Review on Friction Stir Processed TIG and Friction Stir Welded Dissimilar Alloy Joints

Abstract

:1. Introduction

2. Review on Friction Stir Welding, TIG Welding and Friction Stir Processing

2.1. Friction Stir Welding of Similar and Dissimilar Alloys

2.2. TIG Welding of Similar and Dissimilar Alloys and Metals

2.3. Friction Stir Processing of Similar/Dissimilar Alloys/Metals

2.4. Advantages of Friction Stir Welding, TIG Welding and Friction Stir Processing

2.5. Mostly Processed Welded Structures

2.6. Mostly Processed Grades

3. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cam, G.; Kocak, M. Progress in joining of advanced materials. Int. Mater. Rev. 1998, 43, 1–44. [Google Scholar] [CrossRef]

- Nicholas, E.D. Developments in the friction stir welding of metals. In Proceedings of the 6th International Conference on Aluminium Alloys, Toyohashi, Japan, 5–10 July 1998; pp. 139–151. [Google Scholar]

- Patel, V.; Li, W.; Wang, G.; Wang, F.; Vairis, A.; Niu, P. Friction stir welding of dissimilar aluminum alloy combinations: State-of-the-art. Metals 2019, 9, 270. [Google Scholar] [CrossRef] [Green Version]

- Sun, N. Friction Stir Processing of Aluminium Alloys. Master’s Thesis, University of Kentucky, Lexington, KY, USA, 2009. [Google Scholar]

- Marczyk, J.; Nosal, P.; Hebda, M. Effect of Friction Stir Processing on Microstructure and Microhardness of Al-TiC Composites. In Proceedings of the Student’s Conference, Freiberg, Germany, 8–9 November 2018. [Google Scholar]

- Węglowski, M.S. Friction stir processing—State of the art. Arch. Civ. Mech. Eng. 2018, 18, 114–129. [Google Scholar] [CrossRef]

- Chaudhari, R.; Parekh, R.; Ingle, A. Reliability of Dissimilar Metal Joints Using Fusion Welding: A Review. In Proceedings of the International Conference on Machine Learning, Electrical and Mechanical Engineering (ICMLEME’2014), Dubai, UAE, 8–9 January 2014. [Google Scholar]

- Simar, A.; Joncheere, C.; Deplus, K.; Pardoen, T.; de Meester, B. Comparing similar and dissimilar friction stir welds of 2017–6005A aluminium alloys. Sci. Technol. Weld. Join. 2013, 15, 254–259. [Google Scholar] [CrossRef]

- Dilip, J.J.S.; Koilraj, M.; Sundareswaran, V.; Janaki Ram, G.D.; Koteswara Rao, S.R. Microstructural characterization of dissimilar friction stir welds between AA2219 and AA5083. Trans. Indian Inst. Met. 2010, 63, 757–764. [Google Scholar] [CrossRef]

- Morishige, T.; Kawaguchi, A.; Tsujikawa, M.; Hino, M.; Hirata, T.; Higashi, K. Dissimilar welding of Al and Mg alloys by FSW. Mater. Trans. 2008, 49, 1129–1131. [Google Scholar] [CrossRef] [Green Version]

- Cavaliere, P.; Panella, F. Effect of tool position on the fatigue properties of dissimilar 2024-7075 sheets joined by friction stir welding. J. Mater. Process. Technol. 2008, 206, 249–255. [Google Scholar] [CrossRef]

- Peng, G.; Yan, Q.; Hu, J.; Chen, P.; Chen, Z.; Zhang, T. Effect of forced air cooling on the microstructures, tensile strength, and hardness distribution of dissimilar friction stir welded AA5A06-AA6061 joints. Metals 2019, 9, 304. [Google Scholar] [CrossRef] [Green Version]

- Shah, L.H.A.; Sonbolestan, S.; Midawi, A.R.H.; Walbridge, S.; Gerlich, A. Dissimilar friction stir welding of thick plate AA5052-AA6061 aluminum alloys: Effects of material positioning and tool eccentricity. Int. J. Adv. Manuf. Technol. 2019, 105, 889–904. [Google Scholar] [CrossRef]

- Giraud, L.; Robea, H.; Claudina, C.; Desrayaud, C.; Bocherd, P.; Feulvarcha, E. Investigation into the dissimilar friction stir welding of AA7020-T651 and AA6060-T6. J. Mater. Process. Technol. 2016, 235, 220–230. [Google Scholar] [CrossRef]

- Khodir, S.A.; Shibayanagi, T. Dissimilar friction stir welded joints between 2024-T3 aluminum alloy and AZ31 magnesium alloy. Mater. Trans. 2007, 48, 2501–2505. [Google Scholar] [CrossRef] [Green Version]

