Distribution of Transition Temperatures in Magnetic Transformations: Sources, Effects and Procedures to Extract Information from Experimental Data

Abstract

:1. Introduction

2. Sources for a Distribution of Transition Temperatures

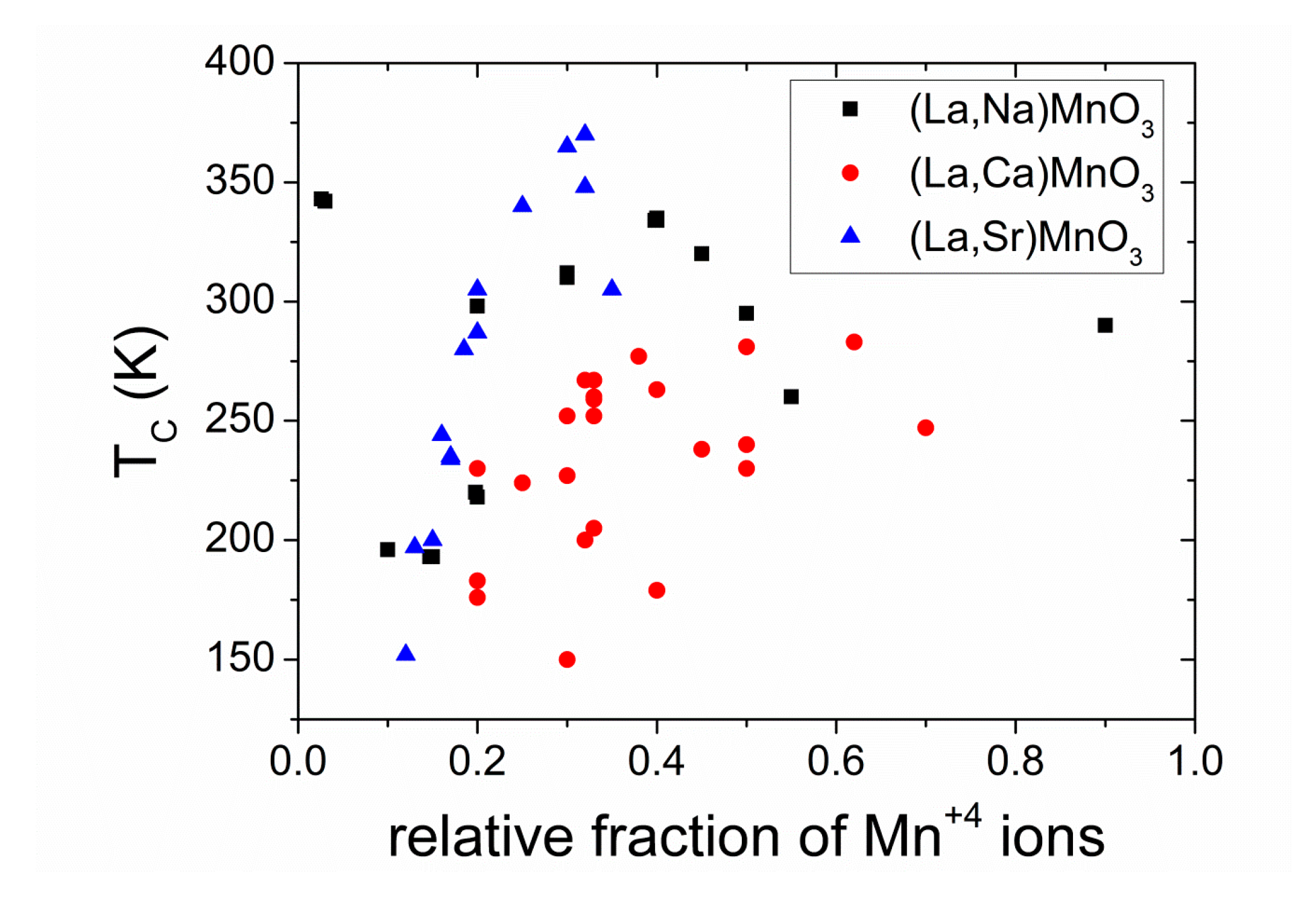

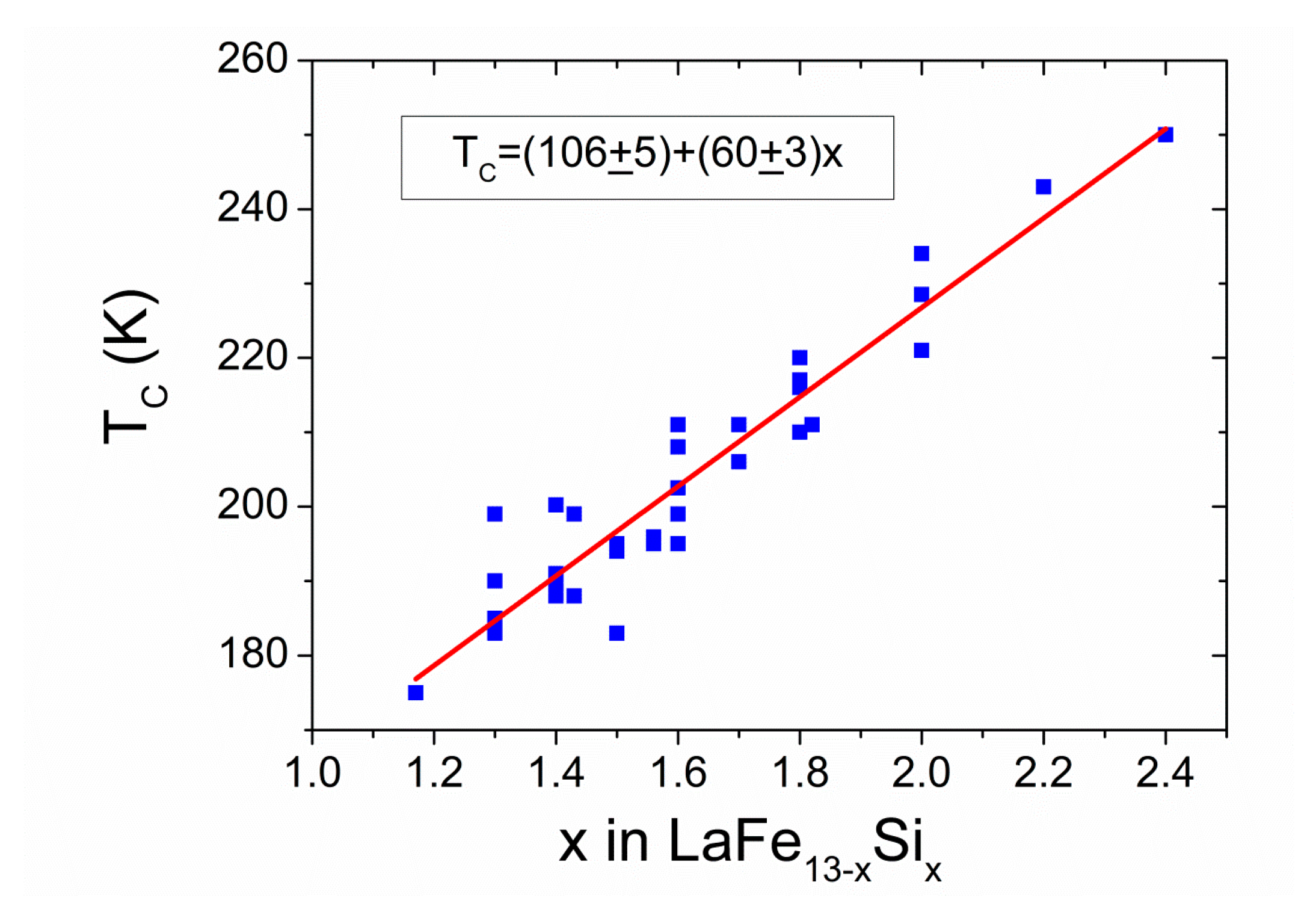

2.1. Compositional Dependence of Transition Temperatures

2.2. Other Factors Affecting Transition Temperature

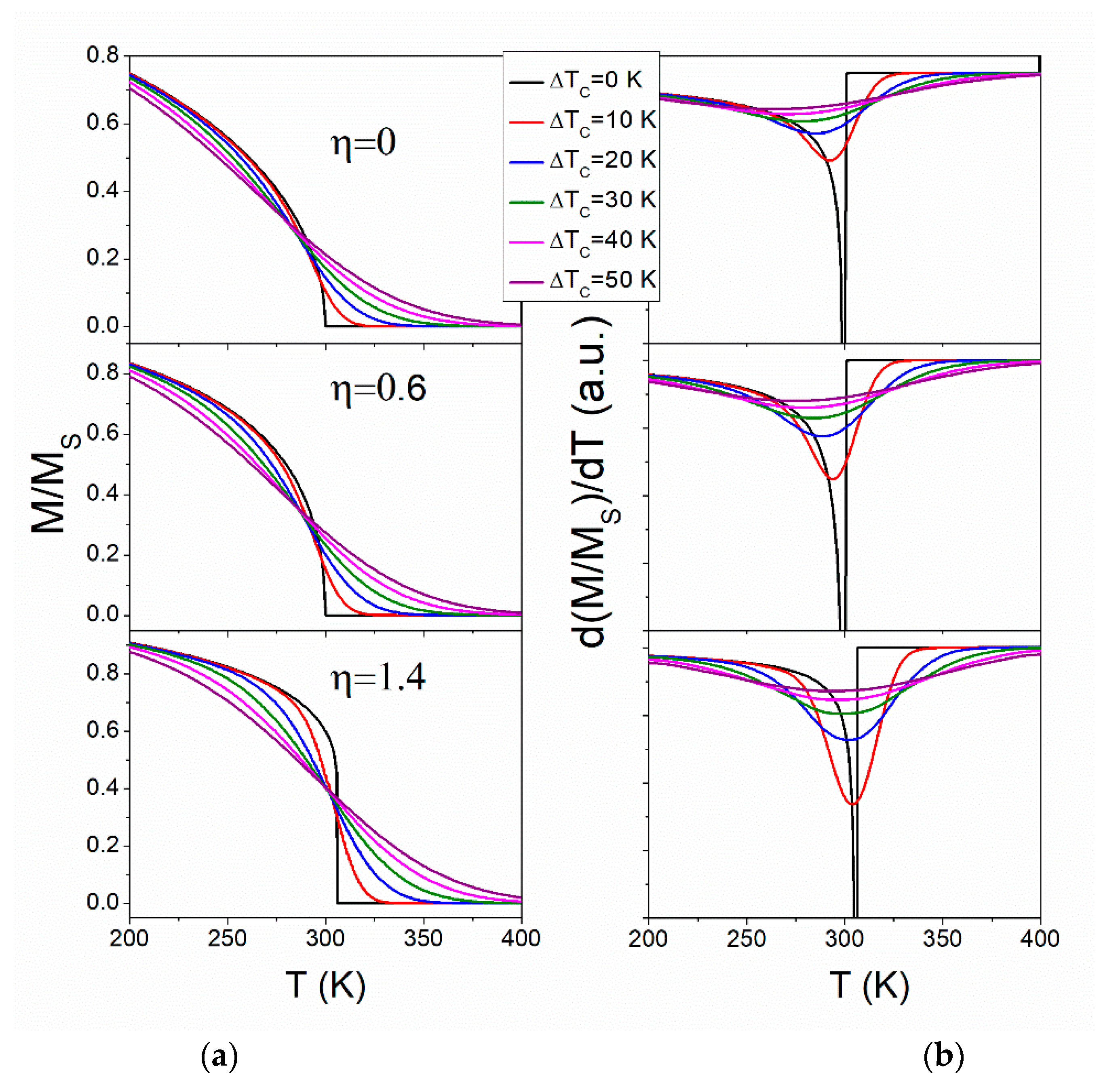

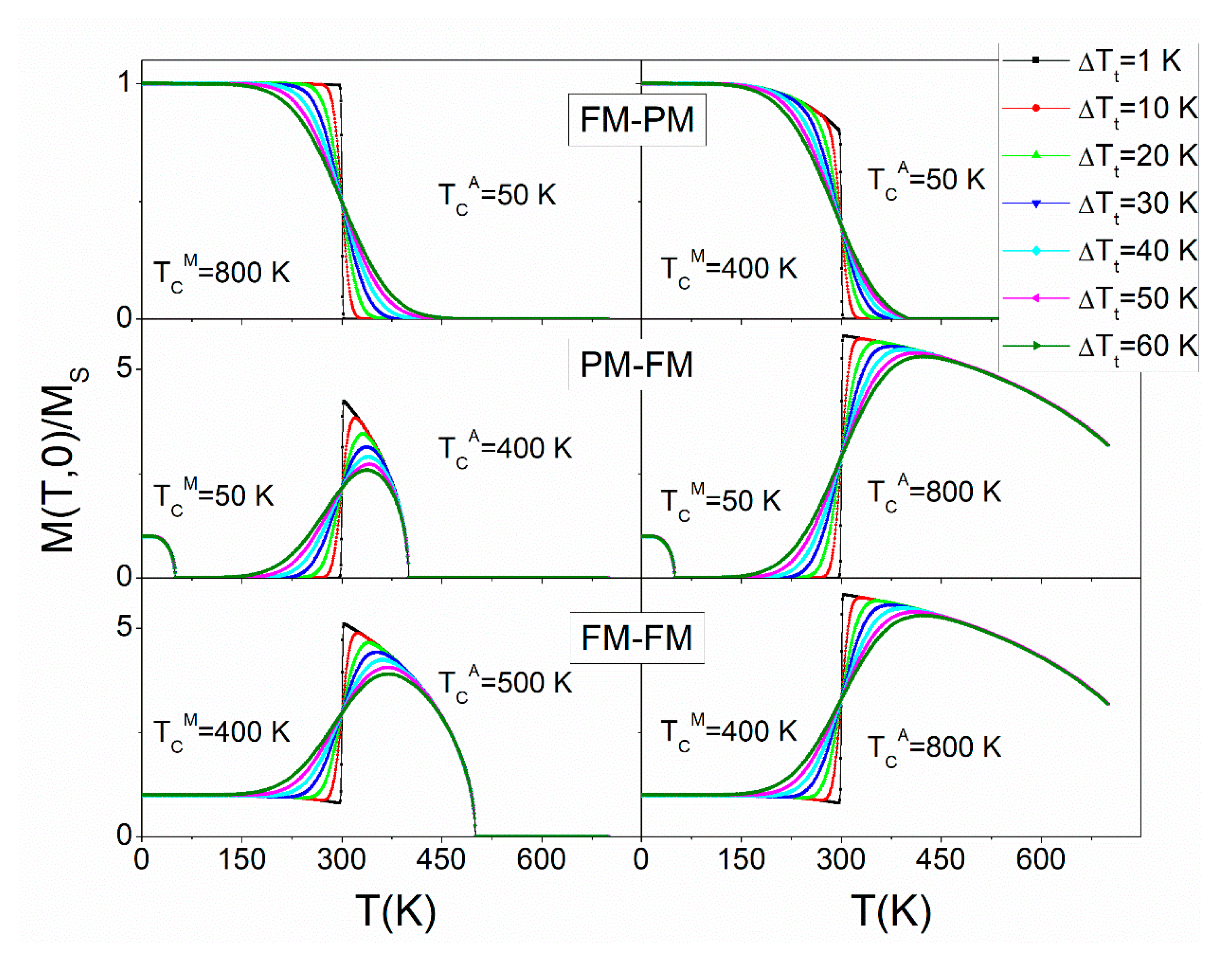

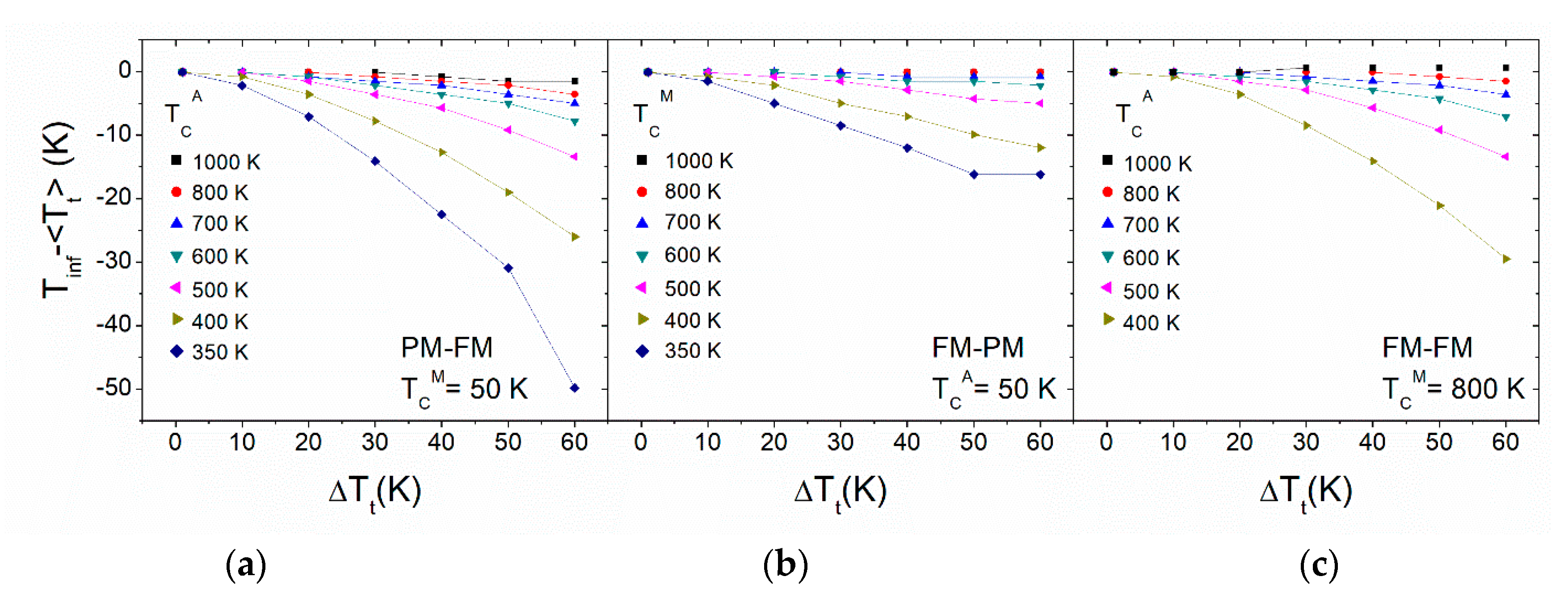

3. Effects of Distribution of Transition Temperatures

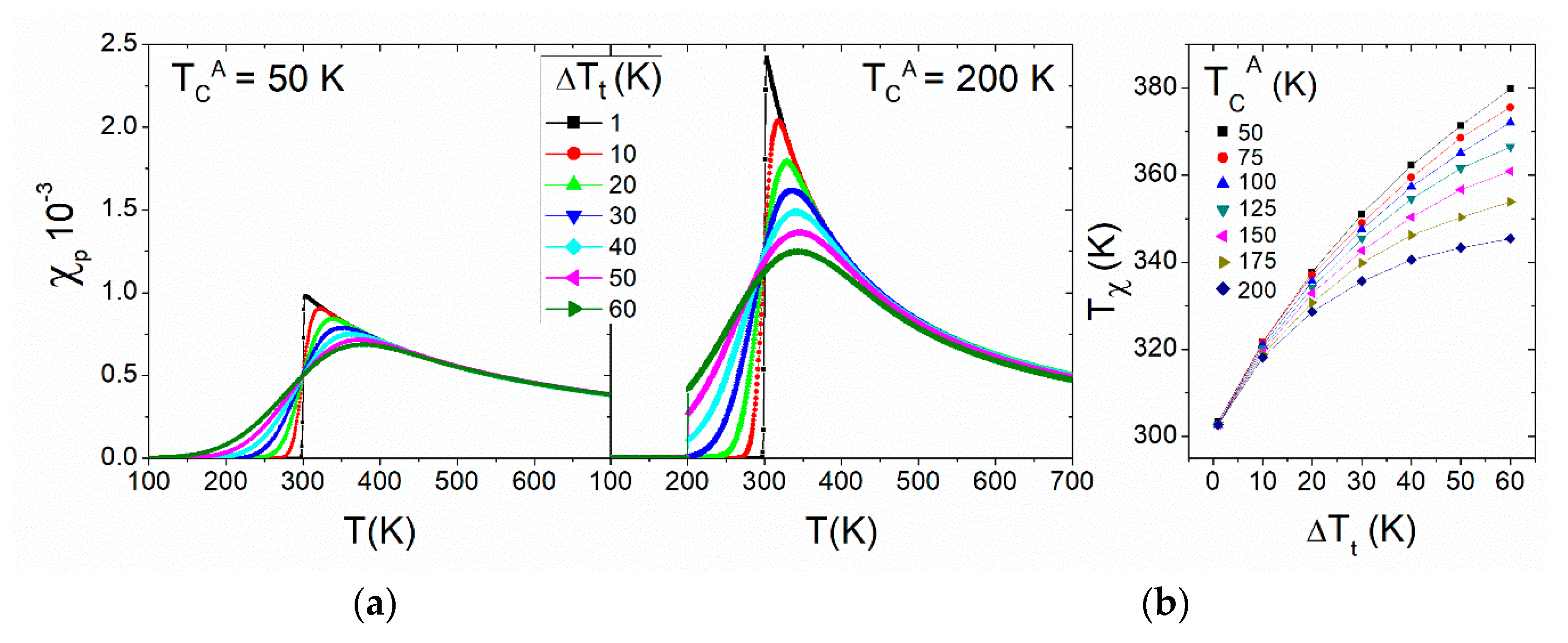

4. Models to Determine the Parameters of a Distribution of Transition Temperatures

5. Experimental Test of the Proposed Model

