Different Aspects of Machinability in Turning of AISI 304 Stainless Steel: A Sustainable Approach with MQL Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specifications of Test Samples

2.2. Cutting Tool and Tool Holder Specifications

2.3. Data Acquisition Equipment

2.4. Experiments and Machine Tool Specifications

3. Results and Discussion

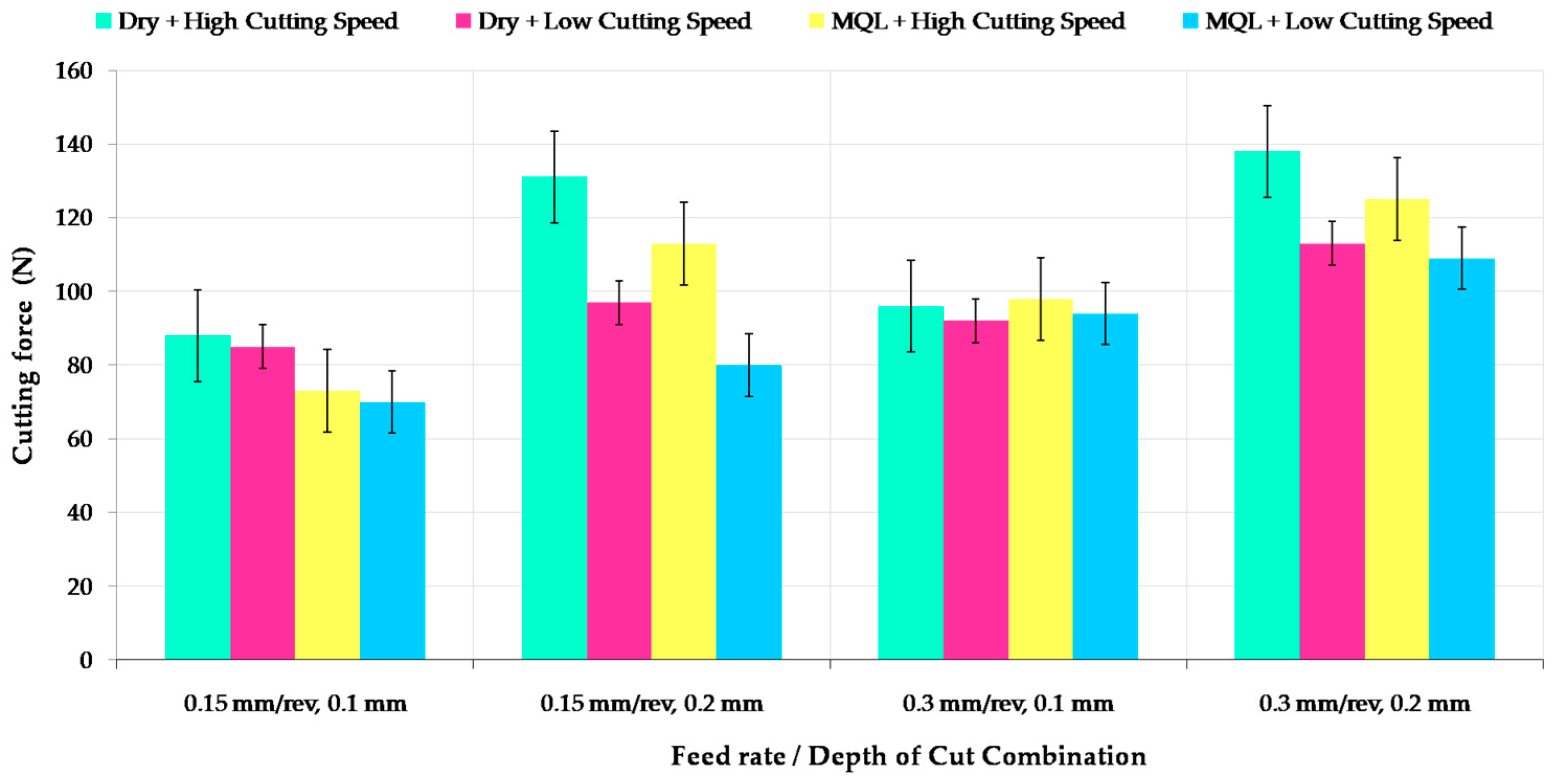

3.1. Evaluation of Cutting Forces

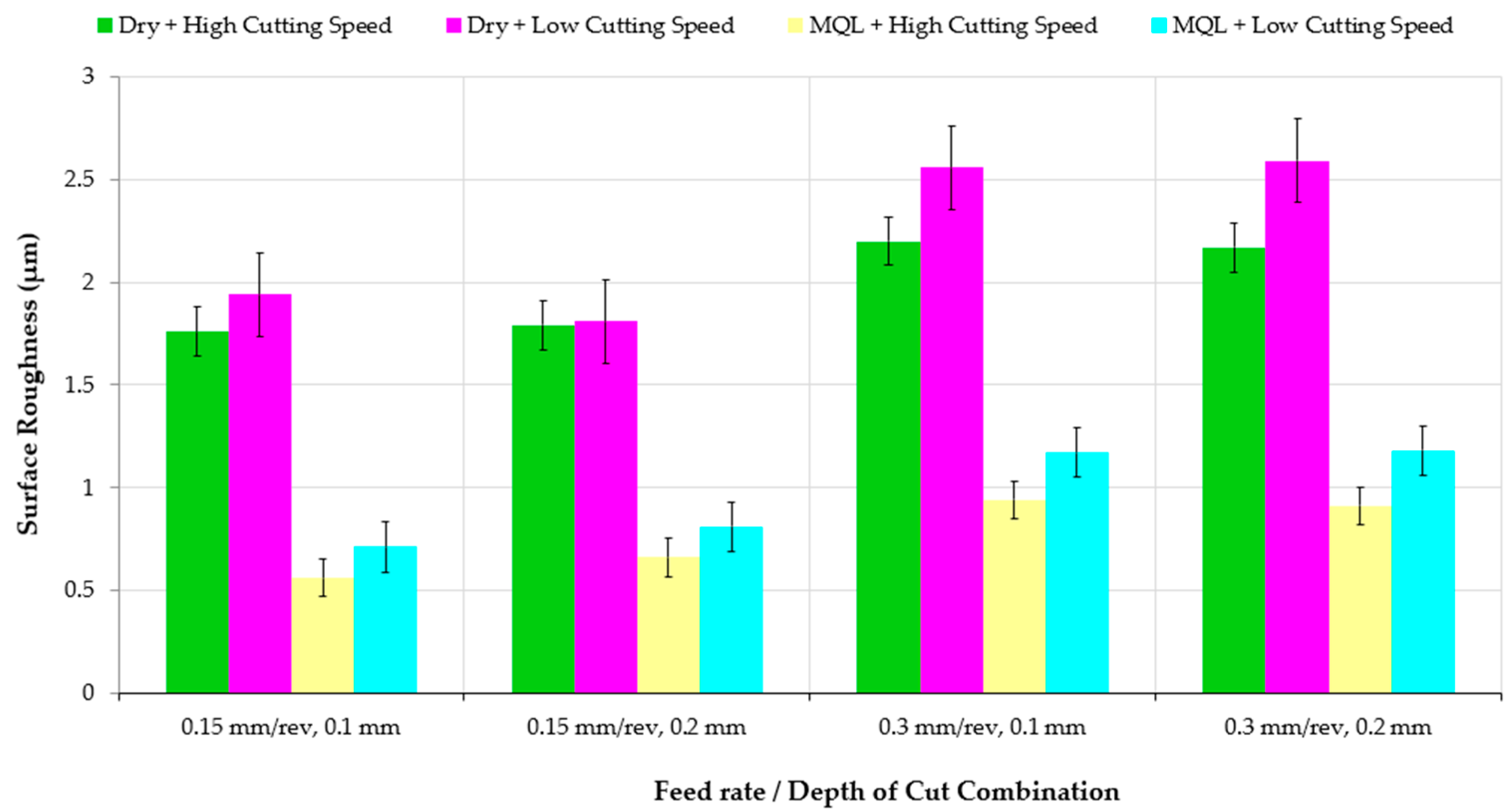

3.2. Evaluation of Surface Quality

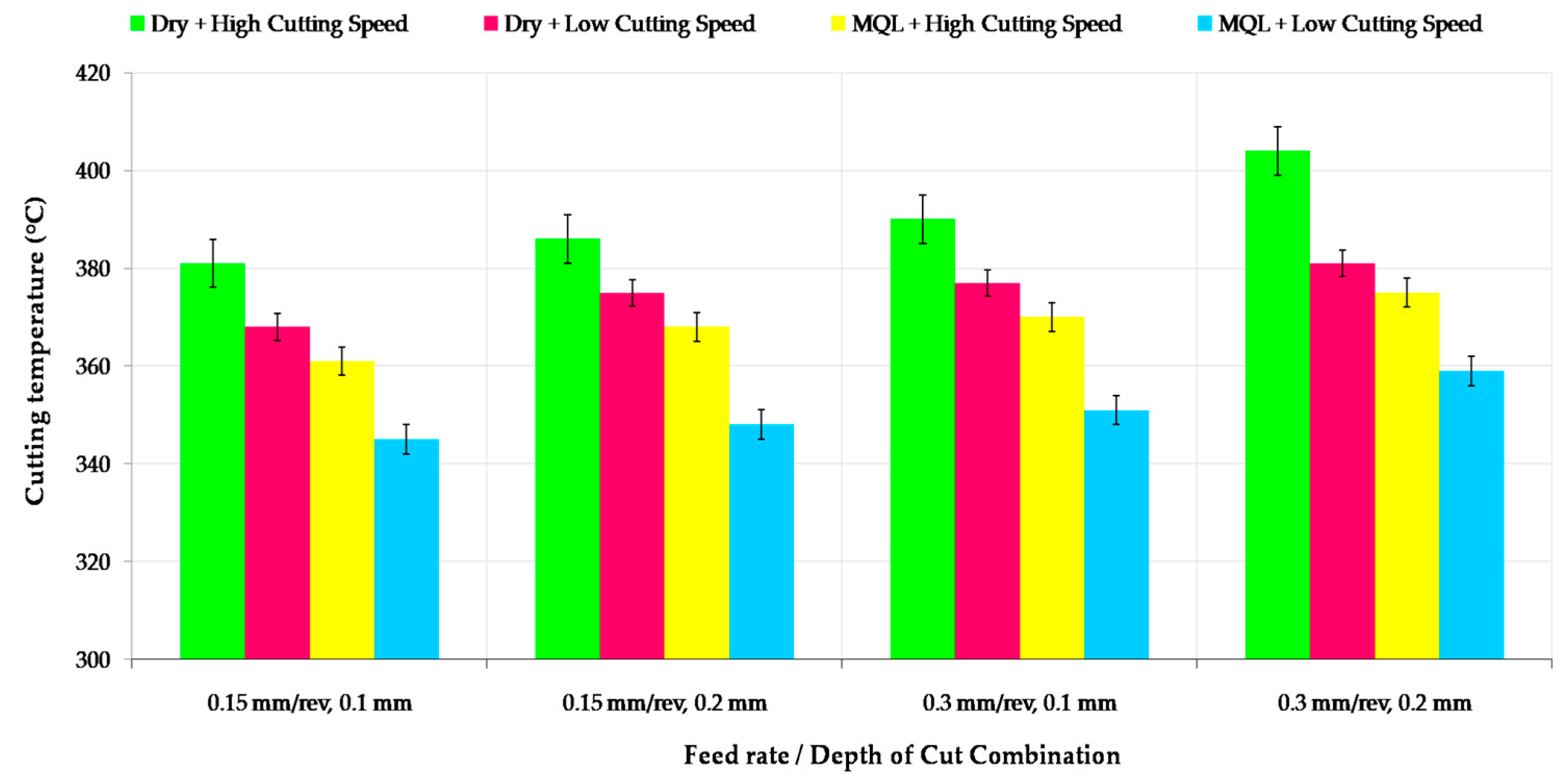

3.3. Evaluation of Cutting Temperatures

3.4. Evaluation of Chip Shape

4. Conclusions

- MQL-assisted machining can lead to improving machinability performance as it reduces the temperature generated during the machining process. This is not only beneficial for decreasing temperature, but it also helps to reduce cutting force.

- Cutting speed is a significant parameter of cutting force in both dry and MQL environment conditions. There was a sharp increase in cutting force depending on the increase in feed rate while the effect of cutting speed was lower at low feed rate.

- The greatest effect on the machining parameters of the cutting medium was observed in the surface roughness value. An improvement of approximately 2.5 times has been achieved. High feed rate and dry cutting parameters have created a situation that increases the surface roughness.

- Temperatures are relatively lower (358 °C) in the MQL environment which provides good transportation of cutting fluid at the cutting region, especially the tool-chip interface. At low cutting speeds, the temperature drops to 345 °C degrees. Results showed that the cutting speed was the most influential parameter on tool tip temperature.

- Segmented-short chip formation, which allows the heat generated during cutting in the environment to be removed, was obtained during machining in the MQL environment.