- Rodriguez, R.I.; Jordon, J.B.; Allison, P.G.; Rushing, T.; Garcia, L. Microstructure and mechanical properties of dissimilar friction stir welding of 6061-To-7050 aluminum alloys. Mater. Des. 2015, 83, 60–65. [Google Scholar] [CrossRef]

- Guo, J.F.; Chen, H.C.; Sun, C.N.; Bi, G.; Sun, Z.; Wei, J. Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters. Mater. Des. 2014, 56, 185–192. [Google Scholar] [CrossRef]

- Mofid, M.A.; Abdollah-Zadeh, A.; Gürza, C.H. Investigating the formation of intermetallic compounds during friction stir welding of magnesium alloy to aluminum alloy in air and under liquid nitrogen. Int. J. Adv. Manuf. Technol. 2014, 71, 1493–1499. [Google Scholar] [CrossRef]

- El-Hafez, H.A.; El-Megharbel, A. Friction stir welding: Dissimilar aluminum alloys. World J. Eng. Technol. 2018, 6, 408–419. [Google Scholar] [CrossRef] [Green Version]

- Cole, E.G.; Fehrenbacher, A.; Duffie, N.A.; Zinn, M.R.; Pfefferkorn, F.E.; Ferrier, N.J. Weld temperature effects during friction stir welding of dissimilar aluminum alloys 6061-T6 and 7075-T6. Int. J. Adv. Manuf. Technol. 2014, 71, 643–652. [Google Scholar] [CrossRef]

- Vivekanandan, P.; Arunachalam, V.P.; Prakash, T.; Savadamuthu, L. The experimental analysis of friction stir welding on aluminium composites. Int. J. Metall. Eng. 2012, 1, 1–6. [Google Scholar]

- Li, X.; Zhang, D.; Qiu, C.; Zhang, W. Microstructure and mechanical properties of dissimilar pure copper/1350 aluminum alloy butt joints by friction stir welding. Trans. Nonferrous Met. Soc. China 2012, 22, 1298–1306. [Google Scholar] [CrossRef]

- Sepe, R.; Armentani, E.; Di Lascio, P.; Citarella, R. Crack growth behavior of welded stiffened panel. Proc. Eng. 2015, 109, 473–483. [Google Scholar] [CrossRef] [Green Version]

- Citarella, R.; Carlone, P.; Lepore, M.; Sepe, R. Hybrid technique to assess the fatigue performance of multiple cracked FSW joints. Eng. Fract. Mech. 2016, 62, 38–50. [Google Scholar] [CrossRef]

- Sheng, X.; Li, K.; Wu, W.; Yang, W.; Liu, Y.; Zhao, Y.; He, G. Microstructure and mechanical properties of friction stir welded joint of an aluminum alloy sheet 6005A-T4. Metals 2019, 9, 1152. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Gong, W.; Sun, D. Effect of tool rotational speed on the microstructure and mechanical properties of bobbin tool friction stir welded 6082-T6 aluminum alloy. Metals 2019, 9, 894. [Google Scholar] [CrossRef] [Green Version]

- Ilangovan, M.; Boopathy, S.R.; Balasubramanian, V. Microstructure and tensile properties of friction stir welded dissimilar AA6061-AA5086 aluminium alloy joints. Trans. Nonferrous Met. Soc. China 2015, 25, 1080–1090. [Google Scholar] [CrossRef]

- Ishak, M.; Noordin, M.N.F.; Shah, L.H.A. Feasibility study on joining dissimilar aluminum alloys AA6061 and AA7075 by tungsten inert gas (TIG). J. Teknol. 2015, 75, 79–84. [Google Scholar] [CrossRef] [Green Version]

- Borrisutthekul, R.; Mitsomwang, P.; Rattanachan, S.; Mutoh, Y. Feasibility of using TIG welding in dissimilar metals between steel/aluminum alloy. Energy Res. J. 2010, 1, 82–86. [Google Scholar]

- Waleed, W.A.; Subbaiah, K. Effect of ER4047 filler rod on tungsten inert gas welding of AA5083-H111 and AA6061-T6 aluminium alloys. JCHPS 2017, 7, 210–213. [Google Scholar]

- Sefika, K. Multi-response optimization using the Taguchi based grey relational analysis: A case study for dissimilar friction stir butt welding of AA6082-T6/AA5754-H111. Int. J. Adv. Manuf. Technol. 2013, 68, 795–804. [Google Scholar]

- Subbaiah, K.; Geetha, M.; Sridhar, N.; Koteswara Rao, S.R. Comparison of Tungsten Inert Gas and Friction Stir Welding of AA 5083-H321 Aluminium Alloy Plates. Trends in Welding Research. In Proceedings of the 9th International Conference, ASM International, Chicago, IL, USA, 4–8 June 2012. [Google Scholar]