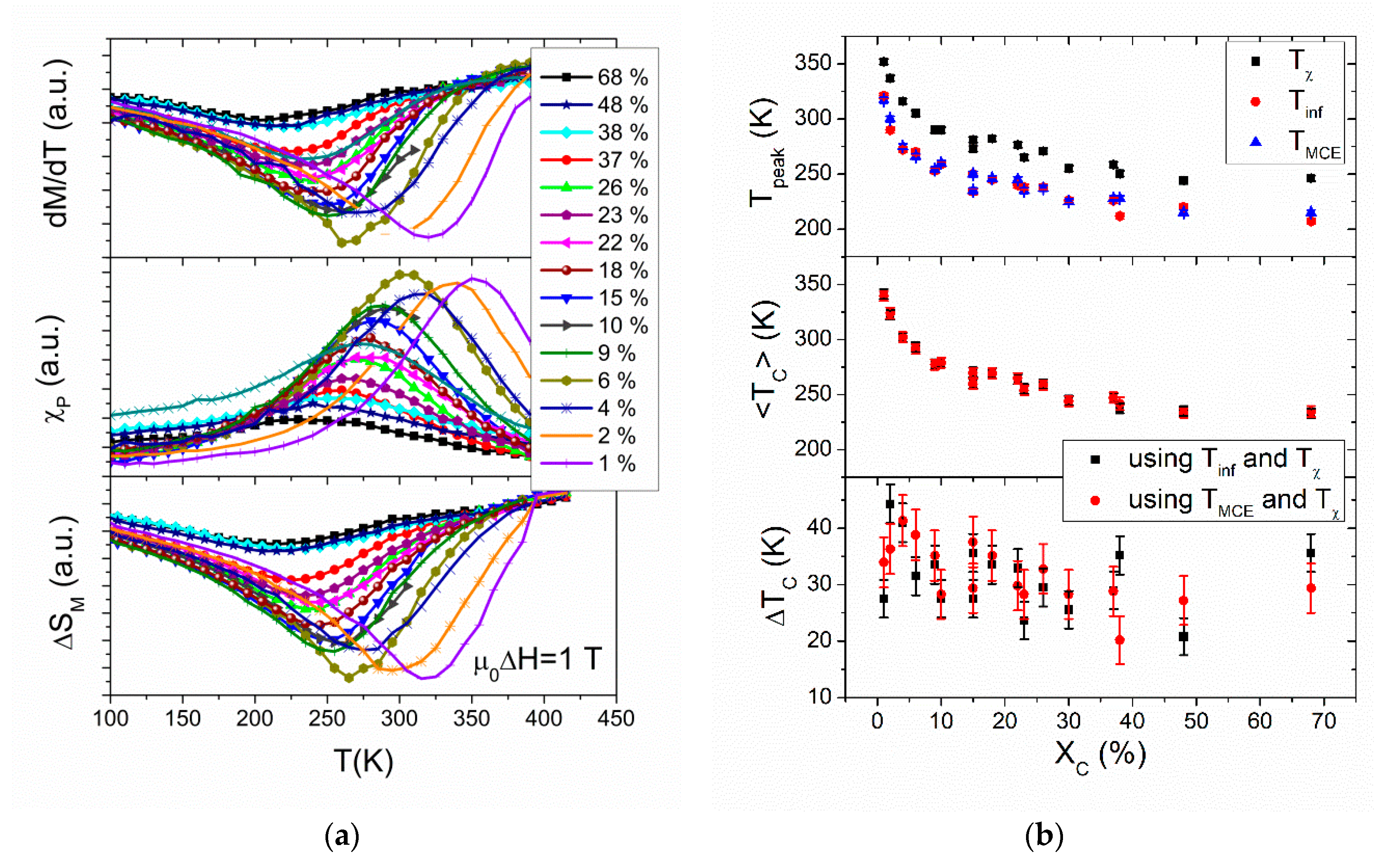

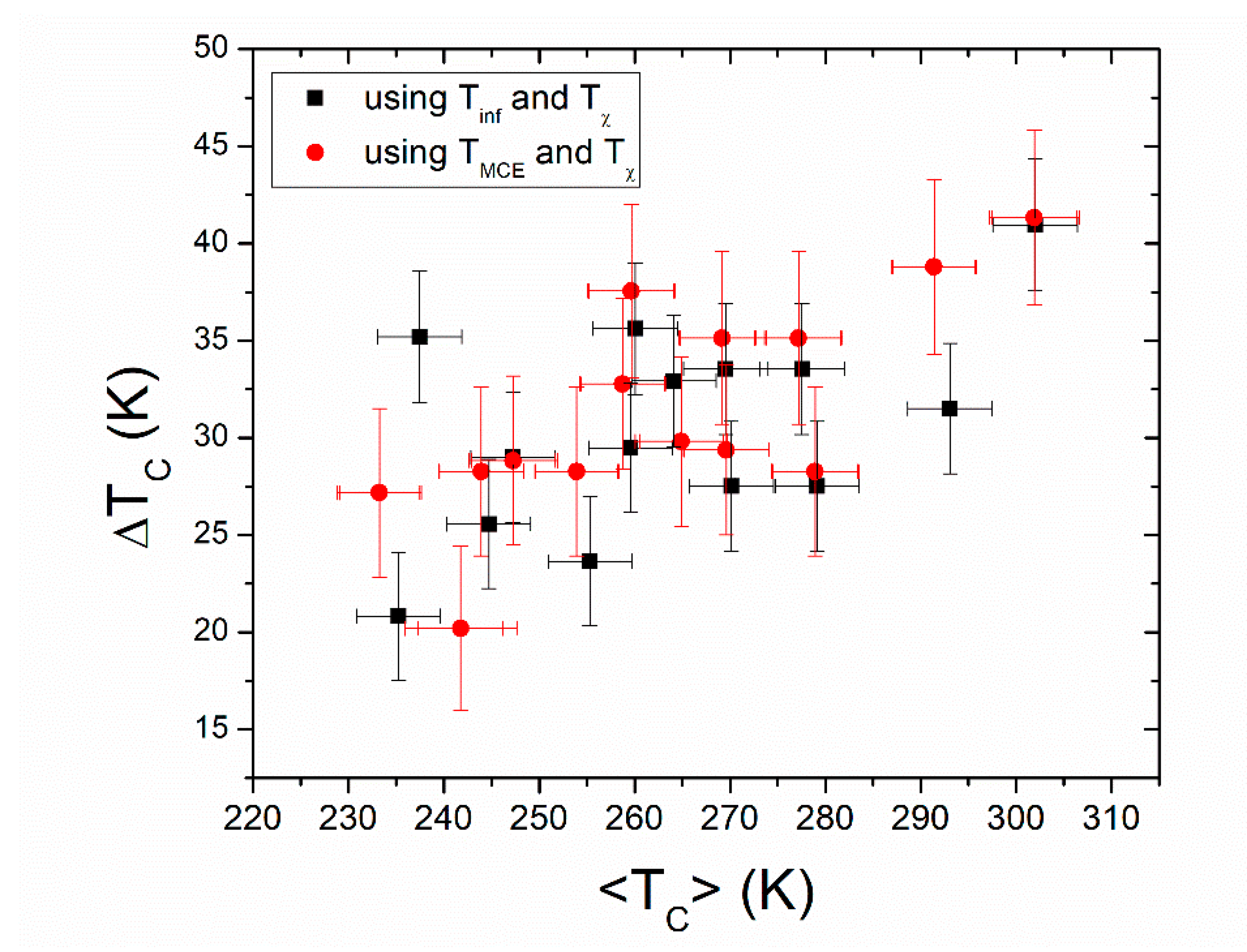

5.1. Partially Amorphous Fe75Nb10B15 Mechanically Alloyed Systems

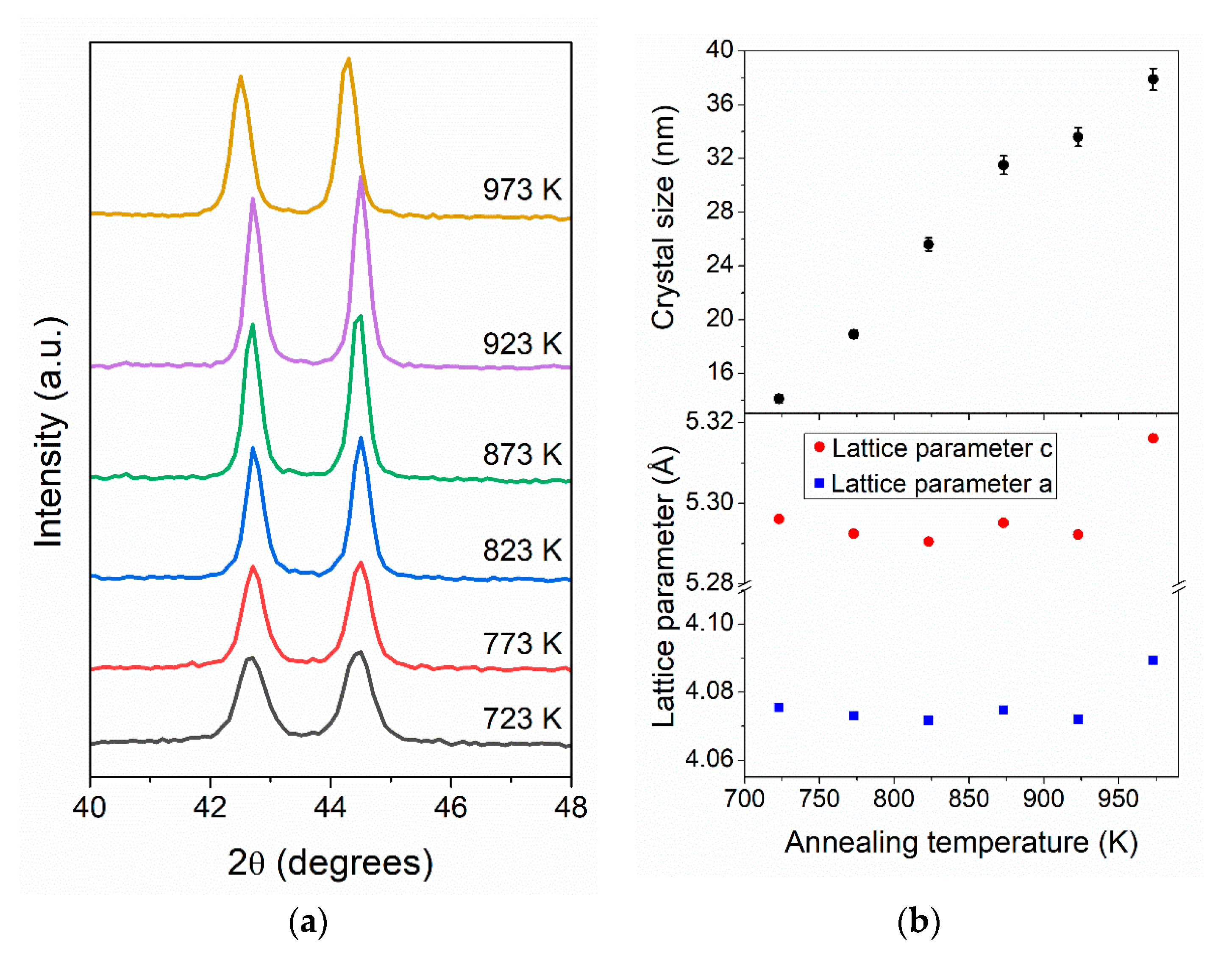

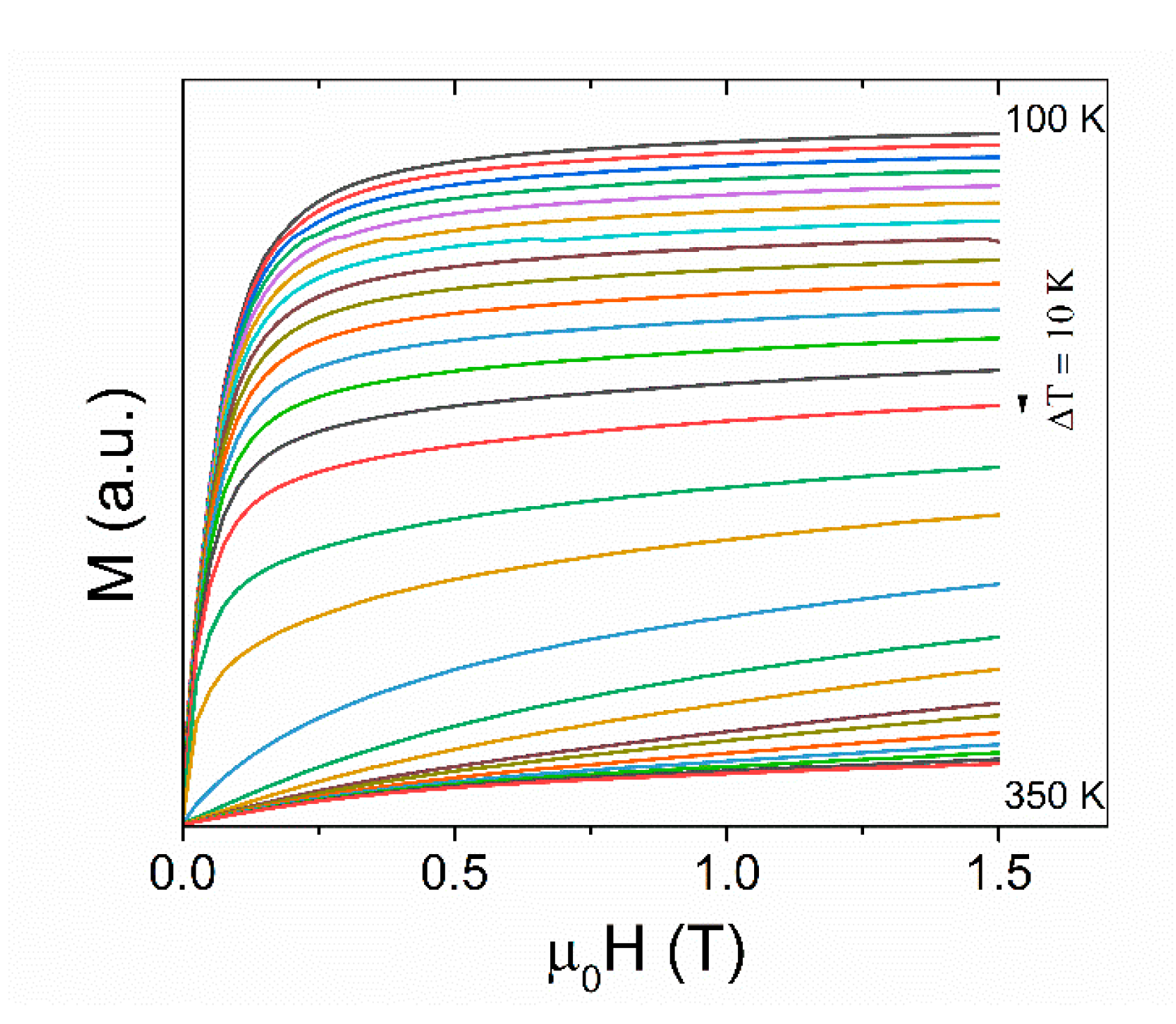

5.2. Half-Heusler MnCo0.8Fe0.2Ge Intermetallics

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Blundell, S. Magnetism in Condensed Matter; Oxford master series in condensed matter physics; Oxford University Press: London, UK, 2001; ISBN 0198505914. [Google Scholar]

- Jia, L.; Sun, J.R.; Shen, J.; Dong, Q.Y.; Zou, J.D.; Gao, B.; Zhao, T.Y.; Zhang, H.W.; Hu, F.X.; Shen, B.G. Magnetocaloric effects in the La(Fe,Si)13 intermetallics doped by different elements. J. Appl. Phys. 2009, 105, 07A924. [Google Scholar] [CrossRef]

