The Atomistic Structure of Metal/Ceramic Interfaces Is the Key Issue for Developing Better Properties

Abstract

:1. Introduction

2. Increasing Importance of Inorganic Interfaces

3. Atomistic Simulations

4. Experimental and Calculation Results

4.1. MgO/Ag Interface: Change of Electron Density

4.2. MgO/TiN/GaN Interface—Avoiding Misfit Dislocations

4.3. TiO2/SrTiO3 and TiO2/Al2O3 Interfaces: Strain Engineering of Epitaxial Grown Thin Films

4.4. Fe/Al2O3 Interface: Model Experiment for Interface Bonds

4.5. Phenomena on Other Inorganic Interfaces

5. Outlook: Additive Manufacturing Allows Efficient Optimization of Device Interface

6. Conclusions

- (1)

- This field of science together with other inorganic interfaces will gain interest in the near future, because of three reasons: (a) thin film devices are cheaper than those made of bulk materials; (b) new additive manufacturing techniques are available; (c) nano-size effects, like the volume fraction of atoms in a crystalline environment and the curvature of interfaces, change properties of functional materials.in non-classical way. Complexity of heterogeneous interfaces can increase by two independent factors, either geometry or when producing interfaces far from equilibrium.

- (2)

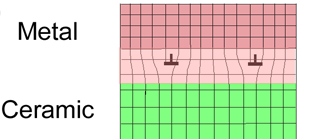

- For atomistic modeling of crystalline interfaces, we need (a) to get the orientation between the facing lattices from experiments; (b) the translation vector of unit cells parallel and/or perpendicular to the interface; (c) individual relaxation of atomic positions forming structural units, which are different from units in bulk materials.

- (3)

- Experimental studies on several metal/ceramic and other interfaces confirmed their importance for future optimizing properties of either thin films on substrates, sandwich structures, or other composite materials. Epitaxial growth allows thin-film engineering by straining up to ±10%. At interfaces new structural units with unique bonding characteristics are formed.

- (4)

- The atomistic structure determines bonding and other properties, especially in functional materials the transport properties like 2DEG or GMR are influenced by new possibilities of the bonding partners. In addition, from the viewpoint of new additive manufacturing techniques such as 3D-printing of composites, compounds or their constituents, this field of science will see a large gain in importance in near future.

Acknowledgments

Conflicts of Interest

References

- Autumn, K.; Sitti, M.; Liang, Y.A.; Peattie, A.M.; Hansen, W.R.; Sponberg, S.; Kenny, T.W.; Fearing, R.; Israelachvili, J.N.; Full, R.J. Evidence for van der Waals adhesion in gecko setae. Proc. Natl. Acad. Sci. USA 2002, 99, 12252–12256. [Google Scholar] [CrossRef]

- Heepe, L.; Kovalev, A.E.; Filippov, A.E.; Gorb, S.N. Adhesion Failure at 180000 Frames per Second: Direct Observation of the Detachment Process of a Mushroom-Shaped Adhesive. Phys. Rev. Lett. 2013, 111, 104301. [Google Scholar] [CrossRef]

- Yurdumakan, B.; Raravikar, N.R.; Ajayanb, P.M.; Dhinojwala, A. Synthetic gecko foot-hairs from multiwalled carbon nanotubes. Chem. Commun. 2005, 3799–3801. [Google Scholar]

- Peisker, H.; Michels, J.; Gorb, S.N. Evidence for a material gradient in the adhesive tarsal setae of the ladybird beetle Coccinella septempunctata. Nat. Commun. 2013, 4, 1661. [Google Scholar] [CrossRef]

- Suga, T.; Hosoda, N. Active disassembly and reversible interconnection. Proc. IEEE Int. Symp. 2000. [Google Scholar] [CrossRef]

- Haisma, J.; Spierings, G.A.C.M. Contact bonding, including direct-bonding in a historical and recent context of materials science. Mater. Sci. Eng. R 2002, 37, 1–60. [Google Scholar] [CrossRef]

