Corrosion Inhibitors: Natural and Synthetic Organic Inhibitors

Abstract

:1. Introduction

2. Types of Corrosion

- Uniform Corrosion: This is the most common type of corrosion and occurs evenly over a large surface area of a material. It is caused by exposure to a corrosive environment, such as water, air, or chemicals.

- Pitting Corrosion: This type of corrosion is characterized by the formation of small holes or pits on the surface of a material. It is caused by localized corrosion, often due to the presence of impurities in the material or environmental factors, such as high chloride levels.

- Galvanic Corrosion: This type of corrosion occurs when two dissimilar metals are in contact with each other and an electrolyte, such as saltwater, is present. One metal becomes anodic and corrodes, while the other becomes cathodic and is protected from corrosion.

- Crevice Corrosion: This type of corrosion occurs in confined areas, such as crevices or seams, where the flow of air and liquids is restricted. This leads to a buildup of corrosive substances and the material corrodes from the inside out.

- Intergranular Corrosion: This type of corrosion occurs along the grain boundaries of a material, causing a loss of material and weakening of the structure. It is often caused by the presence of impurities, such as sulfur or chlorine, in the material.

- Erosion Corrosion: This type of corrosion occurs when a material is exposed to a corrosive fluid that is flowing at a high velocity, causing the material to erode away. This type of corrosion is common in pipelines, valves, and pumps.

- Stress Corrosion Cracking: This type of corrosion occurs when a material is under stress and exposed to a corrosive environment. It is often caused by high tensile stress, high chloride levels, or high temperatures.

3. Classifications of Organic Corrosion Inhibitors

- Inorganic corrosion inhibitors: These inhibitors contain metallic compounds such as nitrates, phosphates, chromates, and molybdates. They work by forming a protective film on the metal surface, which prevents the formation of corrosion cells.

- Organic corrosion inhibitors: These inhibitors contain organic compounds such as amino acids, alcohols, and amines. They work by adsorbing onto the metal surface and forming a barrier between the metal and the corrosive environment. Organic inhibitors are commonly used in industries such as oil and gas, petrochemical, and marine applications.

- Nitrite inhibitors: These inhibitors contain nitrite ions as the active ingredient and are commonly used in cooling water systems and boilers.

- Phosphonic acid inhibitors: This type of inhibitor contains phosphonic acid or its derivatives and is effective at preventing corrosion in high-temperature and high-pressure systems.

- Carboxylic acid inhibitors: Carboxylic acid inhibitors are commonly used in industrial applications and contain compounds such as benzoic acid, salicylic acid, and acetic acid.

- Sulfonic acid inhibitors: Sulfonic acid inhibitors contain sulfonic acid and its derivatives and are used in a wide range of industrial applications.

- Thiophosphoric acid inhibitors: Thiophosphoric acid inhibitors contain thiophosphoric acid and its derivatives and are effective at preventing corrosion in high-temperature systems.

- Ethylenediamine inhibitors: This type of inhibitor contains ethylenediamine as the active ingredient and is used in a variety of industrial applications.

- Amines inhibitors: Amines inhibitors contain amine compounds as the active ingredient and are commonly used in water treatment and oilfield applications.

- Phenol inhibitors: Phenol inhibitors contain phenol or its derivatives as the active ingredient and are used in a variety of industrial applications.

4. Active Functional Groups in Organic Corrosion Inhibitors

- Nitrogen-containing functional groups: These functional groups contain nitrogen atoms, which can form chelating agents with metal ions. The most common nitrogen-containing functional groups used in corrosion inhibitors include amines, imides, and guanidines.

- Oxygen-containing functional groups: These functional groups contain oxygen atoms, which can form a protective film on the metal surface, inhibiting further corrosion. Some of the most common oxygen-containing functional groups used in corrosion inhibitors include carboxylic acids, esters, and ethers.

- Sulfur-containing functional groups: Sulfur-containing functional groups can form a protective film on the metal surface, preventing further corrosion. Some of the most commonly used sulfur-containing functional groups in corrosion inhibitors include sulfonic acids and thiols.

- Phosphorus-containing functional groups: Phosphorus-containing functional groups can form a protective film on the metal surface, inhibiting further corrosion. Some of the most commonly used phosphorus-containing functional groups in corrosion inhibitors include phosphonic acids and phosphates.

- Halogen-containing functional groups: Halogen-containing functional groups, such as halogens (chlorine, fluorine, and bromine), can form a protective film on the metal surface, inhibiting further corrosion.

5. Estimating Organic Corrosion Inhibitors Efficiency

5.1. Electrochemical Techniques

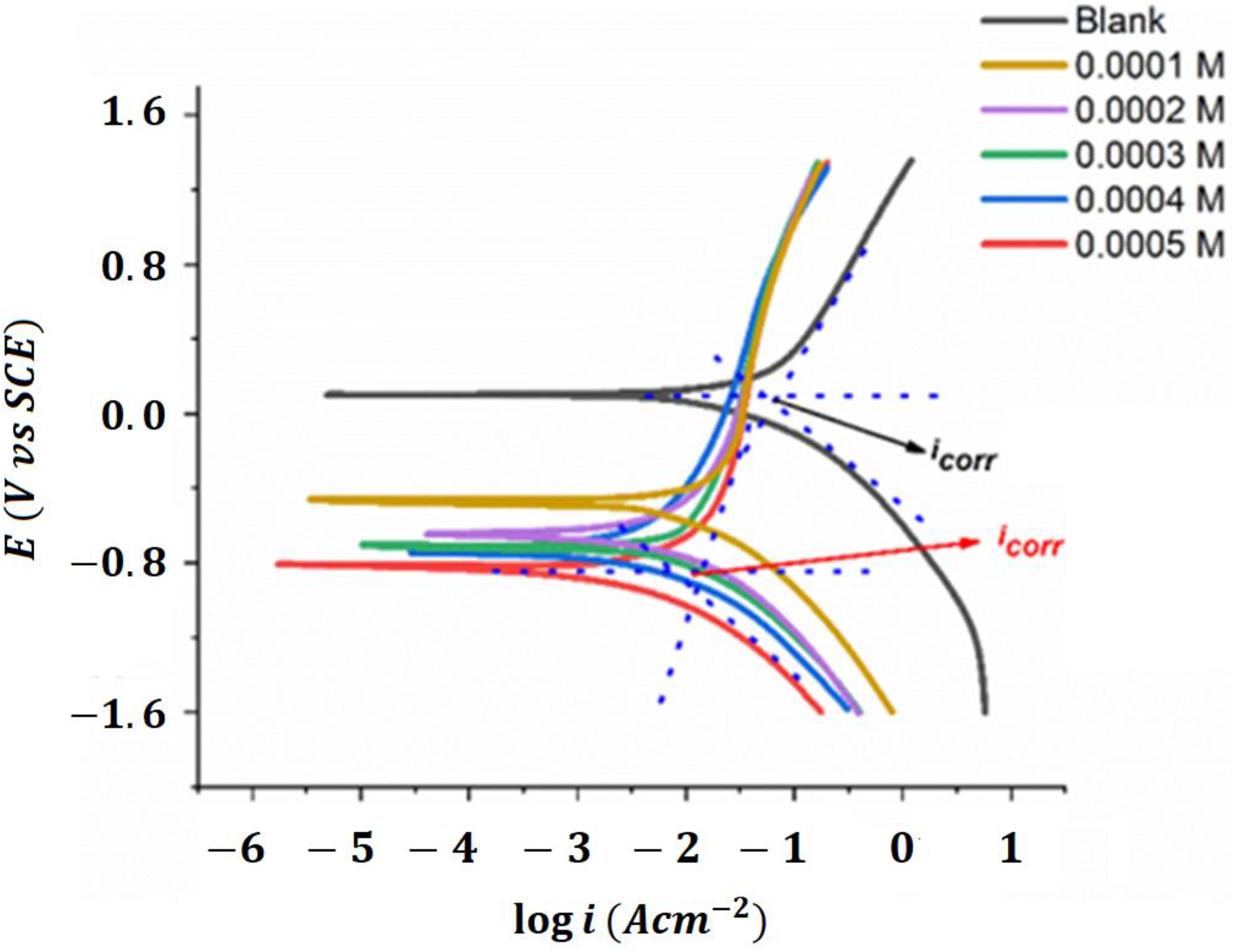

5.1.1. Potentiodynamic Polarization

5.1.2. Electrochemical Impedance Spectroscopy (EIS)

5.2. Weight Loss Tests

- Preparation of specimens: The metal specimens are prepared and cleaned thoroughly. Then, they are coated with a thin layer of the organic inhibitor under study.

- Weight loss measurements: The weight loss of the metal specimens is measured after exposing them to a corrosive environment for a specified period of time. The weight loss is calculated using the following equation:

- Corrosion current density (): The corrosion current density () is calculated using the following equation:

- Corrosion potential (): The corrosion potential () is estimated using a corrosion potential meter. The potential is recorded as a function of time and the steady-state corrosion potential () is determined.

- Comparison with control specimens: Control specimens without the organic inhibitor are prepared and the weight loss and electrochemical estimations such as corrosion potential and polarization resistance are obtained to evaluate the corrosion behavior of the metal [31]. The results obtained from the control specimens are compared with the results obtained from the specimens with the organic inhibitor. The presence of an organic inhibitor in the corrosive environment leads to a decrease in the corrosion current density and an increase in the corrosion potential compared to the control specimens. The efficacy of the organic inhibitor can be determined by comparing the results obtained with the inhibitor with the control specimens. This WLT technique is an effective method to estimate the corrosion current and potential of a metal in the presence of an organic inhibitor. The results obtained from this test provide valuable information on the corrosion protection properties of the organic inhibitor.

5.3. Optical Microscopy

- d(t) is the remaining thickness of the metal after time t;

- is the initial thickness of the metal;

- is the corrosion current density (in A/cm2);

- t is the exposure time (in hours);

- M is the atomic weight of the metal;

- n is the number of electrons transferred in the corrosion reaction;

- F is the Faraday constant (96,485 C/mol);

- A is the surface area of the metal (in cm2).

