Coupling Effect of Intruding Water and Inherent Gas on Coal Strength Based on the Improved (Mohr-Coulomb) Failure Criterion

Abstract

:1. Introduction

2. Development of the Theory

2.1. Effective Stress of Coal Containing Water and Gas

2.2. Failure Criterion for Coal Containing Water and Gas

3. Matrix Suction of Coal

3.1. Methods of Measuring Matrix Suction

3.2. Coal Samples

3.3. Test Procedure

3.4. Test Results

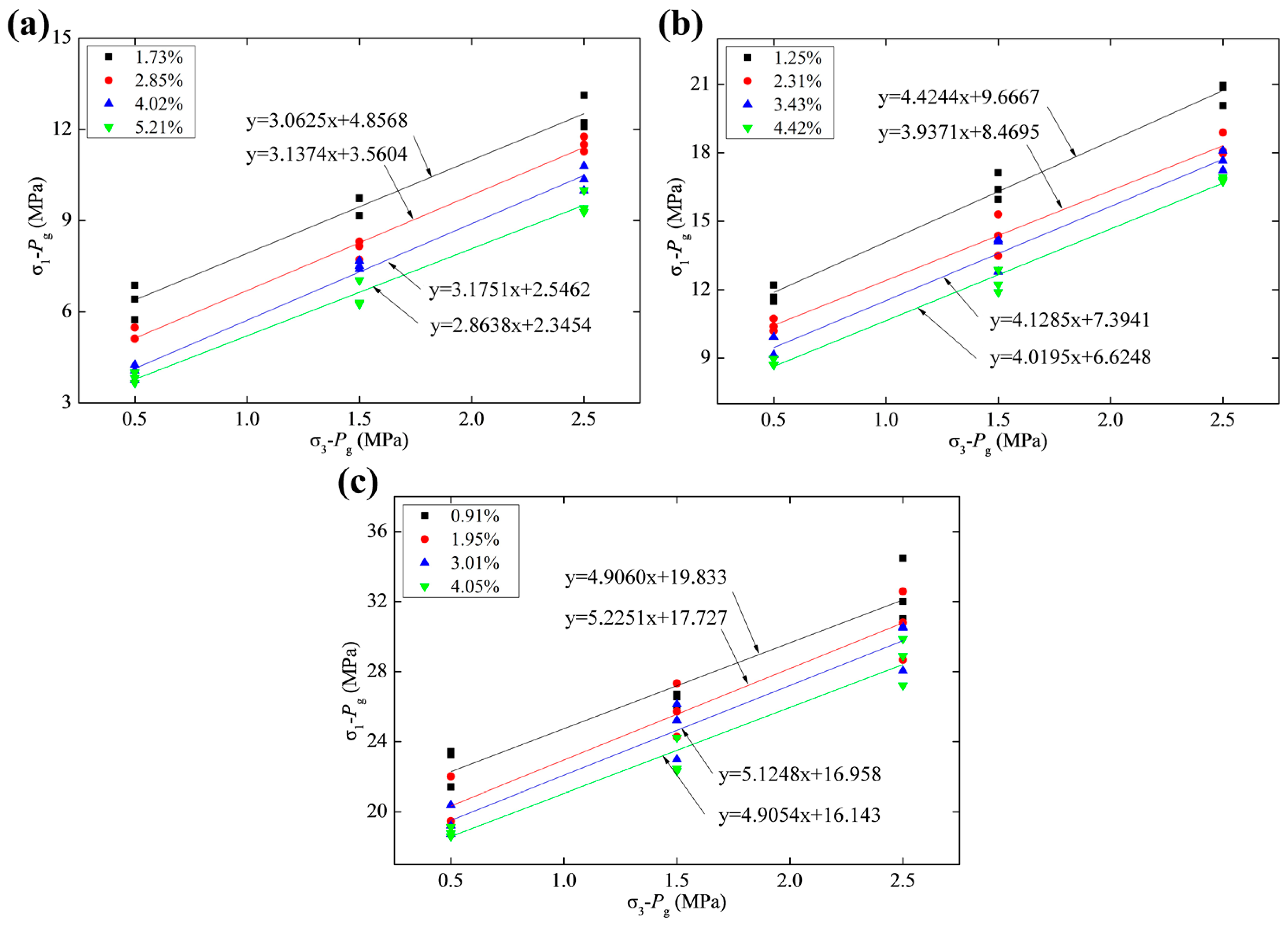

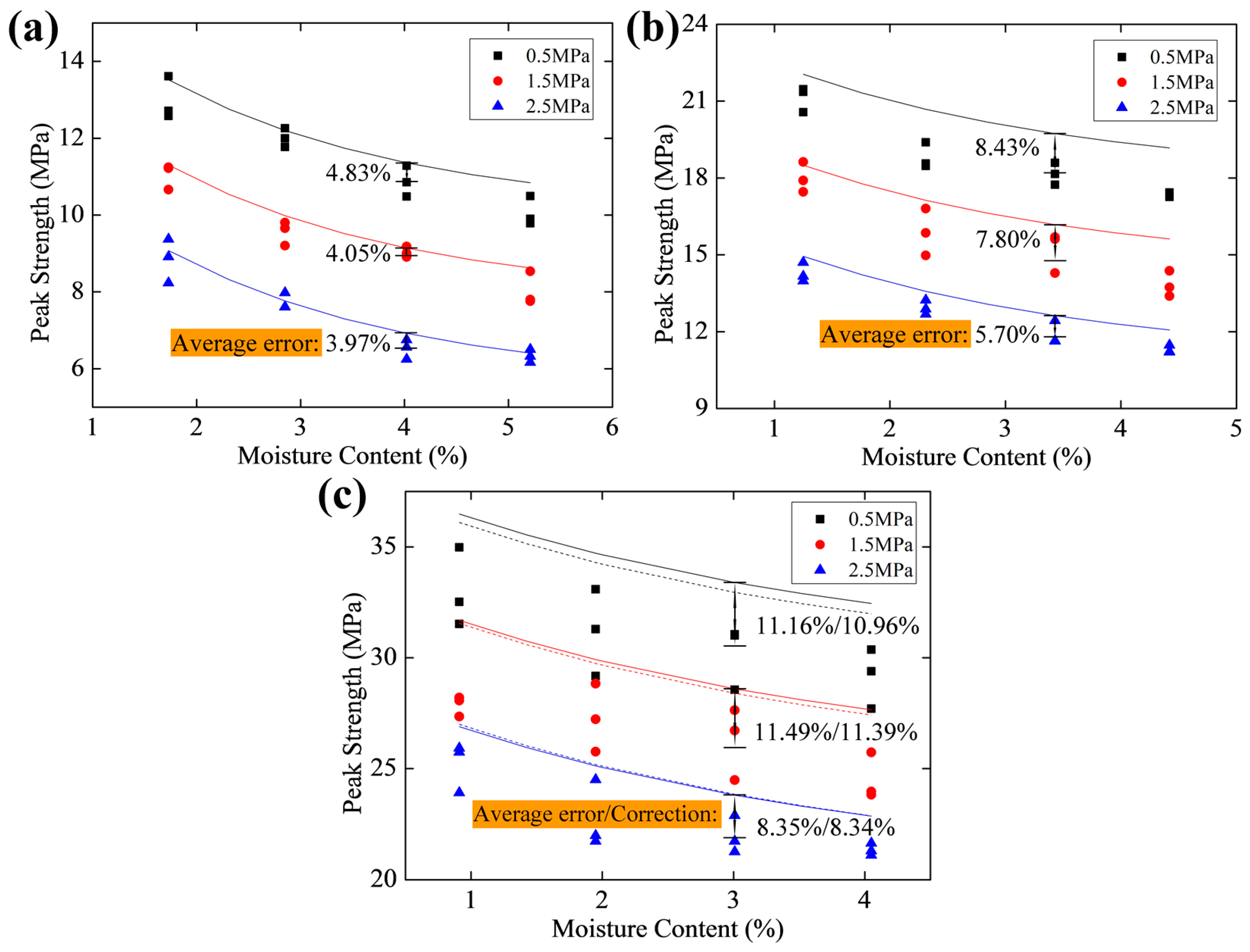

4. Triaxial Compression Strength

4.1. Experimental Methods

4.2. Experimental Results and Analysis

5. Discussion

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tang, J.R.; Lu, Y.Y.; Ge, Z.L.; Xia, B.W.; Sun, H.J.; Du, P. A new method of combined rock drilling. Int. J. Min. Sci. Technol. 2014, 24, 1–6. [Google Scholar] [CrossRef]

- Fisne, A.; Esen, O. Coal and gas outburst hazard in Zonguldak Coal Basin of Turkey, and association with geological parameters. Nat. Hazards 2014, 74, 1363–1390. [Google Scholar] [CrossRef]

