Wettability in Metal Matrix Composites

Abstract

:1. Introduction

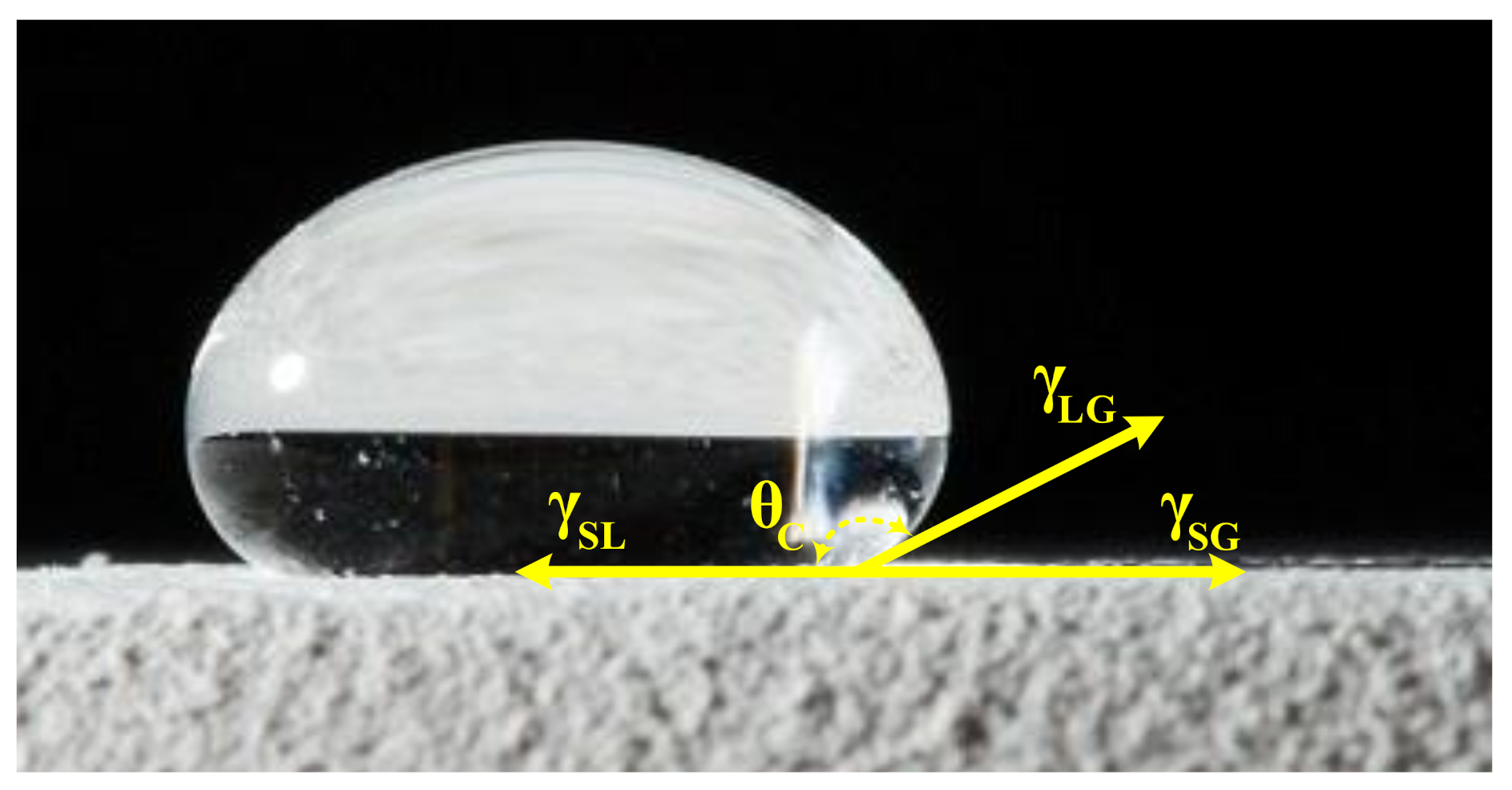

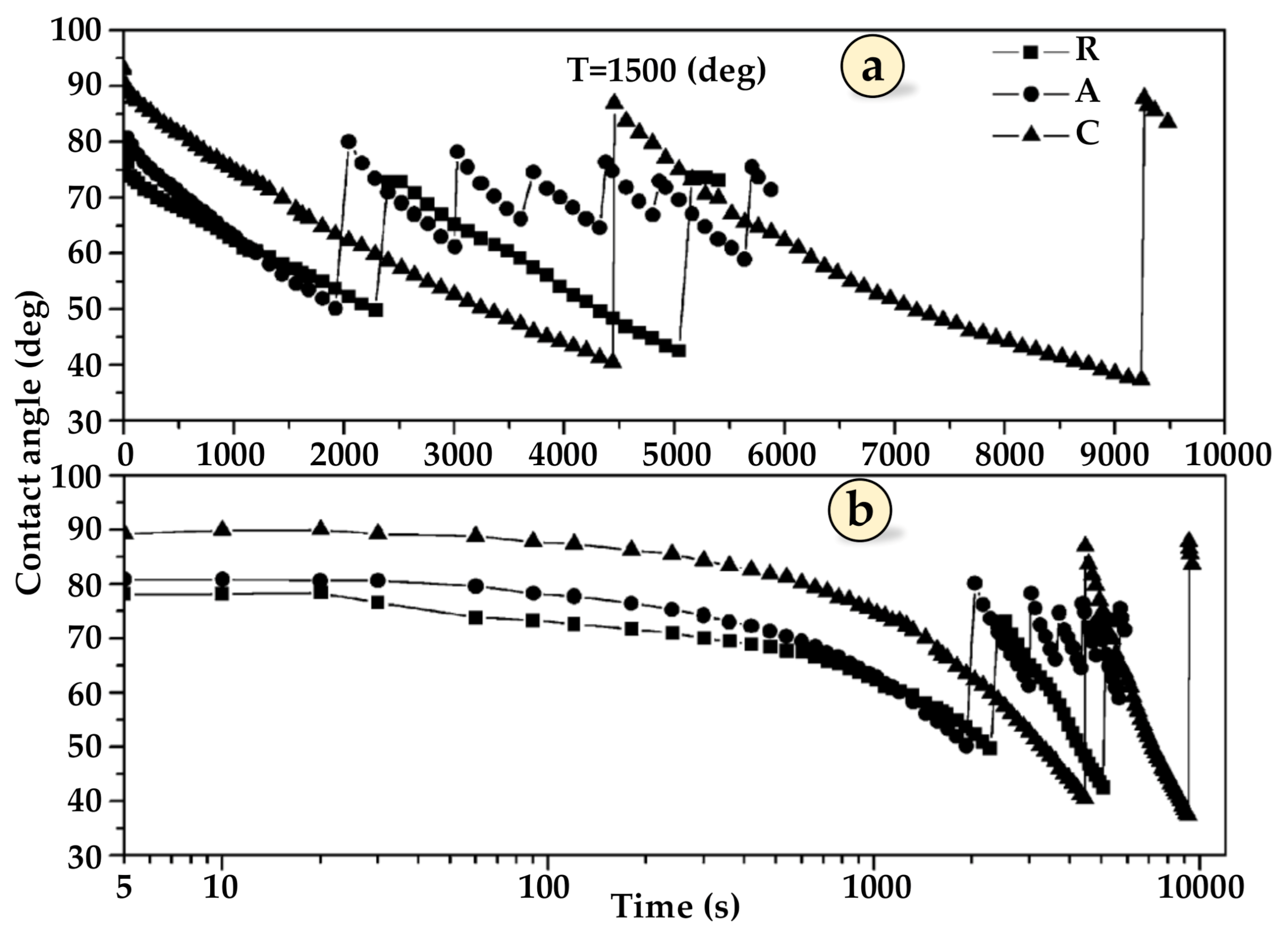

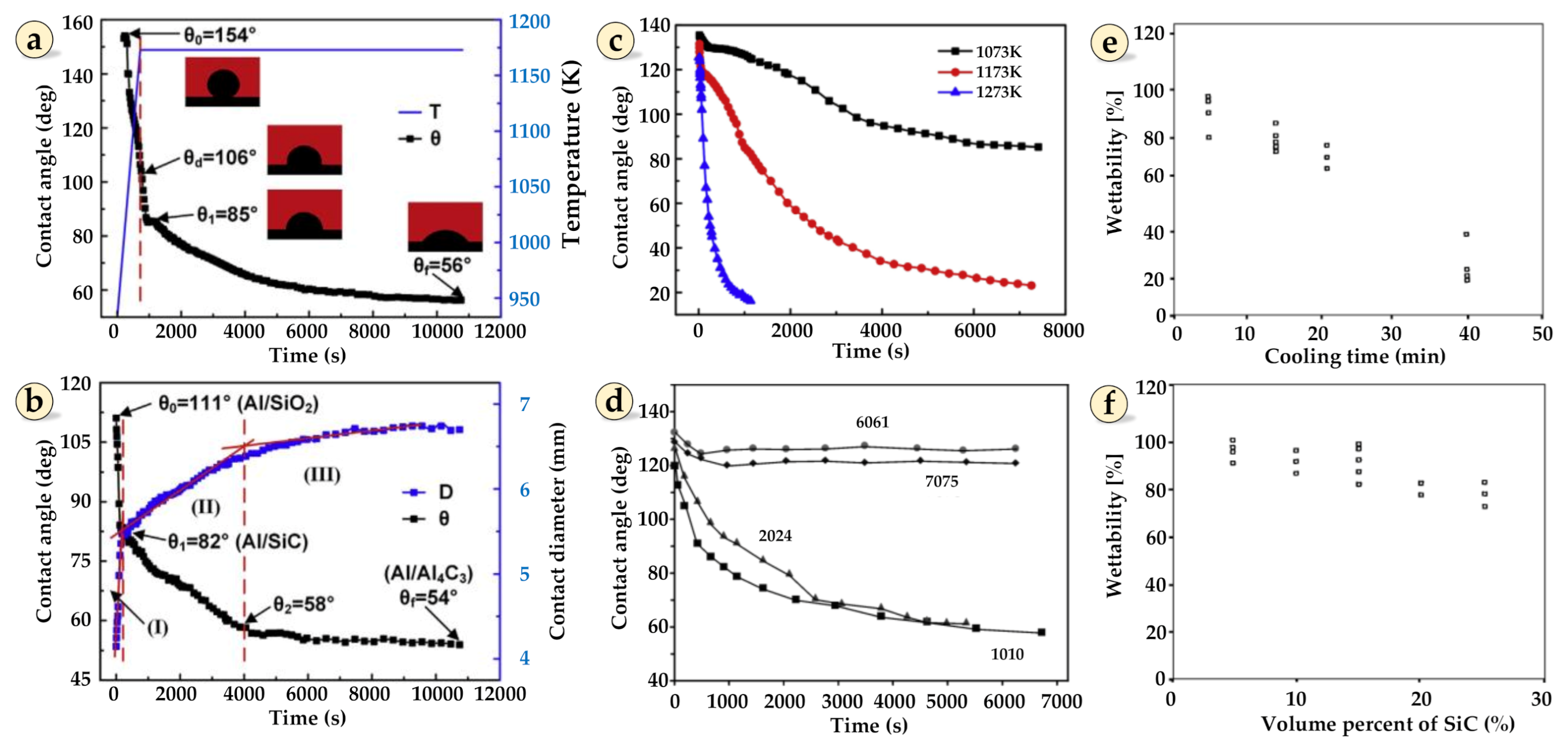

2. Wettability

3. Thermal Treatment and Temperature

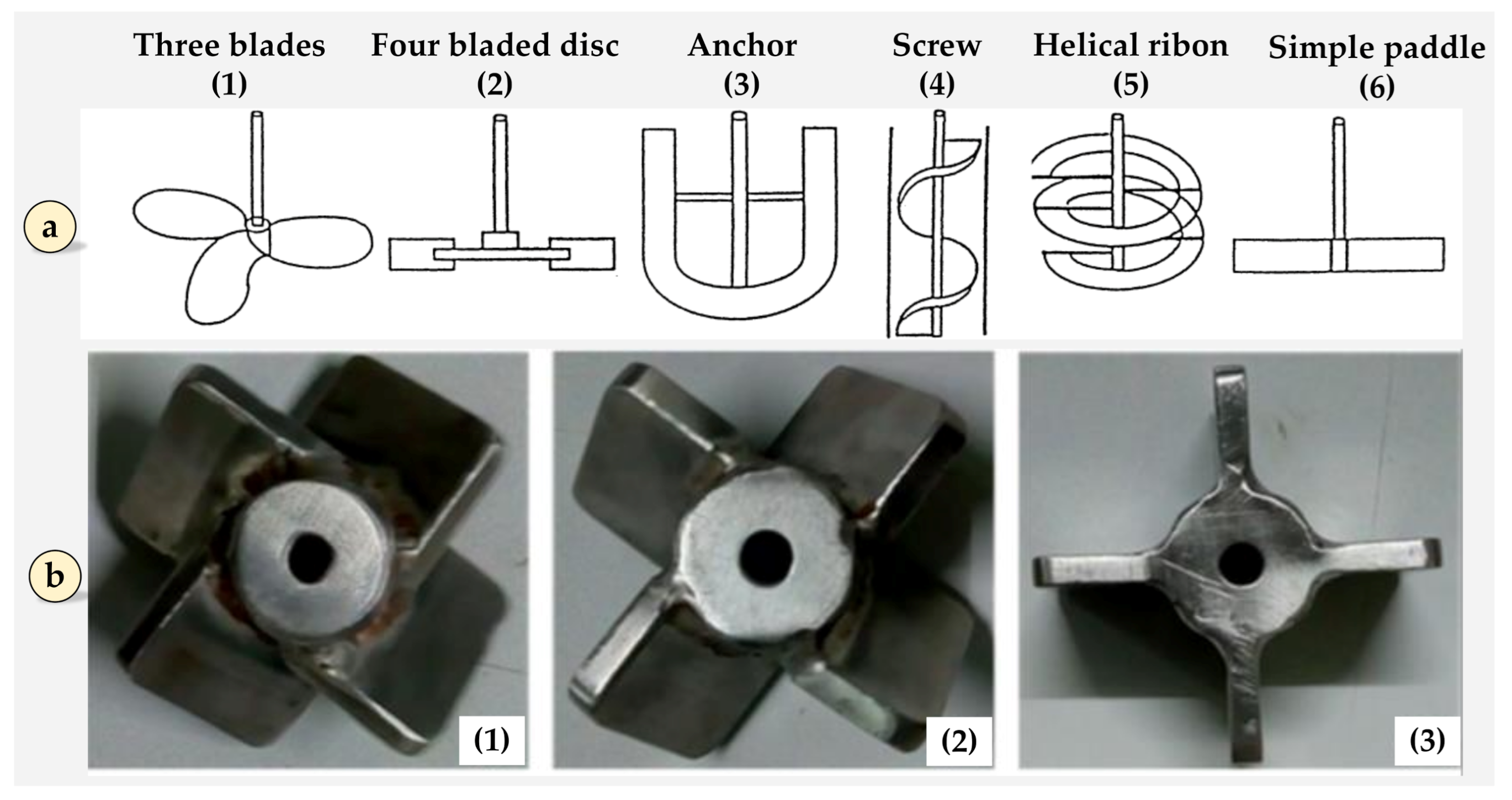

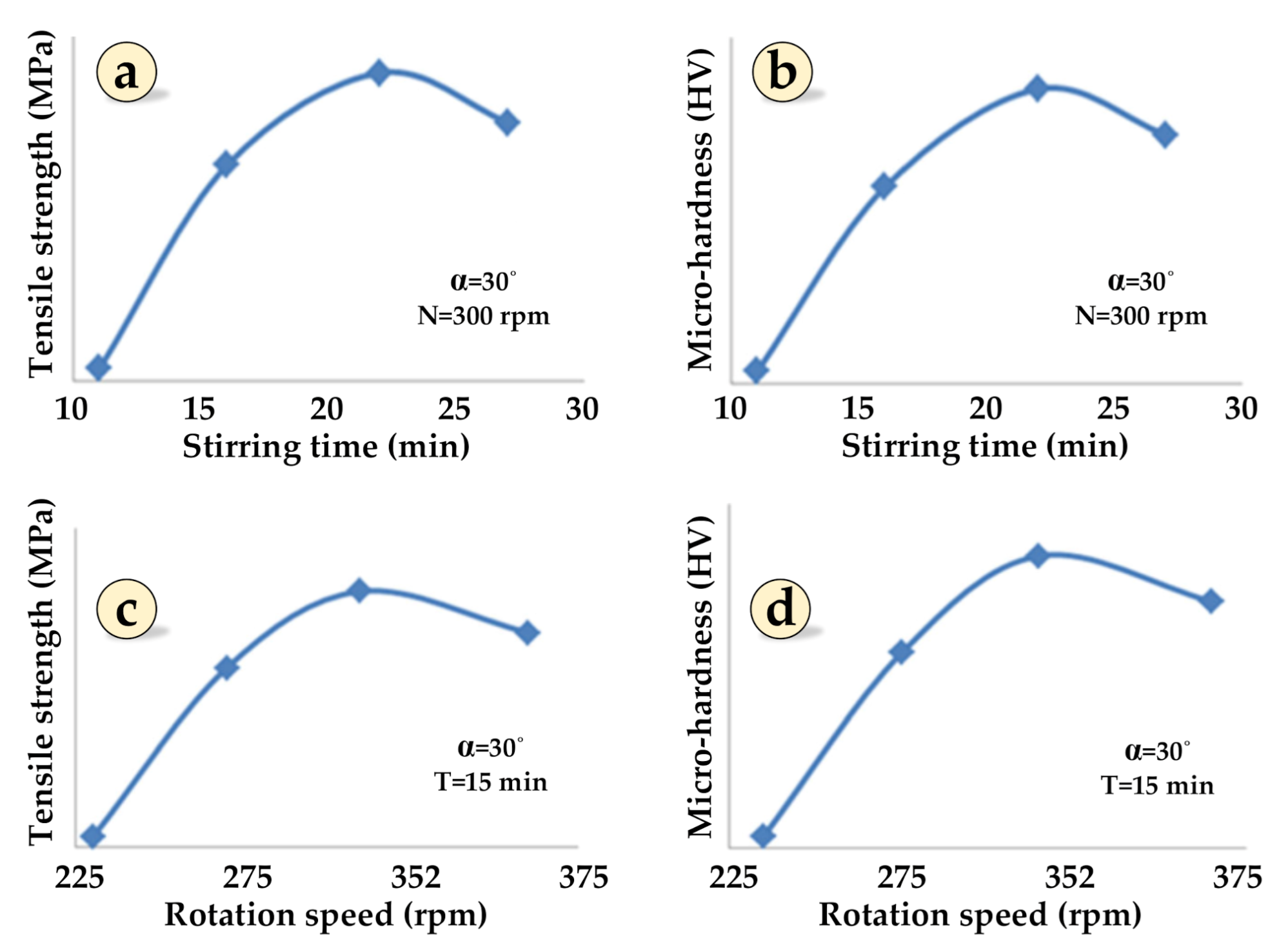

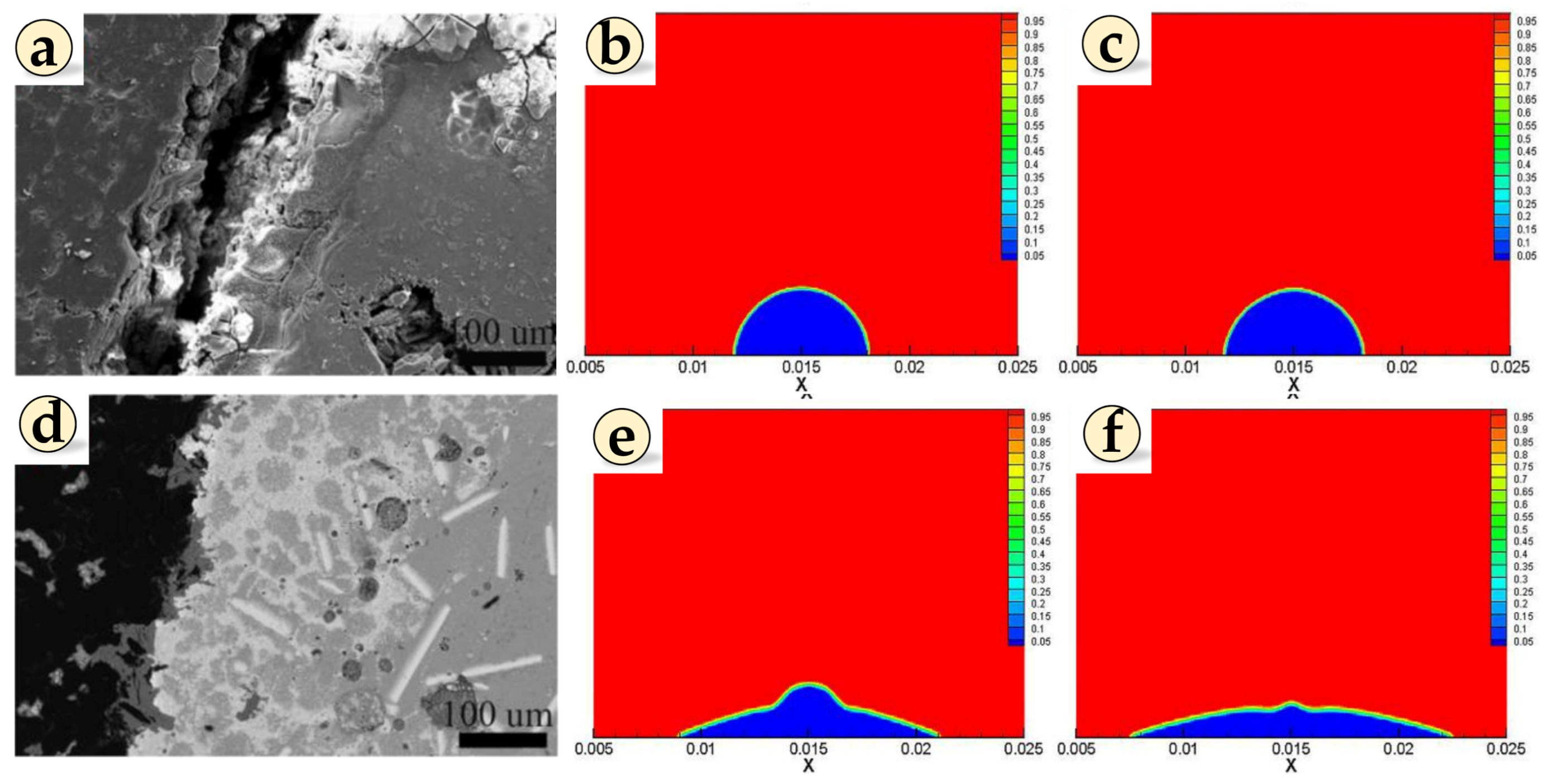

4. Mechanical Treatment

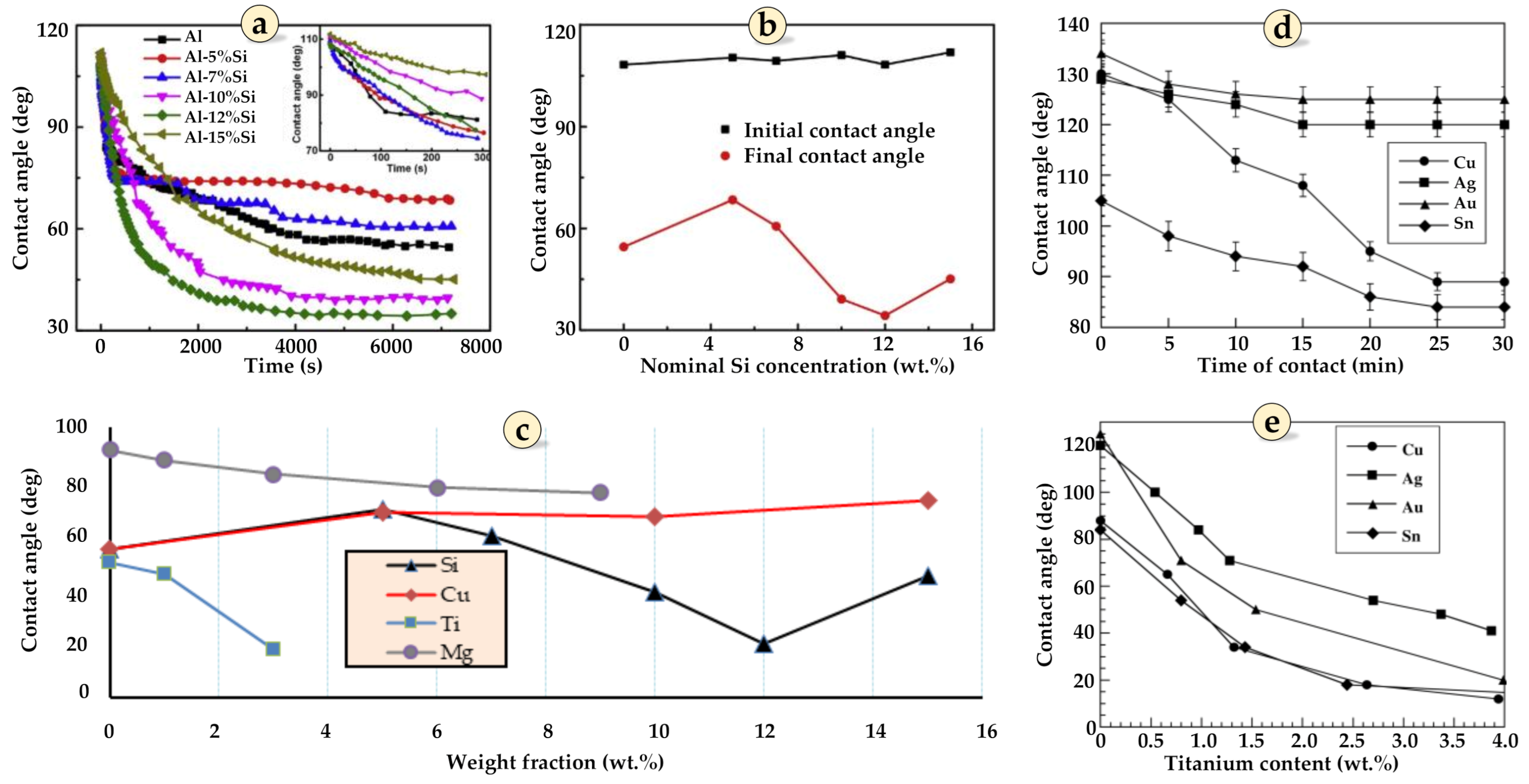

5. Chemical Agent Addition

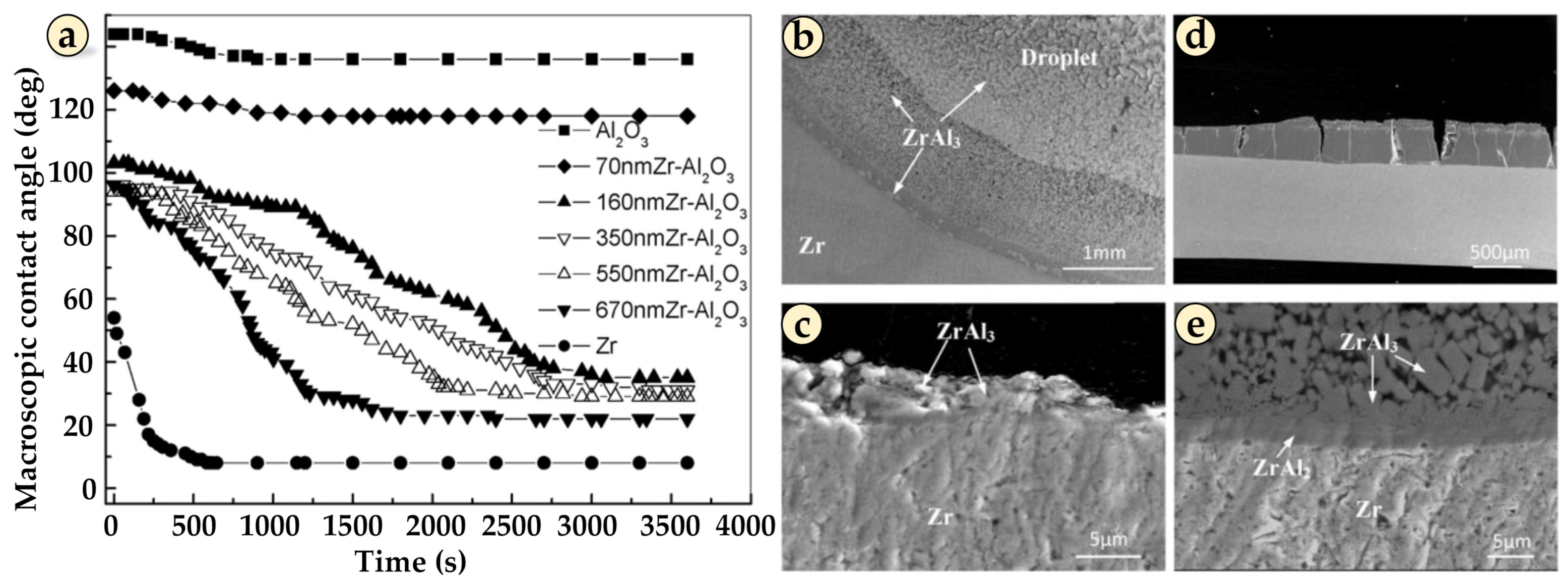

6. Coating

7. Summary and Research Pitfalls

Funding

Conflicts of Interest

References

- Cuevas, A.C.; Bercerril, E.; Martínez, M.S. Metal Matric Composites: Wetting and Infiltration; Springer: Cham, Switzerland, 2018; p. 221. [Google Scholar]

- Abbasipour, B.; Niroumand, B.; Vaghefi, S.M.M.; Abedi, M. Tribological behavior of A356− CNT nanocomposites fabricated by various casting techniques. Trans. Nonferrous Met. Soc. China 2019, 29, 1993–2004. [Google Scholar] [CrossRef]

- Shayan, M.; Eghbali, B.; Niroumand, B. Fabrication of AA2024−TiO2 nanocomposites through stir casting process. Trans. Nonferrous Met. Soc. China 2020, 30, 2891–2903. [Google Scholar] [CrossRef]

- Shayan, M.; Eghbali, B.; Niroumand, B. Synthesis and characterization of AA2024-SiO2 nanocomposites through the vortex method. Int. J. Met. 2021, 15, 1–14. [Google Scholar]

- Amirkhanlou, S.; Jamaati, R.; Niroumand, B.; Toroghinejad, M.R. Fabrication and characterization of Al/SiCp composites by CAR process. Mater. Sci. Eng. A 2011, 528, 4462–4467. [Google Scholar] [CrossRef]