5.4. XPS

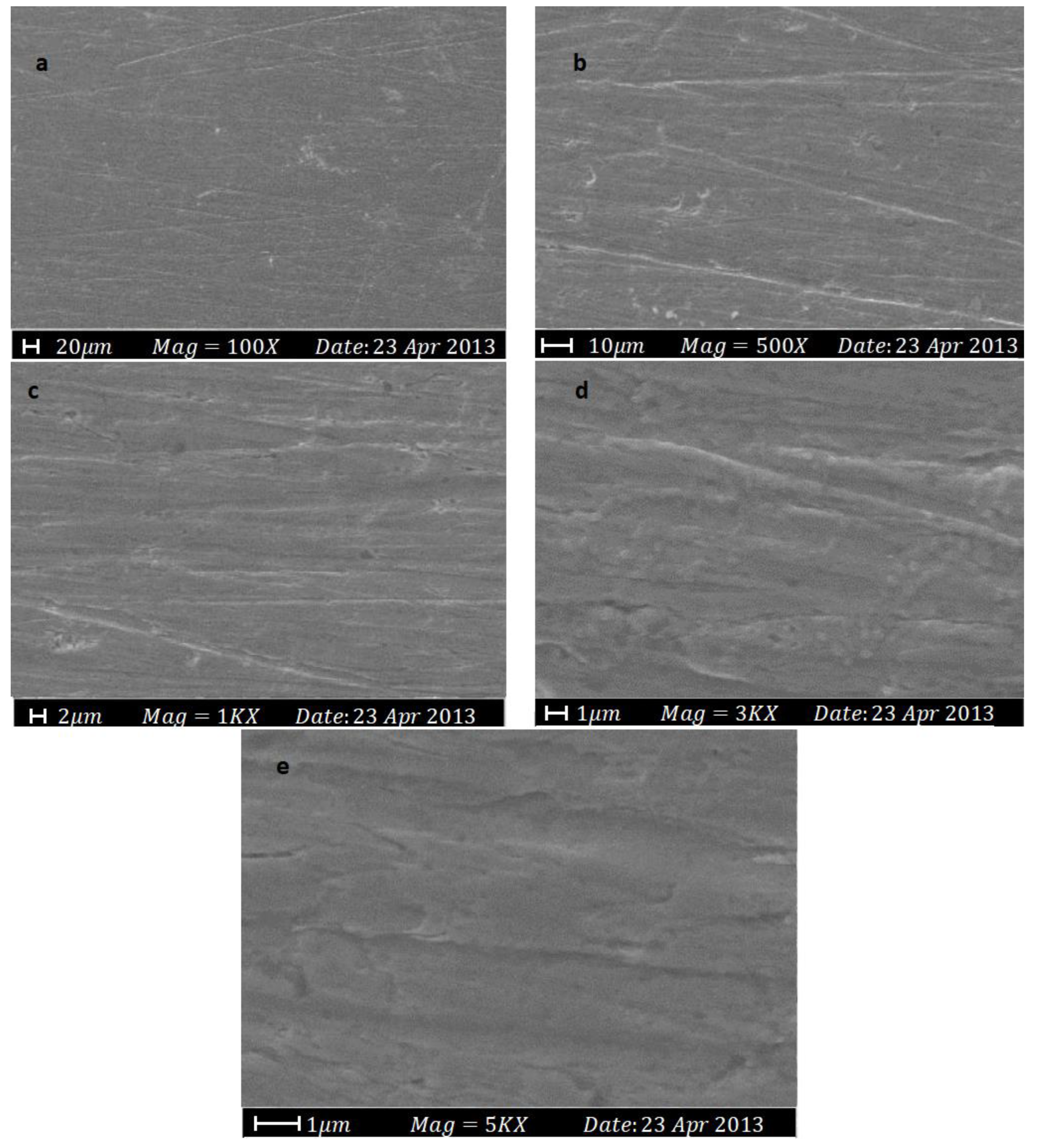

5.5. Scanning Electron Microscopy (SEM)

- Preparation of the sample: The metal sample is prepared for SEM by first cleaning it and removing any surface contaminants. This is typically performed using a solvent cleaning process or an etching process.

- Deposition of the organic inhibitor: The organic inhibitor is then deposited onto the metal surface. This can be performed using various methods, such as chemical deposition, electrodeposition, or physical adsorption.

- SEM imaging: The sample is then placed in the SEM and imaging is performed. The SEM uses a high-energy electron beam to scan the sample and produce a high-resolution image. This image can be used to determine the distribution of the organic inhibitor on the metal surface.

- Current-potential estimation: Current-potential estimations are performed by applying a potential difference between the metal sample and a reference electrode. This creates an electric field, which causes the metal ions to migrate towards the reference electrode. The rate of ion migration is proportional to the corrosion current, which is calculated from equations rather than directly measured.

- Analysis of the data: The corrosion current density and potential are then calculated from the current-potential estimation using appropriate equations. The corrosion potential, Ecorr, can be determined from the Nernst equation:

- 6.

- Interpretation of results: The corrosion current and potential can be used to evaluate the efficacy of the organic inhibitor. A lower corrosion current and a more positive corrosion potential indicate that the organic inhibitor is effectively reducing corrosion.

6. Previous Studies on Using Natural and Synthetic Organic Inhibitors

- Natural organic inhibitors:

- a.

- Using chitosan as a natural inhibitor in the inhibition of the corrosion of mild steel in seawater [52].

- b.

- The use of cinnamon extract as an inhibitor for the corrosion of aluminum in acidic media [53].

- c.

- The application of tannic acid as a natural inhibitor for the corrosion of carbon steel in an aqueous solution [54].

- 2.

- Synthetic organic inhibitors:

- a.

- The effectiveness of benzotriazole as a corrosion inhibitor for aluminum alloys in acidic media [59].

- b.

- The use of triazole derivatives as corrosion inhibitors for mild steel in acidic environments [60].

- c.

- The inhibition performance of imidazoline derivatives in the corrosion of copper in aerated seawater [61].