- Luo, Y.B.; Zheng, M.P. Origin of minerals and elements in the Late Permian coal seams of the Shiping mine, Sichuan, Southwestern China. Minerals 2016, 6, 74. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Liu, Y.; Ge, Z.L.; Li, X.H.; Kang, Y. A new method of drilling long boreholes in low permeability coal by improving its permeability. Int. J. Coal Geol. 2010, 84, 94–102. [Google Scholar] [CrossRef]

- Zheng, Z.T.; Xu, Y.; Li, D.S.; Dong, J.H. Numerical analysis and experimental study of hard roofs in fully mechanized mining faces under sleeve fracturing. Minerals 2015, 5, 758–777. [Google Scholar] [CrossRef]

- Li, Q.G.; Lin, B.Q.; Zhai, C. The effect of pulse frequency on the fracture extension during hydraulic fracturing. J. Nat. Gas Sci. Eng. 2014, 21, 296–303. [Google Scholar] [CrossRef]

- Hawkins, A.B.; McConnell, B.J. Sensitivity of sandstone strength and deformability to changes in moisture content. Q. J. Eng. Geol. 1992, 25, 115–30. [Google Scholar] [CrossRef]

- Erguler, Z.A.; Ulusay, R. Water-induced variations in mechanical properties of clay-bearing rocks. Int. J. Rock Mech. Min. 2009, 46, 355–370. [Google Scholar] [CrossRef]

- Vasarhelyi, B. Statistical analysis of the influence of water content on the strength of the Miocene limestone. Rock. Mech. Rock. Eng. 2005, 38, 69–76. [Google Scholar] [CrossRef]

- Perera, M.S.A.; Ranjith, P.G.; Peter, M. Effects of saturation medium and pressure on strength parameters of Latrobe Valley brown coal: Carbon dioxide, water and nitrogen saturations. Energy 2011, 36, 6941–6947. [Google Scholar] [CrossRef]

- Poulsen, B.A.; Shen, B.; Williams, D.J.; Huddlestone-Holmes, C.; Erarslan, N.; Qin, J. Strength reduction on saturation of coal and coal measures rocks with implications for coal pillar strength. Int. J. Rock Mech. Min. 2014, 71, 41–52. [Google Scholar] [CrossRef]

- Van Eeckhout, E.M. The mechanisms of strength reduction due to moisture in coal mine shales. Int. J. Rock Mech. Min. 1976, 13, 61–67. [Google Scholar] [CrossRef]

- Aziz, N.I.; Ming-Li, W. The effect of sorbed gas on the strength of coal—An experimental study. Geotechnol. Geol. Eng. 1999, 17, 387–402. [Google Scholar] [CrossRef]

- Skoczylas, N.; Dutka, B.; Sobczyk, J. Mechanical and gaseous properties of coal briquettes in terms of outburst risk. Fuel 2014, 134, 45–52. [Google Scholar] [CrossRef]

- Perera, M.S.A.; Ranjith, P.G.; Choi, S.K.; Bouazza, A.; Kodikara, J.; Airey, D. A review of coal properties pertinent to carbon dioxide sequestration in coal seams: With special reference to Victorian brown coals. Environ. Earth Sci. 2011, 64, 223–235. [Google Scholar] [CrossRef]

- George, J.D.; Barakat, M.A. The change in effective stress associated with shrinkage from gas desorption in coal. Int. J. Coal Geol. 2001, 45, 105–113. [Google Scholar] [CrossRef]

- Chen, Z.W.; Pan, Z.J.; Liu, J.S.; Connell, L.D.; Elsworth, D. Effect of the effective stress coefficient and sorption-induced strain on the evolution of coal permeability: Experimental observations. Int. J. Greenh. Gas. Control 2011, 5, 1284–1293. [Google Scholar] [CrossRef]

- Vishal, V.; Ranjith, P.G.; Pradhan, S.P.; Singh, T.N. Permeability of sub-critical carbon dioxide in naturally fractured Indian bituminous coal at a range of down-hole stress conditions. Eng. Geol. 2013, 167, 148–156. [Google Scholar] [CrossRef]

