Shape Change and Crystal Orientation of B19 Martensite in Equiatomic TiPd Alloy by Isobaric Test

Abstract

:1. Introduction

2. Materials and Methods

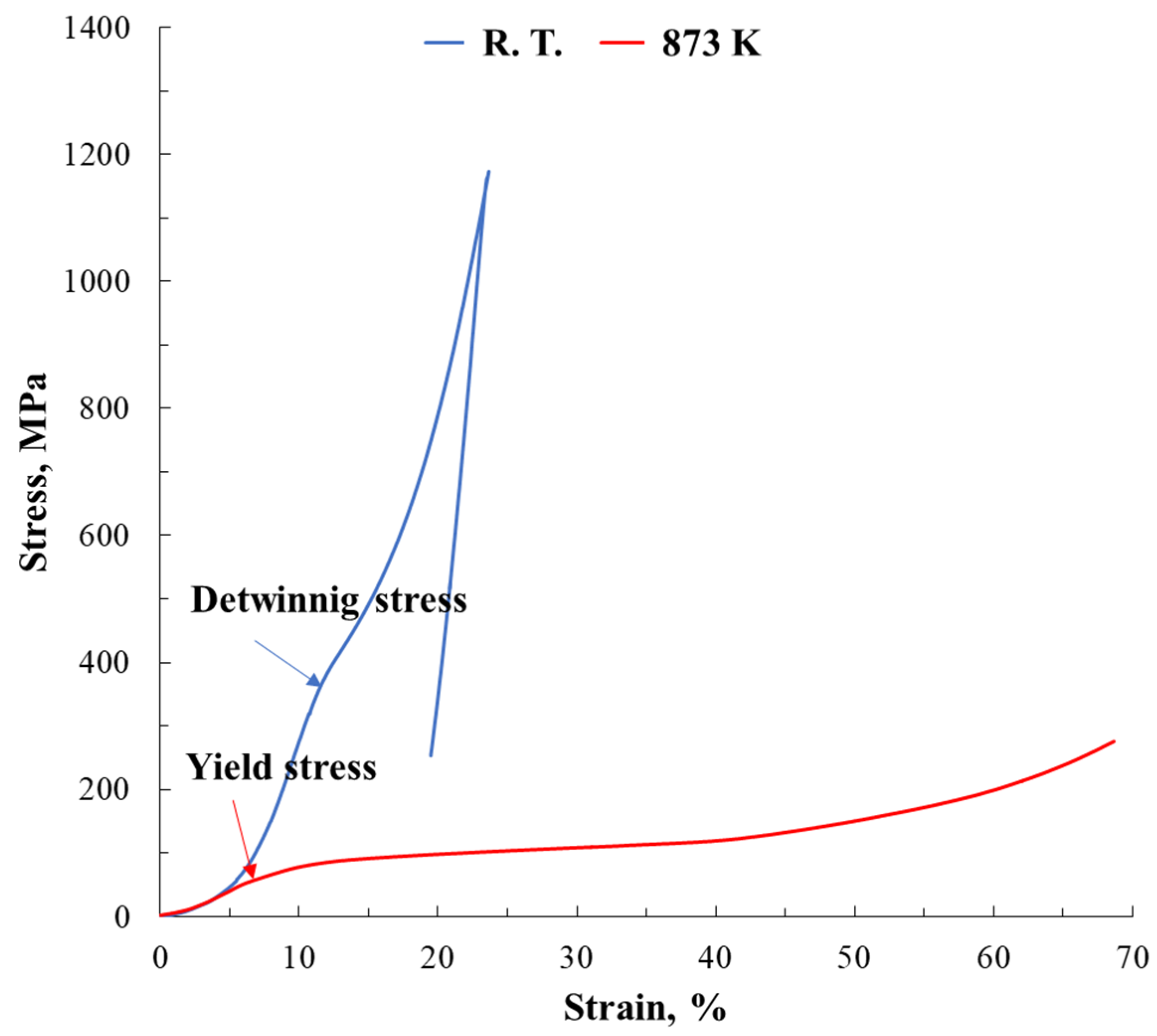

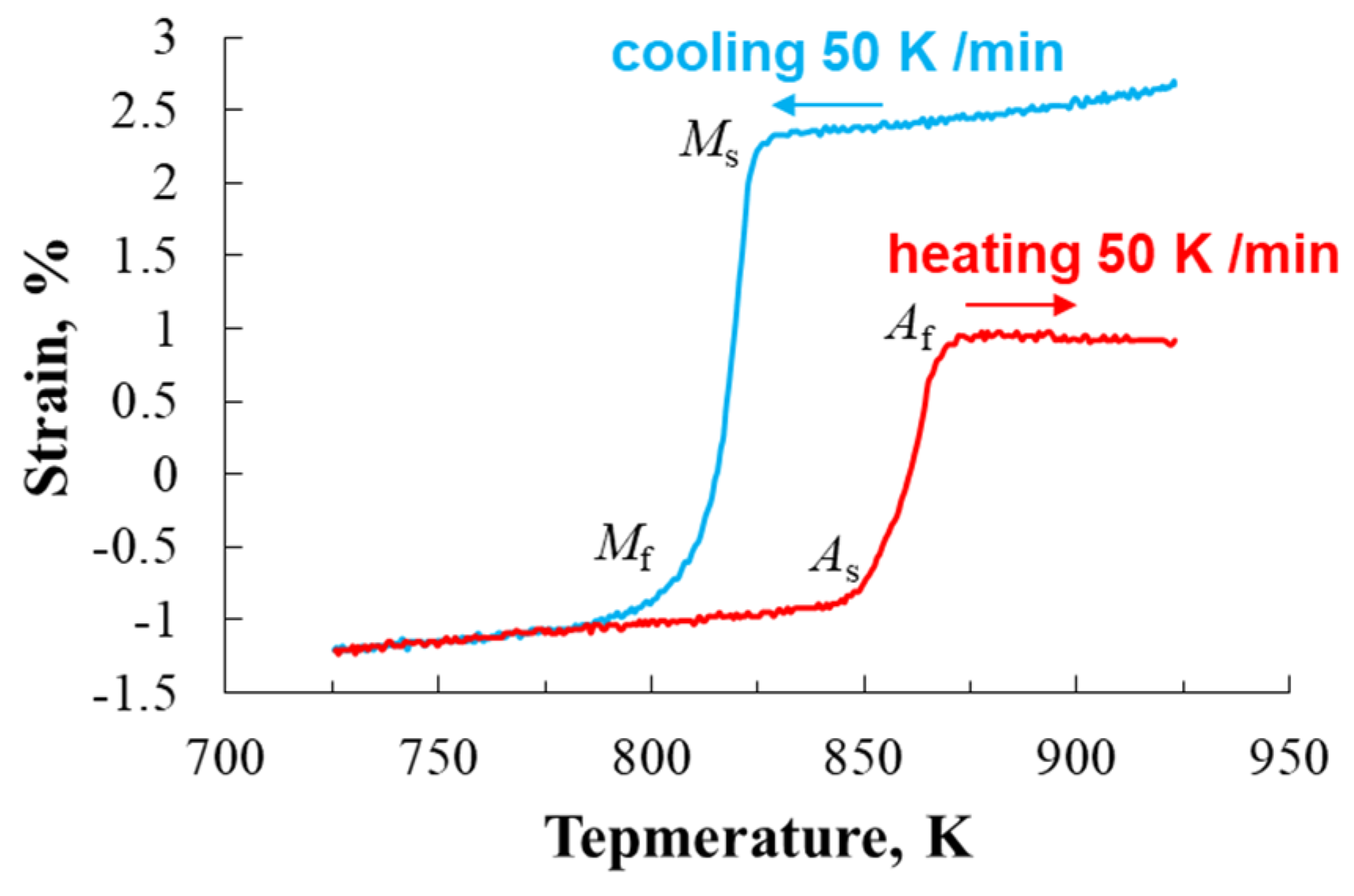

3. Results and Discussions

3.1. Microstructure and Shape Change of Water-Quenched Equiatomic TiPd Alloys

3.2. Microstructure and Shape Change of Equiatomic TiPd Alloy during the Isobaric Test

4. Conclusions

- (1)

- TMA tests indicate that the direction of the shape change was different between the 0° and 90° samples cutting out parallel and perpendicular to the hearth side of button ingot, respectively. In the 0° sample, shrinking and expansion were, respectively, observed during the reverse and forward martensitic transformations, whereas the opposite tendency was confirmed in the 90° sample compared to the 0° sample.