- Floriancic, M.; Mader, W.; Rühle, M.; Turwitt, M. HRTEM and diffraction studies on an Nb-Al2O3 interface. J. Phys. Colloques 1985, 46, C4:129–C4:133. [Google Scholar]

- Blöchl, P.; Das, G.P.; Fischmeister, H.F.; Schönberger, U. Electronic structure of a metal-ceramic interface: ab-initio calculations for MgO/Ag. Metal–Ceramic Interfaces 1990. [Google Scholar] [CrossRef]

- Schönberger, U.; Andersen, O.K.; Methfessel, M. Bonding at metal-ceramic interfaces; Ab-initio density-functional calculations for Ti and Ag on MgO. Acta Metall. Mater. 1992, 40, S1–S10. [Google Scholar] [CrossRef]

- Kohyama, M.; Ebata, Y.; Kose, S.; Kinoshita, M.; Yamamoto, R. Band-theoretical approach to bonding at metal-alumina interfaces. J. Phys. Colloq. 1990, 51, 861–866. [Google Scholar]

- Williamson, B.R.L.; Rabin, B.H.; Drake, J.T. Finite element analysis of thermal residual stresses at graded ceramic-metal interfaces. Part I. Model description and geometrical effects. J. Appl. Phys. 1993, 74, 1310. [Google Scholar]

- Peteves, S.D. Designing Interfaces for Technological Applications, Ceramic-Ceramic, Ceramic-Metal-Joining; Elsevier Applied Science: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Wolf, D.; Yip, S. Material Interfaces; Champman & Hall: London, UK, 1992. [Google Scholar]

- Sutton, A.P.; Balluffi, R.W. Interfaces in Crystalline Materials; Clarendon Press: Oxford, UK, 1995. [Google Scholar]

- Rühle, M.; Evans, A.G.; Hirth, J.P.; Ashby, M.F. Metal–Ceramic Interfaces; Pergamon Press & Elsevier: Oxford, UK, 2009. [Google Scholar]

- Lojkowski, W.; Fecht, H.J. The structure of intercrystalline interfaces. Prog. Mater. Sci. 2000, 45, 339–568. [Google Scholar] [CrossRef]

- Ernst, F. Metal-oxide interfaces. Mater. Sci. Eng. R 1995, 14, 97–156. [Google Scholar] [CrossRef]

- Wunderlich, W. Ceramics Processing on Atomic Scale by Control of Interface Parameter. Interceram 2002, 51, 190–198. [Google Scholar]

- Wunderlich, W.; Niihara, K. Ab-initio Simulations in order to improve processing of Nanoceramics. J. Ceram. Proc. Res. 2003, 4, 10–16. [Google Scholar]

- Wunderlich, W.J. Calculations on different length scales for improving Processing of Nano-Ceramics Ceram. J. Ceram. Proc. Res. 2004, 5, 30–39. [Google Scholar]

- Wunderlich, W.; Oekermann, T.; Miao, L.; Hue, N.T.; Tanemura, S.; Tanemura, M. Electronic properties of Nano-porous TiO2- and ZnO-Thin Films comparison of simulations and experiments. J. Ceram. Proc. Res. 2004, 5, 343–354. [Google Scholar]

- Ertl, G.; Weiss, M.; Lee, S.B. Kinetics of nitrogen adsorption on Fe(111). Surf. Sci. 1982, 114, 515–526. [Google Scholar] [CrossRef]

- Ostrovskii, V.E. Review of the heats of chemisorption of gases at metals in the context of the problem of “Heterogeneous” vs. “Homogeneous” catalytic surfaces. J. Therm. Anal. Calorim. 2009, 95, 609–622. [Google Scholar] [CrossRef]

- Al-Abadleh, H.A.; Grassian, V.H. Oxide surfaces as environmental interfaces. Surf. Sci. Rep. 2003, 52, 63–161. [Google Scholar]

- Binasch, G.; Grünberg, P.; Saurenbach, F.; Zinn, W. Enhanced magnetoresistance in layered magnetic structures with antiferromagnetic interlayer exchange. Phys. Rev. B 1989, 39, 4828. [Google Scholar] [CrossRef]

