Abstract

The commercial application of copper bioleaching, an environmentally-friendly approach for low-grade and secondary mineral resources recycling, has increased worldwide since the 2000s. As the world’s second-largest economic entity and the largest developing country, China has the largest demand for metal resources, significantly advancing the theory and industrial technology of copper bioleaching. This paper reviews the exploration and application of copper bioleaching in China. Two typical bioleaching applications and technological processes, bioheap leaching at the Zijinshan Copper Mine and bioheap leaching at the Dexing Copper Mine, are introduced. The considerable research completed by researchers is summarized, especially focusing on the isolation and identification of leaching bacteria, the bioleaching mechanism and interface reactions, multistage percolation behavior, bioleaching system reconstruction, the multiphysics coupled model, and enhanced copper bioleaching from waste printed circuit boards (WPCBs). Based on this investigation in China, key trends and prospects in copper bioleaching—such as efficiency improvement, environmental protection, and improved technology applications—are proposed.

1. Introduction

Due to its excellent ductility and electric and thermal conductivity, copper has been widely applied in the construction, electricity, transportation, and manufacturing industries [1,2]. Since the 1970s, China has experienced rapid economic growth and a related sharp increase in its rate of urbanization. This has resulted in China increasingly significant driving global growth and improving mineral resource demand since the late 2000s, becoming the world’s second-largest emerging economic giant [3,4,5,6,7].

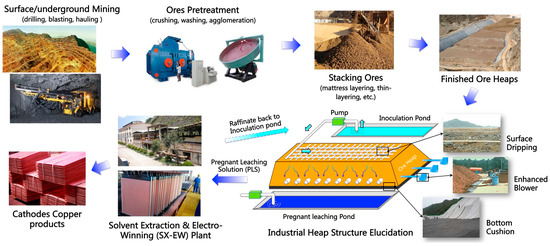

Lower-grade extractions and increasing global demand are noticeable barriers to valuable metal extraction [8]. As an efficient recycling approach used for low-grade minerals, complex polymetallic resource, and solid ore waste [9,10], bioheap leaching and biodump leaching have been broadly applied, having potential given the exhaustion of high-quality copper mines. These approaches have been extensively researched and utilized in China, Chile, Spain, and South Africa [11,12,13,14,15]. Bioleaching drives conventional mining revolution to extract minerals from mineral wastes and ore deposits buried deep in the ground [16,17,18]. The basic and simplified process of bioheap leaching is shown in Figure 1.

Figure 1.

Typical industrial schematic of copper bioheap leaching.

Although copper bioleaching faces many challenges and limitations, progress has been made which mainly focuses on the bioleaching mechanism, pore network, microorganisms cultivation, fluid flow, process catalysis, and so on. Lower-grade copper ore in complex sulfide deposits is extremely difficult to extract [19]. By incorporating the catalytic function of bacteria, the dissolution and copper extraction is increased [20]. Genomic engineering has been implemented to obtain targeted bacteria [21,22]. Additionally, the intervention of precise scanning and observatory technologies—such as computed tomography (CT), magnetic resonance imaging (MRI), particle image velocimetry (PIV), and others [23,24,25,26]—have improved on research. Some characterized models have been improved, like the lattice Boltzmann model (LBM) and so on [27,28,29]. To increase permeability, leaching, and optimal metal extraction rate, some reformative methods like agglomeration of oxide copper minerals [30,31]; enhanced aeration [32,33]; dripping irrigation regulation [34,35]; surfactants like polyethylene glycol, sodium lauryl sulfate, and silver [36,37,38]; and ultrasonic intensification [39] were proposed. Advanced aerial image analysis has been applied to assess particle size segregation in copper heap leaching [40]. Except for Australia, the United States, and other developed mining countries, the factors controlling commercial application are complex, and China plays an essential role in the technological innovation of copper bioleaching. For copper bioleaching in China, we want to compare the fundamental conditions, developed process and status, outstanding breakthroughs, and exemplary industrial cases with similar studies around the world. However, a systematic and summative research of copper bioleaching is still lacking.

In this paper, the biotechnology progress and current status of copper bioleaching in China is considered. To review the copper biotechnology application and status in China, two industrial case studies of copper bioleaching at the Zijinshan Copper Mine (ZCM, bioheap leaching) and the Dexing Copper Mine (DCM, biodump leaching) are presented. Challenges for copper bioleaching are identified, advanced technologies and improved methods to overcome these issues are discussed. Furthermore, the future prospects for copper bioleaching are presented.

2. Copper Bioleaching Development Process in China

2.1. Development and Status of Bioleaching around World

Over the years, bioleaching technology, which has been applied to copper, uranium, coal, nickel, and manganese mining [41,42,43], has progressed considerably, especially in Chile, South Africa, the United States, Australia, India, Mexico, Iran, and China. In 1762, in the Rio Tinto Mine of Spain, Copper (Cu) was leached from pyrite mixed with copper by acid mine drainage (AMD). The appearance of Acidthiobacillus ferrooxidans (A.f) subtly influenced recycling methods used for copper resources. Temple and Hinkle [44] found bacteria associated with AMD in 1947 and naming of Thiobacillus ferrooxidans (T.f) from AMD of coalmine in 1951. Three years later, Bryer and Beck [45] found A.f leached from a wide range of copper sulfide mines using AMD in copper mines. In 1958, copper extraction significantly progressed when biotechnology was first applied to industrial production in the Bingham mine by the Kennecott copper company [46,47,48].

Since the 1970s, bioleaching technology has been researched and applied widely around the world, enabling the industrial production of copper, uranium, and gold [49,50]. To date, the bioheap leaching, biodump leaching, and in situ bioleaching processes (uranium mainly) have become the most common bioleaching approaches. Worldwide, about 20% of Cu is extracted using bioleaching [51,52]. Given the gradual exhaustion of mineral resources located in the shallow surface of the earth, copper biotechnology has been playing a more important role in metal extraction [53,54]. For instance, the European Commission applied some innovation methods to in situ leaching without ore stripping and onerous infrastructure operations in 2015. Some in situ copper leaching studies, including heap leaching, were completed at the University of Cape Town, University of Melbourne, Imperial College London, University of Utah, Cornell University, BacTech, Mintek, Rio Tinto, and other authoritative universities and institutions since the 1990s. As relevant reviews have been systemically performed, these are not covered at length in this paper [55,56].

2.2. Major Characteristics of Copper Resources in China

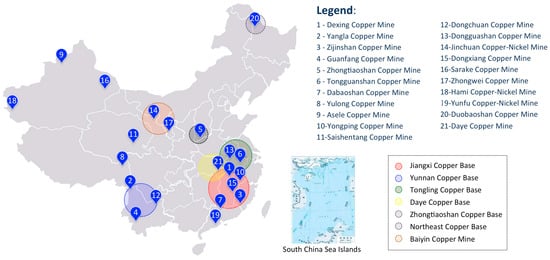

China is one of the largest mining countries in the world, with more than 240 mine sites [57]. China’s copper deposits are mainly divided into porphyry-type (41%), skarn-type (27%), marine volcanic-type (9.24%), copper-nickel (Cu-Ni) sulfide-type (5.67%) and others (17.09%) [58]. For complex reasons, the majority of the condition of conventional surface and underground mining for copper minerals in China are not very suitable, unlike South Africa and Australia. Chinese copper mines tend to be lower-grade, having an average Cu content of around 0.87%, which is hard to extract using conventional mineral processing. In terms of size, the medium-scale (9%) and small-scale (88%) copper mines dominate, compared to the large-scale mines (3%). Due to the limitations in the metal quantity and quality, the application of conventional mining methods tends to be impossible. Chinese copper mines have complex mineral compositions with associated minerals like nickel, gold, and sulfur, among others. Around 76% associated-gold, 32.5% associated-silver, and 76% sulfur come from copper mines. The mines contain heterogeneous dissemination-type ores. Porphyry copper deposits and skarn copper deposits dominate. China has several copper deposits and production bases (Figure 2). The copper bioleaching bases are concentrated in the central and eastern regions, especially in the southeast, due to the suitable mineral composition. Details of each base are:

Figure 2.

Regional distribution of typical bioleaching industrial plants in China.

- Jiangxi Copper Bases. Jiangxi Province has the richest copper resources and its reserves account for more than 34% of the total copper reserves in China. Some large-scale copper mines, like the Dexing Copper Mine, Yongping Copper Mine, Wushan Copper Mine, Chengmenshan Copper Mine, Dongxiang Copper Mine, and others have been established since 1978.

- Yunnan Copper Bases. Yunnan Province is the second-largest copper bases in China, including the Dongchuan Copper Mine, Yimen Copper Mine, Dayao Copper Mine, and Muding Copper Mine.

- Tongling Copper Bases. This base is located in Anhui Province and is the first copper base that produced about 10,000 t/a of copper in China, and includes the Tongguanshan Copper Mine, Dongguanshan Copper Mine, Shizishan Copper Mine, Xinqiao Copper Mine, and Fenghuangshan Copper Mine.

- Daye Copper Bases. Located in Hubei province can produce about 45,600 t electrolytic copper. The Tonglushan Copper Mine, Tongshankou Copper Mine, Xinye Copper Mine are included in this base.

- Zhongtiaoshan Copper Bases. Established in 1956, the base includes the Tongkuangyu Copper Mine, Bizhigou Copper Mine, and Hujiayu Copper Mine.

- Northeast Copper Bases. This base, located in Northeast region of China in Heilongjiang Province, Jilin Province, and Liaoning Province, has been developed since 1948. Some copper mines, like the Qingyuan Copper-Nickel Mine, Huatong Copper Mine, and Tianbao Copper Mine are established, producing 70,000 t/a electrolytic copper metals.

- Baiyin Copper Bases. This base located in Gansu province and can produce more than 60,000 t/a electrolytic copper metal, including the Zheyaoshan Copper Mine and Tongchanggou Copper Mine.

2.3. History and Evolution of Copper Bioleaching in China

According to Morris’ 1984 publication on solution mining for minerals in Australia, China was one of earliest countries to develop solution mining to exploit copper resources. With bronze product smelting and production, copper recycling technology has made considerable progress. As The Classic of Mountains and Seas (third century B.C. to second century A.D.) saying goes, “there is abundant copper resources in the shade of Shicui Mountains”. During the Western Han Dynasty (206 B.C. to 24 A.D.), the copper was obtained from copper sulfate (CuSO4) by displacement reaction as written in the Huainan Encyclopedia of Liuan Wang. Per Qian Zhang’s Copper Leached Synopsis Records, the copper was leached from AMD in the earlier Song Dynasty (960–1127). Due to the technology limitations and feudal government blockade policy, the improvement of biotechnology slowed in ancient China.

