Multi-Scale Surface Texturing in Tribology—Current Knowledge and Future Perspectives

Abstract

:1. Introduction

2. Fabrication Strategies for Multi-Scale Surface Textures

2.1. Multi-Step Processes

2.2. Single-Step Processes

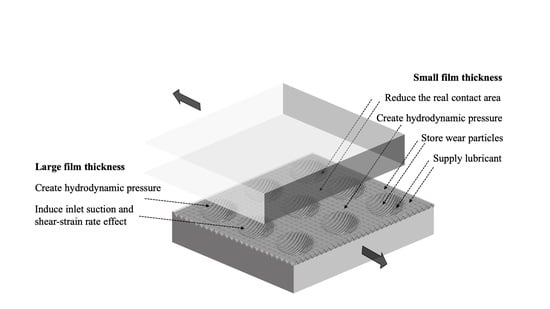

3. Effect of Multi-Scale Textures on Friction and Wear—Experimental Studies

4. Effect of Multi-Scale Textures on Friction and Wear—Numerical Approaches

4.1. CFD Modeling

4.2. Reynolds-Type Equation Modeling

4.2.1. Full Deterministic Methods

4.2.2. Analytical Multi-Scale Methods

Averaging Flow Methods

Homogenization Methods

4.2.3. Semi-Deterministic Methods

4.3. Numerical Multi-Scale Modeling

5. Summary and Future Trends

- (i)

- the modeling approaches previously described to accurately predict the tribological behavior of textured surfaces under different lubrication regimes,

- (ii)

- optimization techniques and, potentially, the use of machine learning algorithms to speed-up the determination of optimum texture designs for friction and wear reduction in different applications,

- (iii)

- the exploration of nature-inspired multi-scale textures for tribological applications.

- (1)

- The effect of surface texture on the global, component-size scale would be determined on the basis of well-posed analytical multi-scale methods. Good candidates are the Patir and Cheng average flow model [151,152], the micro-macro method of de Kraker et al. [155,156], as well as the homogenization techniques proposed by Almqvist [176,177,178,179,180,181,182,183,184,185], Scaraggi [189,190,191,192,193] and the extension of Wassem et at. [197,198] and Yildiran et al. [199] models to mixed lubrication.

- (2)

- Proper calculation of flow factor (or homogenization) tensors using full deterministic simulations. In this case, an extension of the Hu and Zhu mixed-TEHL model [111,114,115,117,121,126] by including mass-conservative cavitation and advanced rheological models for better predictions of the shear flow factor tensors would be a good alternative.

- (3)

- Use of powerful computational techniques and algorithms, such as multi-grid methods and parallel computing, to speed up deterministic simulations for the determination of flow factor tensors.

- (4)

- Explore the use of numerical multi-scale methods, such as domain decomposition methods and numerical discretization schemes, to model and simulate lubrication problems with multi-scale surface textures.

- (5)

- Development of a computational surface engineering simulation framework as an open source project available to the entire tribology community. Furthermore, the construction of an open source library for storing the flow factors and other important simulation parameters obtained from previously simulated surface textures would be helpful, which, in turn, could be used to accelerate the innovative texture design and optimization for a wide range of surface textures.

Author Contributions

Funding

Conflicts of Interest

References

- Dowson, D. History of Tribology; Longman: London, UK, 1979; ISBN 978-0-582-44766-0. [Google Scholar]

- Williams, J. Engineering Tribology; Cambridge University Press: Cambridge, UK, 2005; ISBN 9780511805905. [Google Scholar]

- Amontons, G. De la résistance causée dans les machines. Mémoires l’Académie R. A 1699, 257–282. [Google Scholar]

- Gao, J.; Luedtke, W.D.; Gourdon, D.; Ruths, M.; Israelachvili, J.N.; Landman, U. Frictional forces and Amontons’ law: From the molecular to the macroscopic scale. J. Phys. Chem. B 2004, 108, 3410–3425. [Google Scholar] [CrossRef]

- Bowden, F.P.; Tabor, D. Mechanism of metallic friction. Nature 1942, 150, 197–199. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Williamson, J.B.P. Contact of Nominally Flat Surfaces. Proc. R. Soc. A Math. Phys. Eng. Sci. 1966, 295, 300–319. [Google Scholar]

- Nosonovsky, M.; Bhushan, B. Multiscale Dissipative Mechanisms and Hierarchical Surfaces; NanoScience and Technology; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-78424-1. [Google Scholar]

- Liu, Z.; Yin, W.; Tao, D.; Tian, Y. A glimpse of superb tribological designs in nature. Biotribology 2015, 1, 11–23. [Google Scholar] [CrossRef]

- Malshe, A.P.; Bapat, S.; Rajurkar, K.P.; Haitjema, H. Bio-inspired textures for functional applications. CIRP Ann. 2018, 67, 627–650. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, Z.; Zhang, S. Advances in the application of biomimetic surface engineering in the oil and gas industry. Friction 2019, 7, 289–306. [Google Scholar] [CrossRef] [Green Version]

- Dean, B.; Bhushan, B. Shark-skin surfaces for fluid-drag reduction in turbulent flow: A review. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 4775–4806. [Google Scholar] [CrossRef]

- Bixler, G.D.; Bhushan, B. Fluid drag reduction with shark-skin riblet inspired microstructured surfaces. Adv. Funct. Mater. 2013, 23, 4507–4528. [Google Scholar] [CrossRef]

- Greiner, C.; Arzt, E.; Del Campo, A. Hierarchical gecko-like adhesives. Adv. Mater. 2009, 21, 479–482. [Google Scholar] [CrossRef]

- Murphy, M.P.; Kim, S.; Sitti, M. Enhanced adhesion by gecko-inspired hierarchical fibrillar adhesives. ACS Appl. Mater. Interfaces 2009, 1, 849–855. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Bhushan, B. Nanomanufacturing of bioinspired surfaces. Tribol. Int. 2019, 129, 67–74. [Google Scholar] [CrossRef]

- Koch, K.; Bhushan, B.; Jung, Y.C.; Barthlott, W. Fabrication of artificial Lotus leaves and significance of hierarchical structure for superhydrophobicity and low adhesion. Soft Matter 2009, 5, 1386. [Google Scholar] [CrossRef]

- Lin, J.; Cai, Y.; Wang, X.; Ding, B.; Yu, J.; Wang, M. Fabrication of biomimetic superhydrophobic surfaces inspired by lotus leaf and silver ragwort leaf. Nanoscale 2011, 3, 1258–1262. [Google Scholar] [CrossRef]

- Etsion, I. Improving tribological performance of mechanical components by laser surface texturing. Tribol. Lett. 2004, 17, 733–737. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef] [Green Version]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372–373, 21–41. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Grützmacher, P.G.; Gachot, C.; Costa, H.L. Surface Texturing in Machine Elements—A Critical Discussion for Rolling and Sliding Contacts. Adv. Eng. Mater. 2019, 21, 1900194. [Google Scholar] [CrossRef]

- Sudeep, U.; Tandon, N.; Pandey, R.K. Performance of Lubricated Rolling/Sliding Concentrated Contacts With Surface Textures: A Review. J. Tribol. 2015, 137, 031501. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Costa, H.L.; Profito, F.; Gachot, C.; Medina, S.; Dini, D. Influence of surface texturing on hydrodynamic friction in plane converging bearings—An experimental and numerical approach. Tribol. Int. 2019, 134, 190–204. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribol. Int. 2007, 40, 1227–1238. [Google Scholar] [CrossRef]