- Bean, C.P.; Rodbell, D.S. Magnetic Disorder as a First-Order Phase Transformation. Phys. Rev. 1962, 126, 104–115. [Google Scholar] [CrossRef]

- Planes, A.; Stern-Taulats, E.; Castán, T.; Vives, E.; Mañosa, L.; Saxena, A. Caloric and Multicaloric Effects in Shape Memory Alloys. Mater. Today Proc. 2015, 2, S477–S484. [Google Scholar] [CrossRef]

- Ghahremani, M.; ElBidweihy, H.; Bennett, L.H.; Della Torre, E.; Zou, M.; Johnson, F. Implicit measurement of the latent heat in a magnetocaloric NiMnIn Heusler alloy. J. Appl. Phys. 2013, 113, 17A943. [Google Scholar] [CrossRef]

- Pareti, L.; Solzi, M.; Albertini, F.; Paoluzi, A. Giant entropy change at the co-occurrence of structural and magnetic transitions in the Ni2.19Mn0.81Ga Heusler alloy. Eur. Phys. J. B 2003, 32, 303–307. [Google Scholar] [CrossRef] [Green Version]

- Kosogor, A.; L’vov, A.V.; Lázpita, P.; Seguí, C.; Cesari, E. Magnetocaloric Effect Caused by Paramagnetic Austenite–Ferromagnetic Martensite Phase Transformation. Metals 2018, 9, 11. [Google Scholar] [CrossRef] [Green Version]

- Han, Z.D.; Wang, D.H.; Zhang, C.L.; Xuan, H.C.; Gu, B.X.; Du, Y.W. Low-field inverse magnetocaloric effect in Ni50−xMn39+xSn11 Heusler alloys. Appl. Phys. Lett. 2007, 90, 42507. [Google Scholar] [CrossRef]

- Gottschall, T.; Skokov, K.P.; Benke, D.; Gruner, M.E.; Gutfleisch, O. Contradictory role of the magnetic contribution in inverse magnetocaloric Heusler materials. Phys. Rev. B 2016, 93, 184431. [Google Scholar] [CrossRef]

- Madiligama, A.S.B.; Ari-Gur, P.; Ren, Y.; Koledov, V.v.; Dilmieva, E.T.; Kamantsev, A.P.; Mashirov, A.v.; Shavrov, V.G.; Gonzalez-Legarreta, L.; Grande, B.H. Thermal and magnetic hysteresis associated with martensitic and magnetic phase transformations in Ni52Mn25In16Co7 Heusler alloy. J. Mag. Mag. Mater. 2017, 442, 25–35. [Google Scholar] [CrossRef]

- Sutou, Y.; Imano, Y.; Koeda, N.; Omori, T.; Kainuma, R.; Ishida, K.; Oikawa, K. Magnetic and martensitic transformations of NiMnX(X=In, Sn, Sb) ferromagnetic shape memory alloys. Appl. Phys. Lett. 2004, 85, 4358–4360. [Google Scholar] [CrossRef]

- Manchón-Gordón, A.F.; Moreno-Ramírez, L.M.; Ipus, J.J.; Blázquez, J.S.; Conde, C.F.; Franco, V.; Conde, A. A procedure to obtain the parameters of Curie temperature distribution from thermomagnetic and magnetocaloric data. J. Non. Cryst. Solids 2019, 520, 119460. [Google Scholar] [CrossRef]

