The Preparation and Performance Analysis of a Cr2O3 Gel Abrasive Tool for Sapphire Substrate Polishing

Abstract

:1. Introduction

2. Experimental Conditions

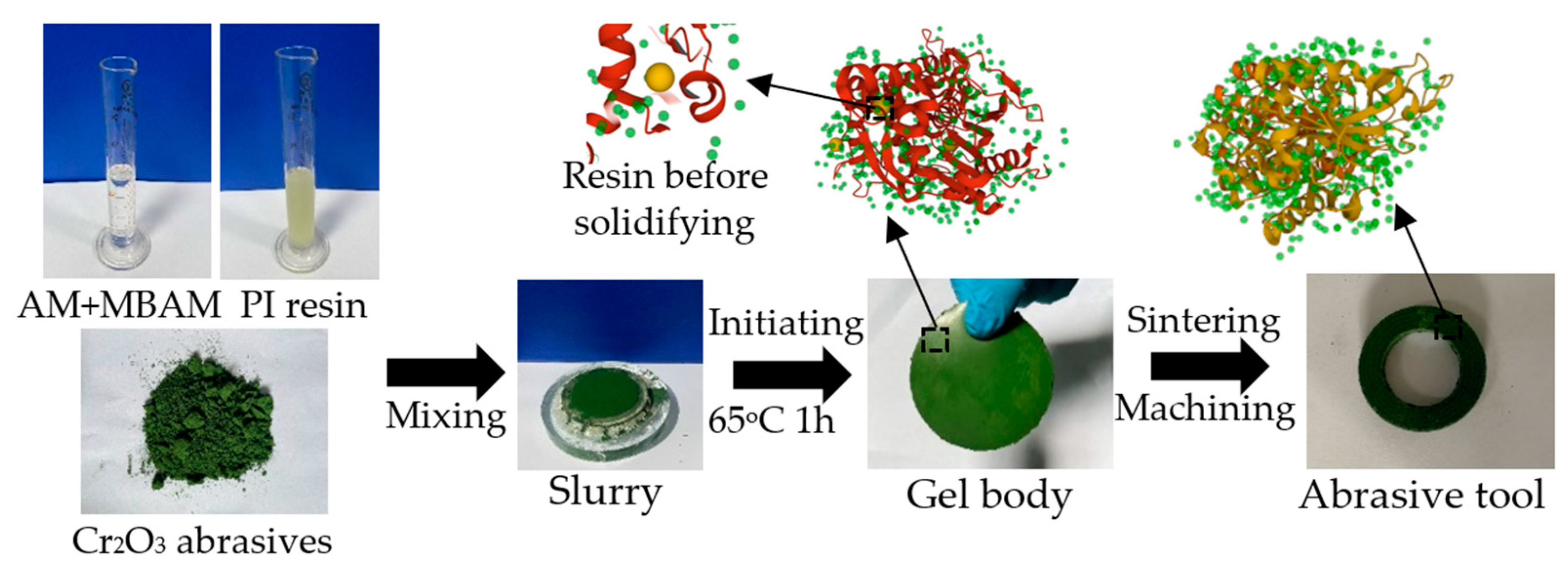

2.1. Abrasive Tool Preparation

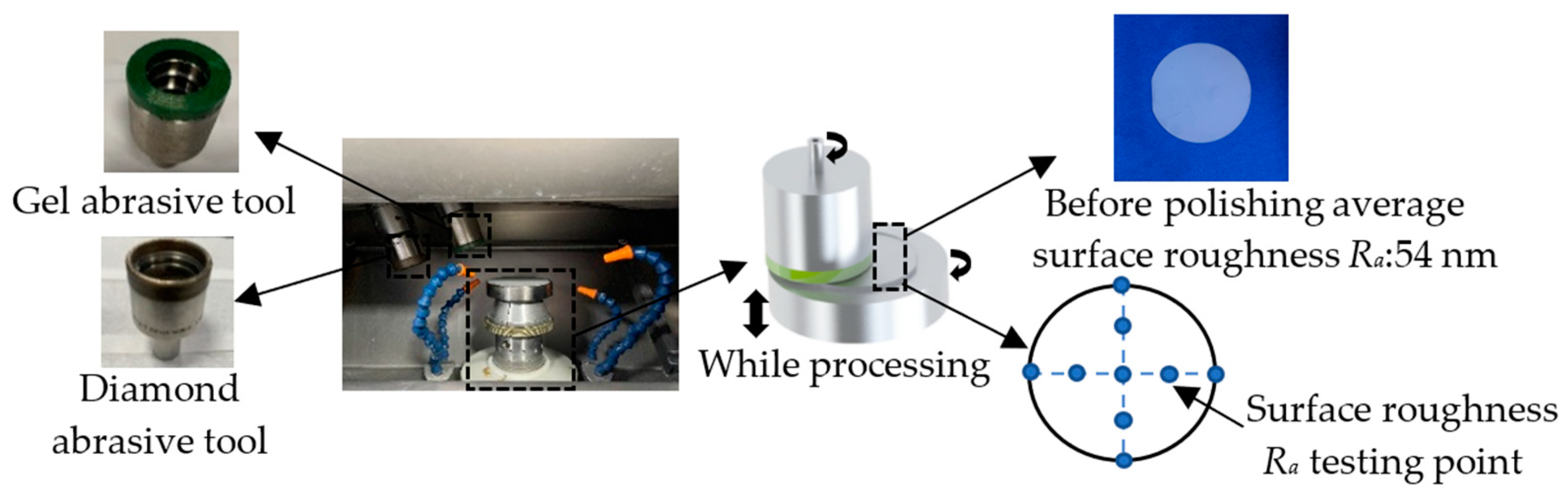

2.2. Experiment Equipment

2.3. Porosity of Abrasive Tool

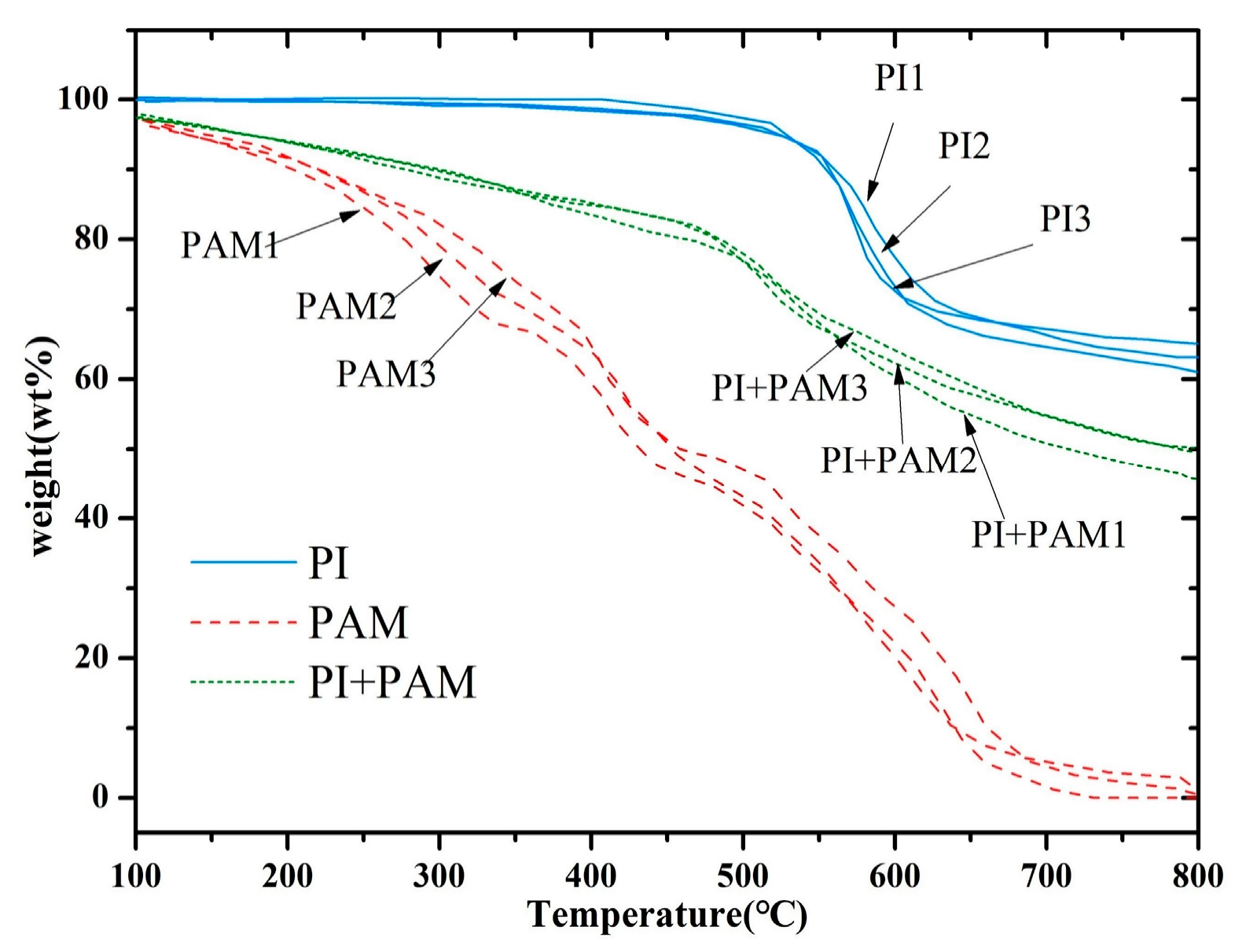

3. Results and Discussion

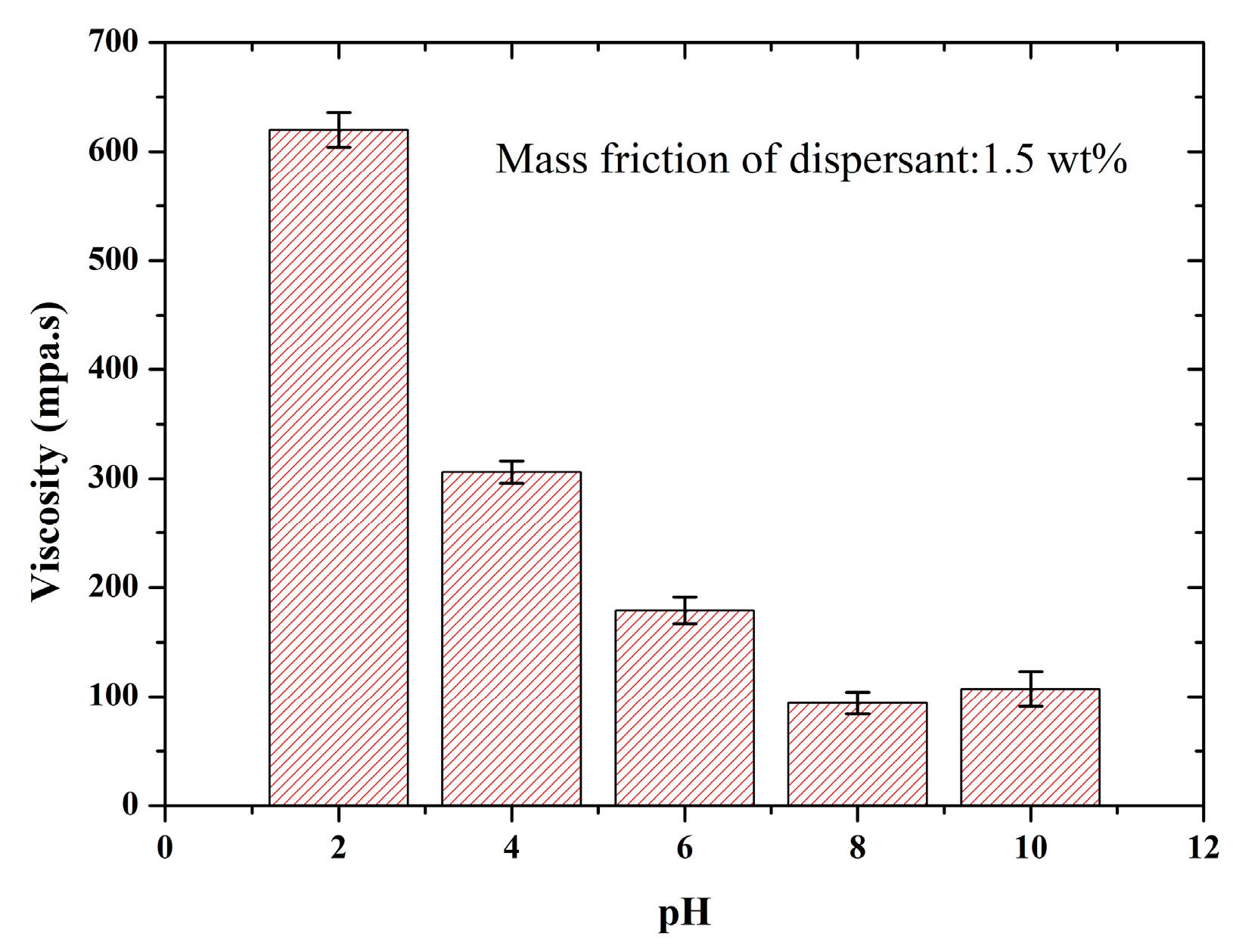

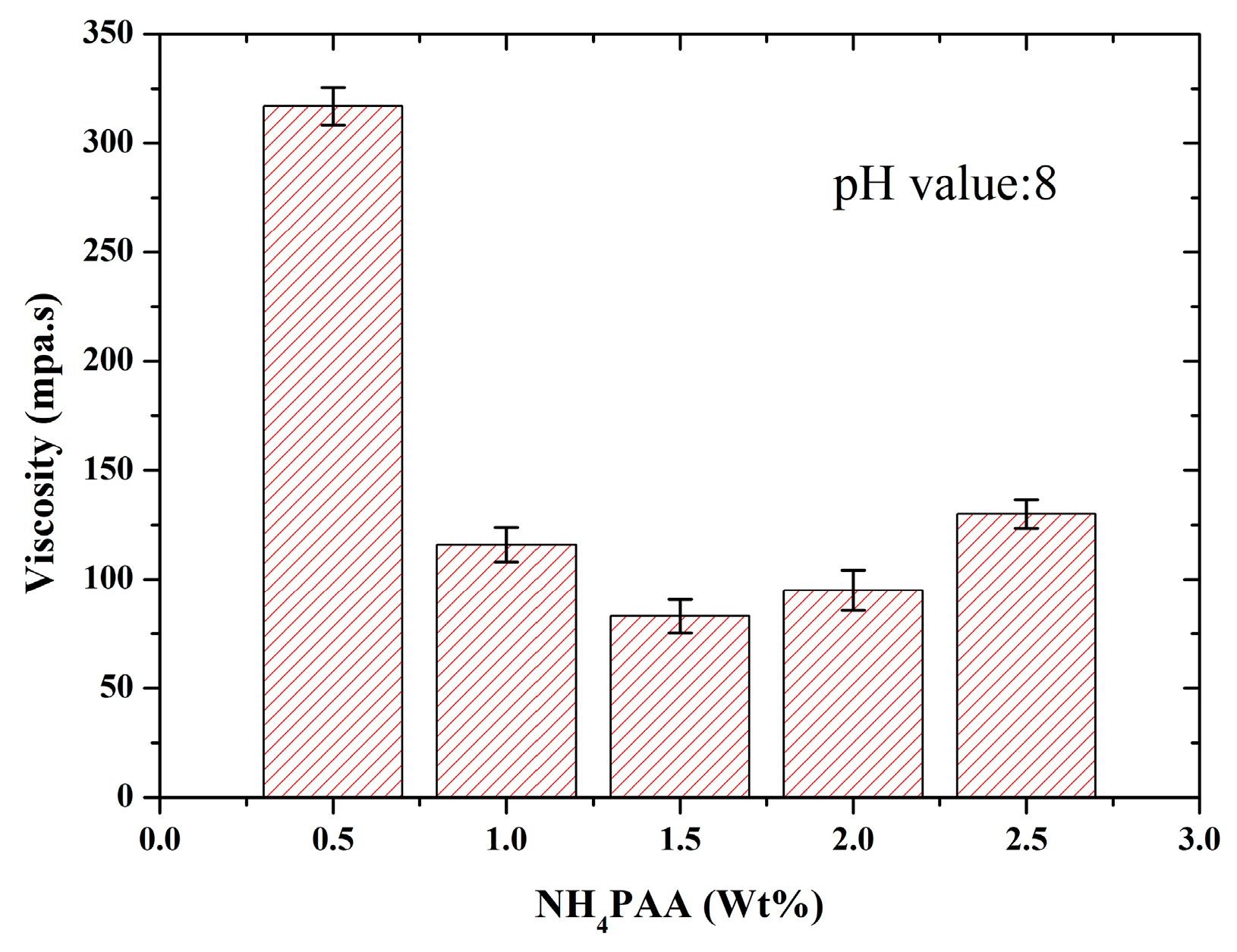

3.1. Influence of the Dispersant Concentration and pH Value on the Slurry Viscosity

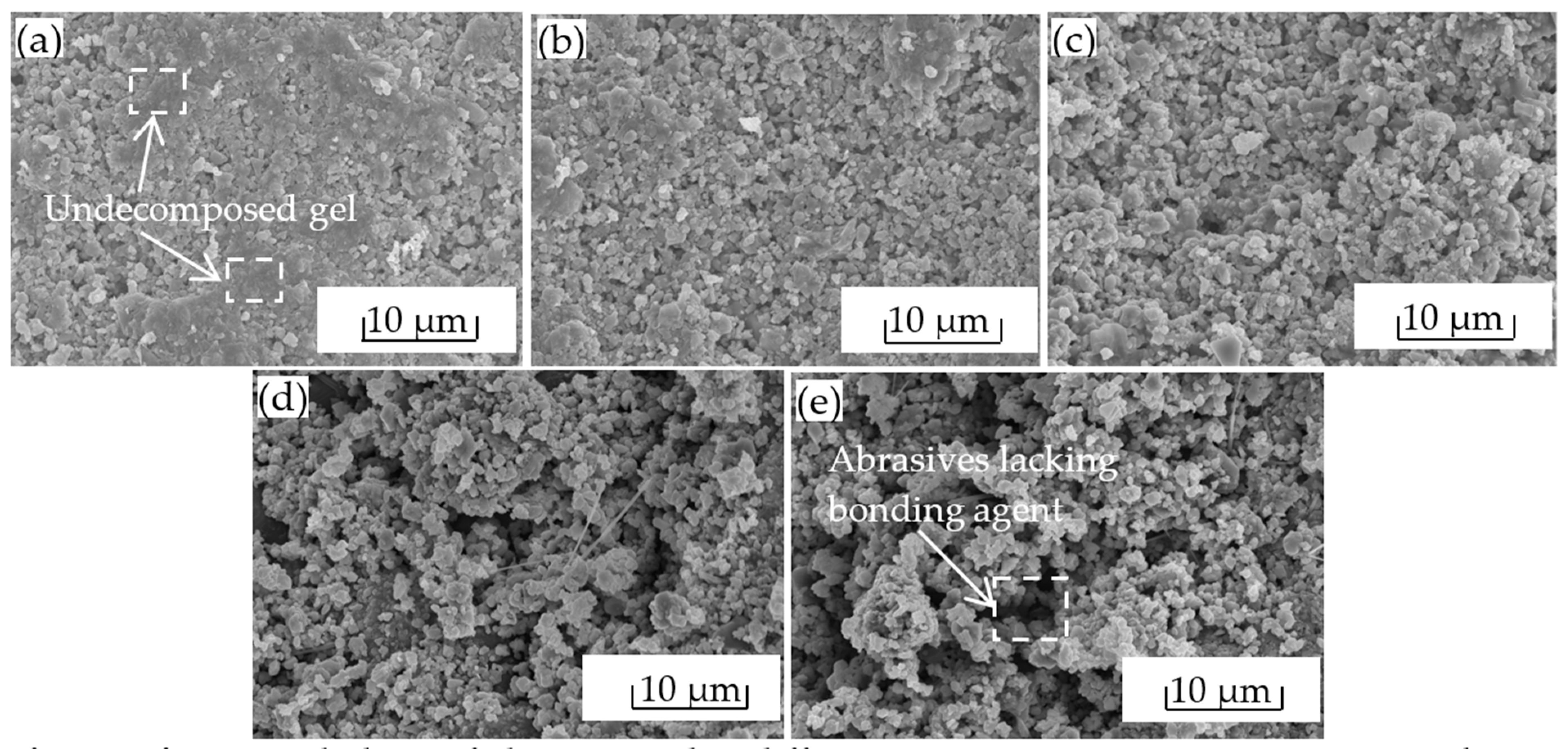

3.2. The Influence of Different Sintering Temperatures on Porosity

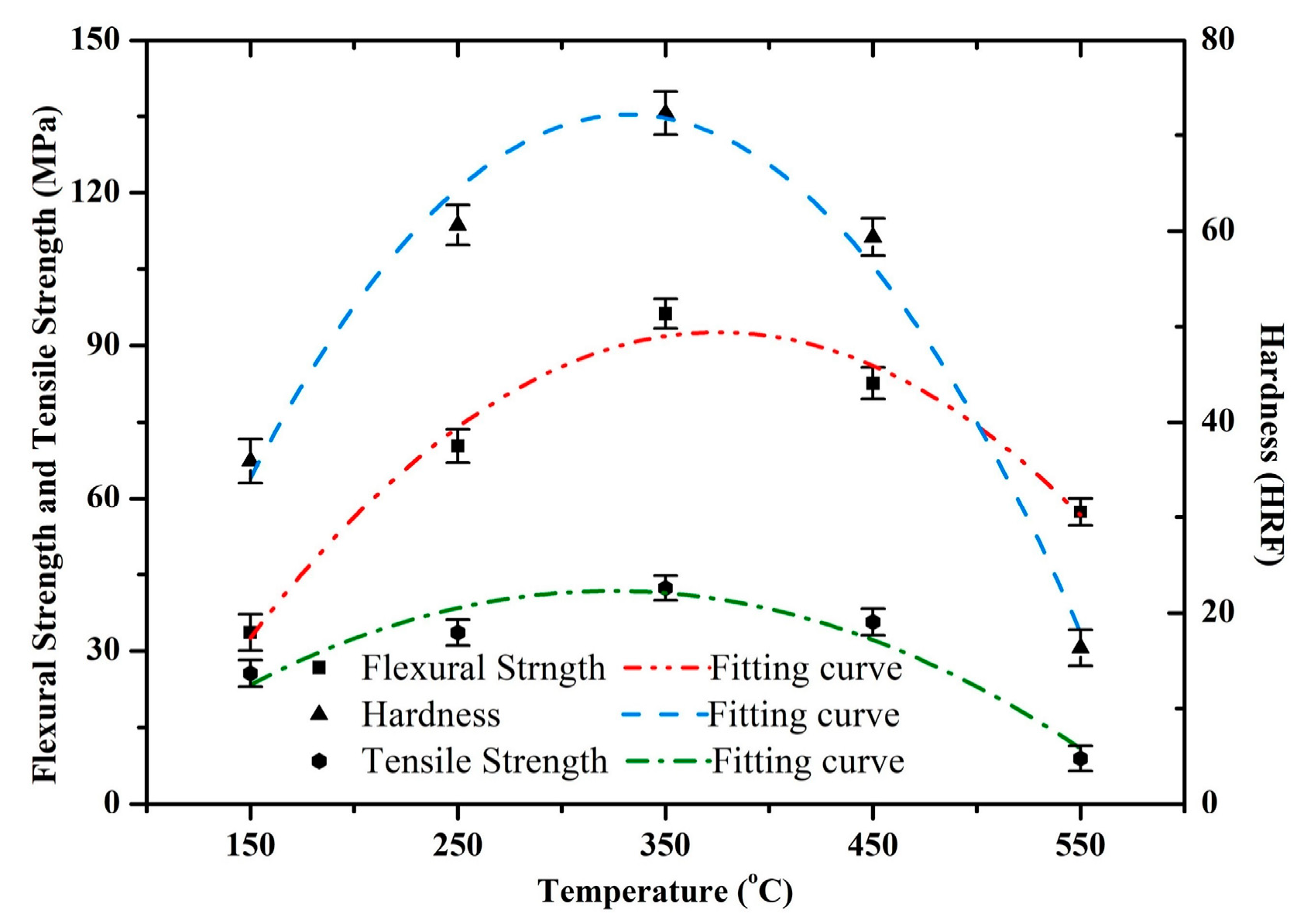

3.3. Influence of Different Sintering Temperatures on the Mechanical Properties

