Facile Synthesis of PtPd Network Structure Nanochains Supported on Multi-Walled Carbon Nanotubes for Methanol Oxidation

Abstract

:1. Introduction

2. Experiments

2.1. Chemical Agents

2.2. Preparation of PtPd NCs/MWCNTs

2.3. Physical Characterization

2.4. Electrochemical Measurements

3. Results and Discussion

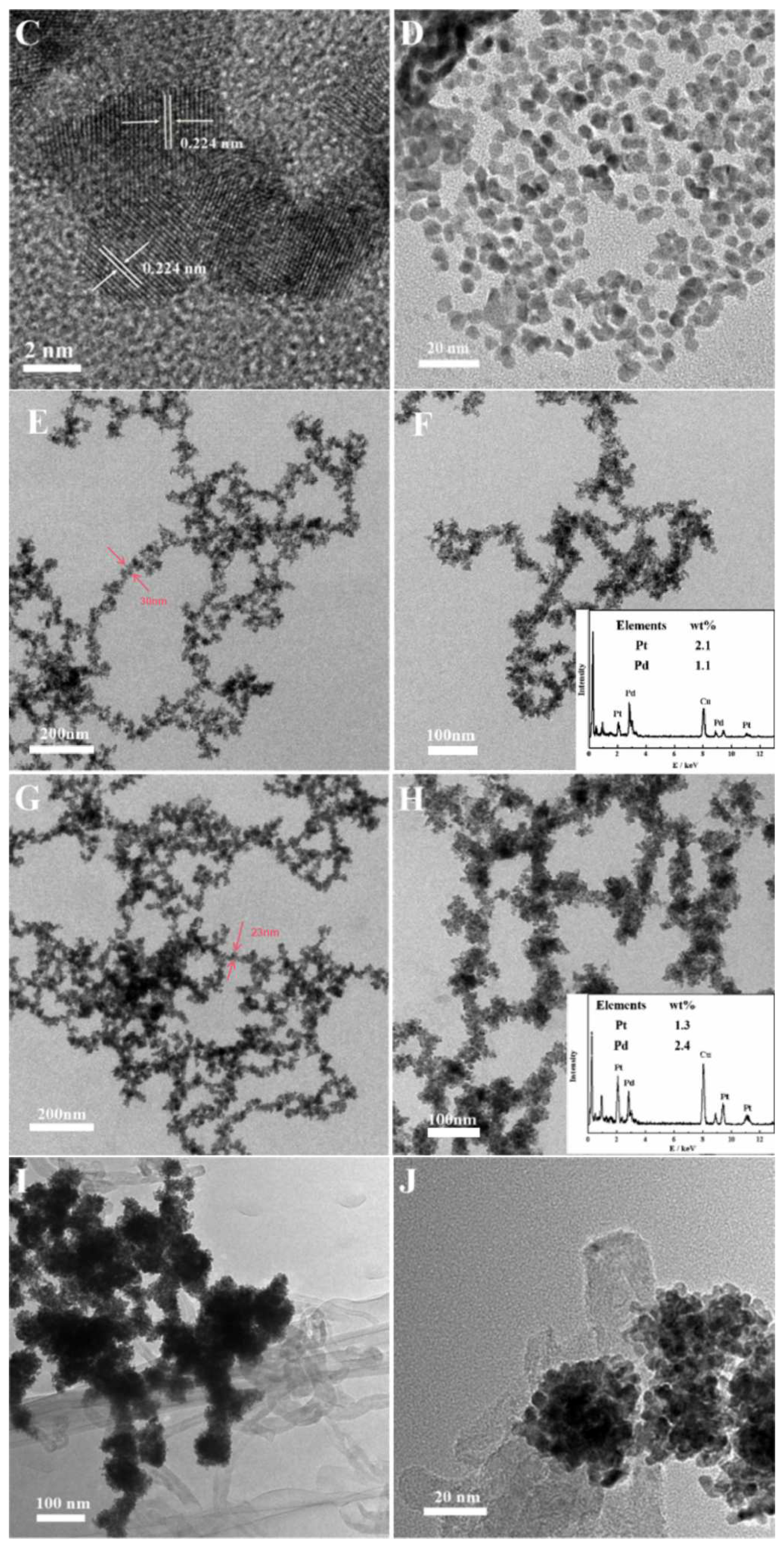

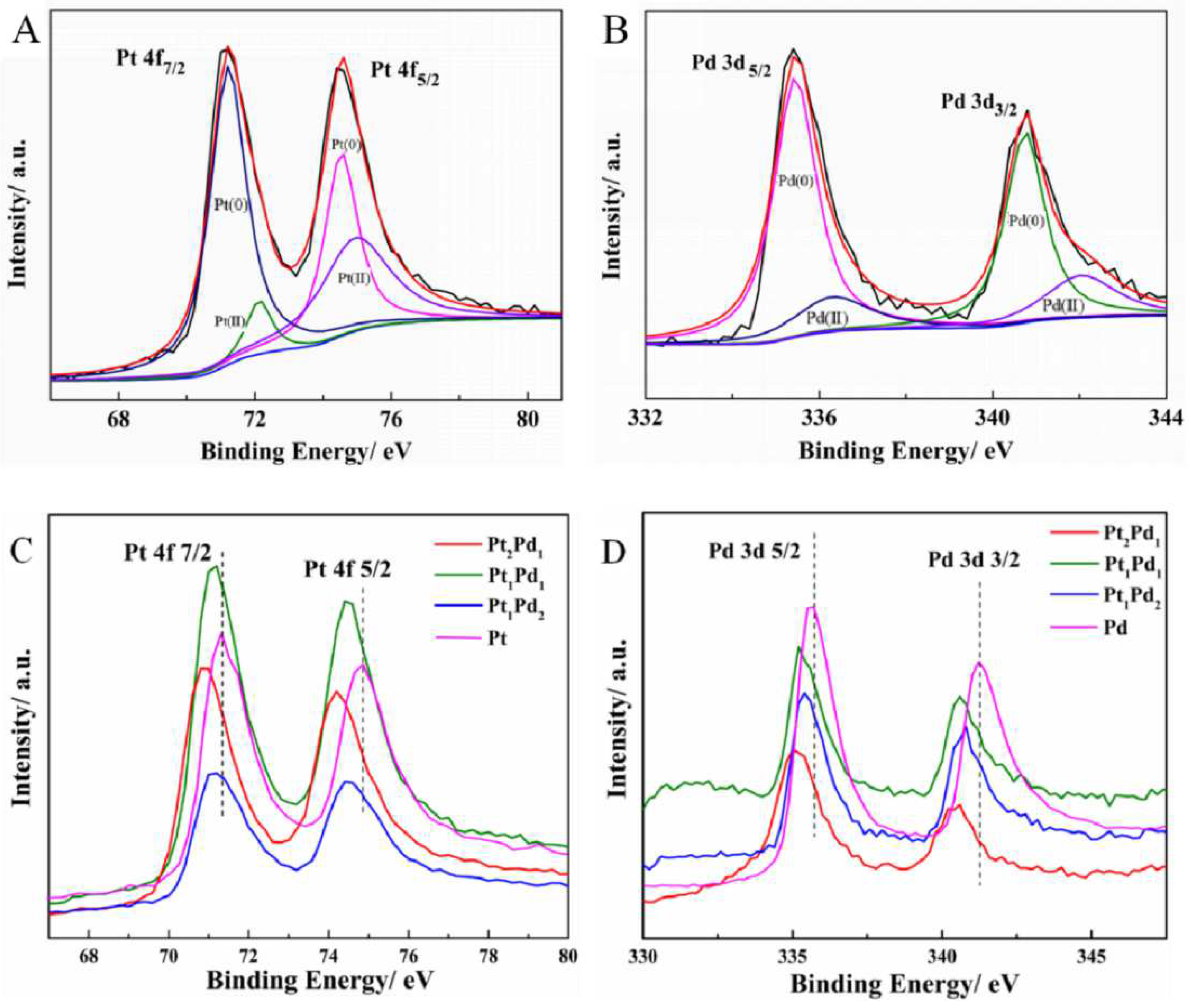

3.1. Physicochemical Characterization

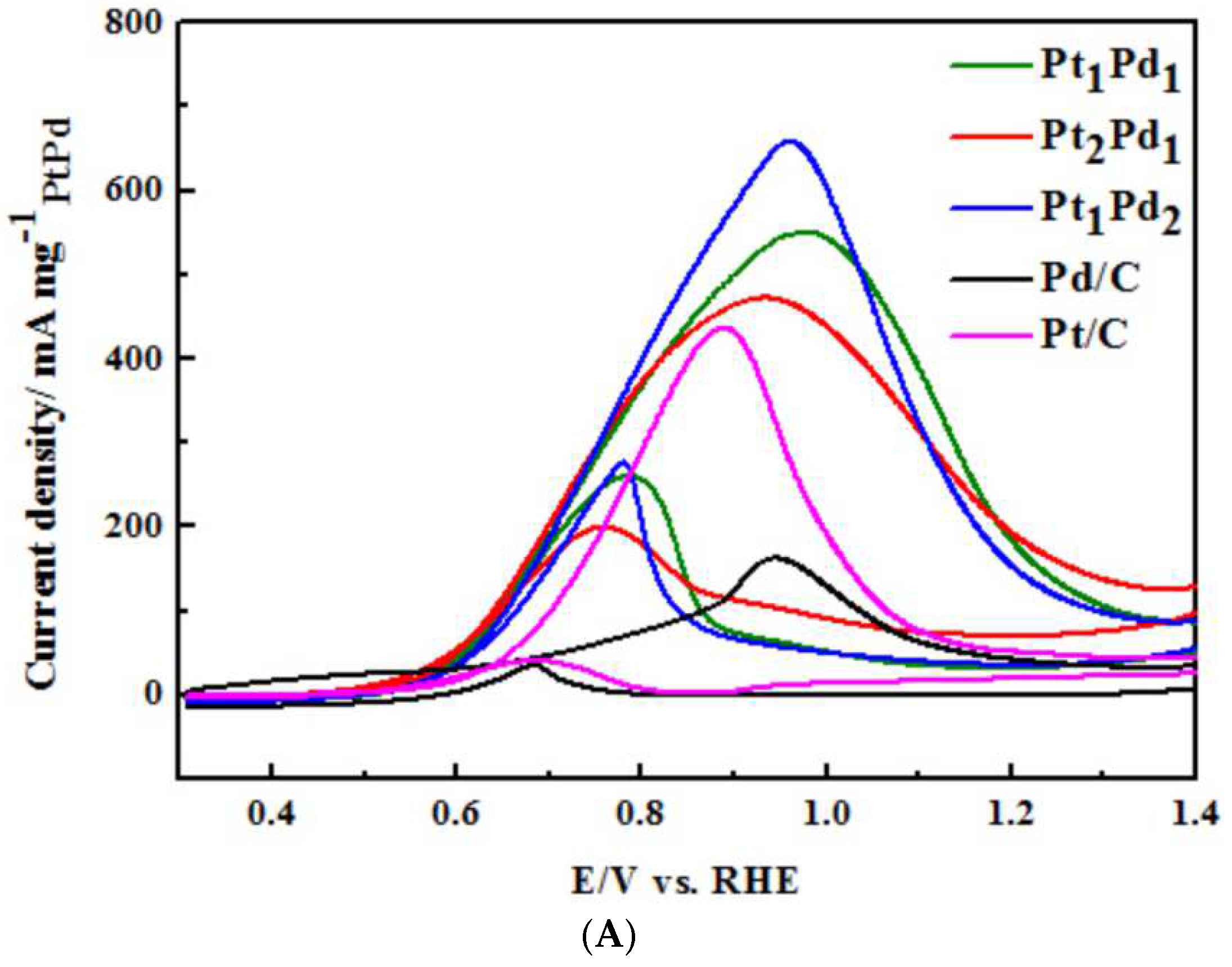

3.2. Electrochemical Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, M.; Zhang, W.; Qu, Y.; Liu, X.; Zhai, C.; Liu, Y. The extended Stӧber method for synthesizing nitrogen-doped porous carbon nanospheres supported Pt nanoparticles towards methanol oxidation in alkaline media. Mater. Lett. 2022, 325, 132894. [Google Scholar] [CrossRef]

- Yuan, Q.; Duan, D.; Ma, Y.; Wei, G.; Zhang, Z.; Hao, X.; Liu, S. Performance of nano-nickel core wrapped with Pt crystalline thin film for methanol electro-oxidation. J. Power Sources 2014, 245, 886–891. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, X.; Wang, X.; Hu, J.; Liu, Y.; Fu, G.; Tang, Y. Concave PtCo nanocrosses for methanol oxidation reaction. Appl. Catal. B Environ. 2020, 277, 119135. [Google Scholar] [CrossRef]

- Yang, G.; Yang, X.; Xu, M.; Min, C.; Xiao, H.; Jiang, K.; Chen, L.; Wang, G. Multi-walled carbon nanotube modified with methylene blue under ultraviolet irradiation as a platinum catalyst support for methanol oxidation. J. Power Sources 2013, 222, 340–343. [Google Scholar] [CrossRef]

