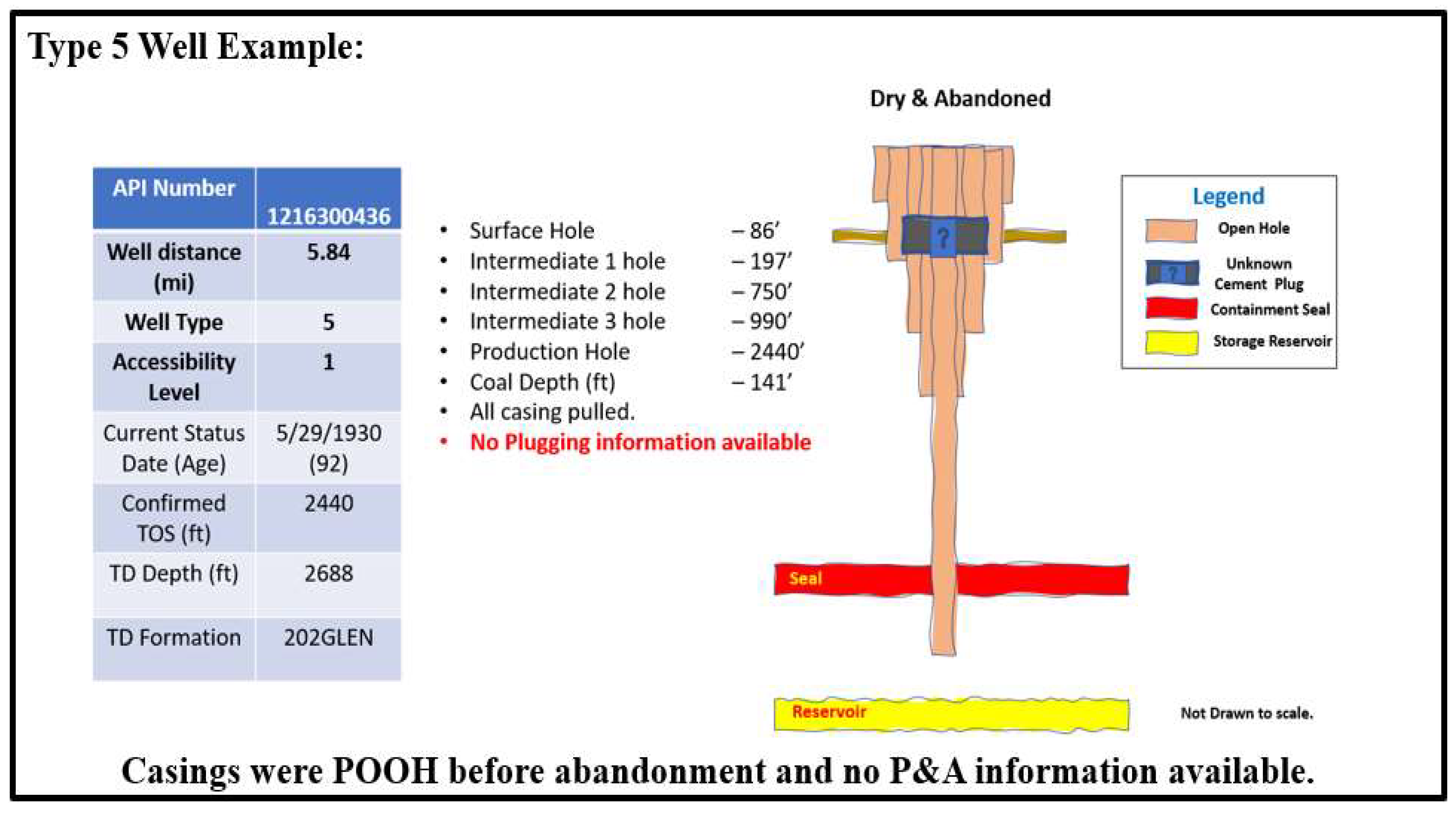

- Type 5 well example: Figure A3 shows the well schematic of the Type 5 well (API#1216300436). All casings were POOH for this well, and plugging information was missing. All the Type 5 wells have dry and abandoned status and do not have plugging information. The well type for these wells would change if the plugging information was available.

