Predicting the Risk of Fault-Induced Water Inrush Using the Adaptive Neuro-Fuzzy Inference System

Abstract

:1. Introduction

2. Brief Description of Fault-Induced Water Inrush

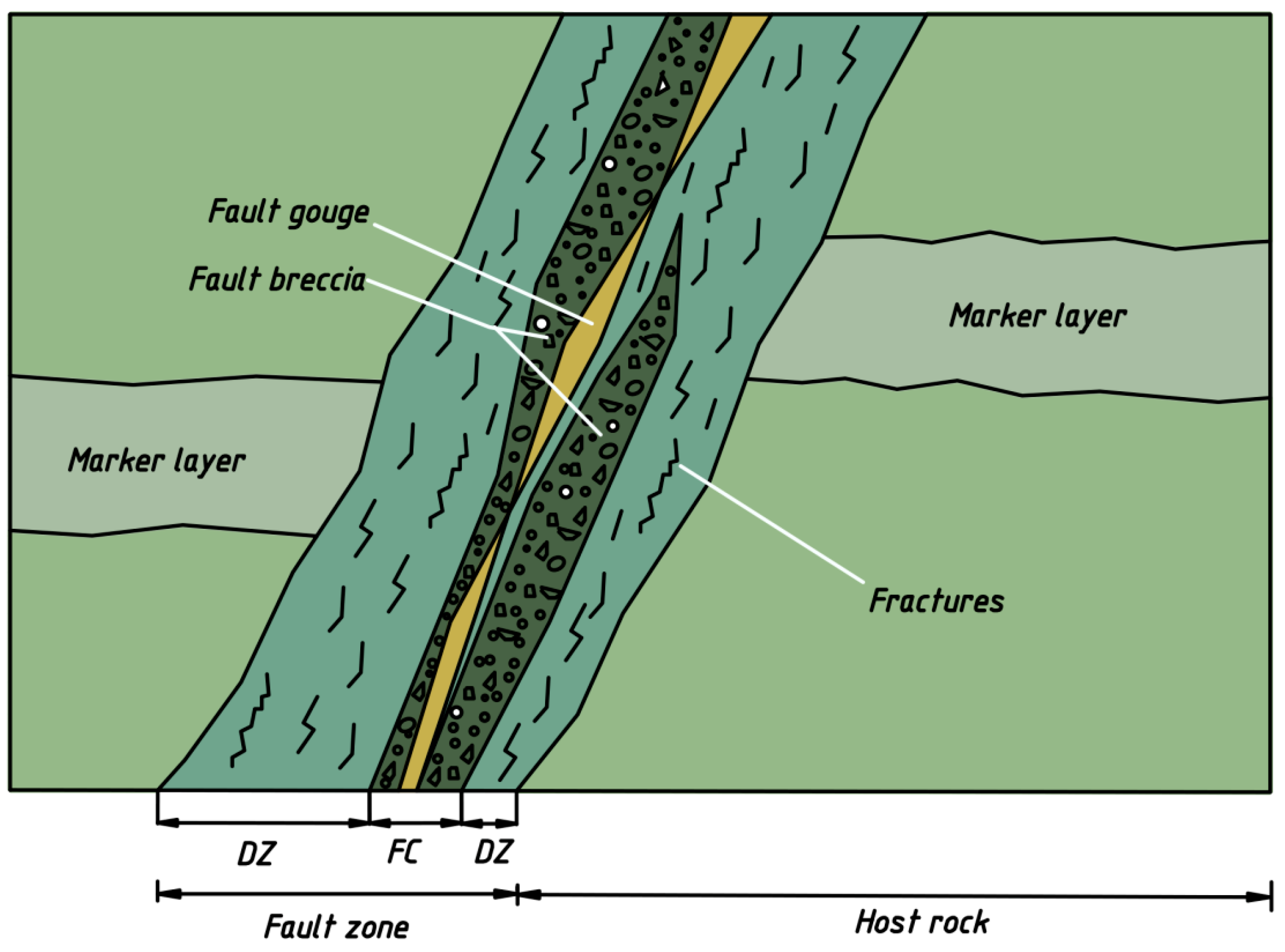

2.1. Water-Conducting Property of Fault

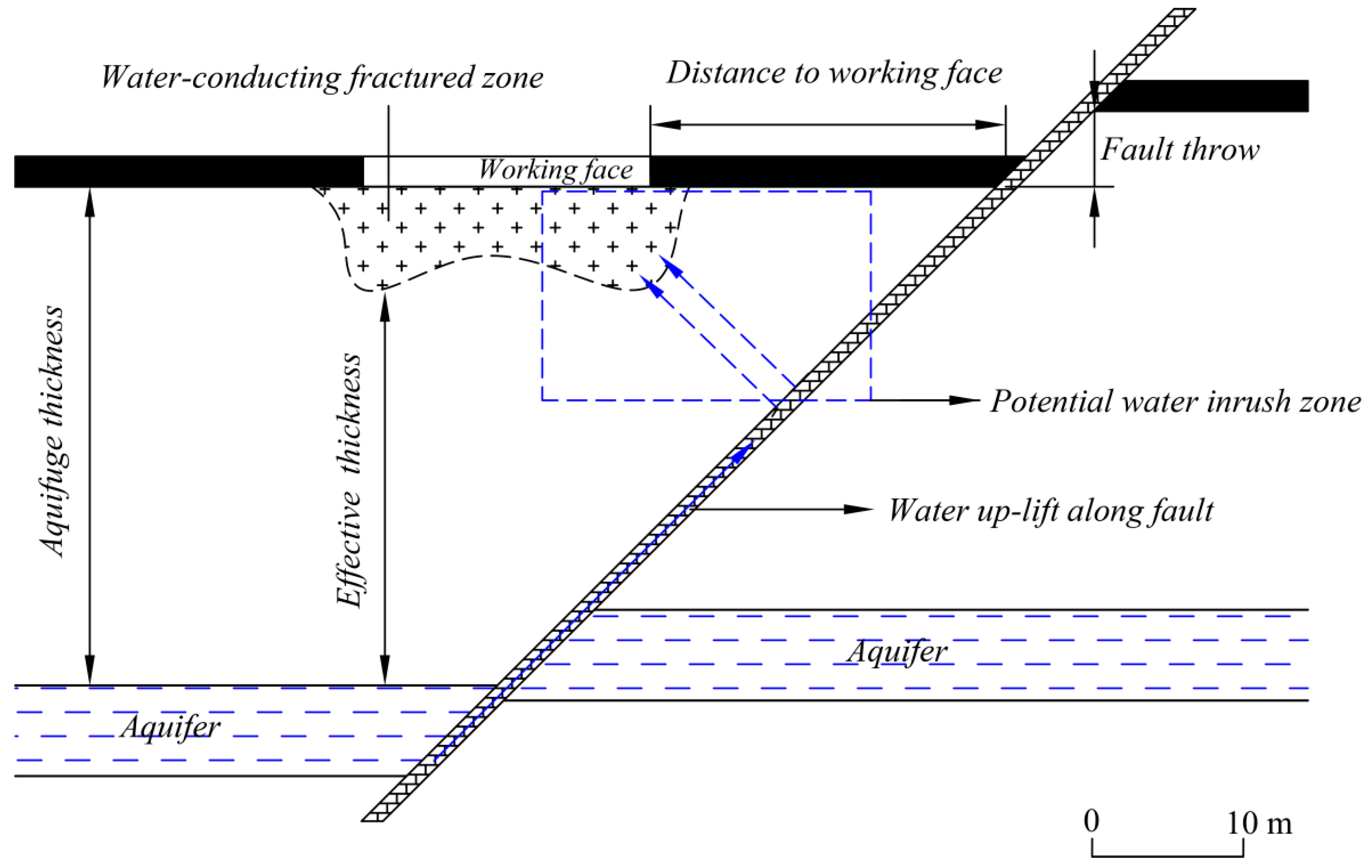