- Corpuz, A.R.; Olson, T.S.; Joghee, P.; Pylypenko, S.; Dameron, A.A.; Dinh, H.N.; O’Neill, K.J.; Hurst, K.E.; Bender, G.; Gennett, T.; et al. Effect of a nitrogen-doped PtRu/carbon anode catalyst on the durability of a direct methanol fuel cell. J. Power Sources 2012, 217, 142–151. [Google Scholar] [CrossRef]

- Zhang, Z.; Xin, L.; Qi, J.; Chadderdon, D.J.; Li, W. Supported Pt, Pd and Au nanoparticle anode catalysts for anion-exchange membrane fuel cells with glycerol and crude glycerol fuels. Appl. Catal. B Environ. 2013, 136, 29–39. [Google Scholar] [CrossRef]

- Tiwari, J.N.; Tiwari, R.N.; Singh, G.; Kim, K.S. Recent progress in the development of anode and cathode catalysts for direct methanol fuel cells. Nano Energy 2013, 2, 553–578. [Google Scholar] [CrossRef]

- Chen, X.; Jiang, Y.; Sun, J.; Jin, C.; Zhang, Z. Highly active nanoporous Pt-based alloy as anode and cathode catalyst for direct methanol fuel cells. J. Power Sources 2014, 267, 212–218. [Google Scholar] [CrossRef]

- Liu, J.; Wang, L.; Okejiri, F.; Luo, J.; Zhao, J.; Zhang, P.; Liu, M.; Yang, S.; Zhang, Z.; Song, W.; et al. Deep understanding of strong metal interface confinement: A journey of Pd/FeO x catalysts. ACS Catal. 2020, 10, 8950–8959. [Google Scholar] [CrossRef]

- Hong, W.; Wang, J.; Wang, E. Facile synthesis of highly active PdAu nanowire networks as self-supported electrocatalyst for ethanol electrooxidation. ACS Appl. Mater. Interfaces 2014, 6, 9481–9487. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, H.; Kim, W.B. PtAg nanotubes for electrooxidation of ethylene glycol and glycerol in alkaline media. Electrochem. Commun. 2014, 46, 36–39. [Google Scholar] [CrossRef]

- Huang, L.; Han, Y.; Zhang, X.; Fang, Y.; Dong, S. One-step synthesis of ultrathin Pt x Pb nerve-like nanowires as robust catalysts for enhanced methanol electrooxidation. Nanoscale 2017, 9, 201–207. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, M.G.; Mahmoodi, R.; Daneshvari-Esfahlan, V. Ni@ Pd core-shell nanostructure supported on multi-walled carbon nanotubes as efficient anode nanocatalysts for direct methanol fuel cells with membrane electrode assembly prepared by catalyst coated membrane method. Energy 2018, 161, 1074–1084. [Google Scholar] [CrossRef]

- Tang, J.X.; Chen, Q.S.; You, L.X.; Liao, H.G.; Sun, S.G.; Zhou, S.G.; Xu, Z.N.; Chen, Y.M.; Guo, G.C. Screw-like PdPt nanowires as highly efficient electrocatalysts for methanol and ethylene glycol oxidation. J. Mater. Chem. A 2018, 6, 2327–2336. [Google Scholar] [CrossRef]

- Sha, R.; Vishnu, N.; Badhulika, S. Bimetallic Pt-Pd nanostructures supported on MoS2 as an ultra-high performance electrocatalyst for methanol oxidation and nonenzymatic determination of hydrogen peroxide. Microchim. Acta 2018, 185, 399. [Google Scholar] [CrossRef]

- Cui, Z.; Hu, J.; Jiang, X.; Zhang, D.; Fang, C. Asymmetric Au/(PdAg alloy) nano-allium giganteums for their enhanced electrocatalytic performances to ethanol oxidation reaction. J. Alloy. Compd. 2021, 855, 157385. [Google Scholar] [CrossRef]

- Kakade, B.A.; Tamaki, T.; Ohashi, H.; Yamaguchi, T. Highly active bimetallic PdPt and CoPt nanocrystals for methanol electro-oxidation. J. Phys. Chem. C 2012, 116, 7464–7470. [Google Scholar] [CrossRef]

- Li, S.S.; Yu, J.; Hu, Y.Y.; Wang, A.J.; Chen, J.R.; Feng, J.J. Simple synthesis of hollow Pt–Pd nanospheres supported on reduced graphene oxide for enhanced methanol electrooxidation. J. Power Sources 2014, 254, 119–125. [Google Scholar] [CrossRef]