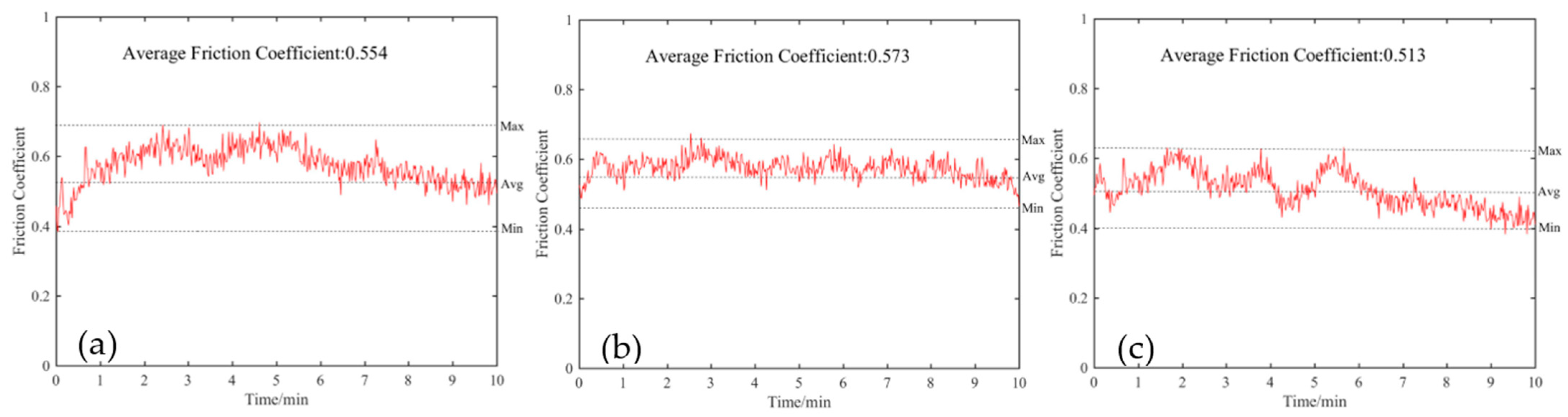

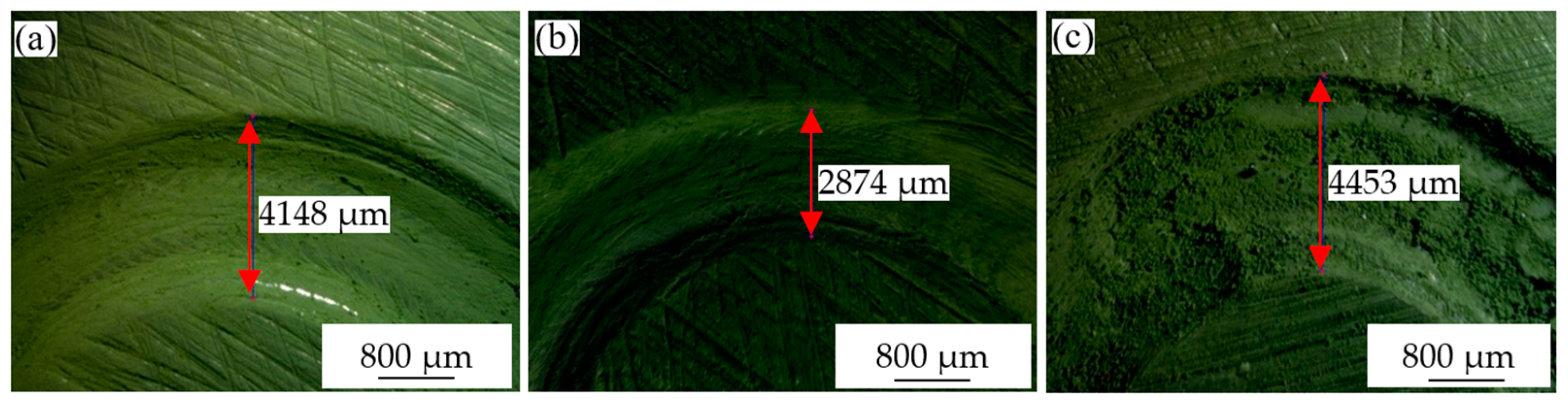

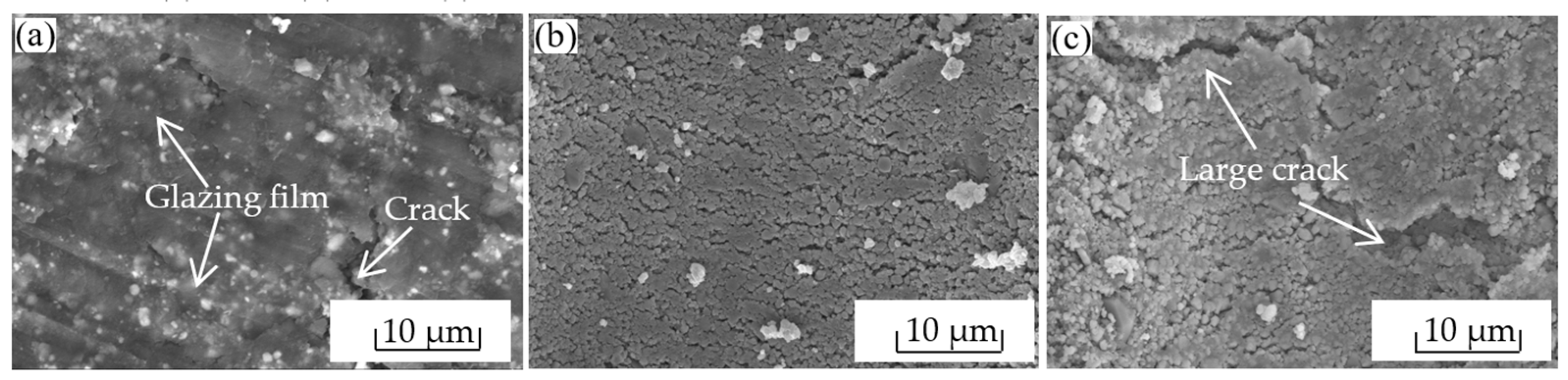

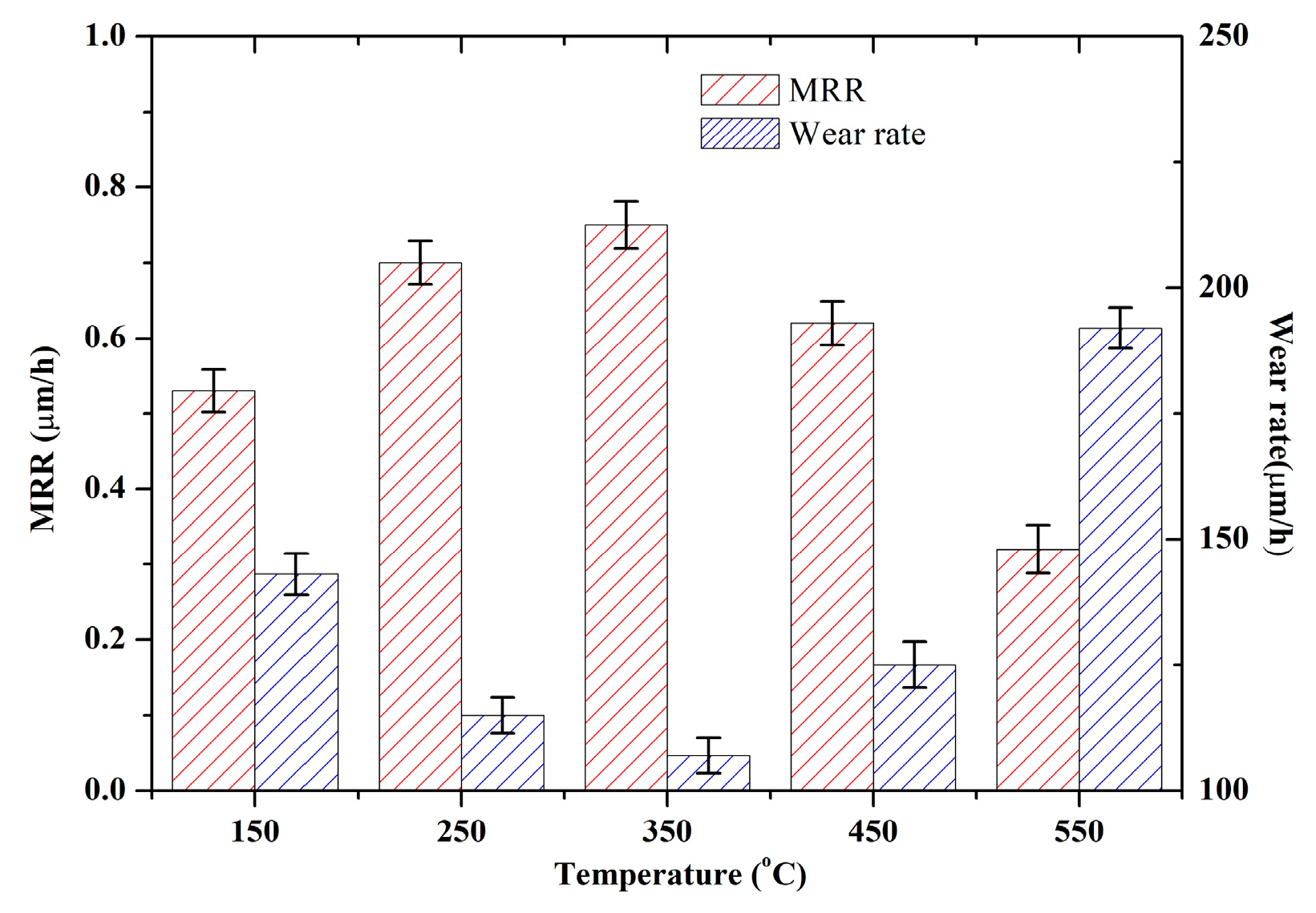

3.4. Influence of Different Sintering Temperatures on Friction and Wear

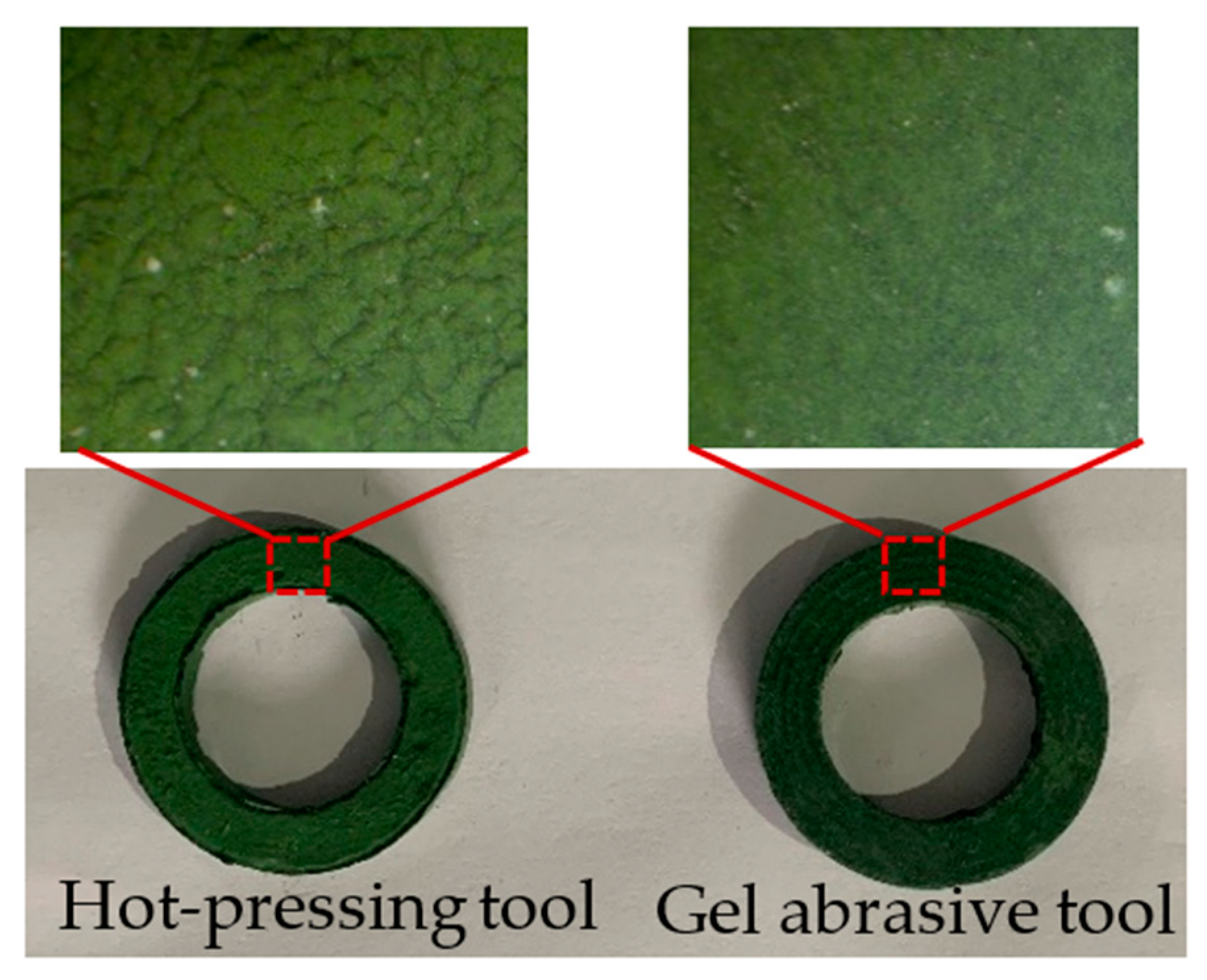

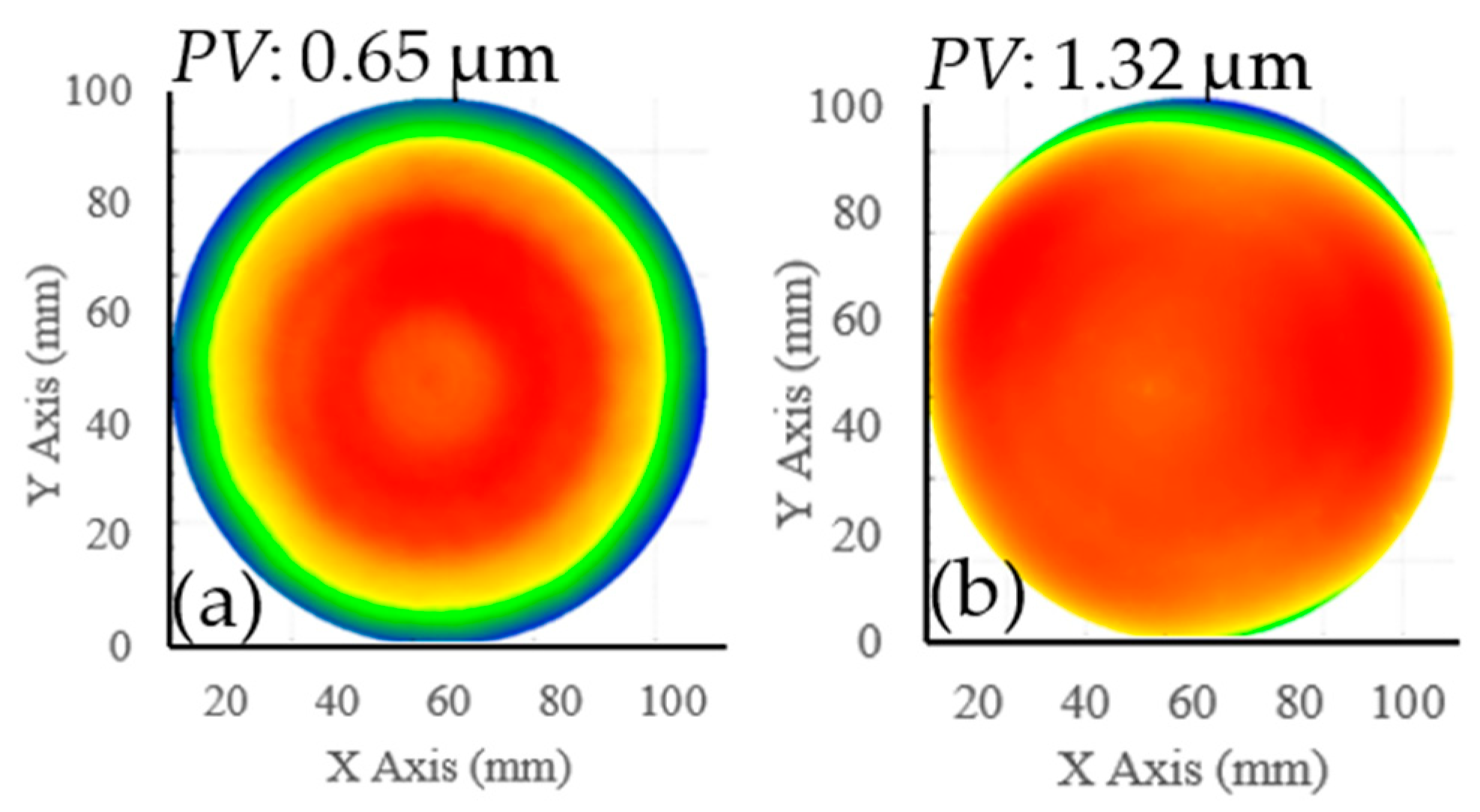

3.5. Processing Experiment

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Lei, H.; Chen, R. CMP behavior of alumina/metatitanic acid core–shell abrasives on sapphire substrates. Precis. Eng. 2017, 50, 263–268. [Google Scholar] [CrossRef]

- Liu, T.; Lei, H. Nd3+-doped colloidal SiO2 composite abrasives: Synthesis and the effects on chemical mechanical polishing (CMP) performances of sapphire wafers. Appl. Surf. Sci. 2017, 413, 16–26. