Carrying Capacity of Spherical Hydrostatic Bearings including Elastic Deformation

Abstract

:1. Introduction

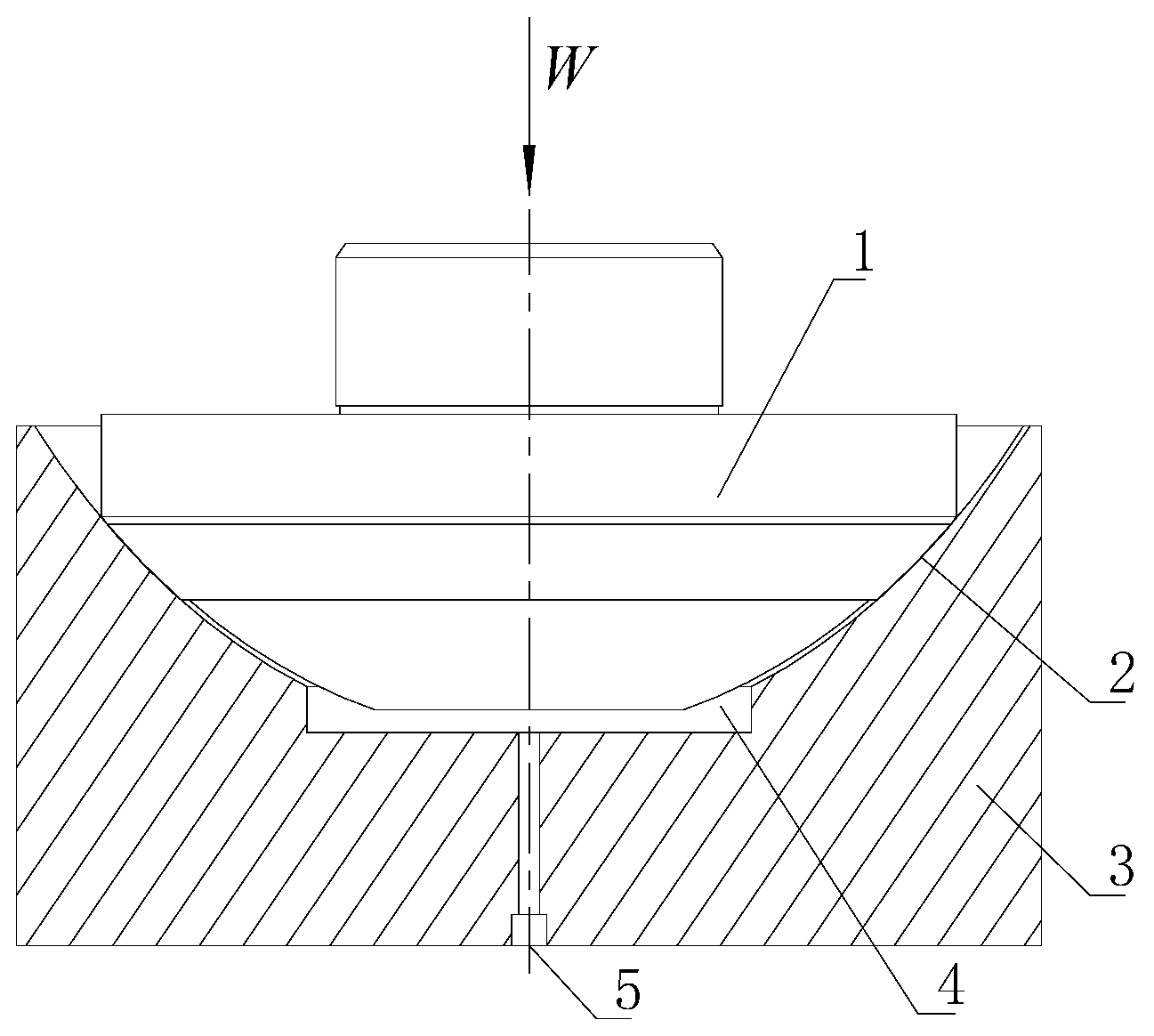

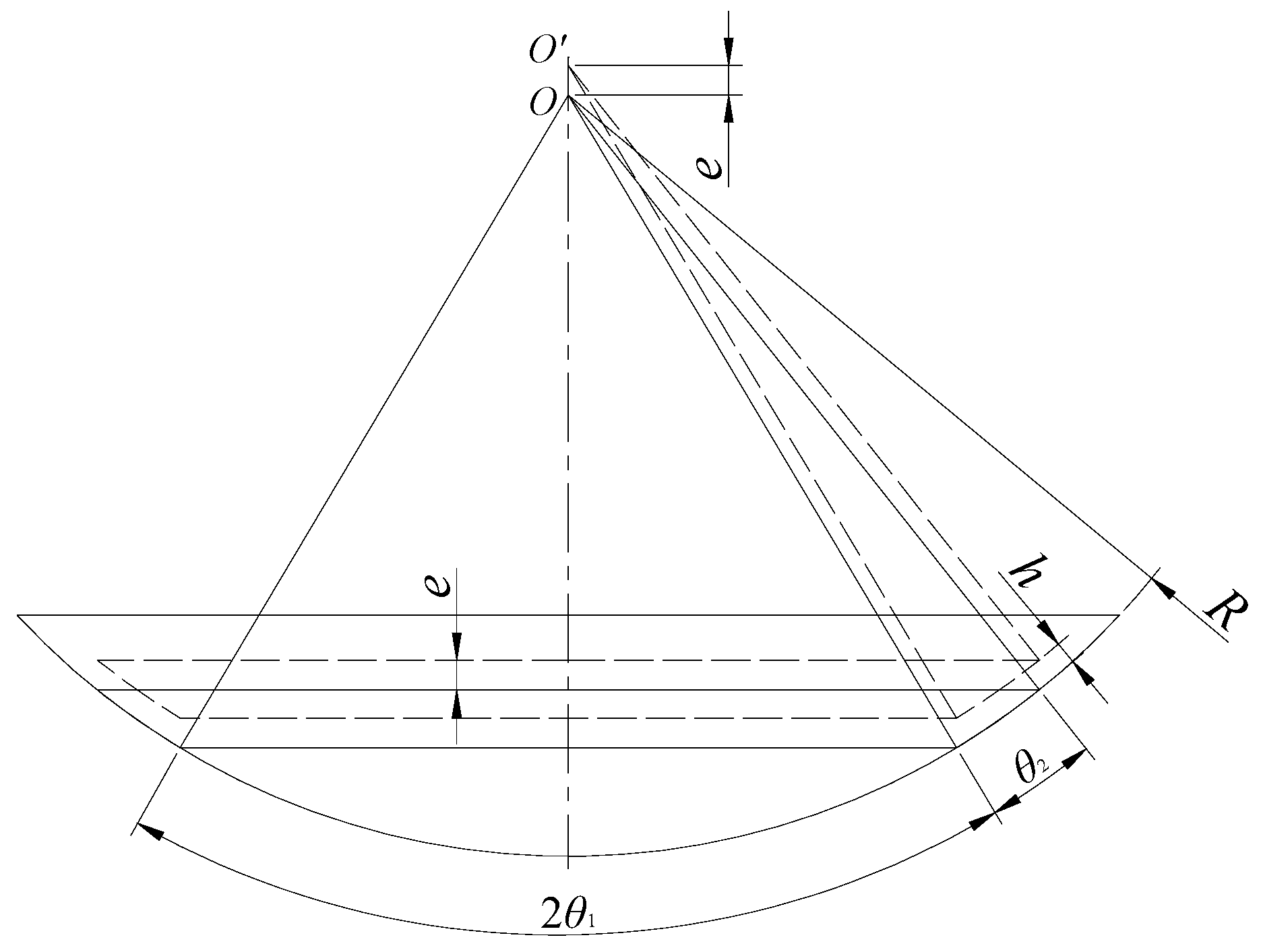

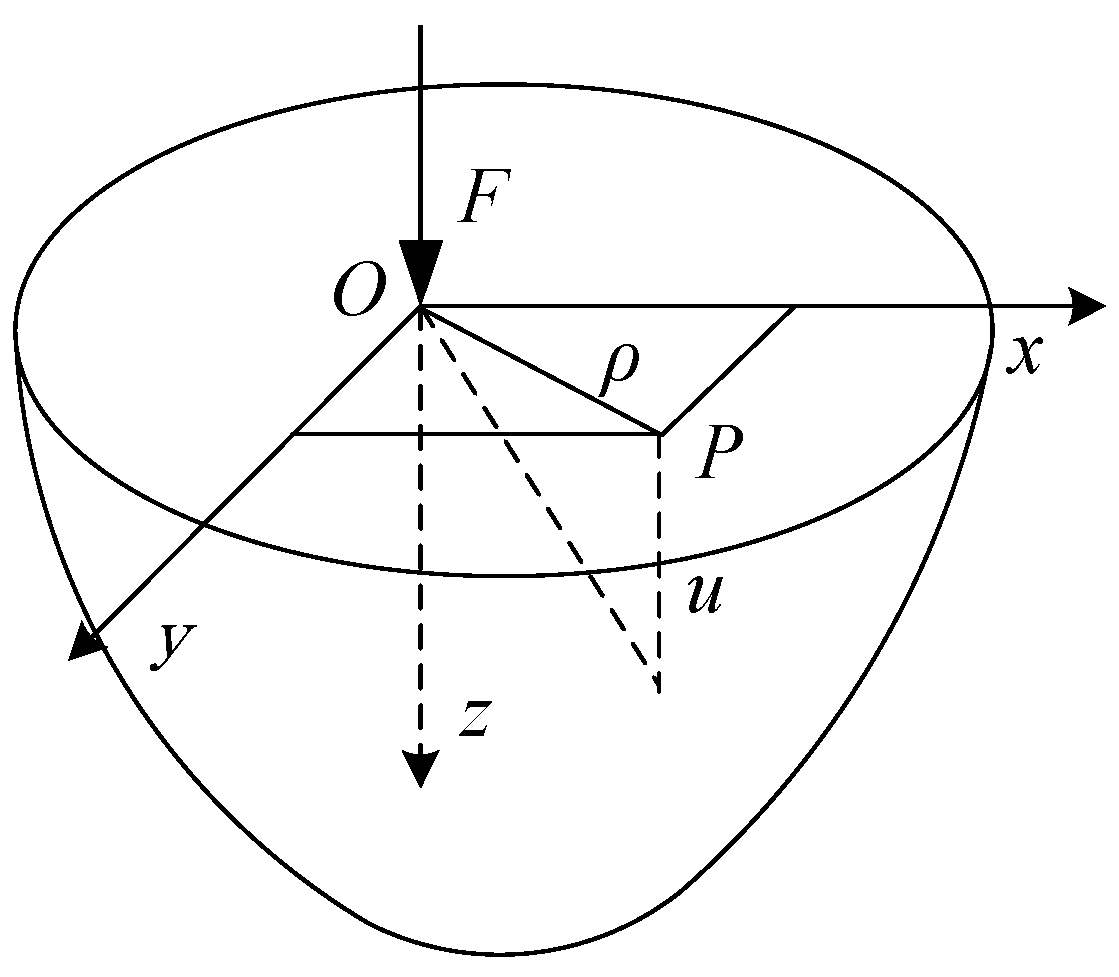

2. Mathematical Model

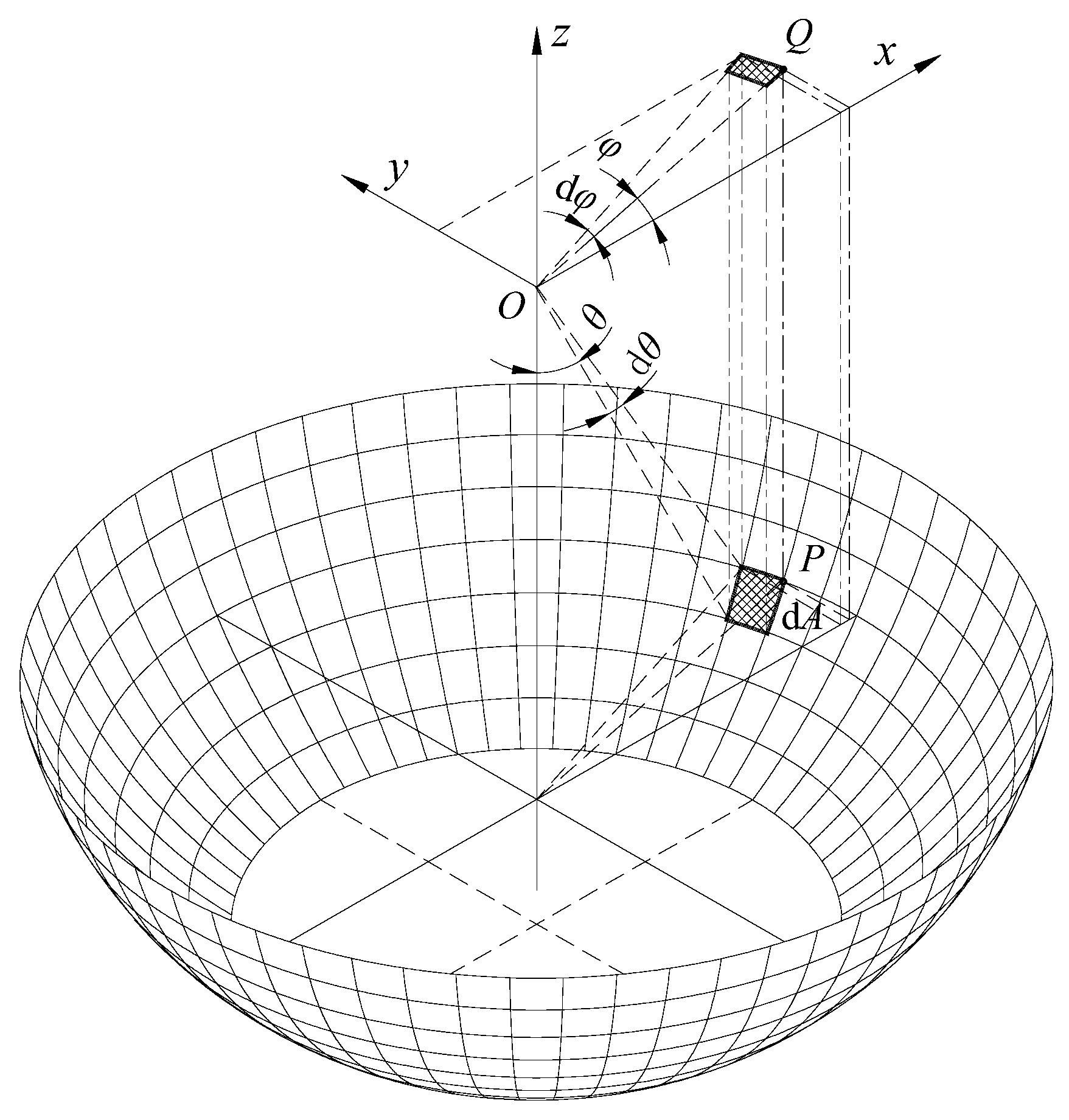