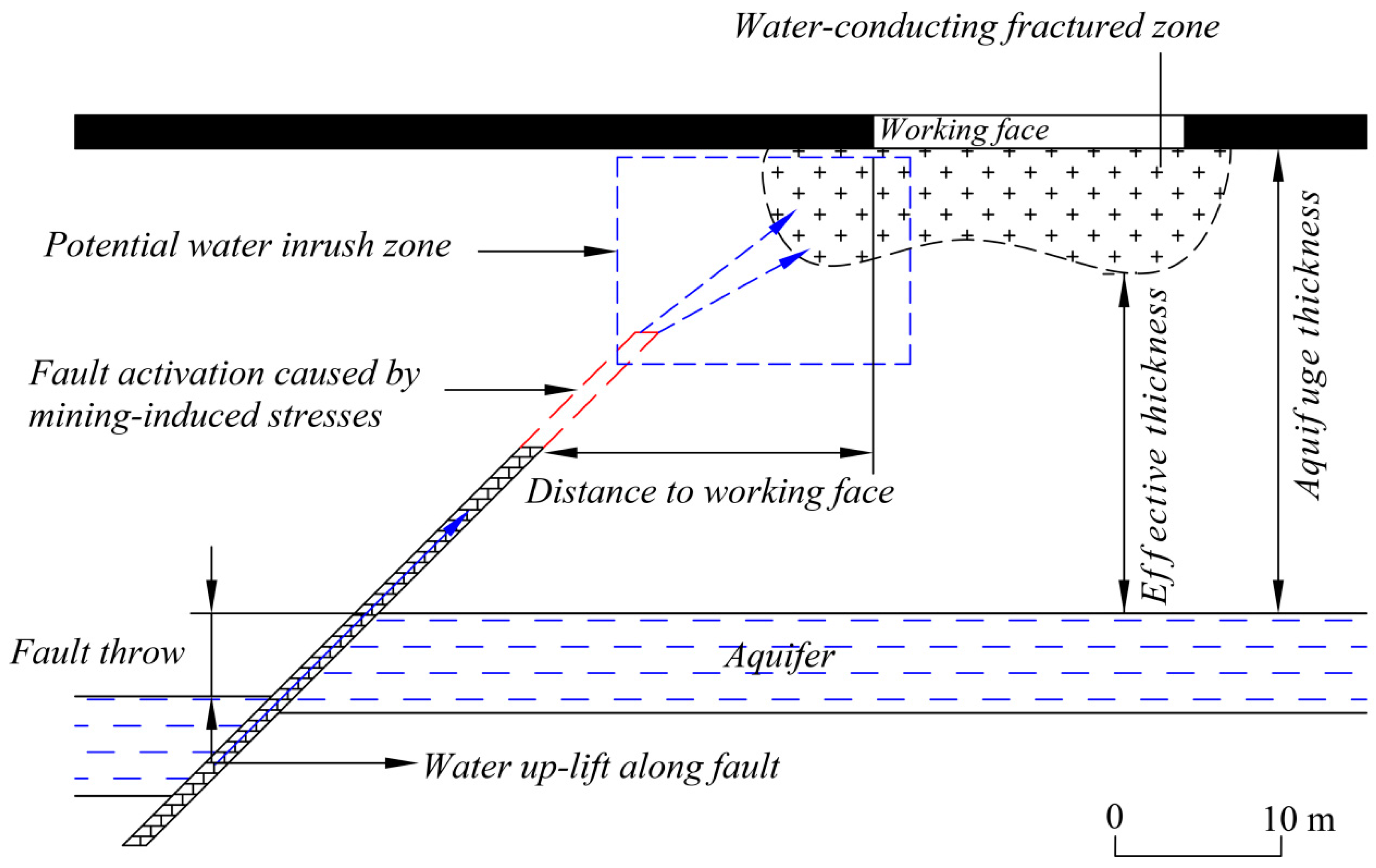

2.2. Brief Introduction to Fault-Induced Water Inrush

3. Methodology of the ANFIS

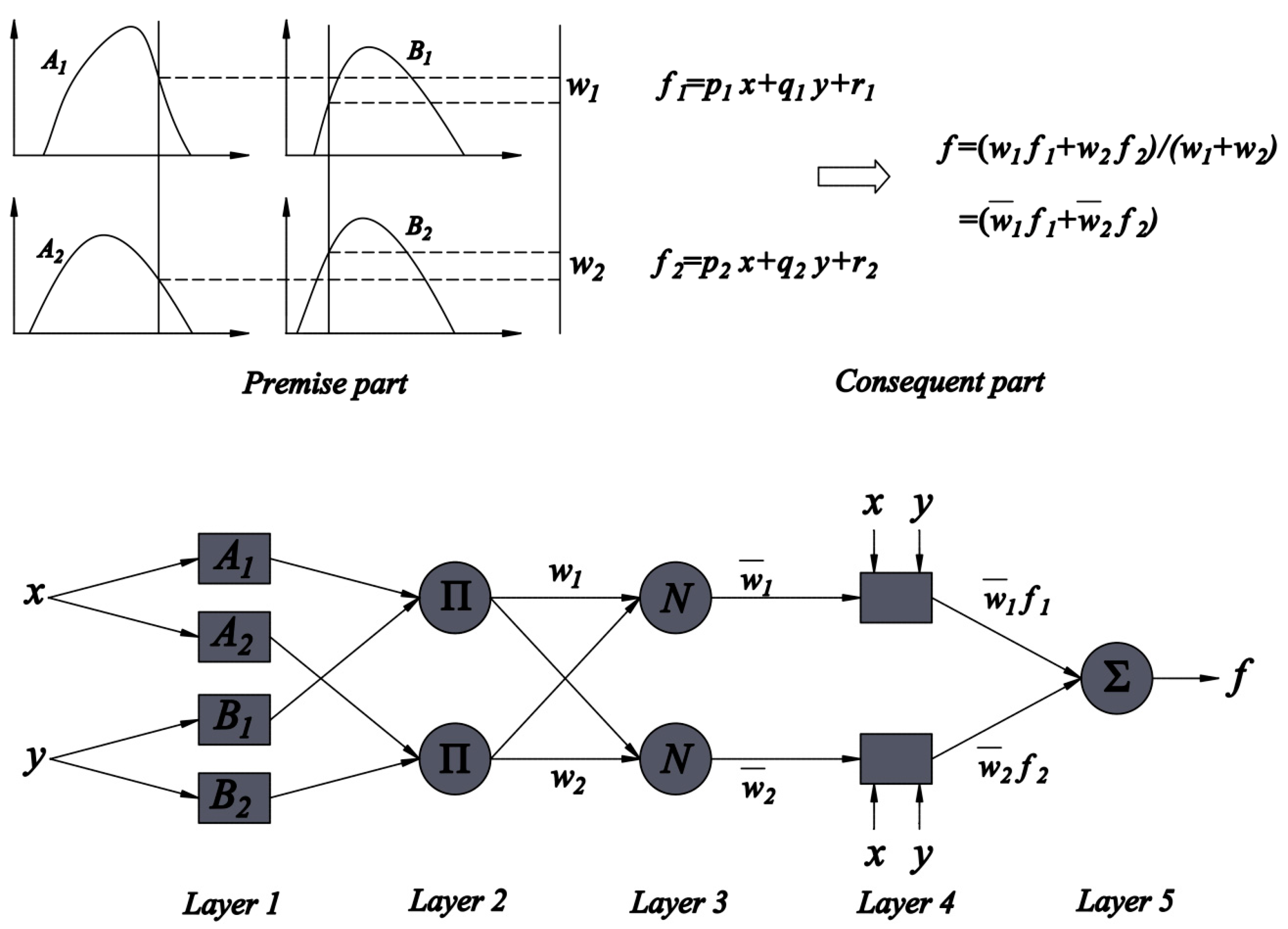

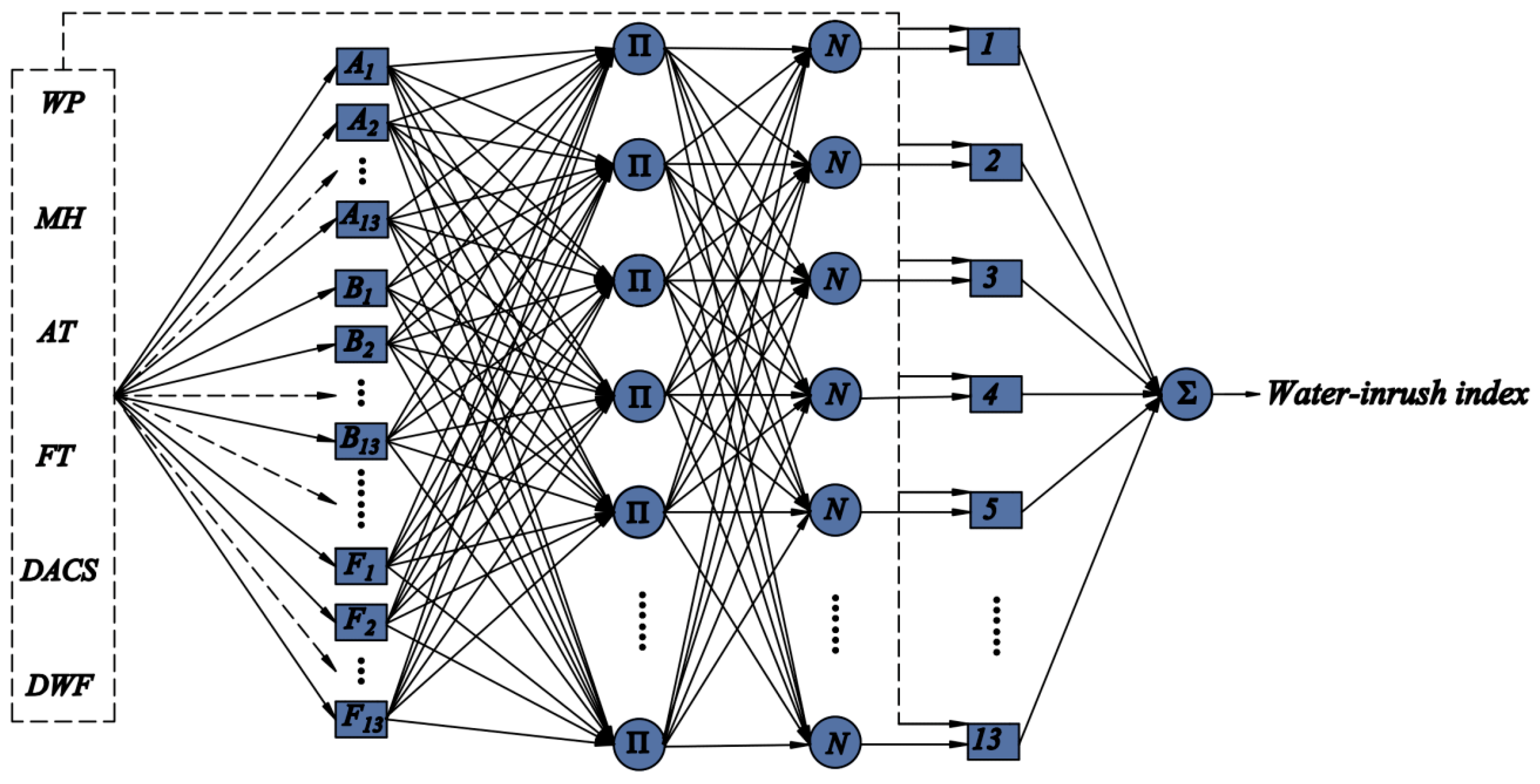

3.1. Architecture of ANFIS

3.2. Hybrid Learning Rule of the ANFIS