- Baibich, M.N.; Broto, J.M.; Fert, A.; Nguyen van Dau, F.; Petroff, F.; Eitenne, P.; Creuzet, G.; Friederich, A.; Chazelas, J. Giant Magnetoresistance of (001)Fe/(001)Cr Magnetic Superlat-tices. Phys. Rev. Lett. 1988, 61, 2472. [Google Scholar] [CrossRef]

- Evans, A.G.; Mumm, D.R.; Hutchinson, J.W.; Meier, G.H.; Pettit, F.S. Mechanisms controlling the durability of thermal barrier coatings. Prog. Mater. Sci. 2001, 46, 505–553. [Google Scholar] [CrossRef]

- Chen, Y.; Reed, R.C.; Marquis, E.A. As-coated thermal barrier coating: Structure and chemistry. Scr. Mater. 2012, 67, 779–782. [Google Scholar] [CrossRef]

- Seiler, P.; Baker, M.; Roesler, J. Multi-scale failure mechanisms of thermal barrier coating systems. J. Comput. Mater. Sci. 2013, 80, 27–34. [Google Scholar] [CrossRef]

- Curry, N.; Markocsan, N.; Li, X.H.; Tricoire, A.; Dorfman, M. Next Generation Thermal Barrier Coatings for the Gas Turbine Industry. J. Therm. Spray Technol. 2011, 20, 108–115. [Google Scholar] [CrossRef]

- Arya, A.; Carter, E.A. Structure, bonding, and adhesion at the TiC(100)/Fe(110) interface from first principles. J. Chem. Phys. 2003, 118, 8982. [Google Scholar]

- Vepek, S. The search for novel, superhard materials. J. Vac. Sci. Technol. A 1999, 17, 2401. [Google Scholar] [CrossRef]

- Holec, D.; Friak, M.; Neugebauer, J.; Mayrhofer, P.H. Trends in the elastic response of binary early transition metal nitrides. Phys. Rev. B 2012, 85, 064101. [Google Scholar] [CrossRef]

- Rachbauer, R.; Gengler, J.J.; Voevodin, A.A.; Resch, K.; Mayrhofer, P.H. Temperature driven evolution of thermal, electrical, and optical properties of Ti-Al-N coatings. Acta Mater. 2012, 60, 2091–2096. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Sonnleitner, D.; Bartosik, M.; Holec, D. Sructural and mechanical evolution of reactively and non-reactively sputtered Zr–Al–N thin films during annealing. Surf Coat Technol. 2014, 244, 52–56. [Google Scholar] [CrossRef]

- Knoth, K.; Engel, S.; Apetrii, C.; Falter, M.; Schlobach, B.; Hühne, R.; Oswald, S.; Schultz, L.; Holzapfel, B. Chemical solution deposition of YBa2Cu3O7−x coated conductors. Curr. Opin. Solid State Mater. Sci. 2006, 10, 205–216. [Google Scholar]

- Suga, T. Low Temperature Bonding for 3D Integration—A Review of the Surface Activated Bonding (SAB). In proceedings of Low Temperature Bonding for 3D Integration (LTB-3D), 2012 3rd IEEE International Workshop on, Tokyo, Japan, 22–23 May 2012; pp. 7–10.

- Howlader, M.M.R.; Zhang, F.; Deen, M.J.; Suga, T.; Yamauchi, A. Surface activated bonding of copper through silicon vias and gold stud bumps at room temperature. J. Vac. Sci. Technol. A 2011, 29, 021007. [Google Scholar]

- Wilk, G.D.; Wallace, R.M.; Anthony, J.M. High-k gate dielectrics: Current status and materials properties considerations. J. Appl. Phys. 2001, 89, 5243–5275. [Google Scholar] [CrossRef]

- Fu, Q.; Wagner, T. MOS field-effect transistor gate and in heterogeneous catalysis. Surf. Sci. Rep. 2007, 62, 431–498. [Google Scholar]