- Shayan, M.; Eghbali, B.; Niroumand, B. The role of accumulative roll bonding after stir casting process to fabricate high-strength and nanostructured AA2024-(SiO2+TiO2) hybrid nanocomposite. J. Alloys Compd. 2020, 845, 156281. [Google Scholar] [CrossRef]

- Pramod, S.L.; Bakshi, S.R.; Murty, B.S. Aluminum-based cast in situ composites: A review. J. Mater. Eng. Perform. 2015, 24, 2185–2207. [Google Scholar] [CrossRef]

- Malaki, M.; Xu, W.; Kasar, A.K.; Menezes, P.L.; Dieringa, H.; Varma, R.S.; Gupta, M. Advanced metal matrix nanocomposites. Metals 2019, 9, 330. [Google Scholar] [CrossRef] [Green Version]

- Eustathopoulos, N.; Voytovych, R. The role of reactivity in wetting by liquid metals: A review. J. Mater. Sci. 2016, 51, 425–437. [Google Scholar] [CrossRef]

- Saiz, E.; Tomsia, A.P.; Cannon, R.M. Ridging effects on wetting and spreading of liquids on solids. Acta Mater. 1998, 46, 2349–2361. [Google Scholar] [CrossRef]

- Malaki, M.; Tehrani, A.F.; Niroumand, B. Fatgiue behavior of metal matrix nanocomposites. Ceram. Int. 2020, 46, 23326–23336. [Google Scholar] [CrossRef]

- Liu, G.W.; Muolo, M.L.; Valenza, F.; Passerone, A. Survey on wetting of SiC by molten metals. Ceram. Int. 2010, 36, 1177–1188. [Google Scholar] [CrossRef]

- Chatain, D.; Carter, W.C. Spreading of metallic drops. Nat. Mater. 2004, 3, 843–845. [Google Scholar] [CrossRef]

