High-Temperature Nano-Indentation Creep Behavior of Multi-Principal Element Alloys under Static and Dynamic Loads

Abstract

:1. Introduction

2. Experimental

3. Results

4. Discussion

5. Conclusions

- (1)

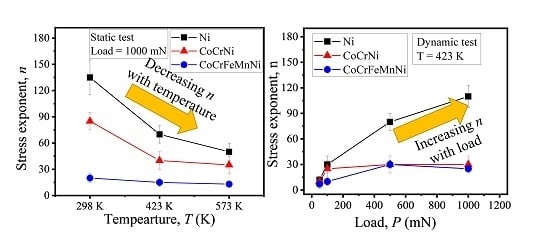

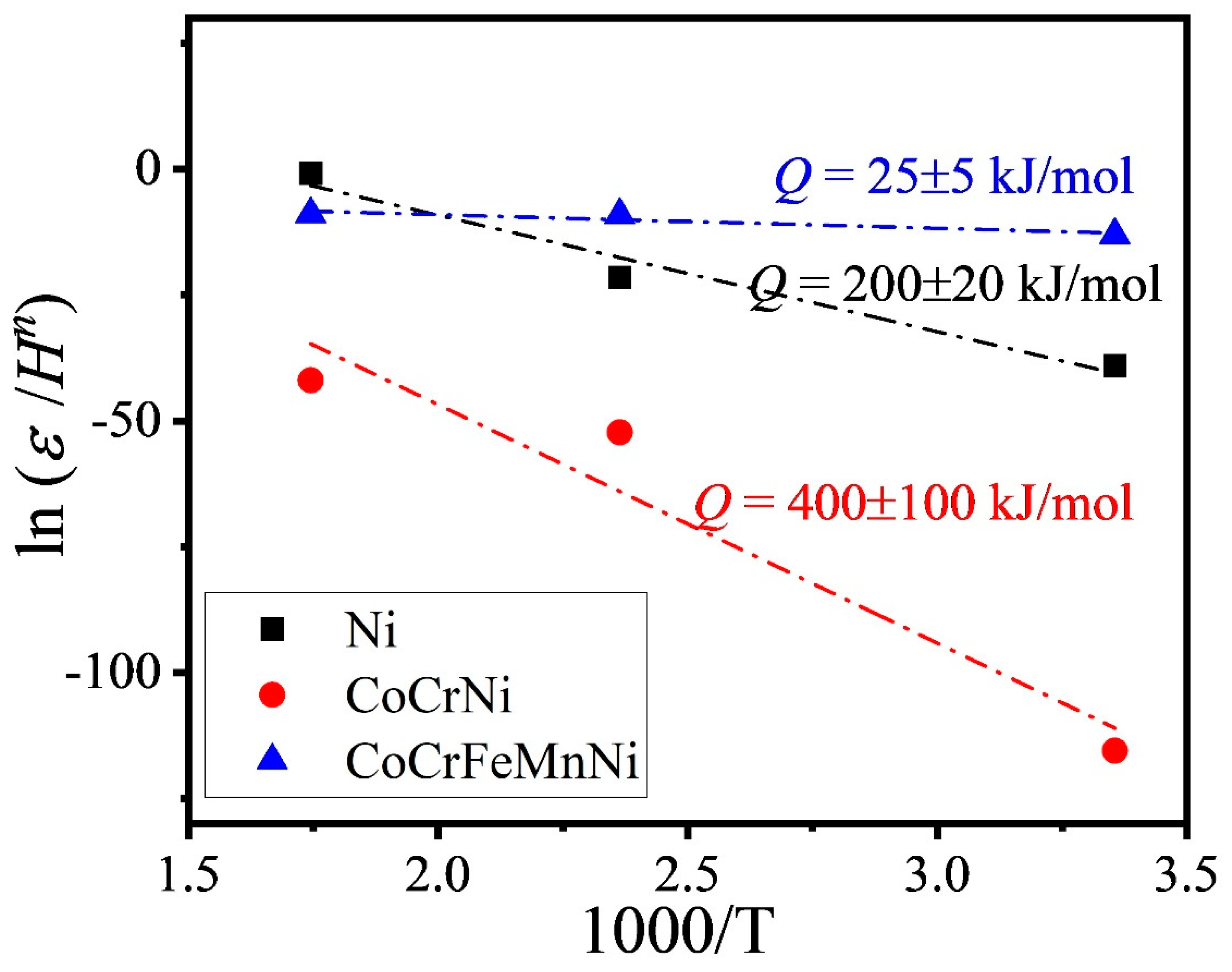

- The value of n was in the range of 15 to 135 indicating that time-dependent deformation for all alloys was dislocation dominated.

- (2)

- Activation volume data suggested dislocation glide dominated deformation mechanism for MPEAs and dislocation-dislocation interaction for pure Ni.

- (3)

- The stress exponent decreased with increasing temperature due to thermally activated dislocations. The stress exponent for CoCrFeMnNi was found to be temperature insensitive possibly due to dislocation glide dominated deformation.

- (4)

- The creep stress exponent increased with increasing load (depth) due to higher generation rate of dislocations and their entanglement at greater depth.

- (5)

- CoCrNi showed creep behavior similar to pure Ni at room temperature while it became closer to CoCrFeMnNi at higher temperatures. This may be due to the local chemical ordering in CoCrNi at lower temperatures while becoming more random solid solution like at higher temperatures.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Senkov, O.N.; Miracle, D.B.; Chaput, K.J.; Couzinie, J.-P. Development and exploration of refractory high entropy alloys—A review. J. Mater. Res. 2018, 33, 3092–3128. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Thurston, K.V.; Bei, H.; Wu, Z.; George, E.P.; Ritchie, R.O. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 2016, 7, 1–8. [Google Scholar] [CrossRef]

