Optimization of Si Content to Inhibit Inhomogeneous Deformation in Al-Mg-Si Alloy Fabricated via Twin-Roll Casting

Abstract

:1. Introduction

2. Experimental Procedure

3. Results

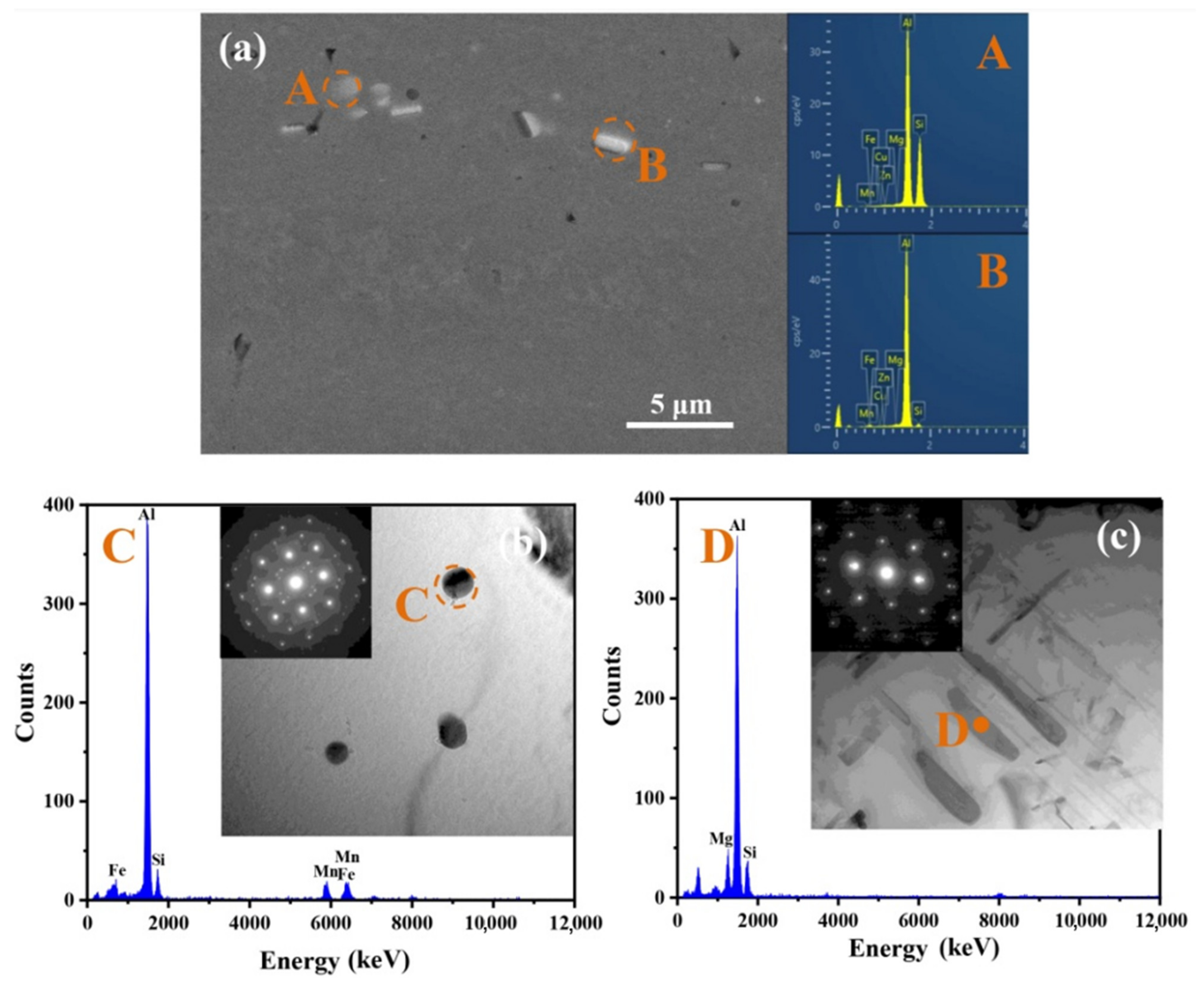

3.1. Second Phase

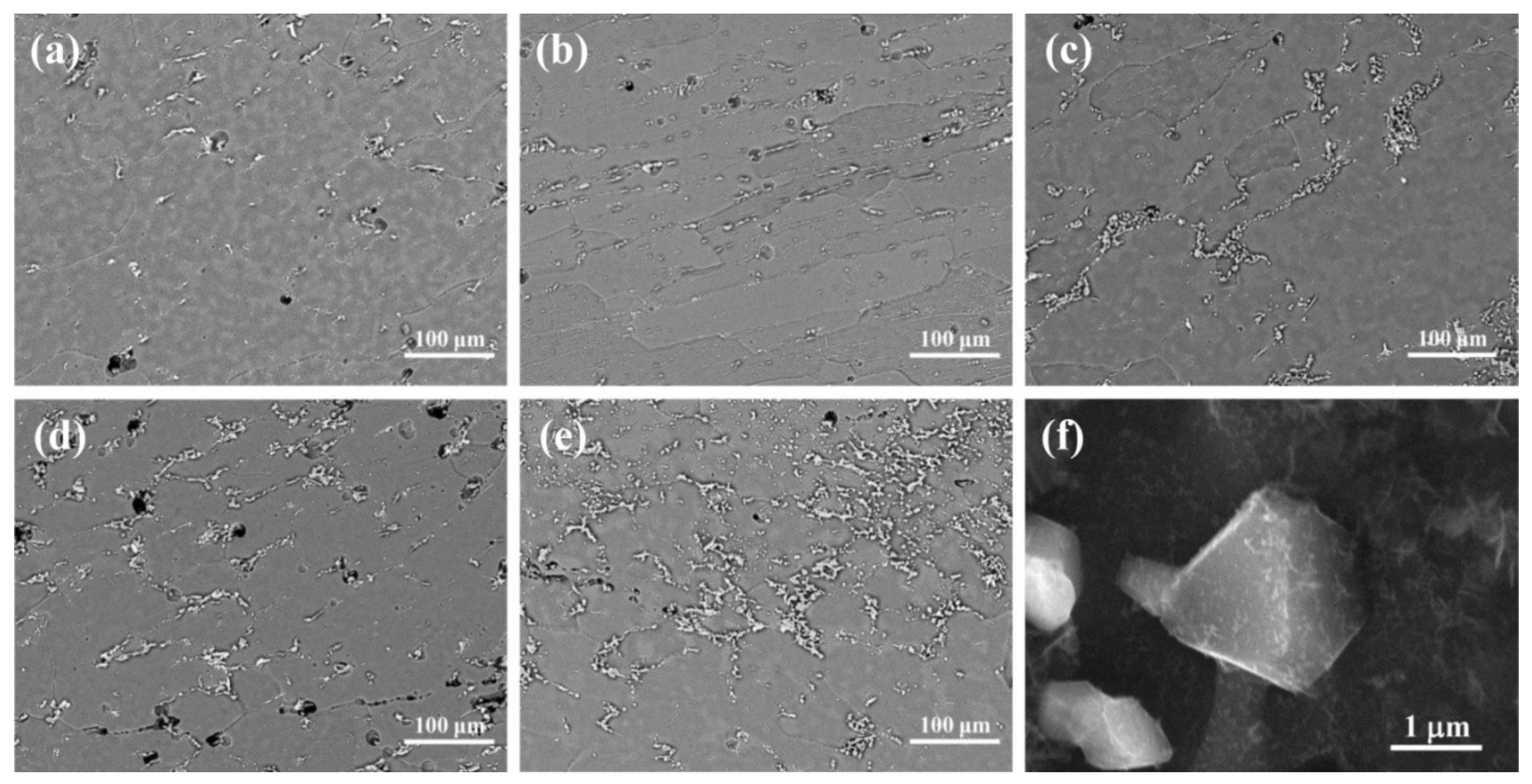

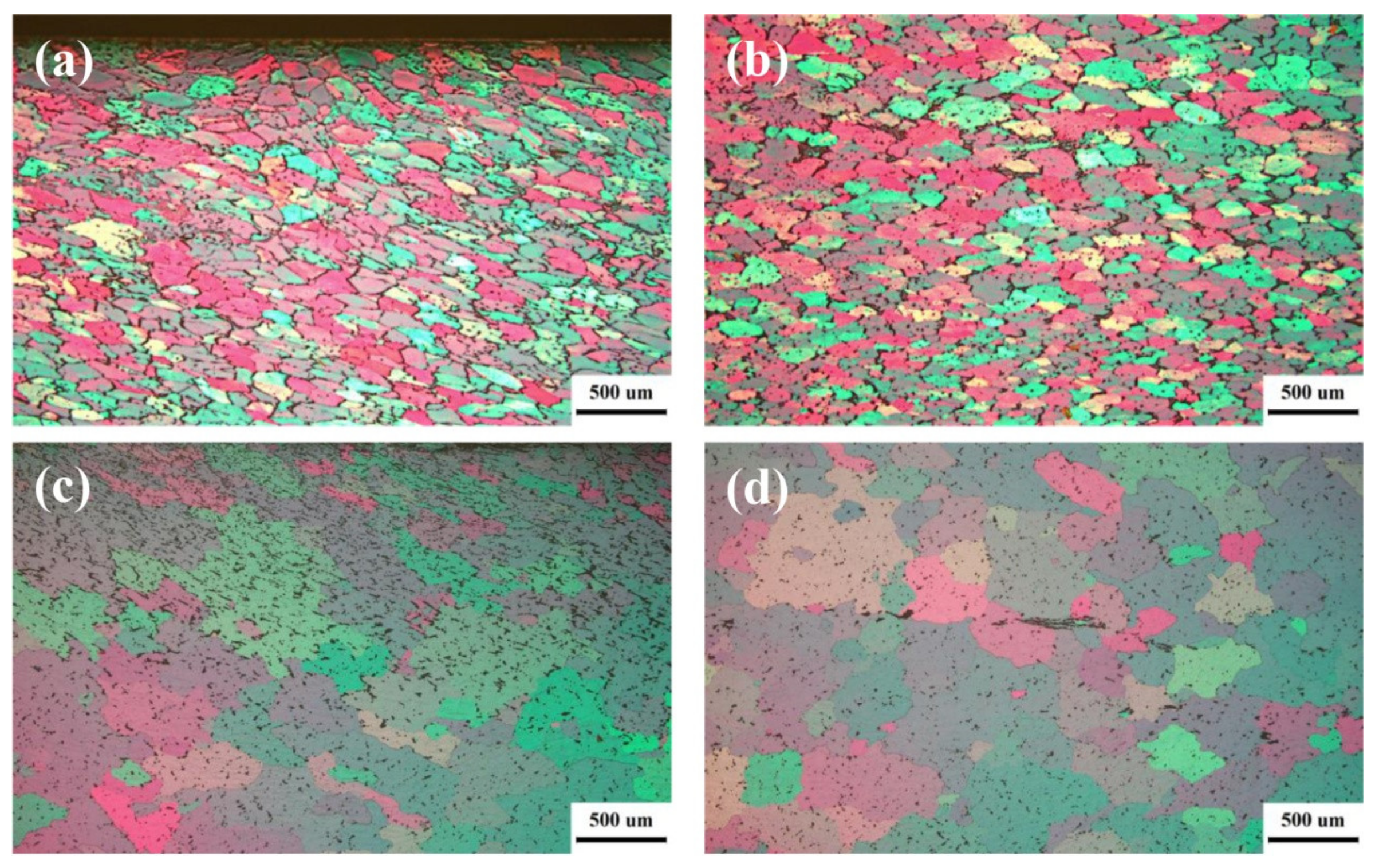

3.2. Solute Gradient

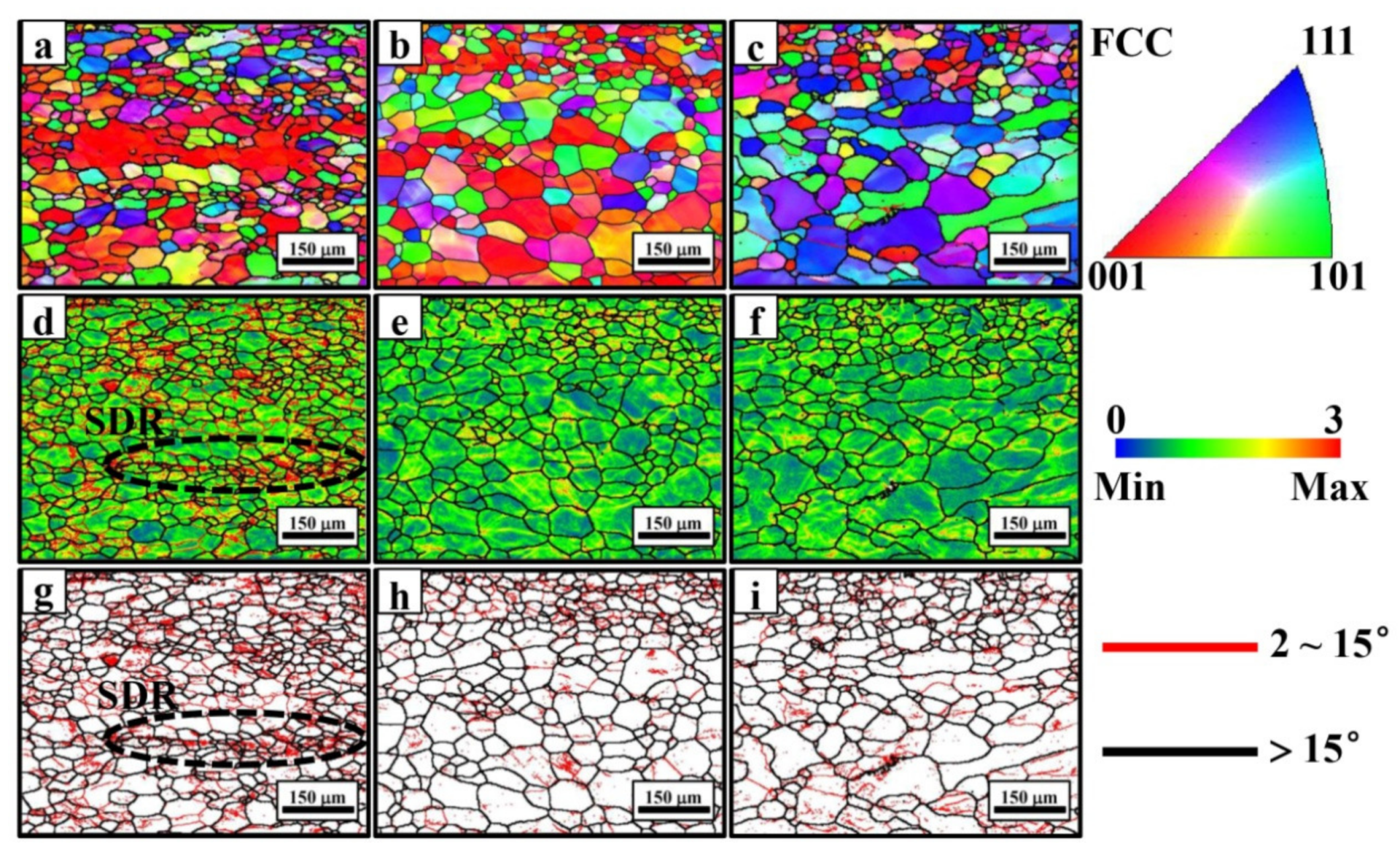

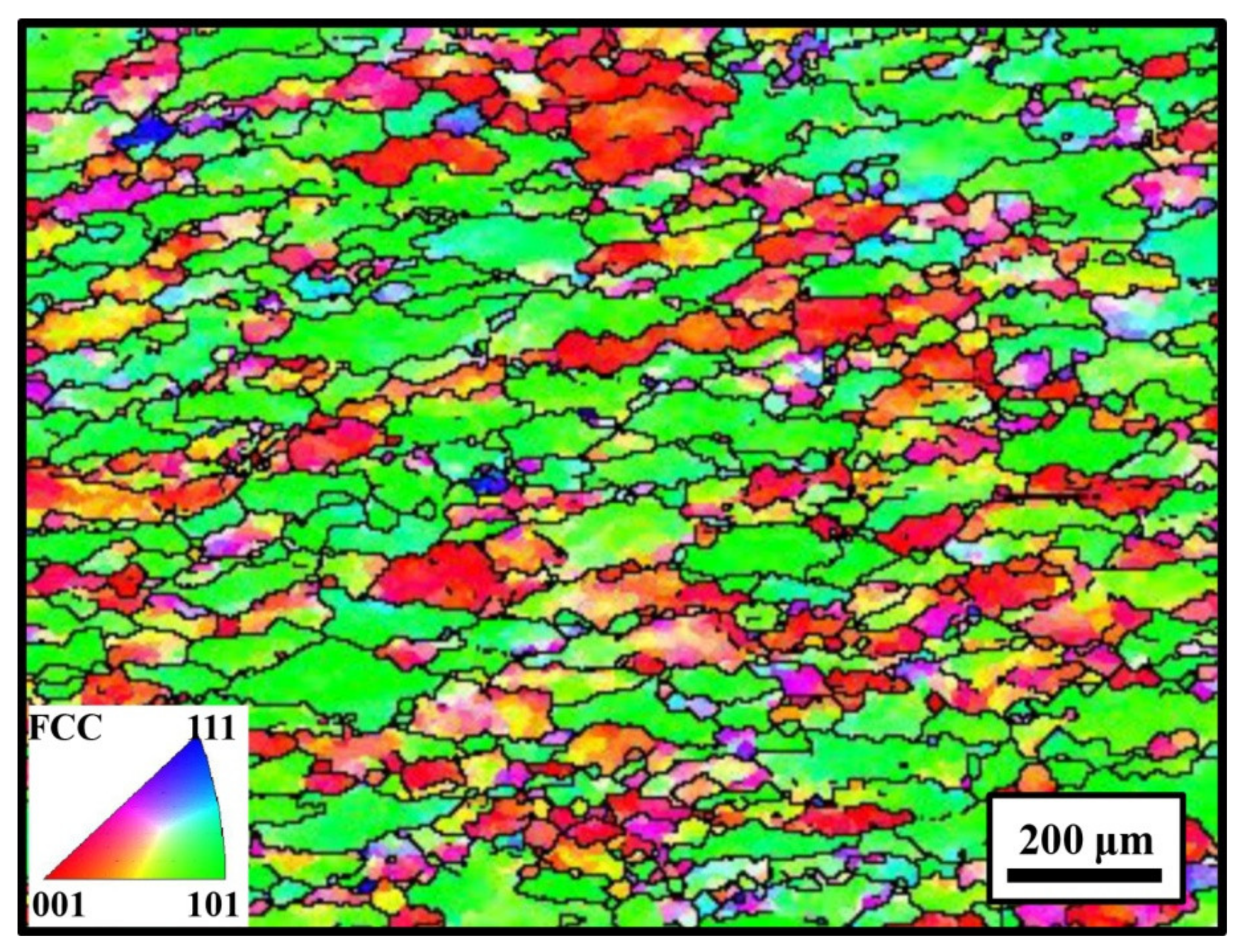

3.3. Pre-Strain Test