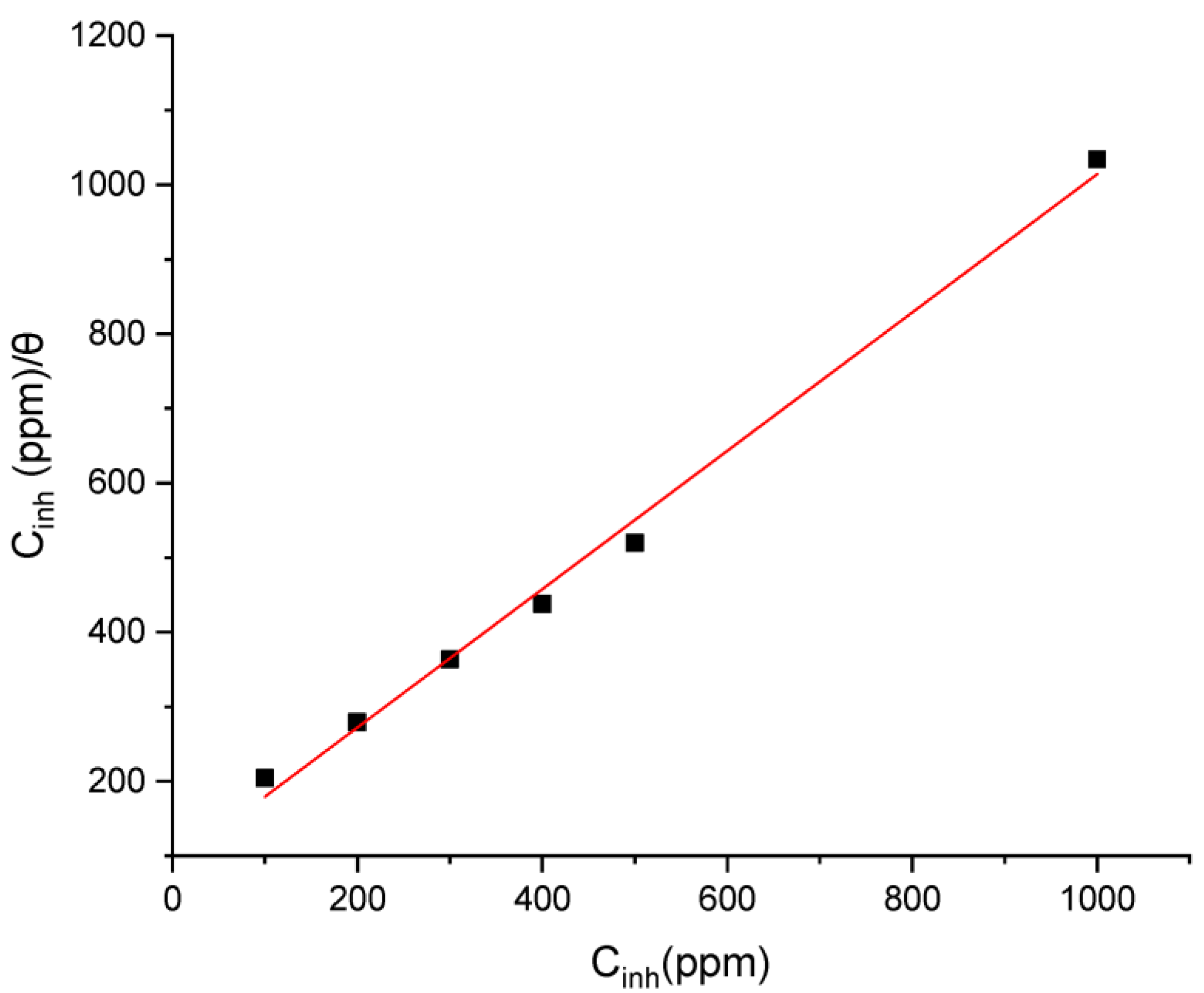

7. Adsorption Isotherms of Organic Corrosion Inhibitors

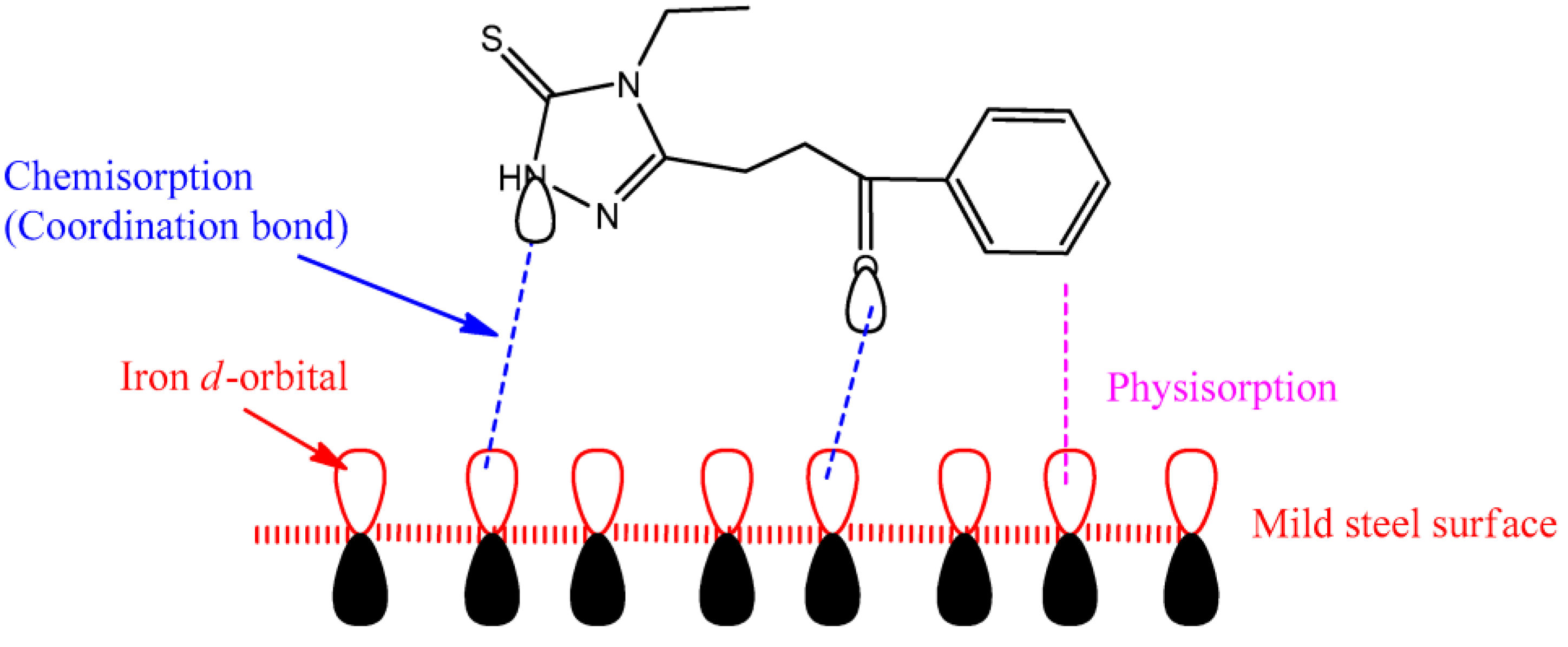

8. Mechanisms of Organic Corrosion Inhibitors

- Adsorption: Adsorption is the most frequently observed mechanism of organic corrosion inhibitors. These inhibitors attach themselves to the surface of the metal, creating a protective layer that serves as a barrier between the metal and the corrosive environment. Several factors, including the concentration of the inhibitor, the surface area, and the presence of other species in the solution, can affect this process [79,80].

- Film formation: Organic corrosion inhibitors can also form a film on the metal surface, which protects it from corrosion. This film acts as a barrier, preventing the corrosive agents from reaching the metal surface.

- Electrostatic repulsion: Organic corrosion inhibitors can use electrostatic repulsion to prevent corrosion. These inhibitors can be charged, which allows them to repel corrosive agents. For example, inhibitors with a positive charge can repel negatively charged corrosive ions, while inhibitors with a negative charge can repel positively charged ions [81,82].

- Complex formation: Organic corrosion inhibitors can form complex compounds with the corrosive agents, thereby reducing their effectiveness. This results in a reduction in the corrosion rate as the corrosive agents are neutralized.

- pH adjustment: Organic corrosion inhibitors can also adjust the pH of the solution to a neutral or slightly alkaline level. This helps to reduce the concentration of corrosive agents in the solution, which in turn reduces the rate of corrosion.

- Cathodic protection: Organic corrosion inhibitors can act as cathodic inhibitors by reducing the cathodic reaction rate, thus reducing the rate of corrosion.

- Oxygen scavenging: Organic corrosion inhibitors are compounds that can reduce the rate of corrosion by scavenging oxygen from the solution. By removing oxygen, the formation of corrosive agents that would otherwise cause corrosion is prevented. These inhibitors function by creating a protective barrier on the metal surface, which prevents the corrosive agents from coming into contact with the metal [83,84].

9. Computational Methods

- Molecular dynamics (MDs) simulations: MD simulations can provide insights into the interaction between inhibitors and metal surfaces at the atomic scale. These simulations can be used to study the adsorption behavior of inhibitors, the effect of the molecular structure on inhibitor performance, and the effect of environmental factors such as pH and temperature on inhibitor efficacy [86].

- Density functional theory (DFT): DFT calculations can be used to study the electronic properties of inhibitors and their interaction with metal surfaces. This approach can be used to predict the adsorption energy of inhibitors and to identify the most effective inhibitors for a particular metal surface [76].

- Monte Carlo simulations: Monte Carlo simulations can be used to predict the coverage and distribution of inhibitors on metal surfaces. This approach can provide insights into the mechanism of inhibitor action and can be used to optimize inhibitor concentrations and application methods [87].

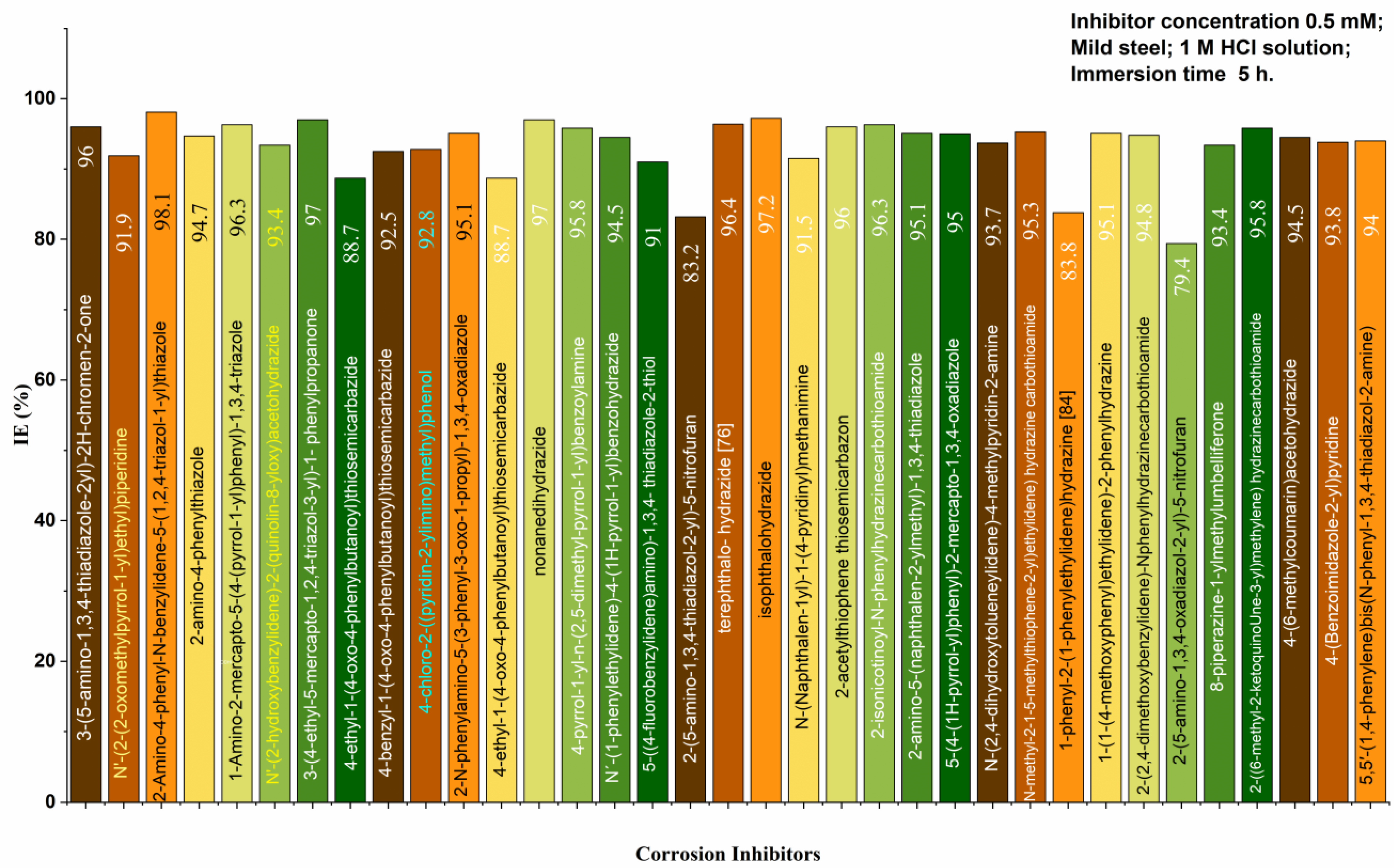

10. Comparison Studies

11. Future Outlooks

- Green corrosion inhibitors: With increasing concern about the environmental impact of chemical inhibitors, there is a growing interest in the development of green corrosion inhibitors. These inhibitors are derived from renewable resources, are biodegradable, and are less toxic to the environment. Researchers are exploring natural sources such as plant extracts, essential oils, and biopolymers as potential green inhibitors.

- Nanotechnology: Nanotechnology has shown promising results in the development of corrosion inhibitors due to its ability to enhance the protective properties of coatings and films. Researchers are exploring the use of nanoparticles as corrosion inhibitors or as carriers of inhibitors to enhance their efficiency.