4. Prediction of Fault-Induced Water Inrush with the ANFIS

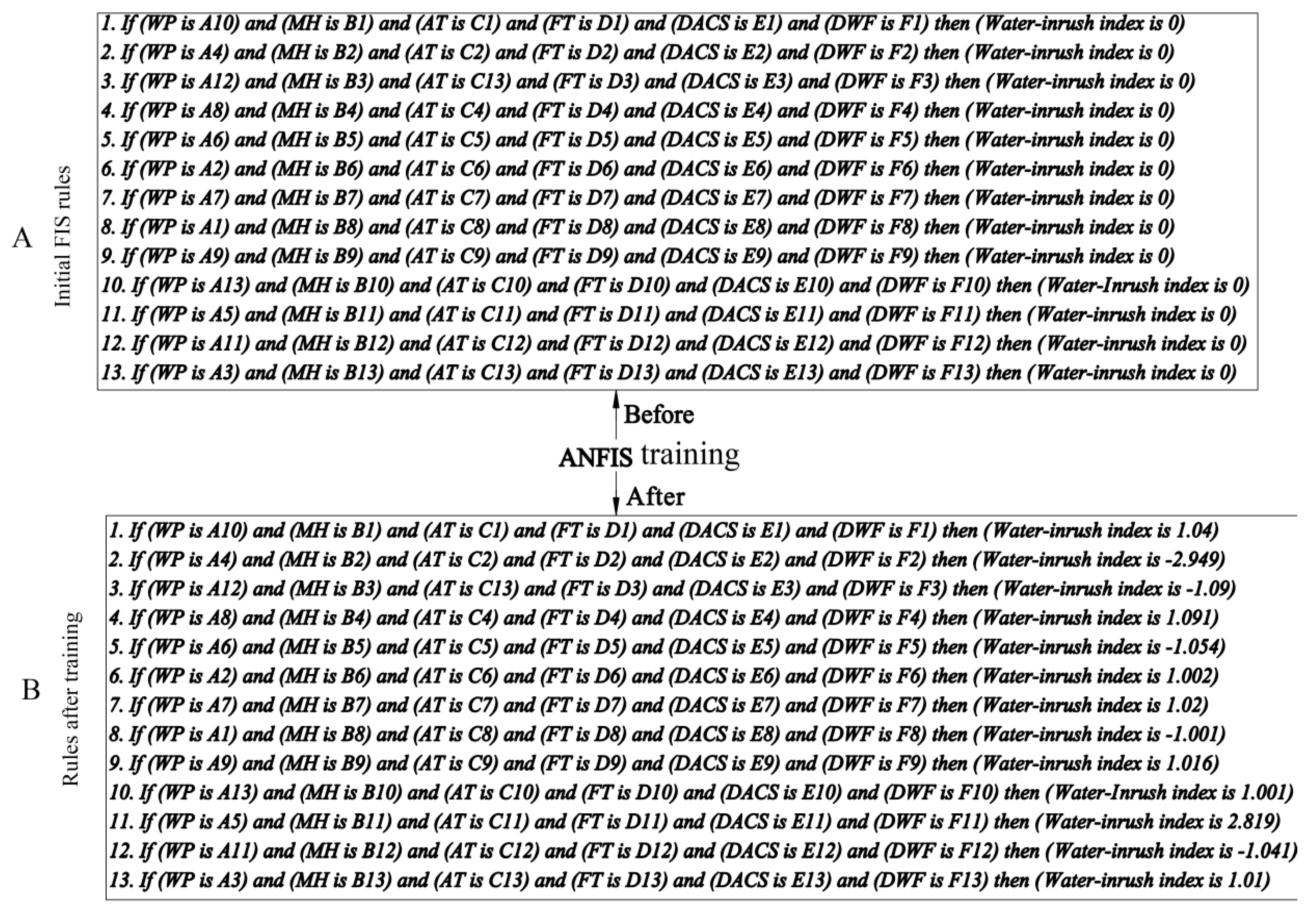

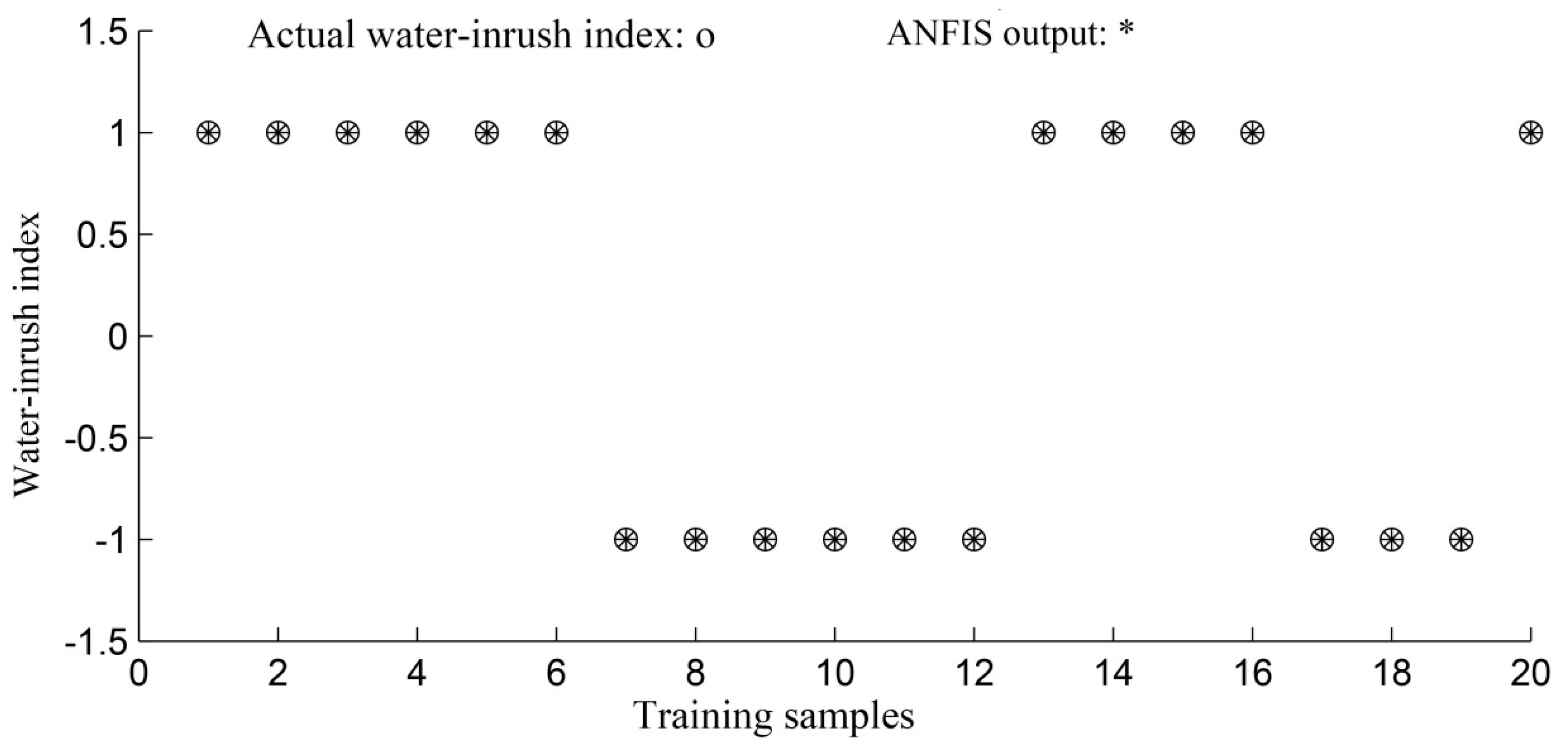

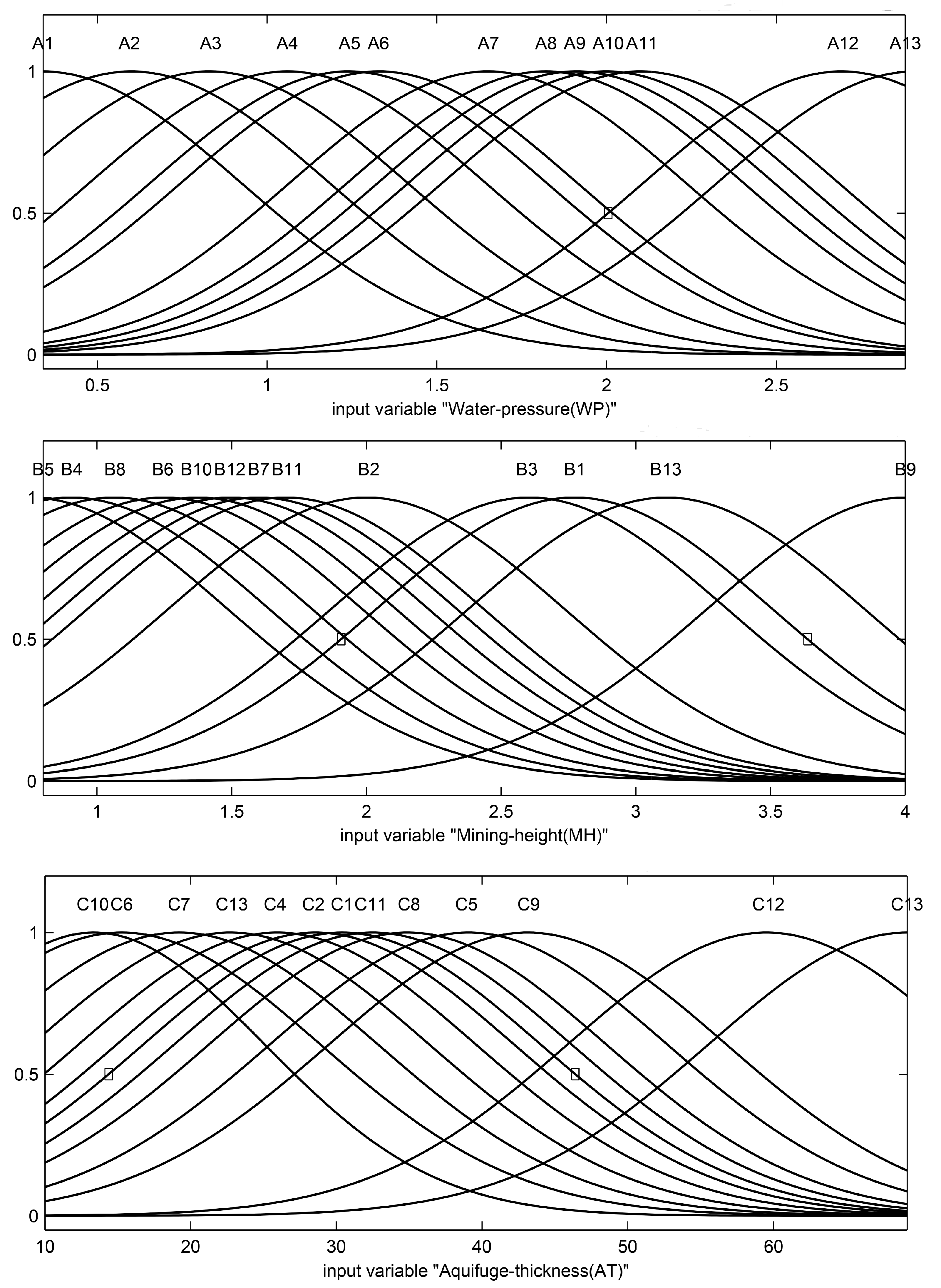

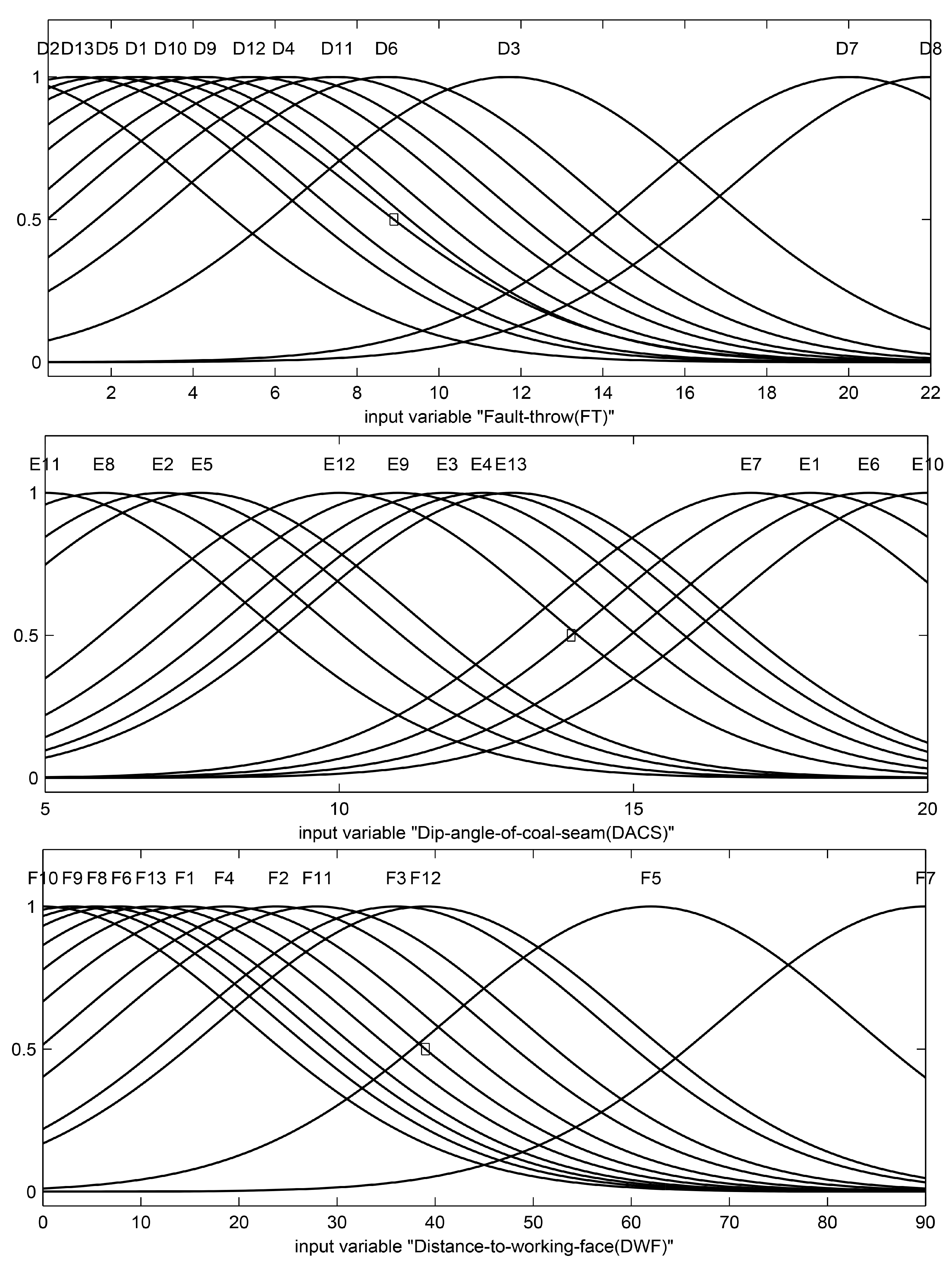

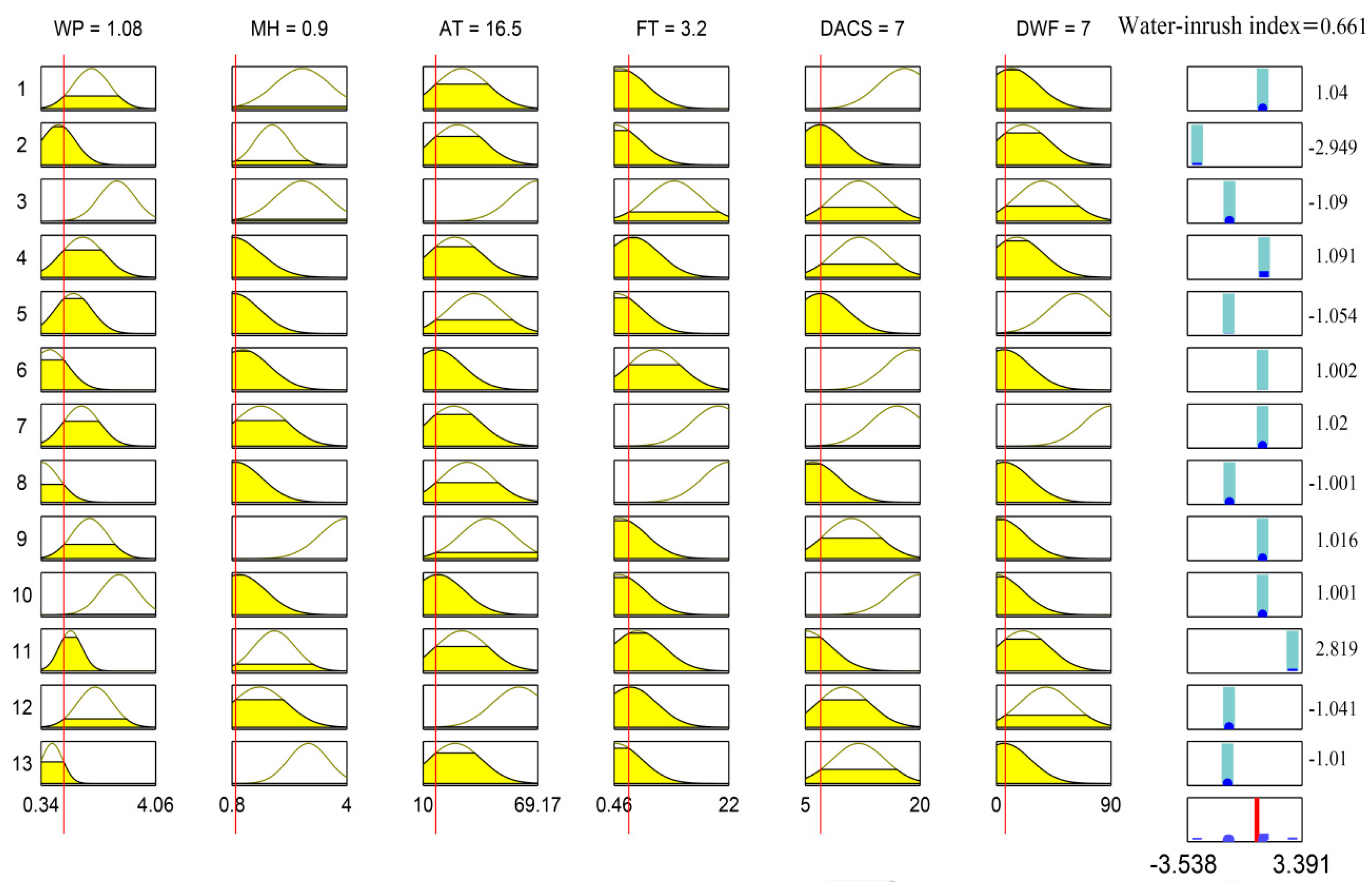

4.1. ANFIS Training

