Surface Engineering of Metals: Techniques, Characterizations and Applications

Abstract

:1. Introduction

2. Techniques for Surface Engineering of Metals

2.1. Physical Techniques

2.2. Chemical Techniques

3. Characterization Methods for Surface Engineering

3.1. Microstructural Characterization

3.2. Surface Topography Analysis

3.3. Mechanical and Tribological Characterization

4. Applications of Surface Engineering in Industry

4.1. Aerospace and Defense

4.2. Automotive Sector

4.3. Electronics and Semiconductor Industry

4.4. Biomedical and Healthcare Sector

4.5. Energy Applications

5. Challenges and Future Directions

5.1. Limitations of Current Surface Engineering Techniques

5.2. Emerging Trends and Technologies in the Field

5.3. Potential Areas for Future Research and Development

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ramezani, M.; Pasang, T.; Chen, Z.; Neitzert, T.; Au, D. Evaluation of carbon diffusion in heat treatment of H13 tool steel under different atmospheric conditions. J. Mater. Res. Technol. 2015, 4, 114–125. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Ramezani, M.; Chen, Z.; Singamneni, S. Effects of Process Parameters on Temperature and Stress Distributions During Selective Laser Melting of Ti–6Al–4V. Trans. Indian Inst. Met. 2019, 72, 3201–3214. [Google Scholar] [CrossRef]

- Awang, M.; Khalili, A.A.; Pedapati, S.R. A review: Thin protective coating for wear protection in high-temperature application. Metals 2020, 10, 42. [Google Scholar] [CrossRef] [Green Version]

- Riquelme, A.; Rodrigo, P. An introduction on the laser cladding coatings on magnesium alloys. Metals 2021, 11, 1993. [Google Scholar] [CrossRef]

- Fotovvati, B.; Namdari, N.; Dehghanghadikolaei, A. On coating techniques for surface protection: A review. J. Manuf. Mater. Process. 2019, 3, 28. [Google Scholar] [CrossRef] [Green Version]

- Butt, M.A. Thin-Film Coating Methods: A Successful Marriage of High-Quality and Cost-Effectiveness—A Brief Exploration. Coatings 2022, 12, 1115. [Google Scholar] [CrossRef]

- Schalk, N.; Tkadletz, M.; Mitterer, C. Hard coatings for cutting applications: Physical vs. chemical vapor deposition and future challenges for the coatings community. Surf. Coat. Technol. 2022, 429, 127949. [Google Scholar] [CrossRef]

- Panwar, A.S.; Singh, A.; Sehgal, S. Material characterization techniques in engineering applications: A review. Mater. Today Proc. 2020, 28, 1932–1937. [Google Scholar] [CrossRef]

- Li, H.; Ramezani, M.; Chen, Z.W. Dry sliding wear performance and behaviour of powder bed fusion processed Ti–6Al–4V alloy. Wear 2019, 440–441, 203103. [Google Scholar] [CrossRef]

- Ghezzi, D.; Boi, M.; Sassoni, E.; Valle, F.; Giusto, E.; Boanini, E.; Baldini, N.; Cappelletti, M.; Graziani, G. Customized biofilm device for antibiofilm and antibacterial screening of newly developed nanostructured silver and zinc coatings. J. Biol. Eng. 2023, 17, 18. [Google Scholar] [CrossRef]

- Leitans, A.; Jansons, E.; Lungevics, J.; Kundzins, K.; Boiko, I.; Kanders, U.; Kovalenko, V.; Linins, O. Tribological and Micromechanical Properties of the Nanostructured Carbonitride/Nitride Coatings of Transition Metals Alloyed by Hf and Nb. Coatings 2023, 13, 552. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Bublikov, J.; Seleznev, A.; Sotova, C.; Rykunov, A. Investigation of the Properties of Multilayer Nanostructured Coating Based on the (Ti,Y,Al)N System with High Content of Yttrium. Coatings 2023, 13, 335. [Google Scholar] [CrossRef]

- Huang, N.; Wang, Y.; Zhang, Y.; Liu, L.; Yuan, N.; Ding, J. Multifunctional coating on magnesium alloy: Superhydrophobic, self-healing, anti-corrosion and wear-resistant. Surf. Coat. Technol. 2023, 463, 129539. [Google Scholar] [CrossRef]

- Nazarzade, K.; Naderi, R.; Mahdavian, M. Fabrication of corrosion-resistant conversion coating based on ZIF-8 on electro-galvanized steel utilizing pulse electrodeposition technique. Surf. Coat. Technol. 2023, 457, 129292. [Google Scholar] [CrossRef]

- Mo, Y.; Ma, X.; Wang, S.; Zhong, H.; Yang, J.; Cao, Z. In-situ constructing and EDTA-enhancing of meta-aluminate passivation films on electroplated zinc surfaces. Colloids Surf. A Physicochem. Eng. Asp. 2023, 657, 130573. [Google Scholar] [CrossRef]

- Kozaderov, O.; Światowska, J.; Dragoe, D.; Burliaev, D.; Volovitch, P. Effect of Cr(III) passivation layer on surface modifications of zinc-nickel coatings in chloride solutions. J. Solid State Electrochem. 2021, 25, 1161–1173. [Google Scholar] [CrossRef]

- Katić, J.; Krivačić, S.; Petrović, Ž.; Mikić, D.; Marciuš, M. Titanium Implant Alloy Modified by Electrochemically Deposited Functional Bioactive Calcium Phosphate Coatings. Coatings 2023, 13, 640. [Google Scholar] [CrossRef]

- Nikolova, M.P.; Apostolova, M.D. Advances in Multifunctional Bioactive Coatings for Metallic Bone Implants. Materials 2023, 16, 183. [Google Scholar] [CrossRef]

- Costa, R.C.; Nagay, B.E.; Dini, C.; Borges, M.H.; Miranda, L.F.; Cordeiro, J.M.; Souza, J.G.; Sukotjo, C.; Cruz, N.C.; Barão, V.A. The race for the optimal antimicrobial surface: Perspectives and challenges related to plasma electrolytic oxidation coating for titanium-based implants. Adv. Colloid Interface Sci. 2023, 311, 102805. [Google Scholar] [CrossRef]

- Wang, C.; Jiu, H.; Zhang, L.; Xu, R.; Che, S.; Guo, Z.; Han, Y.; Ma, J.; Li, H.; Guo, F. Carbon coating hollow NiS nanoparticles anchored on Ti3C2 nanosheet as high-performance anode for lithium-ion batteries. J. Alloys Compd. 2023, 956, 170332. [Google Scholar] [CrossRef]

- Su, Y.L.; Kao, W.H.; Chang, G.Y. Tribological, Anti-corrosion, and Electrical Conductivity Properties of CrCx Coatings Deposited on Stainless Steel 316L and Used as Metal Bipolar Plates for Fuel Cells. J. Mater. Eng. Perform. 2023, 32, 3739–3754. [Google Scholar] [CrossRef]

- Bonu, V.; Barshilia, H.C. High-Temperature Solid Particle Erosion of Aerospace Components: Its Mitigation Using Advanced Nanostructured Coating Technologies. Coatings 2022, 12, 1979. [Google Scholar] [CrossRef]

- Zhang, S.N.; Chen, Z.; Arfaei, B. Graphene Coating as a Corrosion Protection Barrier for Metallic Terminals in Automotive Environments. SAE Int. J. Adv. Curr. Pract. Mobil. 2021, 3, 3176–3183. [Google Scholar] [CrossRef]

- Wasekar, N.P.; Bathini, L.; Ramakrishna, L.; Rao, D.S.; Padmanabham, G. Pulsed electrodeposition, mechanical properties and wear mechanism in Ni-W/SiC nanocomposite coatings used for automotive applications. Appl. Surf. Sci. 2020, 527, 146896. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Su, X.; Xiao, R.; Cheng, H. Polarization Maintaining Fiber Temperature and Stress Gradient Sensitization Sensor Based on Semiconductor-Metal–Polymer Three-Layer Film Coating. ACS Appl. Mater. Interfaces 2022, 14, 20053–20061. [Google Scholar] [CrossRef]

- Li, C.-J.; Luo, X.-T.; Dong, X.-Y.; Zhang, L.; Li, C.-X. Recent Research Advances in Plasma Spraying of Bulk-Like Dense Metal Coatings with Metallurgically Bonded Lamellae. J. Therm. Spray Technol. 2022, 31, 5–27. [Google Scholar] [CrossRef]

