The Research on Recrystallization Behaviors and Mechanism of a Medium-Density Ni-Based Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

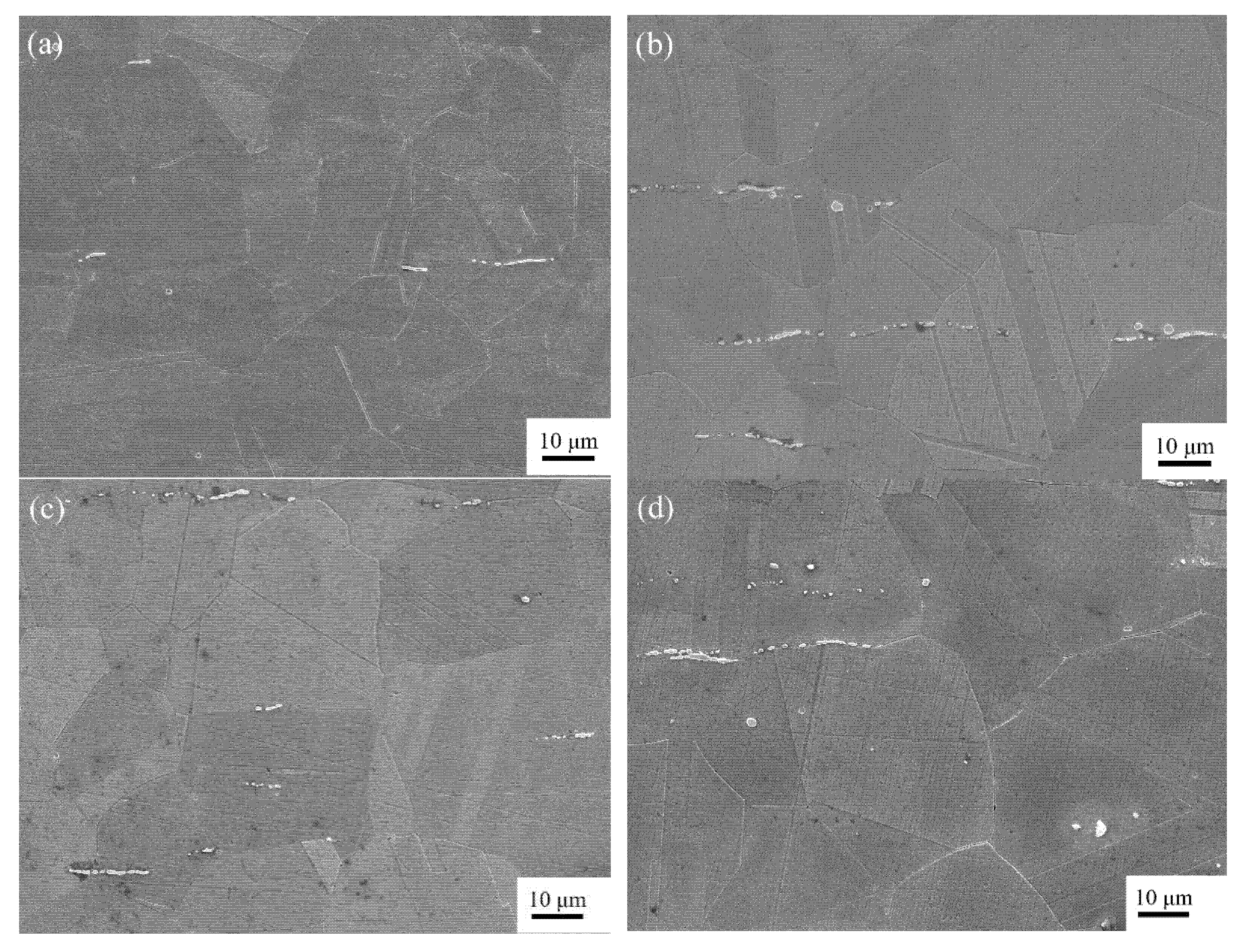

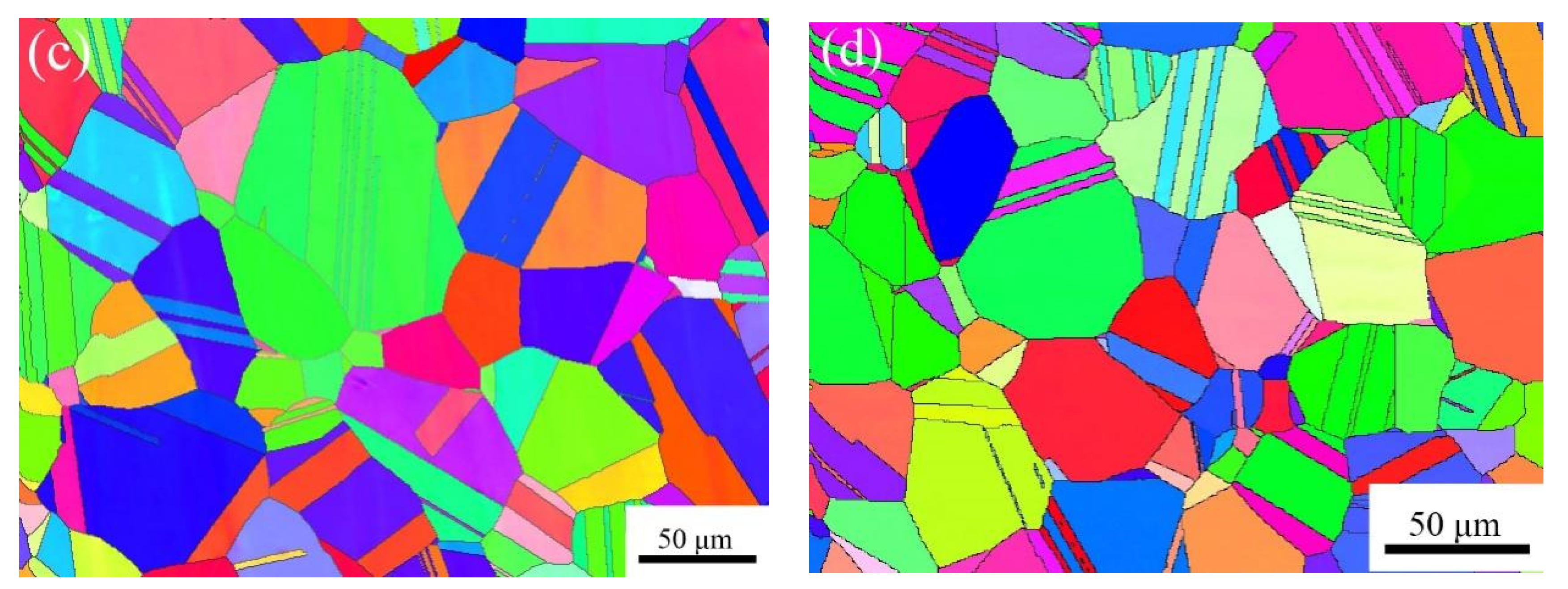

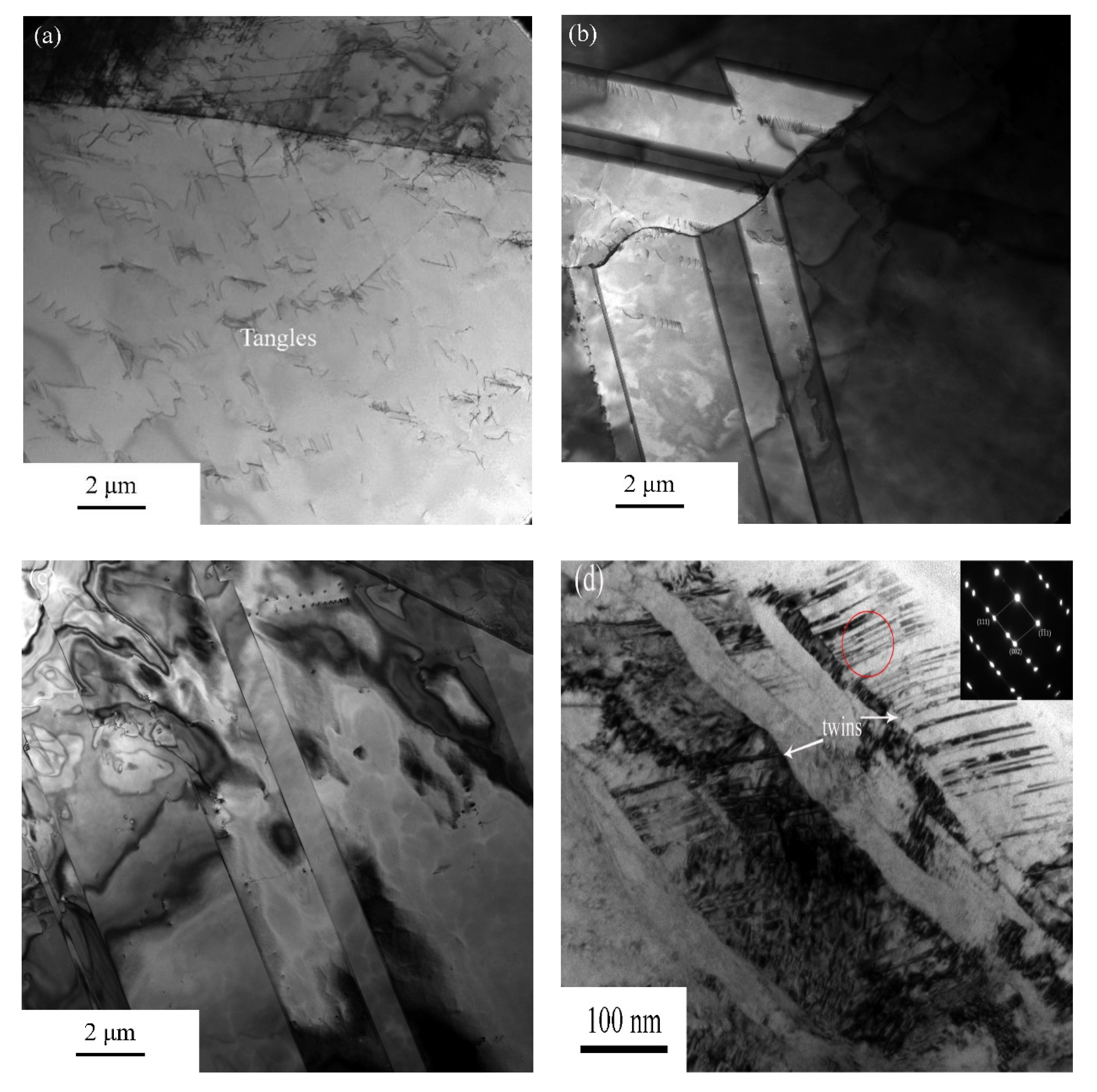

3.1. The Evolution of Microstructure during Recrystallization

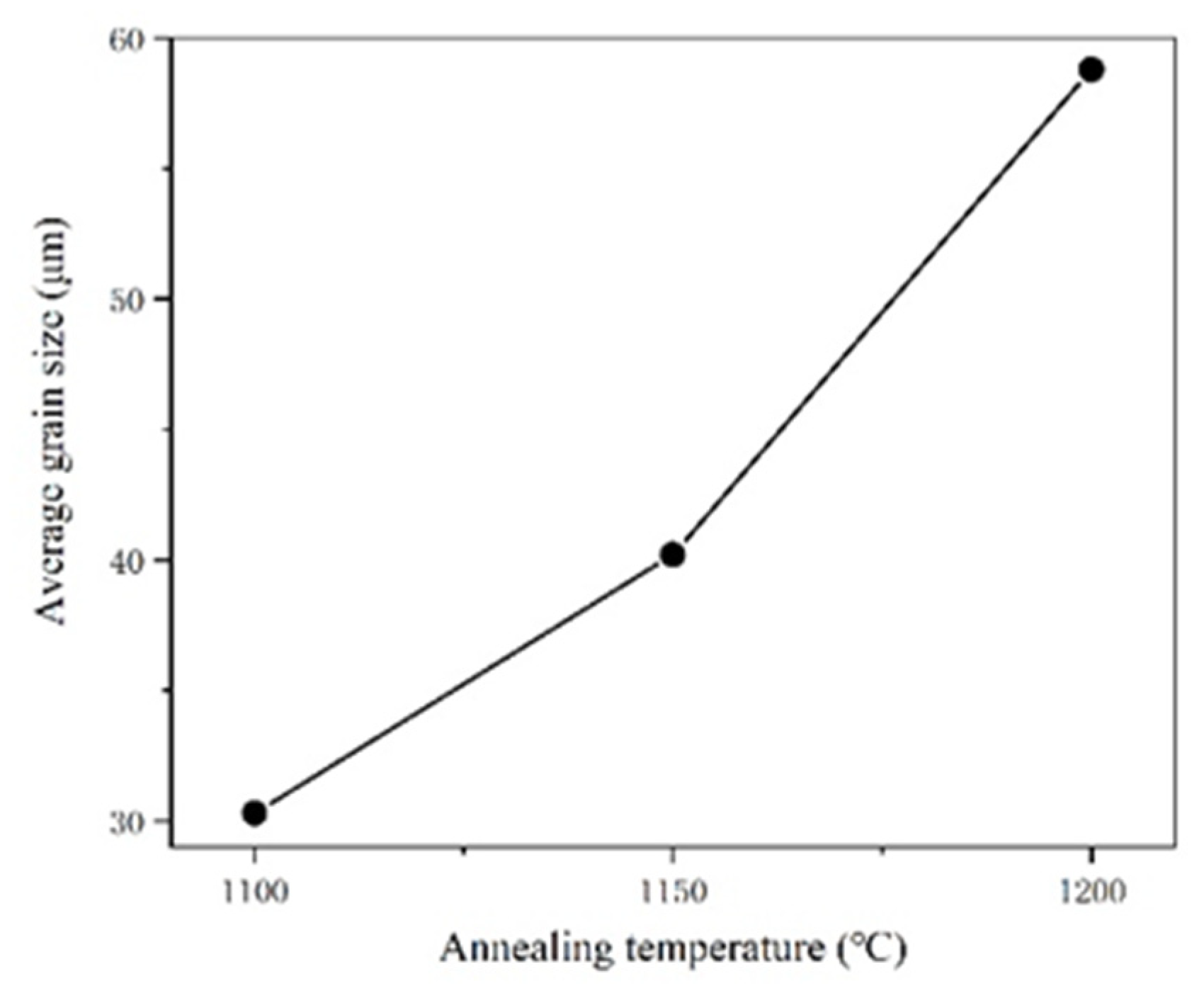

3.2. The Evolution of Grain during Recrystallization

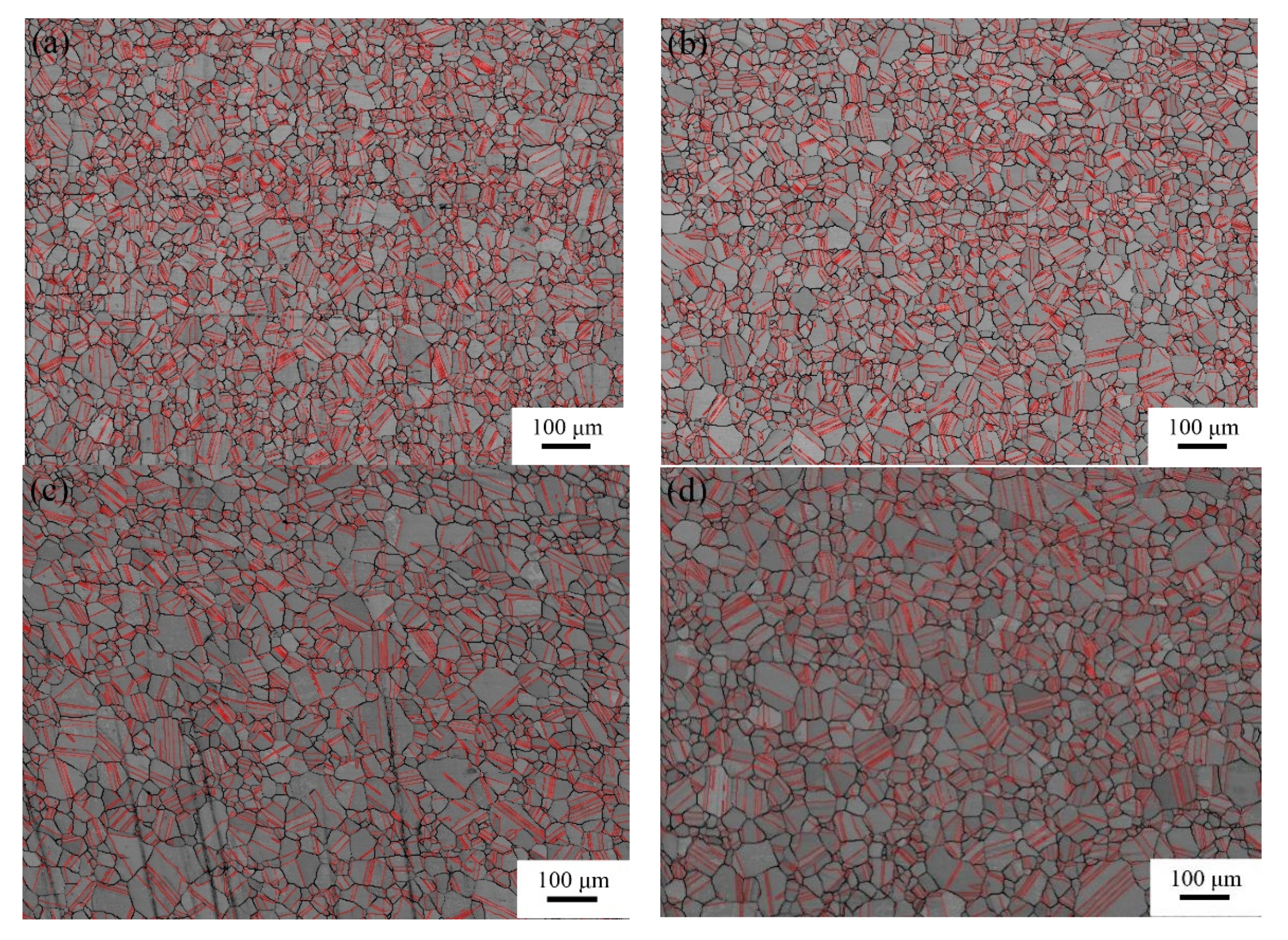

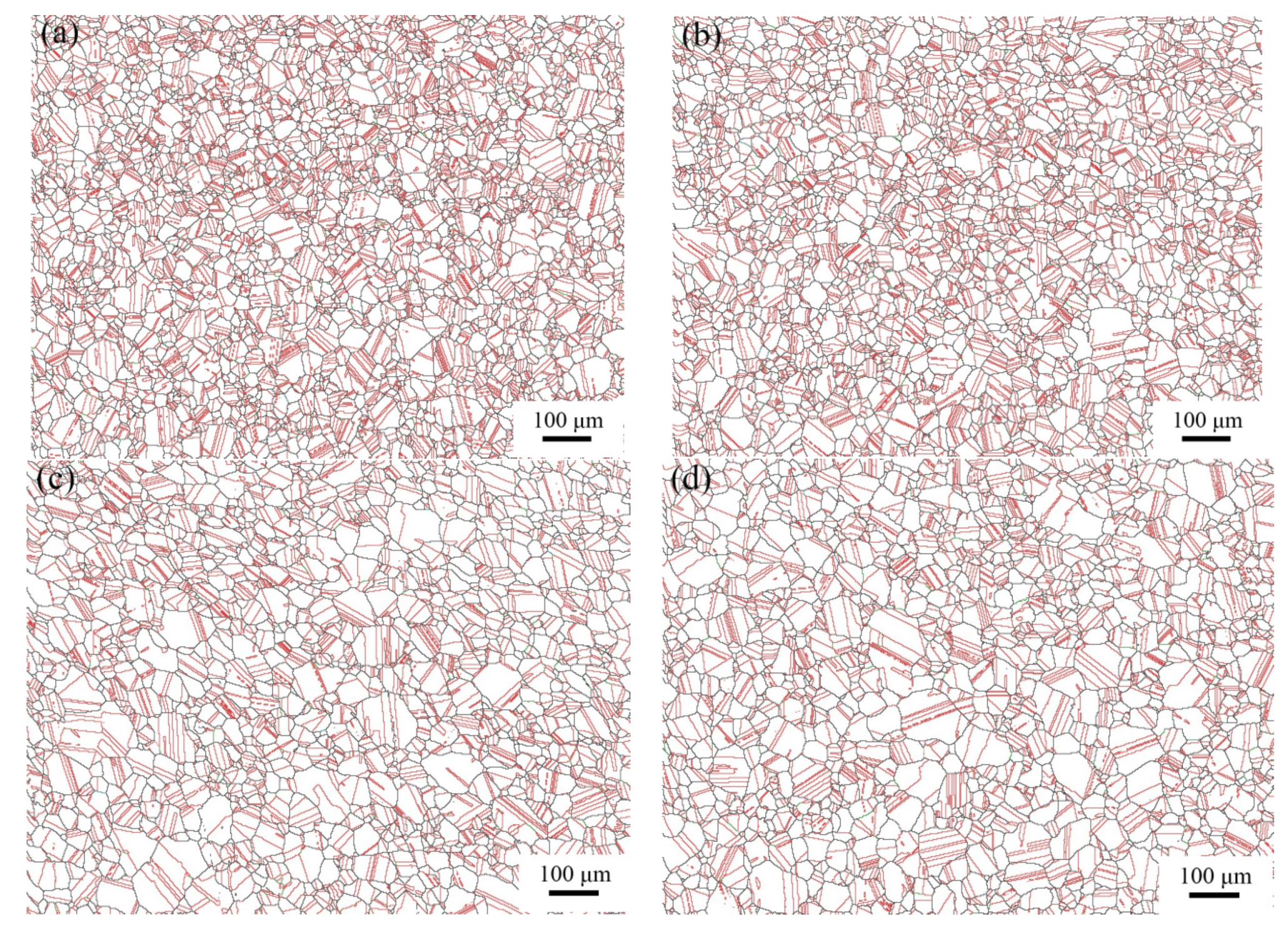