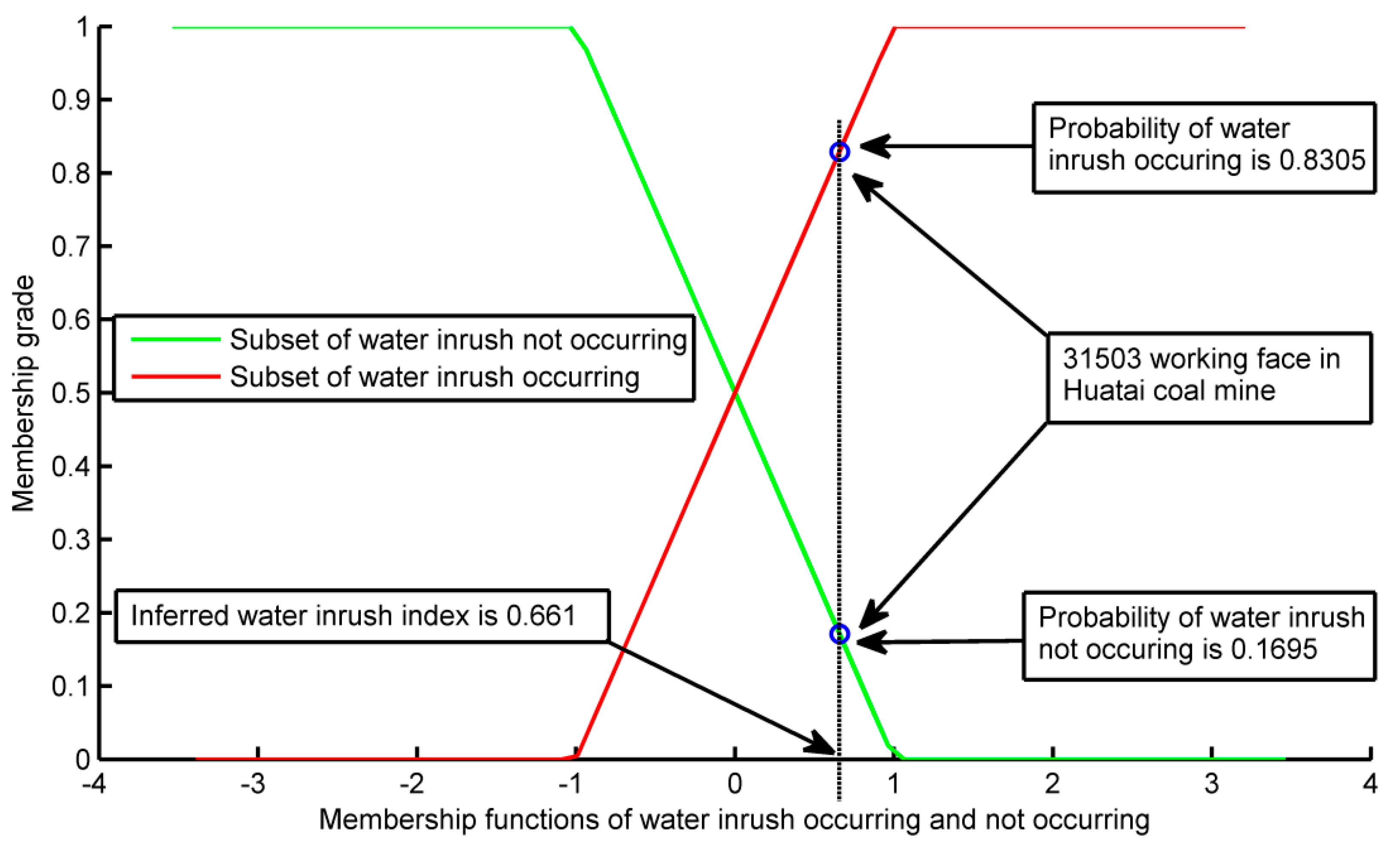

4.2. Results and Remarks

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bringemier, D. Inrush and mine inundation—A real threat to Australian coal mines. In Proceedings of the International Mine Water Association Annual Conference, Bunbury, Australia, 30 September–4 October 2012. [Google Scholar]

- Przemysław, B. Water hazard assessment in active shafts in Upper Silesian Coal Basin Mines. Mine Water Environ. 2011, 30, 302–311. [Google Scholar]

- Zhang, J.C. Investigations of water inrushes from aquifers under coal seams. Int. J. Rock Mech. Min. Sci. 2005, 42, 350–360. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.F.; Li, M.; Liu, X. Risk assessment of floor water inrush in coal mines based on secondary fuzzy comprehensive evaluation. Int. J. Rock Mech. Min. Sci. 2012, 52, 50–55. [Google Scholar] [CrossRef]