- Arrott, A.; Noakes, J.E. Approximate Equation of State For Nickel Near its Critical Temperature. Phys. Rev. Lett. 1967, 19, 786–789. [Google Scholar] [CrossRef]

- Kirchmayr, H.R.; Poldy, C.A. Magnetism in rare earth—3d intermetallics. J. Magn. Magn. Mater. 1978, 8, 1–42. [Google Scholar] [CrossRef]

- Liu, X.B.; Altounian, Z. Magnetocaloric effect in (Er1-xGdx)Co2 pseudobinary compounds. J. Magn. Magn. Mater. 2005, 292, 83–88. [Google Scholar] [CrossRef]

- Jensen, J.; Mackintosh, A.R. Rare Earth Magnetism: Structures and Excitations; International Series of Monographs on Physics; Oxford Science Publications, Clarendon Press: London, UK, 1991; ISBN 0198520271. [Google Scholar]

- Stearns, M.B. Why is iron magnetic? Phys. Today 1978, 31, 34–39. [Google Scholar] [CrossRef]

- Janke-Gilman, N.; Hochstrasser, M.; Willis, R.F. Measuring atomic moment and magnetic order through magnetic linear dichroism with angular dependence studies of transition-metal alloys. Phys. Rev. B 2004, 70, 184439. [Google Scholar] [CrossRef]

- McHenry, M.E.; Willard, M.A.; Laughlin, D.E. Amorphous and nanocrystalline materials for applications as soft magnets. Prog. Mater. Sci. 1999, 44, 291–433. [Google Scholar] [CrossRef]

- Huo, J.T.; Zhao, D.Q.; Bai, H.Y.; Axinte, E.; Wang, W.H. Giant magnetocaloric effect in Tm-based bulk metallic glasses. J. Non. Cryst. Solids 2013, 359, 1–4. [Google Scholar] [CrossRef]

- Du, J.; Zheng, Q.; Li, Y.B.; Zhang, Q.; Li, D.; Zhang, Z.D. Large magnetocaloric effect and enhanced magnetic refrigeration in ternary Gd-based bulk metallic glasses. J. Appl. Phys. 2008, 103, 23918. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.K.; Lai, C.H.; Hsieh, C.C.; Zhao, X.G.; Chang, H.W.; Chang, W.C.; Li, W. Magnetocaloric effect of the Gd-LRE-Al-(Co, Fe) (LRE=La, Ce, Pr, Nd) glassy ribbons in the intermediate temperature. J. Phys. Conf. Ser. 2011, 266, 12002. [Google Scholar] [CrossRef]

- Fang, Y.K.; Chen, H.C.; Hsieh, C.C.; Chang, H.W.; Zhao, X.G.; Chang, W.C.; Li, W. Structures and magnetocaloric effects of Gd65−xRExFe20Al15 (x = 0–20; RE=Tb, Dy, Ho, and Er) ribbons. J. Appl. Phys. 2011, 109, 07A933. [Google Scholar] [CrossRef]

- Foldeaki, M.; Giguère, A.; Gopal, B.R.; Chahine, R.; Bose, T.K.; Liu, X.Y.; Barclay, J.A. Composition dependence of magnetic properties in amorphous rare-earth-metal-based alloys. J. Magn. Magn. Mater. 1997, 174, 295–308. [Google Scholar] [CrossRef]

- Liu, X.Y.; Barclay, J.A.; Gopal, R.B.; Földeàki, M.; Chahine, R.; Bose, T.K.; Schurer, P.J.; LaCombe, J.L. Thermomagnetic properties of amorphous rare-earth alloys with Fe, Ni, or Co. J. Appl. Phys. 1996, 79, 1630–1641. [Google Scholar] [CrossRef]

- Johnson, F.; Shull, R.D. Amorphous-FeCoCrZrB ferromagnets for use as high-temperature magnetic refrigerants. J. Appl. Phys. 2006, 99, 08K909. [Google Scholar] [CrossRef]

- Wang, Y.; Bi, X. The role of Zr and B in room temperature magnetic entropy change of FeZrB amorphous alloys. Appl. Phys. Lett. 2009, 95, 262501. [Google Scholar] [CrossRef]

- Álvarez, P.; Gorria, P.; Sánchez Marcos, J.; Fernández Barquín, L.; Blanco, J.A. The role of boron on the magneto-caloric effect of FeZrB metallic glasses. Intermetallics 2010, 18, 2464–2467. [Google Scholar] [CrossRef]

- Franco, V.; Blázquez, J.S.; Ipus, J.J.; Law, J.Y.; Moreno-Ramírez, L.M.; Conde, A. Magnetocaloric effect: From materials research to refrigeration devices. Prog. Mater. Sci. 2018, 93, 112–232. [Google Scholar] [CrossRef]

- Dörr, K. Ferromagnetic manganites: Spin-polarized conduction versus competing interactions. J. Phys. D. Appl. Phys. 2006, 39, R125–R150. [Google Scholar] [CrossRef]

- Phan, M.-H.; Yu, S.-C. Review of the magnetocaloric effect in manganite materials. J. Magn. Magn. Mater. 2007, 308, 325–340. [Google Scholar] [CrossRef]

- Wali, M.; Skini, R.; Khlifi, M.; Dhahri, E.; Hlil, E.K. A giant magnetocaloric effect with a tunable temperature transition close to room temperature in Na-deficient La0.8Na0.2−x□xMnO3 manganites. Dalt. Trans. 2015, 44, 12796–12803. [Google Scholar] [CrossRef]

- Regaieg, Y.; Sicard, L.; Monnier, J.; Koubaa, M.; Ammar-Merah, S.; Cheikhrouhou, A. Magnetic and magnetocaloric properties of La0.85(Na1−xKx)0.15MnO3 ceramics produced by reactive spark plasma sintering. J. Appl. Phys. 2014, 115, 17A917. [Google Scholar] [CrossRef]

- Skini, R.; Omri, A.; Khlifi, M.; Dhahri, E.; Hlil, E.K. Large magnetocaloric effect in lanthanum-deficiency manganites La0.8−x□xCa0.2MnO3 (0.00≤x≤0.20) with a first-order magnetic phase transition. J. Magn. Magn. Mater. 2014, 364, 5–10. [Google Scholar] [CrossRef]

- Szewczyk, A.; Gutowska, M.; Dabrowski, B.; Plackowski, T.; Danilova, N.P.; Gaidukov, Y.P. Specific heat anomalies in La1-xSrxMnO3 (0.12 <= x <= 0.2). Phys. Rev. B 2005, 71, 224432. [Google Scholar]

- Mira, J.; Rivas, J.; Hueso, L.E.; Rivadulla, F.; López Quintela, M.A. Drop of magnetocaloric effect related to the change from first- to second-order magnetic phase transition in La2/3(Ca1−xSrx)1/3MnO3. J. Appl. Phys. 2002, 91, 8903–8905. [Google Scholar] [CrossRef]

- Barik, S.K.; Mahendiran, R. Effect of Bi doping on magnetic and magnetocaloric properties of La0.7−xBixSr0.3MnO3 (0≤x≤0.4). J. Appl. Phys. 2010, 107, 93906. [Google Scholar] [CrossRef]

- Moreno-Ramírez, L.M.; Romero-Muñiz, C.; Law, J.Y.; Franco, V.; Conde, A.; Radulov, I.A.; Maccari, F.; Skokov, K.P.; Gutfleisch, O. Tunable first order transition in La(Fe,Cr,Si)13 compounds: Retaining magnetocaloric response despite a magnetic moment reduction. Acta Mater. 2019, 175, 406–414. [Google Scholar] [CrossRef]

- Fujita, A.; Fujieda, S.; Hasegawa, Y.; Fukamichi, K. Itinerant-electron meta-magnetic transition and large magnetocaloric effects in La(FexSi1-x)13 compounds and their hydrides. Phys. Rev. B 2003, 67, 104416. [Google Scholar] [CrossRef] [Green Version]

- Hu, F.X.; Gao, J.; Qian, X.L.; Ilyn, M.; Tishin, A.M.; Sun, J.R.; Shen, B.G. Magnetocaloric effect in itinerant electron metamagnetic systems La(Fe1−xCox)11.9Si1.1. J. Appl. Phys. 2005, 97, 10M303. [Google Scholar] [CrossRef] [Green Version]