- Imanaka, Y.; Amada, H.; Kumasaka, F.; Takahashi, N.; Yamasaki, T.; Ohfuchi, M.; Kaneta, C. Nanoparticulated dense and stress-free ceramic thick film for material integration. Adv. Eng. Mater. 2013, 15, 1129–1135. [Google Scholar]

- Falub, C.V.; Känel, H.V.; Isa, F.; Bergamaschini, R.; Marzegalli, A.; Chrastina, D.; Isella, G.; Müller, E.; Niedermann, P.; Miglio, L. Scaling Hetero-Epitaxy from Layers to Three-Dimensional Crystals. Science 2012, 335, 1330–1334. [Google Scholar] [CrossRef] [Green Version]

- Nomura, K.; Ohta, H.; Ueda, K.; Kamiya, T.; Hirano, M.; Hosono, H. Thin-film transistor fabricated in single-crystalline transparent oxide semiconductor. Science 2003, 300, 1269–1272. [Google Scholar] [CrossRef]

- Fortunato, E.; Barquinha, P.; Martins, R. Oxide Semiconductor Thin-Film Transistors: A Review of Recent Advances. Adv. Mater. 2012, 24, 2945–2986. [Google Scholar] [CrossRef]

- Furubayashi, Y.; Hitosugi, T.; Yamamoto, Y.; Inaba, K.; Kinoda, G.; Hirose, Y.; Shimada, T.; Hasegawa, T. A transparent metal: Nb-doped anatase TiO2. Appl. Phys. Lett. 2005, 86, 252101. [Google Scholar] [CrossRef]

- Hautier, G.; Miglio, A.; Ceder, G.; Rignanese, G.-M.; Gonze, X. Identification and design principles of low hole effective mass p-type transparent conducting oxides. Nat. Commun. 2013, 4, 2292. [Google Scholar]

- Ekins-Daukes, N.J.; Lee, K.-H.; Hirst, L.; Chan, A.; Führer, M.; Adams, J.; Browne, B.; Barnham, K.W.J.; Stavrinou, P.; Connolly, J.; et al. Controlling radiative loss in quantum well solar cells. J. Phys. D 2013, 46, 264007:1–264007:8. [Google Scholar]

- Snyder, G.J.; Lim, J.R.; Huang, C.K.; Fleurial, J.P. Thermoelectric microdevice fabricated by a MEMS-like electrochemical process. Nat. Mater. 2003, 2, 528–531. [Google Scholar]

- Ohta, H.; Kim, S.; Mune, Y.; Mizoguchi, T.; Nomura, K.; Ohta, S.; Nomura, T.; Nakanishi, Y.; Ikuhara, Y.; Hirano, M.; et al. Giant thermoelectric Seebeck coefficient of a two-dimensional electron gas in SrTiO3. Nat. Mater. 2007, 6, 129–134. [Google Scholar]

- Takashiri, M.; Shirakawa, T.; Miyazaki, K.; Tsukamoto, H. Fabrication and characterization of bismuth–telluride-based alloy thin film thermoelectric generators. Sens. Actuators A 2007, 138, 329–334. [Google Scholar] [CrossRef]

- Wunderlich, W.; Shinohara, Y.; Matsumura, Y. Magnetron sputtering of (TiZr)NiSn thin films on different substrates for thermoelectric applications. J. Phys. 2012, 379. [Google Scholar] [CrossRef]

- Wunderlich, W.; Takashiri, M.; Wakaki, M. Energy Harvesting by Thermoelectric Materials—Thin Film Development and Characterization. Proc. Sch. Eng. Tokai Univ. 2012, 52, 45–50. [Google Scholar]

- Sluka, T.; Tagantsev, A.K.; Bednyakov, P.; Setter, N. Free-electron gas at charged domain walls in insulating BaTiO3. Nat. Commun. 2013, 4, 1808. [Google Scholar] [CrossRef]

- Felser, C.; Fecher, G.H.; Balke, B. Spintronics: A Challenge for Materials Science and Solid-State Chemistry. Angew. Chem. Int. Ed. 2007, 46, 668–699. [Google Scholar] [CrossRef]