Since the 1960s, bioleaching research for low-grade copper extraction was applied in underground bioleaching of Tonguanshan Copper Mine which was completed in the 1970s. In 1997, the Dexing Copper Mine constructed the first heap leaching plant and started commercial operation [59]. The Chinese government carried out several key foundation projects—such as the “863 Project”, “973 Project”, and “111 Project”—to effectively promote and develop bioleaching technology. To date, a number of Chinese researchers have contributed, and as a result the bioleaching technology system and application have developed considerably [60]. On the 22th July 2016, the Ministry of Science and Technology of the People’s Republic of China commissioned the “13th Five-Year National Science and Technology Innovation Planning” the largest-scale research project ever, focusing on geological prospecting and in situ fluidized bioleaching of copper, gold and uranium ores. This central government project, costing 10 billion dollars, will run until 2030. This investment is for the improvement of technology and equipment for copper bioleaching.

3. Status of Current Copper Bioleaching in China

3.1. Typical Application and Exploration Cases of Copper Bioleaching

Chinese researchers have investigated copper bioleaching in laboratories and industrial applications, in mines such as Dexing Copper Mine and Zijinshan Copper Mine. A review of the application and investigation of copper bioleaching are introduced (Table 1). Figure 2 shows their locations and illustrates the seven copper bases. Bioleaching investigation and application are concentrated in the southeast region, which includes three copper production bases including the Jiangxi Copper Base, Tongling Copper Base, and Daye Copper Base. Among them, the Jiangxi Copper Base—rich in chalcocite and chalcopyrite—is the main base for copper bioleaching due to its mineral richness. Because of lower permeability, in situ copper bioleaching of the deep leachates of primary ores is limited. Some extreme conditions in the area include high attitude, low temperature, and low oxygen content, as found in the Xinjiang Autonomous Region (Sarake Copper Mine, etc.) and Qinghai–Tibet Plateau (Yulong Copper Mine, etc.) potentially have copper resources that may be suitable for bioleaching.

Table 1.

Exploration and successful industrial cases of copper bioleaching in China.

3.2. Typical Commercial Cases of Copper Bioleaching in China

Many bioleaching studies, including laboratory experiments, pilot tests and industrial operations have been conducted on mine sites like the Zijinshan Copper Mine, Dexing Copper Mine, Asele Copper Mine of Xinjiang; Yulong Copper Mine (Table 1). In this section the research conducted on the Zijinshan Copper Mine (ZCM) and Dexing Copper Mine (DCM) mine sites are introduced.

3.2.1. Zijinshan Copper Mine (ZCM)

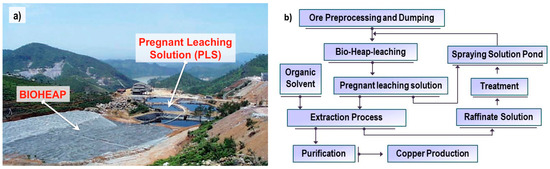

Zijinshan Copper Mine is the largest bio-heap leaching case study, playing a key role in the research and application of copper bioleaching in China. It is located in Shanghang City, Fujian Province. The ZCM has the largest chalcocite deposit, with about 13.9 million tons of low-grade copper sulfide ore (Cu 0.38%). An overview and the flowchart of bioleaching system are shown in Figure 3 [86]. Due to lower recovery and high cost of traditional mining methods, the ZCM has been extracting copper using bioheap leaching since the 1998. A Solvent Extraction/Electro-Winning (SX-EW) commercial bioleaching plant, designed by China ENFI Engineering Corporation was constructed in 2000 and has been operational since the 2005 with a capacity of 20,000 t/a at a copper extraction rate of 80% [87,88,89].

Figure 3.

Heaps and technological process of ZCM. (a) Overall view of bioheap plants in Zijinshan Copper mine; (b) Basic flowchart of bioheap leaching system.

The bacteria are mixture strains of Acidithiobacillus (>51%), Leptospirillum (>48%), and Ferrimicrobium (~1%) obtained from AMD, Zijinshan Copper Mine [90,91]. For the bioleaching of ZCM, the core reaction was originally researched and proposed as the dissolution of chalcocite divided into several steps [92,93,94]

Cu2S + 2Fe3+ → Cu2+ + 2Fe2+ + CuS

CuS + 2Fe3+ → 2Fe2+ + S0

Compared with other large-scale commercial bioheap leaching cases in the world, ZCM’s bio-heap leaching has three main characteristics: lower pH value (0.8–1.0), high Fe3+ concentration (50 g/L), and high temperature (45–60 °C). However, during bioleaching processes, plenty of Fe(III) is precipitated as jarosite, an extracellular polymeric substance (EPS) generated on the ore surface, blocking pores and fractures, causing the copper extraction to reach its peak.

3.2.2. Dexing Copper Mine (DCM)

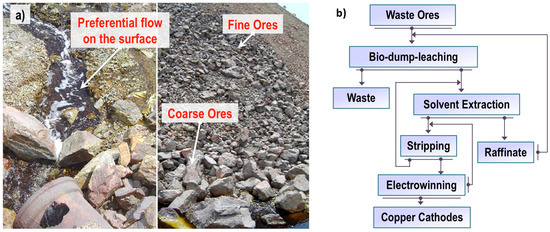

The Dexing copper mine (DCM) is located in Dexing City, Jiangxi Province, which is known as the ‘copper homeland of China’. The mine is one of largest porphyry copper deposits around the world. The mine consists of 80% chalcopyrite, 5% pyrite, 5% quartz, and 5% others. Both underground and open-pit extraction have been occurred since the 1965 and 1971 [95,96,97]. The stripping waste rock dump (WRD) contained 1.2 million tons total copper piled up at a height of 70 m, with an inclination slope angle of 55°and an area of 7,570,000 m2 with about 600 million tons of waste rocks in total [98]. This negatively affects the environment in terms of occupation of land, dust, and dump sliding.

Recovery of ore from dumps was completed from 1984 to 1996, an industrial scale experiment of 1000 t (1984–1991) resulted in considerable progress, increasing the recovery of copper from 0.121% (1984, average grade of Cu in dumps) to 16.59% (1987) and 30% (1991). Moreover, the feasibility study (1993) and primary design (1994) was carried out sequentially. In October 1997, the biodump leaching SX-EW plant of DCM was finally finished with 2000 t/a [99,100]. The key technological process is as follows: initial leaching solution (ILS) is sprayed on the top of dump; the concentration of Cu(II) increases when solution percolates through the ores; then the pregnant leaching solution (PLS) is collected at the bottom of dumps. The Figure 4 shows flowchart in DCM.

Figure 4.

WRD and technological process of DCM. (a) Preferential flow and ore particle segregation; (b) Biodump leaching flowchart.

Compared to bioheap leaching, lacking a pad and higher boulder yield are considered pivotal challenges of biodump leaching. A lower bacteria population and WRD’s intrinsic permeability are thought as bottlenecks to better extraction in DCM, as Figure 4 shows [101]. Due to heap’s lower permeability in the DCM, seepage phenomenon, like preferential flow, was founded based on CT technology, and its effects on extraction and surface morphology were pinpointed [102]. Mutiphysics interactions were researched. Moreover, the WRD’s stability is threatened by certain factors, such as particle size, surface erosion, and bioleaching mechanism, creating a landslide threat. As a notable landmark with great significance, biodump leaching in the DCM confirmed the leachability and potential commercial profits of WRD with lower intrinsic permeability.

4. Recent Technical Progress of Copper Bioleaching

The successful application of these above-mentioned cases cannot be separated from breakthroughs in key technologies, such as bacteria identification, interface reaction, multistage percolation, a pore structure revolution [103,104,105]. Given the unique and complex situation of copper minerals in China, researchers have made significant progress, investigating some new typical technologies and innovations. These effective achievements are summarized and enumerated, mainly focusing on Chinese experts and authorities around the world.

4.1. Isolation, Identification, and Enrichment of Bacteria

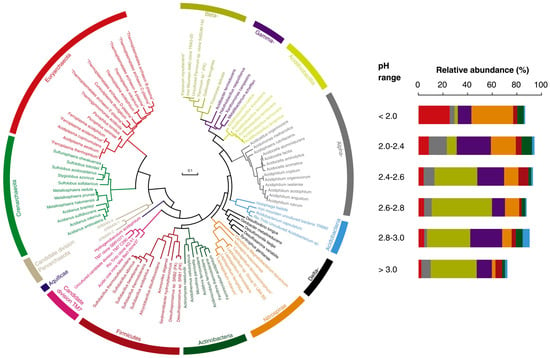

Bacteria play a crucial role in copper bioleaching [106]. The physiological and phylogenetic biodiversity of acidophilic microorganisms are prominent and less definite [107]. These studies deepened the knowledge of genomics, metagenomics, and proteomics [108]. It is noteworthy that the Chinese research on the isolation, identification, molecular diversity, and inhomogeneous catalysis behavior of leaching bacteria have reached the gene level and have proven efficacious for copper bioleaching [109,110,111,112]. For instance, thermophile bacteria are widely distributed in extreme conditions, ranging from 10 °C to 80 °C [113]. The complexity of the microbial community structure differs in different locations of biological heaps [114,115,116,117,118]. Many studies have inferred that mixed bacteria perform better in copper bioleaching from oxide-copper sulfide and nickel-copper sulfide [119,120,121,122,123]. Some methods of rapid specific detection and quantification like real-time PCR, have been proposed for determining functional genes expressions [124]. Moreover, sulfur and nitrogen, putative efflux transport systems, and sensitivity analysis of the bacteria growth have been researched [125,126,127]. The heterotrophic strain and bioleaching mechanism of ammonia producing bacteria, whose the optimal growth condition is 30 °C and initial pH value is 8, is not clearly understood. Mineral–bacteria interactions are visualized by Raman and Fourier transform infrared (FTIR) microspectroscopies. Some novel bacteria-obtaining methods, like ultraviolet irradiation, have been proposed [128,129,130]. The alkaline strain was obtained and its leaching behavior are studied both in China and the world [131,132]. Additionally, a mixed culture of sulfur-oxidizing and iron-oxidizing microorganisms was successfully applied in the bioleaching of arsenopyrite [133]. In 2016, as Figure 5 shows, microbial diversity inside acid solution, biofilms, and sediments of 125 AMD samples with different pH values, were systemically summarized. Anaerobic bioleaching, passivation phenomenon, and removal of surface substances have also been reported.

Figure 5.

Prokaryotic microorganisms in AMD ecosystems insides acid solution, biofilms, and sediments and its distribution with different pH value ranges [134]. Reproduced with permission from Chen, L.X., Current Opinion in Biotechnology, Microbial communities, processes and function in acid mine drainage ecosystems; published by Elsevier, 2012.

4.2. Bioleaching Mechanism and Interface Reaction

One of the challenges in this field has been how to bioleach valuable metal from low-grade ores, this has been the subject of numerous discussions around the world [135]. Due to the complexity of the mineral composition, especially in China, bioleaching mechanisms and interface reactions—such as pH value, ferrous transportation, EPS, quartz addition, and sulfur speciation, etc.—have been extensively studied [136,137,138,139,140,141,142]. Microorganism transportation, mechanisms, and reaction pathways of chalcopyrite, carrollite, and djurleite bioleaching [143,144]; synergistic bioleaching processes, like p-type chalcopyrite, n-type chalcopyrite, bornite [145,146]; and other low-grade resources have been analytically researched. Zhang et al. [147,148] proposed enhancement of copper extraction by the application of bioaugmented treatment and re-inoculation.