2.1. Establishment of Mathematical Model for Carrying Capacity of Hydrostatic Spherical Bearing

- (1)

- The oil density ρ is a constant value.

- (2)

- Mass forces in the oil flow are disregarded, that is, , , ;

- (3)

- The oil flow is constant, and the oil flow in the gap of the sealing edge does not change with time, that is,

- (4)

- Regardless of oil circumferential rotation speed, and ;

- (5)

- Regardless of the radial diffusion of oil flow,

- (1)

- The regularities of radial pressure distribution.

- (2)

- Distribution of axial pressure

- (3)

- The distribution of circumferential pressure

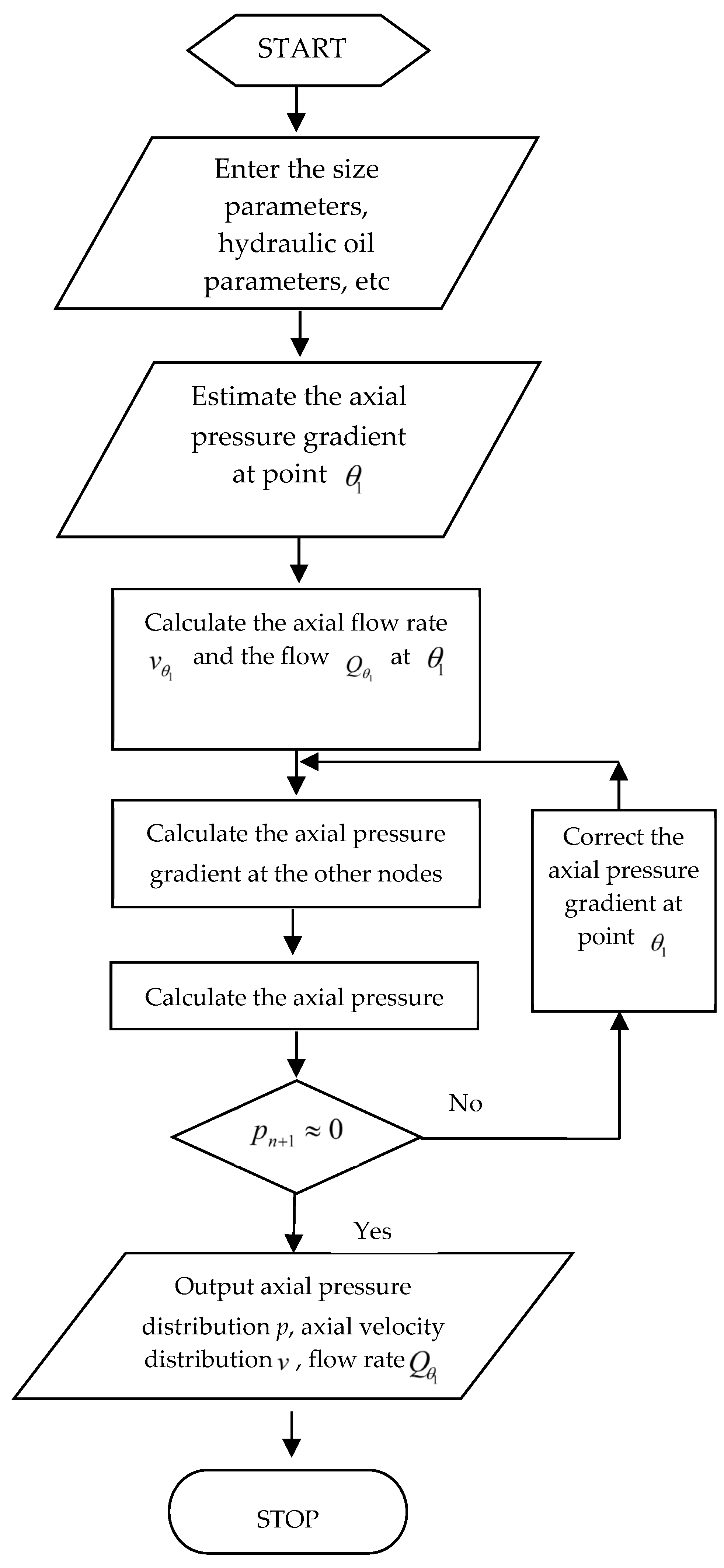

2.2. The Calculation for a Mathematical Model of Hydrostatic Spherical Bearing

- (1)