- Leitao, C.; Louro, R.; Rodrigues, D.M. Analysis of high temperature plastic behavior and its relation with weld ability in friction stir welding for aluminum alloys AA5083-H111 and AA6082-T6. Mater. Des. 2012, 37, 402–409. [Google Scholar] [CrossRef]

- Menzemer, C.C.; Lam, P.C.; Wittell, C.F.; Srivarsan, T.S. A study of fusion zone microstructures of arc-welded joints made from dissimilar aluminum alloys. J. Mater. Eng. Perform. 2001, 10, 173–178. [Google Scholar] [CrossRef]

- Palanivel, R.; Koshy Mathews, P.; Murugan, N. Optimization of process parameters to maximize ultimate tensile strength of friction stir welded dissimilar aluminum alloys using response surface methodology. J. Cent. South Univ. 2013, 20, 2929–2938. [Google Scholar] [CrossRef]

- Chen, Q.; Ge, H.; Yang, C.; Lin, S.; Fan, C. Study on pores in ultrasonic-assisted TIG weld of aluminum alloy. Metals 2017, 7, 53. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Cao, Z.; Liu, K.; Zhang, X.; Zhou, K.; Ou, P. Fabrication and mechanical properties of tungsten inert gas welding ring welded joint of 7A05-T6/5A06-O dissimilar aluminum alloy. Materials 2018, 11, 1156. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Narayanan, A.; Mathew, C.; Baby, V.Y.; Joseph, J. Influence of gas tungsten arc welding parameters in aluminium 5083 alloy. IJESIT 2013, 2, 269–277. [Google Scholar]

- Mohan, P. Study the Effects of Welding Parameters on TIG Welding of Aluminum Plate. Master’s Thesis, National Institute of Technology, Rourkela, India, 2014. [Google Scholar]

- Baghel, P.K.; Nagesh, D.S. Mechanical properties and microstructural characterization of automated pulse TIG welding of dissimilar aluminum alloy. IJEMS 2018, 25, 147–154. [Google Scholar]

- KumarSingh, S.; Tiwari, R.M.; Kumar, A.; Kumar, S.; Murtaza, Q.; Kumar, S. Mechanical Properties and Microstructure of Al-5083 by TIG. In Proceedings of the International Conference on Processing of Materials, Minerals and Energy, Ongole, India, 29–30 July 2018. [Google Scholar]

- Sayer, S.; Yeni, C.; Ertugrul, O. Comparison of mechanical and microstructural behaviors of tungsten inert gas welded and friction stir welded dissimilar aluminum alloys AA 2014 and AA 5083. Kovove Mater. 2011, 49, 155–162. [Google Scholar] [CrossRef]

- Singh, G.; Singh, F.; Singh, H. A Study of mechanical properties on TIG welding at different parameters with and without use of flux. IJTIR 2015, 16. [Google Scholar]

- Patil, C.; Patil, H.; Patil, H. Experimental investigation of hardness of FSW and TIG joints of aluminium alloys of AA7075 and AA6061. Frat. Integrità Strutt. 2016, 10, 325–332. [Google Scholar] [CrossRef]

- Kumara, S.T.; Balasubramanian, V.; Sanavullah, M.Y. Influences of pulsed current tungsten inert gas welding parameters on the tensile properties of AA 6061 aluminum alloy. Mater. Des. 2007, 28, 2080–2092. [Google Scholar] [CrossRef]

- Hameed, A.M.; Resan, K.K.; Eweed, K.M. Effect of Friction Stir Processing Parameters on the Dissimilar Aluminum Alloys. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015. [Google Scholar]

- Karthikeyan, L.; Kumar, V.S. Relationship between process parameters and mechanical properties of friction stir processed AA6063-T6 aluminum alloy. Mater. Des. 2011, 32, 3085–3091. [Google Scholar] [CrossRef]

- Hannard, F.; Castin, E.; Pardoen, T.; Mokso, T.; Maire, E.; Simar, A. Ductilization of aluminium alloy 6056 by friction stir processing. Acta Mater. 2017, 130, 121–136. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Karimzadeh, F.; Enayati, M.H. A novel technique for development of A356/Al2O3 surface nanocomposite by friction stir processing. J. Mater. Process. Technol. 2011, 211, 1614–1619. [Google Scholar] [CrossRef]

- Kalashnikova, T.A.; Chumaevskii, A.V.; Rubtsov, V.E.; Ivanov, A.N.; Alibatyro, A.A.; Kalashnikov, K.N. Structural Evolution of Multiple Friction Stir Processed AA2024. In Proceedings of the International Conference on Advanced Materials with Hierarchical Structure for New Technologies and Reliable Structures (AMHS’17), Tomsk, Russia, 9–13 October 2017. [Google Scholar]