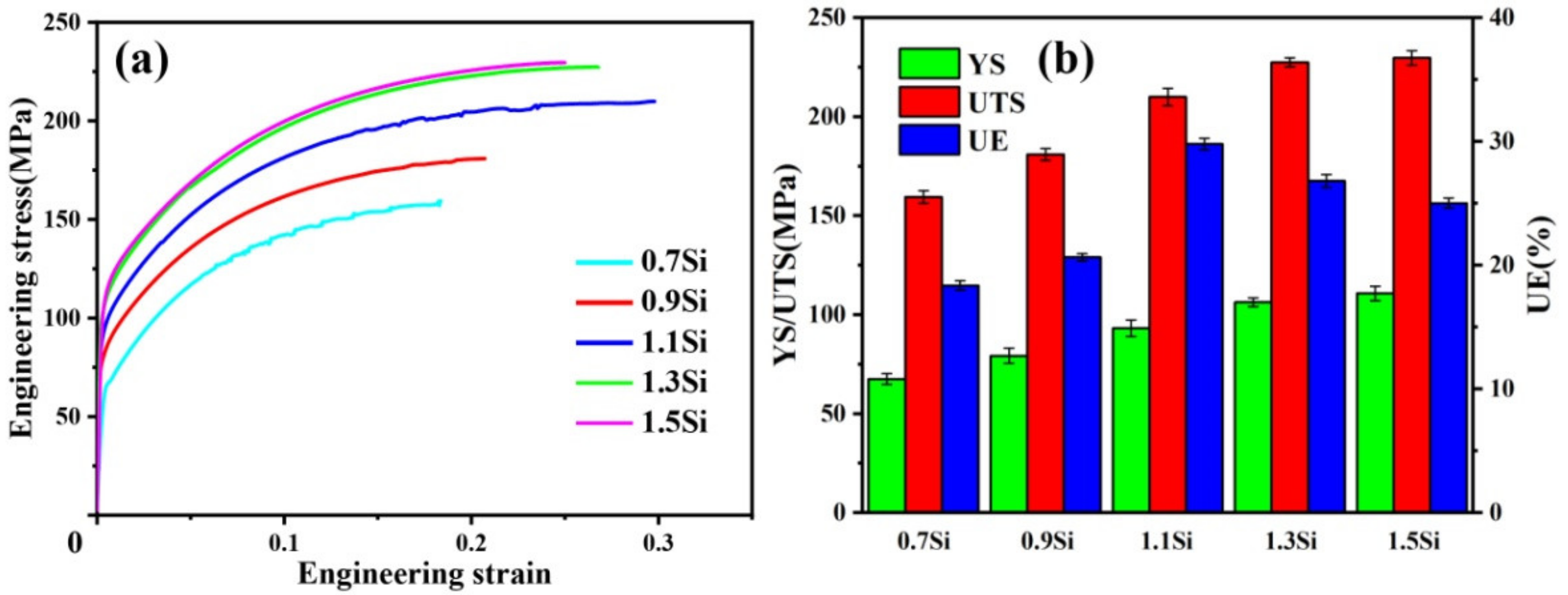

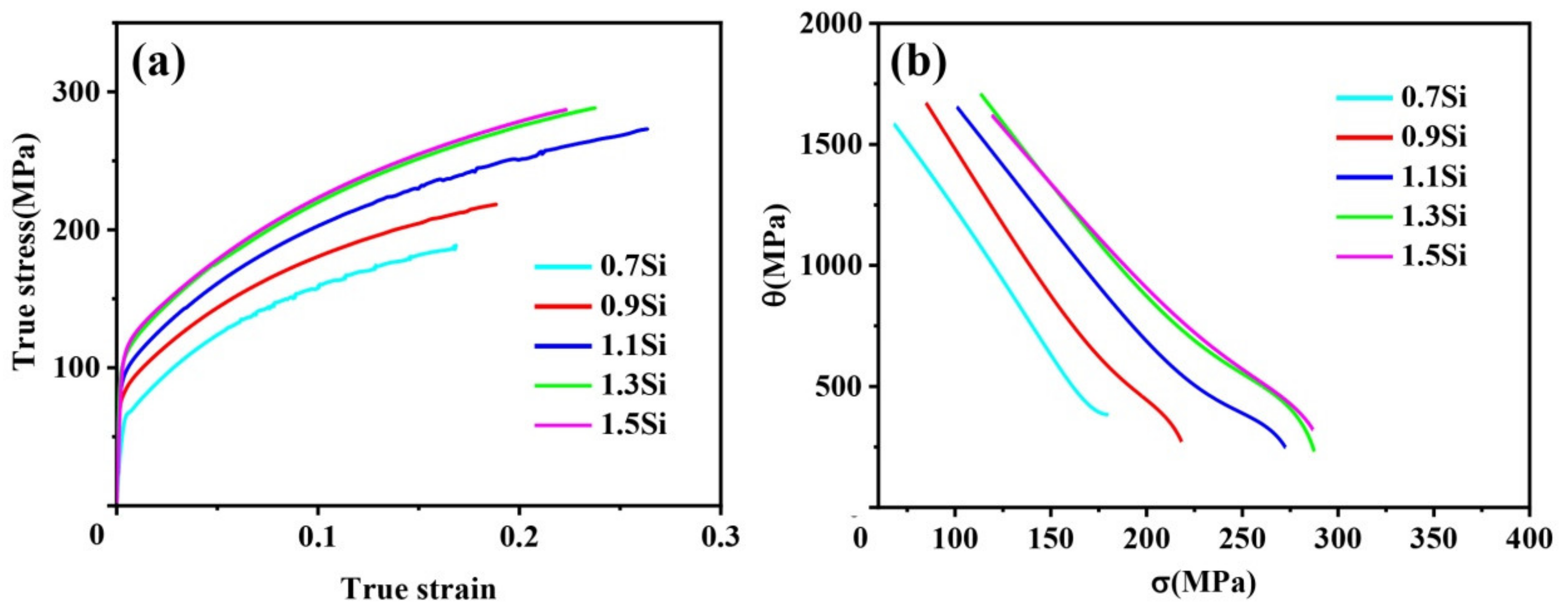

3.4. Hardness and Tensile Properties

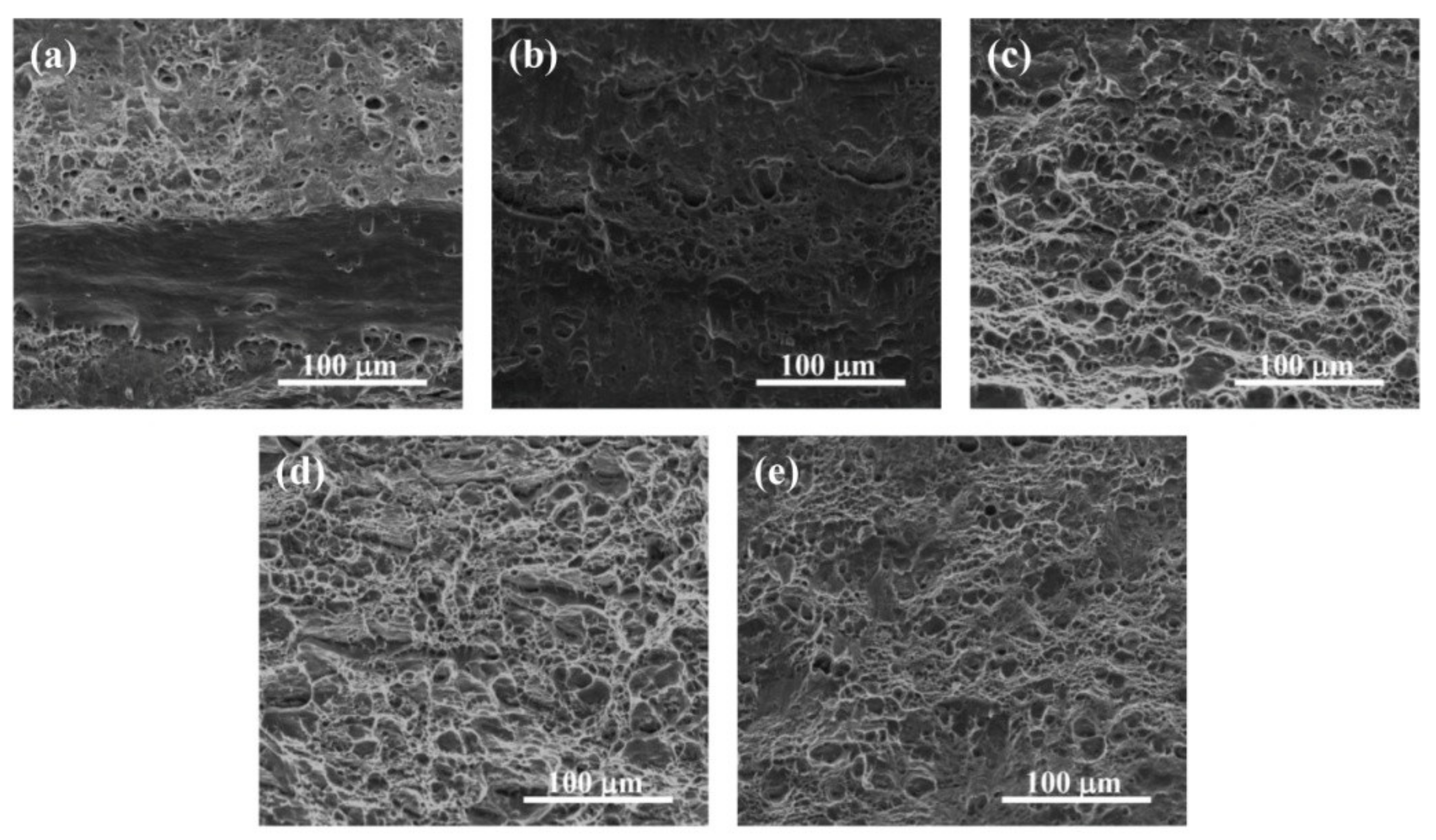

3.5. Fracture Morphology

4. Discussion

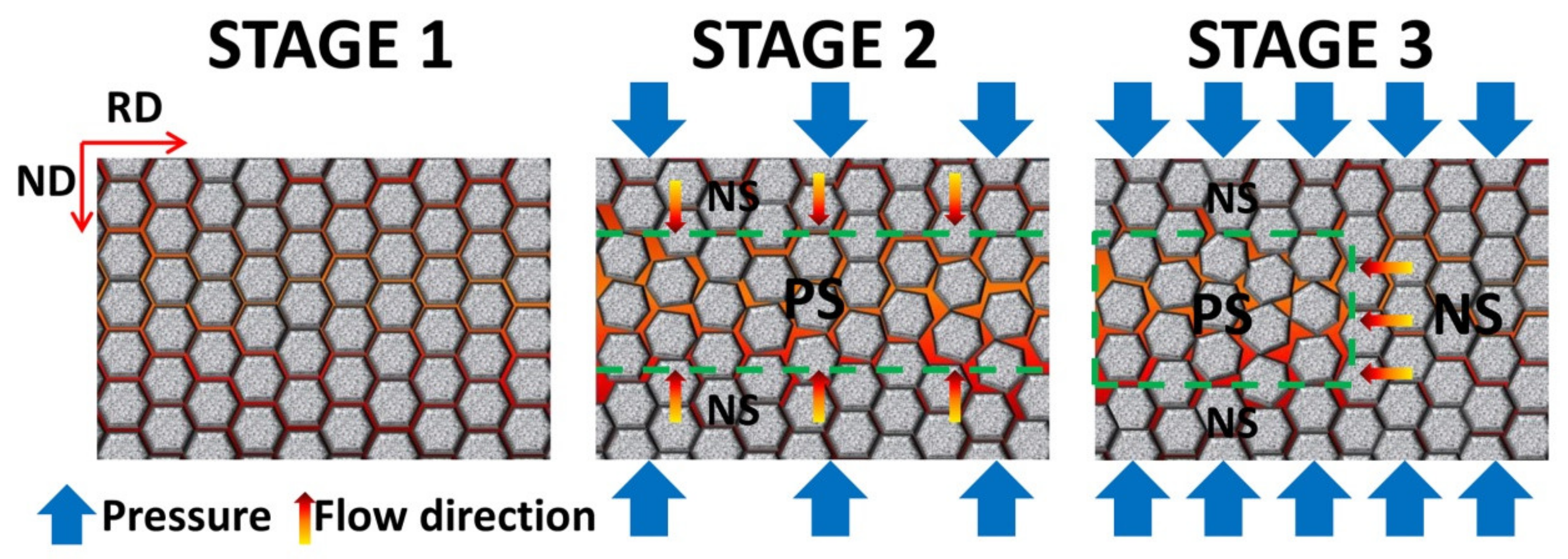

4.1. Solute Gradient and Inhomogeneous Deformation

4.2. Effect of Si on the Inhomogeneous Deformation in TRC Alloy

5. Conclusion

- Sub-rapid solidification and simultaneous deformation provide favorable