- Type 7, 8, and 9 well examples: Figure A4 shows the well schematic of the Type 7 well (API#1216325774), and Figure A5 shows the well schematic of the Type 8 well (API#1215724763). These wells have the least risk as they have appropriate well barriers protecting the primary confining seal and the storage reservoir. Since Type 9 wells are of least risk, their well schematics are not presented in this section.

References

- Adu, E.; Zhang, Y.; Liu, D. Current Situation of Carbon Dioxide Capture, Storage, and Enhanced Oil Recovery in the Oil and Gas Industry. Can. J. Chem. Eng. 2019, 97, 1048–1076. [Google Scholar] [CrossRef]

- Loria, P.; Bright, M.B.H. Lessons Captured from 50 Years of CCS Projects. Electr. J. 2021, 34, 106998. [Google Scholar] [CrossRef]

- Li, Q.; Liu, G. Geologic Carbon Sequestration; Vishal, V., Singh, T.N., Eds.; Springer International Publishing: Heidelberg, Germany, 2016; ISBN 978-3-319-27017-3. [Google Scholar]

- Jackson, R.B. The Integrity of Oil and Gas Wells. Proc. Natl. Acad. Sci. USA 2014, 111, 10902–10903. [Google Scholar] [CrossRef] [PubMed]

- Iyer, J.; Lackey, G.; Edvardsen, L.; Bean, A.; Carroll, S.A.; Huerta, N.; Smith, M.M.; Torsæter, M.; Dilmore, R.M.; Cerasi, P. A Review of Well Integrity Based on Field Experience at Carbon Utilization and Storage Sites. Int. J. Greenh. Gas Control 2022, 113, 103533. [Google Scholar] [CrossRef]

- Iyer, J.; Lackey, G.; Edvardsen, L.; Bean, A.; Carroll, S.; Huerta, N.; Smith, M.; Torsæter, M.; Dilmore, R.; Cerasi, P. A Review of International Field Experience with Well Integrity at Carbon Utilization and Storage Sites; DOE.NETL-2021.2649; NETL Technical Report Series; U.S. Department of Energy, National Energy Technology Laboratory: Morgantown, WV, USA, 2020. [Google Scholar]

- US EPA Geologic Sequestration of Carbon Dioxide Underground Injection Control (UIC) Program Class VI Well Area of Review Evaluation and Corrective Action Guidance. 2013; Volume 96. Available online: http://water.epa.gov/type/groundwater/uic/class6/gsguidedoc.cfm (accessed on 2 June 2023).

- Ide, S.T.; Friedmann, S.J.; Herzog, H.J. CO2 Leakage through Existing Wells: Current Technology and Regulations. In Proceedings of the 8th International Conference on Greenhouse Gas Control Technologies, Trondheim, Norway, 19–22 June 2006; pp. 1–6. [Google Scholar]

- Nyland, C.A. 8th International Conference on Greenhouse Gas Control Technologies (GHGT-8), Trondheim, Norway, 19 th–22 nd June 2006. Environ. Sci. Pollut. Res. 2006, 13, 445–446. [Google Scholar] [CrossRef]

- Boutot, J.; Peltz, A.S.; McVay, R.; Kang, M. Documented Orphaned Oil and Gas Wells Across the United States. Environ. Sci. Technol. 2022, 56, 14228–14236. [Google Scholar] [CrossRef]

- Cahill, A.G.; Samano, P.S.G. Prioritizing Stewardship of Decommissioned Onshore Oil and Gas Wells in the United Kingdom Based on Risk Factors Associated with Potential Long-Term Integrity. Int. J. Greenh. Gas Control 2022, 114, 103560. [Google Scholar] [CrossRef]

- Van Der Kuip, M.D.C.; Benedictus, T.; Wildgust, N.; Aiken, T. High-Level Integrity Assessment of Abandoned Wells. Energy Procedia 2011, 4, 5320–5326. [Google Scholar] [CrossRef]

- Arbad, N.; Teodoriu, C. A Review of Recent Research on Contamination of Oil Well Cement with Oil-Based Drilling Fluid and the Need of New and Accurate Correlations. ChemEngineering 2020, 4, 28. [Google Scholar] [CrossRef]