- Fowell, M.; Olver, A.V.; Gosman, A.D.; Spikes, H.A.; Pegg, I. Entrainment and Inlet Suction: Two Mechanisms of Hydrodynamic Lubrication in Textured Bearings. J. Tribol. 2007, 129, 336. [Google Scholar] [CrossRef]

- Fowell, M.T.; Medina, S.; Olver, A.V.; Spikes, H.A.; Pegg, I.G. Parametric study of texturing in convergent bearings. Tribol. Int. 2012, 52, 7–16. [Google Scholar] [CrossRef]

- Vlădescu, S.C.; Ciniero, A.; Tufail, K.; Gangopadhyay, A.; Reddyhoff, T. Looking into a laser textured piston ring-liner contact. Tribol. Int. 2017, 115, 140–153. [Google Scholar] [CrossRef]

- Profito, F.J.; Vlădescu, S.C.; Reddyhoff, T.; Dini, D. Transient experimental and modelling studies of laser-textured micro-grooved surfaces with a focus on piston-ring cylinder liner contacts. Tribol. Int. 2017, 113, 125–136. [Google Scholar] [CrossRef]

- Dobrica, M.B.; Fillon, M.; Pascovici, M.D.; Cicone, T. Optimizing surface texture for hydrodynamic lubricated contacts using a mass-conserving numerical approach. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 737–750. [Google Scholar] [CrossRef]

- Erdemir, A. Review of engineered tribological interfaces for improved boundary lubrication. Tribol. Int. 2005, 38, 249–256. [Google Scholar] [CrossRef]

- Pettersson, U.; Jacobson, S. Influence of surface texture on boundary lubricated sliding contacts. Tribol. Int. 2003, 36, 857–864. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Heib, T.; Gachot, C.; Mücklich, F. Oil film lifetime and wear particle analysis of laser-patterned stainless steel surfaces. Wear 2015, 334–335, 1–12. [Google Scholar] [CrossRef]

- Braun, D.; Greiner, C.; Schneider, J.; Gumbsch, P. Efficiency of laser surface texturing in the reduction of friction under mixed lubrication. Tribol. Int. 2014, 77, 142–147. [Google Scholar] [CrossRef]

- Ramesh, A.; Akram, W.; Mishra, S.P.; Cannon, A.H.; Polycarpou, A.A.; King, W.P. Friction characteristics of microtextured surfaces under mixed and hydrodynamic lubrication. Tribol. Int. 2013, 57, 170–176. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Reinert, L.; Ramos-Moore, E.; Souza, N.; Müser, M.H.; Mücklich, F. Dry friction between laser-patterned surfaces: Role of alignment, structural wavelength and surface chemistry. Tribol. Lett. 2013, 49, 193–202. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Reinert, L.; Gachot, C.; Mücklich, F. Alignment and wear debris effects between laser-patterned steel surfaces under dry sliding conditions. Wear 2014, 318, 49–61. [Google Scholar] [CrossRef]

- Prodanov, N.; Gachot, C.; Rosenkranz, A.; Mücklich, F.; Müser, M.H. Contact mechanics of laser-textured surfaces: Correlating contact area and friction. Tribol. Lett. 2013, 50, 41–48. [Google Scholar] [CrossRef]

- Abdel-Aal, H.A. Functional surfaces for tribological applications: Inspiration and design. Surf. Topogr. Metrol. Prop. 2016, 4, 1–37. [Google Scholar] [CrossRef]

- Costa, H.L.L.; Hutchings, I.M. Some innovative surface texturing techniques for tribological purposes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 429–448. [Google Scholar] [CrossRef]

- Coblas, D.G.; Fatu, A.; Maoui, A.; Hajjam, M. Manufacturing textured surfaces: State of art and recent developments. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 3–29. [Google Scholar] [CrossRef]

- Abdel-Aal, H.A.; El Mansori, M. Tribological analysis of the ventral scale structure in a Python regius in relation to laser textured surfaces. Surf. Topogr. Metrol. Prop. 2013, 1. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, J.; Guo, X.; Zhang, Q.; Wang, J.; Ding, J.; Yuan, N. Fabrication and tribological properties of superhydrophobic nickel films with positive and negative biomimetic microtextures. Friction 2014, 2, 287–294. [Google Scholar] [CrossRef] [Green Version]

- Shafiei, M.; Alpas, A.T. Fabrication of biotextured nanocrystalline nickel films for the reduction and control of friction. Mater. Sci. Eng. C 2008, 28, 1340–1346. [Google Scholar] [CrossRef]

- Shafiei, M.; Alpas, A.T. Nanocrystalline nickel films with lotus leaf texture for superhydrophobic and low friction surfaces. Appl. Surf. Sci. 2009, 256, 710–719. [Google Scholar] [CrossRef]

- Resendiz, J.; Egberts, P.; Park, S.S. Tribological Behavior of Multi-scaled Patterned Surfaces Machined Through Inclined End Milling and Micro Shot Blasting. Tribol. Lett. 2018, 66, 132. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Rosenkranz, A.; Szurdak, A.; Gachot, C.; Hirt, G.; Mücklich, F. Effects of Multi-Scale Patterning on the Run-In Behavior of Steel-Alumina Pairings under Lubricated Conditions. Adv. Eng. Mater. 2018, 20, 1700521. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Rosenkranz, A.; Szurdak, A.; Gachot, C.; Hirt, G.; Mücklich, F. Lubricant migration on stainless steel induced by bio-inspired multi-scale surface patterns. Mater. Des. 2018, 150, 55–63. [Google Scholar] [CrossRef]

- Rukosuyev, M.V.; Lee, J.; Cho, S.J.; Lim, G.; Jun, M.B.G.G. One-step fabrication of superhydrophobic hierarchical structures by femtosecond laser ablation. Appl. Surf. Sci. 2014, 313, 411–417. [Google Scholar] [CrossRef]

- Jagdheesh, R.; García-Ballesteros, J.J.; Ocaña, J.L. One-step fabrication of near superhydrophobic aluminum surface by nanosecond laser ablation. Appl. Surf. Sci. 2015, 374, 2–11. [Google Scholar] [CrossRef]

- Martínez-Calderon, M.; Rodríguez, A.; Dias-Ponte, A.; Morant-Miñana, M.C.C.; Gómez-Aranzadi, M.; Olaizola, S.M.M. Femtosecond laser fabrication of highly hydrophobic stainless steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS. Appl. Surf. Sci. 2016, 374, 81–89. [Google Scholar] [CrossRef]

- Long, J.; Fan, P.; Zhong, M.; Zhang, H.; Xie, Y.; Lin, C. Superhydrophobic and colorful copper surfaces fabricated by picosecond laser induced periodic nanostructures. Appl. Surf. Sci. 2014, 311, 461–467. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Wietbrock, B.; Hirt, G.; Mücklich, F. Advanced Design of Hierarchical Topographies in Metallic Surfaces by Combining Micro-Coining and Laser Interference Patterning. Adv. Eng. Mater. 2013, 15, 503–509. [Google Scholar] [CrossRef]

- Hsu, S.M.; Jing, Y.; Zhao, F. Self-adaptive surface texture design for friction reduction across the lubrication regimes. Surf. Topogr. Metrol. Prop. 2016, 4, 014004. [Google Scholar] [CrossRef]

- Sugioka, K.; Meunier, M.; Piqué, A. (Eds.) Laser Precision Microfabrication; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2010; Volume 135, ISBN 978-3-642-10522-7. [Google Scholar]

- Vorobyev, A.Y.; Guo, C. Direct femtosecond laser surface nano/microstructuring and its applications. Laser Photonics Rev. 2013, 7, 385–407. [Google Scholar] [CrossRef]