- Computational studies: Computational studies have become an essential tool in the design and development of new inhibitors. With advances in computing power and molecular simulation techniques, researchers can better understand the interactions between inhibitors and metal surfaces and optimize inhibitor structures for maximum effectiveness.

- Synergistic effects: Combining different inhibitors to create synergistic effects is a promising area of research. Researchers are exploring the use of natural and synthetic inhibitors together, as well as the combination of inhibitors with other corrosion protection strategies such as coatings and cathodic protection.

- Application-specific inhibitors: Different industries and applications have specific requirements for corrosion inhibitors. In the future, more research is expected to focus on developing inhibitors tailored to specific industries, such as oil and gas, automotive, or aerospace, to optimize performance and cost-effectiveness.

12. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rani, B.E.; Bharathi Bai, J.B. Green Inhibitors for Corrosion Protection of Metals and Alloys: An Overview. Int. J. Corros. 2012, 2012, 380217. [Google Scholar] [CrossRef]

- Ahmed, E.S.; Junaid; Ganesh, G.M. A Comprehensive Overview on Corrosion in RCC and Its Prevention Using Various Green Corrosion Inhibitors. Buildings 2022, 12, 1682. [Google Scholar] [CrossRef]

- Tamalmani, K.; Husin, H. Review on Corrosion Inhibitors for Oil and Gas Corrosion Issues. Appl. Sci. 2020, 10, 3389. [Google Scholar] [CrossRef]

- Zakeri, A.; Bahmani, E.; Sabour Rouh Aghdam, A. Plant Extracts as Sustainable and Green Corrosion Inhibitors for Protection of Ferrous Metals in Corrosive Media: A Mini Review. Corros. Commun. 2022, 1, 6–17. [Google Scholar] [CrossRef]

- Chauhan, D.S.; Quraishi, M.A.; Sorour, A.A.; Verma, C. A Review on Corrosion Inhibitors for High-Pressure Supercritical CO2 Environment: Challenges and Opportunities. J. Pet. Sci. Eng. 2022, 215, 110695. [Google Scholar] [CrossRef]

- Werle, M. Natural and Synthetic Polymers as Inhibitors of Drug Efflux Pumps. Pharm. Res. 2008, 25, 500–511. [Google Scholar] [CrossRef] [Green Version]

- Finšgar, M.; Jackson, J. Application of Corrosion Inhibitors for Steels in Acidic Media for the Oil and Gas Industry: A Review. Corros. Sci. 2014, 86, 17–41. [Google Scholar] [CrossRef] [Green Version]

- Raja, P.B.; Ismail, M.; Ghoreishiamiri, S.; Mirza, J.; Ismail, M.C.; Kakooei, S.; Rahim, A.A. Reviews on Corrosion Inhibitors: A Short View. Chem. Eng. Commun. 2016, 203, 11451156. [Google Scholar] [CrossRef]

- Olajire, A.A. Recent Advances on the Treatment Technology of Oil and Gas Produced Water for Sustainable Energy Industry-Mechanistic Aspects and Process Chemistry Perspectives. Chem. Eng. J. Adv. 2020, 4, 100049. [Google Scholar] [CrossRef]

- Li, L.; William, H.; Gibson Grant, T.; Wolfson Steve, L. Laboratory Investigation of Corrosion and Corrosion Protection of a Candidate Umbilical Material for Subsea Production Service. In CORROSION 2002; OnePetro: Denver, CO, USA, 2002. [Google Scholar]

- Verma, C.; Ebenso Eno, E.; Quraishi, M.A. Ionic Liquids as Green and Sustainable Corrosion Inhibitors for Metals and Alloys: An Overview. J. Mol. Liq. 2017, 233, 403–414. [Google Scholar] [CrossRef]

- Al-Amiery, A.A.; Al-Azzawi, W.K.; Isahak, W.N.R.W. Isatin Schiff base as an effective corrosion inhibitor for mild steel in hydrochloric acid solution: Gravimetric, electrochemical, and computational investigation. Sci. Rep. 2022, 12, 17773. [Google Scholar] [CrossRef]

- Talat, R.; Asghar, M.A.; Tariq, I.; Akhter, Z.; Liaqat, F.; Nadeem, L.; Haider, A.; Ali, S. Evaluating the Corrosion Inhibition Efficiency of Pyridinium-Based Cationic Surfactants for EN3B Mild Steel in Acidic-Chloride Media. Coatings 2022, 12, 1701. [Google Scholar] [CrossRef]

- Xu, T.; Yang, Y.; Peng, X.; Song, J.; Pan, F. Overview of Advancement and Development Trend on Magnesium Alloy. J. Magnes. Alloys 2019, 7, 536–544. [Google Scholar] [CrossRef]

- Hosseini, M.; Fotouhi, L.; Ehsani, A.; Naseri, M. Enhancement of Corrosion Resistance of Polypyrrole Using Metal Oxide Nanoparticles: Potentiodynamic and Electrochemical Impedance Spectroscopy Study. J. Colloid Interface Sci. 2017, 505, 213–219. [Google Scholar] [CrossRef] [PubMed]

- Mahdi, B.S.; Abbass, M.K.; Mohsin, M.K.; Al-Azzawi, W.K.; Hanoon, M.M.; Al-Kaabi, M.H.H.; Shaker, L.M.; Ismael, M.A.; Al-Rubaie, A.A.A.; Kadhum, A.A.H.; et al. Corrosion Inhibition of Mild Steel in Hydrochloric Acid Environment Using Terephthaldehyde Based on Schiff Base: Gravimetric, Thermodynamic, and Computational Studies. Molecules 2022, 27, 4857. [Google Scholar] [CrossRef] [PubMed]

- Hernandez, H.; Herrera, A.M.; Ruiz Reynoso, A.; Trinidad González, J.C.; González Morán, C.O.; Miranda Hernández, J.G.; Mandujano Ruiz, A.; Morales Hernández, J.; Orozco Cruz, R. Electrochemical Impedance Spectroscopy (EIS): A Review Study of Basic Aspects of the Corrosion Mechanism Applied to Steels. Electrochem. Impedance Spectrosc. 2020, 24, 137–144. [Google Scholar]

- Li, B.; Li, Y. Monte Carlo Simulation of Corrosion Inhibitor Adsorption on the Iron Surface. Langmuir 2006, 22, 3385–3392. [Google Scholar] [CrossRef]

- Liu, J.; Shao, W.; Gao, J.; Wang, J.; Gao, X. Machine Learning Models for Predicting the Inhibition Performance of Imidazoline Derivatives in CO2 Corrosion. Corros. Sci. 2019, 153, 181–190. [Google Scholar] [CrossRef]

- Ashworth, V. Corrosion Inhibitors. In Corrosion Inhibitors: Principles and Recent Applications; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–28. [Google Scholar] [CrossRef]

- Bardal, E.; Krotz, G. Corrosion Inhibitors. In Corrosion and Protection; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2018; pp. 317–357. [Google Scholar] [CrossRef]

- Cook, R.B. Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Hernandez, H.; Ruiz Reynoso, A.; Trinidad, J.C.; González, C.O.; Miranda, J.G.; Mandujano, A.M.R. Electrochemical Impedance Spectroscopy (EIS): A Review Study of Basic Aspects of the Corrosion Mechanism Applied to Steels; IntechOpen: London, UK, 2019. [Google Scholar]

- Jawad, Q.; Zinad, D.S.; Salim, R.D.; Al-Amiery, A.A.; Gaaz, T.S.; Takriff, M.S.; Kadhum, A.A.H. Synthesis, Characterization, and Corrosion Inhibition Potential of Novel Thiosemicarbazone on Mild Steel in Sulfuric Acid Environment. Coatings 2019, 9, 729. [Google Scholar] [CrossRef] [Green Version]

- Hudson, J.B.; Brown, C.A.; Roberge, P.R. Corrosion Monitoring. In Comprehensive Materials Processing; Hashmi, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2014; Volume 4, pp. 305–325. [Google Scholar]

- Nitonye, S.; Ugboga, P. Analysis of the Effectiveness and Efficiency of the VA Solution on Offshore Pipelines and Ship Materials. Open J. Mar. Sci. 2019, 10, 16. [Google Scholar] [CrossRef] [Green Version]

- Fateh, A.; Aliofkhazraei, M.; Rezvanian, A.R. Review of Corrosive Environments for Copper and Its Corrosion Inhibitors. Arab. J. Chem. 2020, 13, 481–544. [Google Scholar] [CrossRef]

- Cinitha, A.; Umesha, P.K.; Iyer, N.R. An Overview of Corrosion and Experimental Studies on Corroded Mild Steel Compression Members. KSCE J. Civ. Eng. 2014, 18, 1735–1744. [Google Scholar] [CrossRef]

- Aziz, I.A.A.; Abdulkareem, M.H.; Annon, I.A.; Hanoon, M.M.; Al-Kaabi, M.H.H.; Shaker, L.M.; Alamiery, A.A.; Wan Isahak, W.N.R.; Takriff, M.S. Weight Loss, Thermodynamics, SEM, and Electrochemical Studies on N-2-Methylbenzylidene-4-antipyrineamine as an Inhibitor for Mild Steel Corrosion in Hydrochloric Acid. Lubricants 2022, 10, 23. [Google Scholar] [CrossRef]

- Smith, J.D. The Technique for Weight Loss Tests (WLT) to Estimate the Corrosion Current and Potential of a Metal in the Presence of an Organic Inhibitor. Materials 2021, 14, 652. [Google Scholar] [CrossRef]

- Noh, H.K.; Jin, Y.G. Corrosion Inhibition of Copper by Piperidine: Experimental and Computational Study. Metals 2019, 9, 822. [Google Scholar] [CrossRef] [Green Version]

- Büchler, M.; Kerimo, J.; Guillaume, F.; Smyrl, W.H. Fluorescence and Near-Field Scanning Optical Microscopy for Investigating Initiation of Localized Corrosion of Al 2024. J. Electrochem. Soc. 2000, 147, 3691. [Google Scholar] [CrossRef]

- Sullivan, J.; Mehraban, S.; Elvins, J. In Situ Monitoring of the Microstructural Corrosion Mechanisms of Zinc–Magnesium–Aluminium Alloys Using Time Lapse Microscopy. Corros. Sci. 2011, 53, 2208–2215. [Google Scholar] [CrossRef]

- Rios, E.C.; Zimer, A.M.; Pereira, E.C.; Mascaro, L.H. Analysis of AISI 1020 Steel Corrosion in Seawater by Coupling Electrochemical Noise and Optical Microscopy. Electrochim. Acta 2014, 124, 211–217. [Google Scholar] [CrossRef]

- NIST X-ray Photoelectron Spectroscopy (XPS) Database. Available online: https://srdata.nist.gov/xps/ (accessed on 23 February 2023).