- Yao, H.-L.; Xia, J.; Yi, D.-L.; Yang, C.; Zhang, M.-X.; Bai, X.-B.; Chen, Q.-Y.; Wang, H.-T.; Li, S.-B. Microstructure and Corrosion Properties of Biodegradable Mg/MgO Composite Coating on Mg Alloy Prepared by High Velocity Suspension Flame Spraying. J. Therm. Spray Technol. 2021, 30, 1544–1556. [Google Scholar] [CrossRef]

- Liu, B.; Xiao, F.; Zhu, H.; Tang, M. Promising WC-30WB-10Co Cemented Carbide Coating with Improved Density and Hardness Deposited by High Velocity Oxy-Fuel Spraying: Microstructure and Mechanical Properties. J. Mater. Eng. Perform. 2023, 32, 6405–6411. [Google Scholar] [CrossRef]

- Lee, H.-S.; Singh, J.K. Deposition and corrosion studies of plasma arc thermal sprayed Zn and 85Zn–15Al films on steel surface. J. Mater. Sci. 2022, 57, 19650–19665. [Google Scholar] [CrossRef]

- Leonov, A.A.; Denisova, Y.A.; Denisov, V.V.; Syrtanov, M.S.; Shmakov, A.N.; Savostikov, V.M.; Teresov, A.D. Structure and Properties of CrN/TiN Multi-Layer Coatings Obtained by Vacuum-Arc Plasma-Assisted Deposition Method. Coatings 2023, 13, 351. [Google Scholar] [CrossRef]

- Li, H.; Chen, Z.W.; Ramezani, M. Wear behaviours of PVD-TiN coating onTi-6Al-4V alloy processed by laser powder bed fusion or conventionally processed. Int. J. Adv. Manuf. Technol. 2021, 113, 1389–1399. [Google Scholar] [CrossRef]

- Zhang, M.; Zhou, T.; Li, H.; Liu, Q. UV-durable superhydrophobic ZnO/SiO2 nanorod arrays on an aluminum substrate using catalyst-free chemical vapor deposition and their corrosion performance. Appl. Surf. Sci. 2023, 623, 157085. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, K.; Qi, Y.; Liu, Z. Chemical Vapor Deposition Method for Graphene Fiber Materials. Wuli Huaxue Xuebao/Acta Phys.-Chim. Sin. 2020, 38, 2006046. [Google Scholar] [CrossRef]

- Seo, J.; Kim, J.; Lee, J.; Koo, D.; Jeong, G.; Choi, Y.; bin Son, E.; Park, H. Intergranular Diffusion-Assisted Liquid-Phase Chemical Vapor Deposition for Wafer-Scale Synthesis of Patternable 2D Semiconductors. Adv. Funct. Mater. 2022, 32, 2205695. [Google Scholar] [CrossRef]

- Su, W.; Cui, X.; Jin, G.; Liu, C.; Liu, E.; Zhao, H.; Cao, B. Effects of different Y compounds on the microstructure and properties of laser cladding NiTi coatings in a semi-open environment. Intermetallics 2023, 160, 107936. [Google Scholar] [CrossRef]

- Brover, G.I.; Shcherbakova, E.E. Aspects of Structure Formation in Surface Layers of Steel after Laser Alloying from Various Coatings. Metallurgist 2022, 66, 672–680. [Google Scholar] [CrossRef]

- Kanazawa, T.; Hayakawa, M.; Vinas, D.; Tahara, Y.; Hata, N.; Yoshimoto, M. Sustainable technology for remanufacturing of carburized steels by laser hardening. J. Mater. Res. Technol. 2023, 24, 39–48. [Google Scholar] [CrossRef]

- Dashtbozorg, B.; Penchev, P.; Romano, J.-M.; Li, X.; Sammons, R.L.; Dimov, S.; Dong, H. Development of surfaces with antibacterial durability through combined S phase plasma hardening and athermal femtosecond laser texturing. Appl. Surf. Sci. 2021, 565, 150594. [Google Scholar] [CrossRef]

- Comparini, A.; Del Pace, I.; Giurlani, W.; Emanuele, R.; Verrucchi, M.; Bonechi, M.; Innocenti, M. Electroplating on Al6082 Aluminium: A New Green and Sustainable Approach. Coatings 2022, 13, 13. [Google Scholar] [CrossRef]

- Zhang, Z.; Kitada, A.; Fukami, K.; Murase, K. Aluminum Electroplating on AZ31 Magnesium Alloy with Acetic Anhydride Pretreatment. Acta Met. Sin. Engl. Lett. 2022, 35, 1996–2006. [Google Scholar] [CrossRef]

- Tian, M.; Jian, Z.; Hai, R.; Chang, F. Non-isothermal crystallization kinetics of amorphous electroless nickel-phosphorus alloy plating. J. Therm. Anal. Calorim. 2023, 148, 1959–1970. [Google Scholar] [CrossRef]

- Dai, G.; Wu, S.; Huang, X.; Wang, M.; Wu, R. Research on the coating formation of Al-induced electroless plating on metallic surfaces. J. Mater. Sci. 2023, 58, 3768–3789. [Google Scholar] [CrossRef]

- Koli, P.B.; Kapadnis, K.H.; Deshpande, U.G.; Tupe, U.J.; Shinde, S.G.; Ingale, R.S. Fabrication of thin film sensors by spin coating using sol-gel LaCrO3 Perovskite material modified with transition metals for sensing environmental pollutants, greenhouse gases and relative humidity. Environ. Chall. 2021, 3, 100043. [Google Scholar] [CrossRef]

- Gautam, A.; Raju, K.R.C.S.; Gobi, K.V.; Subasri, R. Effect of Transition Metal and Different Rare-Earth Inhibitors-Based Sol–gel Coatings on Corrosion Protection of Mild Steel. Met. Mater. Int. 2023. [Google Scholar] [CrossRef]

- Pratima, B.; Subrahmanyam, A. Protective coatings on copper using as-deposited sol-gel TiO2—SiO2 films. Mater. Today Proc. 2023, 80, 1061–1065. [Google Scholar] [CrossRef]

- Lidsky, D.; Cain, J.M.; Hutchins-Delgado, T.; Lu, T.M. Inverse metal-assisted chemical etching of germanium with gold and hydrogen peroxide. Nanotechnology 2023, 34, 065302. [Google Scholar] [CrossRef] [PubMed]

- Rengarajan, S.; Ramaraj, B.K.; Paramashivan, S.S.; Velusamy, S. Oxidation behavior of near nanostructured coating developed by the HVOF process. Mater. Corros. 2023, 74, 482–492. [Google Scholar] [CrossRef]

- Chen, J.; An, Y.; Liu, G.; Chen, G.; Zhao, X.; Jia, L. Tribological Performance and Thermal Stability of a Novel Cold Sprayed Nanostructured Ni-based Lubrication Coating. J. Therm. Spray Technol. 2022, 31, 1702–1711. [Google Scholar] [CrossRef]

- Mahana, D.; Mauraya, A.K.; Singh, P.; Muthusamy, S.K. Evolution of CuO thin films through thermal oxidation of Cu films prepared by physical vapour deposition techniques. Solid State Commun. 2023, 366–367, 115152. [Google Scholar] [CrossRef]

- Monti, J.M.; Stewart, J.A.; Custer, J.O.; Adams, D.P.; Depla, D.; Dingreville, R. Linking simulated polycrystalline thin film microstructures to physical vapor deposition conditions. Acta Mater. 2023, 245, 118581. [Google Scholar] [CrossRef]

- Uno, K.; Ohta, M. Control of Al composition of mist chemical vapor deposition grown α-(AlGa)2O3 alloy thin films by acetylacetonation of Al ion. Jpn. J. Appl. Phys. 2023, 62, SF1026. [Google Scholar] [CrossRef]

- Zhao, Q.; Hu, G.; Huang, R.; Qiang, L.; Zhang, X. Iodide-induced galvanic replacement of nickel film on copper as activator for electroless nickel-phosphorus plating. Mater. Lett. 2022, 314, 131833. [Google Scholar] [CrossRef]

- El Hadad, A.; García-Galván, F.; Mezour, M.; Hickman, G.; Soliman, I.; Jiménez-Morales, A.; Barranco, V.; Galván, J.; Perry, C. Organic-inorganic hybrid coatings containing phosphorus precursors prepared by sol–gel on Ti6Al4V alloy: Electrochemical and in-vitro biocompatibility evaluation. Prog. Org. Coat. 2020, 148, 105834. [Google Scholar] [CrossRef]

- Perrin, F.; Ziarelli, F.; Dupuis, A. Relation between the corrosion resistance and the chemical structure of hybrid sol-gel coatings with interlinked inorganic-organic network. Prog. Org. Coat. 2020, 141, 105532. [Google Scholar] [CrossRef]