- Tian, Y.F.; Ding, J.F.; Lin, W.N.; Chen, Z.H.; David, A.; He, M.; Hu, W.J.; Chen, L.; Wu, T. Anomalous exchange bias at collinear/noncollinear spin interface. Nat. Sci. Rep. 2012, 3, 1094. [Google Scholar]

- Harmer, M.P. The Phase Behavior of Interfaces. Science 2011, 332, 182–183. [Google Scholar] [CrossRef]

- Luo, J.; Cheng, H.; Asl, M.K.; Kiely, C.J.; Harmer, M.P. The Role of a Bilayer Interfacial Phase on Liquid Metal Embrittlement. Science 2011, 332, 1730–1733. [Google Scholar]

- Wunderlich, W.; Mori, T.; Sologub, O.; Baufeld, B. SPS-Sintering of NaTaO3-Fe2O3 Composites. J. Aust. Ceram. Soc. 2011, 47, 57–60. [Google Scholar]

- Chookajorn, T.; Murdoch, H.A.; Schuh, C.A. Design of Stable Nanocrystalline Alloys. Science 2012, 337, 951–953. [Google Scholar] [CrossRef]

- Wunderlich, W.; Ishida, Y.; Maurer, R. HRTEM-Studies of the microstructure of nano-crystalline Pd. Scr. Metall. Mater. 1990, 24, 403–408. [Google Scholar] [CrossRef]

- Wunderlich, W.; Takahashi, M. Characterization of nano-particles during Mg-Al-Spinel-Formation. Ceram. Trans. 2010, 133, 189–194. [Google Scholar]

- Wunderlich, W.; Hue, N.T.; Tanemura, S. Fabrication of nano-structured Titania-Thin-Films. AZojomo 2006, 2, 208. [Google Scholar]

- Han, H.; Kim, Y.; Alexe, M.; Hesse, D.; Lee, W. Nanostructured Ferroelectrics: Fabrication and Structure–Property Relations. Adv. Mater. 2011, 23, 4599–4613. [Google Scholar] [CrossRef]

- Gangopadhyay, S.; Hadjipanayis, G.C.; Shah, S.I.; Sorensen, C.M.; Klabunde, K.J.; Papaefthymiou, V.; Kostikas, A. Effect of oxide layer on the hysteresis behavior of fine Fe particles. J. Appl. Phys. 1991, 70, 5888–5890. [Google Scholar] [CrossRef]

- Kolen’ko, Y.V.; Bañobre-López, M.; Rodríguez-Abreu, C.; Carbó-Argibay, E.; Sailsman, A.; Piñeiro-Redondo, Y.; Cerqueira, F.M.; Petrovykh, D.Y.; Kovnir, K.; Lebedev, O.I.; et al. Large-Scale Synthesis of Colloidal Fe3O4 Nanoparticles Hyperthermia. J. Phys. Chem. C 2014, 118, 8691–8701. [Google Scholar] [CrossRef]

- Wunderlich, W.; Fujimoto, M.; Ohsato, H.; Sekiguchi, S.; Suzuki, T. MD simulation about misfit dislocations at the BaTiO3/SrTiO3 interface. Thin Solid Films 2000, 375, 9–14. [Google Scholar] [CrossRef]

- Lopez, N.; Valeri, S. MgO/Ag 001 interface structure and ST images from first principles. Phys. Rev. B 2004, 70, 125428. [Google Scholar] [CrossRef]

- Shibata, N.; Okubo, S.; Saito, Y.; Wunderlich, W.; Ikuhara, Y. Formation of Cubic-AlN Layer on MgO (100) Substrate by Ion-Assisted MBE. In Proceedings of 7th International Conference on Nitride SemiconductorsFine Ceramic Center, Tokushima, Japan, 27 October 1997; pp. 374–377.

