Common Properties of Lubricants that Affect Vehicle Fuel Efficiency: A North American Historical Perspective

Abstract

:1. Introduction

2. Difficulties with Measuring the Effect of Lubricants on Fuel Economy

3. Effect of Viscosity on Fuel Economy

4. Balance of Viscosity and Elastohydrodynamic Film Thickness

5. Lubricant Effects on Boundary and EHD Friction

6. Relative Effect of Viscosity, Boundary and EHD Friction on Fuel Economy

7. Conclusions

Funding

Conflicts of Interest

References

- National Highway Transportation Administration. Available online: www.NHTSA.gov (accessed on 1 June 2018).

- United States Environmental Protection Agency. Available online: www.epa.gov (accessed on 1 June 2018).

- Wong, V.W.; Tung, S.C. Overview of Automotive Engine Friction and Reduction Trends—Effects of surface, material, and lubricant-additive technologies. Friction 2016, 4, 1–28. [Google Scholar] [CrossRef]

- Tung, S.C.; McMillian, M.L. Automotive tribology overview of current advances and challenges for the future. Tribol. Int. 2004, 37, 517–536. [Google Scholar] [CrossRef]

- McGuire, N. The Drive for Efficient Performance. Tribol. Lubr. Technol. 2018, 74, 34–43. [Google Scholar]

- Spikes, H. Friction Modifier Additives. Tribol. Lett. 2015, 60. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Spikes, H. On the Mechanism of ZDDP Antiwear Film Formation. Tribol. Lett. 2016, 63. [Google Scholar] [CrossRef] [Green Version]

- Topolovec-Miklozic, K.; Forbus, T.R.; Spikes, H. Film Forming and Friction Properties of Overbased Calcium Sulphonate Detergents. Tribol. Lett. 2008, 29, 33–44. [Google Scholar] [CrossRef]

- Jie, Z.; Tan, A.; Spikes, H. Effect of Base Oil Structure on Elastohydrodynamic Friction. Tribol. Lett. 2017, 65, 1–24. [Google Scholar]

- Liu, Z.; Gangopadhyay, A.; Lam, W.; Devlin, M. The Effect of Friction Modifiers and DI Package on Friction Reduction Potential of Next Generation Engine Oils: Part I Fresh Oils; SAE 2018-01-0933; SAE: Warrendale, PA, USA, 2018. [Google Scholar]

- Devlin, M.T.; Guevremont, J.M.; Hewette, C.; Ingram, M.; Pollard, G.; Wyatt, W. Effect of Metallurgy on the Formation of Tribofilms and Wear Prevention; SAE 2017-01-2357; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Kwak, Y.; Cleveland, C. Continuously Variable Transmission (CVT) Fuel Economy; SAE 2017-01-2355; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Liu, Z.; Gangopadhyay, A.; Simko, S.; Lam, W.; Devlin, M.T. The Effect of Friction Modifiers and Additive Packages on Friction Reduction Potential of Next Generation Engine Oils—Part I: Fresh Oils. In Proceedings of the 72nd STLE Annual Meeting, Atlanta, GA, USA, 21–25 May 2017. [Google Scholar]

- Gangopadhyay, A.; Liu, Z.; Simko, S.; Lam, W.; Devlin, M.T. The Effect of Friction Modifiers and Additive Packages on Friction Reduction Potential of Next Generation Engine Oils—Part II: Aged Oils. In Proceedings of the 72nd STLE Annual Meeting, Atlanta, GA, USA, 21–25 May 2017. [Google Scholar]

- Guinther, G.; Devlin, M. Lubricant Developments for Advanced Drivetrain Hardware. In Proceedings of the 71st STLE Annual Meeting, Las Vegas, NV, USA, 15–19 May 2016. [Google Scholar]

- Carroll, J.B. Transmission Fluids and Fuel Economy—What does the future hold? In Proceedings of the SAE 2014 Commercial Vehicle Engineering Congress (COMVEC), Rosemont, IL, USA, 7–9 October 2014. [Google Scholar]

- Yang, L.; Neville, A.; Brown, A.; Ransom, P.; Morina, A. Effect of lubricant additives on the WDLC coating structure when tested in boundary lubrication regime. In Proceedings of the Leeds-Lyon Conference, Leeds, UK, 2–5 September 2014. [Google Scholar]