- Samanta, S.; Jin, S.; Lee, C.-H.; Lee, S.-S.; Struyf, H.; Kim, T.-G.; Park, J.-G. Effect of ammonium halide salts on wet chemical nanoscale etching and polishing of InGaAs surfaces for advanced CMOS devices. Mater. Sci. Semicond. Process. 2023, 161, 107469. [Google Scholar] [CrossRef]

- Li, H.; Chen, Z.W.; Fiedler, H.; Ramezani, M. Wear behaviour of n ion implanted Ti-6Al-4V alloy processed by selective laser melting. Metals 2021, 11, 1639. [Google Scholar] [CrossRef]

- Watanabe, Y.; Capaz, R.B.; Simao, R.A. Surface characterization using Friction Force Microscopy and the Jarzynski equality. Appl. Surf. Sci. 2023, 607, 155070. [Google Scholar] [CrossRef]

- Kuznetsova, T.; Lapitskaya, V.; Warcholinski, B.; Gilewicz, A.; Chizhik, S. Friction and Wear of ZrN Coatings under Conditions of Microcontact Using Atomic-Force Microscopy. J. Frict. Wear 2020, 41, 287–294. [Google Scholar] [CrossRef]

- Mehta, A.; Vasudev, H.; Singh, S. Sustainable manufacturing approach with novel thermal barrier coatings in lowering CO2 emissions: Performance analysis with probable solutions. Int. J. Interact. Des. Manuf. (IJIDeM) 2023. [Google Scholar] [CrossRef]

- Mehta, A.; Vasudev, H.; Singh, S.; Prakash, C.; Saxena, K.K.; Linul, E.; Buddhi, D.; Xu, J. Processing and Advancements in the Development of Thermal Barrier Coatings: A Review. Coatings 2022, 12, 1318. [Google Scholar] [CrossRef]

- Park, S.M.; Nahm, S.; Oh, Y.S. Thermal durability of ytterbium silicate environmental barrier coating prepared by suspension plasma spray. J. Korean Ceram. Soc. 2021, 58, 192–200. [Google Scholar] [CrossRef]

- Molak, R.; Topolski, K.; Spychalski, M.; Dulińska-Molak, I.; Morończyk, B.; Pakieła, Z.; Nieużyła, L.; Mazurkiewicz, M.; Wojucki, M.; Gebeshuber, A.; et al. Functional properties of the novel hybrid coatings combined of the oxide and DLC layer as a protective coating for AZ91E magnesium alloy. Surf. Coat. Technol. 2019, 380, 125040. [Google Scholar] [CrossRef]

- Marin, E.; Lanzutti, A.; Nakamura, M.; Zanocco, M.; Zhu, W.; Pezzotti, G.; Andreatta, F. Corrosion and scratch resistance of DLC coatings applied on chromium molybdenum steel. Surf. Coat. Technol. 2019, 378, 124944. [Google Scholar] [CrossRef]

- Kai-Hui, D.; Ying-Wei, S.; En-Hou, H. Research progress on the preparation of wear-resistant micro-arc oxidation coatings on titanium alloys. Surf. Technol. 2021, 50, 57–65. [Google Scholar] [CrossRef]

- Yang, C.; Zhu, J.; Cui, S.; Chen, P.; Wu, Z.; Ma, Z.; Fu, R.K.; Tian, X.; Chu, P.K.; Wu, Z. Wear and corrosion resistant coatings prepared on LY12 aluminum alloy by plasma electrolytic oxidation. Surf. Coat. Technol. 2021, 409, 126885. [Google Scholar] [CrossRef]

- Peñas-Caballero, M.; Martín-Cordón, J.; Barranco, V.; Galván, J.C.; Santana, M.H.; Lopez-Manchado, M.A.; Verdejo, R. Corrosion control by autonomous self-healing epoxy coatings based on superabsorbent healing agents. Prog. Org. Coat. 2023, 182, 107600. [Google Scholar] [CrossRef]

- Huangfu, H.; Guo, X.; Li, N.; Xiong, Y.; Huang, Y.; Zhang, J.; Wang, L. A smart composite coating with self-reporting and self-healing functions to enhance corrosion protection for magnesium alloys. Prog. Org. Coat. 2023, 181, 107598. [Google Scholar] [CrossRef]

- Prochazka, J.; Studeny, Z.; Nguyen, C.H. Wear resistance enhancement of case-hardening steels by utilizing plasma nitriding in military applications. In Proceedings of the (2021) METAL 2021—30th Anniversary International Conference on Metallurgy and Materials, Brno, Czech Republic, 26–28 May 2021; pp. 612–620. [Google Scholar] [CrossRef]

- Garois, S.; Daoud, M.; Chinesta, F. Data-Driven Inverse Problem for Optimizing the Induction Hardening Process of C45 Spur-Gear. Metals 2023, 13, 997. [Google Scholar] [CrossRef]

- Aprilia, A.; Maharjan, N.; Zhou, W. Decarburization in Laser Surface Hardening of AISI 420 Martensitic Stainless Steel. Materials 2023, 16, 939. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, S.; Ao, N.; Zhou, L.; Wang, L.; Liu, D. The effect of gradient order on impact toughness of carbon S38C axle steels with induction hardening. Eng. Fail. Anal. 2023, 149, 107254. [Google Scholar] [CrossRef]

- Pei, L.; Lin, D.; Yuan, S.; Lu, R.; Bai, Z.; Sun, Y.; Zhu, Y.; Jiang, Y.; Zhu, J.; Wang, H. A multifunctional and long-term waterborne anti-corrosion coating with excellent ‘hexagonal warrior’ properties. Chem. Eng. J. 2023, 457, 141158. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, H.; Guo, S. Sandwich-Structured Surface Coating of a Silver-Decorated Electrospun Thermoplastic Polyurethane Fibrous Film for Excellent Electromagnetic Interference Shielding with Low Reflectivity and Favorable Durability. ACS Appl. Mater. Interfaces 2022, 14, 40351–40360. [Google Scholar] [CrossRef] [PubMed]

- Hernán, D.M.V.; Aida, M.E.; Gilberto, B.G. Detailed study of the electrochemical behavior of low-reflectivity TiAlN coatings. Surf. Innov. 2020, 9, 293–307. [Google Scholar] [CrossRef]

- Picas, J.; Menargues, S.; Martin, E.; Baile, M. Cobalt free metallic binders for HVOF thermal sprayed wear resistant coatings. Surf. Coat. Technol. 2023, 456, 129243. [Google Scholar] [CrossRef]

- Ganvir, A.; Jahagirdar, A.R.; Mulone, A.; Örnfeldt, L.; Björklund, S.; Klement, U.; Joshi, S. Novel utilization of liquid feedstock in high velocity air fuel (HVAF) spraying to deposit solid lubricant reinforced wear resistant coatings. J. Mater. Process. Technol. 2021, 295, 117203. [Google Scholar] [CrossRef]

- Bouabibsa, I.; Lamri, S.; Sanchette, F. Structure, mechanical and tribological properties of Me-doped diamond-like carbon (DLC) (Me = Al, Ti, or Nb) hydrogenated amorphous carbon coatings. Coatings 2018, 8, 370. [Google Scholar] [CrossRef] [Green Version]

- Anderson, N.; Zhang, B.; Meng, A.; Zhang, X.; Lijesh, K.; Khonsari, M.; Meng, W. Cr-containing diamond-like carbon coatings deposited on 316 stainless steel substrates: Characterization and interfacial fracture toughness measurements. Surf. Coat. Technol. 2023, 462, 129462. [Google Scholar] [CrossRef]

- Peng, J.; Liao, J.; Zhang, G.; Huang, J.; Qiu, X. Microstructure evolution and mechanical performance of tetrahedral amorphous carbon coatings with dense droplets during annealing. Mater. Chem. Phys. 2023, 301, 127697. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sheveiko, A.N.; Petrzhik, M.I. Approaches to Increasing the Adhesion Strength of Hard Wear-Resistant Nanostructured Coatings Based on the Ti–B–(Cr, Si, C)–N System. Prot. Met. Phys. Chem. Surfaces 2019, 55, 502–510. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Aksenenko, A.; Sitnikov, N.; Oganyan, G.; Seleznev, A.; Shevchenko, S. Effect of adhesion and the wear-resistant layer thickness ratio on mechanical and performance properties of ZrN—(Zr,Al,Si)N coatings. Surf. Coat. Technol. 2019, 357, 218–234. [Google Scholar] [CrossRef]

- Rashid, M.-U.; Tomkowski, R.; Archenti, A. Effect of Surface Pre-Treatment on the Adhesion between HiPIMS Thick Cu:CuCNx Coating and WC-Co Shim. Coatings 2022, 12, 1484. [Google Scholar] [CrossRef]