- Hussein, S.S.; Al-Hasani, I.D.D.; Abed, A.M.; Hanoon, M.M.; Shaker, L.M.; Al-Amiery, A.; Kadhum, A.A.H.; Roslam Wan Isahak, W.N. Antibacterial Corrosion Inhibitor for the Protection of Mild Steel in 1 M HCl Solution. Prog. Color Color. Coat. 2023, 16, 59–70. [Google Scholar]

- Alamiery, A.; Ali, J.M.; Isahak, W.N.R. Experimental Studies on the Corrosion Inhibition of Mild Steel by 1-(Phenylamino-1,3,4-thiadiazol-5-yl)-3-phenyl-3-oxopropan Complemented with DFT Modeling. KOM–Corros. Mater. Prot. J. 2022, 66, 7–15. [Google Scholar] [CrossRef]

- Betti, N.; Al-Azzawi, W.K.; Alamiery, A. Synthesis and Study of Corrosion Behavior of Terephthalaldehyde-Derived Schiff Base for Low-Carbon Steel in HCl: Experimental, Morphological and Theoretical Investigation. KOM–Corros. Mater. Prot. J. 2022, 66, 103–112. [Google Scholar] [CrossRef]

- Lopez, D.A.; Schreiner, W.H.D.; De Sánchez, S.R.; Simison, S.N. The Influence of Carbon Steel Microstructure on Corrosion Layers: An XPS and SEM Characterization. Appl. Surf. Sci. 2003, 207, 69–85. [Google Scholar] [CrossRef]

- Bruemmer, S.M.; Thomas, L.E. High-Resolution Analytical Electron Microscopy Characterization of Corrosion and Cracking at Buried Interfaces. Surf. Interface Anal. 2001, 31, 571–581. [Google Scholar] [CrossRef]

- Volovitch, P.; Allely, C.; Ogle, K. Understanding Corrosion via Corrosion Product Characterization: I. Case Study of the Role of Mg Alloying in Zn-Mg Coating on Steel. Corros. Sci. 2009, 51, 1251–1262. [Google Scholar] [CrossRef]

- Al-Amiery, A.A.; Kadhum, A.A.H.; Kadihum, A.; Mohamad, A.B.; How, C.K.; Junaedi, S. Inhibition of Mild Steel Corrosion in Sulfuric Acid Solution by New Schiff Base. Materials 2014, 7, 787–804. [Google Scholar] [CrossRef] [Green Version]

- Roberge, P.R. Handbook of Corrosion Engineering; McGraw Hill Professional: New York, NY, USA, 2012. [Google Scholar]

- Song, G.L.; Atrens, A. Understanding Corrosion Mechanisms, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Zhang, X.B.; Wang, D.; Li, X.G.; Hou, B.R.; Ke, W. Inhibition Mechanism of 1H-Benzotriazole on the Corrosion of Copper in Aerated NaCl Solution. Corros. Sci. 2009, 51, 1016–1025. [Google Scholar]

- Gabe, D.R.; Kim, Y.J. Scanning Electron Microscopy and Energy-Dispersive X-ray Spectroscopy for the Analysis of Corrosion and its Inhibition. In Handbook of Materials Failure Analysis with Case Studies from the Chemicals, Concrete and Power Industries; Butterworth-Heinemann: Oxford, UK, 2017; pp. 299–321. [Google Scholar] [CrossRef]

- Gomma, G.K.; Salem, M.A.; Zoromba, M.S.; Elsaid, M.O. Investigation of Corrosion Inhibition of Steel in Hydro-chloric Acid Solution Using Three Schiff Bases as Organic Inhibitors. Mater. Today Commun. 2021, 27, 102371. [Google Scholar] [CrossRef]

- Pardo, A.; Merino, M.C.; Coy, A.E.; Viejo, F.; Arrabal, R.; Matykina, E. Scanning Electron Microscopy with Backscattered Electron Imaging (SEM-BSE) and Energy Dispersive X-ray Spectrometry (EDS) Analysis Applied to Corrosion Research. Mater. Charact. 2011, 62, 956–967. [Google Scholar] [CrossRef]

- El-Enin, S.A.A.; Abo, S.A.; Amin, A. Review of Corrosion Inhibitors for Industrial Applications. Int. J. Eng. Res. Rev. 2015, 3, 127–145. [Google Scholar] [CrossRef]

- Fouda, A.E.S.; Abdel Nazeer, A.; El-Khateeb, A.Y.; Fakih, M. Cinnamon Plant Extract as Corrosion Inhibitor for Steel Used in Waste Water Treatment Plants and Its Biological Effect on Escherichia coli. J. Korean Chem. Soc. 2014, 58, 359–365. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.A.A.; Irfan, O.M.; Djavanroodi, F.; Asad, M. Development of Sustainable Inhibitors for Corrosion Control. Sustainability 2022, 14, 9502. [Google Scholar] [CrossRef]

- El Mouaden, K.; El Ibrahimi, B.; Oukhrib, R.; Bazzi, L.; Hammouti, B.; Jbara, O.; Tara, A.; Chauhan, D.S.; Quraishi, M.A. Chitosan polymer as a green corrosion inhibitor for copper in sulfide-containing synthetic seawater. Int. J. Biol. Macromol. 2018, 119, 1311–1323. [Google Scholar] [CrossRef] [PubMed]

- Bouraoui, M.M.; Chettouh, S.; Chouchane, T.; Khellaf, N. Inhibition efficiency of cinnamon oil as a green corrosion inhibitor. J. Bio Tribo-Corros. 2019, 5, 1–9. [Google Scholar] [CrossRef]

- Ostovari, A.; Hoseinieh, S.M.; Peikari, M.; Shadizadeh, S.R.; Hashemi, S.J. Corrosion inhibition of mild steel in 1 M HCl solution by henna extract: A comparative study of the inhibition by henna and its constituents (Lawsone, Gallic acid, α-d-Glucose and Tannic acid). Corros. Sci. 2009, 51, 1935–1949. [Google Scholar] [CrossRef]

- Adewuyi, A.; Daramola, M.; Babalola, J. Corrosion inhibition of mild steel in hydrochloric acid solution by crude extracts of Vernonia amygdalina and Mangifera indica leaves. J. Mol. Liq. 2016, 215, 506–514. [Google Scholar]

- Mohd Sani, N.; Ahmad, F.; Yusof, F.; Shamsudin, R. Piper nigrum extract as a natural corrosion inhibitor for mild steel in 3.5% NaCl solution. J. Mol. Liq. 2018, 267, 475–483. [Google Scholar]

- Bhat, S.; Nayak, U. Corrosion inhibition of mild steel in 3.5% NaCl solution by polysaccharide extracted from marine algae Padina tetrastromatica. Int. J. Biol. Macromol. 2019, 129, 852–858. [Google Scholar]

- Ebenso, E.; Ajanaku, K.; Olasunkanmi, L. Inhibitory effect of Azadirachta indica and Moringa oleifera leaf extracts in combination with sodium molybdate on the corrosion of mild steel in hydrochloric acid. J. Mol. Liq. 2016, 215, 189–200. [Google Scholar]

- Bokati, K.S.; Dehghanian, C. Adsorption behavior of 1H-benzotriazole corrosion inhibitor on aluminum alloy 1050, mild steel and copper in artificial seawater. J. Environ. Chem. Eng. 2018, 6, 1613–1624. [Google Scholar] [CrossRef]

- Resende, G.O.; Teixeira, S.F.; Figueiredo, I.F.; Godoy, A.A.; Lougon, D.J.F.; Cotrim, B.A.; de Souza, F.C. Synthesis of 1,2,3-Triazole Derivatives and Its Evaluation as Corrosion Inhibitors for Carbon Steel. Int. J. Electrochem. 2019, 2019, 6759478. [Google Scholar] [CrossRef] [Green Version]

- Zarrouk, A.; Hammouti, B.; Al-Deyab, S.S.; Essassi, E.M.; Aouniti, A.; Ramdani, A. Corrosion Inhibition Performance of 3,5-Diamino-1,2,4-Triazole for Protection of Copper in Nitric Acid Solution. Int. J. Electrochem. 2012, 7, 5997–6011. [Google Scholar]

- Kumar, A.; Yadav, D.K.; Singh, A.K. A Comparative Study on Corrosion Inhibition of Mild Steel by Catechin and 2-Mercaptobenzothiazole in Hydrochloric Acid. J. Mater. Sci. 2016, 51, 7588–7600. [Google Scholar] [CrossRef]

- Obot, I.B.; Obi-Egbedi, N.O.; Umoren, S.A. Inhibitive Action of Vanillin on the Corrosion of Mild Steel in Acidic Media. J. Ind. Eng. Chem. 2013, 19, 167–174. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Cheng, Y.; Jiang, L.; Zhai, Y. Inhibitory Effect of Natural and Synthetic Inhibitors on the Corrosion of Carbon Steel in Acidic Solutions. J. Mater. Sci. 2018, 53, 15838–15851. [Google Scholar] [CrossRef]

- El-Etre, A.Y.; Abdallah, M.; El-Tantawy, Z.E. Inhibition of Aluminum Corrosion Using Opuntia Extract. Corros. Sci. 2008, 50, 2993–3000. [Google Scholar] [CrossRef]