- The flow constraints

- (2)

- Boundary constraints for pressure distribution

3. Results and Discussion

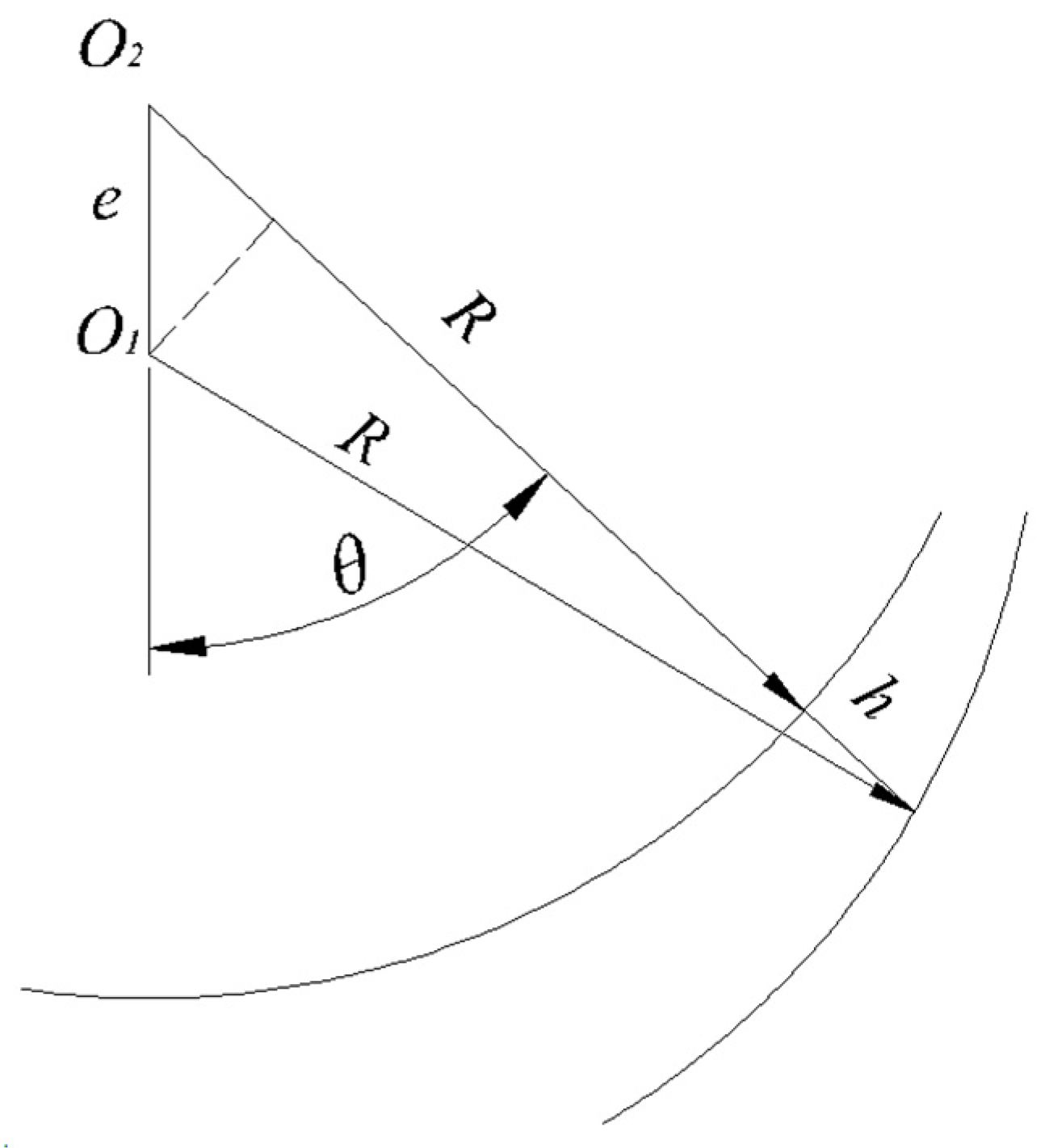

3.1. Calculation of Elastic Deformation of Bearing Surface

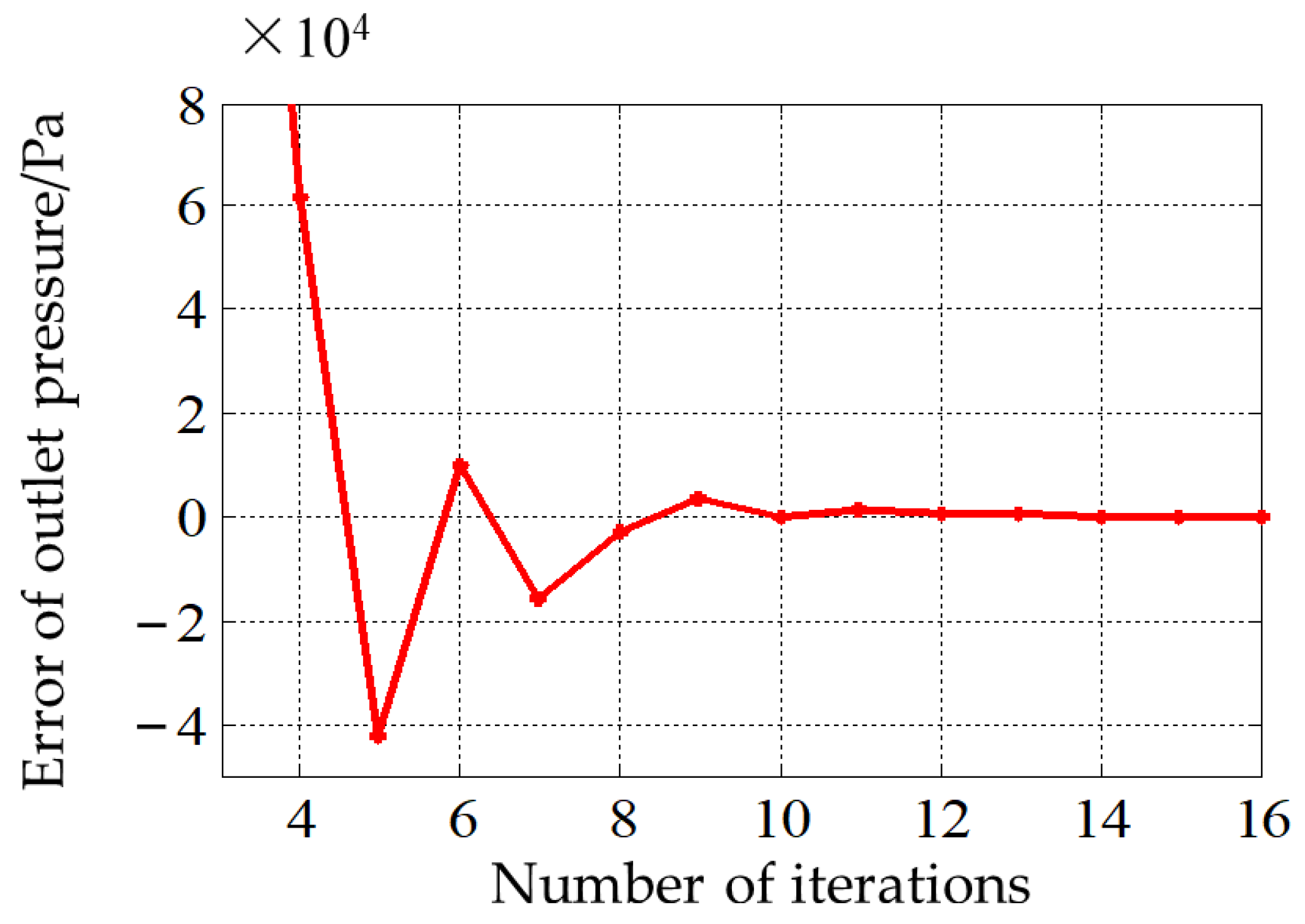

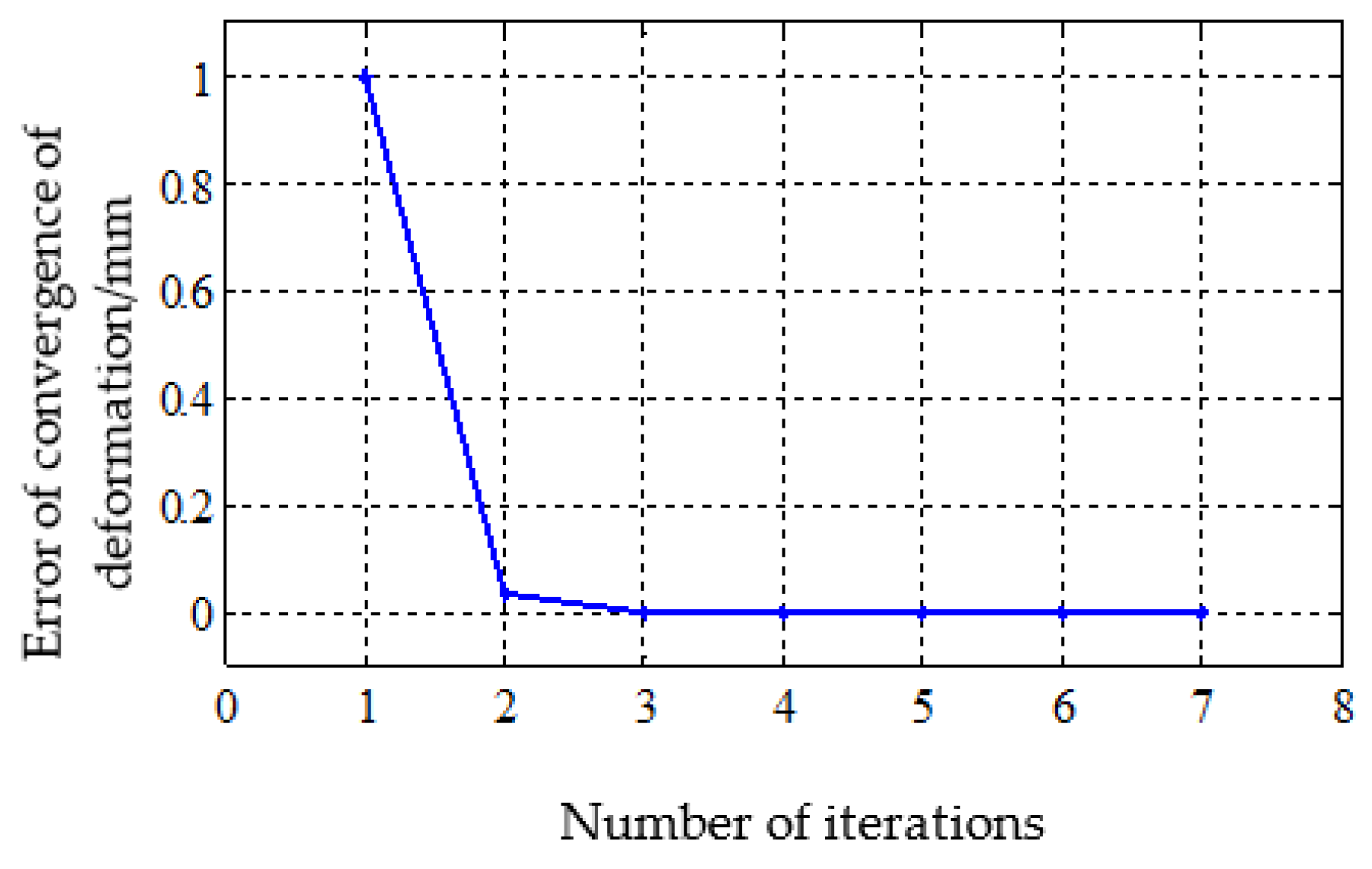

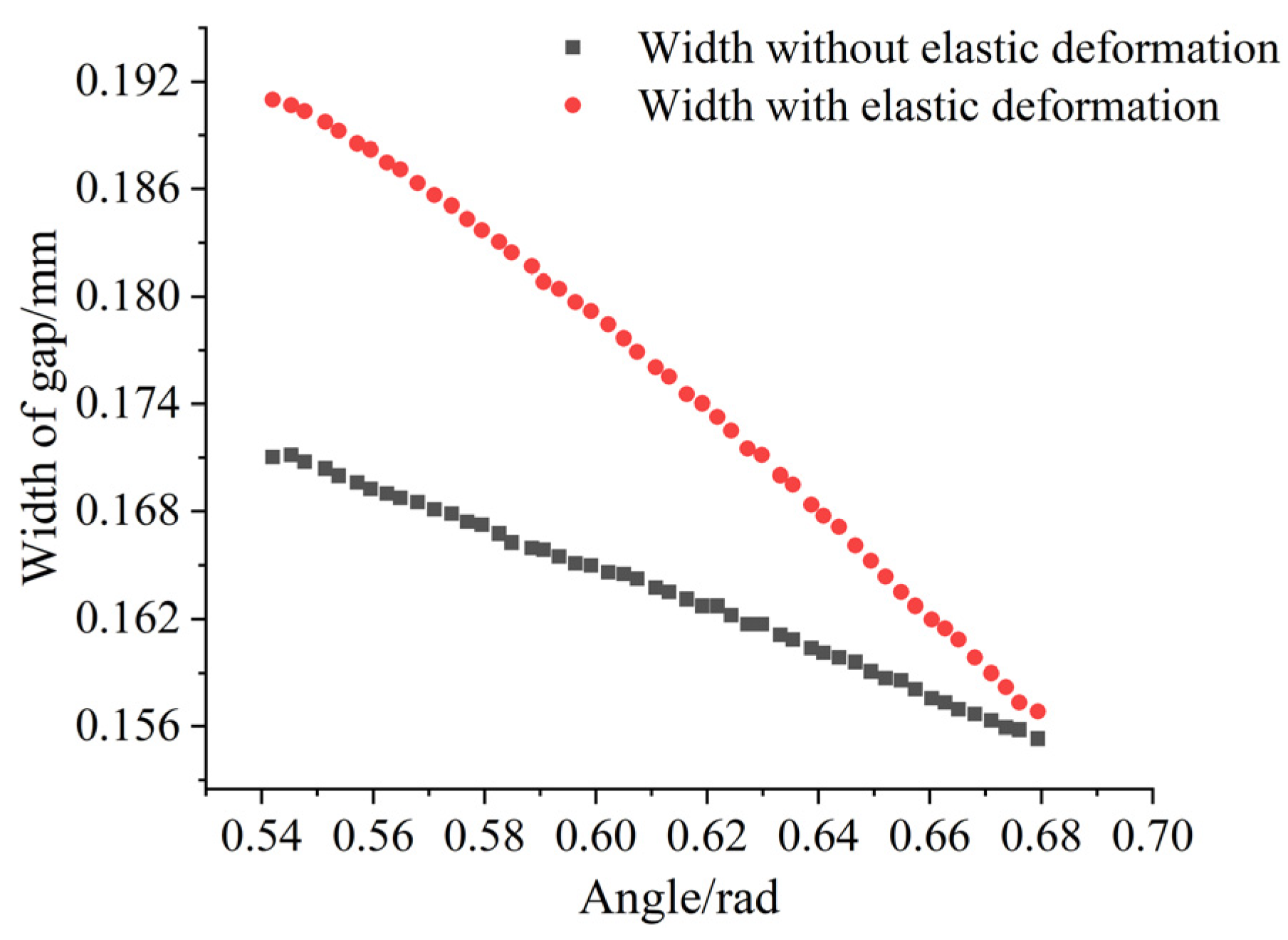

3.2. Coupling Method for Fluid Flow and Surface Elastic Deformation of Oil Seal

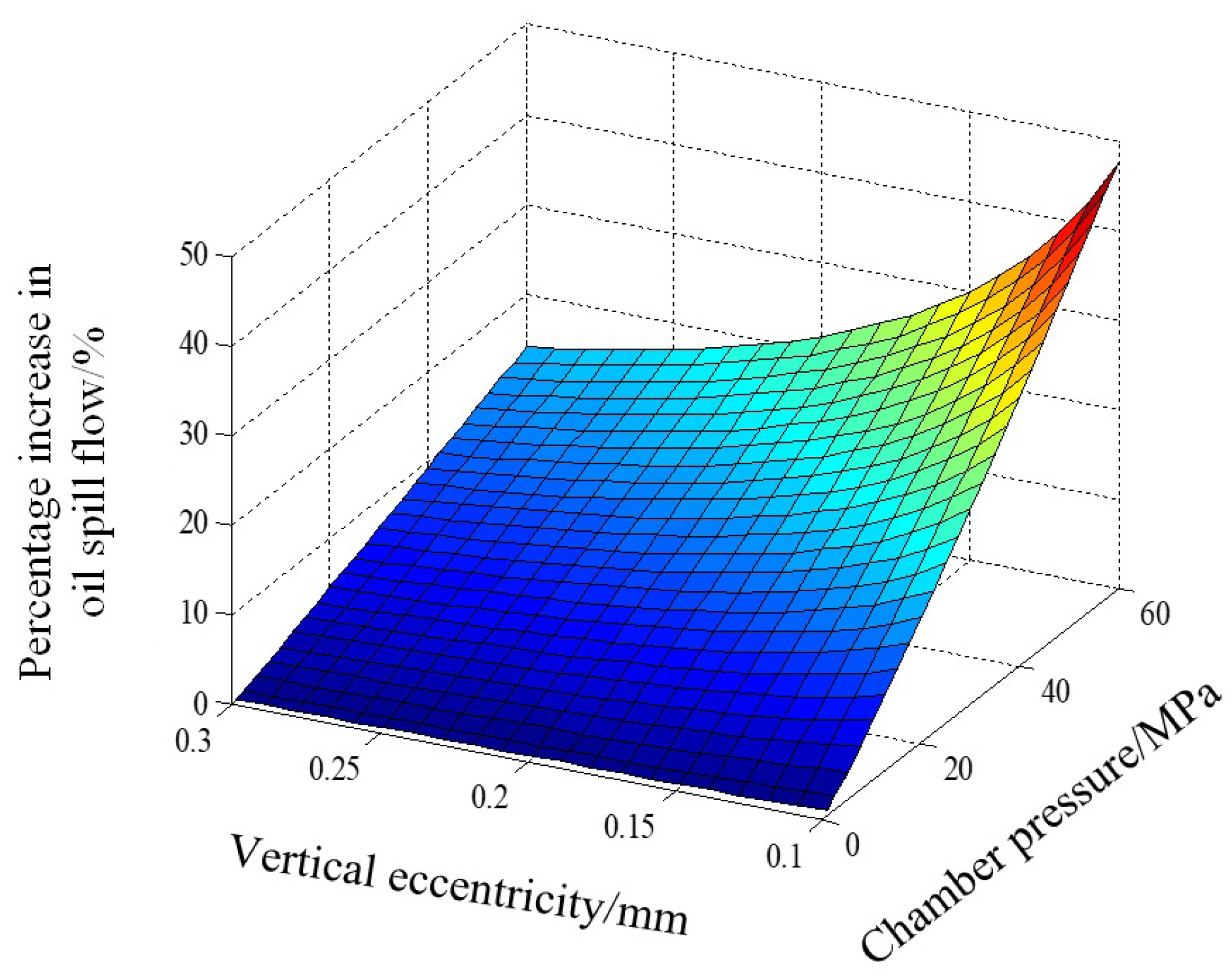

3.3. Influence of Elastic Deformation on Loading Performance Parameters of Bearing

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Deng, H.; Hu, C.; Wang, Q.; Wang, L.; Wang, C. Friction and wear analysis of the external return spherical bearing pair of axial piston pump/motor. Mech. Ind. 2020, 21, 104. [Google Scholar] [CrossRef]

- Lin, S.C. Friction and Lubrication of sliding bearings. Lubricants 2023, 11, 226. [Google Scholar] [CrossRef]

- Li, J.; Yamada, S.; Kishiki, S.; Yamazaki, S.; Watanabe, A.; Terashima, M. Experimental and numerical study of spherical sliding bearing (SSB)-part 2: Friction models. In Proceedings of the 17th World Conference on Earthquake Engineering, 17WCEE, Sendai, Japan, 28 September–2 October 2021. [Google Scholar]

- Ryan, K.L.; Mojidra, R. Analysis of effect of vertical ground shaking in bridges isolated with spherical sliding bearings. Earthq. Eng. Struct. Dyn. 2023, 52, 5010–5032. [Google Scholar] [CrossRef]

