Neutron Diffraction Study of the Martensitic Transformation of Ni2.07Mn0.93Ga Heusler Alloy

Abstract

:1. Introduction

2. Materials and Methods

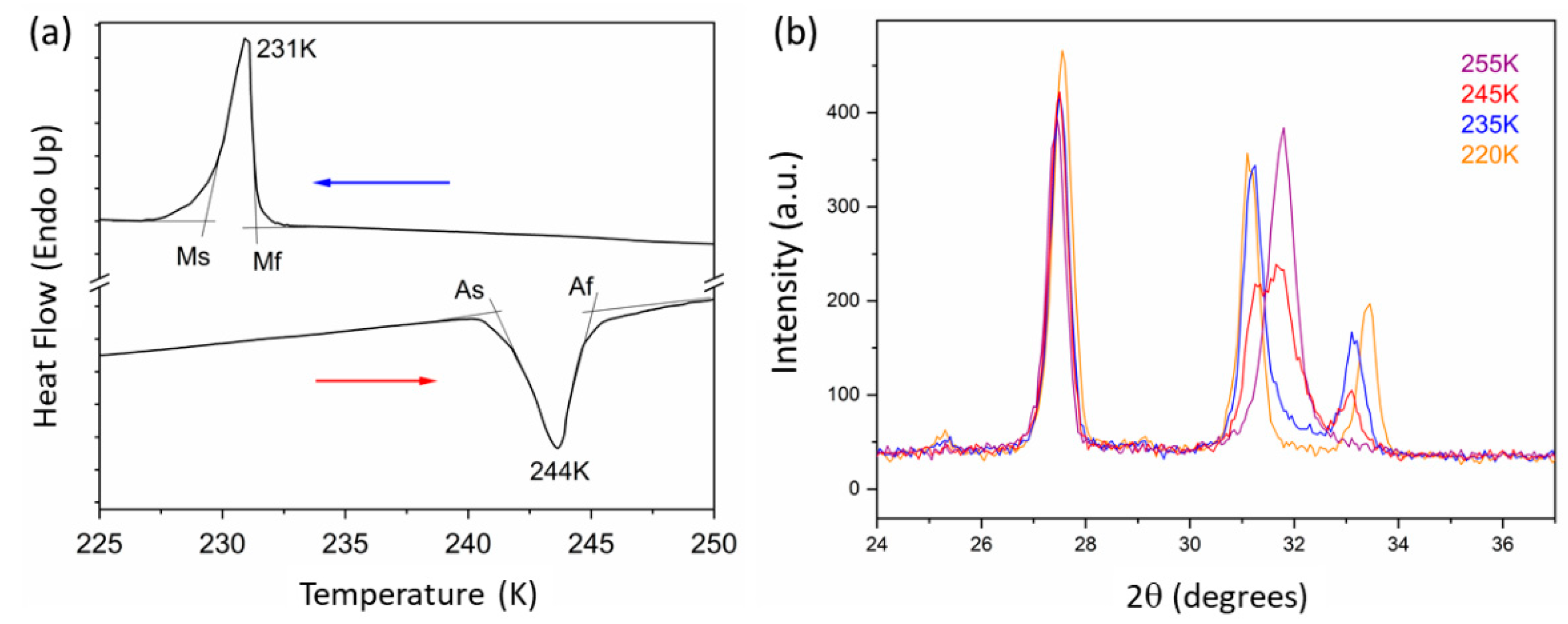

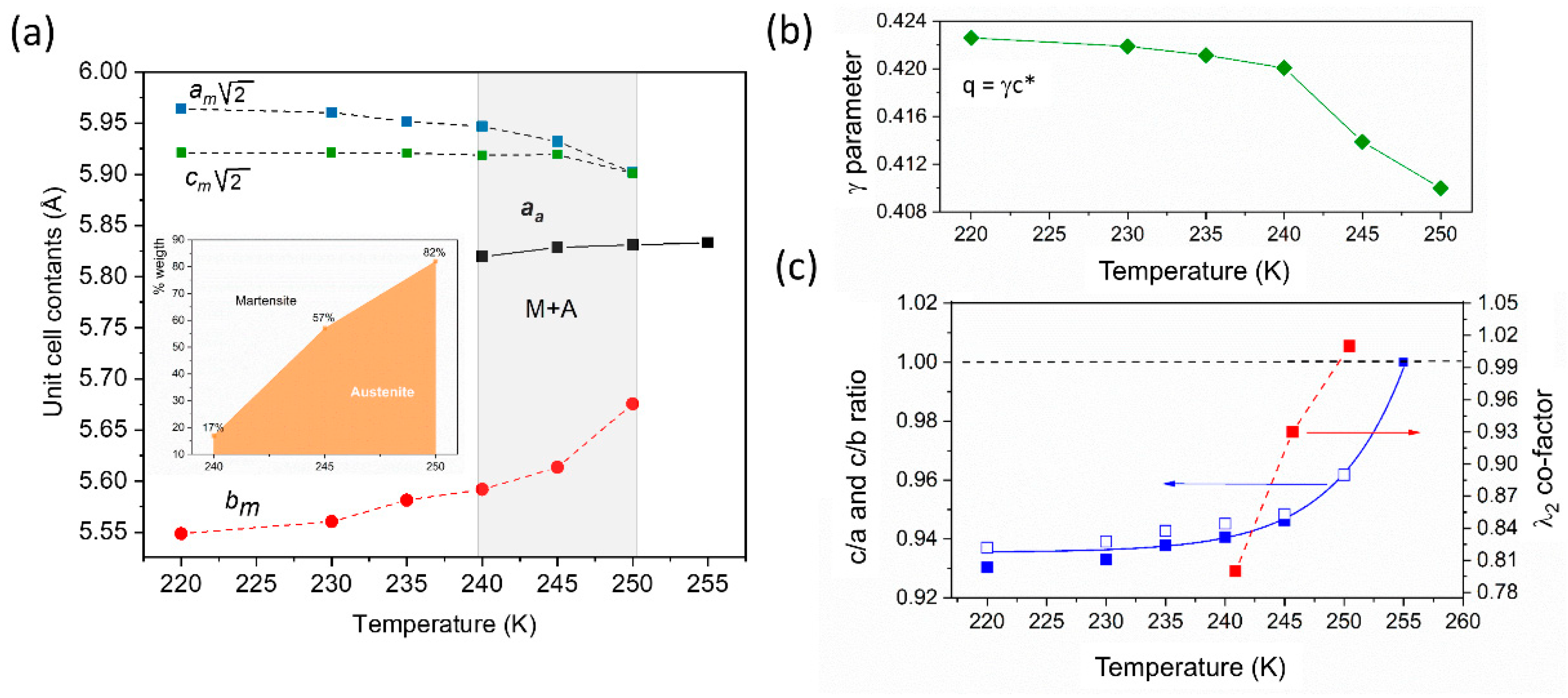

3. Results and Discussion

4. Conclusions

Supplementary Materials

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Franco, V.; Blázquez, J.S.; Ipus, J.J.; Law, J.Y.; Moreno-Ramírez, L.M.; Conde, A. Magnetocaloric ef-fect: From materials research to refrigeration devices. Prog. Mater. Sci. 2018, 93, 112–232. [Google Scholar] [CrossRef]

- Khan, R.A.A.; Ghomashchi, R.; Xie, Z.; Chen, L. Ferromagnetic Shape Memory Heusler Materials: Synthesis, Microstructure Characterization and Magnetostructural Properties. Materials 2018, 11, 988. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Acet, M.; Mañosa, L.; Planes, A. Handbook of Magnetic. Materials 2011, 19, 231–289. [Google Scholar]

- Kainuma, R.; Imano, Y.; Ito, W. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 2006, 439, 957–960. [Google Scholar] [CrossRef] [PubMed]

- Pons, J.; Chernenko, V.A.; Santamarta, R.; Cesari, E. Crystal structure of martensitic phases in Ni–Mn–Ga shape memory alloys. Acta Mater. 2000, 48, 3027–3038. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Cesari, E.; Pons, J.; Segui, C. Phase Transformations in Rapidly Quenched Ni–Mn–Ga Alloys. J. Mater. Res. 2000, 15, 1496–1504. [Google Scholar] [CrossRef]

- Martynov, V.V. X-ray diffraction study of thermally and stress-induced phase transformations in single crystalline Ni-Mn-Ga alloys. J. Phys. IV 1995, C8, 91–99. [Google Scholar] [CrossRef]

- Salazar, M.C.; Küchler, R.; Nayak, A.K.; Felser, C.; Nicklas, M. Uniaxial-stress tuned large mag-netic-shape-memory effect in Ni-Co-Mn-Sb Heusler alloys. Appl. Phys. Lett. 2017, 110, 071901. [Google Scholar] [CrossRef]