- Marczak, J. Micromachining And Pattering In Micro/Nano Scale On Macroscopic Areas. Arch. Metall. Mater. 2015, 60, 2221–2234. [Google Scholar] [CrossRef]

- Kirner, S.V.; Hermens, U.; Mimidis, A.; Skoulas, E.; Florian, C.; Hischen, F.; Plamadeala, C.; Baumgartner, W.; Winands, K.; Mescheder, H.; et al. Mimicking bug-like surface structures and their fluid transport produced by ultrashort laser pulse irradiation of steel. Appl. Phys. A Mater. Sci. Process. 2017, 123, 1–13. [Google Scholar] [CrossRef]

- Hermens, U.; Kirner, S.V.; Emonts, C.; Comanns, P.; Skoulas, E.; Mimidis, A.; Mescheder, H.; Winands, K.; Krüger, J.; Stratakis, E.; et al. Mimicking lizard-like surface structures upon ultrashort laser pulse irradiation of inorganic materials. Appl. Surf. Sci. 2017, 418, 499–507. [Google Scholar] [CrossRef]

- Neuenschwander, B.; Jaeggi, B.; Schmid, M.; Hennig, G. Surface Structuring with Ultra-short Laser Pulses: Basics, Limitations and Needs for High Throughput. Phys. Procedia 2014, 56, 1047–1058. [Google Scholar] [CrossRef] [Green Version]

- Mücklich, F.; Lasagni, A.F.; Daniel, C. Laser interference metallurgy—Using interference as a tool for micro/nano structuring. Int. J. Mater. Res. 2006, 97, 1337–1344. [Google Scholar] [CrossRef]

- Leitz, K.-H.; Redlingshöfer, B.; Reg, Y.; Otto, A.; Schmidt, M. Metal Ablation with Short and Ultrashort Laser Pulses. Phys. Procedia 2011, 12, 230–238. [Google Scholar] [CrossRef] [Green Version]

- Segu, D.Z.; Hwang, P. Effectiveness of multi-shape laser surface texturing in the reduction of friction under lubrication regime. Ind. Lubr. Tribol. 2016, 68, 116–124. [Google Scholar] [CrossRef]

- Segu, D.Z.; Choi, S.G.; Choi, J.H.; Kim, S.S. The effect of multi-scale laser textured surface on lubrication regime. Appl. Surf. Sci. 2013, 270, 58–63. [Google Scholar] [CrossRef]

- Zenebe Segu, D.; Hwang, P. Friction control by multi-shape textured surface under pin-on-disc test. Tribol. Int. 2015, 91, 111–117. [Google Scholar] [CrossRef]

- Kwon, Y.; Patankar, N.; Choi, J.; Lee, J. Design of surface hierarchy for extreme hydrophobicity. Langmuir 2009, 25, 6129–6136. [Google Scholar] [CrossRef] [PubMed]

- Rupp, F.; Scheideler, L.; Rehbein, D.; Axmann, D.; Geis-Gerstorfer, J. Roughness induced dynamic changes of wettability of acid etched titanium implant modifications. Biomaterials 2004, 25, 1429–1438. [Google Scholar] [CrossRef] [PubMed]

- Rosenkranz, A.; Grützmacher, P.G.; Szurdak, A.; Gachot, C.; Hirt, G.; Mücklich, F.; Muecklich, F. Synergetic effect of laser patterning and micro coining for controlled lubricant propagation. Surf. Topogr. Metrol. Prop. 2016, 4, 034008. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Grützmacher, P.G.; Murzyn, K.; Mathieu, C.; Mücklich, F. Multi-scale surface patterning to tune friction under mixed lubricated conditions. Appl. Nanosci. 2019. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Rosenkranz, A.; Szurdak, A.; Grüber, M.; Gachot, C.; Hirt, G.; Mücklich, F. Multi-scale surface patterning—An approach to control friction and lubricant migration in lubricated systems. Ind. Lubr. Tribol. 2019, 71, 1007–1016. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Rosenkranz, A.; Szurdak, A.; König, F.; Jacobs, G.; Hirt, G.; Mücklich, F. From lab to application—Improved frictional performance of journal bearings induced by single- and multi-scale surface patterns. Tribol. Int. 2018, 127, 500–508. [Google Scholar] [CrossRef]

- Kim, M.; Lee, S.M.; Lee, S.J.; Kim, Y.W.; Lee, D.W. Effect on friction reduction of micro/nano hierarchical patterns on sapphire wafers. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 27–35. [Google Scholar] [CrossRef]

- Akkan, C.K.; Hammadeh, M.E.; May, A.; Park, H.W.; Abdul-Khaliq, H.; Strunskus, T.; Aktas, O.C. Surface topography and wetting modifications of PEEK for implant applications. Lasers Med. Sci. 2014, 29, 1633–1639. [Google Scholar] [CrossRef]

- Fürstner, R.; Barthlott, W.; Neinhuis, C.; Walzel, P. Wetting and self-cleaning properties of artificial superhydrophobic surfaces. Langmuir 2005, 21, 956–961. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, J.T.; Aguilar-Morales, A.I.; Alamri, S.; Huerta-Murillo, D.; Cordovilla, F.; Lasagni, A.F.; Ocaña, J.L. Superhydrophobicity on hierarchical periodic surface structures fabricated via direct laser writing and direct laser interference patterning on an aluminium alloy. Opt. Lasers Eng. 2018, 111, 193–200. [Google Scholar] [CrossRef]

- Huerta-Murillo, D.; Aguilar-Morales, A.I.; Alamri, S.; Cardoso, J.T.; Jagdheesh, R.; Lasagni, A.F.; Ocaña, J.L. Fabrication of multi-scale periodic surface structures on Ti-6Al-4V by direct laser writing and direct laser interference patterning for modified wettability applications. Opt. Lasers Eng. 2017, 98, 134–142. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Guo, X.; Sun, L.; Lei, S. Study on the adhesion and tribological behavior of PVD TiAlN coatings with a multi-scale textured substrate surface. Int. J. Refract. Met. Hard Mater. 2018, 72, 292–305. [Google Scholar] [CrossRef]

- Bhushan, B.; Koch, K.; Jung, Y.C. Nanostructures for superhydrophobicity and low adhesion. Soft Matter 2008, 4, 1799. [Google Scholar] [CrossRef]

- Zhang, F.; Low, H.Y. Anisotropic wettability on imprinted hierarchical structures. Langmuir 2007, 23, 7793–7798. [Google Scholar] [CrossRef]

- Tanvir Ahmmed, K.M.; Kietzig, A.M. Drag reduction on laser-patterned hierarchical superhydrophobic surfaces. Soft Matter 2016, 12, 4912–4922. [Google Scholar] [CrossRef]

- Qiu, R.; Wang, P.; Zhang, D.; Wu, J. One-step preparation of hierarchical cobalt structure with inborn superhydrophobic effect. Colloids Surf. A Physicochem. Eng. Asp. 2011, 377, 144–149. [Google Scholar] [CrossRef]

- Wu, B.; Zhou, M.; Li, J.; Ye, X.; Li, G.; Cai, L. Superhydrophobic surfaces fabricated by microstructuring of stainless steel using a femtosecond laser. Appl. Surf. Sci. 2009, 256, 61–66. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Wang, S.; Wood, R.J.K.; Xue, Q. From natural lotus leaf to highly hard-flexible diamond-like carbon surface with superhydrophobic and good tribological performance. Surf. Coat. Technol. 2012, 206, 2258–2264. [Google Scholar] [CrossRef]

- Abdel-Aal, H.A.; El Mansori, M.; Mezghani, S. Multi-scale investigation of surface topography of ball python (python regius) shed skin in comparison to human skin. Tribol. Lett. 2010, 37, 517–527. [Google Scholar] [CrossRef]