- Meng, Z.P.; Li, G.; Xie, X.T. A geological assessment method of floor water inrush risk and its application. Eng. Geol. 2012, 143–144, 51–60. [Google Scholar] [CrossRef]

- Edincliler, A.; Cabalar, A.F.; Cevik, A. Modelling dynamic behaviour of sand–waste tires mixtures using Neural Networks and Neuro-Fuzzy. Eur. J. Environ. Civ. Eng. 2013, 17, 720–741. [Google Scholar] [CrossRef]

- Dieu, T.B.; Biswajeet, P.; Owe, L.; Inge, R.; Oystein, B.D. Landslide susceptibility mapping at Hoa Binh province (Vietnam) using an adaptive neuro-fuzzy inference system and GIS. Comput. Geosci. 2012, 45, 199–211. [Google Scholar]

- Szymczyk, P.; Szymczyk, M. Classification of geological structure using ground penetrating radar and Laplace transform artificial neural networks. Neurocomputing 2005, 148, 354–362. [Google Scholar] [CrossRef]

- Edincliler, A.; Cabalar, A.F.; Cagatay, A.; Cevik, A. Triaxial compression behavior of sand and tire wastes using neural networks. Neural Comput. Appl. 2012, 21, 441–452. [Google Scholar] [CrossRef]

- Alemdag, S.; Gurocak, Z.; Cevik, A.; Cabalar, A.F.; Gokceoglu, C. Modeling deformation modulus of a stratified sedimentary rock mass using neural network, fuzzy inference and genetic programming. Eng. Geol. 2016, 203, 70–82. [Google Scholar] [CrossRef]

- Inhye, P.; Jaewon, C.; Moung, J.L.; Saro, L. Application of an adaptive neuro-fuzzy inference system to ground subsidence hazard mapping. Comput. Geosci. 2012, 48, 228–238. [Google Scholar]

- Yilmaz, I.; Kaynar, O. Multiple regression, ANN (RBF, MLP) and ANFIS models for prediction of swell potential of clayey soils. Expert Syst. Appl. 2011, 38, 5958–5966. [Google Scholar] [CrossRef]

- Cevik, A.; Sezer, E.A.; Cabalar, A.F.; Gokceoglu, C. Modeling of the uniaxial compressive strength of some clay-bearing rocks using neural network. Appl. Soft Comput. 2011, 11, 2587–2594. [Google Scholar] [CrossRef]

- Singh, R.; Kainthola, A.; Singh, T.N. Estimation of elastic constant of rocks using an ANFIS approach. Appl. Soft Comput. 2012, 12, 40–45. [Google Scholar] [CrossRef]

- Bedri, K.; Nicolas, F. Hydraulic head interpolation using ANFIS—Model selection and sensitivity analysis. Comput. Geosci. 2012, 38, 43–51. [Google Scholar]

- Shahin, M.A.; Maier, H.R.; Jaksa, M.B. Settlement prediction of shallow foundations on granular soils using B-spline neurofuzzy models. Comput. Geotech. 2003, 30, 637–647. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Cevik, A.; Gokceoglu, C.; Baykal, G. Neuro-fuzzy based constitutive modeling of undrained response of Leighton Buzzard Sand mixtures. Expert Syst. Appl. 2010, 37, 842–851. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Cevik, A.; Guzelbey, I.H. Constitutive modeling of Leighton Buzzard Sands using genetic programming. Neural Comput. Appl. 2010, 19, 657–665. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Cevik, A. Modelling damping ratio and shear modulus of sand–mica mixtures using neural networks. Eng. Geol. 2009, 104, 31–40. [Google Scholar] [CrossRef]

- Wu, Q.; Xu, H.; Pang, W. GIS and ANN coupling model: An innovative approach to evaluate vulnerability of karst water inrush in coalmines of north China. Environ. Geol. 2008, 54, 937–943. [Google Scholar] [CrossRef]

- Sian, L.; Victor, B.; Jenni, T. Fault architecture and deformation processes within poorly lithified rift Sediments, Central Greece. J. Struct. Geol. 2011, 33, 1554–1568. [Google Scholar]

- Caine, J.S.; Evans, J.P.; Forster, C.B. Fault zone architecture and permeability structure. Geology 1996, 24, 1025–1028. [Google Scholar] [CrossRef]

- Gudmundsson, A.; Simmenes, T.H.; Larsen, B.; Philipp, S.L. Effects of internal structure and local stresses on fracture propagation, deflection, and arrest in fault zones. J. Struct. Geol. 2010, 32, 1643–1655. [Google Scholar] [CrossRef]

- Rawling, G.C.; Goodwin, L.B.; Wilson, J.L. Internal architecture, permeability structure, and hydrologic significance of contrasting fault-zone types. Geology 2011, 29, 43–46. [Google Scholar] [CrossRef]

- Bense, V.F.; Van Balen, R.T. Hydrogeological aspects of fault zones on various scales in the Roer Valley Rift System. J. Geochem. Explor. 2003, 78–79, 317–320. [Google Scholar] [CrossRef]

- Goddard, J.V.; Evans, J.P. Chemical changes and fluid-rock interaction in faults of crystalline thrust sheets, northwestern Wyoming, USA. J. Struct. Geol. 1995, 17, 533–547. [Google Scholar] [CrossRef]

- Sameh, W.A.M.; Broder, J.M. Interpretation of Groundwater Flow into Fractured Aquifer. Int. J. Geosci. 2012, 3, 357–364. [Google Scholar]

- Palchik, V. Formation of fractured zones in overburden due to longwall mining. Environ. Geol. 2003, 41, 28–38. [Google Scholar]

- Liang, D.X.; Jiang, Z.Q.; Guan, Y.Z. Field research: Measuring water pressure resistance in a fault-induced fracture zone. Mine Water Environ. 2015, 34, 320–328. [Google Scholar] [CrossRef]

- Jonny, R.; Antonio, P.R.; Frederic, C.; George, J.M. Modeling of fault activation and seismicity by injection directly into a fault zone associated with hydraulic fracturing of shale-gas reservoirs. J. Petrol. Sci. Eng. 2015, 127, 377–386. [Google Scholar]

- IsIam, M.R.; Ryuichi, S. Mining-induced fault reactivation associated with the main conveyor belt roadway and safety of the Barapukuria Coal Mine in Bangladesh: Constraints from BEM simulations. Int. J. Coal Geol. 2009, 79, 115–130. [Google Scholar]

- Li, J.; Xu, Y.; Xie, X.; Yao, Y.; Gao, Y. Influence of mining height on coal seam floor failure depth. J. China Coal Soc. 2015, 40, 303–310. (In Chinese) [Google Scholar]

- Miao, X.; Cui, X.; Wang, J.; Xu, J. The height of fractured water-conducting zone in undermined rock strata. Eng. Geol. 2011, 120, 32–39. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets as a basis for a theory of possibility. Fuzzy Sets Syst. 1978, 1, 3–28. [Google Scholar] [CrossRef]

- Fukushima, K.; Miyake, S.; Ito, T. Neocognitron: A neural network model for a mechanism of visual pattern recognition. IEEE Trans. Syst. Man Cybern. 1983, 5, 826–834. [Google Scholar] [CrossRef]

- Mcculloch, W.S.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biol. 1943, 5, 115–133. [Google Scholar] [CrossRef]

