The Effects of MQL and Dry Environments on Tool Wear, Cutting Temperature, and Power Consumption during End Milling of AISI 1040 Steel

Abstract

:1. Introduction

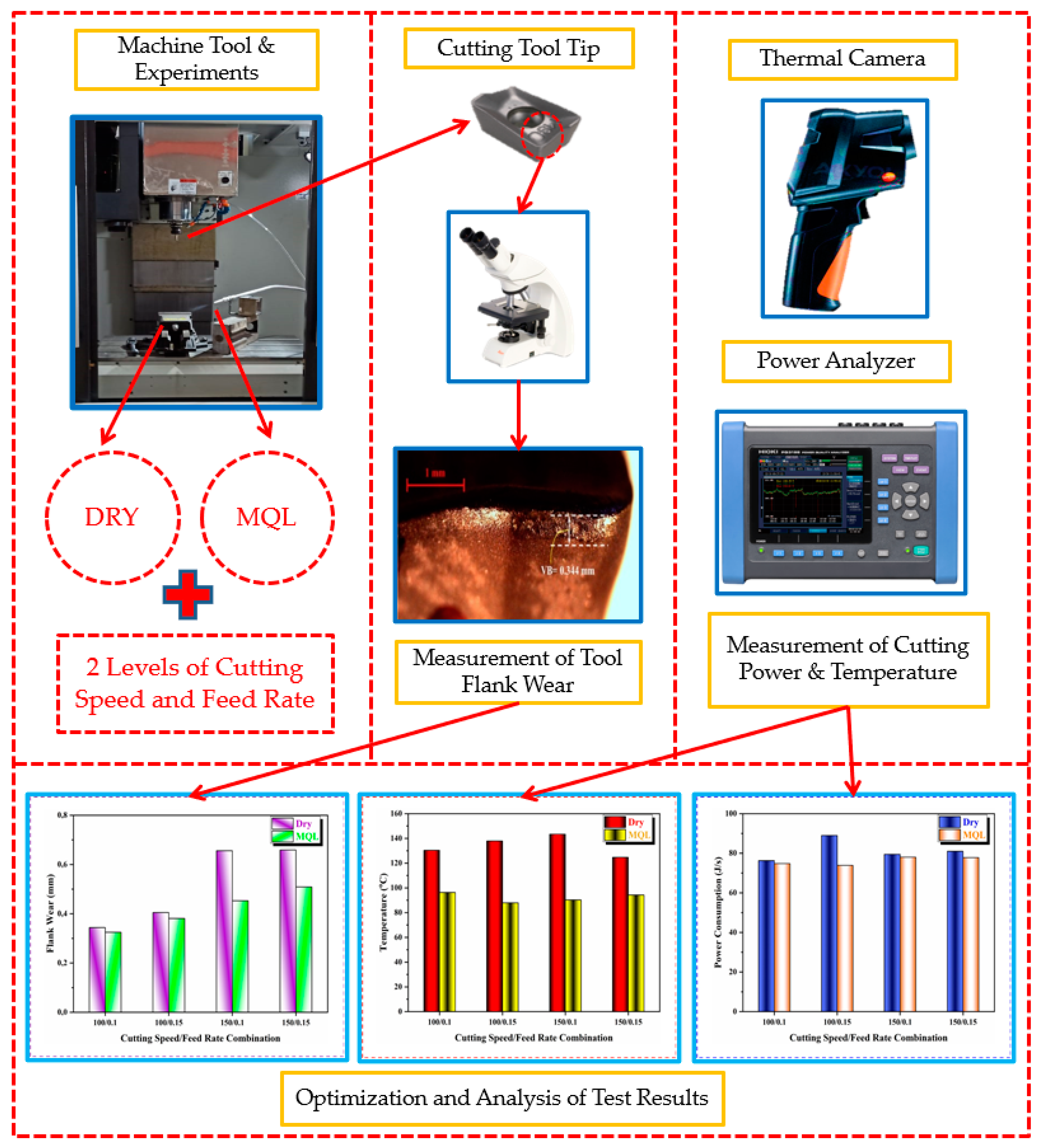

2. Methodology

2.1. Cutting Tool, Workpiece and Machine Tool Conditions

2.2. Experiments and Cutting Environments

2.3. Measurement of Tool Wear, Cutting Temperature, and Consumed Power

2.4. Experimental Design, Optimization Approach, and Statistical Analysis

3. Results and Discussion

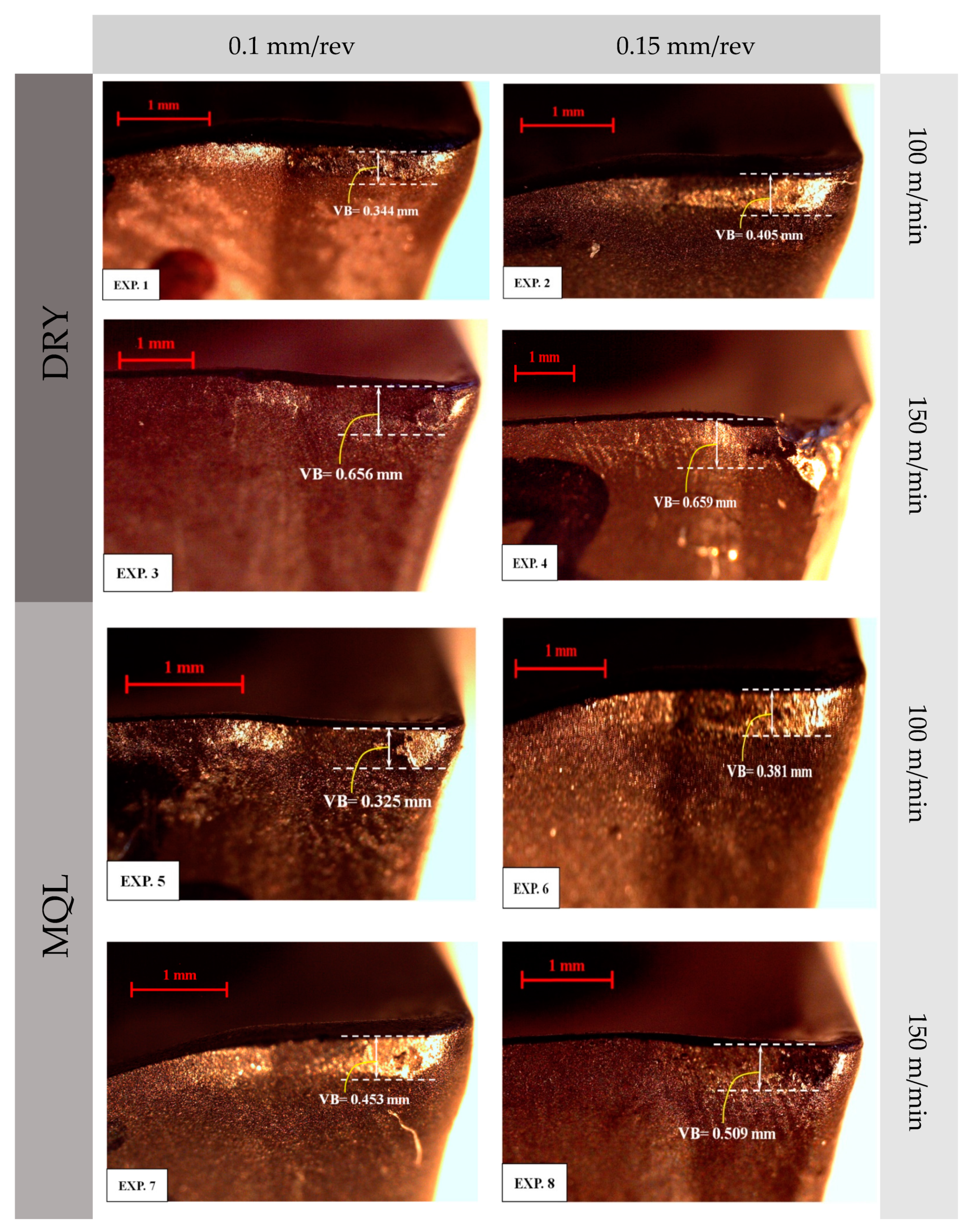

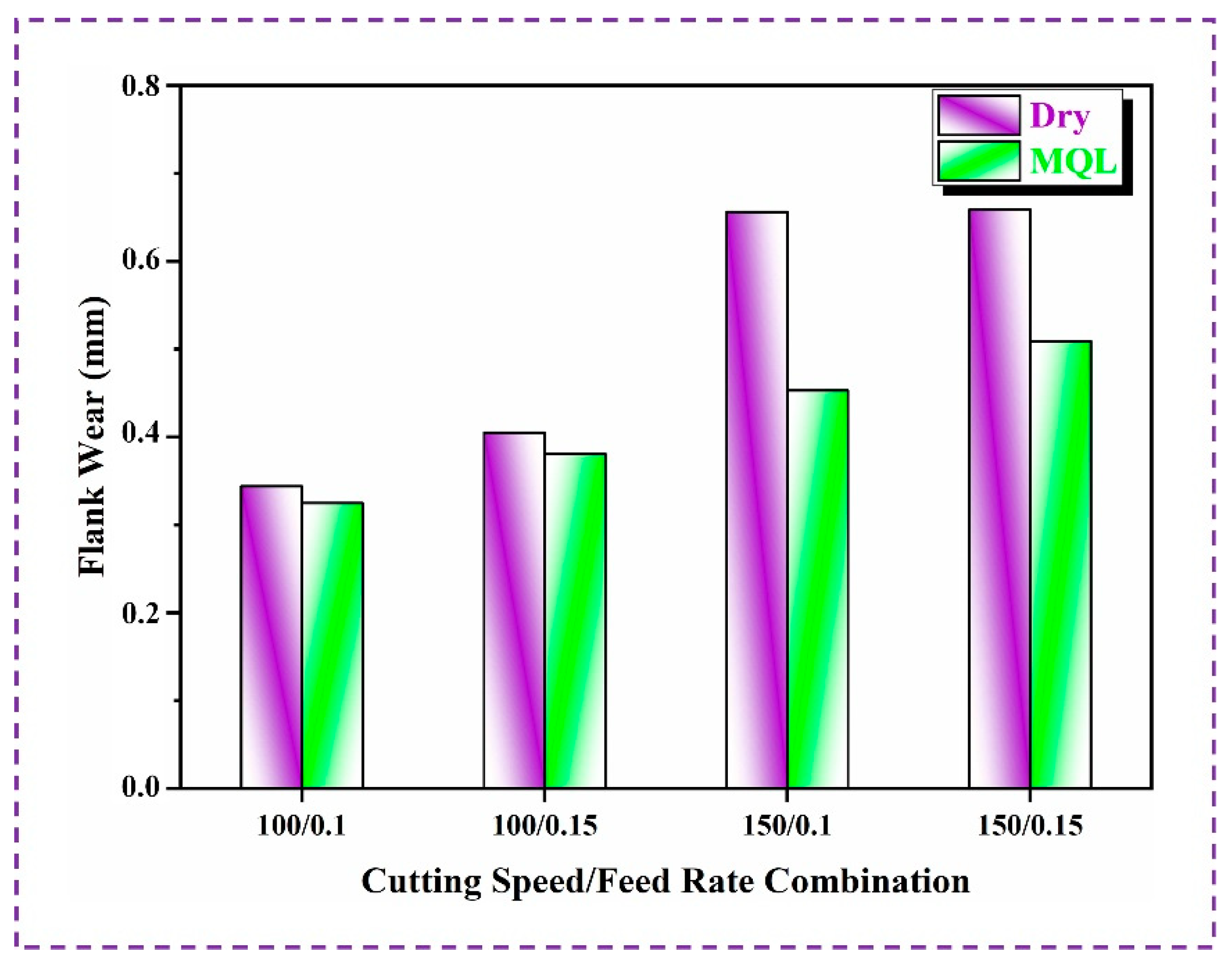

3.1. Evaluation of Flank Wear under MQL and Dry Cutting Conditions

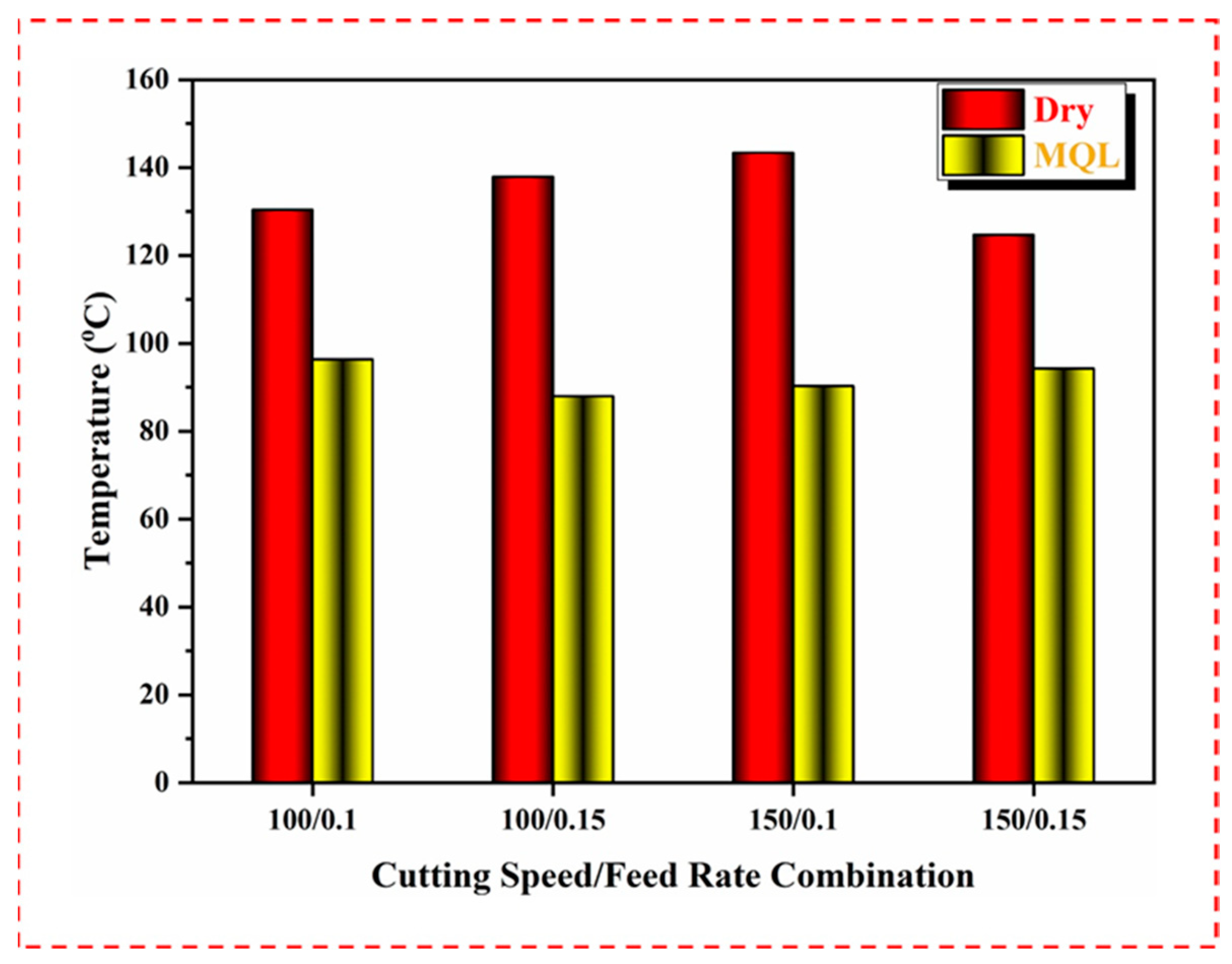

3.2. Evaluation of Cutting Temperature under MQL and Dry Cutting Conditions

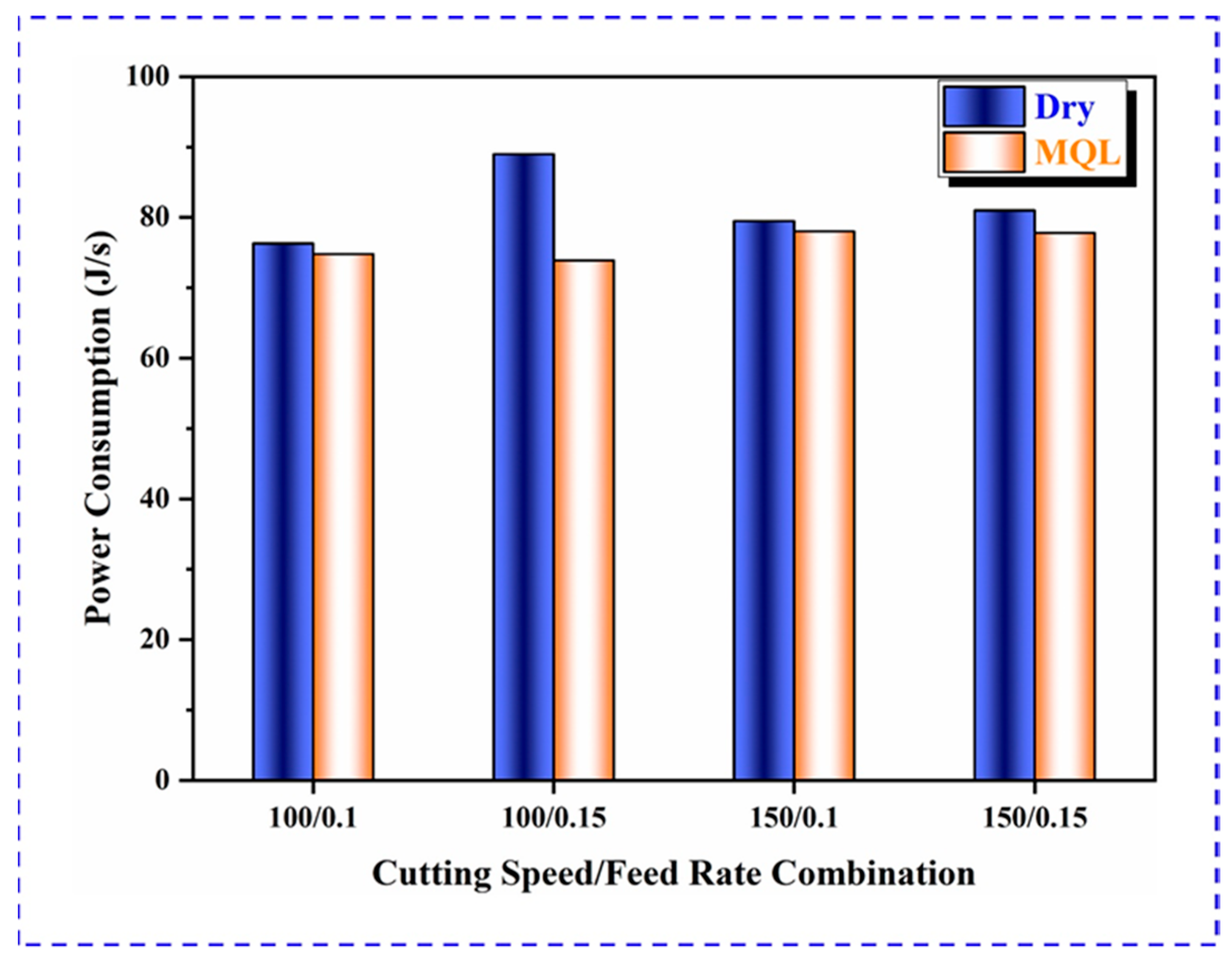

3.3. Evaluation of Power Consumption under MQL and Dry Cutting Conditions

3.4. ANOVA Results for the Wear Rate, Weight Loss, and Coefficient of Friction

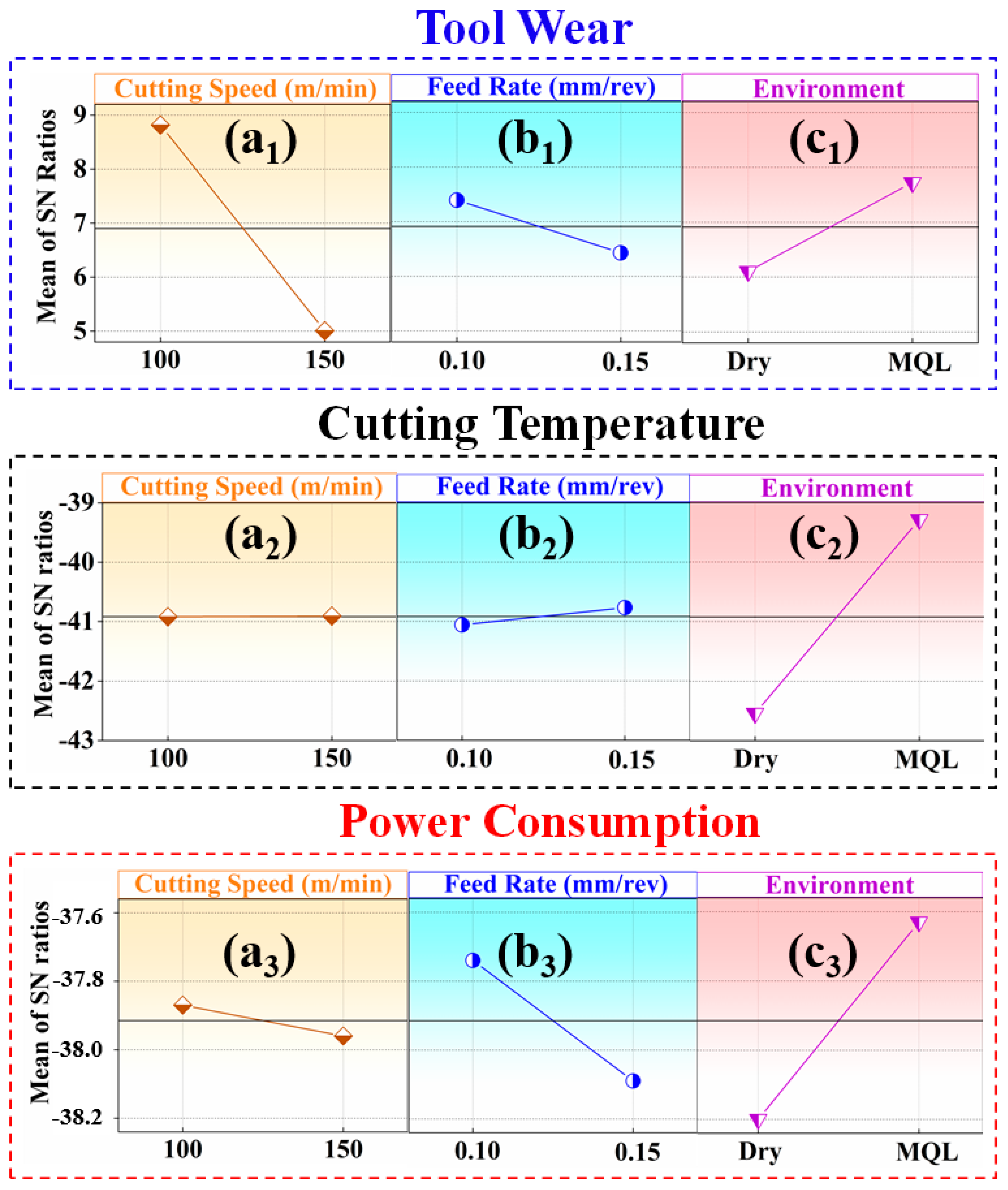

3.5. Optimization of Response Parameters under MQL and Dry Cutting Conditions

4. Conclusions