- Deng, H.; Zhu, P.; Hu, C.; He, T. Study on dynamic lubrication characteristics of the external return spherical bearing pair under full working conditions. Machines 2022, 10, 107. [Google Scholar] [CrossRef]

- Tomar, A.K.; Sharma, S.C. Non-Newtonian lubrication of hybrid multi-recess spherical journal bearings with different geometric shapes of recess. Tribol. Int. 2022, 171, 107579. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Ju, J. Study on the mechanical properties of a type of spherical bearing. J. Theor. Appl. Mech. 2021, 59, 539–550. [Google Scholar] [CrossRef]

- Meyer, D. Reynolds equation for spherical bearings. J. Tribol. 2003, 125, 203–206. [Google Scholar] [CrossRef]

- Elescandarany, A.W. Kugel ball nature: Hydrodynamics-mathematics-design. Appl. Eng. Sci 2002, 9, 100078. [Google Scholar] [CrossRef]

- Kazama, T. Design of hydrostatic spherical bearing’s in fluid film lubrication. J. Tribol. 2000, 1228, 66–69. [Google Scholar] [CrossRef]

- Yacout, A.W.; Ismail, A.S.; Kassab, S.Z. The combined effects of the centripetal inertia and the surface roughness on the hydrostatic thrust spherical bearings performance. Tribol. Int. 2007, 40, 522–532. [Google Scholar] [CrossRef]