conditions for the formation of Al-Mg2Si-Si ternary eutectic phases in large quantities during TRC. The ternary eutectic phase increased significantly with increasing Si addition and was difficult to dissolve completely after homogenization. The Si particles formed at the grain boundaries;

- The Si particles were mainly distributed in the surface region of the strip, due to the negative solute gradient in the thickness direction of TRC strip. The deformation of the TRC strip was inhomogeneous, and the surface area deformation was small during the tensile process, reducing the negative effect of the Si particles on the mechanical properties of the strip. Compared with a DC ingot, a greater amount of Si can be added to a VTRC strip without reducing elongation;

- The TRC strip is a material consisting of a hard shell and soft core, and the soft core bears the earliest deformation. Premature local deformation in the EBR is the main factor limiting the mechanical properties. With the increase in the Si content from 0.7 wt% to 1.1 wt%, the element content and distribution uniformity in EBR are improved, resulting in a higher work-hardening capability, and inhomogeneous deformation is weakened. The tensile strength and uniform elongation of the strip are increased from 159.44 MPa and 18.36% to 209.96 MPa and 29.791%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Huis, M.A.; Chen, J.H.; Sluiter, M.H.F.; Zandbergen, H.W. Phase stability and structural features of matrix-embedded hardening precipitates in Al–Mg–Si alloys in the early stages of evolution. Acta Mater. 2007, 55, 2183–2199. [Google Scholar] [CrossRef]

- Esmaeili, S.; Wang, X.; Lloyd, D.J.; Poole, W.J. On the precipitation-hardening behavior of the Al-Mg-Si-Cu alloy AA6111. Metall. Mater. Trans. A 2003, 34, 751–763. [Google Scholar]