- Laurent, V.; Chatain, D.; Eustathopoulos, N. Wettability of SiO2 and oxidized SiC by aluminium. Mater. Sci. Eng. A 1991, 135, 89–94. [Google Scholar] [CrossRef]

- Xiao, P.; Derby, B. Wetting of titanium nitride and titanium carbide by liquid metals. Acta Mater. 1996, 44, 307–314. [Google Scholar] [CrossRef]

- Rado, C.; Kalogeropoulou, S.; Eustathopoulos, N. Wetting and adhesion in metal-silicon carbide systems: The effect of surface polarity of SiC. Scr. Mater. 1999, 42, 203–208. [Google Scholar] [CrossRef]

- Chatain, D. Anisotropy of wetting. Annu. Rev. Mater. Res. 2008, 38, 45–70. [Google Scholar] [CrossRef]

- Muolo, M.; Ferrera, E.; Novakovic, R.; Passerone, A. Wettability of zirconium diboride ceramics by Ag, Cu and their alloys with Zr. Scr. Mater. 2003, 48, 191–196. [Google Scholar] [CrossRef]

- Kumar, G.; Prabhu, K.N. Review of non-reactive and reactive wetting of liquids on surfaces. Adv. Colloid Interface Sci. 2007, 133, 61–89. [Google Scholar] [CrossRef]

- Earvolino, P.A.; Fine, M.E.; Weertman, J.R.; Parameswaran, V.R. Processing an AlAl3Zr0.25Ti0.75 metal-matrix composite by conventional melting, casting and rolling. Scr. Metall. Mater. 1992, 26, 945–948. [Google Scholar] [CrossRef]

- Tekmen, C.; Saday, F.; Cocen, U.; Ljungberg, L.Y. An Investigation of the Effect of SiC Reinforcement Coating on the Wettability of Al/SiC System. J. Compos. Mater. 2008, 42, 1671–1679. [Google Scholar] [CrossRef]