- Hashim, F.A.; Salim, R.K.; Khudair, B.H. Effect of friction stir processing on (2024-T3) aluminum alloy. IJIRSET 2015, 4, 1822–1829. [Google Scholar]

- Tsai, F.; Kao, P. Improvement of mechanical properties of a cast Al-Si base alloy by friction stir processing. Mater. Lett. 2012, 80, 40–42. [Google Scholar] [CrossRef]

- Jana, S.; Mishra, R.; Baumann, J.; Grant, G. Effect of friction stir processing on fatigue behavior of an investment cast Al–7Si–0.6 Mg alloy. Acta Mater. 2010, 58, 989–1003. [Google Scholar] [CrossRef]

- Kurt, A.; Uygur, I.; Cete, E. Surface modification of aluminium by friction stir processing. J. Mater. Process. Technol. 2010, 211, 313–317. [Google Scholar] [CrossRef]

- John, J.; Shanmuganatan, S.P.; Kiran, M.B.; Senthil Kumar, V.S.; Krishnamurthy, R. Investigation of friction stir processing effect on AA 2014-T6. Mater. Manuf. Process. 2019, 34, 159–176. [Google Scholar] [CrossRef]

- Prakash, T.; Sasikumar, P. The Influences of the friction stir processing on the microstructure and hardness of AA6061 aluminium sheet metal. JMET 2013, 1, 66–72. [Google Scholar]

- Sinhmar, S.; Dwivedi, D.K.; Pancholi, V. Friction Stir Processing of AA 7039 Alloy. In Proceedings of the International Conference on Production and Mechanical Engineering, Bangkok, Thailand, 30–31 December 2014. [Google Scholar]

- Santella, M.L.; Engstrom, T.; Storjohann, D.; Pan, T.Y. Effects of friction stir processing on mechanical properties of the cast aluminum alloys A319 and A356. Scr. Mater. 2005, 53, 201–206. [Google Scholar] [CrossRef]

- Kuncická, L.; Král, P.; Dvorák, J.; Kocich, R. Texture evolution in biocompatible Mg-Y-Re alloy after friction stir processing. Metals 2019, 9, 1181. [Google Scholar] [CrossRef] [Green Version]

- Izadi, H.; Nolting, A.; Munro, C.; Gerlich, A.P. Effect of Friction Stir Processing Parameters on Microstructure and Mechanical Properties of AL 5059. In Proceedings of the 9th International Conference on Trends in Welding Research, Chicago, IL, USA, 4–8 June 2012. [Google Scholar]

- Ni, D.R.; Wang, D.; Feng, A.H.; Yao, G.; Ma, Z. Enhancing the high-cycle fatigue strength of Mg–9Al–1Zn casting by friction stir processing. Scr. Mater. 2009, 61, 568–571. [Google Scholar] [CrossRef]

- Sakurada, D.; Katoh, K.; Tokisue, H. Underwater Friction welding of 6061 aluminum alloy. JILM 2002, 52, 2–6. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Vecchio, K.S. Thermal history analysis of friction stir processed and submerged friction stir processed aluminum. MSEA 2007, 465, 165–175. [Google Scholar] [CrossRef]

- Zhang, H.J.; Liu, H.J.; Yu, L. Microstructure and mechanical properties as a function of rotation speed in underwater friction stir welded aluminum alloy joints. Mater. Des. 2011, 32, 4402–4407. [Google Scholar] [CrossRef]

- Darras, B.; Kishta, E. Submerged friction stir processing of AZ31 Magnesium alloy. Mater. Des. 2013, 47, 133–137. [Google Scholar] [CrossRef]

- Sabari, S.S. Evaluation of Performance of Friction Stir Welded AA2519-T87 Aluminium Alloy Joints. Ph.D. Thesis, Annamalai University, Tamil Nadu, India, 1 September 2016. [Google Scholar]

- El-Danaf, E.A.; El-Rayes, M.M.; Soliman, M.S. Friction stir processing: An effective technique to refine grain structure and enhance ductility. Mater. Des. 2010, 31, 1231–1236. [Google Scholar] [CrossRef]

- Akinlabi, E.T.; Mahamood, R.M.; Akinlabi, S.A.; Ogunmuyiwa, E. Processing parameters influence on wear resistance behaviour of friction stir processed Al-TiC composites. Adv. Mater. Sci. Eng. 2014, 2014, 724590. [Google Scholar] [CrossRef] [Green Version]

- Toma, E.; Karash, B.Y.; Saeed, R.; Taqi, M.; Qasim, E. The effect of the cutting depth of the tool friction stir process on the mechanical properties and microstructures of aluminium alloy 6061-T6. AJMA 2015, 3, 33–41. [Google Scholar]

- Abrahams, R.; Mikhail, J.; Fasihi, P. Effect of friction stir process parameters on the mechanical properties of 5005-H34 and 7075-T651 aluminium alloys. Mater. Sci. Eng. 2019, 751, 363–373. [Google Scholar] [CrossRef]