- Arbad, N.; Teodoriu, C.; Amani, M. Effect of Low OBM Contamination on Long-Term Integrity of API Class H Cement Slurries—Experimental Study. J. Pet. Sci. Eng. 2023, 220, 111191. [Google Scholar] [CrossRef]

- Harder, C.; Carpenter, R.; Wilson, W.; Freeman, E.; Payne, H. Surfactant/Cement Blends Improve Plugging Operations in Oil-Base Muds. In Proceedings of the IADC/SPE Drilling Conference, New Orleans, LA, USA, 18–21 February 1992. [Google Scholar] [CrossRef]

- Morris, E.F.; Motley, H.R. SPE: 4610 Oil Base Spacer System for Use in Cementing Wells Containing Oil Base Drilling Muds. In Proceedings of the 48th Annual Fall Meeting of the Society of Petroleum Engineers of AIME, Las Vegas, NV, USA, 30 September–3 October 1973; American Institute of Mining, Metallurgical, and Petroleum Engineers, Inc.: San Ramon, CA, USA. [Google Scholar]

- Arbad, N.; Rincon, F.; Teodoriu, C.; Amani, M. Experimental Investigation of Deterioration in Mechanical Properties of Oil-Based Mud (OBM) Contaminated API Cement Slurries & Correlations for Ultrasonic Cement Analysis. J. Pet. Sci. Eng. 2021, 205, 108909. [Google Scholar] [CrossRef]

- Arbad, N. Experimental Investigations of the Effect of Oil Based Mud (OBM) Contamination on Long-Term Integrity of API Cements. Master’s Thesis, University of Oklahoma, Norman, OK, USA, 2020. [Google Scholar]

- Nagelhout, A.C.G.; Bosma, M.G.R.; Mul, P.J.J.; Krol, G.G.; van Velzen, J.F.G.; Joldersma, J.S.; James, S.G.; Dargaud, B.; Schreuder, G.J.R.; Théry, F. Laboratory and Field Validation of a Sealant System for Critical Plug-and-Abandon Situations. SPE Drill. Complet. 2010, 25, 314–321. [Google Scholar] [CrossRef]

- Wang, D.; Li, J.; Lian, W.; Yang, H.; Lu, Z.; Liu, P.; Liu, X. Simulation Study of Cement Plug Micro-Annulus in Milling Section of Abandoned Wells. Geoenergy Sci. Eng. 2023, 224, 211606. [Google Scholar] [CrossRef]

- Hunter, K.; Bielicki, J.M.; Middleton, R.; Stauffer, P.; Pawar, R.; Harp, D.; Martinez, D. Integrated CO2 Storage and Brine Extraction. Energy Procedia 2017, 114, 6331–6336. [Google Scholar] [CrossRef]

- Buscheck, T.A.; Bielicki, J.M.; White, J.A.; Sun, Y.; Hao, Y.; Bourcier, W.L.; Carroll, S.A.; Aines, R.D. Managing Geologic CO2 Storage with Pre-Injection Brine Production in Tandem Reservoirs. Energy Procedia 2017, 114, 4757–4764. [Google Scholar] [CrossRef]

- Heath, J.E.; McKenna, S.A.; Dewers, T.A.; Roach, J.D.; Kobos, P.H. Multiwell CO2 Injectivity: Impact of Boundary Conditions and Brine Extraction on Geologic CO2 Storage Efficiency and Pressure Buildup. Environ. Sci. Technol. 2014, 48, 1067–1074. [Google Scholar] [CrossRef] [PubMed]

- Hamling, J.; Klapperich, R. Brine Extraction and Storage Test (Best): Enhancing CO2 Storage through Active Reservoir Management. In Proceedings of the 16th International Conference on Greenhouse Gas Control Technologies, GHGT-16, Lyon, France, 23–27 October 2022. [Google Scholar]

- Carey, J.W. Geochemistry of Wellbore Integrity in CO2 Sequestration: Portland Cement-Steel-Brine-CO2 Interactions. Rev. Mineral. Geochemistry 2013, 77, 505–539. [Google Scholar] [CrossRef]