- Elescandarany, A.W.Y. The effect of the fluid film variable viscosity on the hydrostatic thrust spherical bearing performance in the presence of centripetal inertia and surface roughness. Int. J. Mech. Eng. Appl. 2018, 6, 1–12. [Google Scholar] [CrossRef]

- Yacout, A.W.; Ismail, A.S.; Kassab, S.Z. The surface roughness effect on the hydrostatic thrust spherical bearings performance (part 2 un-recessed clearance type). In Proceedings of the ASME, International Mechanical Engineering Congress and Exposition, IMECE2006-13004, Chicago, IL, USA, 5–10 November 2006. [Google Scholar] [CrossRef]

- Yacout, A.W.; Ismail, A.S.; Kassab, S.Z. The surface roughness effect on the hydrostatic thrust spherical bearings performance (part 3 recessed clearance type of bearings). In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, IMECE 2007-41013, Seattle, WA, USA, 11–15 November 2007. [Google Scholar] [CrossRef]

- Elescandarany, A.W. Externally pressurized thrust spherical bearing performance under variable lubricant viscosity (un-recessed clearance type). Int. J. Mech. Eng. Appl. 2020, 8, 45–64. [Google Scholar]

- Elescandarany, A.W.Y. Design of the hydrostatic thrust spherical bearing with restrictors (fitted type). Int. J. Mech. Eng. Appl. 2019, 7, 34–45. [Google Scholar]

- Elescandarany, A.W.Y. Design of self-restriction hydrostatic thrust spherical bearing (fitted type). Int. J. Mech. Eng. Appl. 2019, 7, 111–122. [Google Scholar]