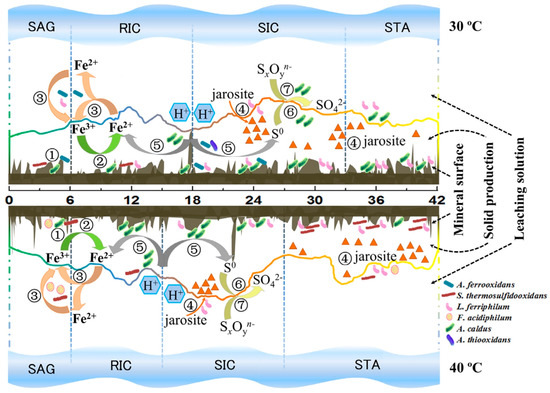

In addition, light illumination catalysis [149] was discussed and been demonstrated to accelerate Fe2+/Fe3+ cycling. Influence of interfacial interaction on bioleaching behavior was also investigated [150,151], and vital parameters were discussed, including pH value [152], ferric iron enrichment [153], dissolved oxygen concentration, temperature, and bacteria community initial proportion and dynamics [154,155,156]. Nickel-copper sulfide bioleaching and its community succession were researched (Figure 6) [157,158,159]. Biosorption processes of physical adsorption, ion exchange, complexation and microprecipitation were discussed by Jing et al. [160]. Additionally, except for biosorption effects, passivations that included EPS, jarosite, and polysulfide are crucial factors limiting copper extraction rate [161,162]. The new integration strategies have been tentatively applied for weakening EPS, jarosite formation [163,164], biofilm formation [165], and other passivation substances [166]. Based on having high-resolution and non-turbulent characteristics, atomic force microscopy (AFM) and epifluorescence microscopy (EFM) were applied to observe the bioleaching interface interaction and organism attachment [167,168,169].

Figure 6.

Mechanism model for chalcopyrite bioleaching coupling with the community succession [170]. Reproduced with permission from Ma, L.Y., Hydrometallurgy, Bioleaching of the mixed oxide-copper sulfide ore by artificial indigenous and exogenous microbial community; published by Elsevier, 2012.

4.3. Multistage Percolation Behavior of Leaching Solution

Whether ILS interacts with recyclable minerals is the key link during bioleaching, thus determining the flow behavior and understanding the regulation of leaching solution are important [171]. Aiming at WRD and heaps with high clay content, heap permeability tends to be smaller, the phenomenon and formative mechanism of preferential flow was proposed and researched systematically [172]. This behavior of preferential flow inside heaps has been simulated by CFD model, confirming convective transport through inter-connected pathways [173].

By relying on the difference of particle kinematics and characteristics—such as roughness, particle size, and viscosity—segregation appears during dumping, promoting the formation of straticulate dumps and preferential flow which is thought of as a rapid fluid passing through pores constructed by coarse ores [174,175]. In 2008, to research flow mechanics especially for preferential flow, a field-scale test was conducted in highly heterogeneous industrial ore heaps. Inhomogeneous fluid flow, called moisture liquid dispersion of unsaturated inter-particles, was determined to rely on capillary process driven by van der Waals force and micro forces. Solution flow behavior, like capillary progress among micro pores, was researched [176]. Fluid flow based on three-dimensional dual pore-network models and solute transport models are successfully established [177,178,179], solute and microbial medium transport, and the response relationship to key operation parameters in heaps [180]. Hydrodynamic dispersion, chaotic advection, and hysteresis phenomenon in liquid holdup and liquid spread mechanisms in unsaturated packed bed and heaps are also described [181]. Furthermore, fine interlayers are resulted to layered structure and obstruct infiltration pathways, influencing the formation of somewhat faint leaching regions [182].

4.4. Reconstruction and Characterization of Multiple Pore Structure

Pore structure insides heaps or dumps are intricate, so Wu et al. searched for a better method to characterize and visualize pore structure [183]. Ore particles with complex shape parameters are accumulated to form ore heaps, configuring unsaturated gas–solid diphase structure especially for ore dumps, creating migration pathways for leaching solution and oxygen. Pore structure is influenced by aperture size, mineral distribution, and connectivity [184]. Compared to ore waste dumps, the permeability of heaps improved remarkably after agglomeration processing, and relevant binders and particle fractions are invented [185,186]. For simple ore particles, the effect of high pressure grinding roll (HPGR) crushing on extraction rate attracted more and more attention [187]. With the introduction of advanced visualization means like uCT, X-ray CT [188], and MRI [189,190], image processing of packed ore particle beds has improved considerably, such as leaching behavior measuring methods [191,192], multi-scale quantification [193], LBM constructions [194], and the three-dimensional characterization, analysis, and reconstructions of ore heap leaching [195,196,197,198].

4.5. Multiphysics Coupled Model of Bioleaching Process

The complexity of bioleaching system has complicated the estimation of extraction rates and effects during leaching processes, as shown by a few specific experiments [199]. Hence, some models were constructed to replace studies where common approaches have not been implemented [200]. For the reaction, fluid flow, and other factors in the complex bioleaching process, model construction and computer simulation have been used as an alternative technology [201]. Besides, some coupled mathematical models and simulations based on Comsol Multiphysics, Fluent, and Simpleware—like solute transportation, seepage, heat transportation and balance, and microbial transport in bioleaching system—were also established [202].

Some comprehensive mathematical models deterministic models of heap leaching have been established for enargite bioleaching [203], grey forecasting model of primary sulfide ore bioleaching, bacterial community monitoring of Ni-Cu sulfide [204], air sparing and distribution inside heaps [205], modeling of copper-sulfide ore in heap and dump, a population balance model of OAs during heap leach operation, kinetics of copper dissolution under pressure oxidative leaching [206], and kinetics modeling of chalcopyrite bioleaching catalyzed by silver ions [207].

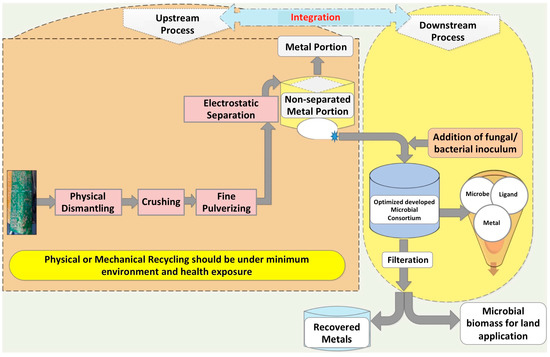

4.6. Enhanced Copper Bioleaching from Waste Printed Circuit Boards (WPCBs)

With the promotion and application of electronic products, the impacts of waste electric and electronic equipment (WEEE) on environment are considerable and hard to eliminate [208]. Bioleaching copper is now being sourced from electronic wastes like WPCBs in China [209,210,211]. Figure 7 shows basic bioprocessing schematic of WPBCs by bacteria. Hence, further exploring strategies to effectively leach valuable metals is an important field of study [212,213,214,215]. Efficiency and electric fields effects of Acidithiobacillus ferrooxidans and mixed culture were also proven in copper bioleaching from PCBs [216,217,218,219]. Furthermore, to enhance the bioleaching process, new catalyzed materials like biochar, nitrogen-doped carbon nanotubes (NCNTs), and new strategies were applied in hydrometallurgy fields [220,221,222]. Bioleaching of e-waste will be applied and developed for new applications, introducing more sustainable and practical ways to recover minerals and metals in the future [223,224].

Figure 7.

Illustration of integrated approach for copper recovery and recycling of WPCBs [225]. Reproduced with permission from Awashi, A.K., Integrated bioleaching of copper metal from waste printed circuit board—a comprehensive review of approaches and challenges; published by Springer, 2016.

5. Future Opportunities and Challenges

Sustainable development is a common worldwide theme [226,227,228,229]. Biotechnology has an important place in the future, especially for the bioleaching of metal from secondary lower-grade ores [230,231,232,233]. Given the conflict between bioleaching and environment protection, issues include environment protection, bio-diversity disturbance, acid pollution, and ore dumping [234,235,236,237]. As mines become deeper, costs and security risks inevitably increase. In this case, in situ copper bioleaching is thought to be a niche technology [238]. In this paper, based on previous research and developing trends, some key opportunities and challenges are proposed, based on the foundations in China.

5.1. Efficiency Improvement and Guarantee

During the bioleaching process, many key factors are uncontrolled—including fluid flow, bacteria proliferation, temperature distribution, and gas transportation—causing out-off-balance of copper extraction in different areas of heaps. To avoid this lower permeability, bacteria culture and efficiency limit efficient and high-volume metal recovery. The diversity of microorganisms and their capabilities and function are waiting to be validated and exploited [239].

- Efficiency bacteria obtained via genetic engineering [240] and other induced domestication means, especially for extremophiles [241,242] in severe environments with high temperature, lower oxygen, high osmotic pressure, and so on.

- Enhanced bioleaching methods using external field energy, like enhanced aeration, permeability regulation, geothermal energy, underground pressure, etc.

- Target minerals activation pre-treatment insides ore and other enhanced minerals exposing technology.

- Bioleaching process control, like weakened passivation methods, especially for copper sulfide bioleaching.

5.2. Environmental Protection and Security

With the exposition of environmental contamination, increased focus has been placed on leakages and insecurity during the bioleaching progress [243]. Hazardous pollution migrations and their effect of acidophiles inside bioheaps of the ZCM on nearby rivers have negative impacts [244]. In 2014, the greenhouse gas of in situ leaching of copper, uranium, and gold resources were researched [245]. Conversely, as far back in 1993, the microbes had been proposed as a treatment for metal pollution like groundwater bioremediation [246,247,248]. Thus, to some extent, balancing application and control of bioleaching is a key factor which has limited the layout space.

- Acid leaching solution is a serious hazard to surface runoff and groundwater, presenting risks such as depositing crop pollution, high cancer rates, and animal deformity.

- Exotic bacterium escaping from bioleaching industrial plants could be a momentous threat to native bio-diversity, even leading to crowning calamity of rare species.

- Ore dump and heap collapse threats under internal bioleaching mechanisma and external environmental factors such as rainstorms.

- Consummation of relevant environmental assessment (EIA) methods and regulations.

5.3. Application of Novel Technology and Methods

Application of advanced technologies and new concepts in copper bioleaching are essential for biotechnology development. For instance, to enhance temperature inside heaps, the solar thermal energy was applied in a Chilean copper mine by setting up flat plate collectors and other integration equipment, improving the copper extraction rates from 67% to 85% [249,250].

- New field energy, like solar thermal energy, wind energy, microwave treatment [251] is used to enhance bioleaching strength, obtaining a better extraction and decreasing environmental pollution.

- New visualization, intellectualization, and fluidization mining methods such as super-precise unperturbed scanning even deeper into the reaction interface, real-time 3D printing during bioleaching, unmanned in situ bioleaching.

- Metal recovery from solid waste like ore dumps WPCBs with surfactant based on bioleaching.

- New leach pad types to increase permeability and decrease OAs of heaps, for instance, standard heap [252], valley fill heap [253], and bacterial thin leaching (BTL) methods [254].

