Effects of Magnetic Field on the Residual Stress and Structural Defects of Ti-6Al-4V

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructure and Element Distribution of the Alloy

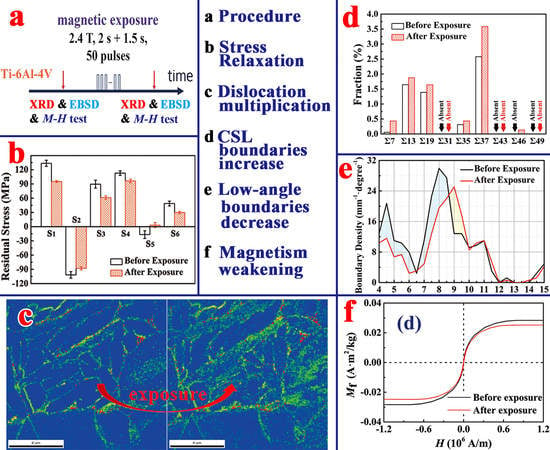

3.2. Effects of Magnetic Field on Residual Stress

3.3. Effects of Magnetic Field on Status of Dislocations

3.4. Effects of Magnetic Field on Status of Grain Boundaries

3.5. Effects of Magnetic Field on Status of Fe-Rich Clusters

3.6. Possible Mechanism of the Magnetically Stimulated Variations

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Manikandan, N.; Arulkirubakaran, D.; Palanisamy, D.; Raju, R. Influence of wire-EDM textured conventional tungsten carbide inserts in machining of aerospace materials (Ti–6Al–4V alloy). Mater. Manuf. Process. 2018, 34, 103–111. [Google Scholar] [CrossRef]

- Wang, K. The use of titanium for medical applications in the USA. Mater. Sci. Eng. A 1996, 213, 134–137. [Google Scholar] [CrossRef]

- Venkatesh, B.D.; Chen, D.L.; Bhole, S.D. Effect of heat treatment on mechanical properties of Ti–6Al–4V ELI alloy. Mater. Sci. Eng. A 2009, 506, 117–124. [Google Scholar] [CrossRef]

- Sharifi, F.; Abouei, V.; Alizadeh, A.; Shajari, Y.; Porhonar, M.; Ghanbari, M.; Ravari, B.K. The effect of different heat treatment cycle on hot corrosion and oxidation behavior of Ti-6Al-4V. Mater. Res. Express 2019, 6, 116599. [Google Scholar] [CrossRef]

- Kobryn, P.A.; Semiatin, S.L. The laser additive manufacture of Ti-6Al-4V. JOM 2001, 53, 40–42. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.P. A study of the micro structural evolution during selective laser melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Ya, B.; Zhou, B.; Yang, H.; Huang, B.; Jia, F.; Zhang, X. Microstructure and mechanical properties of in situ casting TiC/Ti6Al4V composites through adding multi-walled carbon nanotubes. J. Alloys Compd. 2015, 637, 456–460. [Google Scholar] [CrossRef]

- Al’shits, V.I.; Darinskaya, E.V.; Perekalina, T.M.; Urusovskaya, A.A. Motion of dislocations in NaCl crystals under the action of a static magnetic field. Sov. Phys. Solid State 1987, 29, 265–267. [Google Scholar]

- Golovin, Y.I. Magnetoplastic effects in solids. Phys. Solid State 2004, 46, 789–824. [Google Scholar] [CrossRef]

- Alshits, V.I.; Darinskaya, E.V.; Koldaeva, M.V.; Petrzhik, E.A. Magnetoplastic effect: Basic properties and physical mechanisms. Crystallogr. Rep. 2003, 48, 768–795. [Google Scholar] [CrossRef]

- Su, Y.Y.; Hochman, R.F.; Schaffer, J.P. A positron annihilation spectroscopy investigation of magnetically induced changes in defect structures. J. Phys. Condens. Matter 1990, 2, 3629–3642. [Google Scholar] [CrossRef]

- Li, C.; He, S.; Fan, Y.; Engelhardt, H.; Jia, S.; Xuan, W.; Li, X.; Zhong, Y.; Ren, Z. Enhanced diffusivity in Ni-Al system by alternating magnetic field. Appl. Phys. Lett. 2017, 110, 074102. [Google Scholar] [CrossRef]

- Yuan, Z.; Ren, Z.; Li, C.; Xiao, Q.; Wang, Q.; Dai, Y.; Wang, H. Effect of high magnetic field on diffusion behavior of aluminum in Ni-Al alloy. Mater. Lett. 2013, 108, 340–342. [Google Scholar] [CrossRef]

- Wang, H.M.; Li, P.S.; Zheng, R.; Li, G.R.; Yuan, X.T. Mechanism of high pulsed magnetic field treatment of the plasticity of aluminum matrix composites. Acta Phys. Sin. 2015, 64, 087104. [Google Scholar]

- Orlov, A.M.; Skvortsov, A.A.; Gonchar, L.I. Magnetically simulated variation of dislocation mobility in plastically deformed n-silicon. Phys. Solid State 2001, 43, 1252–1256. [Google Scholar] [CrossRef]