- Gali, A.; George, E.P. Tensile properties of high-and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef] [Green Version]

- Nair, R.B.; Arora, H.S.; Mukherjee, S.; Singh, S.; Singh, H.; Grewal, H.S. Exceptionally high cavitation erosion and corrosion resistance of a high entropy alloy. Ultrason. Sonochem. 2018, 41, 252–260. [Google Scholar] [CrossRef]

- Ayyagari, A.; Hasannaeimi, V.; Grewal, H.S.; Arora, H.; Mukherjee, S. Corrosion, erosion and wear behavior of complex concentrated alloys: A review. Metals 2018, 8, 603. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.D.; Liu, P.; Guo, S.; Hirata, A.; Fujita, T.; Nieh, T.G.; Liu, C.T.; Chen, M.W. Nanoscale phase separation in a fcc-based CoCrCuFeNiAl0.5 high-entropy alloy. Acta Mater. 2015, 84, 145–152. [Google Scholar] [CrossRef]

- Sadeghilaridjani, M.; Mukherjee, S. Strain gradient plasticity in multiprincipal element alloys. JOM 2019, 71, 3466–3472. [Google Scholar] [CrossRef]

- Mridha, S.; Sadeghilaridjani, M.; Mukherjee, S. Activation Volume and energy for dislocation nucleation in multi-principal element alloys. Metals 2019, 9, 263. [Google Scholar] [CrossRef] [Green Version]

- Maier, V.; Merle, B.; Göken, M.; Durst, K. An improved long-term nanoindentation creep testing approach for studying the local deformation processes in nanocrystalline metals at room and elevated temperatures. J. Mater. Res. 2013, 28, 1177–1188. [Google Scholar] [CrossRef] [Green Version]

- Sadeghilaridjani, M.; Ayyagari, A.; Muskeri, S.; Hasannaeimi, V.; Salloom, R.; Chen, W.-Y.; Mukherjee, S. Ion irradiation response and mechanical behavior of reduced activity high entropy alloy. J. Nucl. Mater. 2020, 529, 151955. [Google Scholar] [CrossRef]