- A comparison of MQL and dry environments was carried regarding tool wear, cutting temperatures, and power consumption. MQL results in vital performance improvements in the milling of AISI 1040 steel, due to its ability to remove chips and to cool and lubricate the cutting area. The tool wear progressions clearly showed that MQL-assisted milling provided better flank wear results than dry cutting under the same cutting conditions. For higher cutting speeds especially (150 m/min), the differences were much greater than for lower cutting speeds (10 m/min);

- When MQL and dry environments were compared in terms of flank wear, peak temperature, and power consumption, improvements of 30.9%, 32.5%, and 16.9% achieved, respectively;

- The main benefit of the application of MQL is due to the oil droplets being transmitted to the cutting area during milling operation, reducing the cutting forces by improving the cutting ability of the cutting tool and directly decreasing the power consumption. Better cutting ability brings about resistance to wear, meaning a longer tool life can be achieved. The same mechanism allows for lower cutting temperatures due to the better tribological properties provided by MQL;

- Thanks to the better cooling and lubrication properties of MQL, the best flank wear, cutting temperature, and power consumption results were obtained under MQL conditions, along with lower cutting speeds (100 m/min). Regarding the minimum cutting temperature, a high feed rate (0.15 mm/rev) and cutting speed (150 m/min) and MQL-assisted milling should be selected;

- The ANOVA tables outlined the efficacy of the parameters used. Accordingly, the cutting environment is the most effective factor in terms of reducing power consumption (37%) and cutting temperatures (94.5%). On the other hand, flank wear is affected most by cutting speed (74%).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yıldırım, Ç.V. Experimental comparison of the performance of nanofluids, cryogenic and hybrid cooling in turning of Inconel 625. Tribol. Int. 2019, 137, 366–378. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. Investigation of signal behaviors for sensor fusion with tool condition monitoring system in turning. Measurement 2021, 173, 108582. