Effect of Heat Treatment on Microstructure and Hardness of Grade 91 Steel

Abstract

:1. Introduction

2. Experimental Details

2.1. Material

| Element | Nominal | Measured |

|---|---|---|

| Cr | 8.00–9.50 | 8.55 |

| Mo | 0.85–1.05 | 0.88 |

| V | 0.18–0.25 | 0.21 |

| Nb | 0.06–0.10 | 0.08 |

| C | 0.08–0.12 | 0.10 |

| Mn | 0.30–0.60 | 0.51 |

| Cu | 0.4 (max.) | 0.18 |

| Si | 0.20–0.50 | 0.32 |

| N | 0.03–0.07 | 0.035 |

| Ni | 0.40 (max.) | 0.15 |

| P | 0.02 (max.) | 0.012 |

| S | 0.01 (max.) | 0.005 |

| Ti | 0.01 (max.) | 0.002 |

| Al | 0.02 (max.) | 0.007 |

| Zr | 0.01 (max.) | 0.001 |

| Fe | Balance | Balance |

2.2. Heat Treatment

2.3. Metallographic Characterization

2.4. Thermodynamic Modeling

2.5. Differential Scanning Calorimetry

3. Results

3.1. Microstructural Characteristics

3.2. Hardness of Heat Treated Steel

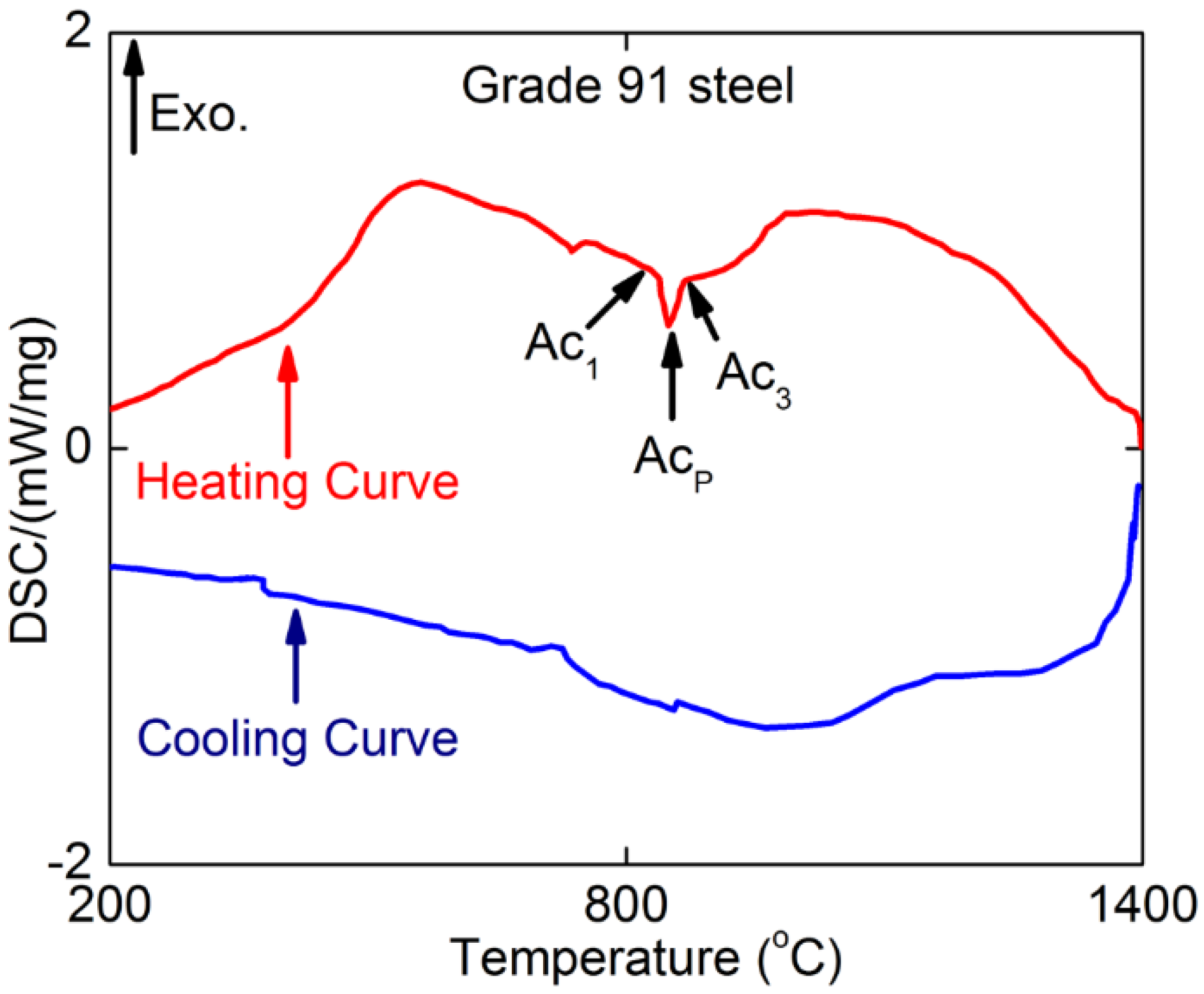

3.3. Differential Scanning Calorimetry

| Description of Phase Change | Temperature (°C) |

|---|---|

| α′ + M23C6 + (V,Nb)(N,C) + Z-phase → α + M23C6 + (V,Nb)(N,C) + Z-phase | 550 |

| Tc (Curie Temperature) | 741 |

| α + M23C6 + (V,Nb)(N,C) + Z-phase → α + M23C6 + (V,Nb)(N,C) + (Nb,V)(C,N) | 770 |

| α + M23C6 + (V,Nb)(N,C) + (Nb,V)(C,N) → α + γ + (V,Nb)(N,C) + (Nb,V)(C,N) + M23C6 | 820 (Ac1) |

| α + γ + (V,Nb)(N,C) + (Nb,V)(C,N) + M23C6 → γ + (V,Nb)(N,C) + (Nb,V)(C,N) | 870 (Ac3) |

| γ + (V,Nb)(N,C) + (Nb,V)(C,N) → γ + (Ti,Nb)(N,C) + (Nb,V)(C,N) | 1045 |

| γ + (Ti,Nb)(N,C) + (Nb,V)(C,N) → δ + γ + (Ti,Nb)(N,C) | 1270 |

| δ + γ + (Ti,Nb)(N,C) → γ + δ | 1397 |

| Martensite start (Ms) | 380 |

3.4. Thermo-Calc Calculations

4. Discussion