- Mekidiche, L.; Chibani, S.; Harek, Y.; Hammouti, B. Corrosion Inhibition of Mild Steel in 1 M HCl Solution by Synthetic and Natural Inhibitors. J. Mater. Environ. Sci. 2018, 9, 2849–2860. [Google Scholar]

- Muster, T.; Rohwerder, M.; Stratmann, M. Quantitative XPS Analysis of Corrosion Inhibitor Films on Iron. Surf. Sci. 2005, 595, 103–112. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, X.; Li, X. Progress in Surface Science Research for Corrosion Inhibition. Prog. Org. Coat. 2014, 77, 548–555. [Google Scholar] [CrossRef]

- Walczak, M.S.; Morales-Gil, P.; Lindsay, R. Determining Gibbs Energies of Adsorption from Corrosion Inhibition Efficiencies: Is It a Reliable Approach? Corros. Sci. 2019, 155, 182–185. [Google Scholar] [CrossRef]

- Tobiason, J.E.; Wesolowski, D.J.; McCormick, S.L.W.; Lewis, E.A. Molecular Dynamics Simulations of Inhibitor Adsorption on the Iron (110) Surface in Aqueous Solutions. J. Phys. Chem. B 2008, 112, 5716–5725. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, Z. Density Functional Theory Study of the Adsorption Behavior of 1,2,3-Benzotriazole on Copper Surface. Appl. Surf. Sci. 2018, 458, 452–458. [Google Scholar] [CrossRef]

- Shreir, L.L.; Jarman, R.A.; Burstein, G.T.; Shimada, H. Corrosion: Fundamentals, Testing, and Protection; Elsevier: Oxford, UK, 2013. [Google Scholar]

- Stern, M.; Geary, A.L. Electrochemical Polarization: I. A Theoretical Analysis of the Shape of Polarization Curves. J. Electrochem. Soc. 1957, 104, 56–63. [Google Scholar] [CrossRef]

- Al-Moubaraki, A.H.; Al-Mayouf, A.M.; Al-Hashem, A. Corrosion Inhibition of Carbon Steel in Acidic Media Using Some Synthetic and Natural Inhibitors. J. Mater. Sci. 2014, 49, 1191–1201. [Google Scholar] [CrossRef]

- Fox, P.G.; Bradley, P.A. 1:2:4-Triazole as a Corrosion Inhibitor for Copper. Corros. Sci. 1980, 20, 643–649. [Google Scholar] [CrossRef]

- Ituen, E.; Akaranta, O.; James, A. Evaluation of Performance of Corrosion Inhibitors Using Adsorption Isotherm Models: An Overview. Chem. Sci. Int. J. 2017, 18, 1–34. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Zhu, S.; Zhang, S.; He, Q.; Li, W. Theoretical Studies of Three Triazole Derivatives as Corrosion Inhibitors for Mild Steel in Acidic Medium. Corros. Sci. 2014, 87, 366–375. [Google Scholar] [CrossRef]

- Mihajlović, M.B.P.; Radovanović, M.B.; Tasić, Ž.Z.; Antonijević, M.M. Imidazole Based Compounds as Copper Corrosion Inhibitors in Seawater. J. Mol. Liq. 2017, 225, 127–136. [Google Scholar] [CrossRef]

- Frankel, G.S. Corrosion Inhibitors. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 1–7. [Google Scholar]

- Abd El Rehim, S.S.; Negm, N.A. Organic Corrosion Inhibitors: A Comprehensive Review. J. Mater. Sci. Res. 2013, 2, 76–84. [Google Scholar]

- Revie, R.W.; Uhlig, H.H. Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2019. [Google Scholar]

- Shivaraj, T.; Karthick, R.; Jeyakumar, M.S.; Anandan, S. Recent Developments in Organic Corrosion Inhibitors for Mild Steel in Different Environments: A Review. J. Ind. Eng. Chem. 2014, 20, 424–438. [Google Scholar]

- Chen, S.; Zhang, D.; Zhou, G. Advances in research on organic corrosion inhibitors: A review. J. Mol. Liq. 2014, 192, 97–109. [Google Scholar] [CrossRef]

- Roberge, P.R. Handbook of Corrosion Engineering, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Al-Kharafi, F.M.; Al-Hajjar, F.H.; Katrib, A. 3-Phenyl-1,2,4-triazol-5-one as a Corrosion Inhibitor for Copper. Corros. Sci. 1986, 26, 257–264. [Google Scholar] [CrossRef]

- Gurjar, S.; Sharma, S.K.; Sharma, A.; Ratnani, S. Performance of Imidazolium Based Ionic Liquids as Corrosion Inhibitors in Acidic Medium: A Review. Appl. Surf. Sci. Adv. 2021, 6, 100170. [Google Scholar] [CrossRef]

- Chaouiki, A.; Chafiq, M.; Ko, Y.G.; Al-Moubaraki, A.H.; Thari, F.Z.; Salghi, R.; Karrouchi, K.; Bougrin, K.; Ali, I.H.; Lgaz, H. Adsorption Mechanism of Eco-Friendly Corrosion Inhibitors for Exceptional Corrosion Protection of Carbon Steel: Electrochemical and First-Principles DFT Evaluations. Metals 2022, 12, 1598. [Google Scholar] [CrossRef]

- Liu, Y.; Lv, P.; Gao, L.; Wang, F.; Wang, H. A Review on Application of X-ray Photoelectron Spectroscopy in Corrosion Inhibition. J. Mater. Sci. Technol. 2019, 35, 717–726. [Google Scholar] [CrossRef]

- Wang, H.-L.; Fan, H.-B.; Zheng, J.-S. Corrosion Inhibition of Mild Steel in Hydrochloric Acid Solution by a Mercapto-Triazole Compound. Mater. Chem. Phys. 2003, 77, 655–661. [Google Scholar]

- Al-Azzawi, W.K.; Hussein, S.S.; Salih, S.M.; Zinad, D.S.; Al-Azzawi, R.K.; Hanoon, M.M.; Al-Amiery, A.; Kadhum, A.A.H.; Takriff, M.S. Efficient Protection of Mild Steel Corrosion in Hydrochloric Acid Using 3-(5-Amino-1, 3, 4-thiadiazole-2yl)-2H-chromen-2-one, a Coumarin Derivative Bearing a 1, 3, 4-thiadiazole Moiety: Gravimetrical Techniques, Computational and Thermodynamic Investigations. Prog. Color Colorants Coat. 2023, 16, 97–111. [Google Scholar] [CrossRef]

- Alamiery, A.A. Study of Corrosion Behavior of N’-(2-(2-oxomethylpyrrol-1-yl)ethyl)piperidine for Mild Steel in the Acid Environment. Biointerface Res. Appl. Chem. 2022, 12, 3638–3646. [Google Scholar] [CrossRef]

- Alamiery, A.; Mohamad, A.B.; Kadhum, A.A.H.; Takriff, M.S. Comparative Data on Corrosion Protection of Mild Steel in HCl Using Two New Thiazoles. Data Brief 2022, 40, 107838. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, A.M.; Sayyid, F.F.; Betti, N.; Shaker, L.M.; Hanoon, M.M.; Alamiery, A.A.; Kadhum, A.A.H.; Takriff, M.S. Inhibition of Mild Steel Corrosion in Hydrochloric Acid Environment by 1-Amino-2-Mercapto-5-(4-(pyrrol-1-yl)phenyl)-1,3,4-triazole. South Afr. J. Chem. Eng. 2022, 39, 42–51. [Google Scholar] [CrossRef]

- Alamiery, A.A. Investigations on Corrosion Inhibitory Effect of Newly Quinoline Derivative on Mild Steel in HCl Solution Complemented with Antibacterial Studies. Biointerface Res. Appl. Chem. 2022, 12, 1561–1568. [Google Scholar] [CrossRef]

- Alkadir Aziz, I.A.; Annon, I.A.; Abdulkareem, M.H.; Hanoon, M.M.; Alkaabi, M.H.; Shaker, L.M.; Alamiery, A.A.; Wan Isahak, W.N.R.; Takriff, M.S. Insights into Corrosion Inhibition Behavior of a 5-Mercapto-1,2,4-triazole Derivative for Mild Steel in Hydrochloric Acid Solution: Experimental and DFT Studies. Lubricants 2021, 9, 122. [Google Scholar] [CrossRef]

- Alamiery, A. Short report of mild steel corrosion in 0.5 M H2SO4 by 4-ethyl-1-(4-oxo-4-phenylbutanoyl)thiosemicarbazide. J. Tribol. 2021, 30, 90–99. [Google Scholar] [CrossRef]

- Alamiery, A.A.; Isahak, W.N.R.W.; Takriff, M.S. Inhibition of Mild Steel Corrosion by 4-Benzyl-1-(4-Oxo-4-Phenylbutanoyl)Thiosemicarbazide: Gravimetrical, Adsorption and Theoretical Studies. Lubricants 2021, 9, 93. [Google Scholar] [CrossRef]

- Dawood, M.A.; Alasady, Z.M.K.; Abdulazeez, M.S.; Ahmed, D.S.; Sulaiman, G.M.; Kadhum, A.A.H.; Shaker, L.M.; Alamiery, A.A. The Corrosion Inhibition Effect of a Pyridine Derivative for Low Carbon Steel in 1 M HCl Medium: Complemented with Antibacterial Studies. Int. J. Corros. Scale Inhib. 2021, 10, 1766–1782. [Google Scholar] [CrossRef]

- Alamiery, A. Corrosion Inhibition Effect of 2-N-Phenylamino-5-(3-Phenyl-3-oxo-1-propyl)-1,3,4-oxadiazole on Mild Steel in 1 M Hydrochloric Acid Medium: Insight from Gravimetric and DFT Investigations. Mater. Sci. Energy Technol. 2021, 4, 398–406. [Google Scholar] [CrossRef]

- Alamiery, A.A. Anticorrosion Effect of Thiosemicarbazide Derivative on Mild Steel in 1 M Hydrochloric Acid and 0.5 M Sulfuric Acid: Gravimetrical and Theoretical Studies. Mater. Sci. Energy Technol. 2021, 4, 263–273. [Google Scholar] [CrossRef]