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Pimenov, D.Y.; Singla, A.K.; Machado, A.R.; da Silva, L.R.R.; Gupta, M.K.; Sarikaya, M.; Krolczyk, G.M. Review on design and development of cryogenic machining setups for heat resistant alloys and composites. J. Manuf. Process. 2021, 68, 398–422. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. Investigation of progressive tool wear for determining of optimized machining parameters in turning. Measurement 2019, 140, 427–436. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoglu, M.; Gunes, A.; Sahin, O.S. Experimental study and analysis of machinability characteristics of metal matrix composites during drilling. Compos. Part B Eng. 2019, 166, 401–413. [Google Scholar] [CrossRef]

- Şirin, Ş.; Sarıkaya, M.; Yıldırım, Ç.V.; Kıvak, T. Machinability performance of nickel alloy X-750 with SiAlON ceramic cutting tool under dry, MQL and hBN mixed nanofluid-MQL. Tribol. Int. 2021, 153, 106673. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Sarıkaya, M.; Kıvak, T.; Şirin, Ş. The effect of addition of hBN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning of Ni-based Inconel 625. Tribol. Int. 2019, 134, 443–456. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Jamil, M.; Mia, M.; Singla, A.K.; Khan, A.M.; Khanna, N.; Pimenov, D.Y. Environment and economic burden of sustainable cooling/lubrication methods in machining of Inconel-800. J. Clean. Prod. 2021, 287, 125074. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P. Comparative analysis of dry, flood, MQL and cryogenic CO2 techniques during the machining of 15-5-PH SS alloy. Tribol. Int. 2020, 146, 106196. [Google Scholar] [CrossRef]

- Sivaiah, P.; Chakradhar, D. Effect of cryogenic coolant on turning performance characteristics during machining of 17-4 PH stainless steel: A comparison with MQL, wet, dry machining. CIRP J. Manuf. Sci. Technol. 2018, 21, 86–96. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Jamil, M.; Mia, M.; Khanna, N.; Krolczyk, G.M. Experimental characterisation of the performance of hybrid cryo-lubrication assisted turning of Ti–6Al–4V alloy. Tribol. Int. 2021, 153, 106582. [Google Scholar] [CrossRef]