- Liu, D.; Li, J.; Jin, X.; Mu, R.; Yang, W. Effect of Coating Pre-Treatment on Surface Recrystallization of DD6 Single Crystal. Materials 2022, 15, 7004. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-K.; Kim, S.-M.; Lee, S.-Y. Influence of Interlayer Materials on the Mechanical Properties and Thermal Stability of a CrAlN Coating on a Tungsten Carbide Substrate. Coatings 2022, 12, 1134. [Google Scholar] [CrossRef]

- Sizova, O.V.; Teryukalova, N.V.; Leonov, A.A.; Denisova, Y.A.; Novitskaya, O.S.; Kolubaev, A.V. Influence of the Intermediate Layer on the Adhesion and Friction of Titanium-Based Nitrided Coatings on a Copper Substrate. Russ. Phys. J. 2022, 65, 1123–1129. [Google Scholar] [CrossRef]

- Ben Hassine, M.; Andrén, H.-O.; Iyer, A.H.; Lotsari, A.; Bäcke, O.; Stiens, D.; Janssen, W.; Manns, T.; Kümmel, J.; Halvarsson, M. Growth model for high-Al containing CVD TiAlN coatings on cemented carbides using intermediate layers of TiN. Surf. Coat. Technol. 2021, 421, 127361. [Google Scholar] [CrossRef]

- Avcı, B.; Kazmanlı, K.; Evren, B.; Ürgen, M. Contribution of galvanic coupling with TiN, TiAlN, and CrN to the corrosion of steel in neutral and acidic chloride solutions. Mater. Corros. 2023. [Google Scholar] [CrossRef]

- Burliaev, D.V.; Kozaderov, O.A.; Volovitch, P. Zinc-nickel alloy coatings: Electrodeposition kinetics, corrosion, and selective dissolution. A review. Kondens. Sredy Mezhfaznye Granitsy 2021, 23, 3–15. [Google Scholar] [CrossRef]

- Shekhanov, R.F.; Gridchin, S.N.; Balmasov, A.V. Electroplating and Physicochemical Properties of Zinc–Nickel Alloy Coatings from Ammonium Oxalate Electrolytes. Surf. Eng. Appl. Electrochem. 2020, 56, 427–431. [Google Scholar] [CrossRef]

- Pinto, J.; Quiroz, D.; Delvasto, P.; Blanco, S. Characterization of a zinc-nickel alloy coating obtained from an electrolytic bath produced with spent batteries as raw materials. J. Phys. Conf. Ser. 2018, 1119, 012005. [Google Scholar] [CrossRef] [Green Version]

- Lei, C.; Skouby, H.; Kellner, R.; Goosey, E.; Goosey, M.; Sellars, J.; Elliott, D.; Ryder, K.S. Barrel electroplating of Zn-Ni alloy coatings from a modified deep eutectic solvent. Trans. IMF 2022, 100, 63–71. [Google Scholar] [CrossRef]

- Lei, C.; Alesary, H.F.; Khan, F.; Abbott, A.P.; Ryder, K.S. Gamma-phase Zn-Ni alloy deposition by pulse-electroplating from a modified deep eutectic solution. Surf. Coat. Technol. 2020, 403, 126434. [Google Scholar] [CrossRef]

- Fashu, S.; Khan, R. Recent work on electrochemical deposition of Zn-Ni (-X) alloys for corrosion protection of steel. Anti-Corros. Methods Mater. 2019, 66, 45–60. [Google Scholar] [CrossRef]

- Xu, L.; Pi, L.; Dou, Y.; Cui, Y.; Mao, X.; Lin, A.; Fernandez, C.; Peng, C. Electroplating of Thick Hard Chromium Coating from a Trivalent Chromium Bath Containing a Ternary Complexing Agent: A Methodological and Mechanistic Study. ACS Sustain. Chem. Eng. 2020, 8, 15540–15549. [Google Scholar] [CrossRef]

- Ramelan, A.; Fauzi, A.; Rachmantyo, R.; Sasmita, F.; Lidya, L.; Eko, A.Z.; Nugroho, A.S. Effect of PEG addition and temperature on hard chromium coating using eco-friendly trivalent chromium. AIP Conf. Proc. 2020, 2262, 040019. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, D.; Liu, X.; Li, W.; Wang, Z.; Wang, Y.; Song, D.; Zhang, T.; Liu, J.; Wang, J. Self-healing nanocomposite coatings containing organic-inorganic inhibitors functionalized dendritic silica nanocontainers for synergistic corrosion protection of carbon steel. Colloids Surf. A Physicochem. Eng. Asp. 2023, 656, 130430. [Google Scholar] [CrossRef]

- Lin, X.-Y.; Yu, Y.-H.; Tse, M.-M.; Cheng, S.-H.; Liu, Y.-H.; Lu, K.-L. Semiconductive (Cu–S)n metal–organic framework incorporated polyimide nanocomposite coatings forming an oxide barrier for durable anticorrosion effects. Prog. Org. Coat. 2023, 180, 107562. [Google Scholar] [CrossRef]

- Ramesh, C.; Tyagi, P.; Kaswan, J.; Yadav, B.S.; Shukla, A.K.; Senthil Kumar, M.; Kushvaha, S.S. Effect of surface modification and laser repetition rate on growth, structural, electronic and optical properties of GaN nanorods on flexible Ti metal foil. RSC Adv. 2020, 10, 2113–2122. [Google Scholar] [CrossRef] [PubMed]

- Deng, K.; Wang, X.; Huang, S.; Li, P.; Jiang, Q.; Yin, H.; Fan, J.; Wei, K.; Zheng, Y.; Shi, J.; et al. Effective Suppression of Amorphous Ga2O and Related Deep Levels on the GaN Surface by High-Temperature Remote Plasma Pretreatments in GaN-Based Metal–Insulator–Semiconductor Electronic Devices. ACS Appl. Mater. Interfaces 2023, 15, 25058–25065. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, M.; Wu, Y.; Yang, M.; Lin, T.; He, P.; Paik, K.-W. A study on the oxygen plasma treatment on the peel adhesion strength and solder wettability of SnBi58 based anisotropic conductive films. In Proceedings of the 2019 Electronic Components and Technology Conference, Las Vegas, NV, USA, 28–31 May 2019; pp. 2022–2028. [Google Scholar] [CrossRef]

- Dong, M.; Li, M.; Hang, T. Application of Ultrathin Organic Insulating Films for Electronic Package. In Proceedings of the 2019 IEEE International Conference on Integrated Circuits, Technologies and Applications (ICTA), Chengdu, China, 13–15 November 2019. [Google Scholar] [CrossRef]

- Kencana, S.D.; Kuo, Y.-L.; Yen, Y.-W.; Schellkes, E.; Chuang, W. Improving the solder wettability via atmospheric plasma technology. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 2067–2071. [Google Scholar] [CrossRef]

- Yan, C.; Byrne, D.; Ondry, J.C.; Kahnt, A.; Moreno-Hernandez, I.A.; Kamat, G.A.; Liu, Z.-J.; Laube, C.; Crook, M.F.; Zhang, Y.; et al. Facet-selective etching trajectories of individual semiconductor nanocrystals. Sci. Adv. 2022, 8, eabq1700. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, B.; Xie, X.; Li, C.; Xu, Y.; Wang, H.; Wang, L. Three-dimensional independent CoZnAl-LDH nanosheets via asymmetric etching of Zn/Al dual ions for high-performance supercapacitors. J. Alloys Compd. 2021, 861, 157933. [Google Scholar] [CrossRef]

- Arora, H.; Jung, Y.; Venanzi, T.; Watanabe, K.; Taniguchi, T.; Hübner, R.; Schneider, H.; Helm, M.; Hone, J.C.; Erbe, A. Effective Hexagonal Boron Nitride Passivation of Few-Layered InSe and GaSe to Enhance Their Electronic and Optical Properties. ACS Appl. Mater. Interfaces 2019, 11, 43480–43487. [Google Scholar] [CrossRef] [PubMed]

- Kavinkumar, T.; Sivagurunathan, A.T.; Kim, D.-H. Construction of highly transparent, flexible, and robust solid-state symmetric supercapacitors using NiO electrodes roughened by conformal atomic layer deposition. Appl. Surf. Sci. 2023, 616, 156453. [Google Scholar] [CrossRef]

- Cheng, L.; Adinolfi, V.; Weeks, S.L.; Barabash, S.V.; Littau, K.A. Conformal deposition of GeTe films with tunable Te composition by atomic layer deposition. J. Vac. Sci. Technol. A 2019, 37, 020907. [Google Scholar] [CrossRef]