- Leon, C.; Drew, R. The influence of nickel coating on the wettability of aluminum on ceramics. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1429–1432. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, X.; Wang, T.; Liu, G.; Shao, H.; Wan, Y.; Qiao, G. Effects of Pd ion implantation and Si addition on wettability of Al/SiC system. Surf. Coat. Technol. 2018, 335, 198–204. [Google Scholar] [CrossRef]

- Zhao, S.T.; Valenza, F.; Liu, G.W.; Muolo, M.L.; Qiao, G.J.; Passerone, A. Surface characterization of Mo-implanted 6H–SiC by high temperature non-reactive wetting tests with the Ni–56Si alloy. Ceram. Int. 2014, 40, 7227–7234. [Google Scholar] [CrossRef]

- Barlak, M.; Piekoszewski, J.; Werner, Z.; Stanislawski, J.; Skladnik-Sadowska, E.; Borkowska, K.; Miskiewicz, M.; Kolitsch, A.; Grötzschel, R.; Starosta, W.; et al. Wettability improvement of carbon ceramic materials by mono and multi energy plasma pulses. Surf. Coat. Technol. 2009, 203, 2536–2540. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, X.; Liu, G.; Valenza, F.; Muolo, M.; Qiao, G.; Passerone, A. Wetting and interfacial behavior of molten Cu on Co–Si (–Mo) coated SiC. Ceram. Int. 2015, 41, 13493–13501. [Google Scholar] [CrossRef]

- Pai, B.; Ramani, G.; Pillai, R.; Satyanarayana, K. Role of magnesium in cast aluminium alloy matrix composites. J. Mater. Sci. 1995, 30, 1903–1911. [Google Scholar] [CrossRef]

- Nakae, H.; Fujii, H.; Sato, K. Reactive wetting of ceramics by liquid metals. Mater. Trans. JIM 1992, 33, 400–406. [Google Scholar] [CrossRef] [Green Version]