- Alamiery, A.A.; Isahak, W.N.R.W.; Aljibori, H.S.S.; Al-Asadi, H.A.; Kadhum, A.A.H. Effect of the Structure, Immersion Time and Temperature on the Corrosion Inhibition of 4-Pyrrol-1-yl-N-(2,5-dimethyl-pyrrol-1-yl)benzoylamine in 1.0 M HCl Solution. Int. J. Corros. Scale Inhib. 2021, 10, 700–713. [Google Scholar] [CrossRef]

- Al-Amiery, A.A.; Mohamad, A.B.; Kadhum, A.A.H.; Allami, T.; Yusop, R.M.; Takriff, M.S. Experimental and Theoretical Study on the Corrosion Inhibition of Mild Steel by Nonanedioic Acid Derivative in Hydrochloric Acid Solution. Sci. Rep. 2022, 12, 4705. [Google Scholar] [CrossRef]

- Alamiery, A.; Mahmoudi, E.; Allami, T. Corrosion Inhibition of Low-Carbon Steel in Hydrochloric Acid Environment Using a Schiff Base Derived from Pyrrole: Gravimetric and Computational Studies. Int. J. Corros. Scale Inhib. 2021, 10, 749–765. [Google Scholar] [CrossRef]

- Eltmimi, A.J.M.; Alamiery, A.; Allami, A.J.; Yusop, R.M.; Kadhum, A.A.H.; Allami, T. Inhibitive Effects of a Novel Efficient Schiff Base on Mild Steel in Hydrochloric Acid Environment. Int. J. Corros. Scale Inhib. 2021, 10, 634–648. [Google Scholar] [CrossRef]

- Alamiery, A.; Shaker, L.M.; Allami, T.; Kadhum, A.H.; Takriff, M.S. A Study of Acidic Corrosion Behavior of Furan-Derived Schiff Base for Mild Steel in Hydrochloric Acid Environment: Experimental, and Surface Investigation. Mater. Today Proc. 2021, 44, 2337–2341. [Google Scholar] [CrossRef]

- Al-Baghdadi, S.B.; Al-Amiery, A.A.; Gaaz, T.S.; Kadhum, A.A.H. Terephthalohydrazide and Isophthalo-Hydrazide as New Corrosion Inhibitors for Mild Steel in Hydrochloric Acid: Experimental and Theoretical Approaches. Koroze Ochr. Mater. 2021, 65, 12–22. [Google Scholar] [CrossRef]

- Hanoon, M.M.; Resen, A.M.; Shaker, L.M.; Kadhum, A.A.H.; Al-Amiery, A.A. Corrosion Investigation of Mild Steel in Aqueous Hydrochloric Acid Environment Using n-(Naphthalen-1yl)-1-(4-pyridinyl)methanimine Complemented with Antibacterial Studies. Biointerface Res. Appl. Chem. 2021, 11, 9735–9743. [Google Scholar] [CrossRef]

- Al-Baghdadi, S.; Gaaz, T.S.; Al-Adili, A.; Al-Amiery, A.A.; Takriff, M.S. Experimental Studies on Corrosion Inhibition Performance of Acetylthiophene Thiosemicarbazone for Mild Steel in HCl Complemented with DFT Investigation. Int. J. Low-Carbon Technol. 2021, 16, 181–188. [Google Scholar] [CrossRef]

- Al-Amiery, A.A. Anti-Corrosion Performance of 2-Isonicotinoyl-N-phenylhydrazinecarbothioamide for Mild Steel Hydrochloric Acid Solution: Insights from Experimental Measurements and Quantum Chemical Calculations. Surf. Rev. Lett. 2021, 28, 2050058. [Google Scholar] [CrossRef]

- Abdulazeez, M.S.; Abdullahe, Z.S.; Dawood, M.A.; Handel, Z.K.; Mahmood, R.I.; Osamah, S.; Kadhum, A.H.; Shaker, L.M.; Al-Amiery, A.A. Corrosion Inhibition of Low Carbon Steel in HCl Medium Using a Thiadiazole Derivative: Weight Loss, DFT Studies and Antibacterial Studies. Int. J. Corros. Scale Inhib. 2021, 10, 1812–1828. [Google Scholar] [CrossRef]

- Mustafa, A.M.; Sayyid, F.F.; Betti, N.; Hanoon, M.M.; Al-Amiery, A.A.; Kadhum, A.A.H.; Takriff, M.S. Inhibition Evaluation of 5-(4-(1H-Pyrrol-1-yl)phenyl)-2-mercapto-1,3,4-oxadiazole for the Corrosion of Mild Steel in an Acidic Environment: Thermodynamic and DFT Aspects. Tribologia 2021, 38, 39–47. [Google Scholar] [CrossRef]

- Abdulsahib, Y.M.; Eltmimi, A.J.M.; Alhabeeb, S.A.; Hanoon, M.M.; Al-Amiery, A.A.; Allami, T.; Kadhum, A.A.H. Experimental and Theoretical Investigations on the Inhibition Efficiency of N-(2,4-Dihydroxytolueneylidene)-4-methylpyridin-2-amine for the Corrosion of Mild Steel in Hydrochloric Acid. Int. J. Corros. Scale Inhib. 2021, 10, 885–899. [Google Scholar] [CrossRef]

- Khudhair, A.K.; Mustafa, A.M.; Hanoon, M.M.; Al-Amiery, A.; Shaker, L.M.; Gazz, T.; Mohamad, A.B.; Kadhum, A.H.; Takriff, M.S. Experimental and Theoretical Investigation on the Corrosion Inhibitor Potential of N-MEH for Mild Steel in HCl. Prog. Color Colorants Coat. 2021, 15, 111–122. [Google Scholar] [CrossRef]

- Zinad, D.S.; Salim, R.D.; Betti, N.; Shaker, L.M.; AL-Amiery, A.A. Comparative Investigations of the Corrosion Inhibition Efficiency of a 1-phenyl-2-(1-phenylethylidene)hydrazine and its Analog Against Mild Steel Corrosion in Hydrochloric Acid Solution. Prog. Color Colorants Coat. 2021, 15, 53–63. [Google Scholar]

- Salim, R.D.; Betti, N.; Hanoon, M.; Al-Amiery, A.A. 2-(2,4-Dimethoxybenzylidene)-N-Phenylhydrazinecarbothioamide as an Efficient Corrosion Inhibitor for Mild Steel in Acidic Environment. Prog. Color Colorants Coat. 2021, 15, 45–52. [Google Scholar]

- Al-Amiery, A.A.; Shaker, L.M.; Kadhum, A.H.; Takriff, M.S. Exploration of Furan Derivative for Application as Corrosion Inhibitor for Mild Steel in Hydrochloric Acid Solution: Effect of Immersion Time and Temperature on Efficiency. Mater. Today Proc. 2021, 42, 2968–2973. [Google Scholar] [CrossRef]

- Resen, A.M.; Hanoon, M.M.; Alani, W.K.; Kadhim, A.; Mohammed, A.A.; Gaaz, T.S.; Kadhum, A.A.H.; Al-Amiery, A.A.; Takriff, M.S. Exploration of 8-Piperazine-1-ylmethylumbelliferone for Application as a Corrosion Inhibitor for Mild Steel in Hydrochloric Acid Solution. Int. J. Corros. Scale Inhib. 2021, 10, 368–387. [Google Scholar] [CrossRef]

- Hanoon, M.M.; Resen, A.M.; Al-Amiery, A.A.; Kadhum, A.A.H.; Takriff, M.S. Theoretical and Experimental Studies on the Corrosion Inhibition Potentials of 2-((6-Methyl-2-Ketoquinolin-3-yl)Methylene) Hydrazinecarbothioamide for Mild Steel in 1 M HCl. Prog. Color Colorants Coat. 2021, 15, 21–33. [Google Scholar]

- Hashim, F.G.; Salman, T.A.; Al-Baghdadi, S.B.; Gaaz, T.; Al-Amiery, A.A. Inhibition Effect of Hydrazine-Derived Coumarin on a Mild Steel Surface in Hydrochloric Acid. Tribologia 2020, 37, 45–53. [Google Scholar] [CrossRef]

- Resen, A.M.; Hanoon, M.; Salim, R.D.; Al-Amiery, A.A.; Shaker, L.M.; Kadhum, A.A.H. Gravimetrical, Theoretical, and Surface Morphological Investigations of Corrosion Inhibition Effect of 4-(Benzoimidazole-2-yl) Pyridine on Mild Steel in Hydrochloric Acid. Koroze Ochr. Mater. 2020, 64, 122–130. [Google Scholar] [CrossRef]

- Salman, A.Z.; Jawad, Q.A.; Ridah, K.S.; Shaker, L.M.; Al-Amiery, A.A. Selected BIS-Thiadiazole: Synthesis and Corrosion Inhibition Studies on Mild Steel in HCL Environment. Surf. Rev. Lett. 2020, 27, 2050014. [Google Scholar] [CrossRef]

- Abdel-Gaber, A.; Khamis, E.; Al-Sabagh, A.; Zaki, M. Inhibition of aluminum corrosion using Opuntia extract. Corros. Sci. 2006, 48, 2765–2779. [Google Scholar] [CrossRef]

- Ashassi-Sorkhabi, H.; Hashemi, S.J.; Shadizadeh, S.R.; Shirazi, M. Comparison of corrosion inhibition effect of imidazole and benzimidazole derivatives on copper in 3. 5% NaCl solution. Mater. Chem. Phys. 2004, 87, 267–272. [Google Scholar] [CrossRef]

- Haque, M.E.; Rahman, M.A.; Islam, M.M.; Ali, M.E. Corrosion inhibition of mild steel in 1 M HCl solution by some organic compounds. J. Mater. Res. Technol. 2012, 1, 33–39. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Li, G.; Li, S.; Gao, X.; Li, J.; Sun, C. A comparative study on the inhibition performance of four synthesized imidazoline derivatives as corrosion inhibitors for mild steel in 1 M hydrochloric acid. J. Mol. Liq. 2020, 306, 112899. [Google Scholar] [CrossRef]