- New in situ copper bioleaching methods to explore mineral resources located in the deep earth.

Last but not least, biotechnology has been proven to be promising for metal recovery from lower-grade ores and wastes [255,256]. In addition to the copper resources discussed in this paper, some critical and scarce metals, even biomining from asteroids in the deep universe and stratums in the deep sea are thought as important directions [257,258].

6. Conclusions

China’s improvements in science and technology are of concern. Thus, this paper provides an in-depth review of the historical investigation and current scientific research processes on copper bioleaching in China over the course of 5000 years, with research spanning macroscopic industrial cases to molecular and genetic understanding. With prominent advances in leaching bacteria isolation, interface reaction, percolation behavior, heap reconstruction, and other technology applicationss, copper bioleaching has quickly developed, gaining a considerable market share. The Zijinshan Copper Mine (bioheap leaching) and Dexing Copper Mine (biodump leaching) have advanced the bioleaching of low grade and dumps. In conclusion, even though there are plenty of unknown obstacles and challenges, the potential for cross-disciplinary and technological development in copper bioleaching is remarkable, this brief review lays a good foundation for future research.

Acknowledgments

This project was sponsored by the National Key R&D Program of China (2016YFC0600704), the National Science Foundation for Excellent Young Scholars of China (51722401), and the Key Program of National Natural Science Foundation of China (51734001).

Author Contributions

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| AMD | Acid Mine Drainage |

| A.f | Acidthiobacillus ferrooxidans |

| AFM | Atomic Force Microscopy |

| CT | Computed Tomography |

| DCM | Dexing Copper Mine |

| EFM | Epifluorescence Microscope |

| EPS | Extracellular Polymeric Substances |

| FTIR | Fourier Transform Infrared |

| HPGR | High Pressure Grinding Rolls |

| ILS | Initial Leaching Solution |

| LBM | Lattice Boltzmann Model |

| MRI | Magnetic Resonance Imaging |

| NCNTs | Nitrogen-Doped Carbon Nanotubes |

| PIV | Particle Image Velocimetry |

| PLS | Pregnant Leaching Solution |

| T.f | Thiobacillus ferrooxidans |

| WEEE | Waste Electric and Electronic Equipment |

| WPCBs | Waste Printed Circuit Boards |

| WRD | Waste Rock Dump |

| ZCM | Zijinshan Copper Mine |

References

- Dunbar, W.S. Biotechnology and the mine of Tomorrow. Trends Biotechnol. 2017, 35, 79–89. [Google Scholar] [CrossRef] [PubMed]

- Panda, S.; Akcil, A.; Pradhan, N.; Deveci, H. Current scenario of chalcopyrite bioleaching: A review on the recent advances to its heap-leach technology. Bioresour. Technol. 2015, 196, 694–706. [Google Scholar] [CrossRef] [PubMed]

- Fang, X.; Shen, Y.; Zhao, J.; Bao, X.M.; Qu, Y.B. Status and prospect of lignocellulosic bioethanol production in China. Bioresour. Technol. 2010, 101, 4814–4819. [Google Scholar] [CrossRef] [PubMed]

- Rawlings, D.E.; Johnson, D.B. The microbiology of biomining: Development and optimization of mineral-oxidizing microbial consortia. Microbiology 2007, 153, 315–324. [Google Scholar] [CrossRef] [PubMed]

- Ehrlich, H.L.; Brierley, C.L. Microbial Mineral Recovery; McGraw Hill Book Co.: New York, NY, USA, 1990. [Google Scholar]

- Gentina, J.C.; Padilla, C.; Poirrier, P. Development of a culture strategy to produce a bacteriocin type substance utilizing a strain of Enterococcus mundtii. J. Biotechnol. 2010, 150, 414. [Google Scholar] [CrossRef]

- Acevedo, F.; Gentina, J.C.; Bustos, S. Bioleaching of minerals—A valid alternative for developing countries. J. Biotechnol. 1993, 31, 115–123. [Google Scholar] [CrossRef]

- Petersen, J. Heap leaching as a key technology for recovery of values from low-grade ores—A brief overview. Hydrometallurgy 2016, 165, 206–212. [Google Scholar] [CrossRef]

- Johnson, D.B. Biomining-biotechnologies for extracting and recovering metals from ores and waste materials. Curr. Opin. Biotechnol. 2014, 30, 24–31. [Google Scholar] [CrossRef] [PubMed]

- Watling, H.R. The bioleaching of sulphide minerals with emphasis on copper sulphides—A review. Hydrometallurgy 2006, 84, 81–102. [Google Scholar] [CrossRef]

- Pradhan, N.; Nathsarma, K.C.; Rao, K.S.; Sukla, L.B.; Mishra, B.K. Heap bioleaching of chalcopyrite: A review. Miner. Eng. 2008, 21, 355–365. [Google Scholar] [CrossRef]

- Wang, Y.G.; Su, L.J.; Zhang, L.J.; Zeng, W.M.; Wu, J.Z.; Wan, L.L.; Qiu, G.Z.; Chen, X.H.; Zhou, H.B. Bioleaching of chalcopyrite by defined mixed moderately thermophilic consortium including a marine acidophilic halotolerant bacterium. Bioresour. Technol. 2012, 121, 348–354. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.C.; Pandey, B.D. Bio-processing of solid wastes and secondary resources for metal extraction—A review. Waste Manag. 2012, 32, 3–18. [Google Scholar] [CrossRef] [PubMed]

- Ndlovu, S. Biohydrometallurgy for sustainable development in the African minerals industry. Hydrometallurgy 2008, 91, 20–27. [Google Scholar] [CrossRef]

- Cloete, T.E.; Nel, L.H.; Theron, J. Biotechnology in South Africa. Trends Biotechnol. 2006, 24, 557–562. [Google Scholar] [CrossRef] [PubMed]

- Johnson, D.B. Biomining goes underground. Nat. Geosci. 2015, 8, 165–166. [Google Scholar] [CrossRef]

- Orell, A.; Navarro, C.A.; Arancibia, R.; Mobarec, J.C.; Jerez, C.A. Life in blue: Copper resistance mechanisms of bacteria and Archaea used in industrial biomining of minerals. Biotechnol. Adv. 2010, 28, 839–848. [Google Scholar] [CrossRef] [PubMed]

- Acevedo, F. Present and Future of bioleaching in developing countries. Electron. J. Biotechnol. 2002, 5, 52–56. [Google Scholar] [CrossRef]

- Huang, T.; Li, D. Presentation on mechanisms and applications of chalcopyrite and pyrite bioleaching in biohydrometallurgy—A presentation. Biotechnol. Rep. 2014, 4, 107–119. [Google Scholar]

- Shiers, D.W.; Collinson, D.M.; Watling, H.R. Life in heaps: A review of microbial responses to variable acidity in sulfide mineral bioleaching heaps for metal extraction. Res. Microbiol. 2016, 167, 576–586. [Google Scholar] [CrossRef] [PubMed]

- Rawlings, D.E.; Johnson, D.B. Biomining; Springer: Heidelberg, Germany, 2007. [Google Scholar]

- Cárdenas, J.P.; Quatrini, R.; Holmes, D.S. Genomic and metagenomic challenges and opportunities for bioleaching: A mini-review. Res. Microbiol. 2016, 167, 529–538. [Google Scholar] [CrossRef] [PubMed]

- Miao, X.X.; Gerke, K.M.; Sizonenko, T.O. A new way to parameterize hydraulic conductances of pore elements: A step towards creating pore-networks without pore shape simplifications. Adv. Water Resour. 2017, 105, 162–172. [Google Scholar] [CrossRef]

- Fagan, M.A.; Ngoma, I.E.; Chiume, R.A.; Minnaar, S.; Sederman, A.J.; Johns, M.L.; Harrison, S.T.L. MRI and gravimetric studies of hydrology in drip irrigated heaps and its effect on the propagation of bioleaching micro-organisms. Hydrometallurgy 2014, 150, 210–221. [Google Scholar] [CrossRef]

- Fagan, M.A.; Harrison, S.T.L.; Johns, M.L.; Sederman, A.J. Magnetic resonance imaging characterization of the influence of flowrate on liquid distribution in drip irrigated heap leaching. Hydrometallurgy 2015, 158, 157–164. [Google Scholar] [CrossRef]

- Fan, Y.; Jacob, K.V.; Freireich, B.; Lueptow, R.M. Segregation of granular materials in bounded heap flow: A review. Powder Technol. 2017, 312, 67–88. [Google Scholar] [CrossRef]

- Lin, C.L.; Videla, A.R.; Miller, J.D. Advanced three-dimensional multiphase flow simulation in porous media reconstructed from X-ray Microtomography using the He–Chen–Zhang Lattice Boltzmann Model. Flow Meas. Instrum. 2010, 21, 255–261. [Google Scholar] [CrossRef]

- Miller, J.D.; Lin, C.L.; Hupka, L.; Al-Wakeel, M.I. Liberation-limited grade/recovery curves from X-ray micro CT analysis of feed material for the evaluation of separation efficiency. Int. J. Miner. Process. 2009, 93, 48–53. [Google Scholar] [CrossRef]

- Dhawan, N.; Safarzadeh, M.S.; Miller, J.D.; Moats, M.S.; Rajamani, R.K.; Lin, C.L. Recent advances in the application of X-ray computed tomography in the analysis of heap leaching systems. Miner. Eng. 2012, 35, 75–86. [Google Scholar] [CrossRef]

- Nosrati, A.; Quast, K.; Xu, D.F.; Skinner, W.; Robinson, D.J. Agglomeration and column leaching behaviour of nickel laterite ores: Effect of ore mineralogy and particle size distribution. Hydrometallurgy 2014, 146, 29–39. [Google Scholar] [CrossRef]

- Quaicoe, I.; Nosrati, A.; Skinner, W.; Ad-Mensah, J. Agglomeration behaviour and product structure of clay and oxide minerals. Chem. Eng. Sci. 2013, 98, 40–50. [Google Scholar] [CrossRef]

- Lizama, H.M. Copper bioleaching behaviour in an aerated heap. Int. J. Miner. Process. 2001, 62, 257–269. [Google Scholar] [CrossRef]

- Bartlett, R.W.; Prisbrey, K.A. Convection and diffusion limited aeration during biooxidation of shallow ore heaps. Int. J. Miner. Process. 1996, 47, 75–91. [Google Scholar] [CrossRef]

- Ilankoon, I.M.S.K.; Neethling, S.J. Liquid spread mechanisms in packed beds and heaps. The separation of length and time scales due to particle porosity. Miner. Eng. 2016, 86, 130–139. [Google Scholar] [CrossRef]

- Chiume, R.; Minnaar, S.H.; Ngoma, I.E.; Bryan, C.G.; Harrison, S.T.L. Microbial colonisation in heaps for mineral bioleaching and the influence of irrigation rate. Miner. Eng. 2012, 39, 156–164. [Google Scholar] [CrossRef]