- Sustainable machining process can be realized as the reduction in cutting force will reduce power consumption.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gardner, L. The use of stainless steel in structures. Prog. Struct. Eng. Mater. 2005, 7, 45–55. [Google Scholar] [CrossRef]

- Rossi, B. Discussion on the use of stainless steel in constructions in view of sustainability. Thin-Walled Struct. 2014, 83, 182–189. [Google Scholar] [CrossRef] [Green Version]

- Cunat, P.-J. Alloying elements in stainless steel and other chromium-containing alloys. Euro Inox 2004, 2004, 1–24. [Google Scholar]

- Kumar, B.R.; Sharma, S.; Munda, P.; Minz, R. Structure and microstructure evolution of a ternary Fe–Cr–Ni alloy akin to super martensitic stainless steel. Mater. Des. 2013, 50, 392–398. [Google Scholar] [CrossRef]

- Davis, J.R. Metals Handbook: Machining; ASM International: New York, NY, USA, 1989. [Google Scholar]

- Gao, F.; Liu, Z.Y. Development of Very Tough Ferritic Stainless Steels by Optimizing the Recrystallized Microstructure. Mater. Sci. Forum 2013, 753, 526–529. [Google Scholar] [CrossRef]

- Haghdadi, N.; Cizek, P.; Hodgson, P.; Tari, V.; Rohrer, G.; Beladi, H. Effect of ferrite-to-austenite phase transformation path on the interface crystallographic character distributions in a duplex stainless steel. Acta Mater. 2018, 145, 196–209. [Google Scholar] [CrossRef]

- Seetharaman, V.; Sundararaman, M.; Krishnan, R. Precipitation hardening in a PH 13-8 Mo stainless steel. Mater. Sci. Eng. 1981, 47, 1–11. [Google Scholar] [CrossRef]

- Järvenpää, A.; Ghosh, S.; Khosravifard, A.; Jaskari, M.; Hamada, A. A new processing route to develop nano-grained structure of a TRIP-aided austenitic stainless-steel using double reversion fast-heating annealing. Mater. Sci. Eng. A 2021, 808, 140917. [Google Scholar] [CrossRef]

- Sedriks, A. Corrosion resistance of austenitic Fe-Cr-Ni-Mo alloys in marine environments. Int. Met. Rev. 1982, 27, 321–353. [Google Scholar] [CrossRef]

- McHenry, H. The properties of austenitic stainless steel at cryogenic temperatures. In Austenitic Steels at Low Temperatures; Springer: Boston, MA, USA, 1983; pp. 1–27. [Google Scholar]

- Handbook, M.M.C.A.P. Sandvik-Coromant Co. Inc.: Sandviken, Sweden, 1997. Available online: https://www.sandvik.coromant.com/en-gb/downloads?filter=%7B%22refiners%22:%7B%22languages%22:%5B%22en-gb%22%5D,%22categories%22:%5B%5D%7D%7D (accessed on 23 May 2023).

- Korkut, I.; Kasap, M.; Ciftci, I.; Seker, U. Determination of optimum cutting parameters during machining of AISI 304 austenitic stainless steel. Mater. Des. 2004, 25, 303–305. [Google Scholar] [CrossRef]

- Jiang, L.; Roos, Å.; Liu, P. The influence of austenite grain size and its distribution on chip deformation and tool life during machining of AISI 304L. Metall. Mater. Trans. A 1997, 28, 2415–2422. [Google Scholar] [CrossRef]

- Ali, M.A.M.; Azmi, A.I.; Murad, M.N.; Zain, M.Z.M.; Khalil, A.N.M.; Shuaib, N.A. Roles of new bio-based nanolubricants towards eco-friendly and improved machinability of Inconel 718 alloys. Tribol. Int. 2020, 144, 106106. [Google Scholar] [CrossRef]

- Hong, S.Y.; Broomer, M. Economical and ecological cryogenic machining of AISI 304 austenitic stainless steel. Clean Prod. Process. 2000, 2, 157–166. [Google Scholar] [CrossRef]

- Haldar, B.; Joardar, H.; Louhichi, B.; Alsaleh, N.A.; Alfozan, A. A Comparative Machinability Study of SS 304 in Turning under Dry, New Micro-Jet, and Flood Cooling Lubrication Conditions. Lubricants 2022, 10, 359. [Google Scholar] [CrossRef]