- Carroll, J.B. Targeted Transmission Fluid Property Design for Improved Fuel Economy. In Proceedings of the 2nd International CTI Symposium China, Shanghai, China, 18–20 September 2013. [Google Scholar]

- Rollin, T.J. Enabling Transmission Fluid Technologies for Improved Fuel Efficiency. In Proceedings of the 19th Annual Fuels and Lubes Asia Conference, Suzhou, China, 13–15 March 2013. [Google Scholar]

- Guinther, G.H.; Bell, I. Global Perspective on Fuel Economy: Correlation of Modern Engine Oil Tests to Real World Performance. In Proceedings of the 2013 STLE Annual Meeting, Detroit, MI, USA, 5–9 May 2013. [Google Scholar]

- Guinther, G.H.; Styer, J. Correlation of the Sequence VI Laboratory Fuel Economy Test to Real World Fuel Economy; SAE 2013-01-0297; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Guinther, G.H. Bumper to Bumper Fuel Economy Demonstration, a Vehicle-Based Approach to Evaluating Energy-Saving Technologies. In Proceedings of the SAE 2013 Fuels, Lubricants & Aftertreatment Symposium, Long Beach, CA, USA, 18–21 November 2013. [Google Scholar]

- Yang, L.; Neville, A.; Brown, A.; Ransom, P.; Morina, A. Study of GMO concentration on the boundary lubricated W-doped DLC coatings. In Proceedings of the 40th Leeds-Lyon Symposium on Tribology, Lyon, France, 4–6 September 2013. [Google Scholar]

- Yang, L.; Neville, A.; Brown, A.; Ransom, P.; Morina, A. Effect of Temperature on Tribological Performances of WDLC Coatings in Model Oils. In Proceedings of the 2013 STLE Annual Meeting, Detroit, MI, USA, 5–9 May 2013. [Google Scholar]

- Styer, J.; Guinther, G.H. Fuel Economy beyond ILSAC GF-5: Correlation of Modern Engine Oil Tests to Real World Performance; SAE 2012-01-1618; SAE: Warrendale, PA, USA, 2012. [Google Scholar]

- Guinther, G.H.; Styer, J. Development of a Novel Vehicle-Based Method to Assess the Impact of Lubricant Quality on Passenger Car Energy Efficiency; SAE 2012-01-1619; SAE: Warrendale, PA, USA, 2012. [Google Scholar]

- Culley, S.A.; Devlin, M.T.; McAllister, J.; Rollins, A.J.; Iyer, R.; Maelger, H. Reduction in CO2 Emissions by Optimization of Transmission Fluids for Improved Vehicle Fuel Economy. In Proceedings of the International Joint Tribology Conference, Hiroshima, Japan, 30 October–3 November 2011. [Google Scholar]

- Guevremont, J.M.; Garelick, K.; Sheets, R.; Hux, K.; Heaps, C.; Devlin, M.T. Composition and Frictional Properties of Tribofilms Formed with Ashless Antiwear Additives. In Proceedings of the 66th STLE Annual Meeting and Exhibition, Atlanta, GA, USA, 15–19 May 2011. [Google Scholar]

- Devlin, M.T.; Hux, K.; Garelick, K.; Warren, S.; Duggal, R.; Ding, J.; Culley, S.; Iyer, R.; Tersigni, S. Effect of ATF Physical Properties on Fuel Efficiency. In Proceedings of the Fall SAE Fuels and Lubricants Conference, San Diego, CA, USA, 26 October 2010. [Google Scholar]

- Hewette, C.; DeGonia, D.; Jao, T.-C.; Rollin, A.J. Development of Fuel Economy Axle Fluid Technology. In Proceedings of the 16th Annual Asia Fuels and Lubes Conference, Singapore, 1–5 March 2010. [Google Scholar]

- Guevremont, J.M.; Garelick, K.; Loper, J.; Lagona, J.; Sheets, R.; Hux, K.; Devlin, M.T. Influence of Friction Modifiers on Boundary Film Formation Properties. In Proceedings of the 65th STLE Annual Meeting and Exhibition, Las Vegas, NV, USA, 19 May 2010. [Google Scholar]

- Tersigni, S.H.; Iyer, R.N.; Henly, T.J.; Yatsunami, K.; Glasgow, M.B.; Carlson, J.; Tang, T.; Devlin, M.T.; Rollin, A.J. Fuel Efficiency Testing of Automatic Transmission Fluids. In Proceedings of the World Tribology Congress IV, Kyoto, Japan, 6–11 September 2009. [Google Scholar]