- Kutchko, B.G.; Strazisar, B.R.; Lowry, G.V.; Dzombak, D.A.; Thaulow, N. Rate of CO2 Attack on Hydrated Class H Well Cement under Geologic Sequestration Conditions. Environ. Sci. Technol. 2008, 42, 6237–6242. [Google Scholar] [CrossRef] [PubMed]

- Kutchko, B.G.; Strazisar, B.R.; Dzombak, D.A.; Lowry, G.V.; Thauiow, N. Degradation of Well Cement by CO2 under Geologic Sequestration Conditions. Environ. Sci. Technol. 2007, 41, 4787–4792. [Google Scholar] [CrossRef]

- Huerta, N.J.; Carey, J.W.; Carroll, S.; Dzombak, D.; Harp, D.; Li, L.; Richard, T.; Walsh, S.D.C.; Um, W.; Zhang, L. Well Integrity in CO2 Storage Operations: Current Understanding and Open Questions; NRAP-TRS-I- 007-2016; NRAP Technical Report Series; U.S. Department of Energy, National Energy Technology Laboratory: Albany, OR, USA, 2016; p. 48. [Google Scholar]

- Carroll, S.; Carey, J.W.; Dzombak, D.; Huerta, N.J.; Li, L.; Richard, T.; Um, W.; Walsh, S.D.C.; Zhang, L. Review: Role of Chemistry, Mechanics, and Transport on Well Integrity in CO2 Storage Environments. Int. J. Greenh. Gas Control 2016, 49, 149–160. [Google Scholar] [CrossRef]

- Duguid, A.; Carey, J.W.; Butsch, R. Well Integrity Assessment of a 68 Year Old Well at a CO2 Injection Project. Energy Procedia 2014, 63, 5691–5706. [Google Scholar] [CrossRef]

- Teodoriu, C.; Bello, O. A Review of Cement Testing Apparatus and Methods under CO2 Environment and Their Impact on Well Integrity Prediction – Where Do We Stand? J. Pet. Sci. Eng. 2020, 187, 106736. [Google Scholar] [CrossRef]

- DePaolo, D.J.; Cole, D.R. Geochemistry of Geologic Carbon Sequestration: An Overview. Rev. Mineral. Geochem. 2013, 77, 1–14. [Google Scholar] [CrossRef]

- Bachu, S. Analysis of Gas Leakage Occurrence along Wells in Alberta, Canada, from a GHG Perspective – Gas Migration Outside Well Casing. Int. J. Greenh. Gas Control 2017, 61, 146–154. [Google Scholar] [CrossRef]

- D’Alesio, P.; Poloni, R.; Valente, P.; Magarini, P.A. Well-Integrity Assessment and Assurance: The Operational Approach for Three CO2-Storage Fields in Italy. SPE Prod. Oper. 2011, 26, 140–148. [Google Scholar] [CrossRef]

- Haagsma, A.; Weber, S.; Moody, M.; Sminchak, J.; Gerst, J.; Gupta, N. Comparative Wellbore Integrity Evaluation across a Complex of Oil and Gas Fields within the Michigan Basin and Implications for CO2 Storage. Greenh. Gases Sci. Technol. 2016, 828–842. [Google Scholar] [CrossRef]

- Ingraffe, A.R.; Wells, M.T.; Santoro, R.L.; Shonkoff, S.B.C. Assessment and Risk Analysis of Casing and Cement Impairment in Oil and Gas Wells in Pennsylvania, 2000–2012. Proc. Natl. Acad. Sci. USA 2014, 111, 10955–10960. [Google Scholar] [CrossRef] [PubMed]

- Lackey, G.; Rajaram, H.; Sherwood, O.A.; Burke, T.L.; Ryan, J.N. Surface Casing Pressure as an Indicator of Well Integrity Loss and Stray Gas Migration in the Wattenberg Field, Colorado. Environ. Sci. Technol. 2017, 51, 3567–3574. [Google Scholar] [CrossRef] [PubMed]

- Lackey, G.; Rajaram, H.; Bolander, J.; Sherwood, O.A.; Ryan, J.N.; Shih, C.Y.; Bromhal, G.S.; Dilmore, R.M. Public Data from Three US States Provide New Insights into Well Integrity. Proc. Natl. Acad. Sci. USA 2021, 118, 1–12. [Google Scholar] [CrossRef]