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, X.; Kang, C.; Wang, R.; Zou, C.; Zhou, Y.; Pan, G. Preparation of a novel catalyst (SoFeIII) and its catalytic performance towards the removal rate of sapphire substrate during CMP process. Tribol. Int. 2018, 120, 99–104. [Google Scholar] [CrossRef]

- Gu, Y.; Wang, L.; Chen, J.; Jiang, Z.; Zhang, Y.; Wang, W.; Chen, H.; Shen, J.; Zhong, J.; Meng, S.; et al. Surface acidity of colloidal silica and its correlation with sapphire surface polishing. Colloids Surf. A: Physicochem. Eng. Asp. 2022, 651, 129718. [Google Scholar] [CrossRef]

- Kwon, T.Y.; Chom, B.J.; Ramachandran, M.; Busnaina, A.A.; Park, J.G. Investigation of source-based Scratch formation during oxide chemical mechanical planarization. Tribol. Lett. 2013, 50, 169–175. [Google Scholar] [CrossRef]

- Li, Z.; Deng, Z.; Ge, J.; Zhuo, R.; Wan, L. Material Removal Rate Prediction for Sapphire Double-sided CMP Based on RSM-SVM. ECS J. Solid State Sci. Technol. 2022, 11, 084002. [Google Scholar] [CrossRef]

- Zhao, P.P.; Yin, T.; Doi, T.; Kurokawa, S.; Seshimo, K.; Ye, D.; Cai, J. Effect of Mn-Based Slurries on Chemical Mechanical Polishing of SiC Substrate. ECS J. Solid State Sci. Technol. 2022, 11, 074002. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, J.; Hu, W.; Zhang, L.; Xie, W.; Liao, L. Chemical mechanical polishing for sapphire wafers using a developed slurry. J. Manuf. Process. 2021, 62, 762–771. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, B.; Shi, Y.; Zhou, D.; Wang, R. Improvement in dispersion stability of alumina suspensions and corresponding chemical mechanical polishing performance. Appl. Surf. Sci. 2022, 597, 153703. [Google Scholar] [CrossRef]