- Zhang, R.T.; Wei, D.Z.; Shen, Y.B.; Liu, W.G.; Lu, T.; Han, C. Catalytic effect of polyethylene glycol on sulfur oxidation in chalcopyrite bioleaching by Acidithiobacillus ferrooxidans. Miner. Eng. 2016, 95, 74–78. [Google Scholar] [CrossRef]

- Ai, C.M.; Wu, A.X.; Wang, Y.M.; Hou, C.L. Optimization and mechanism of surfactant accelerating leaching test. J. Cent. South Univ. (Engl. Ed.) 2016, 23, 1032–1039. [Google Scholar] [CrossRef]

- Muñoz, J.A.; Dreisinger, D.B.; Cooper, W.C.; Young, S.K. Silver-catalyzed bioleaching of low-grade copper ores: Part I: Shake flasks tests. Hydrometallurgy 2007, 88, 3–18. [Google Scholar] [CrossRef]

- Anjum, F.; Bhatti, H.N.; Ghauri, M.A. Enhanced bioleaching of metals from black shale using ultrasonics. Hydrometallurgy 2010, 100, 122–128. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, W.Y. Application of aerial image analysis for assessing particle size segregation in dump leaching. Hydrometallurgy 2017, 171, 99–105. [Google Scholar] [CrossRef]

- Rawlings, D.E.; Silver, S. Mining with Microbes. Nat. Biotechnol. 1995, 133, 17–19. [Google Scholar] [CrossRef]

- Anjum, F.; Shahid, M.; Akcil, A. Biohydrometallurgy techniques of low grade ores: A review on black shale. Hydrometallurgy 2012, 117–118, 1–12. [Google Scholar] [CrossRef]

- Ghosh, S.; Mohanty, S.; Akcil, A.; Sukla, L.B.; Das, A.P. A greener approach for resource recycling: Manganese bioleaching. Chemosphere 2016, 154, 628–639. [Google Scholar] [CrossRef] [PubMed]

- Colmer, A.R.; Temple, K.L.; Hinkle, M.E. An iron-oxidizing bacterium from the acid drainage of some bituminous coal mines. J. Bacteriol. 1950, 59, 317–328. [Google Scholar] [PubMed]

- Ehrlich, H.L. Past, Present and Future of Biohydrometallurgy. Hydrometallurgy 2001, 59, 127–134. [Google Scholar] [CrossRef]

- Brierley, J.A.; Brierley, C.J. Present and future commercial applications of biohydrometallurgy. Hydrometallurgy 2001, 59, 233–239. [Google Scholar] [CrossRef]

- Cowan, D.A. Biotechnology of the Archaea. Trends Biotechnol. 1992, 10, 315–323. [Google Scholar] [CrossRef]

- Tang, K.; Baskaran, V.; Nemati, M. Bacteria of the sulphur cycle: An overview of microbiology, biokinetics and their role in petroleum and mining industries. Biochem. Eng. J. 2009, 44, 73–94. [Google Scholar] [CrossRef]

- Silver, S.; Gupta, A. Mining for biogold. Nat. Biotechnol. 1998, 16, 485. [Google Scholar] [CrossRef]

- Moffat, A.S. Microbial mining boosts the environment, bottom line. Science 1994, 264, 778–779. [Google Scholar] [CrossRef] [PubMed]

- Brierley, J.A. A perspective on development in biohydrometallurgy. Hydrometallurgy 2008, 94, 2–7. [Google Scholar] [CrossRef]

- Latorre, M.; Cortés, M.P.; Travisany, D.; Genova, A.D.; Budinich, M.; Reyes-Jara, A.; Hodar, C.; Gonzalez, M.; Parada, P.; Bobadilla-Fazzini, R.A.; et al. The bioleaching potential of a bacterial consortium. Bioresour. Technol. 2016, 218, 659–666. [Google Scholar] [CrossRef] [PubMed]

- Mishra, D.; Kim, D.J.; Ahn, J.G.; Rhee, Y.H. Bioleaching: A Microbial Process of Metal Recovery. A Review. Met. Mater. Int. 2005, 11, 249–256. [Google Scholar] [CrossRef]

- Kelly, D. Metals and Micro-organisms. Trends Biotechnol. 1990, 8, 271–272. [Google Scholar] [CrossRef]

- Gericke, M.; Neale, J.W.; Staden, P.J.V. A Mintek perspective of the past 25 years in minerals bioleaching. J. South. Afr. Inst. Min. Metall. 2009, 109, 567–585. [Google Scholar]

- Ghorbani, J.; Franzidis, J.P.; Petersen, J. Heap Leaching Technology—Current State, Innovations, and Future Directions: A Review. Min. Process. Extr. Metall. Rev. 2016, 37, 73–119. [Google Scholar] [CrossRef]

- China Mineral Resources 2016; Ministry of Land and Resources People’s Republic of China; Geological Publishing House: Beijing, China, 2016.

- Chen, J.P.; Zhang, Y.; Wang, J.X.; Xiao, K.Y.; Lou, D.B.; Ding, J.H.; Yin, J.N.; Xiang, J. On present situation and potential analysis of copper resources in China. J. Geol. 2013, 37, 358–365. (In Chinese) [Google Scholar]

- Yang, S.R.; Xie, J.Y.; Qiu, G.Z.; Hu, Y.H. Research and application of bioleaching and biooxidation technologies in China. Miner. Eng. 2002, 15, 361–363. [Google Scholar]

- Zhu, X. Mining History in China; Geological Publishing House: Beijing, China, 2010. (In Chinese) [Google Scholar]

- Wu, A.X.; Yin, S.H.; Qin, W.Q.; Liu, J.S.; Qiu, G.Z. The effect of preferential flow on extraction and surface morphology of copper sulphides during heap leaching. Hydrometallurgy 2009, 95, 76–81. [Google Scholar] [CrossRef]

- Hu, K.J.; Wu, A.X.; Wang, H.J.; Wang, S.Y. A New Heterotrophic Strain for Bioleaching of Low Grade Complex Copper Ore. Minerals 2016, 6, 12. [Google Scholar] [CrossRef]

- Ruan, R.M.; Wen, J.K.; Chen, J.H. Bacterial heap-leaching: Practice in Zijinshan copper mine. Hydrometallurgy 2006, 83, 77–82. [Google Scholar]

- Wang, B.Y.; Cong, Z.F.; Dai, S.J. Current Developments and Prospects in Bioleaching of Copper Ores. Non-ferr. Min. Metall. 2008, 24, 28–31. (In Chinese) [Google Scholar]

- He, Z.G.; Xie, X.S.; Liu, J.; Qiu, G. Microbial diversity of mine water at Zhong Tiaoshan copper mine, China. J. Basic Microbiol. 2007, 47, 485–495. (In Chinese) [Google Scholar] [CrossRef] [PubMed]

- Lu, D.K.; Liu, D.X.; Wang, C.; Jiang, K.X.; Luo, Q.H. Research on underground leaching of low-grade copper ore in Zhongtiaoshan. Non-ferr. Smelt. 2001, 1, 17–19. [Google Scholar]

- Zhan, J.; Sun, Q.Y. Development of microbial properties and enzyme activities in copper mine wasteland during natural restoration. Catena 2014, 116, 86–94. [Google Scholar] [CrossRef]

- Qiu, G.Z.; Wan, M.X.; Qian, L.; Huang, Z.Y.; Liu, K.; Liu, X.D.; Shi, W.Y.; Yang, Y. Archaeal diversity in acid mine drainage from Dabaoshan Mine, China. J. Basic Microbiol. 2008, 48, 401–409. [Google Scholar] [CrossRef] [PubMed]

- Li, H.X.; Qiu, G.Z.; Hu, Y.H.; Liu, J.S.; Xu, J. Bacterial leaching of Dabaoshan Discarded Copper Ore. Kuangchan Zonghe Liyong 2000, 5, 31–34. (In Chinese) [Google Scholar]

- Hao, X.D.; Liang, Y.L.; Yin, H.Q.; Ma, L.Y.; Xiao, Y.H.; Liu, Y.Z.; Qiu, G.Z.; Liu, X.D. The effect of potential heap construction methods on column bioleaching of copper flotation tailings containing high levels of fines by mixed cultures. Miner. Eng. 2016, 98, 279–285. [Google Scholar] [CrossRef]

- Yang, H.X.; Zhou, A.D.; Xu, J.Z. Application of Biohydrometallurgy in Copper Indutriy. Non-ferr. Min. Metall. 2003, 19, 15–18. (In Chinese) [Google Scholar]

- Wu, Y.P. Study on Bioleaching of Yongping Low Grade Copper Sulfide Ore in Jiangxi by Mixed Cultures. Master’s Thesis, Jiangxi University of Science and Technology, Ganzhou Shi, China, 2011. (In Chinese). [Google Scholar]

- Wang, H.; Feng, C.Y.; Li, D.X.; Li, C.; Li, T.Z.; Liao, F.Z. Geology, geochronology and geochemistry of the Saishitang Cu deposit, East Kunlun Mountains, NW China: Constraints on ore genesis and tectonic setting. Ore Geol. Rev. 2016, 72, 43–59. [Google Scholar] [CrossRef]

- Li, J.J. Study on Bacteria Bioleaching and Adsorbent for Low Grade Copper Mine in Qinghai Saishitang; Southwest University of Science and Technology: Mianyang, China, 2012. (In Chinese) [Google Scholar]

- Dai, Z.M.; Yin, H.Q.; Zeng, X.X.; Liu, X.D. Comparison of Microbial Community of Acid Mine Drainage from Dongchuan Copper Pyrite. Xiandai Shengwuyixue Jinzhan 2007, 7, 1608–1611. (In Chinese) [Google Scholar]

- Feng, S.; Yang, H.; Wang, W. Improved chalcopyrite bioleaching by Acidithiobacillus sp. via direct step-wise regulation of microbial community structure. Bioresour. Technol. 2015, 192, 75–82. [Google Scholar] [CrossRef] [PubMed]

- Nakazawa, H.; Koizumi, M.; Sato, H. Bacterial Leaching of Copper-nickel Sulfide Ores from Jinchuan Mine, China. J. MMIJ 1992, 108, 731–735. [Google Scholar] [CrossRef]

- Banerjee, I.; Burrell, B.; Reed, C.; West, A.C.; Banta, S. Metals and minerals as a biotechnology feedstock: Engineering biomining microbiology for bioenergy applications. Curr. Opin. Biotechnol. 2017, 45, 144–155. [Google Scholar] [CrossRef] [PubMed]

- Jin, J.M. Experiment Study of Bacteria Enhanced Bioleaching Oxide Copper Mine. Master’s Thesis, Jiangxi University of Science and Technology, Ganzhou, China, 2009. (In Chinese). [Google Scholar]

- Li, J.L.; Li, D.C. The Practice of low grade primary chalcopyrite bacteria leaching technology. Copp. Eng. 2006, 2, 7–10. (In Chinese) [Google Scholar]

- He, Z.G.; Xiao, S.M.; Xie, X.H.; Hu, Y.H. Microbial diversity in acid mineral bioleaching systems of dongxiang copper mine and Yinshan lead-zinc mine. Extremophiles 2008, 12, 225–234. (In Chinese) [Google Scholar] [CrossRef] [PubMed]