- Abdel-Aal, H.A.; Vargiolu, R.; Zahouani, H.; El Mansori, M. A study on the frictional response of reptilian shed skin. J. Phys. Conf. Ser. 2011, 311, 012016. [Google Scholar] [CrossRef]

- Cuervo, P.; López, D.A.; Cano, J.P.; Sánchez, J.C.; Rudas, S.; Estupiñán, H.; Toro, A.; Abdel-Aal, H.A. Development of low friction snake-inspired deterministic textured surfaces. Surf. Topogr. Metrol. Prop. 2016, 4, 1–17. [Google Scholar] [CrossRef]

- Greiner, C.; Schäfer, M. Bio-inspired scale-like surface textures and their tribological properties. Bioinspiration Biomim. 2015, 10, 44001. [Google Scholar] [CrossRef] [PubMed]

- Schneider, J.; Djamiykov, V.; Greiner, C. Friction reduction through biologically inspired scale-like laser surface textures. Beilstein J. Nanotechnol. 2018, 9, 2561–2572. [Google Scholar] [CrossRef]

- Wang, X.; Kato, K.; Adachi, K.; Aizawa, K. Loads carrying capacity map for the surface texture design of SiC thrust bearing sliding in water. Tribol. Int. 2003, 36, 189–197. [Google Scholar] [CrossRef]

- Wang, X.; Adachi, K.; Otsuka, K.; Kato, K. Optimization of the surface texture for silicon carbide sliding in water. Appl. Surf. Sci. 2006, 253, 1282–1286. [Google Scholar] [CrossRef]

- Yu, H.; Huang, W.; Wang, X. Dimple patterns design for different circumstances. Lubr. Sci. 2013, 25, 67–78. [Google Scholar] [CrossRef]

- Hsu, S.M.; Jing, Y.; Hua, D.; Zhang, H. Friction reduction using discrete surface textures: Principle and design. J. Phys. D. Appl. Phys. 2014, 47, 335307. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Szurdak, A.; Gachot, C.; Hirt, G.; Mücklich, F. Friction reduction under mixed and full film EHL induced by hot micro-coined surface patterns. Tribol. Int. 2016, 95, 290–297. [Google Scholar] [CrossRef]

- Choi, H.; Moin, P.; Kim, J. Direct numerical simulation of turbulent flow over riblets. J. Fluid Mech. 1993, 255, 503. [Google Scholar] [CrossRef]

- Choi, H.; Moin, P.; Kim, J. Active turbulence control for drag reduction in wall-bounded flows. J. Fluid Mech. 1994, 262, 75–110. [Google Scholar] [CrossRef]

- Zhang, D.; Luo, Y.; Li, X.; Chen, H. Numerical Simulation and Experimental Study of Drag-Reducing Surface of a Real Shark Skin. J. Hydrodyn. 2011, 23, 204–211. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, Y.; Zhang, D.; NG, E.Y.K. Influence of morphology for drag reduction effect of sharkskin surface. J. Mech. Med. Biol. 2014, 14, 1450029. [Google Scholar] [CrossRef]

- Luo, Y.; Yuan, L.; Li, J.; Wang, J. Boundary layer drag reduction research hypotheses derived from bio-inspired surface and recent advanced applications. Micron 2015, 79, 59–73. [Google Scholar] [CrossRef] [PubMed]

- Martin, S.; Bhushan, B. Modeling and optimization of shark-inspired riblet geometries for low drag applications. J. Colloid Interface Sci. 2016, 474, 206–215. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.F.; Yuan, C.Q.; Bai, X.Q. Marine drag reduction of shark skin inspired riblet surfaces. Biosurface Biotribol. 2017, 3, 11–24. [Google Scholar] [CrossRef]

- Belhadjamor, M.; Belghith, S.; Mezlini, S.; El Mansori, M. Effect of the surface texturing scale on the self-clean function: Correlation between mechanical response and wetting behavior. Tribol. Int. 2017, 111, 91–99. [Google Scholar] [CrossRef]

- Brajdic-Mitidieri, P.; Gosman, A.D.; Ioannides, E.; Spikes, H.A. CFD Analysis of a Low Friction Pocketed Pad Bearing. J. Tribol. 2005, 127, 803. [Google Scholar] [CrossRef]

- Vakilian, M.; Gandjalikhan Nassab, S.A.; Kheirandish, Z. CFD-Based Thermohydrodynamic Analysis of Rayleigh Step Bearings Considering an Inertia Effect. Tribol. Trans. 2014, 57, 123–133. [Google Scholar] [CrossRef]

- Ai, X.; Cheng, H.S.; Zheng, L. A Transient Model for Micro-Elastohydrodynamic Lubrication With Three-Dimensional Irregularities. J. Tribol. 1993, 115, 102. [Google Scholar] [CrossRef]

- Chang, L.; Cusano, C.; Conry, T.F. Effects of Lubricant Rheology and Kinematic Conditions on Micro-Elastohydrodynamic Lubrication. J. Tribol. 1989, 111, 344. [Google Scholar] [CrossRef]

- Chang, L.; Webster, M.N.; Jackson, A. A Line-Contact Micro-EHL Model With Three-Dimensional Surface Topography. J. Tribol. 1994, 116, 21. [Google Scholar] [CrossRef]

- Kweh, C.C.; Evans, H.P.; Snidle, R.W. Micro-Elastohydrodynamic Lubrication of an Elliptical Contact With Transverse and Three-Dimensional Sinusoidal Roughness. J. Tribol. 1989, 111, 577. [Google Scholar] [CrossRef]

- Lubrecht, A.A.; Ten Napel, W.E.; Bosma, R. The Influence of Longitudinal and Transverse Roughness on the Elastohydrodynamic Lubrication of Circular Contacts. J. Tribol. 1988, 110, 421. [Google Scholar] [CrossRef]

- Kweh, C.C.; Patching, M.J.; Evans, H.P.; Snidle, R.W. Simulation of Elastohydrodynamic Contacts Between Rough Surfaces. J. Tribol. 1992, 114, 412. [Google Scholar] [CrossRef]

- Venner, C.H.; ten Napel, W.E. Surface Roughness Effects in an EHL Line Contact. J. Tribol. 1992, 114, 616. [Google Scholar] [CrossRef]

- Zhu, D.; Ai, X. Point Contact EHL Based on Optically Measured Three-Dimensional Rough Surfaces. J. Tribol. 1997, 119, 375. [Google Scholar] [CrossRef]

- Xu, G.; Sadeghi, F. Thermal EHL Analysis of Circular Contacts With Measured Surface Roughness. J. Tribol. 1996, 118, 473. [Google Scholar] [CrossRef]

- Hu, Y.-Z.; Zhu, D. A Full Numerical Solution to the Mixed Lubrication in Point Contacts. J. Tribol. 2000, 122, 1. [Google Scholar] [CrossRef]

- Zhu, D.; Hu, Y.-Z. A Computer Program Package for the Prediction of EHL and Mixed Lubrication Characteristics, Friction, Subsurface Stresses and Flash Temperatures Based on Measured 3-D Surface Roughness. Tribol. Trans. 2001, 44, 383–390. [Google Scholar] [CrossRef]

- Zhu, D.; Jane Wang, Q. Effect of Roughness Orientation on the Elastohydrodynamic Lubrication Film Thickness. J. Tribol. 2013, 135, 031501. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Y.; Zhu, D. Numerical Solution of Mixed Thermal Elastohydrodynamic Lubrication in Point Contacts With Three-Dimensional Surface Roughness. J. Tribol. 2016, 139, 011501. [Google Scholar] [CrossRef]