- Sminchak, J.R. Final Technical Report Integrated Wellbore Integrity Analysis Program for CO2 Storage Applications; Battelle Memorial Inst.: Columbus, OH, USA, 2018. [Google Scholar]

- Sminchak, J.R.; Moody, M.; Theodos, A.; Larsen, G.; Gupta, N. Investigation of Wellbore Integrity Factors in Historical Oil and Gas Wells for CO2 Geosequestration in the Midwestern U.S. Energy Procedia 2014, 63, 5787–5797. [Google Scholar] [CrossRef]

- Watson, T.L.; Bachu, S. Evaluation of the Potential for Gas and CO2 Leakage along Wellbores. SPE Drill. Complet. 2009, 24, 115–126. [Google Scholar] [CrossRef]

- Zulqarnain, M.; Zeidouni, M.; Hughes, R.G. Risk Based Approach to Identify the Leakage Potential of Wells in Depleted Oil and Gas Fields for CO2 Geological Sequestration. In Proceedings of the Carbon Management Technology Conference, Houston, TX, USA, 17 July 2017. [Google Scholar]

- Zulqarnain, M.; Zeidouni, M.; Hughes, R.G. Field-Scale Well Leakage Risk Assessment Using Reduced-Order Models. Greenh. Gases Sci. Technol. 2019, 9, 567–581. [Google Scholar] [CrossRef]

- Watson, T.L.; Bachu, S. Identification of Wells with High CO2-Leakage Potential in Mature Oil Fields Developed for CO2-Enhanced Oil Recovery. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 19–23 April 2008; Volume 1, pp. 234–243. [Google Scholar]

- Arbad, N.; Watson, M.; Heinze, L. Risk Matrix for Legacy Wells within the Area of Review (AoR) of Carbon Capture & Storage (CCS) Projects. Int. J. Greenh. Gas Control 2022, 121, 103801. [Google Scholar] [CrossRef]

- Arbad, N.; Watson, M.; Heinze, L.; Emadi, H. Qualitative Risk Assessment of Legacy Wells Based on Publicly Available Data for Class Vi Well Permit Applications–Illinois Basin Case Study. Int. J. Greenh. Gas Control 2023, 133, 104106. [Google Scholar] [CrossRef]

- Finley, R. An Assessment of Geological Carbon Sequestration Options in the Illinois Basin; Midwest Geological Sequestration Consortium: Pittsburgh, PA, USA; Morgantown, WV, USA, 2005. [Google Scholar]

- Lackey, G.; Vasylkivska, V.S.; Huerta, N.J.; King, S.; Dilmore, R.M. Managing Well Leakage Risks at a Geologic Carbon Storage Site with Many Wells. Int. J. Greenh. Gas Control 2019, 88, 182–194. [Google Scholar] [CrossRef]

- Baek, S.; Bacon, D.H.; Huerta, N.J. Enabling Site-Specific Well Leakage Risk Estimation during Geologic Carbon Sequestration Using a Modular Deep-Learning-Based Wellbore Leakage Model. Int. J. Greenh. Gas Control 2023, 126, 103903. [Google Scholar] [CrossRef]

- Vasylkivska, V.; Dilmore, R.; Lackey, G.; Zhang, Y.; King, S.; Bacon, D.; Chen, B.; Mansoor, K.; Harp, D. NRAP-Open-IAM: A Flexible Open-Source Integrated-Assessment-Model for Geologic Carbon Storage Risk Assessment and Management. Environ. Model. Softw. 2021, 143, 105114. [Google Scholar] [CrossRef]

- Brown, C.F.; Lackey, G.; Mitchell, N.; Baek, S.; Schwartz, B.; Dean, M.; Dilmore, R.; Blanke, H.; O’Brien, S.; Rowe, C. Integrating Risk Assessment Methods for Carbon Storage: A Case Study for the Quest Carbon Capture and Storage Facility. Int. J. Greenh. Gas Control 2023, 129, 103972. [Google Scholar] [CrossRef]

- Bacon, D.H.; Demirkanli, D.I.; White, S.K. Probabilistic Risk-Based Area of Review (AoR) Determination for a Deep-Saline Carbon Storage Site. Int. J. Greenh. Gas Control 2020, 102, 103153. [Google Scholar] [CrossRef]