- Righi, L.; Albertini, F.; Fabbrici, S.; Paoluzi, A. Crystal Structures of Modulated Martensitic Phases of FSM Heusler Alloys. Mater. Sci. Forum 2011, 684, 105–116. [Google Scholar] [CrossRef]

- Righi, L.; Albertini, F.; Calestani, G.; Pareti, L.; Paoluzi, A.; Ritter, C.; Algarabel, P.A.; Morellon, L.; Ibarra, M.R. Incommensurate modulated structure of the ferromagnetic shape-memory Ni2MnGa martensite. J. Solid State Chem. 2006, 179, 3525–3533. [Google Scholar] [CrossRef]

- Singh, S.; Caron, L.; D’Souza, S.W.; Fichtner, T.; Porcari, G.; Fabbrici, S.; Shekhar, C.; Chadov, S.; Solzi, M.; Felser, C. Large Magnetization and Reversible Magnetocaloric Effect at the Second-Order Magnetic Transition in Heusler. Mater. Adv. Mater. 2016, 28, 3321–3325. [Google Scholar] [CrossRef]

- Khovaylo, V.V.; Buchelnikov, V.D.; Kainuma, R.; Koledov, V.V.; Ohtsuka, M.; Shavrov, V.G.; Takagi, T.; Taskaev, S.V.; Vasiliev, A.N. Phase transitions in Ni2+xMn1-xGa with a high Ni excess. Phys. Rev. B 2005, 72, 224408. [Google Scholar] [CrossRef] [Green Version]

- Cherechukin, A.; Takagi, T.; Matsumoto, M.; Buchel’nikovc, V.D. Magnetocaloric effect in Ni2+xMn1−xGa Heusler alloys. Phys Lett. A 2004, 326, 146–151. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Sánchez-Valdés, C.F.; Sánchez Llamazares, J.L.; Esling, C.; Zhao, X.; Zuo, L. Giant magnetocaloric effect in melt-spun Ni-Mn-Ga ribbons with magneto-multistructural transformation. Appl. Phys. Lett. 2014, 104, 044101. [Google Scholar] [CrossRef]

- Khovaylo, V.V.; Skokov, K.P.; Taskaev, S.V.; Karpenkov, D.U.; Dilmieva, E.T.; Koledov, V.V.; Koshkid’ko, Y.S.; Shavrov, V.G.; Buchelnikov, V.D. Magnetocaloric properties of Ni2+xMn1-xGa with coupled magnetostructural phase transition. J. Appl. Phys. 2020, 127, 173903. [Google Scholar] [CrossRef]

- Kamantsev, A.P.; Koledov, V.; Mashirov, A.V.; Dilmieva, E.T.; Shavrov, V.G.; Cwik, J.; Los, A.S.; Nizhankovskii, V.I.; Rogacki, K.; Tereshina, I.S.; et al. Magnetocaloric and thermomagnetic properties of Ni2.18Mn0.82Ga Heusler alloy in high magnetic fields up to 140 kOe. J. Appl. Phys. 2015, 117, 163903. [Google Scholar] [CrossRef] [Green Version]

- Liang, T.; Chengbao, J.; Huibin, X. Temperature dependence of transformation strain and magnet-ic field-induced strain in Ni51Mn24Ga25 single crystal. Mater. Sci. Eng. A 2005, 402, 5–8. [Google Scholar] [CrossRef]

- Young, R.A. The Rietveld Method; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Li, L.Y.; Mattei, G.S.; Li, Z.; Zheng, J.; Zhao, W.; Omenya, F.; Fang, C.; Li, W.; Jianyu Li, J.; Xie, Q.; et al. Extending the limits of powder diffraction analysis: Diffraction parameter space, occupancy defects, and atomic form factors. Rev. Sci. Instrum. 2018, 89, 093002. [Google Scholar]

- Barandiaran, J.M.; Gutiérrez, J.; Lázpita, P.; Feuchtwanger, J. Neutron Diffraction Studies of Magnetic Shape Memory Alloys. Mater. Sci. Forum 2011, 684, 73–84. [Google Scholar] [CrossRef]

- Kushida, H.; Fukuda, K.; Terai, T.; Fukuda, T.; Kakeshita, T.; Ohba, T.; Osakabe, T.; Kakurai, K.; Kato, K. Crystal structure of martensite and intermediate phases in Ni2MnGa studied by neutron diffraction. Eur. Phys. J. 2008, 158, 87–92. [Google Scholar] [CrossRef]

- Van Smaalen, S. Incommensurate crystal structures. Crystallogr. Rev. 1995, 4, 79–202. [Google Scholar] [CrossRef]