- Ma, Y.; Song, J.; Wang, X.; Liu, Y.; Zhou, J. Synthesis, microstructure and properties of magnetron sputtered lead zirconate titanate (Pzt) thin film coatings. Coatings 2021, 11, 944. [Google Scholar] [CrossRef]

- Shamma, K.; Albrithen, H.; Alodhayb, A. Thickness dependence of the response of metal-dioxide-based micromechanical sensors for sensitive gamma-ray detection. Appl. Radiat. Isot. 2022, 186, 110225. [Google Scholar] [CrossRef]

- Beaucejour, R.; D’agati, M.; Kalyan, K.; Olsson, R.H. Compensation of the Stress Gradient in Physical Vapor Deposited Al1−xScxN Films for Microelectromechanical Systems with Low Out-of-Plane Bending. Micromachines 2022, 13, 1169. [Google Scholar] [CrossRef]

- Chou, C.-H.; Nagarjuna, Y.; Yang, Z.-C.; Hsiao, Y.-J.; Wang, S.-C. Catalytic effect of Ag embedded with ZnO prepared by Co-sputtering on H2S gas sensing MEMS device. Vacuum 2022, 202, 111210. [Google Scholar] [CrossRef]

- Hsueh, T.-J.; Li, P.-S.; Fang, S.-Y.; Hsu, C.-L. A vertical CuO-NWS/MEMS NO2 gas sensor that is produced by sputtering. Sens. Actuators B Chem. 2022, 355, 131260. [Google Scholar] [CrossRef]

- Salehi, M.; Heidari, P.; Ruhani, B.; Kheradmand, A.; Purcar, V.; Căprărescu, S. Theoretical and experimental analysis of surface roughness and adhesion forces of MEMS surfaces using a novel method for making a compound sputtering target. Coatings 2021, 11, 1551. [Google Scholar] [CrossRef]

- Auciello, O. Review of materials science and technological applications of transformational integrated multifunctional oxide/ultrananocrystalline diamond (UNCD) films/crystalline diamond for new generation of high-tech and biomedical devices. J. Mater. Res. 2023, 38, 571–585. [Google Scholar] [CrossRef]

- You, Z.-W.; Wei, L.; Zhang, M.-L.; Yang, F.-H.; Wang, X.-D. Design of a novel MEMS implantable blood pressure sensor and stress distribution of parylene-based coatings. In Proceedings of the 2022 IEEE 16th International Conference on Solid-State & Integrated Circuit Technology (ICSICT), Nanjing, China, 25–28 October 2022; pp. 1–3. [Google Scholar] [CrossRef]

- Sun, D.; Böhringer, K.F. Self-Cleaning: From bio-inspired surface modification to MEMS/microfluidics system integration. Micromachines 2019, 10, 101. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, S.; Feng, Y.; Chen, Z.; Zhang, L.; Jiang, X.; Jiao, Q.; Li, J.; Chen, Y.; Li, D.; Liu, L.; et al. Study on Light Extraction from GaN-based Green Light-Emitting Diodes Using Anodic Aluminum Oxide Pattern and Nanoimprint Lithography. Sci. Rep. 2016, 6, 21573. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, J.; Shi, Z.; Li, M.; Chen, S.; Zhong, M.; Liu, X.; Sha, J.; Jia, S. Theoretical investigation of the microfluidic and magnetic field-assisted self-assembly of colloidal magnetic-plasmonic nanoparticles. J. Phys. D Appl. Phys. 2021, 54, 325004. [Google Scholar] [CrossRef]

- Ramezani, M.; Ripin, Z.M. An Overview of Enhancing the Performance of Medical Implants with Nanocomposites. J. Compos. Sci. 2023, 7, 199. [Google Scholar] [CrossRef]

- Ding, Y.; Tao, B.; Ma, R.; Zhao, X.; Liu, P.; Cai, K. Surface modification of titanium implant for repairing/improving microenvironment of bone injury and promoting osseointegration. J. Mater. Sci. Technol. 2023, 143, 1–11. [Google Scholar] [CrossRef]

- Geng, Z.; Li, X.; Ji, L.; Li, Z.; Zhu, S.; Cui, Z.; Wang, J.; Cui, J.; Yang, X.; Liu, C. A novel snail-inspired bionic design of titanium with strontium-substituted hydroxyapatite coating for promoting osseointegration. J. Mater. Sci. Technol. 2021, 79, 35–45. [Google Scholar] [CrossRef]

- Lu, M.; Chen, H.; Yuan, B.; Zhou, Y.; Min, L.; Xiao, Z.; Zhu, X.; Tu, C.; Zhang, X. Electrochemical deposition of nanostructured hydroxyapatite coating on titanium with enhanced early stage osteogenic activity and osseointegration. Int. J. Nanomed. 2020, 15, 6605–6618. [Google Scholar] [CrossRef]

- Ziemba, A.M.; Woodson, M.C.C.; Funnell, J.L.; Wich, D.; Balouch, B.; Rende, D.; Amato, D.N.; Bao, J.; Oprea, I.; Cao, D.; et al. Development of a Slow-Degrading Polymerized Curcumin Coating for Intracortical Microelectrodes. ACS Appl. Bio Mater. 2023, 6, 806–818. [Google Scholar] [CrossRef]

- Cherian, A.M.; Joseph, J.; Nair, M.B.; Nair, S.V.; Vijayakumar, M.; Menon, D. Coupled benefits of nanotopography and titania surface chemistry in fostering endothelialization and reducing in-stent restenosis in coronary stents. Biomater. Adv. 2022, 142, 213149. [Google Scholar] [CrossRef]

- Alcudia, A.; Begines, B.; Rodriguez-Lejarraga, P.; Greyer, V.; Godinho, V.C.F.; Pajuelo, E.; Torres, Y. Development of porous silver nanoparticle/polycaprolactone/polyvinyl alcohol coatings for prophylaxis in titanium interconnected samples for dental implants. Colloid Interface Sci. Commun. 2022, 48, 100621. [Google Scholar] [CrossRef]

- Tran, H.A.; Tran, P.A. In Situ Coatings of Silver Nanoparticles for Biofilm Treatment in Implant-Retention Surgeries: Antimicrobial Activities in Monoculture and Coculture. ACS Appl. Mater. Interfaces 2021, 13, 41435–41444. [Google Scholar] [CrossRef] [PubMed]

- Cordeiro, J.M.; Nagay, B.E.; Dini, C.; Souza, J.G.; Rangel, E.C.; da Cruz, N.C.; Yang, F.; van den Beucken, J.J.; Barão, V.A. Copper source determines chemistry and topography of implant coatings to optimally couple cellular responses and antibacterial activity. Biomater. Adv. 2021, 134, 112550. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Xie, L.; He, M.; Zhang, R.; Tian, Y.; Liu, S.; Gong, T.; Huo, F.; Yang, T.; Zhang, Q.; et al. A wear-resistant TiO2 nanoceramic coating on titanium implants for visible-light photocatalytic removal of organic residues. Acta Biomater. 2019, 97, 597–607. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Chowdhury, S.; Janorkar, A.V.; Marquart, M.; Griggs, J.A.; Bumgardner, J.D.; Roach, M.D. A novel single-step anodization approach for pani-doping oxide surfaces to improve the photocatalytic activity of titanium implants. Biomed. Mater. 2023, 18, 015010. [Google Scholar] [CrossRef]

- Qi, L.; Guo, B.; Lu, Q.; Gong, H.; Wang, M.; He, J.; Jia, B.; Ren, J.; Zheng, S.; Lu, Y. Preparation and Photocatalytic and Antibacterial Activities of Micro/Nanostructured TiO2-Based Photocatalysts for Application in Orthopedic Implants. Front. Mater. 2022, 9, 914905. [Google Scholar] [CrossRef]

- Parfenova, L.V.; Galimshina, Z.R.; Gil’Fanova, G.U.; Alibaeva, E.I.; Danilko, K.V.; Pashkova, T.M.; Kartashova, O.L.; Farrakhov, R.G.; Mukaeva, V.R.; Parfenov, E.V.; et al. Hyaluronic acid bisphosphonates as antifouling antimicrobial coatings for PEO-modified titanium implants. Surf. Interfaces 2022, 28, 101678. [Google Scholar] [CrossRef]

- Akshaya, S.; Rowlo, P.K.; Dukle, A.; Nathanael, A.J. Antibacterial Coatings for Titanium Implants: Recent Trends and Future Perspectives. Antibiotics 2022, 11, 1719. [Google Scholar] [CrossRef]