- Bandilla, K.; Court, B.; Elliot, T.R.; Celia, M.A. Comparison of Brine Production Scenarios for Geologic Carbon Sequestration Operations. In Proceedings of the Carbon Management Technology Conference, Orlando, FL, USA, 5 April 2012. [Google Scholar]

| Storage Reservoir | Name | St. Peter Sandstone |

| Approx. Depth (ft) | 3570 | |

| Approx. thickness (ft) | 170 | |

| Primary Confining Seal | Name | Ordovician Maquoketa Shale Group |

| Approx. Top (ft) | 2790 | |

| Approx. thickness (ft) | 150 | |

| Lowermost USDW | Formation name | Shallow Bedrock deposits |

| Approx. Top (ft) | Within 500 ft | |

| Legacy Wellbores | Well penetrating lowermost storage reservoir | 300 boring records within 25 miles area penetrating through Maquoketa Shale. |

| Southern Illinois | Northern Illinois | ||||

|---|---|---|---|---|---|

| Primary Confining Seal | |||||

| System | Group | Formation | Formation | Group | System |

| Ordovician (209ODVC) | Maquoketa Fm (203MQKT) | Brainard (203BRRD) | Maquoketa Fm (203MQKT) | Ordovician (209ODVC) | |

| Ft. Atkinson (203FRAK) | |||||

| Cape Ls (352CRPR) | Scales Sh (203SCLS) | ||||

| Below Primary Confining Seal | |||||

| Ordovician (209ODVC) | Galena (202GLEN) | Kimmswick Ls (202KMCK) | Dubuque (203DUBQ) | Galena (202GLEN) | Ordovician (209ODVC) |

| Wise Lake (203WSLK) | |||||

| Decorah (202DCRH) | Dunleith (202DNLT) | ||||

| Decorah (202DCRH) | |||||

| Platteville (202PLVL) | Plattin Ls (202PLTN) | Quimbys Mill (202QMBY) | Platteville (202PLVL) | ||

| Nachusa (202NCHS) | |||||

| Grand Detour (202GRDD) | |||||

| Mifflin (202MFLN) | |||||

| Pecatonica (202PCNC) | Pecatonica (202PCNC) | ||||

| Ancell (202ANCL) | Joachim Dol (202JCHM) | Joachim Dol (202JCHM) | Ancell (202ANCL) | ||

| Dutchtown Ls | |||||

| Storage Reservoir | |||||

| Ordovician (209ODVC) | Ancell (202ANCL) | St Peter (202SPTR) | St Peter (202SPTR) | Ancell (202ANCL) | Middle Ordovician (209ODVC) |

| Secondary Storage Reservoir | |||||

| Cambrian (159CMBR) | Knox (169KNOX) | Potosi (153POTS) | Potosi (153POTS) | Knox (169KNOX) | Cambrian (159CMBR) |