- Wang, J. Research and Practice on Bioleaching of Low-Grade Complex Copper Sulfide. Ph.D. Thesis, Central South University, Changsha, China, 2011. (In Chinese). [Google Scholar]

- Zhen, S.J. Application Basis and Technology Research on the Bioleaching of Jinchuan Low Grade Nickel-Bearing Sufide Ore Containing High Magnesium. Ph.D. Thesis, Central South University, Changsha, China, 2010. (In Chinese). [Google Scholar]

- Zhen, S.J.; Qin, W.Q.; Yan, Z.Q.; Zhang, Y.S.; Wang, J.; Ren, L.Y. Bioleaching of low grade nickel sulfide minerals in column reactor. Trans. Nonferr. Met. Soc. China 2008, 18, 1480–1484. [Google Scholar] [CrossRef]

- Zhen, S.J.; Yan, Z.Q.; Zhang, Y.S.; Wang, J.; Campbell, M.; Qin, W.Q. Column bioleaching of a low grade nickel-bearing sulfide ore containing high magnesium as olivine, chlorite and antigorite. Hydrometallurgy 2009, 96, 337–341. [Google Scholar] [CrossRef]

- Liu, X.Y.; Chen, B.W.; Chen, J.H.; Zhang, M.J.; Wen, J.K.; Wang, D.Z.; Ruan, R.M. Spatial variation of microbial community structure in the Zijinshan commercial copper heap bioleaching plant. Miner. Eng. 2016, 94, 76–82. [Google Scholar] [CrossRef]

- Yuan, X.; Yuan, C.X.; Zhong, K.N.; Wei, Y.H. Microbes processing technology study for non-metallic minerals. China Non-Met. Min. Ind. Her. 2000, 4, 17–24. (In Chinese) [Google Scholar]

- Ruan, R.M.; Liu, X.Y.; Zou, G.; Chen, J.H.; Wen, J.K.; Wang, D.Z. Industrial practice of a distinct bioleaching system operated at low pH, high ferric concentration, elevated temperature and low redox potential for secondary copper sulfide. Hydrometallurgy 2011, 108, 130–135. [Google Scholar] [CrossRef]

- Ruan, R.M.; Zou, G.; Zhong, S.P.; Wu, Z.L.; Chan, B.; Wang, D.Z. Why Zijinshan copper bioheapleaching plant works efficiently at low microbial activity—Study on leaching kinetics of copper sulfides and its implications. Miner. Eng. 2013, 48, 36–43. [Google Scholar] [CrossRef]

- Liu, X.Y.; Chen, B.W.; Wen, J.K. Dominance of Acidithiobacillus at ore surface of Zijinshan commercial low-grade copper bioleaching heap. Trans. Nonferr. Met. Soc. China 2008, 18, 1506–1512. [Google Scholar] [CrossRef]

- Liu, X.Y.; Chen, B.W.; Wen, J.K.; Ruan, R.M. Leptospirillum, forms a minor portion of the population in Zijinshan commercial non-aeration copper bioleaching heap identified by 16S rRNA clone libraries and real-time PCR. Hydrometallurgy 2010, 104, 399–403. [Google Scholar]

- Sullivan, J.D. Chemistry of Leaching Covellite; TP 487; US Bureau of Mines: Washington, DC, USA, 1930.

- Sullivan, J.D. Chemistry of Leaching Chalcocite; TP 473; US Bureau of Mines: Washington, DC, USA, 1930.

- Wen, J.K.; Ruan, R.M.; Yao, G.C.; Song, Y.S. Acid equilibrium during bioleaching of alkaline low-grade copper sulfide ore. Rare Met. 2006, 25, 680–686. [Google Scholar] [CrossRef]

- Zhu, W.; Xia, J.L.; Yang, Y.; Nie, Z.Y.; Peng, A.A.; Liu, C.H.; Qiu, G.Z. Thermophilic archaeal community succession and function change associated with the leaching rate in bioleaching of chalcopyrite. Bioresour. Technol. 2013, 133, 405–413. [Google Scholar] [CrossRef] [PubMed]

- He, M.C.; Wang, Z.J.; Tang, H.X. Spatial and temporal patterns of acidity and heavy metals in predicting the potential for ecological impact on the Le An River polluted by acid mine drainage. Sci. Total Environ. 1997, 206, 67–77. [Google Scholar] [CrossRef]

- Liu, Q.M.; Yu, R.L.; Qiu, G.Z.; Feng, Z.; Chen, A.L.; Zhao, Z.W. Optimization of separation processing of copper and iron of dump bioleaching solution by Lix 984N in Dexing Copper Mine. Trans. Nonferr. Met. Soc. China 2008, 18, 1258–1261. [Google Scholar] [CrossRef]

- Yin, S.H.; Wu, A.X.; Wang, H.J.; Zhou, B. Challenges faced by Dexing Copper Mine—A case study of dump leaching in China. In Proceedings of the First International Seminar on the Management of Rock Dumps, Stockpiles and Heap Leach Pads, Perth, Australia, 5–6 March 2008; pp. 179–191. [Google Scholar]

- Liu, J.S.; Xia, H.B.; Wang, Z.H.; Hu, Y.H. Bacterial oxidation activity in heap leaching. J. Cent. South Univ. Technol. (Engl. Ed.) 2004, 11, 375–379. [Google Scholar] [CrossRef]

- Yin, S.H.; Wu, A.X.; Qiu, G.Z. Bioleaching of low-grade copper sulphides. Trans. Nonferr. Met. Soc. China 2008, 18, 707–713. [Google Scholar] [CrossRef]

- Wu, A.X.; Yin, S.H.; Yang, B.H.; Wang, J.; Qiu, G.Z. Study on preferential flow in dump leaching of low-grade ores. Hydrometallurgy 2007, 87, 124–132. [Google Scholar] [CrossRef]

- Wu, A.X.; Yin, S.H.; Wang, H.J.; Qin, W.Q.; Qiu, G.Z. Technological assessment of a mining-waste dump at the Dexing copper mine, China, for possible conversion to an in situ bioleaching operation. Bioresour. Technol. 2009, 100, 1931–1936. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, W.Q.; Fitts, J.P.; Ajo-Franklin, C.M.; Maes, S.; Alvarez-Cohen, L.; Hennebel, T. Recovery of critical metals using biometallurgy. Curr. Opin. Biotechnol. 2015, 33, 327–335. [Google Scholar] [CrossRef] [PubMed]

- Wackett, L.P.; Bruce, N.C. Environmental biotechnology: Towards sustainability. Curr. Opin. Biotechnol. 2000, 11, 229–231. [Google Scholar] [CrossRef]

- He, Z.L.; Nostrand, J.D.V.; Zhou, J.Z. Applications of functional gene microarrays for profiling microbial communities. Curr. Opin. Biotechnol. 2012, 23, 460–466. [Google Scholar] [CrossRef] [PubMed]

- Tuovinen, O.H.; Fry, I.J. Bioleaching and mineral biotechnology. Curr. Opin. Biotechnol. 1993, 4, 344–355. [Google Scholar] [CrossRef]

- Johnson, D.B. Importance of microbial ecology in the development of new mineral technologies. Hydrometallurgy 2001, 59, 147–157. [Google Scholar] [CrossRef]

- Johnson, D.B. Biodiversity and ecology of acidophilic microorganisms. FEMS Microbiol. Ecol. 1998, 27, 307–317. [Google Scholar] [CrossRef]

- Luo, Y.J.; Liu, Y.D.; Zhang, C.G.; Luo, H.L.; Guan, H.; Liao, H.H.; Qiu, G.Z.; Liu, X.D. Insights into Two High Homogenous Genes Involved in Copper Homeostasis in Acidithiobacillus ferrooxidans. Curr. Microbiol. 2008, 57, 274–280. [Google Scholar] [CrossRef] [PubMed]

- Yin, H.Q.; Cao, L.H.; Qiu, G.Z.; Wang, D.Z.; Kellogg, L.; Zhou, J.Z.; Liu, X.X.; Dai, Z.M.; Ding, J.N.; Liu, X.D. Bacterial diversity based on 16S rRNA and gyrB genes at Yinshan mine, China. Syst. Appl. Microbiol. 2008, 31, 302–311. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Zhang, C.G.; Wu, X.L.; Wang, H.H.; Qiu, G.Z. Isolation and identification of a strain of Leptospirillum ferriphilum from an extreme acid mine drainage site. Ann. Microbiol. 2007, 57, 171–176. [Google Scholar] [CrossRef]

- Xie, X.; Xiao, S.; He, Z.; Liu, J.; Qiu, G.Z. Microbial populations in acid mineral bioleaching systems of Tong Shankou Copper Mine, China. J. Appl. Microbiol. 2007, 103, 1227–1238. [Google Scholar] [CrossRef] [PubMed]

- Urbieta, M.S.; Donati, E.R.; Chan, K.G.; Shahar, S.; Sin, L.L.; Goh, K.M. Thermophiles in the genomic era: Biodiversity, science, and applications. Biotechnol. Adv. 2015, 33, 633–647. [Google Scholar] [CrossRef] [PubMed]

- Qiu, G.Z.; Liu, X.D.; Zhou, H.B. Microbial community structure and function in sulfide ore bioleaching systems. Trans. Nonferr. Met. Soc. China 2008, 18, 1295–1301. [Google Scholar] [CrossRef]

- Zhao, H.B.; Wang, J.; Yang, C.R.; Hu, M.H.; Gan, X.W.; Tao, L.; Qin, W.Q.; Qiu, G.Z. Effect of redox potential on bioleaching of chalcopyrite by moderately thermophilic bacteria: An emphasis on solution compositions. Hydrometallurgy 2015, 151, 141–150. [Google Scholar] [CrossRef]

- Hu, Q.; Guo, X.; Liang, Y.L.; Hao, X.D.; Ma, L.Y.; Yin, H.Q.; Liu, X.D. Comparative metagenomics reveals microbial community differentiation in a biological heap leaching system. Res. Microbiol. 2015, 166, 525–534. [Google Scholar] [CrossRef] [PubMed]

- Qin, W.Q.; Yang, C.R.; Lai, S.S.; Wang, J.; Liu, K.; Zhang, B. Bioleaching of chalcopyrite by moderately thermophilic microorganisms. Bioresour. Technol. 2013, 129, 200–208. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Sun, H.Y.; Chen, D.F.; Gao, H.S.; Ruan, R.M. Characterization of microbial community in industrial bioleaching heap of copper sulfide ore at Monywa mine, Myanmar. Hydrometallurgy 2016, 164, 355–361. [Google Scholar] [CrossRef]

- Ma, L.Y.; Wang, X.J.; Feng, X.; Liang, Y.L.; Xiao, Y.H.; Hao, X.D.; Yin, H.Q.; Liu, H.W.; Liu, X.D. Co-culture microorganisms with different initial proportions reveal the mechanism of chalcopyrite bioleaching coupling with microbial community succession. Bioresour. Technol. 2017, 223, 121–130. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Gan, X.W.; Zhao, H.B.; Hu, M.H.; Qin, W.Q.; Qiu, G.Z. Dissolution and passivation mechanisms of chalcopyrite during bioleaching: DFT calculation, XPS and electrochemistry analysis. Miner. Eng. 2016, 98, 264–278. [Google Scholar] [CrossRef]