- Wunderlich, W.; Kremser, T.; Frommeyer, G. Mobile Dislocations at Phase Boundaries in Intermetallic TiAl/Ti3Al-Alloys. Acta Metall. Mater. 1993, 41, 1791–1799. [Google Scholar] [CrossRef]

- Wunderlich, W.; Frommeyer, G.; Czarnowski, P.V. Arrangement of Misfit Dislocations at TiAl/Ti3Al-Phase Boundaries. Mater. Sci. Eng. 1993, A164, 421–427. [Google Scholar] [CrossRef]

- Wunderlich, W.; Miao, L.; Tanemura, M.; Tanemura, S.; Jin, P.; Kaneko, K.; Terai, A.; Nabatova-Gabin, N.; Belkada, R. Ab inito Calculations of the optical Bandgap of TiO2 Thin Films. Int. J. Nanosci. 2004, 3, 439–445. [Google Scholar]

- Tanemura, S.; Miao, L.; Wunderlich, W.; Tanemura, M.; Mori, Y.; Toh, S.; Kaneko, K. Fabrication and characterization of anatase/rutile–TiO2 thin films by magnetron sputtering: A review. Sci. Technol. Adv. Mater. 2005, 6, 11–17. [Google Scholar] [CrossRef]

- Wunderlich, W.; Miao, L.; Tanemura, S.; Tanemura, M. Suitable substrates for rutile TiO2-thin films with narrow band-gap predicted by calculations on atomic scale. In Proceedings of the International Conference on New Frontiers of Process Science and Engineering in Advanced Materails—The 14th Iketani Conference, Kyoto, Japan, 24–26 November 2005; Naka, M., Yamane, T., Eds.; High Temperature Society of Japan: Osaka, Japan, 2005; pp. 1–6. [Google Scholar]

- Choudhury, S.; Betty, C.A. A heterostructured SnO2–TiO2 thin film prepared by Langmuir–Blodgett technique. Mater. Chem. Phys. 2013, 141, 440–444. [Google Scholar]

- Siripala, W.; Ivanovskaya, A.; Jaramillo, T.F.; Baeck, S.H. A Cu2O/TiO2 heterojunction thin film cathode for photoelectrocatalysis. Sol. Energy Mater. Sol. Cells 2003, 77, 229–237. [Google Scholar] [CrossRef]

- Polat, Ö.; Aytug, T.; Lupini, A.R.; Paranthaman, P.M.; Ertugrul, M.; Bogorin, D.F.; Meyer, H.M.; Wang, W.; Pennycook, S.J.; Christen, D.K. Nanostructured columnar heterostructures of TiO2 and Cu2O enabled by a thin-film self-assembly approach: Potential for photovoltaics. Mater. Res. Bull. 2013, 48, 352–356. [Google Scholar] [CrossRef]

- Backhaus-Ricoult, M.; Hagège, S.; Peyrot, A.; Moreau, P. Internal Reduction of Chromium-Doped α-Alumina. J. Am. Cerams. Soc. 1994, 77, 423–430. [Google Scholar] [CrossRef]

- Backhaus-Ricoult, M.; Hagège, S.; Wunderlich, W.; Peyrot, A. Atomic Structure of precipitate interfaces of bcc metals. In Alumina formed by internal reduction, Proceedings of International Conference on Ceramic Microstructures, Berkeley, CA, USA, 24 June 1996; pp. 1–10.

- Först, C.J.; Ashman, C.R.; Schwarz, K.; Blöchl, P.E. The interface between silicon and a high-k oxide. Nature 2004, 427, 53–56. [Google Scholar] [CrossRef]

- Kato, T.; Kung, P.; Saxler, A.; Sun, C.J.; Ohsato, H.; Razeghi, M.; Okuda, T. Simultaneous growth of two differently oriented GaN epilayers on (1 1 • 0) sapphire II. A growth model of (0 0 • 1) and (10 • 0) GaN. J. Cryst. Growth 1998, 183, 131–139. [Google Scholar] [CrossRef]

- Wunderlich, W.; Awaji, H. Molecular Dynamics Simulations of the fracture toughness of Sapphire. Mater. Des. 2001, 22, 53–59. [Google Scholar] [CrossRef]