- Elescandarany, A.W. Kugel ball as an interesting application of designing the hydrosphere. Int. J. Mech. Eng. Appl. 2021, 9, 25–32. [Google Scholar]

- Rajashekar, M.; Kashinath, B. Effect of surface roughness on MHD couple stress squeeze-film characteristics between a sphere and a porous plane surface. Adv. Tribol. 2012, 2012, 935690. [Google Scholar] [CrossRef]

- Rao, R.R.; Gowthami, K.; Kumar, J.V. Effects of velocity-slip and viscosity variation in squeeze film lubrication of spherical bearings. In Proceedings of ICATES; Springer: Delhi, India, 2013; pp. 35–47. [Google Scholar] [CrossRef]

- Tao, J.Z.; Yin, G.F.; Wang, F.Y. An optimism method of air static pressure ball bear parameters. China Mech. Eng. 2004, 15, 48–50. [Google Scholar] [CrossRef]

- Guo, X.P.; He, H.T.; Zhao, L. Optimization design of non-liquid friction spherical sliding bearing based on ANSYS. Bearing. 2007, 2, 4–5. [Google Scholar] [CrossRef]

- Luo, L.; Wang, X. Finite element analysis of self-Lubricating joint bearing liner wear. In Proceedings of the 2017 International Conference on Computer Technology, Electronics and Communication (ICCTEC), Dalian, China, 19–21 December 2017; pp. 245–249. [Google Scholar] [CrossRef]

- Luo, L.; Wang, X.; Liu, H.; Zhu, L. Number simulation analysis of self-lubricating joint bearing liner wear. Int. J. Interact. Des. Manuf. 2019, 13, 23–34. [Google Scholar] [CrossRef]