- Li, S.Z.; Zhong, H.; Hu, Y.H.; Zhao, J.C.; He, Z.G.; Gu, G.H. Bioleaching of a low-grade nickel–copper sulfide by mixture of four thermophiles. Bioresour. Technol. 2014, 153, 300–306. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Diao, M.X.; Liu, K.; Qian, L.; Qiu, G.Z. Column bioleaching of low-grade copper ore by Acidithiobacillus ferrooxidans in pure and mixed cultures with a heterotrophic acidophile Acidiphilium sp. Hydrometallurgy 2013, 131–132, 93–98. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Qin, W.Q.; Wang, J.; Zhen, S.J.; Yang, C.R.; Zhang, J.W.; Lai, S.S.; Qiu, G.Z. Bioleaching of chalcopyrite by pure and mixed culture. Trans. Nonferr. Met. Soc. China 2008, 18, 1491–1496. [Google Scholar] [CrossRef]

- Liu, C.Q.; Plumb, J.; Hendry, P. Rapid specific detection and quantification of bacteria and archaea involved in mineral sulfide bioleaching using real-time PCR. Biotechnol. Bioeng. 2006, 94, 330–336. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; She, S.Y.; Dong, W.L.; Niu, J.J.; Xiao, Y.H.; Liang, Y.L.; Liu, X.D.; Zhang, X.X.; Fan, F.L.; Yin, H.Q. Comparative genomics unravels metabolic differences at the species and/or strain level and extremely acidic environmental adaptation of ten bacteria belonging to the genus Acidithiobacillus. Syst. Appl. Microbiol. 2016, 39, 493–502. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Niu, J.J.; Liang, Y.L.; Liu, X.D.; Yin, H.Q. Metagenome-scale analysis yields insights into the structure and function of microbial communities in a copper bioleaching heap. BMC Gentics 2016, 17, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.L.; Yang, F.C.; Huang, C.H.; Fang, H.W.; Cheng, Y.C. Sensitivity analysis of the semiempirical model for the growth of the indigenous Acidithiobacillus thiooxidans. Chem. Eng. J. 2007, 129, 105–112. [Google Scholar] [CrossRef]

- Dong, Y.B.; Lin, H.; Wang, H.; Mo, X.L.; Fu, K.B.; Wen, H.W. Effects of ultraviolet irradiation on bacteria mutation and bioleaching of low-grade copper tailings. Miner. Eng. 2011, 24, 870–875. [Google Scholar] [CrossRef]

- Xu, A.L.; Xia, J.L.; Zhang, S.; Yang, Y.; Nie, Z.Y.; Qiu, G.Z. Bioleaching of chalcopyrite by UV-induced mutagenized Acidiphilium cryptum and Acidithiobacillus ferrooxidans. Trans. Nonferr. Met. Soc. China 2010, 20, 315–321. [Google Scholar] [CrossRef]

- Meng, C.; Shi, X.A.; Liu, H.; Chen, J.F.; Guo, Y.H. UV induced mutations in Acidianus brierleyi growing in a continuous stirred tank reactor generated a strain with improved bioleaching capabilities. Enzyme Microb. Technol. 2007, 40, 1136–1140. [Google Scholar] [CrossRef]

- Tanda, B.C.; Eksteen, J.J.; Oraby, E.A. An investigation into the leaching behaviour of copper oxide minerals in aqueous alkaline glycine solutions. Hydrometallurgy 2017, 167, 153–162. [Google Scholar] [CrossRef]

- Willscher, S.; Bosecker, K. Studies on the leaching behaviour of heterotrophic microorganisms isolated from an alkaline slag dump. Hydrometallurgy 2003, 71, 257–264. [Google Scholar] [CrossRef]

- Deng, S.; Gu, G.H.; Wu, Z.T.; Xu, X.Y. Bioleaching of arsenopyrite by mixed cultures of iron-oxidizing and sulfur-oxidizing microorganisms. Chemosphere 2017, 185, 403. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.X.; Huang, L.N.; Garcia, C.M.; Kuang, J.L.; Hua, Z.S.; Liu, J.; Shu, W.S. Microbial communities, processes and functions in acid mine drainage ecosystems. Curr. Opin. Biotechnol. 2016, 38, 150–158. [Google Scholar] [CrossRef] [PubMed]

- Rawlings, D.E.; Tributsch, H.; Hansford, G.S. Reasons why Leptospirillum-like species rather than Thiobacillus ferrooxidans are the dominant iron-oxidizing bacteria in many commercial processes for the biooxidation of pyrite and related ores. Microbiology 1999, 145, 5–13. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.F.; Yang, C.R.; Qin, W.Q.; Jiao, F.; Wang, J.; Zhang, Y.S. Sulfur composition on surface of chalcopyrite during its bioleaching at 50 °C. Trans. Nonferr. Met. Soc. China 2015, 12, 4110–4118. [Google Scholar] [CrossRef]

- Gu, G.H.; Sun, X.J.; Hu, K.T.; Li, J.H.; Qiu, G.Z. Electrochemical oxidation behavior of pyrite bioleaching by Acidthiobacillus ferrooxidans. Trans. Nonferr. Met. Soc. China, 2012, 5, 1250–1254. [Google Scholar] [CrossRef]

- Zeng, W.M.; Tan, S.; Chen, M.; Qiu, G.Z. Detection and analysis of attached microorganisms on the mineral surface during bioleaching of pure chalcopyrite with moderate thermophiles. Hydrometallurgy 2011, 1–2, 46–50. [Google Scholar] [CrossRef]

- Zeng, W.M.; Qiu, G.Z.; Zhou, H.Z.; Peng, J.H.; Chen, M.; Tan, S.N.; Chao, W.L.; Liu, X.D.; Zhang, Y.S. Community structure and dynamics of the free and attached microorganisms. Bioresour. Technol. 2010, 101, 7068–7075. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.B.; Lin, H.; Xu, X.F.; Zhang, Y.; Gao, Y.J.; Zhou, S.S. Comparative study on the bioleaching, biosorption and passivation of copper sulfide minerals. Int. Biodeterior. Biodegrad. 2013, 84, 29–34. [Google Scholar] [CrossRef]

- Liu, C.H.; Nie, Z.Y.; Xia, J.L.; Zhu, H.R.; Yang, Y.; Zhao, C.H.; Zheng, L.; Zhao, Y.D. Investigation of copper, iron and sulfur speciation during bioleaching of chalcopyrite by moderate thermophile Sulfobacillus thermosulfidooxidans. Int. J. Miner. Process. 2015, 137, 1–8. [Google Scholar] [CrossRef]

- He, Z.G.; Yang, Y.P.; Zhou, S.; Hu, Y.H.; Zhong, H. Effect of pyrite, elemental sulfur and ferrous ions on EPS production by metal sulfide bioleaching microbes. Trans. Nonferr. Met. Soc. China 2014, 24, 1171–1178. [Google Scholar] [CrossRef]

- Fu, K.B.; Lin, H.; Cheng, H.; Mo, X.L.; Dong, Y.B. Bioleaching of djurleite using Acidithiobacillus ferrooxidans. Miner. Eng. 2013, 40, 38–41. [Google Scholar] [CrossRef]

- Yang, H.Y.; Liu, W.; Chen, G.B.; Liu, Y.Y.; Tong, L.L.; Jin, Z.N.; Liu, Z.L. Function of microorganism and reaction pathway for carrollite dissolution during bioleaching. Trans. Nonferr. Met. Soc. China 2015, 25, 2718–2754. [Google Scholar] [CrossRef]

- Zhao, H.B.; Wang, J.; Hu, M.H.; Qin, W.Q.; Zhang, Y.S.; Qiu, G.Z. Synergistic bioleaching of chalcopyrite and bornite in the presence of Acidithiobacillus ferrooxidans. Bioresour. Technol. 2013, 149, 71–76. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.B.; Huang, X.T.; Wang, J.; Li, Y.N.; Liao, R.; Wang, X.X.; Qiu, X.; Xiong, Y.M.; Qin, W.Q.; Qiu, G.Z. Comparison of bioleaching and dissolution process of p-type and n-type chalcopyrite. Miner. Eng. 2017, 109, 153–161. [Google Scholar] [CrossRef]

- Zhang, L.J.; Mao, F.; Li, K.; Wang, Y.G.; Chen, X.H.; Zhou, H.B. Enhancement in copper extraction from chalcopyrite by re-inoculation of different acidophilic, moderately thermophilic microorganisms. Hydrometallurgy 2015, 156, 142–151. [Google Scholar] [CrossRef]

- Zhang, L.J.; Wu, J.Z.; Wang, Y.G.; Wan, L.L.; Mao, F.; Zhang, W.; Chen, X.H.; Zhou, H.B. Influence of bioaugmentation with Ferroplasma thermophilum on chalcopyrite bioleaching and microbial community structure. Hydrometallurgy 2014, 146, 15–23. [Google Scholar] [CrossRef]

- Zhou, S.; Gan, M.; Zhu, J.Y.; Li, Q.; Jie, S.Q.; Yang, B.J.; Liu, X.D. Catalytic effect of light illumination on bioleaching of chalcopyrite. Bioresour. Technol. 2015, 182, 345–352. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.Y.; Wang, Q.F.; Zhou, S.; Li, Q.; Gan, M.; Jiang, H.; Qin, W.Q.; Liu, X.D.; Hu, Y.H.; Qiu, G.Z. Insights into the relation between adhesion force and chalcopyrite-bioleaching by Acidithiobacillus ferrooxidans. Colloids Surf. B 2015, 126, 351–357. [Google Scholar] [CrossRef] [PubMed]

- Diao, M.X.; Taran, E.; Mahler, S.; Nguyen, A.V. A concise review of nanoscopic aspects of bioleaching bacteria–mineral interactions. Adv. Colloid Interface Sci. 2014, 212, 45–63. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.J.; Yu, R.L.; Liu, A.J.; Liu, J.; Zeng, W.M.; Liu, X.D.; Qiu, G.Z. Effect of pH values on extracellular protein and polysaccharide secretions of Acidithiobacillus ferrooxidans during chalcopyrite bioleaching. Trans. Nonferr. Met. Soc. China 2017, 27, 406–412. [Google Scholar] [CrossRef]

- Peng, T.J.; Zhou, D.; Liu, X.D.; Yu, R.L.; Jiang, T.; Gu, G.H.; Chen, M.; Qiu, G.Z.; Zeng, W.M. Enrichment of ferric iron on mineral surface during bioleaching of chalcopyrite. Trans. Nonferr. Met. Soc. China 2016, 26, 544–550. [Google Scholar] [CrossRef]

- Yang, H.L.; Feng, S.S.; Xin, Y.; Wang, W. Community dynamics of attached and free cells and the effects of attached cells on chalcopyrite bioleaching by Acidithiobacillus sp. Bioresour. Technol. 2014, 154, 185–191. [Google Scholar] [CrossRef] [PubMed]