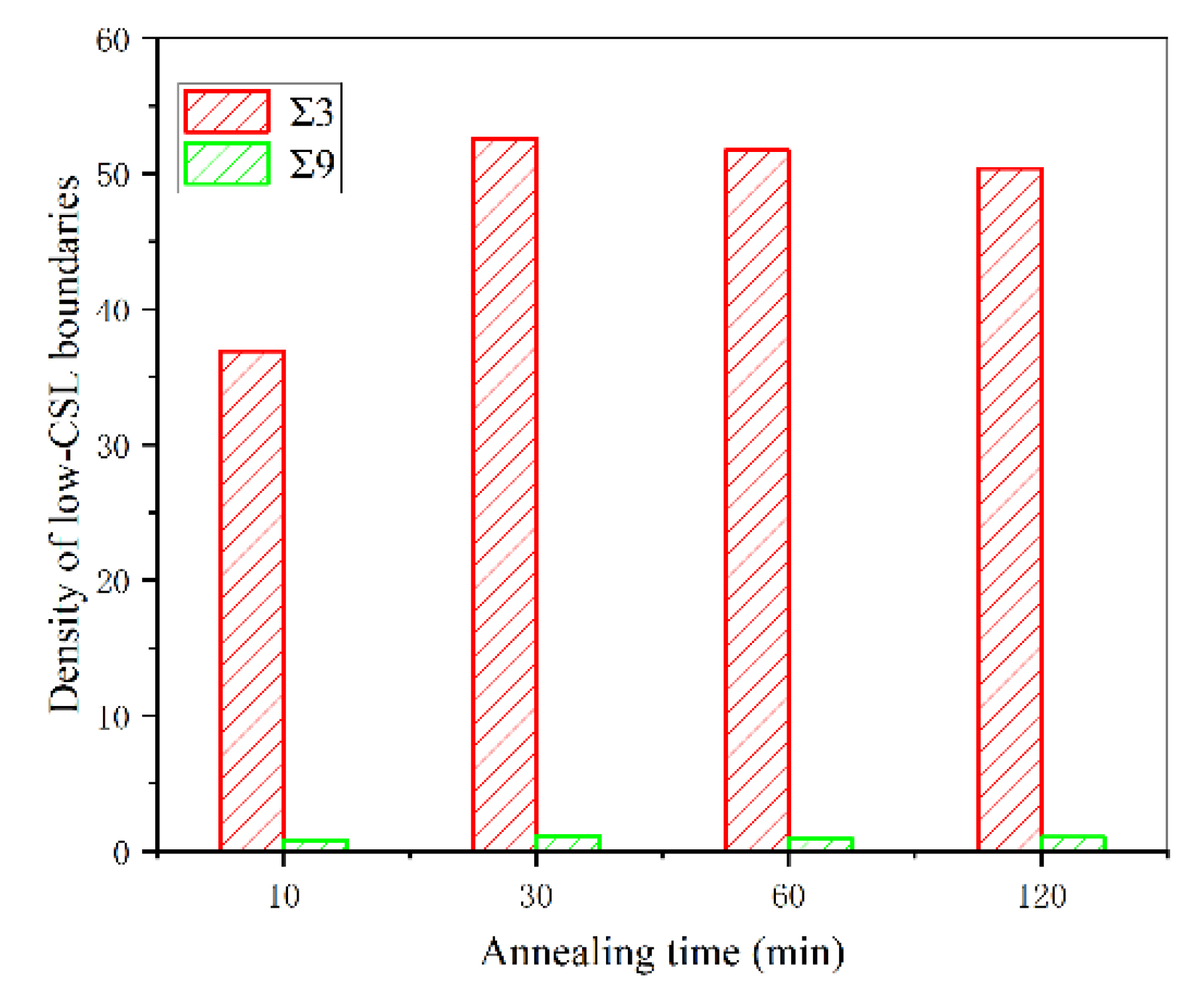

3.3. The Development of Twin during Recrystallization

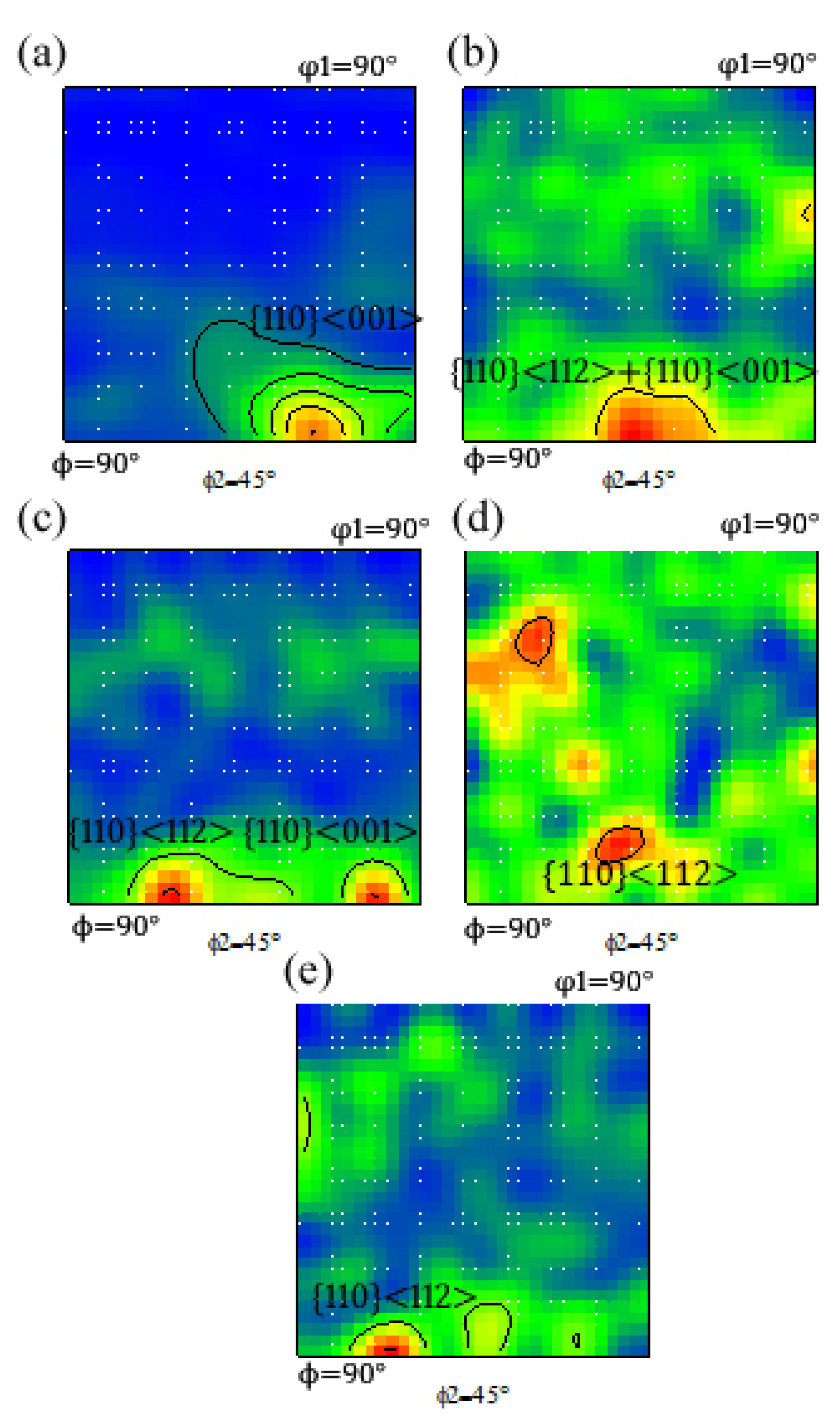

3.4. Variations of Textures

3.5. Recrystallization Process

4. Discussion

5. Conclusions

- (1).

- With the increase in the annealing temperature from 1100 to 1150 and 1200 °C, the grain size grew from 30.3 to 40.2 and 58.8 μm, respectively. Complete recrystallization can occur at above 1150 °C, with the grain size increasing from 