- Lu, Y.; Jiang, Y.; Chen, W. Graphene nanosheet-tailored PtPd concave nanocubes with enhanced electrocatalytic activity and durability for methanol oxidation. Nanoscale 2014, 6, 3309–3315. [Google Scholar] [CrossRef]

- Shahrokhian, S.; Rezaee, S. Vertically standing Cu2O nanosheets promoted flower-like PtPd nanostructures supported on reduced graphene oxide for methanol electro-oxidation. Electrochim. Acta 2018, 259, 36–47. [Google Scholar] [CrossRef]

- Lu, Y.; Jiang, Y.; Wu, H.; Chen, W. Nano-PtPd cubes on graphene exhibit enhanced activity and durability in methanol electrooxidation after CO stripping–cleaning. J. Phys. Chem. C 2013, 117, 2926–2938. [Google Scholar] [CrossRef]

- Lu, Y.; Jiang, Y.; Chen, W. PtPd porous nanorods with enhanced electrocatalytic activity and durability for oxygen reduction reaction. Nano Energy 2013, 2, 836–844. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, R.; Li, L.; Li, X.; Chen, W. Oxygen Electroreduction by Single PtPd Nanocubes Encaged in Hollow Carbon Nanospheres: Improved Durability and Strong Effect of Carbon-Shell Thickness. Part. Part. Syst. Charact. 2017, 34, 1700034. [Google Scholar] [CrossRef]

- Zhu, C.; Guo, S.; Dong, S. Facile synthesis of trimetallic AuPtPd alloy nanowires and their catalysis for ethanol electrooxidation. J. Mater. Chem. 2012, 22, 14851–14855. [Google Scholar] [CrossRef]

- Achari, I.; Dimitrov, N. Ultrathin film PtxPd (1-x) alloy catalysts for formic acid oxidation synthesized by surface limited redox replacement of underpotentially deposited H monolayer. Electrochem 2020, 1, 4–19. [Google Scholar] [CrossRef] [Green Version]

- Li, S.S.; Lv, J.J.; Hu, Y.Y.; Zheng, J.N.; Chen, J.R.; Wang, A.J.; Feng, J.J. Facile synthesis of porous Pt–Pd nanospheres supported on reduced graphene oxide nanosheets for enhanced methanol electrooxidation. J. Power Sources 2014, 247, 213–218. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Wu, D.; Gong, Y.; Liu, H.; Chen, W.; Bi, L. Carbon Monoxide-Templated Synthesis of Coral-Like Clean PtPd Nanochains as Efficient Oxygen Reduction Catalyst. ChemElectroChem 2018, 5, 2403–2408. [Google Scholar] [CrossRef]

- Suzuki, H.; Kimura, T.; Yamamoto, G.; Hashida, T.; Motomiya, K.; Tohji, K.; Sato, Y. Influence of supported PtPd nanoparticles on the tensile strength of individual multi-walled carbon nanotubes: Strength decrease by the interaction of metal and nanotube. RSC Adv. 2017, 7, 49917–49922. [Google Scholar] [CrossRef] [Green Version]

- Bharti, A.; Cheruvally, G. Surfactant assisted synthesis of Pt-Pd/MWCNT and evaluation as cathode catalyst for proton exchange membrane fuel cell. Int. J. Hydrogen Energy 2018, 43, 14729–14741. [Google Scholar] [CrossRef]

- Jin, Z.; Ji, J.; He, Q.; Yang, X.; Zhang, Y.; Xu, M. The enhanced electro-catalytic performance of Au@ Pd nanoparticles self-assembled on fluorine-modified multi-walled carbon nanotubes for methanol oxidation. Catal. Lett. 2018, 148, 3281–3291. [Google Scholar] [CrossRef]