- Simon, N.; Schmid, M.; Blendinger, F.; Bucher, V. Long Term Evaluation of the Barrier Properties of Polymer/Metal Oxide Hybrid Layers for Use in Medical Implants. Curr. Dir. Biomed. Eng. 2022, 8, 435–438. [Google Scholar] [CrossRef]

- Visser, N.L.; Verschoor, J.C.; Smulders, L.C.; Mattarozzi, F.; Morgan, D.J.; Meeldijk, J.D.; van der Hoeven, J.E.; Stewart, J.A.; Vandegehuchte, B.D.; de Jongh, P.E. Influence of carbon support surface modification on the performance of nickel catalysts in carbon dioxide hydrogenation. Catal. Today 2023, 418, 114071. [Google Scholar] [CrossRef]

- Kübler, M.; Wagner, S.; Jurzinsky, T.; Paul, S.; Weidler, N.; Villa, E.D.G.; Cremers, C.; Kramm, U.I. Impact of Surface Functionalization on the Intrinsic Properties of the Resulting Fe–N–C Catalysts for Fuel Cell Applications. Energy Technol. 2020, 8, 2000433. [Google Scholar] [CrossRef]

- Binding, S.C.; Pernik, I.; Gonçales, V.; Wong, C.M.; Webster, R.; Cheong, S.; Tilley, R.D.; Garcia-Bennett, A.; Gooding, J.J.; Messerle, B.A. Simultaneous Functionalization of Carbon Surfaces with Rhodium and Iridium Organometallic Complexes: Hybrid Bimetallic Catalysts for Hydroamination. Organometallics 2019, 38, 780–787. [Google Scholar] [CrossRef]

- Bai, J.; Zhang, J.; Eiler, K.; Yang, Z.; Fan, L.; Yang, D.; Zhang, M.; Hou, Y.; Guan, R.; Sort, J.; et al. Electrochemically fabricated surface-mesostructured cuni bimetallic catalysts for hydrogen production in alkaline media. Nanomaterials 2022, 12, 118. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Shao, X.; Yi, J.; Zhang, J.; Liu, Y. High-efficient carbon dioxide-to-formic acid conversion on bimetallic PbIn alloy catalysts with tuned composition and morphology. Chemosphere 2022, 293, 133595. [Google Scholar] [CrossRef]

- Kottarathil, S.; Narayanaru, S.; Unni, S.M.; Tamaki, T.; Kuroki, H.; Hareesh, U.N.S.; Anilkumar, G.M.; Yamaguchi, T. Selective Borohydride Oxidation Reactions of Zeolitic Imidazolate Framework-Derived Bimetallic Carbon Alloy Electrocatalysts for Alkaline Fuel Cell Applications. ACS Appl. Energy Mater. 2022, 5, 12571–12582. [Google Scholar] [CrossRef]

- Mncwabe, Z.; Farahani, M.D.; Friedrich, H.B. Switching Between Oxidation Types Using Molybdenum Phosphate Catalysts for Paraffin Activation Using Doped Fe as Surface Acidity Modifier and MoOx as an Oxygen Insertion Tool. Catal. Lett. 2020, 150, 728–737. [Google Scholar] [CrossRef]

- Gao, X.; Wen, Y.; Tan, R.; Huang, H.; Kawi, S. A review of catalyst modifications for a highly active and stable hydrogen production from methane. Int. J. Hydrogen Energy 2023, 48, 6204–6232. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Hu, W.; Wang, X.; Yang, R. Microstructure and surface engineering through indium modification on Ni-rich layered cathode materials for enhanced electrochemical performance of lithium-ion batteries. J. Alloys Compd. 2023, 934, 167862. [Google Scholar] [CrossRef]

- Hamidian, K.; Rahimi, R.; Hosseini-Kharat, M.; Alavi, M. Development of the molecular engineering of disazo dye sensitizers and TiO2 semiconductor surface to improve the power conversion efficiency of dye-sensitized solar cells. J. Photochem. Photobiol. A Chem. 2021, 418, 113408. [Google Scholar] [CrossRef]

- Sun, X.; Jing, M.; Dong, H.; Xie, W.; Luo, F. CuO-ZnO submicroflakes with nanolayered Al2O3 coatings as high performance anode materials in lithium-ion batteries. J. Alloys Compd. 2023, 953, 170137. [Google Scholar] [CrossRef]

- Wang, C.; Gann, E.; Chesman, A.S.R.; McNeill, C.R. Residual solvent additive enables the nanostructuring of PTB7-Th:PC71BM solar cells via soft lithography. AIP Adv. 2019, 9, 065024. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.Y.; Fei, G.T.; Xu, S.H.; Wang, B. ZnO–SiO2 composite coating with anti-reflection and photoluminescence properties for improving the solar cell efficiency. Compos. Part B Eng. 2023, 251, 110486. [Google Scholar] [CrossRef]

- Guo, C.; Jia, R.; Li, X.; Tian, X.; Chen, J.; Ge, H.; Huang, H.; Yuan, L.; Xu, C. Influence of backside surface morphology on passivation and contact characteristics of TOPCON solar cells. Sol. Energy 2023, 258, 278–288. [Google Scholar] [CrossRef]

- Singh, N.; Malik, A.; Nohwar, S.; Jana, R.; Mondal, P.C. Covalent surface modification of nickel ferrite nanoparticles for electrochemical supercapacitor performance. N. J. Chem. 2023, 47, 5308–5315. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, S.; Zhao, T.; Chen, D.; Wang, R.; Yu, Y. Ge modified by metal–organic segments as anodes for Ge-air batteries with an alkaline gel polymer electrolyte. Arab. J. Chem. 2023, 16, 105021. [Google Scholar] [CrossRef]

- Ramezani, M.; Ripin, Z.M. 4D printing in biomedical engineering: Advancements, challenges, and future directions. J. Funct. Biomater. 2023, 14, 347. [Google Scholar] [CrossRef]

- Mutharani, B.; Ranganathan, P.; Chen, T.-W.; Chen, S.-M.; Vinoth Kumar, J. Thermoreversible Switchlike Electrocatalytic Reduction of Tizanidine Based on a Graphene Oxide Tethered Stimuli-Responsive Smart Surface Supported Pd Catalyst. Anal. Chem. 2020, 92, 8965–8973. [Google Scholar] [CrossRef]

- Li, H.; Ai, Z.; Yang, L.; Zhang, W.; Yang, Z.; Peng, H.; Leng, L. Machine learning assisted predicting and engineering specific surface area and total pore volume of biochar. Bioresour. Technol. 2023, 369, 128417. [Google Scholar] [CrossRef]

- Aghazadeh, M.; Ganjali, M.R.; Morad, M.M.; Gharailou, D. Saccharide-capped superparamagnetic copper cations-doped magnetite nanoparticles for biomedical applications: A novel and simple synthesis procedure, in-situ surface engineering and characterization. Curr. Nanosci. 2020, 16, 770–778. [Google Scholar] [CrossRef]

| Technique | Deposition Method | Advantages | Limitations |

|---|---|---|---|

| Thermal spray coatings | Spraying molten or powdered material onto a prepared surface |

|

|

| Physical vapor deposition (PVD) | Evaporation or sputtering of material onto a substrate |