- Sadeghilaridjani, M.; Muskeri, S.; Hasannaeimi, V.; Pole, M.; Mukherjee, S. Strain rate sensitivity of a novel refractory high entropy alloy: Intrinsic versus extrinsic effects. Mater. Sci. Eng. A 2019, 766, 138326. [Google Scholar] [CrossRef]

- Mridha, S.; Komarasamy, M.; Bhowmick, S.; Mishra, R.S.; Mukherjee, S. Small-scale plastic deformation of nanocrystalline high entropy alloy. Entropy 2018, 20, 889. [Google Scholar] [CrossRef] [Green Version]

- Li, W.H.; Shin, K.; Lee, C.G.; Wei, B.C.; Zhang, T.H.; He, Y.Z. The characterization of creep and time-dependent properties of bulk metallic glasses using nanoindentation. Mater. Sci. Eng. A 2008, 478, 371–375. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Feng, Y.H.; Debela, T.T.; Peng, G.J.; Zhang, T.H. Nanoindentation study on the creep characteristics of high-entropy alloy films: fcc versus bcc structures. Int. J. Refract. Met. Hard Mater. 2016, 54, 395–400. [Google Scholar] [CrossRef]

- Lee, D.-H.; Seok, M.-Y.; Zhao, Y.; Choi, I.-C.; He, J.; Lu, Z.; Suh, J.-Y.; Ramamurty, U.; Kawasaki, M.; Langdon, T.G.; et al. Spherical nanoindentation creep behavior of nanocrystalline and coarse-grained CoCrFeMnNi high-entropy alloys. Acta Mater. 2016, 109, 314–322. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Peng, G.J.; Wen, D.H.; Zhang, T.H. Nanoindentation creep behavior in a CoCrFeCuNi high-entropy alloy film with two different structure states. Mater. Sci. Eng. A 2015, 621, 111–117. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, S.; Wang, Q.; Liu, Z.; Wang, J.; Yang, Y.; Liu, C.T. Nanoindentation characterized initial creep behavior of a high-entropy-based alloy CoFeNi. Intermetallics 2014, 53, 183–186. [Google Scholar] [CrossRef]

- Wang, X.; Gong, P.; Deng, L.; Jin, J.; Wang, S.; Zhou, P. Nanoindentation study on the room temperature creep characteristics of a senary Ti16.7Zr16.7Hf16.7Cu16.7Ni16.7Be16.7 high entropy bulk metallic glass. J. Non-Cryst. Solids 2017, 470, 27–37. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, P.; Cheng, H.; Zhang, H.; Diao, H.; Shi, Y.; Chen, B.; Chen, P.; Feng, R.; Bai, J.; et al. Nanoindentation creep behavior of an Al0.3CoCrFeNi high-entropy alloy. Metall. Mater. Trans. A 2016, 47, 5871–5875. [Google Scholar] [CrossRef]

- Jiao, Z.-M.; Ma, S.-G.; Yuan, G.-Z.; Wang, Z.-H.; Yang, H.-J.; Qiao, J.-W. Plastic deformation of Al0.3CoCrFeNi and AlCoCrFeNi high-entropy alloys under nanoindentation. J. Mater. Eng. Perform. 2015, 24, 3077–3083. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Ritchie, R.O.; Meyers, M.A. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater. Sci. 2019, 102, 296–345. [Google Scholar] [CrossRef]

- Mridha, S.; Das, S.; Aouadi, S.; Mukherjee, S.; Mishra, R.S. Nanomechanical behavior of CoCrFeMnNi high-entropy alloy. JOM 2015, 67, 2296–2302. [Google Scholar] [CrossRef]

- Wheeler, J.M.; Armstrong, D.E.J.; Heinz, W.; Schwaige, R. High temperature nanoindentation: The state of the art and future challenges. Curr. Opin. Solid State Mater. Sci. 2015, 19, 354–366. [Google Scholar] [CrossRef] [Green Version]