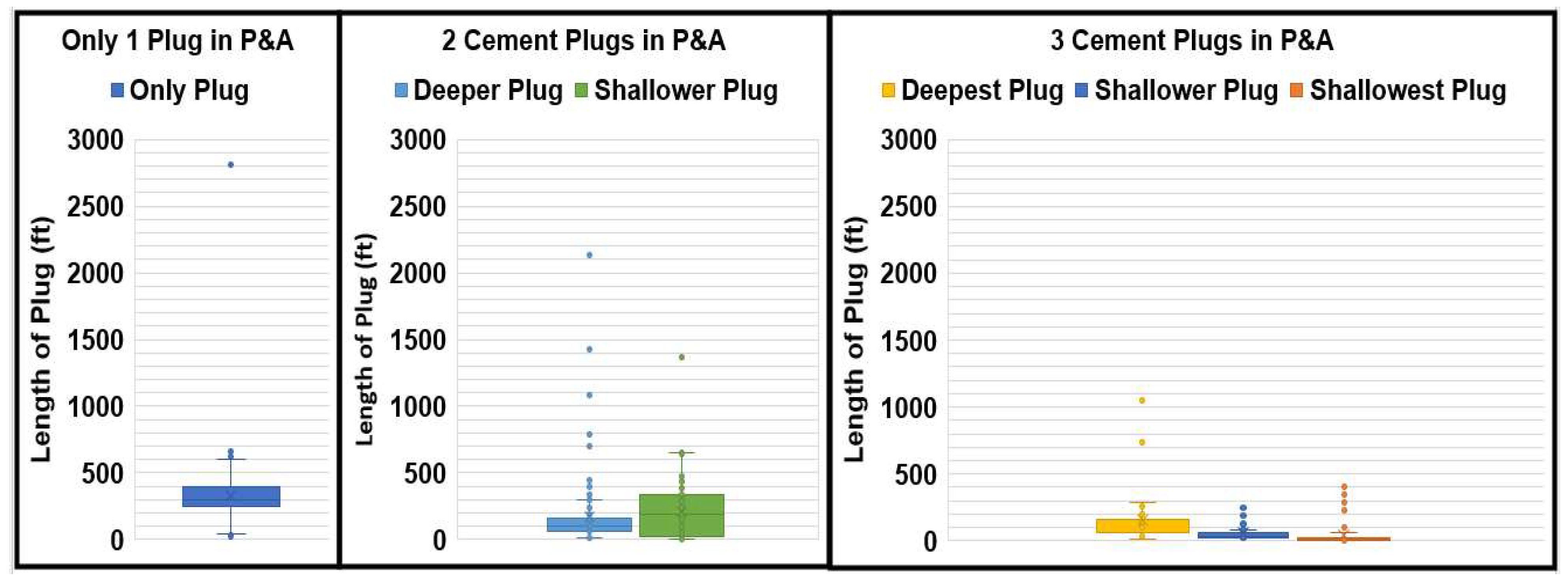

| Number of Cement Plug (s) | Number of Wells |

|---|---|

| 1 | 135 |

| 2 | 115 |

| 3 | 56 |

| 4 | 3 |

| 5 | 1 |

| 6 | 1 |

| Sr. No | Current Well Type | API10P | TD (ft) | Estimated Maquoketa Thickness (ft) | Trenton Tops Estimated (ft) | Maquoketa Below TD (ft) |

|---|---|---|---|---|---|---|

| 1 | Type 1 | 1216329365 | 2613 | 155 | 2655 | 42 |

| 2 | Type 1 | 1216323789 | 2350 | 150 | 2435 | 85 |

| 3 | Type 6 | 1216325631 | 2614 | 145 | 2702 | 88 |

| 4 | Type 6 | 1218924586 | 3300 | 155 | 3327 | 27 |

| 5 | Type 6 | 1218924485 | 3002 | 122 | 3080 | 78 |

| 6 | Type 6 | 1218901772 | 2712 | 145 | 2780 | 68 |

| 7 | Type 6 | 1218902866 | 3601 | 105 | 3655 | 54 |

| 8 | Type 8 | 1215724984 | 2600 | 116 | 2716 | 116 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arbad, N.; Watson, M.; Emadi, H.; Eyitayo, S.; Leggett, S. Strategic Qualitative Risk Assessment of Thousands of Legacy Wells within the Area of Review (AoR) of a Potential CO2 Storage Site. Minerals 2024, 14, 383. https://doi.org/10.3390/min14040383

Arbad N, Watson M, Emadi H, Eyitayo S, Leggett S. Strategic Qualitative Risk Assessment of Thousands of Legacy Wells within the Area of Review (AoR) of a Potential CO2 Storage Site. Minerals. 2024; 14(4):383. https://doi.org/10.3390/min14040383

Chicago/Turabian StyleArbad, Nachiket, Marshall Watson, Hossein Emadi, Stella Eyitayo, and Smith Leggett. 2024. "Strategic Qualitative Risk Assessment of Thousands of Legacy Wells within the Area of Review (AoR) of a Potential CO2 Storage Site" Minerals 14, no. 4: 383. https://doi.org/10.3390/min14040383

APA StyleArbad, N., Watson, M., Emadi, H., Eyitayo, S., & Leggett, S. (2024). Strategic Qualitative Risk Assessment of Thousands of Legacy Wells within the Area of Review (AoR) of a Potential CO2 Storage Site. Minerals, 14(4), 383. https://doi.org/10.3390/min14040383