- Gupta, M.K.; Pruncu, C.I.; Mia, M.; Singh, G.; Singh, S.; Prakash, C.; Sood, P.; Gill, H.S. Machinability investigations of Inconel-800 super alloy under sustainable cooling conditions. Materials 2018, 11, 2088. [Google Scholar] [CrossRef] [Green Version]

- Kuntoğlu, M. Tool Flank Wear Analysis for MQL Assisted Milling of Strenx 1100 Structural Steel. Avrupa Bilim Teknol. Derg. 2021, 629–635. [Google Scholar] [CrossRef]

- Kuntoğlu, M. Surface Roughness Evaluation in Milling of Strenx 1100 Steel under MQL Conditions. Avrupa Bilim Teknol. Derg. 2021, 509–516. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Kıvak, T.; Sarıkaya, M.; Erzincanlı, F. Determination of MQL parameters contributing to sustainable machining in the milling of nickel-base superalloy waspaloy. Arab. J. Sci. Eng. 2017, 42, 4667–4681. [Google Scholar] [CrossRef]

- Sharma, V.S.; Singh, G.; Sørby, K. A review on minimum quantity lubrication for machining processes. Mater. Manuf. Process. 2015, 30, 935–953. [Google Scholar] [CrossRef]

- Behera, B.; Ghosh, S.; Rao, P. Application of nanofluids during minimum quantity lubrication: A case study in turning process. Tribol. Int. 2016, 101, 234–246. [Google Scholar]

- Awale, A.S.; Vashista, M.; Yusufzai, M.Z.K. Multi-objective optimization of MQL mist parameters for eco-friendly grinding. J. Manuf. Process. 2020, 56, 75–86. [Google Scholar] [CrossRef]

- Mia, M. Mathematical modeling and optimization of MQL assisted end milling characteristics based on RSM and Taguchi method. Measurement 2018, 121, 249–260. [Google Scholar] [CrossRef]

- Viswanathan, R.; Ramesh, S.; Subburam, V. Measurement and optimization of performance characteristics in turning of Mg alloy under dry and MQL conditions. Measurement 2018, 120, 107–113. [Google Scholar] [CrossRef]

- Mia, M.; Al Bashir, M.; Khan, M.A.; Dhar, N.R. Optimization of MQL flow rate for minimum cutting force and surface roughness in end milling of hardened steel (HRC 40). Int. J. Adv. Manuf. Technol. 2017, 89, 675–690. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Singh, G.; Królczyk, G.; Pimenov, D.Y. An approach to cleaner production for machining hardened steel using different cooling-lubrication conditions. J. Clean. Prod. 2018, 187, 1069–1081. [Google Scholar] [CrossRef]

- Khan, A.; Liang, L.; Mia, M.; Gupta, M.; Wei, Z.; Jamil, M.; Ning, H. Development of process performance simulator (PPS) and parametric optimization for sustainable machining considering carbon emission, cost and energy aspects. Renew. Sustain. Energy Rev. 2021, 139, 110738. [Google Scholar] [CrossRef]

- Krolczyk, G.; Maruda, R.; Krolczyk, J.; Wojciechowski, S.; Mia, M.; Nieslony, P.; Budzik, G. Ecological trends in machining as a key factor in sustainable production–a review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Padmini, R.; Krishna, P.V.; Rao, G.K.M. Effectiveness of vegetable oil based nanofluids as potential cutting fluids in turning AISI 1040 steel. Tribol. Int. 2016, 94, 490–501. [Google Scholar] [CrossRef]

- Dhar, N.; Ahmed, M.; Islam, S. An experimental investigation on effect of minimum quantity lubrication in machining AISI 1040 steel. Int. J. Mach. Tools Manuf. 2007, 47, 748–753. [Google Scholar] [CrossRef]

- Krishna, P.V.; Srikant, R.; Rao, D.N. Experimental investigation on the performance of nanoboric acid suspensions in SAE-40 and coconut oil during turning of AISI 1040 steel. Int. J. Mach. Tools Manuf. 2010, 50, 911–916. [Google Scholar] [CrossRef]

- Dhar, N.; Islam, M.W.; Islam, S.; Mithu, M.A.H. The influence of minimum quantity of lubrication (MQL) on cutting temperature, chip and dimensional accuracy in turning AISI-1040 steel. J. Mater. Process. Technol. 2006, 171, 93–99. [Google Scholar] [CrossRef]

- Srikant, R.; Ramana, V. Performance evaluation of vegetable emulsifier based green cutting fluid in turning of American Iron and Steel Institute (AISI) 1040 steel–an initiative towards sustainable manufacturing. J. Clean. Prod. 2015, 108, 104–109. [Google Scholar] [CrossRef]

- Sharma, A.K.; Singh, R.K.; Dixit, A.R.; Tiwari, A.K. Characterization and experimental investigation of Al2O3 nanoparticle based cutting fluid in turning of AISI 1040 steel under minimum quantity lubrication (MQL). Mater. Today: Proc. 2016, 3, 1899–1906. [Google Scholar] [CrossRef]

- Kanth, V.K.; Sreeramulu, D.; Srikiran, S.; Kumar, M.P.; Jagdeesh, K.; Govindh, B. Experimental investigation of cutting parameters using nano lubrication on turning AISI 1040 steel. Mater. Today Proc. 2019, 18, 2095–2101. [Google Scholar] [CrossRef]