- Zhao, H.; Pan, Q.; Qin, Q.; Wu, Y.; Su, X. Effect of the processing parameters of friction stir processing on the microstructure and mechanical properties of 6063 aluminum alloy. Mater. Sci. Eng. 2019, 751, 70–79. [Google Scholar] [CrossRef]

- Rouzbehani, R.; Kokabi, A.H.; Sabet, H.; Paidar, M.; Ojo, O.O. Metallurgical and mechanical properties of underwater friction stir welds of Al7075 aluminum alloy. J. Mater. Process. Technol. 2018, 262, 239–256. [Google Scholar] [CrossRef]

- Singh, I.; Singh, T.; Singh, R.; Singh, S.G. Fabrication of AA-6063/Sic composite material by using friction stir processing. IJAR 2017, 5, 1652–1656. [Google Scholar] [CrossRef] [Green Version]

- Sun, N.; Jones, W.J.; Apelian, D. Friction stir processing of aluminum alloy A206: Part II—Tensile and fatigue properties. Int. J. Met. 2019, 13, 244–254. [Google Scholar] [CrossRef]

- Thakral, R.; Sanjeev, S.; Taljeet, S. Experimental analysis of friction stir processing of TIG welded aluminium alloy 6061. IJIRST 2018, 4, 51–57. [Google Scholar]

- Yadav, D.; Bauri, R. Effect of friction stir processing on microstructure and mechanical properties of aluminium. MSEA 2012, 539, 85–92. [Google Scholar] [CrossRef]

- Feng, X.; Liu, H.; Lippold, J.C. Microstructure characterization of the stir zone of submerged friction stir processed aluminum alloy 2219. Mater. Charact. 2013, 82, 97–102. [Google Scholar] [CrossRef]

- Singh, H.; Kumar, P.; Singh, B. Effect of under surface cooling on tensile strength of friction stir processed aluminium alloy 6082. AJEAT 2016, 5, 40–44. [Google Scholar]

- Nourbakhsh, S.H.; Atrian, A. Effect of submerged multi-pass friction stir process on the mechanical and microstructural properties of Al7075. J. Stress Anal. 2017, 2, 51–56. [Google Scholar]

- Mabuwa, S.; Msomi, V. Effect of friction stir processing on gas tungsten arc welded and friction stir welded 5083-H111 aluminium alloy joints. Adv. Mater. Sci. Eng. 2019, 2019, 3510236. [Google Scholar] [CrossRef] [Green Version]

- Dawood, H.I.; Mohammed, K.S.; Raja, M.Y. Advantages of the Green Solid State FSW over the Conventional GMAW Process. Adv. Mater. Sci. Eng. 2014, 2014, 105713. [Google Scholar] [CrossRef] [Green Version]

- Bevilacqua, M.; Ciarapica, P.E.; D’Orazio, A.; Forcellese, A.; Simoncini, M. Sustainability analysis of friction stir welding of AA5754 sheets. Procedia CIRP 2017, 62, 529–534. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding—Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef] [Green Version]

- Shukla, R.K.; Shah, P.K. Comparative study of friction stir welding and tungsten inert gas welding process. IJST 2010, 3, 667–671. [Google Scholar]

- Nicholas, E.D.; Kallee, S.W. Friction stir welding-a decade on. In Proceedings of the IIW Asian Pacific International Congress, Sydney, Australia, 29 October–2 November 2000. [Google Scholar]

- Costa, M.I.; Verdera, D.; Vieira, M.T.; Rodrigues, D.M. Surface enhancement of cold work tool steels by friction stir processing with a pinless tool. Appl. Surf. Sci. 2014, 296, 214–220. [Google Scholar] [CrossRef]

- Li, K.; Liu, X.; Zhao, Y. Research status and prospect of friction stir processing technology. Coatings 2019, 9, 129. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.Q.; Xie, L.C.; Lv, Y.T.; Zhang, L.C.; Chen, L.Y.; Meng, Q.; Qu, J.; Zhang, D.; Lu, W.J. Microstructure evolution and superelastic behavior in Ti-35Nb-2Ta-3Zr alloy processed by friction stir processing. Acta Mater. 2017, 131, 499–510. [Google Scholar] [CrossRef] [Green Version]

- Sun, P.; Wang, K.; Wang, W.; Zhang, X. Influence of process parameter on microstructure of AZ31 magnesium alloy in friction stir processing. Hot Work. Technol. 2008, 37, 99. [Google Scholar]

- Thompson, B.; Doherty, K.; Su, J.; Mishra, R. Nano-sized grain refinement using friction stir processing. In Friction Stir Welding and Processing VII; Springer: Cham, Switzerland, 2013; pp. 9–19. [Google Scholar]