- Vaziri, H.H.; Wang, X.; Palmer, I.D.; Khodaverdian, M.; Mclennan, J. Back analysis of coalbed strength properties from field measurements of wellbore cavitation and methane production. Int. J. Rock Mech. Min. 1997, 34, 963–978. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Perera, M.S.A. Effects of cleat performance on strength reduction of coal in CO2 sequestration. Energy 2012, 45, 1069–1075. [Google Scholar] [CrossRef]

- Liang, B.; Zhang, M.T.; Pan, Y.S.; Wang, Y.J. The experimental research on the effect of gas on mechanical properties and mechanical response of coal. Chin. J. Geotechnol. Eng. 1995, 17, 12–18. [Google Scholar]

- Vasarhelyi, B.; Kovacs, L.; Torok, A. Analysing the modified Hoek–Brown failure criteria using Hungarian granitic rocks. Geomech. Geophys. Geo-Energy Geo-Resour. 2016, 2, 131–136. [Google Scholar] [CrossRef]

- Joubert, J.I.; Grein, C.T. Sorption of methane in moist coal. Fuel 1973, 52, 181–185. [Google Scholar] [CrossRef]

- Laxminarayana, C.; Crosdale, P.J. Controls on methane sorption capacity of Indian coals. AAPG Bull. 2002, 86, 201–212. [Google Scholar]

- Biot, M.A. Theory of propagation of elastic waves in a fluid saturated porous solid. J. Acoust. Soc. Am. 1956, 28, 168–191. [Google Scholar] [CrossRef]

- Chen, W.Y.; Xia, T.D.; Hu, W.T. A mixture theory analysis for the surface-wave propagation in an unsaturated porous medium. Int. J. Solids Struct. 2011, 48, 2402–2412. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, Y.K. Constitutive relation of unsaturated soil by use of the mixture theory (I)-nonlinear constitutive equations and field equations. Appl. Math. Mech. Engl. 2003, 24, 123–137. [Google Scholar]

- Fredlund, D.G.; Houston, S.L. Protocol for the assessment of unsaturated soil properties in geotechnical engineering practice. Can. Geotechnol. J. 2009, 46, 694–707. [Google Scholar] [CrossRef]

- Houston, S.L.; Houston, W.N.; Wagner, M. Laboratory filter paper suction measurements. Geotechnol. Test. J. 1994, 17, 1209–1217. [Google Scholar]

- Gardner, R. A method of measuring the capillary tension of soil moisture over a wide moisture range. Soil Sci. 1937, 43, 277–284. [Google Scholar] [CrossRef]

- Lang, A.R.G. Osmotic coefficient and water potentials of sodium chloride solutions from 0 to 40 °C. Aust. J. Chem. 1967, 20, 2017–2023. [Google Scholar] [CrossRef]

- Hamblin, A.P. Filter-paper method for routine measurement of field water potential. J. Hydrol. 1981, 53, 355–360. [Google Scholar] [CrossRef]

- Li, X.S.; Yin, G.Z.; Zhao, H.B.; Wang, W.Z.; Jing, X.F. Experimental study of mechanical properties of outburst coal containing gas under triaxial compression. Chin. J. Rock. Mech. Eng. 2010, 29, 3350–3358. [Google Scholar]

- Gamson, P.; Beamish, B.; Johnson, D. Coal microstructure and secondary mineralization: Their effect on methane recovery. J. Geol. Soc. 1996, 199, 165–179. [Google Scholar] [CrossRef]

- Okolo, G.N.; Everson, R.C.; Neomagus, H.W.J.P.; Roberts, M.J.; Sakurovs, R. Comparing the porosity and surface areas of coal as measured by gas adsorption, mercury intrusion and SAXS techniques. Fuel 2015, 141, 293–304. [Google Scholar] [CrossRef]

- Akbarzadeh, H.; Chalaturnyk, R.J. Structural changes in coal at elevated temperature pertinent to underground coal gasification: A review. Int. J. Coal Geol. 2014, 131, 126–146. [Google Scholar] [CrossRef]

| Location | Coal Type | Fixed Carbon | Volatile Matter Content | Porosity | Average Pore Size |

|---|---|---|---|---|---|

| Songzao | Meagre coal | 66.4% | 13.2% | 5.88% | 4.08 nm |

| Pingdingshan | Fat coal | 57.1% | 17.7% | 5.16% | 8.60 nm |

| Tashan | 1/3 Coking coal | 57.8% | 28.1% | 4.23% | 14.65 nm |

| No. | Soaking Time (Day) | Moisture Content | ||

|---|---|---|---|---|

| Songzao | Pingdingshan | Tashan | ||

| 1 | 1 | 1.73% | 1.25% | 0.91% |

| 2 | 2 | 2.85% | 2.31% | 1.95% |

| 3 | 4 | 4.02% | 3.43% | 3.01% |

| 4 | 8 | 5.21% | 4.42% | 4.05% |

| No. | 25 °C, NaCl Solution, Related Parameters | Moisture Content of Filter Paper | |