- Gugulothu, S.; Pasam, V.K. Experimental investigation to study the performance of CNT/MoS2 hybrid nanofluid in turning of AISI 1040 stee. Aust. J. Mech. Eng. 2020, 1–11. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. ANOVA and fuzzy rule based evaluation and estimation of flank wear, temperature and acoustic emission in turning. CIRP J. Manuf. Sci. Technol. 2021, 35, 589–603. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Acar, O.; Gupta, M.K.; Sağlam, H.; Sarikaya, M.; Giasin, K.; Pimenov, D.Y. Parametric Optimization for Cutting Forces and Material Removal Rate in the Turning of AISI 5140. Machines 2021, 9, 90. [Google Scholar] [CrossRef]

- Şap, E.; Usca, Ü.A.; Gupta, M.K.; Kuntoğlu, M.; Sarıkaya, M.; Pimenov, D.Y.; Mia, M. Parametric optimization for improving the machining process of cu/mo-sicp composites produced by powder metallurgy. Materials 2021, 14, 1921. [Google Scholar] [CrossRef] [PubMed]

- Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Şap, S.; Giasin, K.; Pimenov, D.Y. Tribological aspects, optimization and analysis of Cu-B-CrC composites fabricated by powder metallurgy. Materials 2021, 14, 4217. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, Y.; Luo, M.; Zhang, D. Investigation of tool wear and chip morphology in dry trochoidal milling of titanium alloy Ti–6Al–4V. Materials 2019, 12, 1937. [Google Scholar] [CrossRef] [Green Version]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Mia, M.; Jamil, M.; Singla, A.K.; Bansal, A.; Pimenov, D.Y.; Kuntoğlu, M. Tribological performance based machinability investigations in cryogenic cooling assisted turning of α-β titanium alloy. Tribol. Int. 2021, 160, 107032. [Google Scholar] [CrossRef]

- Aslan, A. Optimization and analysis of process parameters for flank wear, cutting forces and vibration in turning of AISI 5140: A comprehensive study. Measurement 2020, 163, 107959. [Google Scholar] [CrossRef]

- Sarikaya, M.; Gupta, M.K.; Tomaz, I.; Danish, M.; Mia, M.; Rubaiee, S.; Jamil, M.; Pimenov, D.Y.; Khanna, N. Cooling techniques to improve the machinability and sustainability of light-weight alloys: A state-of-the-art review. J. Manuf. Process. 2021, 62, 179–201. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Wojciechowski, S.; Powalka, B.; Klos, S.; Szczotkarz, N.; Matuszak, M.; Khanna, N. Evaluation of turning with different cooling-lubricating techniques in terms of surface integrity and tribologic properties. Tribol. Int. 2020, 148, 106334. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Gupta, M.K.; Song, Q.; Singla, A.K. Sustainability and machinability improvement of Nimonic-90 using indigenously developed green hybrid machining technology. J. Clean. Prod. 2020, 263, 121402. [Google Scholar] [CrossRef]

- Jamil, M.; Zhao, W.; He, N.; Gupta, M.K.; Sarikaya, M.; Khan, A.M.; Siengchin, S.; Pimenov, D.Y. Sustainable milling of Ti–6Al–4V: A trade-off between energy efficiency, carbon emissions and machining characteristics under MQL and cryogenic environment. J. Clean. Prod. 2021, 281, 125374. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Jamil, M.; Mia, M.; Kushvaha, V.; Singla, A.K.; Li, Z. Ecological, economical and technological perspectives based sustainability assessment in hybrid-cooling assisted machining of Ti-6Al-4 V alloy. Sustain. Mater. Technol. 2020, 26, e00218. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, Z.; He, Y.; Cao, H.; Guo, Y. Energy consumption in machining: Classification, prediction, and reduction strategy. Energy 2017, 133, 142–157. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Güllü, A. Multi-response optimization of minimum quantity lubrication parameters using Taguchi-based grey relational analysis in turning of difficult-to-cut alloy Haynes 25. J. Clean. Prod. 2015, 91, 347–357. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Rubaiee, S.; Ahmed, A.; Korkmaz, M.E. Influence of hybrid Cryo-MQL lubri-cooling strategy on the machining and tribological characteristics of Inconel 718. Tribol. Int. 2021, 163, 107178. [Google Scholar] [CrossRef]

- Danish, M.; Ginta, T.L.; Habib, K.; Abdul Rani, A.M.; Saha, B.B. Effect of cryogenic cooling on the heat transfer during turning of AZ31C magnesium alloy. Heat Transf. Eng. 2019, 40, 1023–1032. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Kıvak, T.; Sarıkaya, M.; Şirin, Ş. Evaluation of tool wear, surface roughness/topography and chip morphology when machining of Ni-based alloy 625 under MQL, cryogenic cooling and CryoMQL. J. Mater. Res. Technol. 2020, 9, 2079–2092. [Google Scholar] [CrossRef]

- Öndin, O.; Kıvak, T.; Sarıkaya, M.; Yıldırım, Ç.V. Investigation of the influence of MWCNTs mixed nanofluid on the machinability characteristics of PH 13-8 Mo stainless steel. Tribol. Int. 2020, 148, 106323. [Google Scholar] [CrossRef]