- Laurent, V.; Rado, C.; Eustathopoulos, N. Wetting kinetics and bonding of Al and Al alloys on α-SiC. Mater. Sci. Eng. A 1996, 205, 1–8. [Google Scholar] [CrossRef]

- An, Q.; Cong, X.-S.; Shen, P.; Jiang, Q.-C. Roles of alloying elements in wetting of SiC by Al. J. Alloys Compd. 2019, 784, 1212–1220. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. The wettability of SiC particles by molten aluminium alloy. J. Mater. Process. Technol. 2001, 119, 324–328. [Google Scholar] [CrossRef]

- Feng, A.; McCoy, B.J.; Munir, Z.A.; Cagliostro, D. Wettability of transition metal oxide surfaces. Mater. Sci. Eng. A 1998, 242, 50–56. [Google Scholar] [CrossRef]

- Ray, S. Casting of composite components. In Proceedings of the 1995 Conference on Inorganic Matrix Composites, Delhi, India, 5 June 1996; pp. 69–89. [Google Scholar]

- Zhou, W.; Xu, Z.M. Casting of SiC reinforced metal matrix composites. J. Mater. Process. Technol. 1997, 63, 358–363. [Google Scholar] [CrossRef]

- Warren, R.; Andersson, C. Silicon carbide fibres and their potential for use in composite materials. Part II. Composites 1984, 15, 101–111. [Google Scholar] [CrossRef]

- Aguilar, E.; León, C.; Contreras, A.; López, V.; Drew, R.; Bedolla, E. Wettability and phase formation in TiC/Al-alloys assemblies. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1425–1428. [Google Scholar] [CrossRef]

- Jebeen Moses, J.; Joseph Sekhar, S. Investigation on the Tensile Strength and Microhardness of AA6061/TiC Composites by Stir Casting. Trans. Indian Inst. Met. 2017, 70, 1035–1046. [Google Scholar] [CrossRef]

- Naher, S.; Brabazon, D.; Looney, L. Computational and experimental analysis of particulate distribution during Al–SiC MMC fabrication. Compos. Part A Appl. Sci. Manuf. 2007, 38, 719–729. [Google Scholar] [CrossRef] [Green Version]

- Naidich, Y.V. The wettability of solids by liquid metals. Prog. Surf. Membr. Sci. 1972, 14, 353–484. [Google Scholar]

- Kohler, W. Investigations into the Wetting of Al2O3- and SiC- Crystals by Aluminum and Aluminum Alloys. Aluminium 1975, 51, 443–447. [Google Scholar]

- Halverson, D.C.; Pyzik, A.J.; Aksay, I.A. Processing and microstructural characterization of B4C-AI cermets. In Proceedings of the 9th Annual Conference on Composites and Advanced Ceramic Materials: Ceramic Engineering and Science Proceedings; Wiley: New York, NY, USA, 1985; pp. 736–744. [Google Scholar]

- Brennan, J.J.; Pask, J.A. Effect of nature of surfaces on wetting of sapphire by liquid aluminum. J. Am. Ceram. Soc. 1968, 51, 569–573. [Google Scholar] [CrossRef]

- Wolf, S.; Levitt, A.; Brown, J. Whisker-metal matrix bonding. Chem. Eng. Prog. 1966, 62, 74. [Google Scholar]

- Champion, J.; Keene, B.; Sillwood, J. Wetting of aluminium oxide by molten aluminium and other metals. J. Mater. Sci. 1969, 4, 39–49. [Google Scholar] [CrossRef]

- Rohatgi, P.; Asthana, R.; Das, S. Solidification, structures, and properties of cast metal-ceramic particle composites. Int. Met. Rev. 1986, 31, 115–139. [Google Scholar] [CrossRef]

- Eskin, G.I.; Eskin, D.G. Ultrasonic Treatment of Light Alloy Melts, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2015; p. 346. [Google Scholar]

- Egry, I.; Ricci, E.; Novakovic, R.; Ozawa, S. Surface tension of liquid metals and alloys—Recent developments. Adv. Colloid Interface Sci. 2010, 159, 198–212. [Google Scholar] [CrossRef]

- Shen, P.; Fujii, H.; Matsumoto, T.; Nogi, K. The influence of surface structure on wetting of α-Al2O3 by aluminum in a reduced atmosphere. Acta Mater. 2003, 51, 4897–4906. [Google Scholar] [CrossRef]

- Park, J.; Lucas, J. Moisture effect on SiCp/6061 Al MMC: Dissolution of interfacial Al4C3. Scr. Mater. 1997, 37, 511–516. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. The enhancement of wettability of SiC particles in cast aluminium matrix composites. J. Mater. Process. Technol. 2001, 119, 329–335. [Google Scholar] [CrossRef]

- Thanh, L.N.; Suéry, M. Influence of oxide coating on chemical stability of SiC particles in liquid aluminium. Scr. Metall. Mater. 1991, 25, 2781–2786. [Google Scholar] [CrossRef]

- Prabu, S.B.; Karunamoorthy, L.; Kathiresan, S.; Mohan, B. Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite. J. Mater. Process. Technol. 2006, 171, 268–273. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Gao, X.; Hu, Q.-G.; Talha, M.; Liu, H.; Chai, S. Study on Interface Behavior of SiC/SiO2/Al and SiC/Ni/Al. Trans. Indian Inst. Met. 2019, 72, 3171–3178. [Google Scholar] [CrossRef]

- Nowak, R.; Sobczak, N.; Bruzda, G.; Wojewoda-Budka, J.; Litynska-Dobrzynska, L.; Homa, M.; Kaban, I.; Xi, L.; Jaworska, L. Wettability and Reactivity of ZrB2 Substrates with Liquid Al. J. Mater. Eng. Perform. 2016, 25, 3310–3316. [Google Scholar] [CrossRef] [Green Version]

- Řeháčková, L.; Novák, V.; Váňová, P.; Matýsek, D.; Konečná, K.; Smetana, B.; Dobrovská, J. High-temperature interaction of molten Fe–C–O–Cr alloys with corundum. J. Alloys Compd. 2021, 854, 157128. [Google Scholar] [CrossRef]

- Nogi, K.; Ogino, K. Wettability of SiC by liquid pure metals. Trans. Jpn. Inst. Met. 1988, 29, 742–747. [Google Scholar] [CrossRef] [Green Version]

- Kalogeropoulou, S.; Baud, L.; Eustathopoulos, N. Relationship between wettability and reactivity in Fe/SiC system. Acta Metall. Mater. 1995, 43, 907–912. [Google Scholar] [CrossRef]

- Nikolopoulos, P.; Los, S.A.P.; Angelopoulos, G.; Naoumidis, A.; Grübmeier, H. Wettability and interfacial energies in SiC-liquid metal systems. J. Mater. Sci. 1992, 27, 139–145. [Google Scholar] [CrossRef]

- Li, J.; Hausner, H. Wettability of silicon carbide by gold, germanium and silicon. J. Mater. Sci. Lett. 1991, 10, 1275–1276. [Google Scholar] [CrossRef]

- Ferro, A.; Derby, B. Development of a micro-droplet technique for wettability studies: Application to the Al-Si/SiC system. Scr. Metall. Mater. 1995, 33, 837–842. [Google Scholar] [CrossRef]

- Jones, H.; Atkinson, H. The wettability of silicon carbide by liquid aluminium: The effect of free silicon in the carbide and of magnesium, silicon and copper alloy additions to the aluminium. J. Mater. Sci. 1993, 28, 2654–2658. [Google Scholar]

- Takahashi, S.; Kuboi, O. Study on contact angles of Au, Ag, Cu, Sn, Al and Al alloys to SiC. J. Mater. Sci. 1996, 31, 1797–1802. [Google Scholar] [CrossRef]

- Rado, C.; Drevet, B.; Eustathopoulos, N. The role of compound formation in reactive wetting: The Cu/SiC system. Acta Mater. 2000, 48, 4483–4491. [Google Scholar] [CrossRef]

- Gnesin, G.; Naidich, Y.V. Contact reaction of silicon carbide with fused copper. Sov. Powder Metall. Met. Ceram. 1969, 8, 128–132. [Google Scholar] [CrossRef]

- Li, S.; Zhou, Y.; Duan, H. Wettability and interfacial reaction in SiC/Ni plus Ti system. J. Mater. Sci. 2002, 37, 2575–2579. [Google Scholar] [CrossRef]

- Kaiser, N.; Cröll, A.; Szofran, F.; Cobb, S.; Benz, K. Wetting angle and surface tension of germanium melts on different substrate materials. J. Cryst. Growth 2001, 231, 448–457. [Google Scholar] [CrossRef]

- Fu, W.; Song, X.; Tian, R.; Lei, Y.; Long, W.; Zhong, S.; Feng, J. Wettability and joining of SiC by Sn-Ti: Microstructure and mechanical properties. J. Mater. Sci. Technol. 2020, 40, 15–23. [Google Scholar] [CrossRef]

- Jian-Guo, L. Wettability of silicon carbide by liquid silver and binary silver-silicon alloy. Mater. Lett. 1994, 18, 291–298. [Google Scholar] [CrossRef]