- Jang, J.S.R. Input selection for ANFIS learning. In Proceedings of the Fifth IEEE International Conference on Fuzzy Systems, New Orleans, LA, USA, 8–11 September 1996; Volume 3, pp. 1493–1499. [Google Scholar]

- Jang, J.S.R. Fuzzy modeling using generalized neural networks and Kalman filter algorithm. In Proceedings of the Ninth National Conference on Artificial Intelligence, Anaheim, CA, USA, 14–19 July 1991; Volume 2, pp. 762–767. [Google Scholar]

- Takagi, T.; Sugeno, M. Fuzzy identification of systems and its applications to modeling and control. IEEE Trans. Syst. Man. Cybern. 1985, 15, 116–132. [Google Scholar] [CrossRef]

- Mamdani, E.H.; Assilian, S. An experiment in linguistic synthesis with a fuzzy logic controller. Int. J. Man Mach. Stud. 1999, 51, 135–147. [Google Scholar] [CrossRef]

- Larsen, P. Industrial applications of fuzzy-logic control. Int. J. Man Mach. Stud. 1980, 12, 3–10. [Google Scholar] [CrossRef]

- Jang, J.S.R. Anfis: Adaptive-network-based fuzzy inference system. IEEE Trans. Syst. Man. Cybern. 1993, 23, 665–685. [Google Scholar] [CrossRef]

- Shi, L.Q.; Tan, X.P.; Wang, J.; Ji, X.K.; Niu, C.; Xu, D.J. Risk assessment of water inrush based on PCA_Fuzzy_PSO_SVC. J. China Coal Soc. 2015, 40, 167–171. (In Chinese) [Google Scholar]

- Chiu, S.L. Fuzzy model identification based on cluster estimation. J. Intell. Fuzzy Syst. 1994, 2, 267–278. [Google Scholar]

- Chiu, S.L. An efficient method for extracting fuzzy classification rules from high dimensional data. J. Adv. Comput. Intell. 1997, 1, 1–7. [Google Scholar]

| Mines | (WP)/MPa | (MH)/m | (AT)/m | (FT)/m | (DACS)/° | (DWF)/m | Whether Water Inrush Accident Occurred in Actual Situation? |

|---|---|---|---|---|---|---|---|

| Xiazhuang coal mine case 1 | 1.82 | 0.8 | 26.39 | 4 | 12 | 16 | Yes |

| Xiazhuang coal mine case 2 | 1.65 | 1.6 | 25.85 | 50 | 17 | 90 | Yes |

| Xiazhuang coal mine case 3 | 1 | 0.9 | 22.33 | 2 | 13 | 16 | Yes |

| Xiazhuang coal mine case 4 | 2.88 | 1 | 17.68 | 1.3 | 20 | 0 | Yes |

| Jingxing coal mine case 1 | 2.01 | 8 | 28 | 0.6 | 18 | 10 | Yes |

| Jingxing coal mine case 2 | 1.91 | 8 | 43 | 1.5 | 11 | 2 | Yes |

| Hongshan coal mine case 1 | 1.33 | 0.85 | 36.38 | 0.8 | 7 | 62 | No |

| Hongshan coal mine case 2 | 0.95 | 1.45 | 26.89 | 1 | 6 | 55 | No |

| Hongshan coal mine case 3 | 0.92 | 1.4 | 33.61 | 0.5 | 8 | 0 | No |

| Hongshan coal mine case 4 | 0.34 | 0.9 | 32.65 | 22 | 6 | 6 | No |

| Heishan coal mine case 1 | 1.06 | 2 | 27.79 | 0.46 | 7 | 21 | No |

| Heishan coal mine case 2 | 0.83 | 2.85 | 26.56 | 0.7 | 12 | 6 | No |

| Xieyi coal mine | 2 | 2.81 | 30 | 1.5 | 18 | 12 | Yes |

| Jiulishan coal mine | 1.87 | 1.9 | 23 | 0.5 | 15 | 17 | Yes |

| Pandong coal mine | 1.7 | 2.8 | 10 | 5 | 17 | 10 | Yes |

| Taoyang coal mine | 0.6 | 1.1 | 17 | 8 | 19 | 6 | Yes |

| Huatai coal mine | 2.1 | 1.6 | 59.5 | 3.5 | 10 | 39 | No |

| Panxi coal mine case 1 | 2.8 | 2.75 | 69.17 | 11.7 | 12 | 36 | No |

| Panxi coal mine case 2 | 2.8 | 2.55 | 66.11 | 16 | 12 | 29 | No |

| Xiezhuang coal mine | 1.3 | 1.7 | 30 | 4.9 | 5 | 21 | Yes |

| Working Faces | (WP)/MPa | (MH)/m | (AT)/m | (FT)/m | (DACS)/° | (DWF)/m |

|---|---|---|---|---|---|---|

| 31,503 working face in Huatai coal mine | 1.08 | 0.90 | 16.50 | 3.2 | 7 | 7 |

| 51,302 working face in Liangzhuang coal mine | 1.10 | 1.60 | 20.00 | 15.0 | 11 | 16 |

| 6194 working face in Panxi coal mine | 4.06 | 2.75 | 65.86 | 10.0 | 10 | 11 |

| 9602 working face in Baizhuang coal mine | 3.11 | 2.61 | 44.30 | 3.5 | 11 | 12 |

| 61,106 working face in Huahen coal mine | 2.70 | 2.55 | 66.97 | 16.0 | 12 | 31 |

| Working Faces | Water Inrush Index Obtained by FIS Reasoning | Probability of Water Inrush Occurring | Probability of Water Inrush Not Occurring | Whether Water Inrush Occurred in Actual Situation | Whether the Prediction Is Consistent with the Actual Situation |

|---|---|---|---|---|---|

| 31,503 working face in Huatai coal mine | 0.661 | 0.8305 | 0.1695 | Yes | Yes |

| 51,302 working face in Liangzhuang coal mine | 0.658 | 0.829 | 0.171 | Yes | Yes |

| 6194 working face in Panxi coal mine | −0.999 | 0.0005 | 0.9995 | No | Yes |

| 9602 working face in Baizhuang coal mine | 0.122 | 0.561 | 0.439 | Yes | Yes |

| 61,106 working face in Huahen coal mine | −1 | 0 | 1 | No | Yes |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Q.; Herrera-Herbert, J.; Hidalgo, A. Predicting the Risk of Fault-Induced Water Inrush Using the Adaptive Neuro-Fuzzy Inference System. Minerals 2017, 7, 55. https://doi.org/10.3390/min7040055

Zhou Q, Herrera-Herbert J, Hidalgo A. Predicting the Risk of Fault-Induced Water Inrush Using the Adaptive Neuro-Fuzzy Inference System. Minerals. 2017; 7(4):55. https://doi.org/10.3390/min7040055

Chicago/Turabian StyleZhou, Qinglong, Juan Herrera-Herbert, and Arturo Hidalgo. 2017. "Predicting the Risk of Fault-Induced Water Inrush Using the Adaptive Neuro-Fuzzy Inference System" Minerals 7, no. 4: 55. https://doi.org/10.3390/min7040055

APA StyleZhou, Q., Herrera-Herbert, J., & Hidalgo, A. (2017). Predicting the Risk of Fault-Induced Water Inrush Using the Adaptive Neuro-Fuzzy Inference System. Minerals, 7(4), 55. https://doi.org/10.3390/min7040055