- Dimitrakopulos, G.P.; Komninou, P.; Pond, R.C. Topological Analysis of Defects in Epitaxial Nitride Films and Interfaces. Phys. Stat. Sol.(b) 2001, 227, 45–92. [Google Scholar] [CrossRef]

- Wunderlich, W.; Ohta, H.; Koumoto, K. Enhanced effective mass in doped SrTiO3 and related perovskites. Phys. B 2009, 404, 2202–2212. [Google Scholar] [CrossRef]

- Wunderlich, W.; Koumoto, K. Development of high-temperature thermoelectric materials based on SrTiO3-layered perovskites. Int. J. Mater. Res. 2006, 97, 657–662. [Google Scholar]

- Wunderlich, W. Reduced bandgap due to phonons in SrTiO3 analyzed by ab-initio calculations. Solid State Electron. 2008, 52, 1082–1087. [Google Scholar] [CrossRef]

- Wunderlich, W.; Ohta, S.; Ohta, H.; Koumoto, K. Effective mass and thermoelectric properties of SrTiO 3-based natural superlattices evaluated by ab-initio calculations. In proceedings of 24th International Conference on Thermoelectrics, Clemson University, SC, USA, 19–23 June 2005; IEEE: Piscataway, NJ, USA, 2005; pp. 252–255. [Google Scholar]

- Wunderlich, W.; Ohta, H.; Koumoto, K. Effective mass calculations of SrTiO3-based superlattices for thermoelectric applications lead to new layer design. Mater. Sci. 2008. [Google Scholar]

- Wunderlich, W. NaTaO3 composite ceramics—A new thermoelectric material for energy generation. J. Nucl. Mater. 2009, 389, 57–61. [Google Scholar] [CrossRef]

- Wunderlich, W.; Baufeld, B. Chapter 1: Development of Thermoelectric materials based on NaTaO3 –composite ceramics. In Ceramic Materials; Wunderlich, W., Ed.; InTech Publisher: Rijeka, Croatia, 2010; pp. 1–27. [Google Scholar]

- Wunderlich, W.; Fujiwara, H. The Difference between thermo- and pyroelectric Co-based RE-(= Nd, Y, Gd, Ce)-oxide composites measured by high-temperature gradient. J. Electron. Mater. 2011, 40, 127–133. [Google Scholar] [CrossRef]

- Graf, T.; Felser, C.; Parkin, S.S. Simple rules for the understanding of Heusler compounds. Prog. Solid. State. Chem. 2011, 39, 1–50. [Google Scholar]

- Wunderlich, W.; Motoyama, Y. Screening and Fabrication of Half-Heusler phases for thermoelectric applications. MRS Proc. 2009, 1128, 1–6. [Google Scholar]

- Wunderlich, W.; Motoyama, Y.; Sugisawa, Y.; Matsumura, Y. Large Seebeck Closed-Circuit Currents in Quaternary (Ti,Zr)NiSn Heusler-Alloys. J. Electron. Mater. 2011, 40, 583–588. [Google Scholar] [CrossRef]

- Santos, E.C.; Shiomi, M.; Osakada, K.; Laoui, T. Rapid manufacturing of metal components by laser forming. Int. J. Mach. Tools Manuf. 2006, 46, 1459–1468. [Google Scholar] [CrossRef]

- Levi, G.N.; Schindel, R.; Kruth, J.P. Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. CIRP Ann. Manuf. Technol. 2003, 52, 589–609. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Wunderlich, W. The Atomistic Structure of Metal/Ceramic Interfaces Is the Key Issue for Developing Better Properties. Metals 2014, 4, 410-427. https://doi.org/10.3390/met4030410

Wunderlich W. The Atomistic Structure of Metal/Ceramic Interfaces Is the Key Issue for Developing Better Properties. Metals. 2014; 4(3):410-427. https://doi.org/10.3390/met4030410

Chicago/Turabian StyleWunderlich, Wilfried. 2014. "The Atomistic Structure of Metal/Ceramic Interfaces Is the Key Issue for Developing Better Properties" Metals 4, no. 3: 410-427. https://doi.org/10.3390/met4030410