- Naidich, Y.V.; Zhuravlev, V.; Krasovskaya, N. The wettability of silicon carbide by Au–Si alloys. Mater. Sci. Eng. A 1998, 245, 293–299. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.Y.; Du, Y.H.; Zhang, P.; Wang, Y.J. Air-isolated stir casting of homogeneous Al-SiC composite with no air entrapment and Al4C3. J. Mater. Process. Technol. 2019, 271, 226–236. [Google Scholar] [CrossRef]

- Andersson, C.; Warren, R. Silicon carbide fibres and their potential for use in composite materials. Part 1. Composites 1984, 15, 16–24. [Google Scholar] [CrossRef]

- Salvo, L.; L’Espérance, G.; Suéry, M.; Legoux, J.G. Interfacial reactions and age hardening in Al-Mg-Si metal matrix composites reinforced with SiC particles. Mater. Sci. Eng. A 1994, 177, 173–183. [Google Scholar] [CrossRef]

- Eustathopoulos, N.; Sobczak, N.; Passerone, A.; Nogi, K. Measurement of contact angle and work of adhesion at high temperature. J. Mater. Sci. 2005, 40, 2271–2280. [Google Scholar] [CrossRef]

- Rajan, T.; Pillai, R.; Pai, B. Reinforcement coatings and interfaces in aluminium metal matrix composites. J. Mater. Sci. 1998, 33, 3491–3503. [Google Scholar] [CrossRef]

- Levi, G.; Kaplan, W.D. Oxygen induced interfacial phenomena during wetting of alumina by liquid aluminium. Acta Mater. 2002, 50, 75–88. [Google Scholar] [CrossRef]

- Yu, Z.; Wu, G.; Sun, D.; Jiang, L. Coating of Y2O3 additive on Al2O3 powder and its effect on the wetting behaviour in the system Al2O3p/Al. Mater. Lett. 2003, 57, 3111–3116. [Google Scholar] [CrossRef]

- Sangghaleh, A.; Halali, M. Effect of magnesium addition on the wetting of alumina by aluminium. Appl. Surf. Sci. 2009, 255, 8202–8206. [Google Scholar] [CrossRef]

- Naher, S.; Brabazon, D.; Looney, L. Development and assessment of a new quick quench stir caster design for the production of metal matrix composites. J. Mater. Process. Technol. 2005, 166, 430–439. [Google Scholar] [CrossRef]

- Naher, S.; Brabazon, D.; Looney, L. Simulation of the stir casting process. J. Mater. Process. Technol. 2003, 143, 567–571. [Google Scholar] [CrossRef] [Green Version]

- Shabani, M.O.; Heydari, F.; Khorram, A. The effect of electromagnetic stirrer on the size and morphology of intermetallic particles in Al-Si metal matrix composite. Silicon 2019, 11, 2539–2546. [Google Scholar] [CrossRef]

- Dehnavi, M.R. Effects of Sequentional Ultrasonic Treatment on Mechanical Properties and Microstructural Characteristics of Cast Al413-SiCnp Nanocomposites. Ph.D Thesis, Isfahan University of Technology, , Isfahan, Iran; p. 2015.

- Shayan, M.; Eghbali, B.; Niroumand, B. Synthesis of AA2024-(SiO2np + TiO2np) hybrid nanocomposite via stir casting process. Mater. Sci. Eng. A 2019, 756, 484–491. [Google Scholar] [CrossRef]

- Krishnan, P.K.; Arunachalam, R.; Husain, A.; Al-Maharbi, M. Studies on the Influence of Stirrer Blade Design on the Microstructure and Mechanical Properties of a Novel Aluminum Metal Matrix Composite. J. Manuf. Sci. Eng. 2021, 143, 021008. [Google Scholar] [CrossRef]

- Mehta, V.R.; Sutaria, M.P. Investigation on the Effect of Stirring Process Parameters on the Dispersion of SiC Particles inside Melting Crucible. Met. Mater. Int. 2020, 26, 1–14. [Google Scholar] [CrossRef]

- Yamamoto, T.; Suzuki, A.; Komarov, S.V.; Ishiwata, Y. Investigation of impeller design and flow structures in mechanical stirring of molten aluminum. J. Mater. Process. Technol. 2018, 261, 164–172. [Google Scholar] [CrossRef]

- Rohatgi, P.; Sobczak, J.; Asthana, R.; Kim, J. Inhomogeneities in silicon carbide distribution in stirred liquids—a water model study for synthesis of composites. Mater. Sci. Eng. A 1998, 252, 98–108. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M. Metal matrix composites: Production by the stir casting method. J. Mater. Process. Technol. 1999, 92, 1–7. [Google Scholar] [CrossRef]

- Ghosh, P.; Ray, S. Fabrication and properties of compocast aluminium-alumina particulate composite. Indian J. Technol. 1988, 26, 83–94. [Google Scholar]

- Saternus, M. Influence of impeller shape on the gas bubbles dispersion in aluminium refining process. J. Achiev. Mater. Manuf. Eng. 2012, 55, 285–290. [Google Scholar]

- Nagata, S. Mixing Principles and Applications; Wiley: New York, NY, USA, 1975. [Google Scholar]

- Moon, H.-K. Rheological Behavior and Microstructure of Ceramic Particulate/Aluminum Alloy Com Posites. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1990. [Google Scholar]

- Bui, R.T.; Ouellet, R.; Kocaefe, D. A two-phase flow model of the stirring of Al-SiC composite melt. Metall. Mater. Trans. B 1994, 25, 607–618. [Google Scholar] [CrossRef]

- Torotwa, I.; Ji, C. A study of the mixing performance of different impeller designs in stirred vessels using computational fluid dynamics. Designs 2018, 2, 10. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Pullum, L. Performance analysis of axial-flow mixing impellers. AIChE J. 2000, 46, 489–498. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M. Particle distribution in cast metal matrix composites—Part II. J. Mater. Process. Technol. 2002, 123, 258–263. [Google Scholar] [CrossRef]

- Ravi, K.R.; Sreekumar, V.M.; Pillai, R.M.; Mahato, C.; Amaranathan, K.R.; Arul kumar, R.; Pai, B.C. Optimization of mixing parameters through a water model for metal matrix composites synthesis. Mater. Des. 2007, 28, 871–881. [Google Scholar] [CrossRef]

- Bhandare, R.G.; Sonawane, P.M. Preparation of aluminium matrix composite by using stir casting method. Int. J. Eng. Adv. Technol. (IJEAT) 2013, 3, 61–65. [Google Scholar]

- Sajjadi, S.A.; Ezatpour, H.R.; Beygi, H. Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting. Mater. Sci. Eng. A 2011, 528, 8765–8771. [Google Scholar] [CrossRef]

- Eskin, G.; Eskin, D. Production of natural and synthesized aluminum-based composite materials with the aid of ultrasonic (cavitation) treatment of the melt. Ultrason. Sonochem. 2003, 10, 297–301. [Google Scholar] [CrossRef]

- Abdullah, A.; Malaki, M.; Baghizadeh, E. On the impact of ultrasonic cavitation bubbles. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 681–694. [Google Scholar] [CrossRef]

- Dehnavi, M.; Niroumand, B.; Ashrafizadeh, F.; Rohatgi, P. Effects of continuous and discontinuous ultrasonic treatments on mechanical properties and microstructural characteristics of cast Al413–SiCnp nanocomposite. Mater. Sci. Eng. A 2014, 617, 73–83. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, Z.; Zhu, J.; Zhang, S.; Li, Y. Wetting of carbon by molten aluminum under ultrasonic field. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Nanning, China, 22–24 May 2021; p. 012008. [Google Scholar]

- Puga, H.; Barbosa, J.; Teixeira, J.C.; Prokic, M. A new approach to ultrasonic degassing to improve the mechanical properties of aluminum alloys. J. Mater. Eng. Perform. 2014, 23, 3736–3744. [Google Scholar] [CrossRef]

- Kudryashova, O.; Vorozhtsov, S. On the Mechanism of Ultrasound-Driven Deagglomeration of Nanoparticle Agglomerates in Aluminum Melt. JOM 2016, 68, 1307–1311. [Google Scholar] [CrossRef]

- Tzanakis, I.; Xu, W.W.; Eskin, D.G.; Lee, P.D.; Kotsovinos, N. In situ observation and analysis of ultrasonic capillary effect in molten aluminium. Ultrason. Sonochem. 2015, 27, 72–80. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Xu, J.-Q.; Choi, H.; Pozuelo, M.; Ma, X.; Bhowmick, S.; Yang, J.-M.; Mathaudhu, S.; Li, X.-C. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 2015, 528, 539. [Google Scholar] [CrossRef]

- Shen, P.; Wang, Y.; Ren, L.; Li, S.; Liu, Y.; Jiang, Q. Influence of SiC surface polarity on the wettability and reactivity in an Al/SiC system. Appl. Surf. Sci. 2015, 355, 930–938. [Google Scholar] [CrossRef]

- Dieringa, H. Properties of magnesium alloys reinforced with nanoparticles and carbon nanotubes: A review. J. Mater. Sci. 2011, 46, 289–306. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Kobashi, M.; Choh, T. The wettability and the reaction for SiC particle/Al alloy system. J. Mater. Sci. 1993, 28, 684–690. [Google Scholar] [CrossRef]

- Glass, S.J.; RolfWaesche, K.U.; Naito, M. Effects of titanium on wettability and interfaces in aluminum/ceramic systems. Charact. Control. Interfaces High Qual. Adv. Mater. 2005, 83, 81–91. [Google Scholar]