22.8 to 29.4, 40.2 and 43.3 μm with the extension of the annealing time from 10 to 30, 60 and 120 min. The {110}<001> texture generated by cold deformation was completely replaced by the {110}<112> texture when annealed at 1150 °C for 60 min, which means that the alloy was completely recrystallized at this time.

- (2).

- The value of the apparent activation energy Q1 is 701 kJ/mol, suggesting that the recrystallization of the studied alloy requires a large driving force and high recrystallization temperature. It is believed that the recrystallization mechanism of the studied alloy shall be different from that of the superalloy, since the recrystallization of the studied alloys is relatively slow.

- (3).

- The early appearance of sub-grains and identically oriented twins revealed the difference in the recrystallization mechanism of the alloy. The twin mechanism is considered as the dominant recrystallization mechanism of the studied alloy according to the evolution of microstructures and texture distributions, although the formation and development of sub-grains appear in the early stage of recrystallization.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, K.; Li, X.Q.; Ai, X. Fabrication, characterization, and mechanical properties of 93W-4.9Ni-2.1Fe/95W-2.8Ni-1.2Fe-1Al2O3 heavy alloy composites. Mater. Sci. Eng. A 2015, 636, 452–458. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, F. Thermomechanical behavior and constitutive modeling of tungsten-based composite over wide temperature and strain rate range. Int. J. Plast. 2013, 40, 163–184. [Google Scholar] [CrossRef]

- German, R.M.; Bourguignon, L.L.; Rabin, B.H. Critical developments in tungsten heavy alloys. Powder Metall. 1992, 5, 3–13. [Google Scholar]

- Li, Y.Y.; Hu, K.; Li, X.; Ai, X.; Qu, S.G. Fine-grained 93W–5.6Ni–1.4Fe heavy alloys with enhanced performance prepared by spark plasma sintering. Mater. Sci. Eng. A 2013, 573, 245–252. [Google Scholar] [CrossRef]