- Yun, M.; Lokyer, S.; Hunt, J.D. Twin roll casting of aluminium alloys. Mater. Sci. Eng. A 2000, 280, 116–123. [Google Scholar] [CrossRef]

- Birol, Y. Analysis of macro segregation in twin-roll cast aluminium strips via solidification curves. J. Alloys Compd. 2009, 486, 168–172. [Google Scholar] [CrossRef]

- Šlapáková, M.; Zimina, M.; Zaunschirm, S.; Kastner, J.; Bajer, J.; Cieslar, M. 3D analysis of macrosegregation in twin-roll cast AA3003 alloy. Mater. Charact. 2016, 118, 44–49. [Google Scholar] [CrossRef]

- Haga, S.S.T. A high speed twin roll caster for aluminum alloy strip. J. Mater. Process. Technol. 2001, 113, 291–295. [Google Scholar] [CrossRef]

- Sun, K.M.; Li, L.; Chen, S.D.; Xu, G.M.; Chen, G.; Misra, R.D.K.; Zhang, G. A new approach to control centerline macrosegregation in Al-Mg-Si alloys during twin roll continuous casting. Mater. Lett. 2017, 190, 205–208. [Google Scholar] [CrossRef]

- Shiju, L.; Jiang, T.; Wang, J.; Chen, L.; Wei, B.; Li, Y.; Xu, G.; Wang, Z. Effects of different external fields on the microstructure and mechanical properties of novel Al Cu Li alloy during twin-roll casting. Mater. Sci. Eng. A 2019, 757, 14–22. [Google Scholar] [CrossRef]

- He, C.; Li, Y.; Li, J.; Xu, G.; Wang, Z.; Wu, D. Effect of electromagnetic fields on microstructure and mechanical properties of sub-rapid solidification-processed Al–Mg–Si alloy during twin-roll casting. Mater. Sci. Eng. A 2019, 766, 138328. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, R. Grain size-dependent Mg/Si ratio effect on the microstructure and mechanical/electrical properties of Al-Mg-Si-Sc alloys. J. Mater. Sci. Technol. 2019, 35, 1354–1363. [Google Scholar] [CrossRef]

- Aucote, J.; Evans, D.W. Effects of excess silicon addition. on ductility of AL-0.95%M92Si alloy. Met. Sci. 1978, 12, 57–63. [Google Scholar] [CrossRef]

- Remøe, M.S.; Marthinsen, K.; Westermann, I.; Pedersen, K.; Røyset, J.; Marioara, C. The effect of alloying elements on the ductility of Al-Mg-Si alloys. Mater. Sci. Eng. A 2017, 693, 60–72. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.T.; Wang, C.; Luo, Q.; You, J.; Zhou, X.L.; Xu, J.; Mo, Y.T.; Song, J.W.; Zha, M.; Wang, H.Y. Effects of Mg contents on the microstructure evolution and Fe–bearing phase selection of Al–Mg–Si–Fe alloys under sub–rapid solidification. Materialia 2020, 13, 100850. [Google Scholar] [CrossRef]

- Liu, X.; Wang, C.; Zhang, S.-Y.; Song, J.-W.; Zhou, X.-L.; Zha, M.; Wang, H.-Y. Fe-bearing phase formation, microstructure evolution, and mechanical properties of Al-Mg-Si-Fe alloy fabricated by the twin-roll casting process. J. Alloys Compd. 2021, 886, 161202. [Google Scholar] [CrossRef]

- Wang, X.; Ma, P.-K.; Meng, Z.-Y.; Zhang, S.-Y.; Liu, X.; Wang, C.; Wang, H.-Y. Effect of trace Cr alloying on centerline segregations in sub-rapid solidified Al–Mg–Si (AA6061) alloys fabricated by twin-roll casting. Mater. Sci. Eng. A 2021, 825, 141896. [Google Scholar] [CrossRef]

- Engler, O.; Miller-Jupp, S. Control of second-phase particles in the Al-Mg-Mn alloy AA 5083. J. Alloys Compd. 2016, 689, 998–1010. [Google Scholar] [CrossRef]

- Kumar, S.; O’Reilly, K.A.Q. Influence of Al grain structure on Fe bearing intermetallics during DC casting of an Al-Mg-Si alloy. Mater. Charact. 2016, 120, 311–322. [Google Scholar] [CrossRef]

- Park, Y.S.; Lee, S.B.; Kim, N.J. Microstructure and Mechanical Properties of Strip Cast Al-Mg-Si-X Alloys. Mater. Trans. 2003, 44, 2617–2624. [Google Scholar]

- Ji, Y.-L.; Guo, F.-A.; Pan, Y.-F. Microstructural characteristics and paint-bake response of Al-Mg-Si-Cu alloy. Trans. Nonferrous Met. Soc. China 2008, 18, 126–131. [Google Scholar] [CrossRef]

- Lodgaard, N.R.L. Precipitation of dispersoids containing Mn and/or Cr in Al–Mg–Si alloys. Mater. Sci. Eng. A 2000, 283, 144–152. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, P.; Jia, Z.; Liu, Z.; Xie, Z. Effects of Mg and Si contents on the microstructure and mechanical properties of AA6014 alloys in T4P and T6P temper. Mater. Sci. Eng. A 2019, 740–741, 187–200. [Google Scholar] [CrossRef]

- Liu, Y.L.; Kang, S.B.; Kim, H.W. The complex microstructures in an as-cast Al–Mg–Si alloy. Mater. Lett. 1999, 41, 267–272. [Google Scholar] [CrossRef]

- Grydin, O.; Stolbchenko, M.; Nürnberger, F.; Schaper, M. Influence of the twin-roll casting parameters on the microsegregation in thin strips of the aluminium alloy EN AW-6082. Light Met. 2014, 2014, 411–414. [Google Scholar]