- Devlin, M.T.; Guevremont, J.M.; Garelick, K.; Hux, K.; Smith, A.; Jao, T.-C. The Effect of Sulfur and Phosphorus Content of Anti-wear Additives on Friction and Boundary Film Formation. In Proceedings of the Royal Society of Chemistry’s Additives 2009 Conference, York, UK, 20–21 June 2009. [Google Scholar]

- Devlin, M.T.; Guevremont, J.M.; Thompson, K.; Kolakowski, K.; Garelick, K.; Jao, T.-C. Boundary Film Formation Properties of Anti-wear/Friction Modifiers Combinations. In Proceedings of the 16th International Colloquium Tribology, Esslingen, Germany, 15–17 January 2008. [Google Scholar]

- Devlin, M.T.; Guevremont, J.M.; Thompson, K.; Smith, A.; Garelick, K.; Jao, T.-C. Boundary Film Strength and Composition of Tribofilms formed by Anti-wear/Friction Modifier Combinations. In Proceedings of the STLE Annual Meeting, Cleveland, OH, USA, 19–21 May 2008. [Google Scholar]

- Devlin, M.T.; Aradi, A.A.; Guevremont, J.M.; Jao, T.-C.; Abdelsayed, V.; El-Shall, M. Friction and Film-Formation Properties of Oil-Soluble Inorganic Nanoparticles; SAE 2008-01-2460; SAE: Warrendale, PA, USA, 2008. [Google Scholar]

- Devlin, M.T.; Kuo, C.C.; Pietras, J.M.; Yun, Z. Bench Test Modeling for Current and Future PCMO Fuel Economy Requirements. In Proceedings of the PetroChina Lubricants Conference 2007, Ningbo, China, 17–18 September 2007. [Google Scholar]

- Devlin, M.T.; Senn, J.; Turner, T.L.; Milner, J.; Jao, T.-C. Reduction in Axle Oil Operating Temperatures by Fluids with Optimized Torque Transfer Efficiencies. Lubr. Sci. 2006, 18, 7–23. [Google Scholar] [CrossRef]

- Devlin, M.T. Effect of Changes in SAE J300 Low Temperature Specifications on Fuel Economy. In Proceedings of the SAE J300 Open Forum, SAE Powertrain and Fluid Systems Conference, San Antonio, TX, USA, 25 October 2005. [Google Scholar]

- Devlin, M.T.; Senn, J.; Sturtz, M.; Bala, V.; Milner, J.; Jao, T.-C. Improved Understanding of Axle Oil Rheology Effects on Torque Transfer Efficiency and Axle Oil Operating Temperature; SAE 2003-01-1972; SAE: Warrendale, PA, USA, 2003. [Google Scholar]

- Bala, V.; Brandt, G.; Walters, D.K. Fuel Economy of Multigrade Gear Lubricants. Lubr. Tribol. 2000, 52, 165–173. [Google Scholar] [CrossRef]

- Devlin, M.T.; Burgess, T.; Rezba, E.; Cole, A.J. Relationship between the Oil Performance in Standard Industry Fuel Economy Tests and Fuel Economy Measured in Vehicles. In Proceedings of the Royal Society of Chemistry’s Additives 2001 Conference, Oxford, UK, 26–27 March 2001. [Google Scholar]

- Bala, V.; Rollin, A.J.; Brandt, G. Rheological Properties Affecting the Fuel Economy of Multigrade Automotive Gear Lubricants; SAE 2000-01-2051; SAE: Warrendale, PA, USA, 2000. [Google Scholar]

- Devlin, M.T.; Naumann, J.K.; Saathoff, L.D.; Walters, D.K. Predicting the Fuel Economy Properties of Gear Oils Using Laboratory Friction Tests. In Proceedings of the GFC Conference, Paris, France, 23 June 1999. [Google Scholar]

- Devlin, M.T.; Lam, W.Y.; McDonnell, T.F. Critical Oil Physical Properties that Control the Fuel Economy Performance of General Motors Vehicles; SAE 982503; SAE: Warrendale, PA, USA, 1998. [Google Scholar]

- Devlin, M.T.; Lam, W.Y.; McDonnell, T.F. Comparison of the Physical and Chemical Changes Occurring in Oils During Aging in Vehicle and Engine Fuel Economy Tests; SAE 982504; SAE: Warrendale, PA, USA, 1998. [Google Scholar]