- Fujieda, S.; Fujita, A.; Fukamichi, K. Enhancement of magnetocaloric effects in La1−zPrz(Fe0.88Si0.12)13 and their hydrides. J. Appl. Phys. 2007, 102, 23907. [Google Scholar] [CrossRef]

- Herzer, G. Soft Magnetic Materials—Nanocrystalline Alloys. Handb. Magn. Adv. Magn. Mater. 2007. [Google Scholar]

- Gutfleisch, O.; Willard, M.A.; Brück, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic Materials and Devices for the 21st Century: Stronger, Lighter, and More Energy Efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef]

- Wohlfarth, E.P. Magnetic properties of single domain ferromagnetic particles. J. Magn. Magn. Mater. 1983, 39, 39–44. [Google Scholar] [CrossRef]

- Morup, S.; Hansen, M.F. Handbook of Magnetic and Advanced Magnetic Materials; John Willey & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Cao, L.; Xie, D.; Guo, M.; Park, H.S.; Fujita, T. Size and shape effects on Curie temperature of ferromagnetic nanoparticles. Trans. Nonferrous Met. Soc. China 2007, 17, 1451–1455. [Google Scholar] [CrossRef]

- Jensen, P.J.; Dreyssé, H.; Bennemann, K.H. Thickness dependence of the magnetization and the Curie temperature of ferromagnetic thin films. Surf. Sci. 1992, 269–270, 627–631. [Google Scholar] [CrossRef]

- Santos, J.D.; Sanchez, T.; Alvarez, P.; Sanchez, M.L.; Sanchez Llamazares, J.L.; Hernando, B.; Escoda, L.; Escoda, L.; Suñol, J.J.; Varga, R. Microstructure and magnetic properties of Ni50Mn37Sn13 Heusler alloy ribbons. J. Apply. Phys. 2008, 103, 07B326. [Google Scholar] [CrossRef]

- Andrade, V.M.; Vivas, R.J.C.; Pedro, S.S.; Tedesco, J.C.G.; Rossi, A.L.; Coelho, A.A.; Rocco, D.L.; Reis, M.S. Magnetic and magnetocaloric properties of La0.6Ca0.4MnO3 tunable by particle size and dimensionality. Acta Mater. 2016, 102, 49–55. [Google Scholar] [CrossRef] [Green Version]

- Das, K.; Das, I. Giant enhancement of magnetocaloric effect at room temperature by the formation of nanoparticle of La0.48Ca0.52MnO3 compound. J. Appl. Phys. 2016, 119, 93903. [Google Scholar] [CrossRef]

- Dong, Q.; Shen, B.; He, S.; Jiang, H.; Zheng, W.; Sun, J. Effect of Crystal Grain Dimension on the Magnetic Properties and Magnetocaloric Effects in DyCuAl Compound. J. Nanosci. Nanotechnol. 2012, 12, 1040–1043. [Google Scholar] [CrossRef]

- Gorria, P.; Álvarez, P.; Marcos, J.S.; Sánchez Llamazares, J.L.; Pérez, M.J.; Blanco, J.A. Crystal structure, magnetocaloric effect and magnetovolume anomalies in nanostructured Pr2Fe17. Acta Mater. 2009, 57, 1724–1733. [Google Scholar] [CrossRef]

- Wang, W.; Yu, J.; Zhai, Q.; Luo, Z.; Zheng, H. Origin of retarded martensitic transformation in Heusler Ni–Mn–Sn melt-spun ribbons. Intermetallics 2013, 42, 126–129. [Google Scholar] [CrossRef]

- Dasa, R.; Saravanan, P.; Arvindha Babu, D.; Perumal, A.; Srinivasan, A. Influence of solidification rate and heat treatment on magnetic refrigerant properties of melt spun Ni51Mn34In14Si1 ribbons. J. Magn. Magn. Mater. 2013, 344, 152–157. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, Q.; Xia, W.; Zhang, J.; Du, J.; Yan, A. Enhanced large magnetic entropy change and adiabatic temperature change of Ni43Mn46Sn11 alloys by a rapid solidification method. Scr. Mater. 2015, 104, 41–44. [Google Scholar] [CrossRef]

- Aguilar-Ortiz, C.O.; Camarillo-García, J.P.; Vergara, J.; Álvarez-Alonso, P.; Salazar, D.; Chernenko, V.A.; Flores-Zúñiga, H. Effect of solidification rate on martensitic transformation behavior and adiabatic magnetocaloric effect of Ni50Mn35In15 ribbons. J. Alloys Compd. 2018, 748, 464–472. [Google Scholar] [CrossRef]

- Waitz, T.; Karnthaler, H.P. Martensitic transformation of NiTi nanocrystals embedded in an amorphous matrix. Acta Mater. 2004, 52, 5461–5469. [Google Scholar] [CrossRef]

- Seki, K.; Kura, H.; Sato, T.; Taniyama, T. Size dependence of martensite transformation temperature in ferromagnetic shape memory alloy FePd. J. Apply. Phys. 2008, 103, 063910. [Google Scholar] [CrossRef]

- Amaral, J.S.; Tavares, P.B.; Reis, M.S.; Araújo, J.P.; Mendonça, T.M.; Amaral, V.S.; Vieira, J.M. The effect of chemical distribution on the magnetocaloric effect: A case study in second-order phase transition manganites. J. Non. Cryst. Solids 2008, 354, 5301–5303. [Google Scholar] [CrossRef]

- Pizarro, R.; Garitaonandia, J.S.; Plazaola, F.; Barandiarán, J.M.; Greneche, J.M. Magnetic and Mössbauer study of multiphase Fe-Zr amorphous powders obtained by high energy ball milling. J. Phys. Condens. Matter. 2000, 12, 3101–3112. [Google Scholar] [CrossRef]

- Fujita, A.; Fukamichi, K.; Gejima, F.; Kainuma, R.; Ishida, K. Magnetic properties and large magnetic-field-induced strains in off-stoichiometric Ni–Mn–Al Heusler alloys. Appl Phys. Lett. 2000, 77, 3054. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, W.; Gao, Z.Y.; Sui, J.H. Microstructures and magnetic property in Mn-rich off-stoichiometric Mn2NiGa Heusler alloys. Scripta Mater. 2008, 58, 798–801. [Google Scholar] [CrossRef]

- Rama Rao, N.V.; Gopalan, R.; Manivel Raja, M.; Chandrasekaran, V.; Suresh, K.G. Mössbauer studies on structural ordering and magnetic properties of melt-spun Ni–Fe–Ga ribbon. Appl. Phys. Lett. 2008, 93, 202503. [Google Scholar] [CrossRef]

- Passamani, E.C.; Córdova, C.; Alves, A.L.; Moscon, P.S.; Larica, C.; Takeuchi, A.Y.; Biondo, A. Magnetic studies of Fe-doped martensitic Ni2Mn1.44Sn0.56-type Heusler alloy. J. Phys. D: Appl. Phys. 2009, 42, 215006. [Google Scholar] [CrossRef]

- D’Souza, S.W.; Roy, T.; Barman, S.R.; Chakrabarti, A. Magnetic properties and electronic structure of Mn–Ni–Ga magnetic shape memory alloys. J. Phys. Condens. Matter 2014, 26, 506001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gutierrez, J.; Lazpita, P.; Barandiaran, J.M.; Fdez-Gubieda, M.L.; Chaboy, J.; Kawamura, N. Annealing influence on the atomic ordering and magnetic moment in a Ni–Mn–Ga alloy. J. Magn. Magn. Mater. 2007, 316, e610. [Google Scholar] [CrossRef]

- Slater, J.C. Note on the Effect of Pressure on the Curie Point of Iron-Nickel Alloys. Phys. Rev. 1940, 58, 54–56. [Google Scholar] [CrossRef]

- Singh, N.K.; Suresh, K.G.; Nigam, A.K.; Malik, S.K.; Coelho, A.A.; Gama, S. Itinerant electron metamagnetism and magnetocaloric effect in RCo2-based Laves phase compounds. J. Magn. Magn. Mater. 2007, 317, 68–79. [Google Scholar] [CrossRef] [Green Version]