- Pramanick, A.; Wang, X.P.; An, K.; Stoica, A.D.; Yi, J.; Gai, Z.; Hoffmann, C.; Wang, X.L. Structural modulations and magnetic properties of off-stoichiometric Ni-Mn-Ga magnetic shape memory alloys. Phys. Rev. B 2012, 85, 144412. [Google Scholar] [CrossRef] [Green Version]

- Devi, P.; Singh, S.; Dutta, B.; Manna, K.; D’Souza, S.W.; Ikeda, Y.; Suard, E.; Petricek, V.; Simon, P.; Werner, P.; et al. Adaptive modulation in the Ni2Mn1.4In0.6 magnetic shape-memory Heusler alloy. Phys. Rev. B 2018, 97, 224102. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.; Ziebeck, A.; Suard, E.; Rajput, P.; Bhardwaj, S.; Awasthi, A.M.; Barman, S.R. Modulated structure in the martensite phase of Ni1.8Pt0.2MnGa: A neutron diffraction study. Appl. Phys. Lett. 2012, 101, 171904. [Google Scholar] [CrossRef] [Green Version]

- Lázpita, P.; Barandiarán, J.M.; Gutiérrez, J.; Feuchtwanger, J.; Chernenko, V.A.; Richard, M.L. Magnetic moment and chemical order in off-stoichiometric Ni–Mn–Ga ferromagnetic shape memory alloys. New J. Phys. 2011, 13, 033039. [Google Scholar] [CrossRef]

- Ahuja, B.L.; Sharma, B.K.; Mathur, S.; Heda, N.L.; Itou, M.; Andrejczuk, A.; Sakurai, Y.; Chakrabarti, A.; Banik, S.; Awasthi, A.M.; et al. Magnetic Compton scattering study of Ni2+xMn1-xGa ferromagnetic shape-memory alloys. Phys. Rev. B 2007, 75, 134403. [Google Scholar] [CrossRef]

- Zheludev, A.; Shapiro, S.M.; Wochner, P.; Tanner, L.E. Precursor effects and premartensitic transformation in Ni2MnGa. Phys. Rev. B 1996, 54, 15045. [Google Scholar] [CrossRef]

- Airoldi, G. Shape Memory Alloys: From Microstructure to Macroscopic Properties; Bhattacharya, G., Airoldi, I., Müller, S., Miyazaki, S., Eds.; Trans Tech Publications: Bäch, Switzerland, 1997. [Google Scholar]

- Ball, J.M.; Carstensen, C. Nonclassical austenite-martensite interfaces. J. Phys. IV 1997, 7, 35–40. [Google Scholar] [CrossRef] [Green Version]

- Ball, J.M.; James, R.D. Fine phase mixtures as minimizers of energy. Arch. Ration. Mech. Anal. 1987, 100, 13–52. [Google Scholar] [CrossRef]

- Della, F.P. On the cofactor conditions and further conditions of supercompatibility. J. Mech. Phys. Solids 2019, 122, 27–53. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Srivastava, V.; Dabade, V.; James, R.D. Study of the cofactor conditions: Conditions of supercompatibility between phases. J. Mech. Phys. Solids 2013, 61, 2566–2587. [Google Scholar] [CrossRef] [Green Version]

- James, R.D.; Hane, K.F. Martensitic transformations and shape-memory materials. Acta Mater. 2000, 48, 197–222. [Google Scholar] [CrossRef]

- Devi, P.; Salazar Mejia, C.; Ghorbani Zavareh, M.; Dubey, K.K.; Kushwaha, P.; Skourski, Y.; Felser., C.; Nicklas, M.; Singh, S. Improved magnetostructural and magnetocaloric reversibility in magnetic Ni-Mn-In shape memory Heusler alloy by optimizing the geometric compatibility condition. Phys. Rev. Mater. 2019, 3, 062401. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Righi, L. Neutron Diffraction Study of the Martensitic Transformation of Ni2.07Mn0.93Ga Heusler Alloy. Metals 2021, 11, 1749. https://doi.org/10.3390/met11111749

Righi L. Neutron Diffraction Study of the Martensitic Transformation of Ni2.07Mn0.93Ga Heusler Alloy. Metals. 2021; 11(11):1749. https://doi.org/10.3390/met11111749

Chicago/Turabian StyleRighi, Lara. 2021. "Neutron Diffraction Study of the Martensitic Transformation of Ni2.07Mn0.93Ga Heusler Alloy" Metals 11, no. 11: 1749. https://doi.org/10.3390/met11111749