- Yang, K.; Fletcher, K.A.; Styer, J.P.; Lam, W.Y.; Guinther, G.H. Engine Oil Components Effects on Turbocharger Protection and the Relevance of the TEOST 33C Test for Gasoline Turbocharger Deposit Protection; SAE 2017-01-2341; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Yang, K.; Fletcher, K.A.; Styer, J.P.; Lam, W.Y.; Guinther, G.H. Advanced Lubrication—Enabling and Protecting Turbocharged, Direct Injection Gasoline Engines for Optimum Efficiency; SAE 2016-01-2275; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Shao, H.; Lam, W.Y.; Remias, J.; Roos, J.; Choi, S.; Seong, H. Effect of Lubricant Oil Properties on the Performance of Gasoline Particulate Filter (GPF); SAE 2016-01-2287; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Shao, H.; Wang, Y.; Yang, F.; He, S.M.; Gu, D.; Chang, C.; Hua, L.; Jinchong, J.P.; Jin, Y. Effect of Lubricant Properties on GPF performance. In Proceedings of the SAE China, Beijing, China, 24–26 October 2017. [Google Scholar]

- Gupta, A.; Seeley, R.; Shao, H.; Remias, J.; Roos, J.; Wang, Z.; Qi, Y. Impact of Particle Characteristics and Engine Conditions on Deposit Induced Preignition and Superknock in Turbocharged Gasoline Engines; SAE 2017-01-2345; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Long, Y.; Wang, Z.; Qi, Y.; Xiang, S.; Zeng, G.; Zhang, P.; He, X.; Gupta, A.; Shao, H.; Wang, Y. Effect of Oil and Gasoline Properties on Pre-Ignition and Super-Knock in a Thermal Research Engine (TRE) and an Optical Rapid Compression Machine (RCM); SAE 2016-01-0720; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Gupta, A.; Shao, H.; Remias, J.; Roos, J.; Wang, Y.; Long, Y.; Wang, Z.; Shuai, S.-J. Relative Impact of Chemical and Physical Properties of the Oil-Fuel Droplet on Pre-Ignition and Super-Knock in Turbocharged Gasoline Engines; SAE 2016-01-2278; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Fletcher, K.A.; Dingwell, L.; Yang, K.; Lam, W.Y.; Styer, J.P. Engine Oil Additive Impacts on Low Speed Pre-Ignition; SAE 2016-01-2277; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Roos, J.; Gupta, A.; Shao, H.; Remias, J.; Wang, Y.-H.; Yan, L.; Wang, Z.; Shuai, S.-J. The Effect of Oil Droplet Characteristics on Preignition and Superknock in Turbocharged Gasoline Engines. In Proceedings of the 5th Aachen Colloquium China Automobile and Engine Technology 2015, Beijing, China, 5–6 November 2015. [Google Scholar]

- Fletcher, K.A.; Gupta, A.; Garelick, K.; Pollard, G.; Guevremont, J. Balancing Friction and Wear in Next Generation Engine Oils with New Formulation Constraints Introduced with Low Speed Pre-Ignition. In Proceedings of the 2015 STLE Tribology Frontiers, Denver, CO, USA, 25–27 October 2015. [Google Scholar]

- Yang, S.; Reddyhoff, T.; Spikes, H. Influence of Lubricant Properties on ARKL Temperature Rise and Transmission Efficiency. Tribol. Trans. 2013, 56, 1119–1136. [Google Scholar] [CrossRef]

- Bitsis, D.; Miwa, J. Optimization of Heavy Duty Diesel Engine Lubricant and Coolant Pumps for Parasitic Loss Reduction; SAE 2018-01-0980; SAE: Warrendale, PA, USA, 2018. [Google Scholar]