- Khmelevskyi, S.; Mohn, P. The order of the magnetic phase transitions in RCo2(R = rare earth) intermetallic compounds. J. Phys. Condens. Matter 2000, 12, 9453–9464. [Google Scholar] [CrossRef]

- Syschenko, O.; Sechovsky, V.; Divis, M.; Fujita, T.; Hauser, R.; Fujii, H. Magnetism in rare earth Co2 compounds under high pressures. J. Appl. Phys. 2001, 89, 7323. [Google Scholar] [CrossRef]

- Kozlenko, D.P.; Burzo, E.; Vlaic, P.; Kichanov, S.E.; Rutkauskas, A.V.; Savenko, B.N. Sequential Cobalt Magnetization Collapse in ErCo2: Beyond the Limits of Itinerant Electron Metamagnetism. Sci. Rep. 2015, 5, 8620. [Google Scholar] [CrossRef] [Green Version]

- Lyubina, J.; Nenkov, K.; Schultz, L.; Gutfleisch, O. Multiple Metamagnetic Transitions in the Magnetic La(Fe,Si)13Hx. Phys. Rev. Lett. 2008, 101, 177203. [Google Scholar] [CrossRef]

- Bose, S.K.; Kudrnovsky, J.; Drchal, V.; Turek, I. Pressure dependence of Curie temperature and resistivity in complex Heusler alloys. Phys. Rev. B 2011, 84, 174422. [Google Scholar] [CrossRef] [Green Version]

- Moreno-Ramírez, L.M.; Ipus, J.J.; Franco, V.; Blázquez, J.S.; Conde, A. Analysis of magnetocaloric effect of ball milled amorphous alloys: Demagnetizing factor and Curie temperature distribution. J. Alloys Compd. 2015, 622, 606–609. [Google Scholar] [CrossRef]

- M’Nassri, R.; Cheikhrouhou-Koubaa, W.; Koubaa, M.; Boudjada, N.; Cheikhrouhou, A. Magnetic and magnetocaloric properties of Pr0.6-xEuxSr0.4MnO3 manganese oxides. Sol. Stat. Comm. 2011, 151, 1579–1582. [Google Scholar] [CrossRef]

- Alvarez-Alonso, P.; Sánchez Llamazares, J.L.; Sánchez-Valdés, C.F.; Cuello, G.J.; Franco, V.; Gorria, P.; Blanco, J.A. On the broadening of the magnetic entropy change due to Curie temperature distribution. J. Appl. Phys. 2008, 115, 17A929. [Google Scholar] [CrossRef] [Green Version]

- Blázquez, J.S.; Franco, V.; Conde, A. Enhancement of the magnetic refrigerant capacity in partially amorphous Fe70Zr30 powders obtained by mechanical alloying. Intermetallics 2012, 26, 52–56. [Google Scholar] [CrossRef]

- Franco, V.; Blázquez, J.S.; Conde, A. Field dependence of the magnetocaloric effect in materials with a second order phase transition: A master curve for the magnetic entropy change. Appl. Phys. Lett. 2006, 89, 222512. [Google Scholar] [CrossRef]

- Bahl, C.R.H.; Bjørk, R.; Smith, A.; Nielsen, K.K. Properties of magnetocaloric materials with a distribution of Curie temperatures. J. Magn. Magn. Mater. 2012, 324, 564–568. [Google Scholar] [CrossRef]

- Blázquez, J.S.; Moreno-Ramírez, L.M.; Ipus, J.J.; Kiss, L.F.; Kaptás, D.; Kemény, T.; Franco, V.; Conde, A. Effect of α-Fe impurities on the field dependence of magnetocaloric response in LaFe11.5Si1.5. J. Alloys Compd. 2015, 646, 101–105. [Google Scholar] [CrossRef]

- Ipus, J.J.; Moreno-Ramírez, L.M.; Blázquez, J.S.; Franco, V.; Conde, A. A procedure to extract the magnetocaloric parameters of the single phases from experimental data of a multiphase system. Appl. Phys. Lett. 2014, 105, 172405. [Google Scholar] [CrossRef] [Green Version]

- Campillo, G.; Berger, A.; Osorio, J.; Pearson, J.E.; Bader, S.D.; Baca, E.; Prieto, P. Substrate dependence of magnetic properties of La0.67Ca0.33MnO3 films. J. Magn. Magn. Mater. 2001, 237, 61–68. [Google Scholar] [CrossRef]

- Berger, A.; Campillo, G.; Vivas, P.; Pearson, J.E.; Bader, S.D.; Baca, E.; Prieto, P. Critical exponents of inhomogeneous ferromagnets. J. Appl. Phys. 2002, 91, 8393–8395. [Google Scholar] [CrossRef] [Green Version]

- Bebenin, N.G.; Zainullina, R.I.; Ustinov, V. V Magnetocaloric effect in inhomogeneous ferromagnets. J. Appl. Phys. 2013, 113, 73907. [Google Scholar] [CrossRef]

- Brown, W.F. Theory of the Approach to Magnetic Saturation. Phys. Rev. 1940, 58, 736–743. [Google Scholar] [CrossRef]

- Ipus, J.J.; Blázquez, J.S.; Franco, V.; Lozano-Pérez, S.; Conde, A. Role of starting phase of boron on the mechanical alloying of FeNbB composition. J. Alloys Compd. 2013, 553, 119–124. [Google Scholar] [CrossRef]

- Ipus, J.J.; Blázquez, J.S.; Franco, V.; Conde, A. The use of amorphous boron powder enhances mechanical alloying in soft magnetic FeNbB alloy: A magnetic study. J. Appl. Phys. 2013, 113, 17A330. [Google Scholar] [CrossRef]

- Vidal-Crespo, A.; Ipus, J.J.; Blázquez, J.S.; Conde, A. Mechanical Amorphization and Recrystallization of Mn-Co(Fe)-Ge(Si) Compositions. Metals 2019, 9, 534. [Google Scholar] [CrossRef] [Green Version]

- Available online: http://www.lakeshore.com/products/Vibrating-Sample-Magnetometer/Pages/MCE.aspx (accessed on 1 December 2019).

- Blázquez, J.S.; Franco, V.; Conde, A. The influence of Cu addition on the crystallization and magnetic properties of FeCoNbB alloys. J. Phys. Condens. Matter 2002, 14, 11717–11727. [Google Scholar] [CrossRef] [Green Version]

- Vidal-Crespo, A.; Ipus, J.J.; Blázquez, J.S.; Conde, A. Optimization of thermal treatment to produce magnetocaloric MnCo(Fe)Ge intermetallic from mechanical alloying precursors. submitted.

- Johnson, V. Diffusionless orthorhombic to hexagonal transitions in ternary silicides and germanides. Inorg. Chem. 1975, 14, 1117–1120. [Google Scholar] [CrossRef]

- Li, G.J.; Liu, E.K.; Zhang, H.G.; Zhang, Y.J.; Chen, J.L.; Wang, W.H.; Zhang, H.W.; Wu, G.H.; Yu, S.Y. Phase diagram, ferromagnetic martensitic transformation and magnetoresponsive properties of Fe-doped MnCoGe alloys. J. Magn. Magn. Mater. 2013, 332, 146–150. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manchón-Gordón, A.F.; López-Martín, R.; Vidal-Crespo, A.; Ipus, J.J.; Blázquez, J.S.; Conde, C.F.; Conde, A. Distribution of Transition Temperatures in Magnetic Transformations: Sources, Effects and Procedures to Extract Information from Experimental Data. Metals 2020, 10, 226. https://doi.org/10.3390/met10020226

Manchón-Gordón AF, López-Martín R, Vidal-Crespo A, Ipus JJ, Blázquez JS, Conde CF, Conde A. Distribution of Transition Temperatures in Magnetic Transformations: Sources, Effects and Procedures to Extract Information from Experimental Data. Metals. 2020; 10(2):226. https://doi.org/10.3390/met10020226

Chicago/Turabian StyleManchón-Gordón, Alejandro F., Raúl López-Martín, Antonio Vidal-Crespo, Jhon J. Ipus, Javier S. Blázquez, Clara F. Conde, and A. Conde. 2020. "Distribution of Transition Temperatures in Magnetic Transformations: Sources, Effects and Procedures to Extract Information from Experimental Data" Metals 10, no. 2: 226. https://doi.org/10.3390/met10020226