- Pradeep, A.; Kavitha, N.; Rao, T.J.; Vijayakumar, S. Influence of nano alumina/vegetable oil based cutting fluid on MQL turning of stainless steel 304. Mater. Today Proc. 2022, 69, 658–661. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Y.; Liu, Z.; Zhang, S.; Wang, S.; Lin, Z. Effect of cutting parameters on the corrosion resistance of 7A04 aluminum alloy in high speed cutting. Vacuum 2023, 212, 111968. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, Z.; Yue, X.; Wang, P.; Zhai, Y. Water jet impact damage mechanism and dynamic penetration energy absorption of 2A12 aluminum alloy. Vacuum 2022, 206, 111532. [Google Scholar] [CrossRef]

- Ahmadi, M.; Pahlavani, M.; Rahmatabadi, D.; Marzbanrad, J.; Hashemi, R.; Afkar, A. An exhaustive evaluation of fracture toughness, microstructure, and mechanical characteristics of friction stir welded Al6061 alloy and parameter model fitting using response surface methodology. J. Mater. Eng. Perform. 2022, 31, 3418–3436. [Google Scholar] [CrossRef]

- Ciftci, I. Machining of austenitic stainless steels using CVD multi-layer coated cemented carbide tools. Tribol. Int. 2006, 39, 565–569. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, R.; Kumar, S.; Verma, P. A review on machining performance of AISI 304 steel. Mater. Today Proc. 2022, 56, 2945–2951. [Google Scholar] [CrossRef]

- De, S.; Chakraborty, K. The machining behaviour of Cr-Mn austenitic stainless steel. Mater. Today Proc. 2022. [Google Scholar] [CrossRef]

- Singh, T.; Dureja, J.; Dogra, M.; Bhatti, M.S. Machining performance investigation of AISI 304 austenitic stainless steel under different turning environments. Int. J. Automot. Mech. Eng. 2018, 15, 5837–5862. [Google Scholar] [CrossRef]

- Muthuswamy, P. Investigation on sustainable machining characteristics of tools with serrated cutting edges in face milling of AISI 304 Stainless Steel. Procedia CIRP 2022, 105, 865–871. [Google Scholar] [CrossRef]

- Ahmed, Y.S.; Paiva, J.M.; Bose, B.; Veldhuis, S.C. New observations on built-up edge structures for improving machining performance during the cutting of superduplex stainless steel. Tribol. Int. 2019, 137, 212–227. [Google Scholar] [CrossRef]

- Seid Ahmed, Y.; Fox-Rabinovich, G.; Mario Paiva, J.; Wagg, T.; Clarence Veldhuis, S. Effect of built-up edge formation during stable state of wear in AISI 304 stainless steel on machining performance and surface integrity of the machined part. Materials 2017, 10, 1230. [Google Scholar] [CrossRef]

- Ahmed, Y.S.; Arif, A.; Veldhuis, S.C. Application of the wavelet transform to acoustic emission signals for built-up edge monitoring in stainless steel machining. Measurement 2020, 154, 107478. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K. Application of surface modification techniques during hard turning: Present work and future prospects. Int. J. Refract. Met. Hard Mater. 2018, 76, 112–127. [Google Scholar] [CrossRef]

- Hong, S.Y. Lubrication mechanisms of LN2 in ecological cryogenic machining. Mach. Sci. Technol. 2006, 10, 133–155. [Google Scholar] [CrossRef]

- Nalbant, M.; Yildiz, Y. Effect of cryogenic cooling in milling process of AISI 304 stainless steel. Trans. Nonferrous Met. Soc. China 2011, 21, 72–79. [Google Scholar] [CrossRef]

- Mahdavinejad, R.; Saeedy, S. Investigation of the influential parameters of machining of AISI 304 stainless steel. Sadhana 2011, 36, 963–970. [Google Scholar] [CrossRef]

- Xavior, M.A.; Adithan, M. Determining the influence of cutting fluids on tool wear and surface roughness during turning of AISI 304 austenitic stainless steel. J. Mater. Process. Technol. 2009, 209, 900–909. [Google Scholar] [CrossRef]

- Xu, X.; Huang, S.; Wang, M.; Yao, W. A study on process parameters in end milling of AISI-304 stainless steel under electrostatic minimum quantity lubrication conditions. Int. J. Adv. Manuf. Technol. 2017, 90, 979–989. [Google Scholar] [CrossRef]

- Huang, S.; Wang, Z.; Xu, L.; Huang, C. Friction and Wear Characteristics of Aqueous ZrO2/GO Hybrid Nanolubricants. Lubricants 2022, 10, 109. [Google Scholar] [CrossRef]