- Şap, E.; Usca, U.A.; Gupta, M.K.; Kuntoğlu, M. Tool wear and machinability investigations in dry turning of Cu/Mo-SiC p hybrid composites. Int. J. Adv. Manuf. Technol. 2021, 114, 379–396. [Google Scholar] [CrossRef]

| Fe | Mn | C | S | P |

| bal. | 0.9 | 0.44 | 0.05 | 0.04 |

| Signature | Parameters | Unit | Level 1 | Level 2 |

|---|---|---|---|---|

| vC | Cutting Speed | m/min | 100 | 150 |

| f | Feed Rate | mm/rev | 0.1 | 0.15 |

| e | Environment | - | DRY | MQL |

| Experiment Number | Factor A Environment (mL/h) | Factor B Cutting Speed (m/min) | Factor C Feed Rate (mm/rev) |

|---|---|---|---|

| 1 | 1 | 1 | 1 |

| 2 | 1 | 1 | 2 |

| 3 | 1 | 2 | 1 |

| 4 | 1 | 2 | 2 |

| 5 | 2 | 1 | 1 |

| 6 | 2 | 1 | 2 |

| 7 | 2 | 2 | 1 |

| 8 | 2 | 2 | 2 |

| Experiment Number | Environment | Cutting Speed (m/min) | Feed Rate (mm/rev) | Flank Wear (mm) | Cutting Temperature (°C) | Consumed Power (J/s) |

|---|---|---|---|---|---|---|

| 1 | DRY | 100 | 0.1 | 0.344 | 130.4 | 76.3 |

| 2 | DRY | 100 | 0.15 | 0.405 | 137.9 | 89 |

| 3 | DRY | 150 | 0.1 | 0.656 | 143.4 | 79.5 |

| 4 | DRY | 150 | 0.15 | 0.659 | 124.7 | 81 |

| 5 | MQL | 100 | 0.1 | 0.325 | 96.4 | 74.8 |

| 6 | MQL | 100 | 0.15 | 0.381 | 88 | 73.9 |

| 7 | MQL | 150 | 0.1 | 0.453 | 90.3 | 78.02 |

| 8 | MQL | 150 | 0.15 | 0.509 | 94.3 | 77.8 |

| Source | DOF | SS | MS | F Value | p-Value | PC (%) |

|---|---|---|---|---|---|---|

| Flank Wear | ||||||

| Cutting Speed | 1 | 29.0157 | 29.0157 | 227.62 | 0.042 | 74 |

| Feed Rate | 1 | 1.8536 | 1.8536 | 14.54 | 0.163 | 4.8 |

| Environment | 1 | 5.2546 | 5.2546 | 41.22 | 0.098 | 13.4 |

| Cutting Speed × Feed Rate | 1 | 0.3814 | 0.3814 | 2.99 | 0.334 | 1 |

| Cutting Speed × Environment | 1 | 2.4591 | 2.4591 | 19.29 | 0.143 | 6.3 |

| Feed Rate × Environment | 1 | 0.1094 | 0.1094 | 0.86 | 0.524 | 0.2 |

| Error | 1 | 0.1275 | 0.1275 | - | - | 0.3 |

| Total | 7 | 39.20 | - | - | - | 100 |

| Cutting Temperature | ||||||

| Cutting Speed | 1 | 0.000 | 0.00 | 0.00 | 0.997 | 0 |

| Feed Rate | 1 | 0.1634 | 0.1634 | 0.16 | 0.758 | 0.8 |

| Environment | 1 | 21.0275 | 21.0275 | 20.45 | 0.139 | 94.5 |

| Cutting Speed × Feed Rate | 1 | 0.0352 | 0.0352 | 0.03 | 0.883 | 0.1 |

| Cutting Speed × Environment | 1 | 0.0008 | 0.0008 | 0.00 | 0.982 | 0 |

| Feed Rate × Environment | 1 | 0.0122 | 0.0122 | 0.01 | 0.931 | 0.1 |

| Error | 1 | 1.0280 | 1.0280 | - | - | 4.5 |

| Total | 7 | 22.2672 | - | - | - | 100 |

| Power Consumption | ||||||

| Cutting Speed | 1 | 0.01545 | 0.01545 | 0.08 | 0.826 | 0.8 |

| Feed Rate | 1 | 0.23461 | 0.23461 | 1.19 | 0.472 | 13 |

| Environment | 1 | 0.66165 | 0.66165 | 3.36 | 0.318 | 37 |

| Cutting Speed × Feed Rate | 1 | 0.14970 | 0.14970 | 0.76 | 0.544 | 8.3 |

| Cutting Speed × Environment | 1 | 0.20290 | 0.20290 | 1.03 | 0.495 | 11.3 |

| Feed Rate × Environment | 1 | 0.33184 | 0.33184 | 1.68 | 0.418 | 18.6 |

| Error | 1 | 0.19706 | 0.19706 | - | - | 11 |

| Total | 7 | 1.79320 | - | - | - | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salur, E.; Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y. The Effects of MQL and Dry Environments on Tool Wear, Cutting Temperature, and Power Consumption during End Milling of AISI 1040 Steel. Metals 2021, 11, 1674. https://doi.org/10.3390/met11111674

Salur E, Kuntoğlu M, Aslan A, Pimenov DY. The Effects of MQL and Dry Environments on Tool Wear, Cutting Temperature, and Power Consumption during End Milling of AISI 1040 Steel. Metals. 2021; 11(11):1674. https://doi.org/10.3390/met11111674

Chicago/Turabian StyleSalur, Emin, Mustafa Kuntoğlu, Abdullah Aslan, and Danil Yurievich Pimenov. 2021. "The Effects of MQL and Dry Environments on Tool Wear, Cutting Temperature, and Power Consumption during End Milling of AISI 1040 Steel" Metals 11, no. 11: 1674. https://doi.org/10.3390/met11111674

APA StyleSalur, E., Kuntoğlu, M., Aslan, A., & Pimenov, D. Y. (2021). The Effects of MQL and Dry Environments on Tool Wear, Cutting Temperature, and Power Consumption during End Milling of AISI 1040 Steel. Metals, 11(11), 1674. https://doi.org/10.3390/met11111674