- Xin, R.L.; Zheng, X.; Liu, Z.; Liu, D.; Qiu, R.S.; Li, Z.Y.; Liu, Q. Microstructure and texture evolution of an Mg-Gd-Y-Nd-Zr alloy during friction stir processing. J. Alloy. Compd. 2016, 659, 51–59. [Google Scholar] [CrossRef]

- Han, J.Y.; Chen, J.; Peng, L.M.; Zheng, F.Y.; Rong, W.; Wu, Y.J.; Ding, W.J. Influence of processing parameters on thermal field in Mg-Nd-Zn-Zr alloy during friction stir processing. Mater. Des. 2016, 94, 186–194. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Gerlich, A.P.; Svec, P. Fabrication of a high strength ultra-fine grained Al-Mg-SiC nanocomposite by multi-step friction-stir processing. Mater. Sci. Eng. A 2017, 698, 313–325. [Google Scholar] [CrossRef]

- Msomi, V.; Mbana, N.; Mabuwa, S. Microstructural analysis of the friction stir welded 1050-H14 and 5083-H111 aluminium alloys. Mater. Today Proc. 2019. [Google Scholar] [CrossRef]

- Raj, K.H.; Sharma, R.H.; Singh, P.; Dayal, A. Study of friction stir processing (FSP) and high pressure torsion (HPT) and their effect on mechanical properties. Proc. Eng. 2011, 10, 2904–2910. [Google Scholar] [CrossRef] [Green Version]

| Material Used | FSW Tool | Welding Parameters | Material Positioning | Comments | Reference |

|---|---|---|---|---|---|

| AA2219-T87 and AA5083-H321 | Material—M2 grade tool steel, straight cylindrical shape. | TRS—650 rpm, WS—55 mm/min, Axial load—9.8 kN. | AS—AA2219-T87, RS—AA5083-H321 | Maximum UTS: 265 MPa, YS: 228 MPa, El 13, JE—61% | [9] |

| AA5052H and AZ31B | JIS SKD61 tool steel | Optimum: TRS—1000 rpm, WS—200 mm/min, Tool tilt 3° | AS—AA5052, RS—AZ31 | The maximum UTS—147 MPa, YS—64 MPa, El—3.4%, JE—61%, microhardness—60 HV. | [10] |

| AA5052-H32 and AA6061-T651 | Material—H13 steel, M6-threaded tool with tri-flats and an 8° taper. | TRS—1120 rpm, WS—90 mm/min, Tool tilt 2.5°, Dwell time 10 s | AS—AA6061 and RS—AA5052, AS—AA5052 and RS—AA6061 | Better results with AA6061 on the AS. Maximum UTS—215.2 MPa, YS—141 MPa and El of 7.6%, microhardness SZ—~80 HV. | [13] |

| AA2024-T3 and AZ31 | SKD61 Tool steel (threaded). | TRS—2500 rev/min, WS—200, 300, 400 and 550 mm/min, | AS—AA2024-T3 and RS—AZ31 | In the HAZ AND TMAZ of AA2040A hardness distribution was significantly affected by increasing welding speed HAZ and TMAZ of 2024 A | [15] |

| AA5086-O and AA6061-T6 | High speed steel, straight cylindrical, threaded cylindrical and tapered cylindrical | AA6061-AA6061: TRS—1300 rpm to 1200 rpm and WS—35 mm/min, axial force—6 kN, AA5086-AA5086: TRS—500 rpm, WS—5 mm/min, axial force—4.6 kN | AS—AA5086, RS—AA6061 | Dissimilar joint at TRS of 500 rpm and WS of 10 mm/min. cylindrical plain tool resulted in Maximum UTS—140 MPa, YS—120 MPa, El—5.5%, JE—56%. | [27] |

| Material Used | Thickness | Welding Parameters | Comments | Reference |

|---|---|---|---|---|

| AA2195 | 2 mm | Ultrasonic TIG welding and ordinary TIG, Q—15 L/min, WC—70 A, WS—100 to 200 mm/min, UP—0 to 40 W, F—35 kHz | Porosity decreases with a decrease in welding speed for normal TIG. Porosity and pore size in UP TIG first decrease and increase with an increase in the UP. | [36] |

| AA5A06-O and AA7A05-T6 | NS | Butt joint TIG, FW—ER5356, WC—260 A, V—25 V, WS—200 mm/min, Q—24 L/min, SG—99.99% argon. | The maximum UTS—78.87% BM, YS—97.24% BM, El—84.29% of BM, JE—61%, FZ had coarse grains resulted to 120 HV microhardness. | [37] |

| AA2014 and AA5083 | 5 mm | V joint, Q—10 L/min, SG—argon, V—14 V, WC—140 to 150 A, FW—TAL 4043 | Maximum UTS—175 MPa, YS—128 MPa and El of 2.6%, microhardness SZ—~125 HV. | [42] |