- Xiang, D.P.; Ding, L.; Li, Y.Y.; Chen, X.Y.; Zhang, T.M. Fabricating fine-grained tungsten heavy alloy by spark plasma sintering of low-energy ball-milled W–2Mo–7Ni–3Fe powders. Mater. Sci. Eng. A 2013, 578, 18–23. [Google Scholar] [CrossRef]

- Rittel, D.; Levin, R.; Dorogoy, A. On the isotropy of the dynamic mechanical and failure properties of swaged tungsten heavy alloys. Metall. Mater. Trans. A 2004, 35, 3787. [Google Scholar] [CrossRef]

- Liu, J.X.; Li, S.K.; Fan, A.L.; Sun, H.C. Effect of fibrous orientation on dynamic mechanical properties and susceptibility to adiabatic shear band of tungsten heavy alloy fabricated through hot-hydrostatic extrusion. Mater. Sci. Eng. A 2008, 487, 235–242. [Google Scholar] [CrossRef]

- Liu, J.X.; Li, S.K.; Zhou, X.Q.; Zhang, Z.H.; Zheng, H.Y.; Wang, Y.C. Adiabatic shear banding in a tungsten heavy alloy processed by hot-hydrostatic extrusion and hot torsion. Scr. Mater. 2008, 59, 1271–1274. [Google Scholar] [CrossRef]

- Hsu, C.; Lin, S. Coalescence of tungsten grains around molybdenum grains in the presence of a liquid phase. Scr. Mater. 2005, 46, 869–873. [Google Scholar] [CrossRef]

- Gu, D.D.; Li, Y.L.; Wang, H.Q.; Jia, Q.B.; Zhang, G.Q. Microstructural development and its mechanism of mechanical alloyed nanocrystalline W–10Ni alloy reinforced with Y2O3 nanoparticles. Int. J. Refract. Met. Hard Mater. 2014, 44, 113–122. [Google Scholar] [CrossRef]

- German, R.M.; Bourguignon, L.L.; Rabin, B.H. Microstructure Limitations of High Tungsten Content Heavy Alloys. JOM 1985, 37, 36–39. [Google Scholar] [CrossRef]

- Li, Y.; Liu, G.Q.; Hu, X.B.; Wu, L.H.; Tan, C.W.; Vinayak, P.; Dravid Liu, S.Z. A novel medium heavy alloy (MHA) with excellent static/dynamic properties and impact toughness. Scr. Mater. 2018, 162, 311–315. [Google Scholar]

- Wang, D.l.; Li, J.B.; Jin, T. Recrystallization of Ni base superalloy DZ4. Acta Metall. Sin. 2006, 2, 167–171. [Google Scholar]

- Hu, B.F.; Chen, H.M. Static recrystallization mechanism of FGH95 superalloy. Chin. J. Nonferrous Met. 2004, 6, 901–906. [Google Scholar]

- Yang, J.; Luo, J.; Li, X.Y.; Li, M.Q. Evolution mechanisms of recrystallized grains and twins during isothermal compression and subsequent solution treatment of GH4586 superalloy. J. Alloys Compd. 2021, 850, 1–12. [Google Scholar] [CrossRef]

- Guan, D.K.; Rainforth, W.M.; Ma, L.; Wynne, B.; Gao, J.H. Twin recrystallization mechanisms and exceptional contribution to texture evolution during annealing in a magnesium alloy. Acta Mater. 2017, 126, 132–144. [Google Scholar] [CrossRef]

- Basu; Al-Samman, T. Twin recrystallization mechanisms in magnesium-rare earth alloys. Acta Mater. 2015, 96, 111–132. [Google Scholar] [CrossRef]

- Suh, B.-C.; Shim, M.-S.; Shin, K.S.; Kim, N.J. Current issues in magnesium sheet alloys: Where do we go from here? Scr. Mater. 2014, 84–85, 1–6. [Google Scholar] [CrossRef]

- Hiesch, J.; Al-Samma, T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications. Acta Mater. 2013, 61, 818–843. [Google Scholar]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Li, X.; Yang, P.; Wang, L.N.; Meng, L.; Cui, F. Orientational analysis of static recrystallization at compression twins in a magnesium alloy AZ31. Mater. Sci. Eng. A. 2009, 517, 160–169. [Google Scholar] [CrossRef]

- Al-Samman, T.; Molodov, K.D.; Molodov, D.A.; Gottstein, G.; Suwas, S. Softening and dynamic recrystallization in magnesium single crystals during c-axis compression. Acta Mater. 2012, 60, 537–545. [Google Scholar] [CrossRef]

- Jia, D.; Sun, W.R.; Xu, D.S.; Yu, L.X.; Xin, X.; Zhang, W.H.; Qi, F. Abnormal dynamic recrystallization behavior of a nickel-based superalloy during hot deformation. J. Alloys Compd. 2019, 787, 196–205. [Google Scholar] [CrossRef]

- Prithiv, T.S.; Bhuyan, P.; Pradhan, S.K.; Sarma, V.S.; Mandal, S. A critical evaluation on efficacy of recrystallization vs. strain induced boundary migration in achieving grain boundary engineered microstructure in a Ni-base superalloy. Acta Mater. 2018, 146, 187–201. [Google Scholar] [CrossRef]