|---|---|---|---|

| Molarity (mol/L) | Suction (MPa) | ||

| 1 | 0.4 | 9.75 | 17.05% |

| 2 | 0.5 | 12.56 | 15.36% |

| 3 | 1 | 25.43 | 11.66% |

| 4 | 2 | 51.47 | 7.75% |

| 5 | 3 | 77.50 | 5.46% |

| 6 | 4 | 103.53 | 3.87% |

| Location | Moisture Content | Strength (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Gas Pressure = 0.5 MPa | Gas Pressure = 1.5 MPa | Gas Pressure = 2.5 MPa | ||||||||

| Songzao | 1.73% | 12.57 | 13.61 | 12.71 | 11.24 | 11.22 | 10.66 | 9.37 | 8.23 | 8.91 |

| 2.85% | 11.77 | 11.99 | 12.25 | 9.65 | 9.20 | 9.80 | 7.97 | 7.60 | 7.61 | |

| 4.02% | 11.28 | 10.85 | 10.48 | 9.00 | 8.90 | 9.17 | 6.56 | 6.24 | 6.75 | |

| 5.21% | 9.90 | 9.78 | 10.49 | 7.79 | 8.53 | 7.75 | 6.32 | 6.50 | 6.16 | |

| Pingdingshan | 1.25% | 21.46 | 21.36 | 20.57 | 17.45 | 17.89 | 18.62 | 14.16 | 13.98 | 14.70 |

| 2.31% | 19.39 | 18.47 | 18.56 | 15.85 | 14.97 | 16.80 | 12.88 | 12.68 | 13.23 | |

| 3.43% | 18.15 | 17.73 | 18.59 | 15.69 | 15.61 | 14.28 | 11.63 | 12.42 | 11.64 | |

| 4.42% | 17.43 | 17.31 | 17.25 | 13.39 | 13.72 | 14.37 | 11.19 | 11.47 | 11.21 | |

| Tashan | 0.91% | 34.97 | 31.52 | 32.51 | 27.35 | 28.06 | 28.09 | 23.91 | 25.74 | 25.92 |

| 1.95% | 31.29 | 33.08 | 29.17 | 27.22 | 28.83 | 25.76 | 24.50 | 21.72 | 21.97 | |

| 3.01% | 31.00 | 31.05 | 28.55 | 24.48 | 26.71 | 27.62 | 21.73 | 21.24 | 22.88 | |

| 4.05% | 30.36 | 27.70 | 29.38 | 23.82 | 23.96 | 25.72 | 21.10 | 21.64 | 21.28 | |

| Location | Sample Condition | Moisture Content | Gas Pressure (MPa) | Experimental Strength (MPa) | Theoretical Value (MPa) | Deviation |

|---|---|---|---|---|---|---|

| Songzao | dry | 0% | 0 | 17.91 | 18.42 | 2.85% |

| dry + methane | 0% | 2.5 | 12.19 | 12.87 | 5.58% | |

| water saturated | 5.21% | 0 | 11.36 | 11.95 | 5.19% |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Zhou, Z.; Ge, Z.; Zhang, X.; Li, Q. Coupling Effect of Intruding Water and Inherent Gas on Coal Strength Based on the Improved (Mohr-Coulomb) Failure Criterion. Minerals 2016, 6, 118. https://doi.org/10.3390/min6040118

Lu Y, Zhou Z, Ge Z, Zhang X, Li Q. Coupling Effect of Intruding Water and Inherent Gas on Coal Strength Based on the Improved (Mohr-Coulomb) Failure Criterion. Minerals. 2016; 6(4):118. https://doi.org/10.3390/min6040118

Chicago/Turabian StyleLu, Yiyu, Zhe Zhou, Zhaolong Ge, Xinwei Zhang, and Qian Li. 2016. "Coupling Effect of Intruding Water and Inherent Gas on Coal Strength Based on the Improved (Mohr-Coulomb) Failure Criterion" Minerals 6, no. 4: 118. https://doi.org/10.3390/min6040118