- Tsao, T.-K.; Yeh, A.-C.; Kuo, C.-M.; Kakehi, K.; Murakami, H.; Yeh, J.-W.; Jian, S.-R. The high temperature tensile and creep behaviors of high entropy superalloy. Sci. Rep. 2017, 7, 12658. [Google Scholar] [CrossRef] [PubMed]

- Kang, Y.B.; Shim, S.H.; Lee, K.H.; Hong, S.I. Dislocation creep behavior of CoCrFeMnNi high entropy alloy at intermediate temperatures. Mater. Res. Lett. 2018, 6, 689–695. [Google Scholar] [CrossRef]

- Sawant, A.; Tin, S.; Zhao, J.-C. High Temperature Nano-Indentation of Ni-Based Superalloys. Proceeding of the 11th International Symposium on Superalloys, TMS (The Minerals, Metals & Materials Society), Champion, PA, USA, 14–17 September 2008; pp. 863–871. [Google Scholar]

- Haghshenas, M.; Wang, Y.; Cheng, Y.-T.; Gupta, M. Indentation-based rate-dependent plastic deformation of polycrystalline pure magnesium. Mater. Sci. Eng. A 2018, 716, 63–71. [Google Scholar] [CrossRef]

- McElhaney, K.W.; Vlassak, J.J.; Nix, W.D. Determination of indenter tip geometry and indentation contact area for depth-sensing indentation experiments. J. Mater. Res. 1998, 13, 1300–1306. [Google Scholar] [CrossRef]

- Chen, J.; Shen, Y.; Liu, W.; Beake, B.D.; Shi, X.; Wang, Z.; Zhang, Y.; Guo, X. Effects of loading rate on development of pile-up during indentation creep of polycrystalline copper. J. Mater. Sci. A 2016, 656, 216–221. [Google Scholar] [CrossRef]

- Wang, H.; Dhiman, A.; Ostergaard, H.E.; Zhang, Y.; Siegmund, T.; Kruzic, J.J.; Tomar, V. Nanoindentation based properties of Inconel 718 at elevated temperatures: A comparison of conventional versus additively manufactured samples. Int. J. Plast. 2019, 120, 380–394. [Google Scholar] [CrossRef]

- Zhang, W.-D.; Liu, Y.; Wu, H.; Lan, X.-D.; Qiu, J.; Hu, T.; Tang, H.-P. Room temperature creep behavior of Ti–Nb–Ta–Zr–O alloy. Mater. Charact. 2016, 118, 29–36. [Google Scholar] [CrossRef]

- MorrisJr, J.W. Dislocation-controlled plasticity of crystalline materials: Overview. In Encyclopedia of Materials: Science and Technology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2001; pp. 2245–2255. [Google Scholar]

- Laplanche, G.; Kostka, A.; Reinhart, C.; Hunfeld, J.; Eggeler, G.; George, E.P. Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi. Acta Mater. 2017, 128, 292–303. [Google Scholar] [CrossRef]

- Li, Q.-J.; Sheng, H.; Ma, E. Strengthening in multi-principal element alloys with local-chemical-order roughened dislocation pathways. Nat. commun. 2019, 10, 3563. [Google Scholar] [CrossRef] [Green Version]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Li, H.; Ngan, A.H.W. Size effects of nanoindentation creep. J. Mater. Res. 2004, 19, 513–522. [Google Scholar] [CrossRef]

- Almasri, A.H.; Voyiadjis, G.Z. Effect of strain rate on the dynamic hardness in metals. J. Eng. Mater. Tech. 2007, 129, 505–512. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, C.; Bei, H.; He, X.; Hu, W. Room temperature nanoindentation creep of nanocrystalline Cu and Cu alloys. Mater. Lett. 2012, 70, 26–29. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, F.; Huang, P.; Lu, T.J.; Xu, K.W. Depth dependent strain rate sensitivity and inverse indentation size effect of hardness in body-centered cubic nanocrystalline metals. Mater. Sci. Eng. A 2014, 615, 87–91. [Google Scholar] [CrossRef]