- Mao, Y.; Mombello, D.; Baroni, C. Wettability of Ni–Cr filler on SiC ceramic and interfacial reactions for the SiC/Ni–51Cr system. Scr. Mater. 2011, 64, 1087–1090. [Google Scholar] [CrossRef]

- Xiong, H.-P.; Chen, B.; Kang, Y.-S.; Mao, W.; Kawasaki, A.; Okamura, H.; Watanabe, R. Wettability of Co–V, and PdNi–Cr–V system alloys on SiC ceramic and interfacial reactions. Scr. Mater. 2007, 56, 173–176. [Google Scholar] [CrossRef]

- Tao, Z.; Guo, Q.; Gao, X.; Liu, L. The wettability and interface thermal resistance of copper/graphite system with an addition of chromium. Mater. Chem. Phys. 2011, 128, 228–232. [Google Scholar] [CrossRef]

- Nosko, M.; Nagy, Š.; Weber, L.; Maťko, I.; Mihalkovič, M.; Iždinský, K.; Orovčík, Ľ. Effect of Ca addition on interface formation in Al(Ca)/Al2O3 composites prepared by gas pressure assisted infiltration. Mater. Des. 2016, 108, 618–623. [Google Scholar] [CrossRef]

- Garcia-Hinojosa, J.A.; Gonzalez, C.R.; Juárez, J.I.; Surappa, M.K. Effect of Sr addition on an Al–7Si–10 vol.% SiCp cast composites. Mater. Sci. Eng. A 2004, 382, 315–320. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Sufizadeh, A.R.; Emamy, M. The effect of strontium on the microstructure and wear properties of A356–10%B4C cast composites. Mater. Des. 2010, 31, 2187–2195. [Google Scholar] [CrossRef]

- Abedi, K.; Emamy, M. The effect of Fe, Mn and Sr on the microstructure and tensile properties of A356–10% SiC composite. Mater. Sci. Eng. A 2010, 527, 3733–3740. [Google Scholar] [CrossRef]

- Agarwala, V.; Dixit, D. Fabrication of aluminium base composite by foundry technique. Trans. Jpn. Inst. Met. 1981, 22, 521–526. [Google Scholar] [CrossRef] [Green Version]

- Cao, C.; Chen, L.; Xu, J.; Choi, H.; Li, X. Strengthening Al–Bi–TiC0. 7N0. 3 nanocomposites by Cu addition and grain refinement. Mater. Sci. Eng. A 2016, 651, 332–335. [Google Scholar] [CrossRef]

- Wójcik-Grzybek, D.; Frydman, K.; Sobczak, N.; Nowak, R.; Piątkowska, A.; Pietrzak, K. Effect of Ti and Zr additions on wettability and work of adhesion in Ag/c system. Mater. Elektron. 2017, 45, 4–11. [Google Scholar]

- Cong, X.S.; Shen, P.; Wang, Y.; Jiang, Q. Wetting of polycrystalline SiC by molten Al and Al− Si alloys. Appl. Surf. Sci. 2014, 317, 140–146. [Google Scholar] [CrossRef]

- Ashok Kumar, B.; Murugan, N. Metallurgical and mechanical characterization of stir cast AA6061-T6–AlNp composite. Mater. Des. 2012, 40, 52–58. [Google Scholar] [CrossRef]

- McLeod, A.; Gabryel, C. Kinetics of the growth of spinel, MgAl2O4, on alumina particulate in aluminum alloys containing magnesium. Metall. Trans. A 1992, 23, 1279–1283. [Google Scholar] [CrossRef]

- Sukumaran, K.; Pillai, S.; Pillai, R.; Kelukutty, V.; Pai, B.; Satyanarayana, K.; Ravikumar, K. The effects of magnesium additions on the structure and properties of Al-7 Si-10 SiC p composites. J. Mater. Sci. 1995, 30, 1469–1472. [Google Scholar] [CrossRef]

- Korol’kov, A.M. Casting Properties of Metals and Alloys; Consultants Bureau: New York, NY, USA, 1963. [Google Scholar]

- Contreras, A.; Bedolla, E.; Pérez, R. Interfacial phenomena in wettability of TiC by Al–Mg alloys. Acta Mater. 2004, 52, 985–994. [Google Scholar] [CrossRef]

- Fujii, H.; Nakae, H.; Okada, K. Interfacial reaction wetting in the boron nitride/molten aluminum system. Acta Metall. Mater. 1993, 41, 2963–2971. [Google Scholar] [CrossRef]

- Pashmforoosh, S.; Shahriyari, S.; Mirzaee, O. Evaluation of Mechanical and Microstructure Properties of Mg-Modified Aluminum Matrix Composite by Vortical Casting Method. Met. Mater. Int. 2020, 26, 1–13. [Google Scholar] [CrossRef]

- Shao, N.; Dai, J.; Li, G.; Nakae, H.; Hane, T. Effect of La on the wettability of Al2O3 by molten aluminum. Mater. Lett. 2004, 58, 2041–2044. [Google Scholar] [CrossRef]

- Froumin, N.; Frage, N.; Polak, M.; Dariel, M. Wetting phenomena in the TiC/(Cu–Al) system. Acta Mater. 2000, 48, 1435–1441. [Google Scholar] [CrossRef]

- Lee, J.-C.; Park, S.-B.; Seok, H.-K.; Oh, C.-S.; Lee, H.-I. Prediction of Si contents to suppress the interfacial reaction in the SiCp/2014 Al composite. Acta Mater. 1998, 46, 2635–2643. [Google Scholar] [CrossRef]

- Lee, J.-C.; Byun, J.-Y.; Park, S.-B.; Lee, H.-I. Prediction of Si contents to suppress the formation of Al4C3 in the SiCp/Al composite. Acta Mater. 1998, 46, 1771–1780. [Google Scholar] [CrossRef]

- Ferro, A.C.; Derby, B. Wetting behaviour in the Al-Si/SiC system: Interface reactions and solubility effects. Acta Metall. Mater. 1995, 43, 3061–3073. [Google Scholar] [CrossRef]

- Nakae, H.; Yamamoto, K.; Sato, K. Measurement of wetting of graphite by Al and Al–Si alloys using meniscography. Mater. Trans. JIM 1991, 32, 531–538. [Google Scholar] [CrossRef] [Green Version]

- Shen, P.; Fujii, H.; Nogi, K. Wetting, Adhesion and Adsorption in Al-Si/(0112) α-Alumina System at 1723 K. Mater. Trans. 2004, 45, 2857–2863. [Google Scholar] [CrossRef] [Green Version]

- Frage, N.; Froumin, N.; Aizenshtein, M.; Kutsenko, L.; Fuks, D.; Dariel, M.P. Reactive wetting in titanium carbide/non-reactive metal systems. Curr. Opin. Solid State Mater. Sci. 2005, 9, 189–195. [Google Scholar] [CrossRef]

- Zhao, B.; Cai, Q.; Li, X.; Li, B.; Cheng, J. Effect of TiC Nanoparticles Supported by Ti Powders on the Solidification Behavior and Microstructure of Pure Aluminum. Met. Mater. Int. 2018, 24, 945–954. [Google Scholar] [CrossRef]

- Schuster, J.C.; Palm, M. Reassessment of the binary Aluminum-Titanium phase diagram. J. Phase Equilibria Diffus. 2006, 27, 255–277. [Google Scholar] [CrossRef]

- Kumar, A.; Gautam, R.; Tyagi, R. Dry sliding wear characteristics of in situ synthesized Al-TiC composites. Compos. Interfaces 2016, 23, 469–480. [Google Scholar] [CrossRef]

- Zheng, B.; Li, W.; Tu, X.; Xu, F.; Liu, K.; Song, S. Effect of titanium binder addition on the interface structure and three-body abrasive wear behavior of ZTA ceramic particles-reinforced high chromium cast iron. Ceram. Int. 2020, 46, 13798–13806. [Google Scholar] [CrossRef]

- Xu, Q.-G.; Guo, L.-W.; Zhang, L.; Liu, H. Wettability of zirconium-coated alumina by molten aluminum. Surf. Coat. Technol. 2016, 302, 150–157. [Google Scholar] [CrossRef]

- Kennedy, A.; Wood, J.; Weager, B. The wetting and spontaneous infiltration of ceramics by molten copper. J. Mater. Sci. 2000, 35, 2909–2912. [Google Scholar] [CrossRef]

- Pan, S.; Guan, Z.; Yao, G.; Yuan, J.; Li, X. Mo-enhanced chemical stability of TiC nanoparticles in molten Al. J. Alloys Compd. 2021, 856, 158169. [Google Scholar] [CrossRef]

- Auger, J.M.; Martin, S.; Gruy, F. Wettability-enabling coating on oxide particles through controlled milling. Powder Technol. 2019, 344, 302–306. [Google Scholar] [CrossRef]

- Zhao, S.T.; Zhang, X.Z.; Liu, G.W.; Xia, H.Y.; Shi, Z.Q.; Qiao, G.J. Wetting and Interfacial Behavior of Molten Al on Mo-Ni (Co)-Si Coated SiC Ceramic. In Key Engineering Materials; Trans Tech Publications Ltd.: Stafa, Switzerland, 2016; pp. 481–484. [Google Scholar]