- He, Y.; Yuan, Z.; Duan, Z.; Zhang, Y. High-productively ultraprecise polishing technique of single crystal SiC wafer. J. Harbin Inst. Technol. 2019, 51, 115–121. [Google Scholar]

- Ji, J.; Liang, Z.; Zhou, H.; Jiang, W.; Ren, X. Composition Optimization of Polishing Slurry for C-Plane Sapphire. J. Synth. Cryst. 2021, 50, 2354–2361. [Google Scholar]

- Xu, Y. Technical Research on the Processing of Sapphire Substrate by Flexible Polishing Tool with Mixed Abrasive. Ph.D. Thesis, Hua Qiao University, Quanzhou, China, 2017. [Google Scholar]

- Zhang, Z.; Cui, J.; Wang, B.; Wang, Z.; Kang, R.; Guo, D. A novel approach of mechanical chemical grinding. J. Alloy. Compd. 2017, 726, 514–524. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, F.; Zhang, X. Removal function of computer controlled polishing SiC mirror with fixed abrasive. Opt. Precis. Eng. 2009, 17, 951–957. [Google Scholar]

- Niu, F.; Wang, K.; Sun, T.; Zhou, P.; Hu, W.; Zhu, Y. Lapping performance of mixed-size agglomerated diamond abrasives in fixed abrasives pads. Diam. Relat. Mater. 2021, 118, 108499. [Google Scholar] [CrossRef]

- Feng, K.; Lyu, B.; Zhao, T.; Zhou, Z. Fabrication and Application of Gel Forming Ultrafine Diamond Abrasive Tools. ECS J. Solid State Sci. Technol 2021, 10, 063009. [Google Scholar] [CrossRef]

- Feng, K.; Zhao, T.; Lyu, B.; Zhou, Z. Ultra-precision grinding of 4H-SiC wafer by PVA/PF composite sol-gel diamond wheel. Adv. Mech. Eng. 2021, 13, 16878140211044929. [Google Scholar] [CrossRef]

- Feng, K.; Lyu, B.; Zhu, G.; Zhao, T.; Zhou, Z. Study on Precision Grinding of SiC Ceramic by PAV/PF Composite Sol-gel Grinding Abrasive Tool. Surf. Technol. 2022, 51, 347–357. [Google Scholar]

- Zhang, J.; Zhang, B.; Zhou, X.; Wang, W.; Wu, Z. Preparation and Testing of Lignin-Furfuryl Alcohol-Glyoxal resin Based Grinding Wheel. J. Southwest For. Univ. 2018, 38, 173–178. [Google Scholar]

- Lu, J.; Luo, Q.F.; Song, Y.Y.; Hu, G.Q.; Xu, X.P. Fabrication and Application of Gel-bonded Ultrafine Diamond Abrasive Tools. Chin. J. Mech. Eng. 2015, 51, 205–212. (In Chinese) [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Yuan, J.L.; Bing-Hai, L.; Xun, L.; Cao, L.L.; Peng, C.F.; UPM Center. Experimental Study on Processing of Sapphire with Bonded Large Particle Size SiO2 Grain Bonded Grain Bonded Abrasive Tool. Surf. Technol. 2017, 46, 258–263. [Google Scholar]