- Yu, R.L.; Shi, L.J.; Gu, G.H.; Zhou, D.; You, L.; Chen, M.; Qiu, G.Z.; Zeng, W.M. The shift of microbial community under the adjustment of initial and processing pH during bioleaching of chalcopyrite concentrate by moderate thermophiles. Bioresour. Technol. 2014, 162, 300–307. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yin, H.Q.; Zeng, W.M.; Liang, Y.L.; Liu, Y.; Baba, N.; Qiu, G.Z.; Shen, L.; Fu, X.; Liu, X.D. The effect of the introduction of exogenous strain Acidithiobacillus thiooxidans A01 on functional gene expression, structure and function of indigenous consortium during pyrite bioleaching. Bioresour. Technol. 2011, 102, 8092–8098. [Google Scholar] [CrossRef] [PubMed]

- Li, R.R.; Yang, Y.S.; Pan, J.X.; Pereira, G.G.; Taylor, J.A.; Clennell, B.; Zou, C.N. Lattice Boltzmann modeling of permeability in porous materials with partially percolating voxels. Phys. Rev. E 2014, 90, 1–10. [Google Scholar] [CrossRef] [PubMed]

- He, Z.G.; Gao, F.L.; Zhong, H.; Hu, Y.H. Effects of L-cysteine on Ni–Cu sulfide and marmatite bioleaching by Acidithiobacillus caldus. Bioresour. Technol. 2009, 100, 1383–1387. [Google Scholar] [CrossRef] [PubMed]

- He, Z.G.; Hu, Y.T.; Yin, Z.; Hu, Y.H.; Zhong, H. Microbial Diversity of Chromium-Contaminated Soils and Characterization of Six Chromium-Removing Bacteria. Environ. Manag. 2016, 57, 1319–1328. [Google Scholar] [CrossRef] [PubMed]

- Jing, R.; Kjellerup, B.V. Biogeochemical cycling of metals impacting by microbial mobilization and immobilization. J. Environ. Sci. 2017, 4, 35. [Google Scholar] [CrossRef]

- Dong, Y.B.; Lin, H.; Zhou, S.S.; Xu, X.F.; Zhang, Y. Effects of quartz addition on chalcopyrite bioleaching in shaking flasks. Miner. Eng. 2013, 46–47, 177–179. [Google Scholar] [CrossRef]

- Pan, H.D.; Yang, H.Y.; Tong, L.L.; Zhong, C.B.; Zhao, Y.S. Control method of chalcopyrite passivation in bioleaching. Trans. Nonferr. Met. Soc. China 2012, 22, 2255–2260. [Google Scholar] [CrossRef]

- Jiang, J.; Lawson, F. Reaction mechanism for the formation of ammonium jarosite. Hydrometallurgy 2006, 82, 195–198. [Google Scholar] [CrossRef]

- Feng, S.S.; Yang, H.L.; Zhan, X.; Wang, W. Novel integration strategy for enhancing chalcopyrite bioleaching by Acidithiobacillus sp. in a 7-L fermenter. Bioresour. Technol. 2014, 161, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Bellenberg, S.; Castro, L.; Neu, T.R.; Sand, W.; Vera, M. Colonization and biofilm formation of the extremely acidophilic archaeon Ferroplasma acidiphilum. Hydrometallurgy 2014, 150, 245–252. [Google Scholar] [CrossRef]

- Wang, J.; Tao, L.; Zhao, H.B.; Hu, M.H.; Zheng, X.H.; Peng, H.; Gan, X.W.; Xiao, W.; Cao, P.; Qin, W.Q.; et al. Cooperative effect of chalcopyrite and bornite interactions during bioleaching by mixed moderately thermophilic culture. Miner. Eng. 2016, 95, 116–123. [Google Scholar] [CrossRef]

- Li, Q.; Sand, W. Mechanical and chemical studies on EPS from Sulfobacillus thermosulfidooxidans: From planktonic to biofilm cells. Colloids Surf. B 2017, 153, 34–40. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.S.; Sun, F.Y.; Xu, Y.H.; Cong, Z.C.; Wang, E.K. Applications of electrochemical techniques in mineral analysis. Talanta 2014, 127, 211–218. [Google Scholar] [CrossRef] [PubMed]

- Li, H.X.; Li, C.; Zhang, Z.Q. Decomposition mechanism of pentlandite during eletrochamical bio-oxidation process. Trans. Nonferr. Met. Soc. China 2012, 22, 731–739. [Google Scholar] [CrossRef]

- Ma, L.Y.; Wang, X.J.; Tao, J.M.; Feng, X.; Zou, K.; Xiao, Y.H.; Liang, Y.L.; Yin, H.Q.; Liu, X.D. Bioleaching of the mixed oxide-copper sulfide ore by artificial indigenous and exogenous microbial community. Hydrometallurgy 2017, 169, 41–46. [Google Scholar] [CrossRef]

- Cariaga, E.; Concha, F.; Sepúlveda, M. Flow through porous media with applications to heap leaching of copper ores. Chem. Eng. J. 2005, 111, 151–165. [Google Scholar] [CrossRef]

- Yin, S.H.; Wu, A.X.; Su, Y.D.; Zhang, J. Experimental study on preferential solution flow during dump leaching of low-grade ores. J. Cent. South Univ. (Engl. Ed.) 2007, 14, 584–588. [Google Scholar] [CrossRef]

- Mcbride, D.; Ilankoon, I.M.S.K.; Neehling, S.J.; Gebhardt, J.E.; Cross, M. Preferential flow behaviour in unsaturated packed beds and heaps: Incorporating into a CFD model. Hydrometallurgy 2017, 171, 402–411. [Google Scholar] [CrossRef]

- Wu, A.X.; Yin, S.H.; Liu, J.Z.; Yang, B.H. Formative mechanism of preferential solution flow during dump leaching. J. Cent. South Univ. (Engl. Ed.) 2006, 13, 590–594. [Google Scholar] [CrossRef]

- Wang, H.J.; Wu, A.X.; Su, Y.D.; Yang, B.H.; Zhang, J. Seepage anisotropy of heterogeneous body. J. China Univ. Min. Technol. (Engl. Ed.) 2007, 17, 572–577. [Google Scholar] [CrossRef]

- Yin, S.H.; Wang, L.M.; Chen, X.; Wu, A.X. Effect of ore size and heap porosity on capillary process inside leaching heap. Trans. Nonferr. Met. Soc. China 2016, 26, 835–841. [Google Scholar] [CrossRef]

- Liu, J.Z.; Jiang, Z.Y.; Wu, A.X. The existence of periodic solutions for a class of nonlinear functional differential equations. Appl. Math. 2008, 53, 97–103. [Google Scholar] [CrossRef]

- Liu, J.Z.; Wu, A.X.; Yang, B.H.; Jiang, H.C. Dynamic experiment and numerical simulation of solute transmission in heap leaching processing. J. Cent. South Univ. Technol. (Engl. Ed.) 2007, 14, 838–841. [Google Scholar] [CrossRef]

- Miao, X.X.; Narsilio, G.A.; Wu, A.X.; Yang, B.H. A 3D dual pore-system leaching model. Part 1: Study on fluid flow. Hydrometallurgy 2017, 167, 173–182. [Google Scholar] [CrossRef]

- Liu, W.Y.; Hashemzadeh, M. Solution flow behavior in response to key operating parameters in heap leaching. Hydrometallurgy 2017, 169, 183–191. [Google Scholar] [CrossRef]

- Yin, S.H.; Wang, L.M.; Xie, F.F.; Chen, X.; Pan, C.Y.; Ai, C.M. Effect of heap structure on column leaching of secondary copper sulfide. Chin. J. Nonferr. Met. 2017, 27, 2340–2348. (In Chinese) [Google Scholar]

- Yin, S.H.; Wang, L.M.; Pan, C.Y.; Chen, X.; Xie, F.F. Fluid flowing characteristics in ore granular with fine interlayers existed. Chin. J. Nonferr. Met. 2017, 27, 574–581. (In Chinese) [Google Scholar]

- Wu, A.X.; Xi, Y.; Yang, B.H.; Chen, X.S.; Jiang, H.C. Study on grey forecasting model of copper extraction rate with bioleaching of primary sulfide ore. Acta Metall. Sin. (Engl. Lett.) 2007, 20, 117–128. [Google Scholar] [CrossRef]

- Miao, X.X.; Wu, A.X.; Yang, B.H.; Liu, J.Z.; Yin, S.H.; Wang, H.J. Unsaturated flow and solute transport in a porous column using spherical ore particles. Int. J. Miner. Metall. Mater. 2014, 21, 113–121. [Google Scholar] [CrossRef]

- Dhawan, N.; Safarzadeh, M.S.; Miller, J.D.; Moats, M.S.; Rajamani, R.K. Crushed ore agglomeration and its control for heap leach operations. Miner. Eng. 2013, 41, 53–70. [Google Scholar] [CrossRef]

- Ghorbani, Y.; Mainza, A.N.; Petersen, J.; Becker, M.; Franzidis, J.P.; Kalala, J.T. Investigation of particles with high crack density produced by HPGR and its effect on the redistribution of the particle size fraction in heaps. Miner. Eng. 2013, 43, 44–51. [Google Scholar] [CrossRef]

- Kodali, P.; Dhawan, N.; Depci, T.; Lin, C.L.; Miller, J.D. Particle damage and exposure analysis in HPGR crushing of selected copper ores for column leaching. Miner. Eng. 2011b, 24, 1478–1487. [Google Scholar] [CrossRef]

- Miller, J.D.; Lin, C.L.; Garcia, C.; Arias, H. Ultimate recovery in heap leaching operations as established from mineral exposure analysis by X-ray microtomography. Int. J. Miner. Process. 2003, 72, 331–340. [Google Scholar] [CrossRef]

- Fagan, M.A.; Sederman, A.J.; Harrison, S.T.L.; John, M.L. Phase distribution identification in the column leaching of low grade ores using MRI. Miner. Eng. 2013, 48, 94–99. [Google Scholar] [CrossRef]

- Fagan, M.A.; Cilliers, J.J.; Sederman, A.J.; Harrison, S.T.L. Spatial variations in leaching of a low-grade, low-porosity chalcopyrite ore identified using X-ray μCT. Miner. Eng. 2017, 105, 63–68. [Google Scholar] [CrossRef]

- Lin, Q.; Barker, D.; Dobson, K.; Lee, P.; Neethling, S. Modelling particle scale leach kinetics based on X-ray computed micro-tomography images. Hydrometallurgy 2016, 162, 25–36. [Google Scholar] [CrossRef]

- Lin, Q. Use of X-ray Computed Microtomography to Measure the Leaching Behaviour of Metal Sulphide Ores. Ph.D. Thesis, Imperial College London, London, UK, 2015. [Google Scholar]

- Lin, Q.; Neethling, S.J.; Courtois, L.; Dobson, K.J.; Lee, P.D. Multi-scale quantification of leaching performance using X-ray tomography. Hydrometallurgy 2016, 164, 265–277. [Google Scholar] [CrossRef]