- Santuan, Z.; Xiangzhao, Z.; Guiwu, L.; Fabrizio, V.; MariaLuigia, M.; Guanjun, Q.; Alberto, P. Surface Metallization of SiC Ceramic by Mo-Ni-Si Coatings for Improving Its Wettability by Molten Ag. Rare Met. Mater. Eng. 2018, 47, 759–765. [Google Scholar] [CrossRef]

- Yu, J.; Li, H.; Shang, B. A functionally gradient coating on carbon fibre for C/Al composites. J. Mater. Sci. 1994, 29, 2641–2647. [Google Scholar] [CrossRef]

- Ko, Y.J.; Yoon, J.; Lee, J.; Han, J.H. Effects of Cu interlayer on the wettability of aluminum on carbon. J. Alloys Compd. 2013, 574, 526–531. [Google Scholar] [CrossRef]

- Warrier, S.; Blue, C.; Lin, R. Control of interfaces in Al-C fibre composites. J. Mater. Sci. 1993, 28, 760–768. [Google Scholar] [CrossRef]

- Mousavian, R.T.; Damadi, S.R.; Khosroshahi, R.A.; Brabazon, D.; Mohammadpour, M. A comparison study of applying metallic coating on SiC particles for manufacturing of cast aluminum matrix composites. Int. J. Adv. Manuf. Technol. 2015, 81, 433–444. [Google Scholar] [CrossRef] [Green Version]

- Bardal, A. The effect of antimony on the interfaces of cast AlSi-SiC composites. J. Mater. Sci. 1993, 28, 2699–2705. [Google Scholar] [CrossRef]

- Warrier, S.; Lin, R. Silver coating on carbon and SiC fibres. J. Mater. Sci. 1993, 28, 4868–4877. [Google Scholar] [CrossRef]

- Zhang, L.-J.; Yang, D.-L.; Qiu, F.; Wang, J.-G.; Jiang, Q.-C. Effects of reinforcement surface modification on the microstructures and tensile properties of SiCp/Al2014 composites. Mater. Sci. Eng. A 2015, 624, 102–109. [Google Scholar] [CrossRef]

- Singh, B.B.; Balasubramanian, M. Processing and properties of copper-coated carbon fibre reinforced aluminium alloy composites. J. Mater. Process. Technol. 2009, 209, 2104–2110. [Google Scholar] [CrossRef]

- Maqbool, A.; Hussain, M.A.; Khalid, F.A.; Bakhsh, N.; Hussain, A.; Kim, M.H. Mechanical characterization of copper coated carbon nanotubes reinforced aluminum matrix composites. Mater. Charact. 2013, 86, 39–48. [Google Scholar] [CrossRef]

- León, C.A.; Mendoza-Suarez, G.; Drew, R.A.L. Wettability and spreading kinetics of molten aluminum on copper-coated ceramics. J. Mater. Sci. 2006, 41, 5081–5087. [Google Scholar] [CrossRef]

- Carotenuto, G.; Gallo, A.; Nicolais, L. Stability of nickel coatings on carbon fiber preforms: A SEM investigation. Appl. Compos. Mater. 1994, 1, 231–245. [Google Scholar] [CrossRef]

- Asthana, R.; Mileiko, S.; Sobczak, N. Wettability and interface considerations in advanced heat-resistant Ni-base composites. Bull. Pol. Acad. Sci. Tech. Sci. 2006, 54, 147–166. [Google Scholar]

- Surappa, M.; Rohatgi, P. Technical note. Met. Technol. 1978, 5, 358–361. [Google Scholar] [CrossRef]

- Ciby, S.; Pai, B.; Satyanarayana, K.; Vaidyan, V.; Rohatgi, P. Structure formation during processing short carbon fiber-reinforced aluminum alloy matrix composites. J. Mater. Eng. Perform. 1993, 2, 353–357. [Google Scholar] [CrossRef]

- Ip, S.; Sridhar, R.; Toguri, J.; Stephenson, T.; Warner, A. Wettability of nickel coated graphite by aluminum. Mater. Sci. Eng. A 1998, 244, 31–38. [Google Scholar] [CrossRef]

- Elahinejad, S.; Sharifi, H.; Tayebi, M.; Rajaee, A. The influence of nickel coating on the interface of pressureless infiltrated with vibration Al–SiC composites. Mater. Res. Express 2017, 4, 116506. [Google Scholar] [CrossRef]

- Xie, J.-F.; Liu, T.-S.; Li, Q.; Li, Q.-Y.; Xu, Z.-H.; Qiu, F.; Tang, J.; Yang, H.-Y.; Jiang, Q.-C. Nanoparticulate dispersion, microstructure refinement and strengthening mechanisms in Ni-coated SiCp/Al-Cu nanocomposites. Mater. Sci. Eng. A 2019, 762, 138092. [Google Scholar] [CrossRef]

- Sameer Kumar, D.; Suman, K.; Poddar, P. A study on the impact and fatigue failure of AZ91E–Ni coated alumina composites. Can. Metall. Q. 2020, 59, 316–323. [Google Scholar] [CrossRef]

- Ru, J.; Jia, Y.; Jiang, Y.; Feng, J.; Zhou, R.; Hua, Y.; Wang, D. Modification of ZTA particles with Ni coating by electroless deposition. Surf. Eng. 2017, 33, 353–361. [Google Scholar] [CrossRef]

- Ru, J.; He, H.; Jiang, Y.; Zhou, R.; Hua, Y. Wettability and interaction mechanism for Ni-modified ZTA particles reinforced iron matrix composites. J. Alloys Compd. 2019, 786, 321–329. [Google Scholar] [CrossRef]

- Pourhosseini, S.; Beygi, H.; Sajjadi, S.A. Effect of metal coating of reinforcements on the microstructure and mechanical properties of Al-Al2O3 nanocomposites. Mater. Sci. Technol. 2018, 34, 145–152. [Google Scholar] [CrossRef]

- Wang, Y.-Q.; Zheng, J.-H.; Wang, Z.-M.; Zhou, B.-L.; Zhou, L.-J.; Zhang, F.-Q. SiC coated carbon fibres by solution coating and their application to preparing Cf/Al composite. Acta Metall. Sin. 1994, 30, 194–197. [Google Scholar]

- Kitahara, A.; Akiyama, S.; Ueno, H. Effects of alumina coating on degradation, wettability and bonding ability of carbon fiber with aluminum. Jpn. Inst. Light Met. J. 1990, 40, 305–311. [Google Scholar] [CrossRef]

- Carpenter, G.; Lo, S. Characterization of graphite-aluminium composites using analytical electron microscopy. J. Mater. Sci. 1992, 27, 1827–1841. [Google Scholar] [CrossRef]

- Clement, J.; Rack, H.; Wu, K.; Spencer, H. Interfacial modification in metal matrix composites by the sol-gel process. Mater. Manuf. Process. 1990, 5, 17–33. [Google Scholar] [CrossRef]

- Pierson, H.O.; Randich, E. Titanium diboride coatings and their interaction with the substrates. Thin Solid Film. 1978, 54, 119–128. [Google Scholar] [CrossRef]

- Ribes, H.; Da Silva, R.; Suery, M.; Bretheau, T. Effect of interfacial oxide layer in Al–SiC particle composites on bond strength and mechanical behaviour. Mater. Sci. Technol. 1990, 6, 621–628. [Google Scholar] [CrossRef]

- Arslan, G.; Kalemtas, A. Processing of silicon carbide–boron carbide–aluminium composites. J. Eur. Ceram. Soc. 2009, 29, 473–480. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, R.; Liu, M. Improved sintering ability of SiC ceramics from SiC@Al2O3 core-shell nanoparticles prepared by a slow precipitation method. Ceram. Int. 2019, 45, 8032–8036. [Google Scholar] [CrossRef]

- Suéry, M.; L’Espérance, G.; Hong, B.; Thanh, L.N.; Bordeaux, F. Development of particulate treatments and coatings to reduce SiC degradation by liquid aluminum. J. Mater. Eng. Perform. 1993, 2, 365–373. [Google Scholar] [CrossRef]

- Patankar, S.; Gopinathan, V.; Ramakrishnan, P. Processing of carbon fibre reinforced aluminium composite using K2ZrF6 treated carbon fibres: A degradation study. J. Mater. Sci. Lett. 1990, 9, 912–913. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malaki, M.; Fadaei Tehrani, A.; Niroumand, B.; Gupta, M. Wettability in Metal Matrix Composites. Metals 2021, 11, 1034. https://doi.org/10.3390/met11071034

Malaki M, Fadaei Tehrani A, Niroumand B, Gupta M. Wettability in Metal Matrix Composites. Metals. 2021; 11(7):1034. https://doi.org/10.3390/met11071034

Chicago/Turabian StyleMalaki, Massoud, Alireza Fadaei Tehrani, Behzad Niroumand, and Manoj Gupta. 2021. "Wettability in Metal Matrix Composites" Metals 11, no. 7: 1034. https://doi.org/10.3390/met11071034

APA StyleMalaki, M., Fadaei Tehrani, A., Niroumand, B., & Gupta, M. (2021). Wettability in Metal Matrix Composites. Metals, 11(7), 1034. https://doi.org/10.3390/met11071034