- Lu, J.; Xu, Y.; Zhang, Y.; Xu, X. The effects of SiO2 coating on diamond abrasives in sol-gel tool for SiC substrate polishing. Diamond Related Mater. 2017, 76, 123–131. [Google Scholar] [CrossRef]

- Li, M.; Liu, M.; Riemer, O.; Karpuschewski, B.; Tang, C. Origin of material removal mechanism in shear thickening-chemical polishing. Int. J. Mach. Tools Manuf. 2021, 170, 103800. [Google Scholar] [CrossRef]

- Li, M.; Liu, M.; Riemer, O.; Song, F.; Lyu, B. Anhydrous based shear-thickening polishing of KDP crystal. Chin. J. Aeronaut. 2021, 34, 90–99. [Google Scholar] [CrossRef]

- Li, M.; Karpuschewski, B.; Ohmori, H.; Riemer, O.; Wang, Y.; Dong, T. Adaptive shearing-gradient thickening polishing (AS-GTP) and subsurface damage inhibition. Int. J. Mach. Tools Manuf. 2021, 160, 103651. [Google Scholar] [CrossRef]

- Li, M.; Xie, J. Green-chemical-jump-thickening polishing for silicon carbide. Ceram. Int. 2022, 48, 1107–1124. [Google Scholar] [CrossRef]

- Li, M.; Song, F.; Huang, Z. Control strategy of machining efficiency and accuracy in weak-chemical-coordinated-thickening polishing (WCCTP) process on spherical curved 9Cr18 components. J. Manuf. Process. 2022, 74, 266–282. [Google Scholar] [CrossRef]

- Li, M.; Karpuschewski, B.; Riemer, O. Controllable polishing process for machining of barium borate. CIRP J. Manuf. Sci. Technol. 2022, 37, 291–301. [Google Scholar] [CrossRef]

- Li, M.; Karpuschewski, B.; Riemer, O. High-efficiency nano polishing of steel materials. Nanotechnol. Rev. 2021, 10, 1329–1338. [Google Scholar] [CrossRef]

- Wu, K.; Touse, D.; Zhou, L.; Lin, W.; Shimizu, J.; Onuki, T.; Yuan, J. Chemo-mechanical grinding by applying grain boundary cohesion fixed abrasive for monocrystal sapphire. Precis. Eng. Precis. Eng. 2021, 70, 110–116. [Google Scholar] [CrossRef]

- Feng, Y.; Lu, Z.; Ma, Y.; Lei, Y. Research Progress in Gel-Casting Technology of Different Systems. China Ceramics. 2020, 56, 1–6. [Google Scholar]

- An, K.; Liu, M.; Li, K. Modification and application of polyimide in diamond abrasives. Diam. Abras. Eng. 2013, 33, 61–66. [Google Scholar]

- JB/T 7999–2013; Bonded Abrasive Products-Testing Method for the Volume Density; General Porosity and Water Absorption. Zhengzhou Institute of Abrasive Grinding Abrasive: Zhengzhou, China, 2013.

- Davies, J.; Binner, J. The role of ammonium polyacrylate in dispersing concentrated alumina suspensions. J. Eur. Ceram. Soc. 2000, 20, 1539–1553. [Google Scholar] [CrossRef]

- Wang, X. Powder Synthetization, Gel Casting and Sintering of BeO. Ph.D. Thesis, Central South University, Hunan, China, 2011. [Google Scholar]

- Di, L.; Ding, C.; Lu, C.; Yang, D. Preparation of dense Cr2O3 refractories by gel-casting. Refractories 2017, 51, 414–417. [Google Scholar]

- Miao, W.; Ding, Y.; Luo, M.; Xiong, H. Effect of sintering system on cellular structures of vitrified bond diamond wheels. Diam. Abras. Eng. 2020, 10, 56–60. [Google Scholar]

- Wan, L.; Zhang, L.; Liu, X.; Song, D.; Hu, W. Microstructure and performance of LZAS vitrified bond /diamond grinding wheel by in-situ sol-gel method. Mater. Sci. Eng. Powder Metall. 2016, 21, 939–945. [Google Scholar]

- Duan, C.J.; Cui, Y.; Wang, C.; Tao, L.M.; Wang, Q.H.; Xie, H.; Wang, T.M. High Temperature Tribological Properties of Thermosetting Polyimide. Tribology 2017, 37, 717–724. [Google Scholar]

- Cong, P.; Li, T.; Xue, Q. Friction and wear of polyimide and its composites. Lubr. Eng. 1998, 4, 2–7. [Google Scholar]

- Wu, K.; Zhou, L.; Shimizu, J.; Onuki, T.; Yamamoto, T.; Ojima, H.; Yuan, J. Study on the potential of chemo-mechanical-grinding (CMG) process of sapphire wafer. Int. J. Adv. Manuf. Technol. 2017, 91, 1539–1546. [Google Scholar] [CrossRef]

| Component | Solid Content (wt%) |

|---|---|

| PAM + PI | 15 |

| Cr2O3 Powder | 82.5 |

| PEG 400 | 1 |

| Wetting agent | 0.5 |

| Dispersant | 1.5 |

| Defoamer | 1 |

| Dibutyl | 0.5 |

| Parameters | Value |

|---|---|

| Abrasive | Diamond, Cr2O3 |

| Wheel revolution | 900 rpm |

| Sapphire revolution | 100 rpm |

| Time | 30 min |

| Wheel type | Hot-pressing, gel |

| Coolant | water |

| Testing Points Ra (nm) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | AVG (nm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gel abrasive | 2.45 | 3.07 | 2.62 | 2.34 | 2.47 | 2.84 | 2.82 | 2.91 | 2.73 | 2.66 | 2.69 |

| Hot-pressing | 4.26 | 4.65 | 4.59 | 4.61 | 4.17 | 4.49 | 4.56 | 4.47 | 4.33 | 4.63 | 4.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, L.; Feng, K.; Zhao, T.; Zhou, Z.; Ding, J. The Preparation and Performance Analysis of a Cr2O3 Gel Abrasive Tool for Sapphire Substrate Polishing. Lubricants 2022, 10, 324. https://doi.org/10.3390/lubricants10120324

Zhao L, Feng K, Zhao T, Zhou Z, Ding J. The Preparation and Performance Analysis of a Cr2O3 Gel Abrasive Tool for Sapphire Substrate Polishing. Lubricants. 2022; 10(12):324. https://doi.org/10.3390/lubricants10120324

Chicago/Turabian StyleZhao, Liang, Kaiping Feng, Tianchen Zhao, Zhaozhong Zhou, and Junkai Ding. 2022. "The Preparation and Performance Analysis of a Cr2O3 Gel Abrasive Tool for Sapphire Substrate Polishing" Lubricants 10, no. 12: 324. https://doi.org/10.3390/lubricants10120324