- Wang, H.; Gao, L.; Wang, F.; Hou, B. Comparative study of inhibition effect of lignin and modified lignin on mild steel corrosion in acidic medium. J. Mol. Liq. 2016, 222, 600–608. [Google Scholar] [CrossRef]

- Bhat, S.K.; Pujari, P.H. Corrosion Inhibition of Mild Steel by Some Natural Products in Acidic Media. J. Mater. Sci. 2001, 36, 467–474. [Google Scholar] [CrossRef]

- Abdel-Gaber, A.; Abd-El-Nabey, B.; Sidahmed, I.; El-Zayady, M.A. The Role of Some Organic Compounds as Corrosion Inhibitors for Steel in Acidic Solutions. Appl. Surf. Sci. 2002, 198, 388–397. [Google Scholar] [CrossRef]

- Xu, J.; Li, X.; Huang, X.; Wang, L. Evaluation of Tannins as Natural Corrosion Inhibitors for Mild Steel in Acidic Media. Corros. Sci. 2011, 53, 2364–2371. [Google Scholar] [CrossRef]

- Souza, M.T.; Santos, A.O.; Silva, C.C.; Souza, R.A.M.A. Eco-Friendly Corrosion Inhibitors: A Review of Recent Progress in Marine and Coastal Biofouling Control. Mar. Drugs 2020, 18, 136. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, A.M. Eco-Friendly Corrosion Inhibitors from Natural Sources: A Review. J. Environ. Chem. Eng. 2021, 9, 104877. [Google Scholar] [CrossRef]

- Oliveira Filho, J.G.d.; Silva, G.d.C.; Oldoni, F.C.A.; Miranda, M.; Florencio, C.; Oliveira, R.M.D.d.; Gomes, M.d.P.; Ferreira, M.D. Edible Coating Based on Carnauba Wax Nanoemulsion and Cymbopogon martinii Essential Oil on Papaya Postharvest Preservation. Coatings 2022, 12, 1700. [Google Scholar] [CrossRef]

- Chen, C.; Yang, H.; Liu, J.; Luo, H.; Zou, W. Systematic Review of Actinomycetes in the Baijiu Fermentation Microbiome. Foods 2022, 11, 3551. [Google Scholar] [CrossRef]

- Farhadian, A.; Rahimi, A.; Safaei, N.; Shaabani, A.; Abdouss, M.; Alavi, A. A Theoretical and Experimental Study of Castor Oil-Based Inhibitor for Corrosion Inhibition of Mild Steel in Acidic Medium at Elevated Temperatures. Corros. Sci. 2020, 175, 108871. [Google Scholar] [CrossRef]

- Biswas, A.; Pal, S.; Udayabhanu, G. Experimental and Theoretical Studies of Xanthan Gum and Its Graft Co-Polymer as Corrosion Inhibitor for Mild Steel in 15% HCl. Appl. Surf. Sci. 2015, 353, 173–183. [Google Scholar] [CrossRef]

- Rafiee, J.S.; Mohamed, A.M.A.; Sulaiman, A.; Abdullah, M.R. Review on Natural Corrosion Inhibitors for Oil and Gas Industries. J. Mater. Environ. Sci. 2015, 6, 1725–1739. [Google Scholar]

- Khayat, M.S.; Ebenso, E.E.; Kabanda, M.M. Green Inhibitors for Acid Corrosion of Metals: A Review. J. Ind. Eng. Chem. 2014, 20, 1149–1169. [Google Scholar]

- Quraishi, M.A.; Al-Mulhem, N.A.; Mohamed, A.M.A. Eco-Friendly Inhibitors for Corrosion Protection of Metals and Alloys: An Overview. Int. J. Electrochem. Sci. 2010, 5, 704–728. [Google Scholar]

- Shafaei, T.; Bahramian, A.; Khaki, S.D. Natural Corrosion Inhibitors in the Oil Industry: A Review. Oil Gas Sci. Technol. 2016, 71, 86. [Google Scholar]

- Al-Sabagh, A.M.; Al-Azizi, N.M.; Quraishi, M.A. Corrosion Inhibition of Mild Steel in Acidic Solution Using Essential Oils. Arab. J. Chem. 2017, 3, S67–S76. [Google Scholar]

- Abd El-Rehim, S.S.; Al-Sarawy, A.A.; Diab, M.A. Natural Essential Oils as Corrosion Inhibitors for Steel in HCl Solution. Mater. Chem. Phys. 2016, 184, 109–117. [Google Scholar] [CrossRef]

- Javid, M.; Zahoor, A.F.; Sadiq, M.; Zahid, M.; Ali, A.; Abbas, S.M. Investigation of Corrosion Inhibition Behavior of a Novel Schiff Base for Carbon Steel in HCl. Arab. J. Chem. 2018, 11, 1079–1089. [Google Scholar] [CrossRef]

- Hossain, M.A.; Yasmin, T.; Khan, M.K.; Rafique, M.S.; Siddique, M.A.B. Corrosion Inhibition Performance of 1,3-Dimethylimidazolium Chloride and Its Synergistic Effect with Sodium Nitrite for Mild Steel in HCl Solution. VJChroma 2022, 61, 15–42. [Google Scholar] [CrossRef]

- Brycki, B.E.; Kowalczyk, I.H.; Szulc, A.; Kaczerewska, O.; Pakiet, M. Organic Corrosion Inhibitors. In Corrosion Inhibitors, Principles and Recent Applications; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef] [Green Version]

- Raja, P.B.; Sethuraman, M.G.; Shanmugam, N. Corrosion Inhibitors: A Review. Rev. Adv. Mater. Sci. 2017, 49, 185–218. [Google Scholar] [CrossRef]

- Idris, A.M.; Mohamad, A.A. Corrosion Inhibitors: Principles, Mechanisms and Applications; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Ahmad, Z.; Riaz, S. Recent Advances in the Development of Organic Corrosion Inhibitors: A Review. J. Mol. Liq. 2019, 293, 111419. [Google Scholar] [CrossRef]

- Popova, A.; Sokolova, E.; Raicheva, S.; Christov, M.; Vasilev, A. AC and DC Study of the Temperature Effect on Mild Steel Corrosion in Acid Media in the Presence of Benzimidazole Derivatives. Corros. Sci. 2003, 45, 33–58. [Google Scholar] [CrossRef]

- Raja, P.B.; Sethuraman, M.G.; Shanmugam, N. Corrosion Inhibition of Mild Steel in Acidic Media by Carissa Carandas Extract: Experimental and Theoretical Approach. J. Mol. Liq. 2018, 250, 56–69. [Google Scholar] [CrossRef]

| Source | Natural Inhibitors | Mechanisms of Inhibition | Applications | Advantages | Disadvantages | Ref. |

|---|---|---|---|---|---|---|

| Plants | Tannins, flavonoids, alkaloids | Formation of a protective layer on the metal surface, adsorption of the inhibitor molecules on the metal surface | Inhibiting corrosion of metals in aqueous solutions | Renewable, biodegradable, low toxicity | Limited effectiveness, degradation over time, sensitivity to environmental conditions | [127,128,129] |

| Fungi | Lignin, chitosan, polysaccharides | Formation of a barrier film, adsorption of the inhibitor molecules on the metal surface | Protection of metals against corrosion in aqueous solutions | Low cost, biodegradable, high efficiency | Limited stability, sensitivity to environmental conditions | [130,131,132] |

| Microorganisms | Bacteria, yeasts, actinomycetes | Formation of a protective layer on the metal surface, production of organic acids, adsorption of the inhibitor molecules on the metal surface | Inhibiting corrosion of metals in aqueous solutions | Renewable, biodegradable, effective at low concentrations | Limited stability, sensitivity to environmental conditions | [133] |

| Natural oils | Castor oil, soybean oil, coconut oil | Formation of a barrier film, adsorption of the inhibitor molecules on the metal surface | Protection of metals against corrosion in aqueous solutions | Low cost, readily available, biodegradable | Limited effectiveness, sensitivity to environmental conditions | [134] |

| Polysaccharides | Xanthan gum, carrageenan, starch | Formation of a barrier film, adsorption of the inhibitor molecules on the metal surface | Protection of metals against corrosion in aqueous solutions | Biodegradable, renewable, cost-effective | Limited stability, sensitivity to environmental conditions | [135] |

| Plant extracts | - | Adsorption | Metal protection | Abundant, eco-friendly, low cost | Performance may vary depending on the plant species and extraction method | [136,137,138] |

| Essential oils | - | Film formation, adsorption, complexation | Oil and gas industries, metal surface protection | Good antimicrobial and antifungal properties, biodegradable | Strong odors may limit their use | [139,140] |

| Amino acids | - | Adsorption, complexation | Metal surface protection | Non-toxic, biodegradable, low cost | Limited effectiveness at high temperatures and low pH | [141] |

| Polysaccharides | - | Adsorption, film formation | Metal surface protection, concrete reinforcement | Eco-friendly, non-toxic, and biodegradable | Can be time-consuming to prepare and to apply | [142] |

| Proteins | - | Adsorption, complexation | Metal surface protection | Biodegradable, non-toxic | Can be expensive and may cause fouling in certain systems | [143] |

| Enzymes | - | Adsorption, complexation | Metal surface protection | High selectivity, biodegradable | Limited effectiveness at high temperatures and low pH, can be expensive | [144] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Amiery, A.A.; Isahak, W.N.R.W.; Al-Azzawi, W.K. Corrosion Inhibitors: Natural and Synthetic Organic Inhibitors. Lubricants 2023, 11, 174. https://doi.org/10.3390/lubricants11040174

Al-Amiery AA, Isahak WNRW, Al-Azzawi WK. Corrosion Inhibitors: Natural and Synthetic Organic Inhibitors. Lubricants. 2023; 11(4):174. https://doi.org/10.3390/lubricants11040174

Chicago/Turabian StyleAl-Amiery, Ahmed A., Wan Nor Roslam Wan Isahak, and Waleed Khalid Al-Azzawi. 2023. "Corrosion Inhibitors: Natural and Synthetic Organic Inhibitors" Lubricants 11, no. 4: 174. https://doi.org/10.3390/lubricants11040174