- Zhang, X.; Cai, Z.P. Effect of magnetic field on the nanohardness of monocrystalline silicon and its mechanism. JETP Lett. 2018, 108, 23–29. [Google Scholar] [CrossRef]

- Alshits, V.I.; Darinskaya, E.V.; Kazakova, O.L. Magnetoplastic effect in irradiated NaCl and LiF crystals. J. Exp. Theor. Phys. 1997, 84, 338–344. [Google Scholar] [CrossRef]

- Golovin, Y.I.; Morgunov, R.B.; Lopatin, D.V.; Baskakov, A.A.; Evgen’ev, Y.E. Reversible and irreversible magnetic-field-induced changes in the plastic properties of NaCl crystals. Phys. Solid State 1998, 40, 1870–1872. [Google Scholar] [CrossRef]

- Golovin, Y.I.; Morgunov, R.B. Effect of a weak magnetic field on the state of structural defects and the plasticity of ionic crystals. J. Exp. Theor. Phys. 1999, 88, 332–341. [Google Scholar] [CrossRef]

- Golovin, Y.I. Magnetoplastic effects in crystals in the context of spin-dependent chemical kinetics. Crystallogr. Rep. 2004, 49, 668–675. [Google Scholar] [CrossRef]

- Morgunov, R.B.; Buchachenko, A.L. Magnetoplasticity and magnetic memory in diamagnetic solids. J. Exp. Theor. Phys. 2009, 109, 434–441. [Google Scholar] [CrossRef]

- Kamaya, M.; Wilkinson, A.J.; Titchmarsh, J.M. Measurement of plastic strain of polycrystalline material by electron backscatter diffraction. Nucl. Eng. Des. 2005, 235, 713–725. [Google Scholar] [CrossRef]

- Fujiyama, K.; Mori, K.; Kaneko, D.; Kimachi, H.; Saito, T.; Ishii, R.; Hino, T. Creep damage assessment of 10Cr-1Mo-1W-VNbN steel forging through EBSD observation. Int. J. Press. Vessel. Pip. 2009, 86, 570–577. [Google Scholar] [CrossRef]

- Rui, S.S.; Niu, L.S.; Shi, H.J.; Wei, S.L.; Tasan, C.C. Diffraction-based misorientation mapping: A continuum mechanics description. J. Mech. Phys. Solids 2019, 133, 103709. [Google Scholar] [CrossRef]

- Zak, A.K.; Majid, W.H.A.; Abrishami, M.E.; Yousefi, R. X-ray analysis of ZnO nanoparticles by Williamson-Hall and size-strain plot methods. Solid State Sci. 2011, 13, 251–256. [Google Scholar]

- Mote, V.D.; Purushotham, Y.; Dole, B.N. Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J. Theor. Appl. Phys. 2012, 6, 6. [Google Scholar] [CrossRef] [Green Version]

- Aly, K.A.; Khalil, N.M.; Algamal, Y.; Saleem, Q.M.A. Lattice strain estimation for CoAl2O4 nano particles using Williamson-Hall analysis. J. Alloys Compd. 2016, 676, 606–612. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E. Dislocation densities in some annealed and cold-worked metals from measurements on the x-ray Debye-Scherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Buchachenko, A.L. Magnetoplasticity of diamagnetic crystals in microwave fields. J. Exp. Theor. Phys. 2007, 105, 593–598. [Google Scholar] [CrossRef]

- Darinskaya, E.V.; Petrzhik, E.A.; Erofeev, S.A.; Kisel’, V.P. Magnetoplastic effect in InSb. JETP Lett. 1999, 70, 309–313. [Google Scholar] [CrossRef]

- Molotskii, M.; Fleurov, V. Spin effects in plasticity. Phys. Rev. Lett. 1997, 78, 2779–2782. [Google Scholar] [CrossRef]

- Wang, F.E. Bonding Theory for Metals and Alloys; Elsevier: Amsterdam, The Netherlands, 2005; pp. 6–7. [Google Scholar]

- Turro, N.J. Micelles, magnets and molecular mechanisms—Application to cage effects and isotope-separation. Pure Appl. Chem. 1981, 53, 259–286. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhao, Q.; Cai, Z.; Pan, J. Effects of Magnetic Field on the Residual Stress and Structural Defects of Ti-6Al-4V. Metals 2020, 10, 141. https://doi.org/10.3390/met10010141

Zhang X, Zhao Q, Cai Z, Pan J. Effects of Magnetic Field on the Residual Stress and Structural Defects of Ti-6Al-4V. Metals. 2020; 10(1):141. https://doi.org/10.3390/met10010141

Chicago/Turabian StyleZhang, Xu, Qian Zhao, Zhipeng Cai, and Jiluan Pan. 2020. "Effects of Magnetic Field on the Residual Stress and Structural Defects of Ti-6Al-4V" Metals 10, no. 1: 141. https://doi.org/10.3390/met10010141