|

|

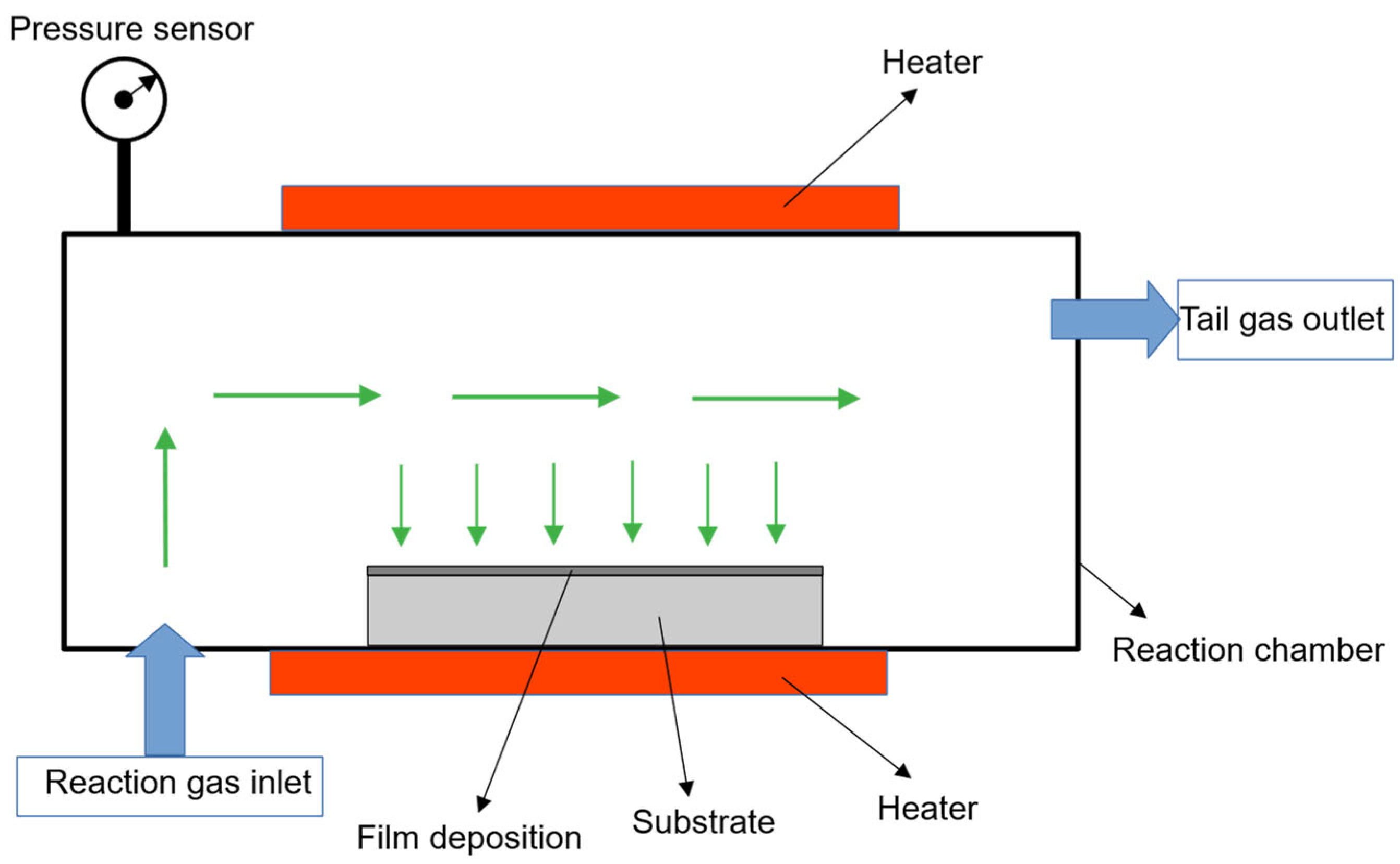

| Chemical vapor deposition (CVD) | Chemical reaction to deposit solid material onto a substrate |

|

|

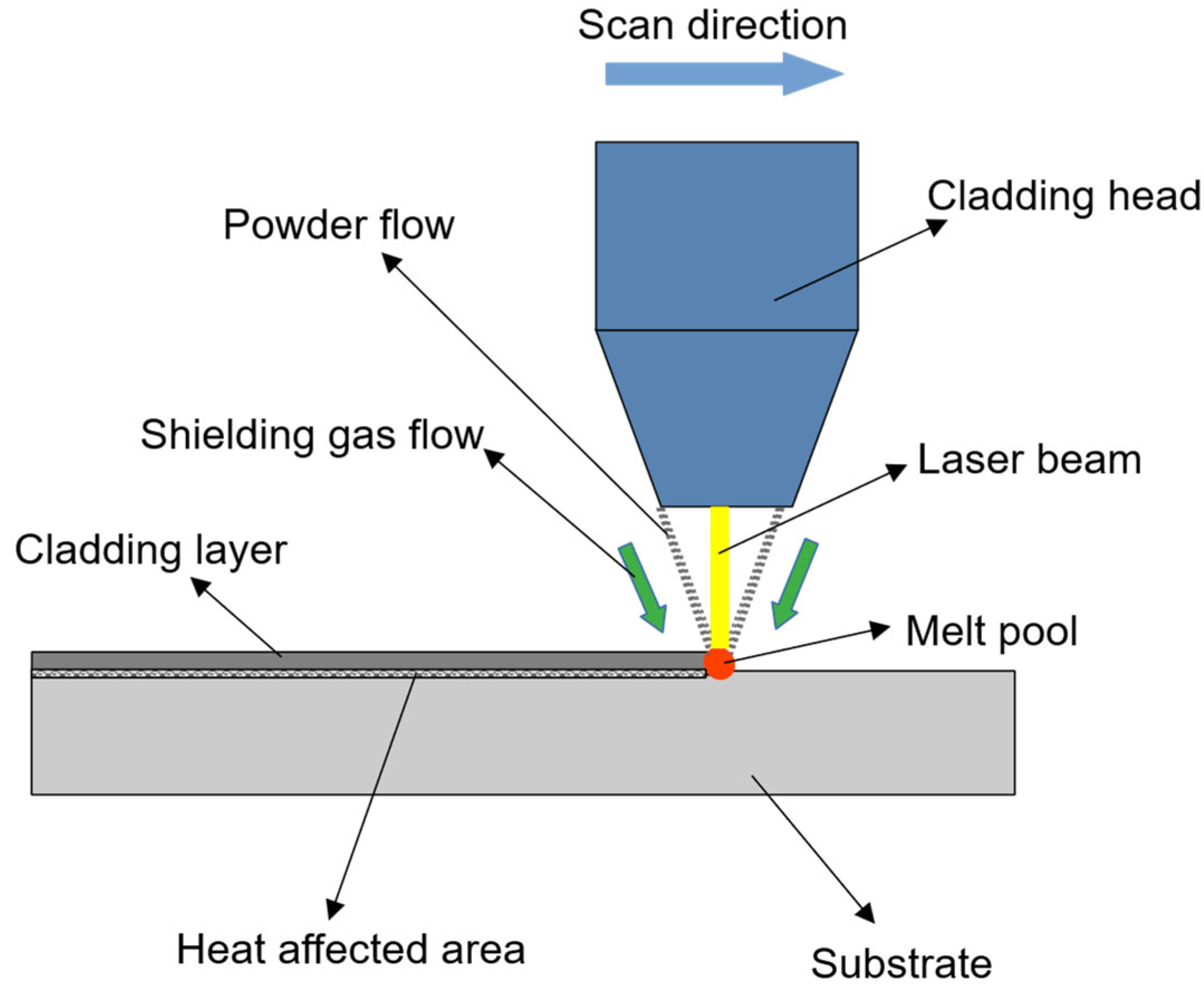

| Laser surface engineering | Laser beam melts or heats the surface of the material |