- Oikawa, H.; Karashima, S. On the stress exponent and the rate-controlling mechanism of high-temperature creep in some solid solutions. Metall. Trans. 1974, 5, 1179–1182. [Google Scholar] [CrossRef]

- Phani, P.S.; Oliver, W.C. A direct comparison of high temperature nanoindentation creep and uniaxial creep measurements for commercial purity aluminum. Acta Mater. 2016, 111, 31–38. [Google Scholar] [CrossRef]

- Owen, L.R.; Pickering, E.J.; Playford, H.Y.; Stone, H.J.; Tucker, M.G.; Jones, N.G. An assessment of the lattice strain in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2017, 122, 11–18. [Google Scholar] [CrossRef] [Green Version]

- Monclús, M.A.; Molina-Aldareguia, J.M. High temperature nanomechanical testing. In Handbook of Mechanics of Materials; Hsueh, C.H., Schmauder, S., Chen, C.-S., Chawla, K.K., Chawla, N., Chen, W., Kagawa, Y., Eds.; Springer: Singapore, 2018. [Google Scholar]

- He, J.Y.; Zhu, C.; Zhou, D.Q.; Liu, W.H.; Nieh, T.G.; Lu, Z.P. Steady state flow of the FeCoNiCrMn high entropy alloy at elevated temperatures. Intermetallics 2014, 55, 9–14. [Google Scholar] [CrossRef]

- Li, Y.J.; Mueller, J.; Hoppel, H.W.; Goken, M.; Blum, W. Deformation kinetics of nanocrystalline nickel. Acta Mater. 2007, 55, 5708–5717. [Google Scholar] [CrossRef]

- Shen, L.; Wu, Y.; Wang, S.; Chen, Z. Creep behavior of Sn–Bi solder alloys at elevated temperatures studied by nanoindentation. J. Mater. Sci.: Mater. Electron. 2017, 28, 4114–4124. [Google Scholar] [CrossRef]

- Ginder, R.S.; Pharr, G.M. Characterization of power-law creep in the solid-acid CsHSO4 via nanoindentation. J. Mater. Res. 2019, 34, 1130–1137. [Google Scholar] [CrossRef]

- Rouault-Rogez, H.; Dupeux, M.; Ignat, M. High temperature tensile creep of CMSX-2 Nickel base superalloy single crystals. Acta Metall. Mater. 1994, 42, 3137–3148. [Google Scholar] [CrossRef]

- Picasso, A.C.; Marzocca, A.J. On apparent activation energies of creep in nickel-base superalloys. Scrp. Mater. 1999, 41, 797–802. [Google Scholar] [CrossRef]

- Hu, J.; Sun, G.; Zhang, X.; Wang, G.; Jiang, Z.; Han, S.; Zhang, J.; Lian, J. Effects of loading strain rate and stacking fault energy on nanoindentation creep behaviors of nanocrystalline Cu, Ni-20 wt. %Fe and Ni. J. Alloys Compd. 2015, 647, 670–680. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadeghilaridjani, M.; Mukherjee, S. High-Temperature Nano-Indentation Creep Behavior of Multi-Principal Element Alloys under Static and Dynamic Loads. Metals 2020, 10, 250. https://doi.org/10.3390/met10020250

Sadeghilaridjani M, Mukherjee S. High-Temperature Nano-Indentation Creep Behavior of Multi-Principal Element Alloys under Static and Dynamic Loads. Metals. 2020; 10(2):250. https://doi.org/10.3390/met10020250

Chicago/Turabian StyleSadeghilaridjani, Maryam, and Sundeep Mukherjee. 2020. "High-Temperature Nano-Indentation Creep Behavior of Multi-Principal Element Alloys under Static and Dynamic Loads" Metals 10, no. 2: 250. https://doi.org/10.3390/met10020250