- Hong, H.-S.; Engel, C.; Filippini, B.; Slocum, S.; Qureshi, F.; Higuchi, T. Challenging Conventional Wisdom by Utilizing Group II Base Oils in Fuel Efficient Axle Oils; SAE 2017-01-2356; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Tormos, B.; Ramirez, L.; Miro, G.; Perez, T. Real World Fleet Test to Determine the Impact of Low Viscosity Engine Oils from Heavy-Duty CNG and Diesel Buses—Part I: Fuel Consumption; SAE 2017-01-2353; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Seth, S.; Maloth, S.; Kumar, P.; Tyagi, B.; Kumar, L.; Mahapatra, R.; Garg, S.; Saxena, D.; Suresh, R.; Ramakumar, S. New Generation Fuel Efficient Engine Oils with Superior Viscometrics; SAE 2017-01-2349; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Kocsis, M.C.; Morgan, P.; Michlberger, A.; Delbridge, E.E.; Smith, O. Optimizing Engine Oils for Fuel Economy with Advanced Test Methods; SAE 2017-01-2348; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Taylor, R.; Hu, H.; Stow, C.; Davenport, T.; Mainwaring, R.; Rappaport, S.; Remmert, S. Extending the Limits of Fuel Economy through Lubrication; SAE 2017-01-2344; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Brandt, A.; Comfort, A.; Frame, E. Development of a Stationary Axle Efficiency Test Stand and Methodology for Identifying Fuel Efficient Gear Oils for Military Applications—Part 1; SAE 2017-01-0889; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Kumar, P.; Mathai, R.; Kumar, S.; Kachhawa, A.; Sehgal, A.K.; Praharaj, S. Fuel Economy Benefits with Low Viscosity Engine Oil Formulations on Small Trucks with Chassis Dynamometer Tests; SAE 2017-01-0888; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Michlberger, A.; Morgan, P.; Delbridge, E.E.; Gieselman, M.D.; Kocsis, M. Engine Oil Fuel Economy Testing—A Tale of Two Tests; SAE 2017-01-0882; SAE: Warrendale, PA, USA, 2017. [Google Scholar]

- Singh, S.K.; Singh, S.; Sehgal, A.K. Impact of Low Viscosity Engine Oil on Performance, Fuel Economy and Emissions of Light Duty Diesel Engine; SAE 2016-01-2316; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Morgan, P.; Michlberger, A.; Kocsis, M.; Gieselman, M.; Delbridge, E. Advanced Test Methods Aid in Formulating Engine Oils for Fuel Economy; SAE 2016-01-2269; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Hoshino, T.; Qureshi, F.; Virostko, N.; Schferl, E.; Gajanayake, A.; Hiroki, M.; Higuchi, T.; Ishizaki, K. A Study of Axle Fluid Viscosity and Friction Impact on Axle Efficiency; SAE 2016-01-0899; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Ishikawa, M.; Yamamori, K.; Hirano, S.; Kowalski, T.; Linden, J. Introduction of Fuel Economy Engine Oil Performance Target with New SAE Viscosity Grade; SAE 2016-01-0896; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Taylor, O.P.; Pearson, R.; Stone, R. Reduction of CO2 Emissions through Lubricant Thermal Management During the Warm Up of Passenger Car Engines; SAE 2016-01-0892; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Butcher, R. Spotting the Difference—Measuring Worthwhile Lubricant Related CO2 Benefits; SAE 2016-01-0890; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- Ito, A.; Chubachi, Y.; Yamamoto, T.; Tanaka, N.; Moriizumi, Y.; Yari, K.; Otterholm, B. A Study on Effects of Low Viscosity Engine Oil and MoDTC on Piston Friction Losses in a DI Diesel Engine; SAE 2015-01-2044; SAE: Warrendale, PA, USA, 2015. [Google Scholar]