- Liu, X.; Zhao, Q.; Ji, Z.; Wang, B.; Zhu, Y.; Jiang, Q. Effectively mitigated macro-segregation and improved tensile properties of twin-roll casting Al-Cu strips via the addition of TiC nanoparticles. J. Mater. Process. Technol. 2021, 296, 117200. [Google Scholar] [CrossRef]

- Kim, M.-S.; Kim, S.-H.; Kim, H.-W. Deformation-induced center segregation in twin-roll cast high-Mg Al–Mg strips. Scr. Mater. 2018, 152, 69–73. [Google Scholar] [CrossRef]

- Wei, B.; Li, S.; Jiang, T.; Xu, G.; Li, Y.; Wang, Z. Effect of a novel semi-solid middle-layer structure formed during twin-roll casting on the mechanical properties of AA6022 alloy. Mater. Sci. Eng. A 2021, 812, 141083. [Google Scholar] [CrossRef]

- Forbord, B.; Andersson, B.; Ingvaldsen, F.; Austevik, O.; Horst, J.A.; Skauvik, I. The formation of surface segregates during twin roll casting of aluminium alloys. Mater. Sci. Eng. A 2006, 415, 12–20. [Google Scholar] [CrossRef]

- Eskin, D.G.; Zuidema, J.; Savran, V.I.; Katgerman, L. Structure formation and macro segregation under different process conditions during DC casting. Mater. Sci. Eng. A 2004, 384, 232–244. [Google Scholar] [CrossRef]

- Hirth, S.M.; Marshall, G.J.; Court, S.A.; Lloyd, D.J. Effects of Si on the aging behaviour and formability of aluminium. Mater. Sci. Eng. A 2001, 319–321, 452–456. [Google Scholar] [CrossRef]

- Onurlu, A.T.S. Effect of heat treatment on the insoluble intermetallic phases present in an AA 6063 alloy. J. Mater. Sci. 1994, 29, 1652–1655. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, Y.; Dai, Q.; Jiang, K.; Chen, J.; Guo, X. Microstructures and strengthening mechanisms of high Fe containing Al–Mg–Si–Mn–Fe alloys with Mg, Si and Mn modified. Mater. Sci. Eng. A 2021, 803, 140477. [Google Scholar] [CrossRef]

- Sidor, J.J.; Decroos, K.; Petrov, R.H.; Kestens, L.A.I. Evolution of recrystallization textures in particle containing Al alloys after various rolling reductions: Experimental study and modeling. Int. J. Plast. 2015, 66, 119–137. [Google Scholar] [CrossRef]

- Engler, O.; Kong, X.W.; Yang, P. Influence of particles stimulated nucleation on the recrystallization textures in cold deformed Al-alloys Part I-experimental observations. Scr. Mater. 1997, 37, 1665–1674. [Google Scholar] [CrossRef]

- Liu, Z.-T.; Wang, B.-Y.; Wang, C.; Zha, M.; Liu, G.-J.; Yang, Z.-Z.; Wang, J.-G.; Li, J.-H.; Wang, H.-Y. Microstructure and mechanical properties of Al-Mg-Si alloy fabricated by a short process based on sub-rapid solidification. J. Mater. Sci. Technol. 2020, 41, 178–186. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, P.; Yang, C.; Zhang, J.; Sun, J. Aluminum Alloys: Solute Atom Clusters and Their Strengthening. Jinshu Xuebao Acta Metall. Sin. 2021, 57, 1484–1498. [Google Scholar]

- Zhao, X.L.; Kuang, J.; Shi, K.K.; Zhang, P.; Xue, H.; Zhang, J.Y.; Liu, G.; Sun, J.; Xu, G.M.; Wang, Z.D. Heterogeneous microstructure-mediated ductile fracture of twin-roll cast Al–Mn strip. Mater. Sci. Eng. A 2020, 783, 139222. [Google Scholar] [CrossRef]

| Mass Percentage (%) | ||||||

|---|---|---|---|---|---|---|

| Si (Additive Amount) | Al | Mg | Si | Fe | Mn | Cu |

| 0.7 | 97.87 | 0.516 | 0.685 | 0.121 | 0.093 | 0.089 |

| 0.9 | 97.82 | 0.505 | 0.892 | 0.133 | 0.085 | 0.103 |

| 1.1 | 97.55 | 0.498 | 1.107 | 0.142 | 0.108 | 0.097 |

| 1.3 | 97.24 | 0.491 | 1.318 | 0.138 | 0.102 | 0.113 |

| 1.5 | 97.03 | 0.509 | 1.473 | 0.147 | 0.097 | 0.107 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, B.; Li, S.; Jiang, T.; Zhang, Y.; Xu, G.; Li, Y.; Wang, Z. Optimization of Si Content to Inhibit Inhomogeneous Deformation in Al-Mg-Si Alloy Fabricated via Twin-Roll Casting. Metals 2022, 12, 941. https://doi.org/10.3390/met12060941

Wei B, Li S, Jiang T, Zhang Y, Xu G, Li Y, Wang Z. Optimization of Si Content to Inhibit Inhomogeneous Deformation in Al-Mg-Si Alloy Fabricated via Twin-Roll Casting. Metals. 2022; 12(6):941. https://doi.org/10.3390/met12060941

Chicago/Turabian StyleWei, Bowen, Shiju Li, Tao Jiang, Youyun Zhang, Guangming Xu, Yong Li, and Zhaodong Wang. 2022. "Optimization of Si Content to Inhibit Inhomogeneous Deformation in Al-Mg-Si Alloy Fabricated via Twin-Roll Casting" Metals 12, no. 6: 941. https://doi.org/10.3390/met12060941