- (2)

- During the isobaric test, the martensitic variants arranged and oriented to a (010) plane with compressive loading, and the B2 parent phase crystals also became coarse. There was a close relationship between the shape change due to the crystal orientation by the isobaric test and the shear-shuffling direction due to martensitic transformation. The sample shrank along the compression direction, which is perpendicular to the shear-shuffling orientation. In the vertical direction for the compressive loading, the sample expands in a direction parallel to the shear-shuffling orientation.

Author Contributions

Funding

Conflicts of Interest

References

- Otsuka, K.; Sawamura, T.; Shimizu, K. Crystal Structure and Internal Defects of Equiatomie TiNi Martensite. Physica Status Solidi 1971, 5, 457–470. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Donkersloot, H.C.; Van Vucht, J.H.N. Martensitic transformations in gold-titanium, palladium-titanium and platinum-titanium alloys near the equiatomic composition. J. Less Common Metals 1970, 20, 83–91. [Google Scholar] [CrossRef]

- Yamabe-Mitarai, Y. Development of High-Temperature Shape Memory Alloys Above 673 K. Mater. Sci. Forum 2016, 879, 107–112. [Google Scholar] [CrossRef]

- Yamabe-Mitarai, Y.; Arockiakumar, R.; Wadood, A.; Suresh, K.S.; Kitashima, T.; Hara, T.; Shimojo, M.; Tasaki, W.; Takahashi, M.; Takahashi, S.; et al. Ti(Pt, Pd, Au) based high temperature shape memory alloys. Mater. Today Proc. 2015, 2S, 517–522. [Google Scholar] [CrossRef]

- Sato, H.; Kim, H.Y.; Shimojo, M.; Yamabe-Mitarai, Y. Training effect on microstructure and shape recovery in Ti-Pd-Zr alloys. Mater. Trans. 2017, 58, 1479–1486. [Google Scholar] [CrossRef] [Green Version]

- Wayman, C.M.; Duerig, T.W. Engineering Aspects of Shape Memory Alloys; Butterworth-Heinemann: Oxford, UK, 1990; p. 10. [Google Scholar]

- Bigelow, G.S.; Padula, S.A., II; Garg, A.; Noebe, R.D. Correlation between mechanical behavior and actuator-type performance of Ni-Ti-Pd high-temperature shape memory alloys. In Proceedings of the 14th International Symposium on: Smart Structures and Materials & Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 18–22 March 2007. [Google Scholar]

- Hisada, S.; Matsuda, M.; Takashima, K.; Yamabe-Mitarai, Y. Structural analysis and martensitic transformation in equiatomic HfPd alloy. J. Solid State Chem. 2018, 258, 712–717. [Google Scholar] [CrossRef]

- Mohapatra, G.; Sommer, F.; Mittemeijer, E.J. Calibration of a quenching and deformation differential dilatometer upon heating and cooling: Thermal expansion of Fe and Fe-Ni alloys. Thermochimica Acta 2007, 453, 31–41. [Google Scholar] [CrossRef]

- Wang, J.J.; Omori, T.; Sutou, Y.; Kainuma, R.; Ishida, K. Two-way shape memory effect induced by cold-rolling in Ti-Ni and Ti-Ni-Fe alloys. Scr. Mater. 2005, 52, 311–316. [Google Scholar] [CrossRef]

- Inoue, H.; Miwa, N.; Inakazu, N. Texture and shape memory strain in TiNi alloy sheets. Acta Mater. 1996, 44, 4825–4834. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Z.L.; Van Humbeeck, J.; Delaey, L. Effect on texture orientation on the martensite deformation of NiTi shape memory alloy sheet. Acta Mater. 1999, 47, 645–660. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti-Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Shu, Y.C.; Bhattacharya, K. The influence of texture on the shape memory effect in polycrystals. Acta Mater. 1998, 46, 5457–5473. [Google Scholar] [CrossRef] [Green Version]