- Royston, T.J.; Basdogan, I. Vibration transmission through self-aligning (spherical) rolling element bearings: Theory and experiment. J. Sound Vib. 1998, 215, 997–1014. [Google Scholar] [CrossRef]

- Geng, K.; Lin, S. Effect of angular misalignment on the stiffness of the double-row self-aligning ball bearing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 946–962. [Google Scholar] [CrossRef]

- Ambrożkiewicz, B.; Syta, A.; Gassner, A.; Georgiadis, A.; Litak, G.; Meier, N. The influence of the radial internal clearance on the dynamic response of self-aligning ball bearings. Mech. Syst. Signal Process. 2022, 171, 108954. [Google Scholar] [CrossRef]

- Zhuo, Y.; Zhou, X.; Yang, C. Dynamic analysis of double-row self-aligning ball bearings due to applied loads, internal clearance, surface waviness and number of balls. J. Sound Vib. 2014, 333, 6170–6189. [Google Scholar] [CrossRef]

- Parmar, V.; Saran, V.H.; Harsha, S.P. Effect of an unbalanced rotor on dynamic characteristics of double-row self-aligning ball bearing. Eur. J. Mech. A/Solids 2020, 82, 104006. [Google Scholar] [CrossRef]

- Parmar, V.; Saran, V.H.; Harsha, S.P. Nonlinear vibration response analysis of a double-row self-aligning ball bearing due to surface imperfections. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2020, 234, 514–535. [Google Scholar] [CrossRef]

- Liu, Z.L.; Lu, J.; Zhou, J.N. The research on the design of largescale static pressure spherical bearing used in propeller balancing installation. J. Wuhan Univ. Technol. (Transp. Sci. Eng.) 2003, 27, 429–432. [Google Scholar]

- Liu, Z.L.; Xiao, H.L.; Zhou, J.N. Design of large-sized static pressure ball bearing. Ship Eng. 1999, 05, 25–27. [Google Scholar]

- Wang, C.T.; Wu, U.J.; Chen, L. Algorithm improvement and experimental research for propeller static balancing detection. Sci. Technol. Eng. 2015, 15, 294–297. [Google Scholar]

- Qian, L.B.; Jiang, Y.H. Design of mechanical prop based on space and tracks movement. Equip. Manuf. Technol. 2012, 03, 8–9. [Google Scholar]

- Li, Y.L.; Guo, W.; Wu, S.S. R & T on high precision static balancing machine of propeller hanging type for large marine. Mach. Des. Manuf. 2011, 59–61. [Google Scholar] [CrossRef]

- Huang, W.X.; Li, J.M.; Xiao, Z.Y. Engineering Fluid Mechanics; Chemical Industry Press: Beijing, China, 2009. [Google Scholar]

- Xu, X.L.; Deng, H.S.; Wang, C.L. Theory study of spherical interstitial flow. Chin. Hydraul. Pneum. 2004, 10, 3–5. [Google Scholar]

- Ouyang, W.; Liu, Q.; Xiao, J.; Huang, J.; Zhang, Z.; Wang, L. Experimental study on the distributed lubrication characteristics of full-size water-lubricated stern bearings under hull deformation. Ocean Eng. 2023, 267, 113226. [Google Scholar] [CrossRef]

- Tieu, A.K.; Freund, N.O. A high performance journal bearing with controlled elastic deflection. J. Tribol. 1995, 117, 702. [Google Scholar] [CrossRef]

- Sun, Y.H.; Ma, X.Z. Influence of elastic deformation on ball mill bearing. Lubr. Eng. 2011, 36, 65–69. [Google Scholar]

- Duan, F.L.; Wei, Y.L. Effect of elastic deformation on the lubrication performance of journal bearing. Lubr. Eng. 2000, 06, 9–10. [Google Scholar]

| Cases | Symbol | Unit | Value |

|---|---|---|---|

| Spherical radius | R | mm | 350 |

| The angle of a high-pressure oil chamber | (°) | 62.0 | |

| The angle of the unilateral oil seal side | (°) | 8.00 | |

| Average oil film thickness | h | mm | 0.20 |

| Max speed of circumference | 200 | ||

| The pressure of a high-pressure oil chamber | MPa | 4.00 | |

| Viscosity of hydraulic oil | Pa·s | 0.0495 | |

| Density of hydraulic oil | 900 |

| Components | Material | Density /(kg·m−3) | Elastic Modulus E/GPa | Poisson’s Ratio |

|---|---|---|---|---|

| Bearing body | Bronze | 8300 | 110 | 0.37 |

| Bearing housings | Cast steel | 7800 | 210 | 0.31 |

| Components | The Maximum Amount of Elastic Deformation | The Minimum Amount of Elastic Deformation |

|---|---|---|

| Bearing body | 1.284 × 10−2 | 9.610 × 10−4 |

| Bearing housings | 7.05 × 10−3 | 5.27 × 10−4 |

| Parameters | With Elastic Deformation | Without Elastic Deformation | Increase Rate/% |

|---|---|---|---|

| Bearing capacity of sealing the oil side F2/kN | 1623 | 1539 | 5.45 |

| Total bearing capacity F/kN | 7874 | 7790 | 1.07 |

| Flow of oil spill Q/(L·min−1) | 290.2 | 238.4 | 21.74 |

| Average speed of output vavg/(m·s−1) | 22.28 | 18.47 | 20.62 |

| Frictional moment of rotational resistance M/(N·m) | 7.49 | 7.97 | −6.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Yang, D.; Li, G.; Cheng, Y.; Chen, G.; Zhang, Z.; Li, J. Carrying Capacity of Spherical Hydrostatic Bearings including Elastic Deformation. Lubricants 2024, 12, 97. https://doi.org/10.3390/lubricants12030097

Zhang S, Yang D, Li G, Cheng Y, Chen G, Zhang Z, Li J. Carrying Capacity of Spherical Hydrostatic Bearings including Elastic Deformation. Lubricants. 2024; 12(3):97. https://doi.org/10.3390/lubricants12030097

Chicago/Turabian StyleZhang, Shengdong, Dongjiang Yang, Guangming Li, Yongchao Cheng, Guang Chen, Zhiming Zhang, and Jichao Li. 2024. "Carrying Capacity of Spherical Hydrostatic Bearings including Elastic Deformation" Lubricants 12, no. 3: 97. https://doi.org/10.3390/lubricants12030097