- Chu, Y.Y.; Wang, Z.B.; Cao, J.; Gu, D.M.; Yin, G.P. Ultrahigh durable PtPd/C nanowire networks catalyst synthesized by modified phase transfer method for methanol oxidation. Fuel Cells 2013, 13, 380–386. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, X.; Schechter, J.M.; Yang, Y. Revisiting the oxidation peak in the cathodic scan of the cyclic voltammogram of alcohol oxidation on noble metal electrodes. RSC Adv. 2016, 6, 5384–5390. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, J.; Tiwary, C.S.; Ma, Z.; Huang, H.; Zhang, J.; Lu, Z.; Huang, W.; Wu, Y. Palladium nanoparticles supported on nitrogen and sulfur dual-doped graphene as highly active electrocatalysts for formic acid and methanol oxidation. ACS Appl. Mater. Interfaces 2016, 8, 10858–10865. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Zhang, X.; Yang, S.; Wei, X.; Sun, Z. Electrocatalytic performance for methanol oxidation on nanoporous Pd/NiO composites prepared by one-step dealloying. Fuel 2016, 181, 269–276. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhan, L.; Tian, J.; Nie, S.; Ning, Z. MnO2 modified multi-walled carbon nanotubes supported Pd nanoparticles for methanol electro-oxidation in alkaline media. Int. J. Hydrogen Energy 2010, 35, 10522–10526. [Google Scholar] [CrossRef]

- Kang, Z.; Zhao, M.; Wu, Y.; Xia, T.; Cao, J.P.; Cai, W.; Chen, L. Facial fabrication of yolk-shell Pd-Ni-P alloy with mesoporous structure as an advanced catalyst for methanol electro-oxidation. Appl. Surf. Sci. 2019, 484, 441–445. [Google Scholar] [CrossRef]

- Zhou, L.N.; Zhang, X.T.; Wang, Z.H.; Guo, S.; Li, Y.J. Cubic superstructures composed of PtPd alloy nanocubes and their enhanced electrocatalysis for methanol oxidation. Chem. Commun. 2016, 52, 12737–12740. [Google Scholar] [CrossRef]

- Ensafi, A.A.; Jafari-Asl, M.; Rezaei, B.; Abarghoui, M.M.; Farrokhpour, H. Facile synthesis of Pt–Pd@ Silicon nanostructure as an advanced electrocatalyst for direct methanol fuel cells. J. Power Sources 2015, 282, 452–461. [Google Scholar] [CrossRef]

| Samples | Pt 4f7/2 | Pt 4f5/2 | Pd 3d5/2 | Pd 4d3/2 |

|---|---|---|---|---|

| Pt | 71.34 | 74.88 | - | - |

| Pt:Pd = 2:1 | 70.82 | 74.21 | 335.07 | 340.43 |

| Pt:Pd = 1:1 | 71.18 | 74.44 | 335.22 | 340.60 |

| Pt:Pd = 1:2 | 71.16 | 74.41 | 335.43 | 340.78 |

| Pd | - | - | 335.74 | 341.24 |

| Catalysts | Electrolytes | Scan Rate (mV·s−1) | Current (mA·mg−1Pd) | Ref. |

|---|---|---|---|---|

| Pd/NS-G | 0.5 M NaOH + 1.0 M Methanol | 50 | 399 | [34] |

| Nanoporous Pd/NiO | 0.5 M NaOH + 0.5 M Methanol | 50 | 344 | [35] |

| Pt-MnO2/MWCNTs | 0.5 M NaOH + 1.0 M Methanol | 50 | 431 | [36] |

| YS Pd-Ni-P/C | 0.5 M KOH + 1.0 M Methanol | 50 | 524 | [37] |

| Pt50Pd50/SCs | 1.0 M KOH + 1.0 M Methanol | 50 | 336 | [38] |

| Pt2Pd1/MWCNTs | 0.5 M KOH + 2.0 M Methanol | 50 | 472 | This work |

| Pt1Pd1/MWCNTs | 0.5 M KOH + 2.0 M Methanol | 50 | 531 | This work |

| Pt1Pd2/MWCNTs | 0.5 M KOH + 2.0 M Methanol | 50 | 685 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Ren, Y.; Jin, Z.; Duan, Y.; Xu, M.; Yu, J. Facile Synthesis of PtPd Network Structure Nanochains Supported on Multi-Walled Carbon Nanotubes for Methanol Oxidation. Metals 2022, 12, 1911. https://doi.org/10.3390/met12111911

Zhang D, Ren Y, Jin Z, Duan Y, Xu M, Yu J. Facile Synthesis of PtPd Network Structure Nanochains Supported on Multi-Walled Carbon Nanotubes for Methanol Oxidation. Metals. 2022; 12(11):1911. https://doi.org/10.3390/met12111911

Chicago/Turabian StyleZhang, Dawei, Yanrong Ren, Zhenhua Jin, Yonghua Duan, Mingli Xu, and Jie Yu. 2022. "Facile Synthesis of PtPd Network Structure Nanochains Supported on Multi-Walled Carbon Nanotubes for Methanol Oxidation" Metals 12, no. 11: 1911. https://doi.org/10.3390/met12111911