- Sutou, Y.; Omori, T.; Yamauchi, K.; Ono, N.; Kainuma, R.; Ishida, K. Effect of grain size and texture on pseudoelasticity in Cu-Al-Mn-based shape memory wire. Acta Mater. 2005, 53, 4121–4133. [Google Scholar] [CrossRef]

- Kim, H.Y.; Sasaki, T.; Okutsu, K.; Kim, J.I.; Inamura, T.; Hosoda, H.; Miyazaki, S. Texture and shape memory behavior of Ti-22Nb-6Ta alloy. Acta Mater. 2006, 54, 423–433. [Google Scholar] [CrossRef]

- Pawley, G.S. Unit-cell refinement from powder diffraction scans. J. Appl. Cryst. 1981, 14, 357–361. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Recent developments in the research of shape memory alloys. Intermetallics 1999, 7, 511–528. [Google Scholar] [CrossRef]

| (a) | (b) | ||||||

|---|---|---|---|---|---|---|---|

| Area | ε(%) | Area | ε(%) | Area | ε(%) | Area | ε(%) |

| 1 | −0.807 | 1 | −0.314 | 19 | 0.003 | 37 | −0.003 |

| 2 | −0.805 | 2 | −0.313 | 20 | −0.147 | 38 | −0.014 |

| 3 | −0.751 | 3 | −0.073 | 21 | −0.043 | 39 | 0.013 |

| 4 | 0.268 | 4 | −0.107 | 22 | −0.019 | 40 | 0.005 |

| 5 | 0.773 | 5 | 0.039 | 23 | 0.218 | 41 | 0.099 |

| Total | −0.649 | 6 | −0.171 | 24 | −0.033 | 42 | 0.037 |

| 7 | −0.031 | 25 | 0.101 | 43 | 0.007 | ||

| 8 | −0.014 | 26 | −0.084 | 44 | −0.013 | ||

| 9 | −0.075 | 27 | 0.026 | 45 | 0.001 | ||

| 10 | −0.050 | 28 | −0.058 | 46 | 0.026 | ||

| 11 | 0.020 | 29 | 0.003 | 47 | 0.018 | ||

| 12 | −0.123 | 30 | 0.041 | 48 | 0.020 | ||

| 13 | 0.071 | 31 | −0.025 | 49 | −0.018 | ||

| 14 | −0.061 | 32 | −0.019 | 50 | 0.011 | ||

| 15 | −0.040 | 33 | 0.031 | 51 | −0.007 | ||

| 16 | 0.048 | 34 | 0.029 | 52 | 0.041 | ||

| 17 | −0.047 | 35 | 0.019 | Total | −1.091 | ||

| 18 | −0.002 | 36 | −0.110 | ||||

| (a) | (b) | ||

|---|---|---|---|

| Area | ε (%) | Area | ε (%) |

| 1 | 0.660 | 1 | −1.165 |

| 2 | 0.828 | 2 | 0.159 |

| 3 | −0.051 | 3 | −3.059 |

| 4 | 0.285 | 4 | −2.906 |

| 5 | 0.010 | 5 | −0.535 |

| 6 | −0.012 | 6 | −0.288 |

| 7 | −0.029 | 7 | −3.993 |

| Total | 1.690 | 8 | −3.950 |

| 9 | −3.982 | ||

| Total | −2.863 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hisada, S.; Matsuda, M.; Yamabe-Mitarai, Y. Shape Change and Crystal Orientation of B19 Martensite in Equiatomic TiPd Alloy by Isobaric Test. Metals 2020, 10, 375. https://doi.org/10.3390/met10030375

Hisada S, Matsuda M, Yamabe-Mitarai Y. Shape Change and Crystal Orientation of B19 Martensite in Equiatomic TiPd Alloy by Isobaric Test. Metals. 2020; 10(3):375. https://doi.org/10.3390/met10030375

Chicago/Turabian StyleHisada, Shota, Mitsuhiro Matsuda, and Yoko Yamabe-Mitarai. 2020. "Shape Change and Crystal Orientation of B19 Martensite in Equiatomic TiPd Alloy by Isobaric Test" Metals 10, no. 3: 375. https://doi.org/10.3390/met10030375