| AA5083-O and AA6061-T651 | 6.35 mm | 60° groove weld joint, FW—ER 5356, SG—pure argon, V—13.2 V, Q—6 L/min, WS—155 mm/min, WC—105 to 175 A, F—2 Hz. | FZ microhardness increased with higher cooling rate, finer dimples, higher YS and UTS. | [40] |

| AA5083 | 3 mm | Pulsed TIG, WC—118 to 134 A, WS—90 to 105 mm/min, Q—of 6 to 7 L/min | Maximum UTS at WC—134 A, with Q—7 L/min and WS—98 mm/min. Fused welding seams. | [41] |

| Material Used | FSP Tool | Condition | Surface/Joint | Processing Parameters | Enhanced Property | Reference |

|---|---|---|---|---|---|---|

| AA6063-T6 | NS | Normal | surface | Optimum: TRS—1200 and 1400 rpm, TS—40.2 mm/min, axial force—10 kN | UTS, ductility, microhardness | [47] |

| AA6061 | EN 31 steel | Normal | TIG welded joint | TRS—1200 rpm, TS—75 mm/min | UTS, microhardness | [75] |

| Pure Al (99.2%) | M2 steel | Normal (air) | surface | TRS—640 rpm, TS—150 mm/min | significant improvement in UTS and hardness. Marginal increase in ductility | [76] |

| AA2219-T6 | standard tool steel | Submerged | Surface | TRS—600 to 800 rpm, TS—200 mm/min, Tool tilt 2.5° | As the TRS increase the SZ hardness decreases; Refinement of grains. | [77] |

| AA7075 | NS | Submerged and normal (air) | Surface | TRS 800 and 1250 rpm, TS and 40 and 63 mm/min | Ductility; Tensile strength; Uniform grain sizes | [79] |

| AA5083-H111 | high-carbon steel | Unsubmerged | TIG joint, FSW joint | TRS—1000 rpm and TS—30 mm/min Tool tilt 2° | Ductility; Grain sizes refined and UTS | [80] |

| Material Processed | Tool Material | Tool Profile | Tool Dimensions | Reference |

|---|---|---|---|---|

| A356 Aluminium | H13 steel | Threaded | PL: 4 mm, PD: 3.6 mm, SD: 18 mm, SL: 10 mm. | [49] |

| AC8A alloy | NS | NS | SD—18 mm, PD—5.2 mm, PH—2.7 mm, | [52] |

| Cast F357 | NS | Conical pin with a stepped spiral feature | PD—4 mm, PH—2 mm, SD—12 mm, | [53] |

| AA6061-T6 | Alloy steel | Concave shoulder | SD—15 mm, | [69] |

| AA6063-T5 | H13 steel | Conical pin | SD—18 mm, PL—5.7 mm, end PD—4 mm, Root PD—6 mm, | [71] |

| AA7075-T651 and AA5005-H34 | NS | Square base pin with conical head | PL—3.2 mm, SD—14 mm, PD—3.6 mm, SBPL—2.3 mm, CHL—3 mm. | [70] |

| AA7075-T651 and AA5005-H34 | NS | Pyramid shape | PL—3.2 mm, PD—3 mm, | [70] |

| NS | Conical threaded | PL—3.2 mm, PD—3 mm. |

| Feature | Friction Stir Welding | TIG Welding | Friction Stir Processing |

|---|---|---|---|

| Environment | Considered as a green technology technique, due to its clean and environment-friendly. No toxic gas emission nor radiation involved [81,82]. | Uses gas (helium/argon) [37,40,42]. | Also a green technology since same principle as from FSW. |

| Surface finish | Good surface finish and no welds finishing costs [83,84,85] | Weld joint with pores and cracks [30,36,80]. Sometimes requires grinding to get good surface. | Good surface finishing especially with pin-less tool [86]. No pores or cracks on FSPed welded joint [80,87]. |

| Microstructure evolution | uniform arrangement with fine grains [13,14,15,17,80]. | Nonhomogeneous, coarse less equiaxed grain distribution with bigger diameters [30,37,42,80]. | Thermal mechanical effects and DRX during FSP results in coarse grains transformation to UFG. [52,54,60,70,87,88,89,90,91]. |

| Microhardness | Microhardness of the joint increased when compared to base BM ones [11,27]. But remains circumstantially. | Microhardness decreases [37,38,39]. | FSP resulted in an increase in hardness when compared to the unprocessed surface [89,90,92,93]. |