- Jang, J.; Lee, Y.-J.; Kwon, O.; Lee, M.; Kim, J. The Effect of Engine Oil on Particulate Matter, Emissions and Fuel Economy in Gasoline and Diesel Vehicle; SAE 2014-01-2837; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Evans, S.D. Delivering Axle Efficiency and Fuel Economy through Optimised Fluid Design; SAE 2014-01-2799; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Macian, V.; Tormos, B.; Ruiz, S.; Roa, L.R.; de Diego, J. In-Use Comparison Test to Evaluate the Effect of Low Viscosity Oils on Fuel Consumption of Diesel and CNG Public Buses; SAE 2014-01-2794; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Browne, D.; Dewey, M.; Graham, S.; Sutton, M.; Munday, M.; Blackshaw, J.; Clegg, A.; Timmis, P. Novel Fuel Efficiency Engine Lubricants for Urban Transit Applications; SAE 2014-01-2793; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Van Dam, W.; Booth, J.; Parsons, G. Taking Heavy Duty Diesel Engine Oil Performance to the Next Level, Part 1: Optimizing for Improved Fuel Economy; SAE 2014-01-2792; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Plumley, M.J.; Wong, V.; Molewyk, M.; Park, S.-Y. Optimizing Base Oil Viscosity Temperature Dependence for Power Cylinder Friction Reduction; SAE 2014-01-1658; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Sagawa, T.; Katayama, T.; Suzuki, R.; Okuda, S. Development of GF-5 0W-SAE 20 Fuel-Saving Engine Oil for DLC-Coated Valve Lifters; SAE 2014-01-1478; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Carvalho, M.; Richard, K.; Goldmints, I.; Tomanik, E. Impact of Lubricant Viscosity and Additives on Engine Fuel Economy; SAE 2014-36-0507; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Ushioda, N.; Miller, T.W.; Sims, C.B.; Parsons, G.; Sztenderowicz, M. Effect of Low Viscosity Passenger Car Motor Oils on Fuel Economy Engine Tests; SAE 2013-01-2606; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Manni, M.; Florio, S. An Experimental Evaluation of the Impact of Ultra Low Viscosity Engine Oils on Fuel Economy and CO2 Emissions; SAE 2013-01-2566; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Carden, P.; Pisani, C.; Andersson, J.; Field, I.; Laine, E.; Bansal, J.; Devine, M. The Effect of Low Viscosity Oil on the Wear, Friction and Fuel Consumption of a Heavy Duty Truck Engine; SAE 2013-01-0331; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Profito, F.J.; Tomanik, E.; Lastres, L.F.; Zachariadis, D.C. Effect of Lubricant Viscosity and Friction Modifier on Reciprocating Tests; SAE 2013-36-0155; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Singh, D.; Shukla, M.; Singh, S.; Singh, Y., Sr.; Singh, N. Fuel Economy of SI Vehicle Fueled by Ethanol/Gasoline Blends—Role of Engine Lubricant Viscosity; SAE 2013-01-0051; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Symonds, M.; Ritchie, C.; Rai, R. Co-Engineering Durable, Fuel Efficient Engine Oils for Diesel Passenger Cars; SAE 2013-26-0004; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Tseregounis, S.I.; McMillan, M.L.; Olree, R. Engine Oil Effects on Fuel Economy in GM Vehicles—Separation of Viscosity and Friction Modifier Effects; SAE 982502; SAE: Warrendale, PA, USA, 1998. [Google Scholar]

- Bovington, C.; Anghel, V.; Spikes, H.A. Predicting Sequence VI and VIA Fuel Economy from Laboratory Bench Tests; SAE 961142; SAE: Warrendale, PA, USA, 1996. [Google Scholar]

- Gangopadhyay, A.K.; Sorab, J.; Willermet, P.A.; Schriewer, K.; Fyfe, K.; Lai, P.K.S. Prediction of ASTM Sequence VI and VIA Fuel Economy Based on Laboratory Bench Tests; SAE 961140; SAE: Warrendale, PA, USA, 1996. [Google Scholar]

- Moore, A.J. Influences of Lubricant Properties on ASTM Sequence VI and Sequence VI-A Fuel Efficiency Performance; SAE 961138; SAE: Warrendale, PA, USA, 1996. [Google Scholar]

- Tseregounis, S.I.; McMillan, M.L. Engine Oil Effects on Fuel Economy in GM Vehicles—Comparison with the ASTM Sequence VI-A Engine Dynamometer Test; SAE 952347; SAE: Warrendale, PA, USA, 1995. [Google Scholar]

- Benchaita, M.T.; Lockwood, F.E. Reliable Models of Lubricant-Related Friction in Internal Combustion Engines. Lubr. Sci. 1993, 5, 259–281. [Google Scholar] [CrossRef]

- Consortium to Develop a New Sequence VID Fuel Efficiency Test for Engine Oils, Final Report. 15 October 2008. Available online: ftp://ftp.astmtmc.cmu.edu/docs/gas/sequencevi/minutes/VID%20ConsortiumMatrixInfo/VID%20Consortium/Final%20Report%2010-16-08.pdf (accessed on 1 June 2018).