- Ren, N.; Nanbu, T.; Yasuda, Y.; Zhu, D.; Wang, Q. Micro Textures in Concentrated-Conformal-Contact Lubrication: Effect of Distribution Patterns. Tribol. Lett. 2007, 28, 275–285. [Google Scholar] [CrossRef]

- Wang, Q.J.; Zhu, D.; Zhou, R.; Hashimoto, F. Investigating the Effect of Surface Finish on Mixed EHL in Rolling and Rolling-Sliding Contacts. Tribol. Trans. 2008, 51, 748–761. [Google Scholar] [CrossRef]

- Zhu, D.; Hu, Y.-Z. Effects of Rough Surface Topography and Orientation on the Characteristics of EHD and Mixed Lubrication in Both Circular and Elliptical Contacts. Tribol. Trans. 2001, 44, 391–398. [Google Scholar] [CrossRef]

- Wang, Q.J.; Zhu, D. Virtual Texturing: Modeling the Performance of Lubricated Contacts of Engineered Surfaces. J. Tribol. 2005, 127, 722. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Q.J.; Wang, W.; Hu, Y.; Zhu, D. Effects of Differential Scheme and Mesh Density on EHL Film Thickness in Point Contacts. J. Tribol. 2006, 128, 641. [Google Scholar] [CrossRef]

- Zhu, D. On some aspects of numerical solutions of thin-film and mixed elastohydrodynamic lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2007, 221, 561–579. [Google Scholar] [CrossRef]

- Ren, N.; Zhu, D.; Chen, W.W.; Liu, Y.; Wang, Q.J. A Three-Dimensional Deterministic Model for Rough Surface Line-Contact EHL Problems. J. Tribol. 2008, 131, 011501. [Google Scholar] [CrossRef]

- Zhu, D.; Jane Wang, Q. Elastohydrodynamic Lubrication: A Gateway to Interfacial Mechanics—Review and Prospect. J. Tribol. 2011, 133, 041001. [Google Scholar] [CrossRef]

- Zhu, D.; Nanbu, T.; Ren, N.; Yasuda, Y.; Wang, Q.J. Model-based virtual surface texturing for concentrated conformal-contact lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 685–696. [Google Scholar] [CrossRef]

- Demirci, I.; Mezghani, S.; Yousfi, M.; Zahouani, H.; Mansori, M. El The Scale Effect of Roughness on Hydrodynamic Contact Friction. Tribol. Trans. 2012, 55, 705–712. [Google Scholar] [CrossRef]

- Mezghani, S.; Demirci, I.; Zahouani, H.; El Mansori, M. The effect of groove texture patterns on piston-ring pack friction. Precis. Eng. 2012, 36, 210–217. [Google Scholar] [CrossRef] [Green Version]

- Demirci, I.; Mezghani, S.; Yousfi, M.; El Mansori, M. Multiscale Analysis of the Roughness Effect on Lubricated Rough Contact. J. Tribol. 2013, 136, 011501. [Google Scholar] [CrossRef] [Green Version]

- Profito, F.J.; Tomanik, E.; Zachariadis, D.C. Effect of cylinder liner wear on the mixed lubrication regime of TLOCRs. Tribol. Int. 2016, 93, 723–732. [Google Scholar] [CrossRef]

- Li, Y. Multiphase Oil Transport at Complex Micro Geometry; Massachusetts Institute of Technology: Cambridge, MA, USA, 2011. [Google Scholar]

- Li, Y.; Chen, H.; Tian, T. A Deterministic Model for Lubricant Transport within Complex Geometry under Sliding Contact and its Application in the Interaction between the Oil Control Ring and Rough Liner in Internal Combustion Engines. In Proceedings of the SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2010; Volume 1. [Google Scholar]

- Chen, H. Modeling the Lubrication of the Piston Ring Pack of Internal Combustion Engines Using Deterministic Method; Massachusetts Institute of Technology: Cambridge, MA, USA, 2011. [Google Scholar]

- Chen, H.; Li, Y.; Tian, T. A Novel Approach to Model the Lubrication and Friction between the Twin-Land Oil Control Ring and Liner with Consideration of Micro Structure of the Liner Surface Finish in Internal Combustion Engines. In Proceedings of the SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2010; Volume 1. [Google Scholar]

- Liao, K.; Liu, Y.; Kim, D.; Urzua, P.; Tian, T. Practical challenges in determining piston ring friction. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 112–125. [Google Scholar] [CrossRef]

- Tomanik, E.; El Mansori, M.; Souza, R.; Profito, F. Effect of waviness and roughness on cylinder liner friction. Tribol. Int. 2018, 120, 547–555. [Google Scholar] [CrossRef] [Green Version]

- Biboulet, N.; Bouassida, H.; Lubrecht, A.A. Cross hatched texture influence on the load carrying capacity of oil control rings. Tribol. Int. 2015, 82, 12–19. [Google Scholar] [CrossRef]

- Noutary, M.-P.; Biboulet, N.; Lubrecht, A.A. Dimple influence on load carrying capacity of parallel surfaces. Tribol. Int. 2018. [Google Scholar] [CrossRef]

- Noutary, M.-P.; Biboulet, N.; Lubrecht, A.A. A robust piston ring lubrication solver: Influence of liner groove shape, depth and density. Tribol. Int. 2016, 100, 35–40. [Google Scholar] [CrossRef]

- Minet, C.; Brunetière, N.; Tournerie, B. A Deterministic Mixed Lubrication Model for Mechanical Seals. J. Tribol. 2011, 133, 042203. [Google Scholar] [CrossRef]

- Pavliotis, G.A.; Stuart, A.M. Multiscale Methods: Averaging and Homogenization; Texts Applied in Mathematics; Springer: New York, NY, USA, 2008; ISBN 9788578110796. [Google Scholar]

- Cioranescu, D.; Donato, P. An Introduction to Homogenization; Oxford University Press: Oxford, UK, 1999. [Google Scholar]

- Weinan, E. Principles of Multiscale Modeling; Cambridge University Press: Cambridge, UK, 2011; ISBN 9781107096547. [Google Scholar]

- Horstemeyer, M.F. Multiscale Modeling: A Review. In Practical Aspects of Computational Chemistry; Springer: Dordrecht, The Netherlands, 2009; pp. 87–135. ISBN 9789048126866. [Google Scholar]

- Vakis, A.I.; Yastrebov, V.A.; Scheibert, J.; Nicola, L.; Dini, D.; Minfray, C.; Almqvist, A.; Paggi, M.; Lee, S.; Limbert, G.; et al. Modeling and simulation in tribology across scales: An overview. Tribol. Int. 2018, 125, 169–199. [Google Scholar] [CrossRef]

- Tzeng, S.T.; Saibel, E. Surface roughness effect on slider bearing lubrication. ASLE Trans. 1967, 10, 334–348. [Google Scholar] [CrossRef]

- Christensen, H. Stochastic Models for Hydrodynamic Lubrication of Rough Surfaces. Proc. Inst. Mech. Eng. 1969, 184, 1013–1026. [Google Scholar] [CrossRef]

- Christensen, H. Some aspects of the functional influence of surface roughness in lubrication. Wear 1971, 17, 149–162. [Google Scholar] [CrossRef]

- Christensen, H. A Theory of Mixed Lubrication. Proc. Inst. Mech. Eng. 1972, 186, 421–430. [Google Scholar] [CrossRef]

- Chow, L.S.H.; Cheng, H.S. The Effect of Surface Roughness on the Average Film Thickness Between Lubricated Rollers. J. Lubr. Technol. 1976, 98, 117. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. Application of Average Flow Model to Lubrication Between Rough Sliding Surfaces. J. Lubr. Technol. 1979, 101, 220. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. An Average Flow Model for Determining Effects of Three-Dimensional Roughness on Partial Hydrodynamic Lubrication. J. Lubr. Technol. 1978, 100, 12. [Google Scholar] [CrossRef]