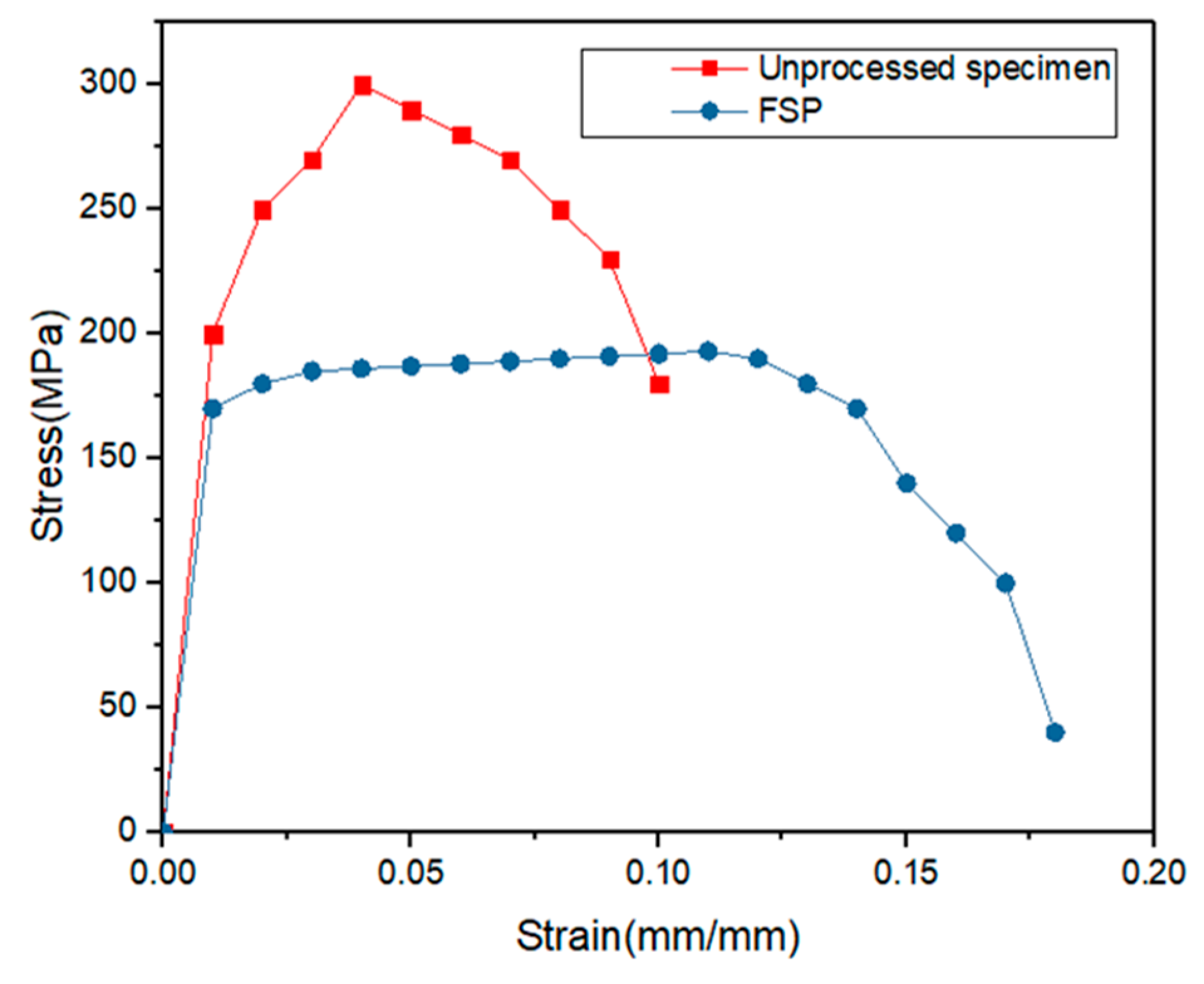

| Tensile properties (UTS, YS, El) | Tensile properties are mostly lower when welding dissimilar alloys due to the formation of IMC (circumstantial) compared to the BM ones [10,11,12,13,15,21,94]. | Tensile properties decrease compared to BM ones [38,40,41]. | FSP also improves the tensile properties of a material [54,56,68,87]. Improved ductility of the processed surface in comparison to the unprocessed one [80,95]. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mabuwa, S.; Msomi, V. Review on Friction Stir Processed TIG and Friction Stir Welded Dissimilar Alloy Joints. Metals 2020, 10, 142. https://doi.org/10.3390/met10010142

Mabuwa S, Msomi V. Review on Friction Stir Processed TIG and Friction Stir Welded Dissimilar Alloy Joints. Metals. 2020; 10(1):142. https://doi.org/10.3390/met10010142

Chicago/Turabian StyleMabuwa, Sipokazi, and Velaphi Msomi. 2020. "Review on Friction Stir Processed TIG and Friction Stir Welded Dissimilar Alloy Joints" Metals 10, no. 1: 142. https://doi.org/10.3390/met10010142