|

|

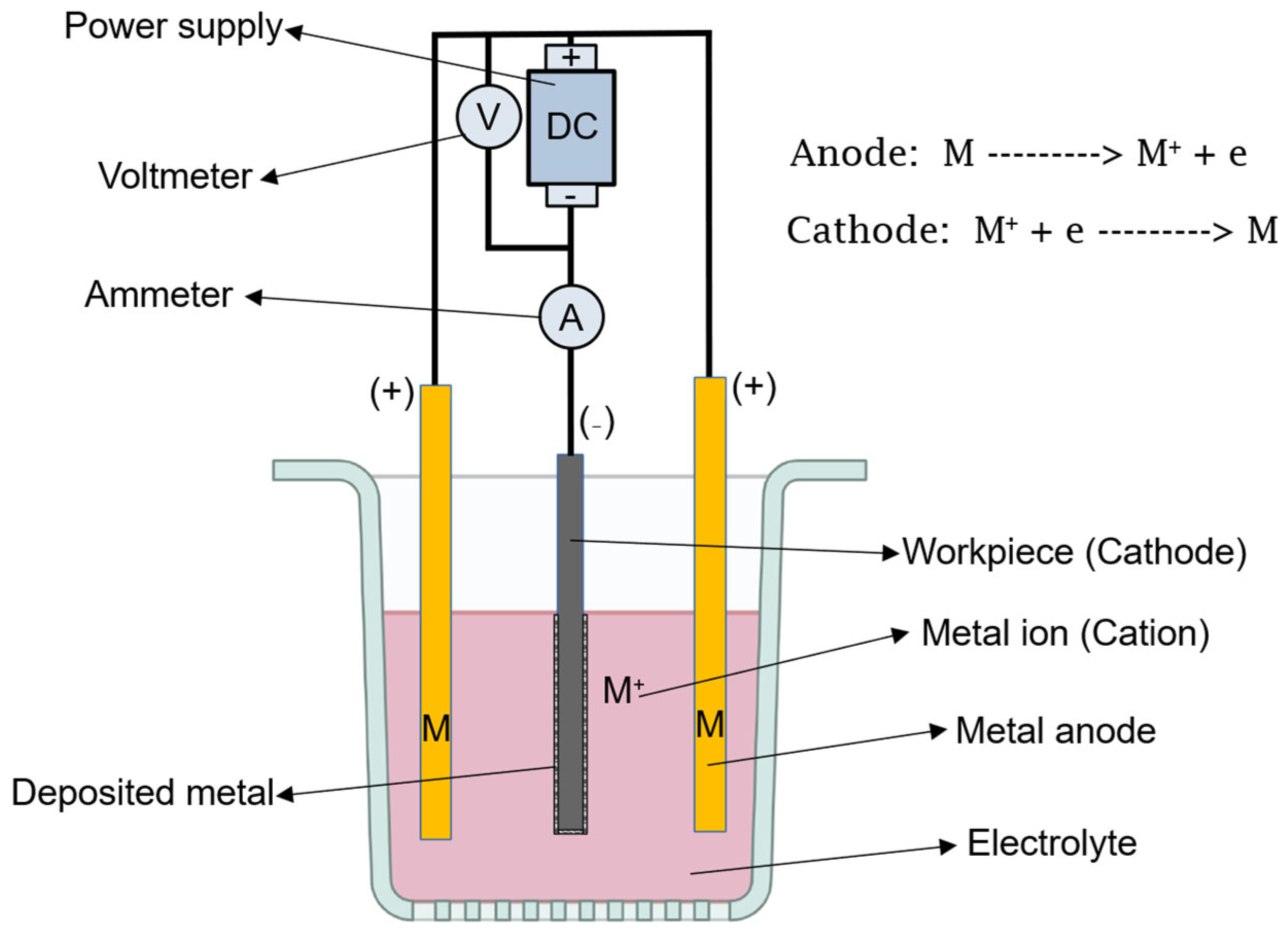

| Technique | Coating Method | Coating Properties | Substrate Compatibility | Applications |

|---|---|---|---|---|

| Electroplating | Electrochemical deposition of metal coatings onto a conductive substrate | Controlled thickness and composition Good adhesion and surface finish |

|

|

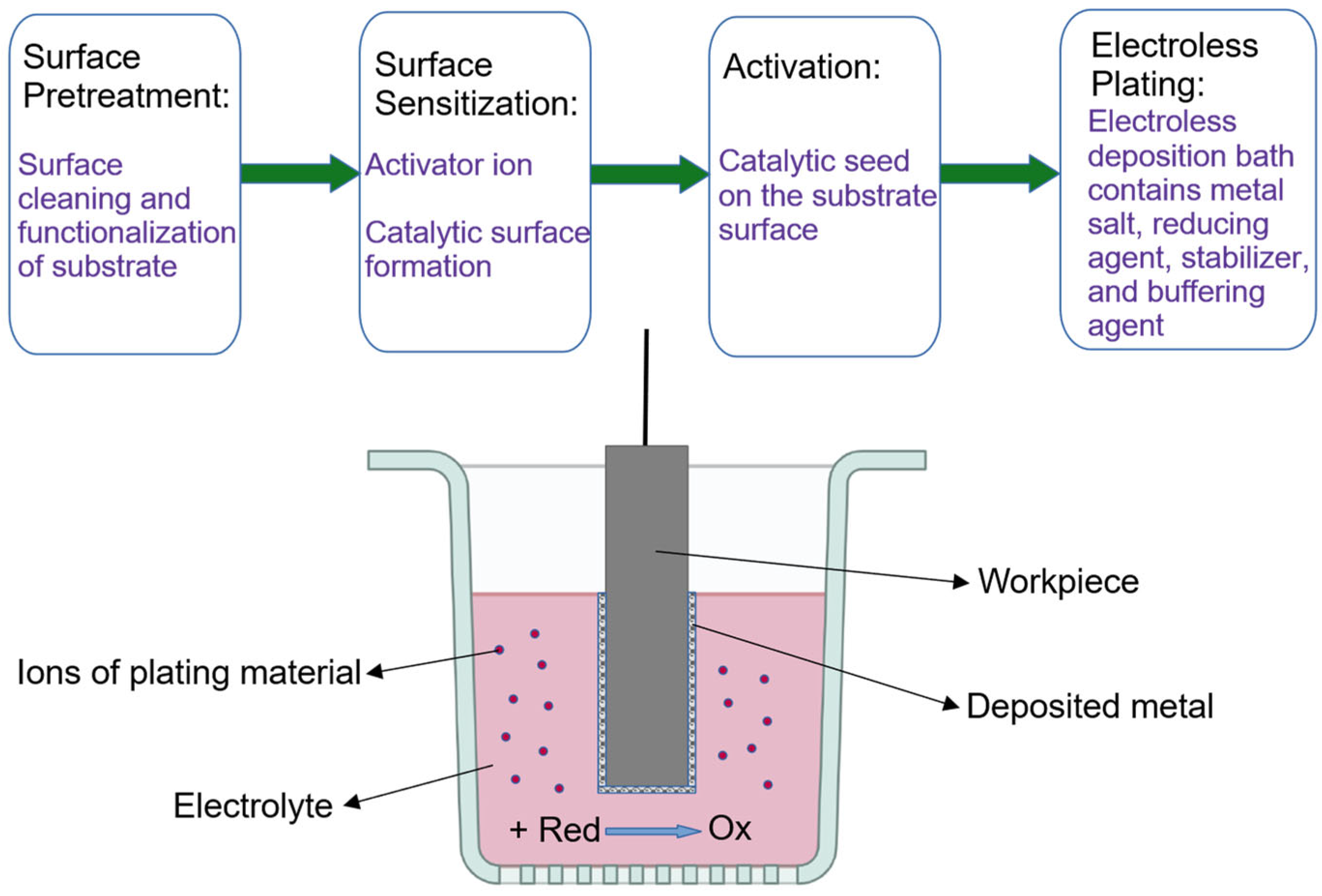

| Electroless plating | Auto-catalytic deposition of metal coatings onto a variety of substrates | Uniform and conformal coatings High corrosion and wear resistance Self-catalyzing and self-limiting |

|

|

| Sol–gel coatings | Chemical solution deposition and controlled gelation on substrates | Tailorable composition and properties Excellent adhesion and porosity Adjustable thickness and porosity |

|

|

| Chemical etching | Chemical dissolution of material from surface to create desired patterns or structures | Precise control over etched features High aspect ratio and fine details Surface texturing and roughening |

|

|

| Characterization Method | Principle | Key Parameters Measured | Advantages |

|---|---|---|---|

| Scanning Electron Microscopy (SEM) | Scanning electron beam interaction with sample surface |

|

|

| Transmission Electron Microscopy (TEM) | Transmission of electron beam through sample |

|

|

| X-ray Diffraction (XRD) | Diffraction of X-rays by crystal lattice planes |

|

|

| Atomic Force Microscopy (AFM) | Sensing the forces between a probe and the sample surface |

|

|

| Scanning Tunneling Microscopy (STM) | Tunneling current between a sharp tip and sample surface |

|

|

| Surface Profilometry | Optical or mechanical measurement of surface profile |

|

|

| Challenges | Future Directions |

|---|---|

| Process Complexity and Cost |

|

| Durability and Longevity |

|

| Compatibility and Adhesion |

|

| Complex Geometries |

|

| Environmental Impact |

|

| Limited Material Selection |

|

| Process Control and Reproducibility |

|

| Integration with Existing Manufacturing Processes |

|

| Emerging Trend/Technology | Potential Benefits | Potential Applications |

|---|---|---|

| Multifunctional Coatings |

|

|

| Nanotechnology and Nanomaterials |

|

|

| Biomimetic Surfaces |

|

|

| Additive Manufacturing for Surface Engineering |

|

|

| Smart Surfaces |

|

|

| Machine Learning and Artificial Intelligence |

|

|

| In Situ Characterization and Monitoring |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramezani, M.; Mohd Ripin, Z.; Pasang, T.; Jiang, C.-P. Surface Engineering of Metals: Techniques, Characterizations and Applications. Metals 2023, 13, 1299. https://doi.org/10.3390/met13071299

Ramezani M, Mohd Ripin Z, Pasang T, Jiang C-P. Surface Engineering of Metals: Techniques, Characterizations and Applications. Metals. 2023; 13(7):1299. https://doi.org/10.3390/met13071299

Chicago/Turabian StyleRamezani, Maziar, Zaidi Mohd Ripin, Tim Pasang, and Cho-Pei Jiang. 2023. "Surface Engineering of Metals: Techniques, Characterizations and Applications" Metals 13, no. 7: 1299. https://doi.org/10.3390/met13071299

APA StyleRamezani, M., Mohd Ripin, Z., Pasang, T., & Jiang, C.-P. (2023). Surface Engineering of Metals: Techniques, Characterizations and Applications. Metals, 13(7), 1299. https://doi.org/10.3390/met13071299