- Elrod, H.G. A General Theory for Laminar Lubrication With Reynolds Roughness. J. Lubr. Technol. 1979, 101, 8. [Google Scholar] [CrossRef]

- Tripp, J.H. Surface Roughness Effects in Hydrodynamic Lubrication: The Flow Factor Method. J. Lubr. Technol. 1983, 105, 458. [Google Scholar] [CrossRef]

- de Kraker, A.; van Ostayen, R.A.J.; Rixen, D.J. Development of a texture averaged Reynolds equation. Tribol. Int. 2010, 43, 2100–2109. [Google Scholar] [CrossRef]

- de Kraker, A.; van Ostayen, R.A.J.; van Beek, A.; Rixen, D.J. A Multiscale Method Modeling Surface Texture Effects. J. Tribol. 2007, 129, 221. [Google Scholar] [CrossRef]

- Jocsak, J.; Li, Y.; Tian, T.; Wong, V.W. Analyzing the Effects of Three-Dimensional Cylinder Liner Surface Texture on Ring-Pack Performance with a Focus on Honing Groove Cross-Hatch Angle. In Proceedings of the ASME 2005 Internal Combustion Engine Division Fall Technical Conference (ICEF2005), Ottawa, ON, Canada, 11–14 September 2005; pp. 621–632. [Google Scholar]

- Leighton, M.; Rahmani, R.; Rahnejat, H. Surface-specific flow factors for prediction of friction of cross-hatched surfaces. Surf. Topogr. Metrol. Prop. 2016, 4, 025002. [Google Scholar] [CrossRef] [Green Version]

- Bartel, D.; Bobach, L.; Illner, T.; Deters, L. Simulating transient wear characteristics of journal bearings subjected to mixed friction. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2012, 226, 1095–1108. [Google Scholar] [CrossRef]

- Kim, T.W.; Cho, Y.J. The Flow Factors Considering the Elastic Deformation for the Rough Surface with a Non-Gaussian Height Distribution. Tribol. Trans. 2008, 51, 213–220. [Google Scholar] [CrossRef]

- Peeken, H.J.; Knoll, G.; Rienäcker, A.; Lang, J.; Schönen, R. On the Numerical Determination of Flow Factors. J. Tribol. 1997, 119, 259. [Google Scholar] [CrossRef]

- Pusterhofer, M.; Bergmann, P.; Summer, F.; Grün, F.; Brand, C. A Novel Approach for Modeling Surface Effects in Hydrodynamic Lubrication. Lubricants 2018, 6, 27. [Google Scholar] [CrossRef]

- Dobrica, M.B.; Fillon, M.; Maspeyrot, P. Mixed Elastohydrodynamic Lubrication in a Partial Journal Bearing—Comparison Between Deterministic and Stochastic Models. J. Tribol. 2006, 128, 778. [Google Scholar] [CrossRef]

- Bayada, G.; Chambat, M. New Models in the Theory of the Hydrodynamic Lubrication of Rough Surfaces. J. Tribol. 1988, 110, 402. [Google Scholar] [CrossRef]

- Bayada, G.; Cid, B.; Vázquez, C. Two-scale homogenization study of a Reynolds-Rod elastohydrodynamic model. Math. Model. Methods Appl. Sci. 2003, 13, 259–293. [Google Scholar] [CrossRef]

- Bayada, G.; Faure, J.B. A Double Scale Analysis Approach of the Reynolds Roughness Comments and Application to the Journal Bearing. J. Tribol. 1989, 111, 323. [Google Scholar] [CrossRef]

- Bayada, G.; Martin, S.; Vázquez, C. Two-scale homogenization of a hydrodynamic Elrod–Adams model. Asymptot. Anal. 2005, 44, 75–110. [Google Scholar]

- Bayada, G.; Martin, S.; Vázquez, C. An Average Flow Model of the Reynolds Roughness Including a Mass-Flow Preserving Cavitation Model. J. Tribol. 2005, 127, 793. [Google Scholar] [CrossRef]

- Jai, M. Homogenization and two-scale convergence of the compressible Reynolds lubrication equation modelling the flying characteristics of a rough magnetic head over a rough rigid-disk surface. ESAIM Math. Model. Numer. Anal. 1995, 29, 199–233. [Google Scholar] [CrossRef] [Green Version]

- Jai, M.; Bou-Saïd, B. A Comparison of Homogenization and Averaging Techniques for the Treatment of Roughness in Slip-Flow-Modified Reynolds Equation. J. Tribol. 2002, 124, 327. [Google Scholar] [CrossRef]

- Kane, M.; Bou-Saïd, B. Comparison of Homogenization and Direct Techniques for the Treatment of Roughness in Incompressible Lubrication. J. Tribol. 2004, 126, 733. [Google Scholar] [CrossRef]

- Buscaglia, G.C.; Jai, M. Homogenization of the Generalized Reynolds Equation for Ultra-Thin Gas Films and Its Resolution by FEM. J. Tribol. 2004, 126, 547. [Google Scholar] [CrossRef]

- Buscaglia, G.; Ciuperca, I.; Jai, M. Homogenization of the transient Reynolds equation. Asymptot. Anal. 2002, 32, 131–152. [Google Scholar]

- Buscaglia, G.C.; Jai, M. A new numerical scheme for non uniform homogenized problems: Application to the non linear Reynolds compressible equation. Math. Probl. Eng. 2001, 7, 355–378. [Google Scholar] [CrossRef]

- Prat, M.; Plouraboué, F.; Letalleur, N. Averaged Reynolds equation for flows between rough surfaces in sliding motion. Transp. Porous Media 2002, 48, 291–313. [Google Scholar] [CrossRef]

- Almqvist, A.; Dasht, J. The homogenization process of the Reynolds equation describing compressible liquid flow. Tribol. Int. 2006, 39, 994–1002. [Google Scholar] [CrossRef]

- Almqvist, A.; Essel, E.K.; Fabricius, J.; Wall, P. Reiterated homogenization applied in hydrodynamic lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2008, 222, 827–841. [Google Scholar] [CrossRef] [Green Version]

- Almqvist, A.; Essel, E.K.; Persson, L.-E.; Wall, P. Homogenization of the unstationary incompressible Reynolds equation. Tribol. Int. 2007, 40, 1344–1350. [Google Scholar] [CrossRef]

- Almqvist, A. Homogenization of the Reynolds Equation Governing Hydrodynamic Flow in a Rotating Device. J. Tribol. 2011, 133, 021705. [Google Scholar] [CrossRef]

- Almqvist, A.; Fabricius, J.; Spencer, A.; Wall, P. Similarities and Differences Between the Flow Factor Method by Patir and Cheng and Homogenization. J. Tribol. 2011, 133, 031702. [Google Scholar] [CrossRef]

- Almqvist, A.; Lukkassen, D.; Meidell, A.; Wall, P. New concepts of homogenization applied in rough surface hydrodynamic lubrication. Int. J. Eng. Sci. 2007, 45, 139–154. [Google Scholar] [CrossRef] [Green Version]

- Spencer, A.; Almqvist, A.; Larsson, R. A semi-deterministic texture-roughness model of the piston ring–cylinder liner contact. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2011, 225, 325–333. [Google Scholar] [CrossRef]

- Söderfjäll, M.; Almqvist, A.; Larsson, R. A model for twin land oil control rings. Tribol. Int. 2016, 95, 475–482. [Google Scholar] [CrossRef] [Green Version]