- Wu, H.; Jia, F.; Zhao, J.; Huang, S.; Wang, L.; Jiao, S.; Huang, H.; Jiang, Z. Effect of water-based nanolubricant containing nano-TiO2 on friction and wear behaviour of chrome steel at ambient and elevated temperatures. Wear 2019, 426, 792–804. [Google Scholar] [CrossRef]

- Huang, S.; Lin, W.; Li, X.; Fan, Z.; Wu, H.; Jiang, Z.; Huang, H. Roughness-dependent tribological characteristics of water-based GO suspensions with ZrO2 and TiO2 nanoparticles as additives. Tribol. Int. 2021, 161, 107073. [Google Scholar] [CrossRef]

- Huang, H.; Li, X.; Mu, D.; Lawn, B.R. Science and art of ductile grinding of brittle solids. Int. J. Mach. Tools Manuf. 2021, 161, 103675. [Google Scholar] [CrossRef]

- Li, C.; Li, X.; Huang, S.; Li, L.; Zhang, F. Ultra-precision grinding of Gd3Ga5O12 crystals with graphene oxide coolant: Material deformation mechanism and performance evaluation. J. Manuf. Process. 2021, 61, 417–427. [Google Scholar] [CrossRef]

- Veiga, F.; Arizmendi, M.; Jiménez, A.; Del Val, A.G. Analytical thermal model of orthogonal cutting process for predicting the temperature of the cutting tool with temperature-dependent thermal conductivity. Int. J. Mech. Sci. 2021, 204, 106524. [Google Scholar] [CrossRef]

- Li, C.; Piao, Y.; Hu, Y.; Wei, Z.; Li, L.; Zhang, F. Modelling and experimental investigation of temperature field during fly-cutting of KDP crystals. Int. J. Mech. Sci. 2021, 210, 106751. [Google Scholar] [CrossRef]

- Li, B.; Zhang, R. Analytical prediction of cutting forces in cylindrical turning of 304 stainless steel using unequal division shear zone theory. Int. J. Adv. Manuf. Technol. 2023, 124, 3201–3215. [Google Scholar] [CrossRef]

- Phanphet, S.; Bangphan, S. Application of Full Factorial Design for Optimization of Production Process by Turning Machine. J. Tianjin Univ. Sci. Technol 2021, 54, 35–55. [Google Scholar]

- Youssef, Y.A.; Beauchamp, Y.; Thomas, M. Comparison of a full factorial experiment to fractional and Taguchi designs in a lathe dry turning operation. Comput. Ind. Eng. 1994, 27, 59–62. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. ANOVA and fuzzy rule based evaluation and estimation of flank wear, temperature and acoustic emission in turning. CIRP J. Manuf. Sci. Technol. 2021, 35, 589–603. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Şap, S.; Uzun, M.; Kuntoğlu, M.; Salur, E.; Karabiber, A.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S. Estimation, optimization and analysis based investigation of the energy consumption in machinability of ceramic-based metal matrix composite materials. J. Mater. Res. Technol. 2022, 17, 2987–2998. [Google Scholar] [CrossRef]

| Element (wt.%) | C | Si | Mn | Cr | P | Mo | Ni | Al | Fe |

|---|---|---|---|---|---|---|---|---|---|

| AISI 304 | <0.08 | 0.5 | 2 | 18.5 | 0.1 | 0.2 | 8 | 0.02 | Bal. |

| Cutting Parameters | Levels | |

|---|---|---|

| I | II | |

| Cutting speed (m/min) | 30 | 60 |

| Depth of cut (mm) | 0.1 | 0.2 |

| Feed rate (mm/rev) | 0.15 | 0.3 |

| Cutting environment | Dry | MQL |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Binali, R.; Demirpolat, H.; Kuntoğlu, M.; Salur, E. Different Aspects of Machinability in Turning of AISI 304 Stainless Steel: A Sustainable Approach with MQL Technology. Metals 2023, 13, 1088. https://doi.org/10.3390/met13061088

Binali R, Demirpolat H, Kuntoğlu M, Salur E. Different Aspects of Machinability in Turning of AISI 304 Stainless Steel: A Sustainable Approach with MQL Technology. Metals. 2023; 13(6):1088. https://doi.org/10.3390/met13061088

Chicago/Turabian StyleBinali, Rüstem, Havva Demirpolat, Mustafa Kuntoğlu, and Emin Salur. 2023. "Different Aspects of Machinability in Turning of AISI 304 Stainless Steel: A Sustainable Approach with MQL Technology" Metals 13, no. 6: 1088. https://doi.org/10.3390/met13061088