| Parameter | Stage 1 | Stage 2 | Stage 3 | Stage 4 | Stage 5 | Stage 6 |

|---|---|---|---|---|---|---|

| Speed, r/min | 2000 ± 5 | 2000 ± 5 | 1500 ± 5 | 695 ± 5 | 695 ± 5 | 695 ± 5 |

| Load Cell, N·m | 105.0 ± 0.1 | 105.0 ± 0.1 | 105.0 ± 0.1 | 20.0 ± 0.1 | 20.0 ± 0.1 | 40.0 ± 0.1 |

| Oil Gallery, °C | 115 ± 2 | 65 ± 2 | 115 ± 2 | 115 ± 2 | 35 ± 2 | 115 ± 2 |

| SAE Viscosity Grade | Low T Cranking Viscosity (mPa·s) ASTM D5293 | Low T Pumping Viscosity (mPa·s) ASTM D4684 | Kinematic Viscosity at 100 °C (mm2/s) ASTM D445 or D7042 | High Shear Viscosity at 150 °C (mPa·s) ASTM D4683, D4741 or D5481 |

|---|---|---|---|---|

| 2009 | ||||

| 0 W | <6200 at −35 °C | <60,000 at −40 °C | >3.8 | |

| 5 W | <6600 at −30 °C | <60,000 at −35 °C | >3.8 | |

| 20 | 6.9–9.3 | >2.6 | ||

| 30 | 9.2–12.5 | >2.9 | ||

| 2015 | ||||

| 0 W | <6200 at −35 °C | <60,000 at −40 °C | >3.8 | |

| 5 W | <6600 at −30 °C | <60,000 at −35 °C | >3.8 | |

| 8 | 4.0–6.1 | >1.7 | ||

| 12 | 5.0–7.1 | >2.0 | ||

| 16 | 6.1–8.2 | >2.3 | ||

| 20 | 6.9–9.3 | >2.6 | ||

| 30 | 9.2–12.5 | >2.9 |

| Oil | Kinematic Viscosity at 100 °C (cSt) | HSV at 100 °C (mPa·s) | Operating Temperature (°C) | HSV at Operating Temperature (mPa·s) |

|---|---|---|---|---|

| GO17 | 14.92 | 11.91 | 104 | 7.72 |

| GO14 | 15.41 | 12.52 | 120 | 7.52 |

| GO13 | 15.79 | 13.02 | 116 | 7.30 |

| GO16 | 16.21 | 13.07 | 119 | 8.10 |

| GO15 | 16.40 | 13.09 | 117 | 8.38 |

| GO20 | 17.66 | 13.94 | 118 | 12.45 |

| GO18 | 16.79 | 14.10 | 116 | 7.30 |

| GO19 | 17.11 | 14.15 | 129 | 9.24 |

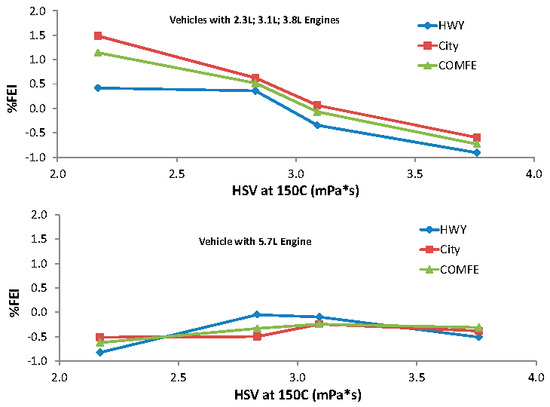

| Fuel Economy Test | %FEI That Results from 20% Reduction in Viscosity | %FEI That Results from 20% Reduction in Boundary Friction | %FEI That Results from 20% Reduction in EHD Friction |

|---|---|---|---|

| COMFE Vehicles with 2.3 L, 3.1 L and 3.8 L engines | 1.2% | 0.4% | 0.5% |

| COMFE Vehicle with 5.7 L engine | 0.0 | 0.6 | 0.0 |

| Sequence VIB | 2.0 | 0.3 | 0.4 |

| Sequence VID | 0.2 | 0.3 | 0.2 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Devlin, M.T. Common Properties of Lubricants that Affect Vehicle Fuel Efficiency: A North American Historical Perspective. Lubricants 2018, 6, 68. https://doi.org/10.3390/lubricants6030068

Devlin MT. Common Properties of Lubricants that Affect Vehicle Fuel Efficiency: A North American Historical Perspective. Lubricants. 2018; 6(3):68. https://doi.org/10.3390/lubricants6030068

Chicago/Turabian StyleDevlin, Mark T. 2018. "Common Properties of Lubricants that Affect Vehicle Fuel Efficiency: A North American Historical Perspective" Lubricants 6, no. 3: 68. https://doi.org/10.3390/lubricants6030068