- Sahlin, F.; Larsson, R.; Almqvist, A.; Lugt, P.M.; Marklund, P. A mixed lubrication model incorporating measured surface topography. Part 1: Theory of flow factors. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 335–351. [Google Scholar] [CrossRef]

- Sahlin, F.; Larsson, R.; Marklund, P.; Almqvist, A.; Lugt, P.M. A mixed lubrication model incorporating measured surface topography. Part 2: Roughness treatment, model validation, and simulation. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 353–365. [Google Scholar] [CrossRef]

- Hu, Y.; Meng, X.; Xie, Y. A computationally efficient mass-conservation-based, two-scale approach to modeling cylinder liner topography changes during running-in. Wear 2017, 386, 139–156. [Google Scholar] [CrossRef]

- Hu, Y.; Meng, X.; Xie, Y. A new efficient flow continuity lubrication model for the piston ring-pack with consideration of oil storage of the cross-hatched texture. Tribol. Int. 2018, 119, 443–463. [Google Scholar] [CrossRef]

- Rom, M.; Muller, S. A Reduced Basis Method for the Homogenized Reynolds Equation Applied to Textured Surfaces. Commun. Comput. Phys. 2018, 24, 481–509. [Google Scholar] [CrossRef]

- Scaraggi, M.; Carbone, G.; Dini, D. Lubrication in soft rough contacts: A novel homogenized approach. Part II—Discussion. Soft Matter 2011, 7, 10407. [Google Scholar] [CrossRef]

- Scaraggi, M.; Carbone, G.; Persson, B.N.J.; Dini, D. Lubrication in soft rough contacts: A novel homogenized approach. Part I-Theory. Soft Matter 2011, 7, 10395. [Google Scholar] [CrossRef]

- Scaraggi, M. Optimal Textures for Increasing the Load Support in a Thrust Bearing Pad Geometry. Tribol. Lett. 2014, 53, 127–143. [Google Scholar] [CrossRef]

- Scaraggi, M. Textured surface hydrodynamic lubrication: Discussion. Tribol. Lett. 2012, 48, 375–391. [Google Scholar] [CrossRef]

- Scaraggi, M. Lubrication of textured surfaces: A general theory for flow and shear stress factors. Phys. Rev. E 2012, 86, 026314. [Google Scholar] [CrossRef]

- Gao, L.; Hewson, R. A Multiscale Framework for EHL and Micro-EHL. Tribol. Trans. 2012, 55, 713–722. [Google Scholar] [CrossRef] [Green Version]

- Gao, L.; de Boer, G.; Hewson, R. The role of micro-cavitation on EHL: A study using a multiscale mass conserving approach. Tribol. Int. 2015, 90, 324–331. [Google Scholar] [CrossRef] [Green Version]

- Lahmar, M.; Bou-Saïd, B.; Tichy, J. The homogenization method of roughness analysis in turbulent lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 1090–1100. [Google Scholar] [CrossRef]

- Waseem, A.; Temizer, İ.; Kato, J.; Terada, K. Homogenization-based design of surface textures in hydrodynamic lubrication. Int. J. Numer. Methods Eng. 2016, 108, 1427–1450. [Google Scholar] [CrossRef]

- Waseem, A.; Temizer, İ.; Kato, J.; Terada, K. Micro-texture design and optimization in hydrodynamic lubrication via two-scale analysis. Struct. Multidiscip. Optim. 2017, 56, 227–248. [Google Scholar] [CrossRef] [Green Version]

- Yildiran, I.N.; Temizer, I.; Çetin, B. Homogenization in Hydrodynamic Lubrication: Microscopic Regimes and Re-Entrant Textures. J. Tribol. 2017, 140, 011701. [Google Scholar] [CrossRef]

- Gu, C.; Meng, X.; Xie, Y.; Zhang, D. Mixed lubrication problems in the presence of textures: An efficient solution to the cavitation problem with consideration of roughness effects. Tribol. Int. 2016, 103, 516–528. [Google Scholar] [CrossRef]

- Ma, C.; Duan, Y.; Yu, B.; Sun, J.; Tu, Q. The comprehensive effect of surface texture and roughness under hydrodynamic and mixed lubrication conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 231, 1307–1319. [Google Scholar] [CrossRef]

- Xie, Y.; Li, Y.; Suo, S.; Liu, X.; Li, J.; Wang, Y. A mass-conservative average flow model based on finite element method for complex textured surfaces. Sci. China Physics Mech. Astron. 2013, 56, 1909–1919. [Google Scholar] [CrossRef]

- Profito, F.J.; Vladescu, S.-C.; Reddyhoff, T.; Dini, D. Experimental Validation of a Mixed-Lubrication Regime Model for Textured Piston-Ring-Liner Contacts. Mater. Perform. Charact. 2017, 6, 112–129. [Google Scholar] [CrossRef]

- Zhang, H.; Hua, M.; Dong, G.; Zhang, D.; Chin, K.-S. A mixed lubrication model for studying tribological behaviors of surface texturing. Tribol. Int. 2016, 93, 583–592. [Google Scholar] [CrossRef]

- Meng, X.; Gu, C.; Xie, Y. Elasto-plastic contact of rough surfaces: A mixed-lubrication model for the textured surface analysis. Meccanica 2017, 52, 1541–1559. [Google Scholar] [CrossRef]

- Qiu, Y.; Khonsari, M.M. Performance Analysis of Full-Film Textured Surfaces With Consideration of Roughness Effects. J. Tribol. 2011, 133, 021704. [Google Scholar] [CrossRef]

- Brunetière, N.; Tournerie, B. Numerical analysis of a surface-textured mechanical seal operating in mixed lubrication regime. Tribol. Int. 2012, 49, 80–89. [Google Scholar] [CrossRef]

- Venner, C.H.; Lubrecht, A.A. (Eds.) Multi-Level Methods in Lubrication; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Zhao, J.; Vollebregt, E.A.H.; Oosterlee, C.W. A full multigrid method for linear complementary problems arising from elastic normal contact problems. Math. Model. Anal. 2014, 19, 216–240. [Google Scholar] [CrossRef]

- Zhang, B.; Boffy, H.; Venner, C.H. Multigrid solution of 2D and 3D stress fields in contact mechanics of anisotropic inhomogeneous materials. Tribol. Int. 2019. [Google Scholar] [CrossRef]

- Checo, H.M.; Jai, M.; Buscaglia, G.C. An Improved Fixed-Point Algorithm to Solve the Lubrication Problem with Cavitation. Mecánica Comput. 2016, 34, 1973–1987. [Google Scholar]

- Boffy, H.; Venner, C.H. Multigrid solution of the 3D stress field in strongly heterogeneous materials. Tribol. Int. 2014, 74, 121–129. [Google Scholar] [CrossRef]

- Goodyer, C.E.; Berzins, M. Parallelization and scalability issues of a multilevel elastohydrodynamic lubrication solver. Concurr. Comput. Pract. Exp. 2007, 19, 369–396. [Google Scholar] [CrossRef]

- Li, L.; Bogy, D.B. A Local Adaptive Multigrid Control Volume Method for the Air Bearing Problem in Hard Disk Drives. J. Tribol. 2013, 135, 032001. [Google Scholar] [CrossRef]

- Lu, H.; Berzins, M.; Goodyer, C.E.; Jimack, P.K.; Walkley, M. Adaptive high-order finite element solution of transient elastohydrodynamic lubrication problems. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2006, 220, 215–225. [Google Scholar] [CrossRef] [Green Version]

- Nilsson, B.; Hansbo, P. Adaptive finite element methods for hydrodynamic lubrication with cavitation. Int. J. Numer. Methods Eng. 2007, 72, 1584–1604. [Google Scholar] [CrossRef]