- Field, D.P.; Bradford, L.T.; Nowell, M.M.; Lillo, T.M. The role of annealing twins during recrystallization of Cu. Acta Mater. 2007, 55, 4233–4241. [Google Scholar] [CrossRef]

- Jin, Y.; Lin, B.; Bernacki, M.; Rohrer, G.S.; Rollett, A.D.; Bozzolo, N. Annealing twin development during recrystallization and grain growth in pure nickel. Mater. Sci. Eng. A. 2014, 597, 295–303. [Google Scholar] [CrossRef] [Green Version]

- Burke, J.E. The formation of annealing twins. JOM 1950, 188, 1324–1328. [Google Scholar] [CrossRef]

- Jin, Y.; Lin, B.; Rollett, A.D.; Rohrer, G.S.; Bernacki, M.; Bozzolo, N. Thermo-mechanical factors influencing annealing twin development in nickel during recrystallization. J. Mater. Sci. 2015, 50, 5191–5203. [Google Scholar] [CrossRef]

- Wang, W.; Lartigue-Korinek, S.; Brisset, F.; Helbert, A.L.; Bourgon, J.; Baudin, T. Formation of annealing twins during primary recrystallization of two low stacking fault energy Ni-based alloys. J. Mater. Sci. 2015, 50, 2167–2177. [Google Scholar] [CrossRef]

- Chen, X.M.; Lin, Y.C.; Wu, F. EBSD study of grain growth behavior and annealing twin evolution after full recrystallization in a nickel-basd superalloy. J. Alloys Compd. 2017, 724, 198–207. [Google Scholar] [CrossRef]

- Roucoules, C.; Hodgson, P.D.; Yue, S.; Jones, J.J. Softening and microstructure change following the dynamic recrystallization of Austenite. Metall. Mater. Trans. A 1994, 25, 389–400. [Google Scholar] [CrossRef]

- Jang, Y.S.; Ko, D.C.; Kim, B.M. Application of the finite element method to predict microstructure evolution in the hot forging of steel. J. Mater. Process. Technol. 2000, 101, 85–94. [Google Scholar] [CrossRef]

- Gao, Y.B.; Ding, Y.T.; Chen, J.J.; Meng, B.; Ma, Y.J.; Xu, J.Y. Behavior of cold work hardening and annealing softening and microstructure characteristics of GH3625 superalloy. Chin. J. Nonferrous Metals. 2019, 29, 44. [Google Scholar]

- Randle, V.; Rios, P.R.; Hu, Y. Grain growth and twinning in nickel. Scr. Mater. 2008, 58, 130–133. [Google Scholar] [CrossRef]

- Grube, W.L.; Rouze, S.R. The origin, growth and annihilation of annealing twins in austenite. Can. Metall. Q. 1963, 2, 31–52. [Google Scholar] [CrossRef]

- Sarma, V.S.; Eickemeyer, J.; Schultz, L.; Holzapfel. Recrystallisation texture and magnetisation behaviour of some FCC Ni–W alloys. Scr. Mater. 2004, 50, 7. [Google Scholar]

- Leffers, T.; Ray, R.K. The brass-type texture and its deviation from the copper-type texture. Prog. Mater. Sci. 2008, 54, 351–396. [Google Scholar] [CrossRef]

- Chen, J.J.; Ding, Y.T.; Gao, Y.B.; Ma, Y.J.; Wang, X.M.; Yan, K. Static Recrystallization Behavior of Deformation Induced Inconel 625 Superalloy Pipe. Chin. J. Nonferrous Met. 2021, 50, 14–22. [Google Scholar]

- Wang, J.; Liu, Y.; Liu, B.; Wang, Y.; Cao, Y.; Li, T.; Zhou, R. Flow behavior and microstructure of powder metallurgical CrFeCoNiMo0.2 high entropy alloy during high temperature deformation. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2017, 689, 233–242. [Google Scholar] [CrossRef]

- Chen, X.P.; Li, L.F.; Sun, H.F.; Wang, L.X.; Liu, Q. Studies on the evolution of annealing twins during recrystallization and grain growth in highly rolled pure nickel. Mater. Sci. Eng. A 2015, 622, 108–113. [Google Scholar] [CrossRef]

- Mahajan, S. Critique of mechanisms of formation of deformation, annealing and growth twins: Face-centered cubic metals and alloys. Scr. Mater. 2013, 68, 95–99. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, K.; Huang, X.; Wang, R.; Xue, W.; Fu, Y.; Li, Z. The Research on Recrystallization Behaviors and Mechanism of a Medium-Density Ni-Based Alloy. Metals 2022, 12, 137. https://doi.org/10.3390/met12010137

Feng K, Huang X, Wang R, Xue W, Fu Y, Li Z. The Research on Recrystallization Behaviors and Mechanism of a Medium-Density Ni-Based Alloy. Metals. 2022; 12(1):137. https://doi.org/10.3390/met12010137

Chicago/Turabian StyleFeng, Kai, Xiaxu Huang, Rui Wang, Wenli Xue, Yilei Fu, and Zhaoxin Li. 2022. "The Research on Recrystallization Behaviors and Mechanism of a Medium-Density Ni-Based Alloy" Metals 12, no. 1: 137. https://doi.org/10.3390/met12010137

APA StyleFeng, K., Huang, X., Wang, R., Xue, W., Fu, Y., & Li, Z. (2022). The Research on Recrystallization Behaviors and Mechanism of a Medium-Density Ni-Based Alloy. Metals, 12(1), 137. https://doi.org/10.3390/met12010137