- Lu, H.; Berzins, M.; Goodyer, C.E.; Jimack, P.K. Adaptive high-order Discontinuous Galerkin solution of elastohydrodynamic lubrication point contact problems. Adv. Eng. Softw. 2012, 45, 313–324. [Google Scholar] [CrossRef]

- Ahmed, S.; Goodyer, C.E.; Jimack, P.K. An adaptive finite element procedure for fully-coupled point contact elastohydrodynamic lubrication problems. Comput. Methods Appl. Mech. Eng. 2014, 282, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Babuška, I.; Osborn, J.E. Generalized Finite Element Methods: Their Performance and Their Relation to Mixed Methods. SIAM J. Numer. Anal. 1983, 20, 510–536. [Google Scholar] [CrossRef]

- Efendiev, Y.; Hou, T. Multiscale Finite Element Methods; Springer: New York, NY, USA, 2009; ISBN 978-0-387-09495-3. [Google Scholar]

- Moyner, O.; Lie, K.-A. The Multiscale Finite Volume Method on Unstructured Grids. In Proceedings of the SPE Reservoir Simulation Symposium, The Woodlands, TX, USA, 18–20 February 2013; Society of Petroleum Engineers: Richardson, TX, USA, 2013. [Google Scholar] [Green Version]

- Jiang, L.; Mishev, I.D. Mixed Multiscale Finite Volume Methods for Elliptic Problems in Two-Phase Flow Simulations. Commun. Comput. Phys. 2012, 11, 19–47. [Google Scholar] [CrossRef] [Green Version]

- Jenny, P.; Lee, S.; Tchelepi, H. Multi-scale finite-volume method for elliptic problems in subsurface flow simulation. J. Comput. Phys. 2003, 187, 47–67. [Google Scholar] [CrossRef]

- Weinan, E.; Engquist, B.; Li, X.; Ren, W.; Vanden-Eijnden, E. Heterogeneous Multiscale Methods: A Review. Commun. Comput. Phys. 2007, 2, 367–450. [Google Scholar]

- Steinhauser, M.O. Computational Multiscale Modeling of Fluids and Solids; Springer: Berlin/Heidelberg, Germany, 2017; ISBN 978-3-662-53222-5. [Google Scholar]

- Pei, S.; Ma, S.; Xu, H.; Wang, F.; Zhang, Y. A multiscale method of modeling surface texture in hydrodynamic regime. Tribol. Int. 2011, 44, 1810–1818. [Google Scholar] [CrossRef]

- Pei, S.; Xu, H.; Shi, F. A deterministic multiscale computation method for rough surface lubrication. Tribol. Int. 2016, 94, 502–508. [Google Scholar] [CrossRef]

- Pei, S.; Xu, H.; Yun, M.; Shi, F.; Hong, J. Effects of surface texture on the lubrication performance of the floating ring bearing. Tribol. Int. 2016, 102, 143–153. [Google Scholar] [CrossRef]

- Nyemeck, A.P.; Brunetière, N.; Tournerie, B. A Multiscale Approach to the Mixed Lubrication Regime: Application to Mechanical Seals. Tribol. Lett. 2012, 47, 417–429. [Google Scholar] [CrossRef]

- Nyemeck, A.P.; Brunetiere, N.; Tournerie, B. A Mixed Thermoelastohydrodynamic Lubrication Analysis of Mechanical Face Seals by a Multiscale Approach. Tribol. Trans. 2015, 58, 836–848. [Google Scholar] [CrossRef]

- Pérez-Ràfols, F.; Larsson, R.; Lundström, S.; Wall, P.; Almqvist, A. A stochastic two-scale model for pressure-driven flow between rough surfaces. Proc. R. Soc. A Math. Phys. Eng. Sci. 2016, 472, 20160069. [Google Scholar] [CrossRef] [PubMed]

- De Boer, G.N.; Hewson, R.W.; Thompson, H.M.; Gao, L.; Toropov, V.V. Two-scale EHL: Three-dimensional topography in tilted-pad bearings. Tribol. Int. 2014, 79, 111–125. [Google Scholar] [CrossRef]

- Brunetière, N.; Francisco, A. Multiscale Modeling Applied to the Hydrodynamic Lubrication of Rough Surfaces for Computation Time Reduction. Lubricants 2018, 6, 83. [Google Scholar] [CrossRef]

- Costagliola, G.; Bosia, F.; Pugno, N.M. Hierarchical Spring-Block Model for Multiscale Friction Problems. ACS Biomater. Sci. Eng. 2017, 3, 2845–2852. [Google Scholar] [CrossRef] [Green Version]

- Costagliola, G.; Bosia, F.; Pugno, N.M. A 2-D model for friction of complex anisotropic surfaces. J. Mech. Phys. Solids 2018, 112, 50–65. [Google Scholar] [CrossRef] [Green Version]

- Costagliola, G.; Bosia, F.; Pugno, N.M. Static and dynamic friction of hierarchical surfaces. Phys. Rev. E 2016, 94, 063003. [Google Scholar] [CrossRef] [Green Version]

- Costagliola, G.; Bosia, F.; Pugno, N.M. Tuning friction with composite hierarchical surfaces. Tribol. Int. 2017, 115, 261–267. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Ge, Z.; Niu, H.; Ruan, J.; Zhang, J. Edge effect factor affecting the tribological properties in water of protrusion surface textures on stainless steel. Biosurface Biotribol. 2018, 4, 46–49. [Google Scholar] [CrossRef]

- Joshi, G.S.; Putignano, C.; Gaudiuso, C.; Stark, T.; Kiedrowski, T.; Ancona, A.; Carbone, G. Effects of the micro surface texturing in lubricated non-conformal point contacts. Tribol. Int. 2018, 127, 296–301. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Wang, J.; Zhang, B.; Huang, W. Design principles for the area density of dimple patterns. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 229, 538–546. [Google Scholar] [CrossRef]

- Greiner, C.; Merz, T.; Braun, D.; Codrignani, A.; Magagnato, F. Optimum dimple diameter for friction reduction with laser surface texturing: The effect of velocity gradient. Surf. Topogr. Metrol. Prop. 2015, 3, 044001. [Google Scholar] [CrossRef]

- Sahlin, F.; Glavatskih, S.B.; Almqvist, T.; Larsson, R. Two-Dimensional CFD-Analysis of Micro-Patterned Surfaces in Hydrodynamic Lubrication. J. Tribol. 2005, 127, 96. [Google Scholar] [CrossRef]

| Type | Methods |

|---|---|

| Mechanical | Microcutting, Microcoining |

| Chemical | Chemical etching, chemical vapor deposition (CVD) |

| Physical | Physical vapor deposition (PVD), focused ion beam (FIB) texturing |

| Thermal | Laser interference texturing, electrical beam texturing |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grützmacher, P.G.; Profito, F.J.; Rosenkranz, A. Multi-Scale Surface Texturing in Tribology—Current Knowledge and Future Perspectives. Lubricants 2019, 7, 95. https://doi.org/10.3390/lubricants7110095

Grützmacher PG, Profito FJ, Rosenkranz A. Multi-Scale Surface Texturing in Tribology—Current Knowledge and Future Perspectives. Lubricants. 2019; 7(11):95. https://doi.org/10.3390/lubricants7110095

Chicago/Turabian StyleGrützmacher, Philipp G., Francisco J. Profito, and Andreas Rosenkranz. 2019. "Multi-Scale Surface Texturing in Tribology—Current Knowledge and Future Perspectives" Lubricants 7, no. 11: 95. https://doi.org/10.3390/lubricants7110095