4.1. As-Normalized Microstructure

4.2. Tempered Microstructure

4.3. DSC Study

4.4. Thermo-Calc Calculations

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Charit, I.; Murty, K.L. Structural materials issues for the next generation fission reactors. JOM 2010, 62, 67–74. [Google Scholar] [CrossRef]

- Murty, K.L.; Charit, I. Structural materials for Gen-IV nuclear reactors: Challenges and opportunities. J. Nucl. Mater. 2008, 383, 189–195. [Google Scholar] [CrossRef]

- Rojas, D. 9%–12% Cr Heat Resistant Steels: Alloy Design, Tem Characterization of Microstructure Evolution and Creep Response at 650 °C. Ph.D. Thesis, Ruhr-University Bochum, North Rhine-Westphalia, Germany, 2011. [Google Scholar]

- Vishwanathan, R.; Bakker, W.T. Materials for boilers in ultra-supercritical power plants. In Proceedings of the 2000 International Joint Power Generation Conference, Miami Beach, FL, USA, 23–26 July 2000; pp. 1–22.

- Buhre, B.J.P.; Gupta, R.; Richardson, S.; Sharma, A.; Spero, C.; Wall, T. PF-Fired supercritical boilers: Operational issues and coal quality impacts. Available online: http://www.steamforum.com/pictures/Supercritical%20TN%2020%20PF%20Super%20Critical.pdf (accessed on 20 January 2015).

- Shrestha, T.; Basirat, M.; Charit, I.; Potirniche, G.P.; Rink, K.K. Creep deformation mechanisms in modified 9Cr-1Mo steel. J. Nucl. Mater. 2012, 423, 110–119. [Google Scholar] [CrossRef]

- Basirat, M.; Shrestha, T.; Potirniche, G.P.; Charit, I.; Rink, K. A study of the creep behavior of modified 9Cr-1Mo steel using continuum damage modeling. Int. J. Plast. 2012, 37, 95–107. [Google Scholar] [CrossRef]

- Shrestha, T.; Basirat, M.; Charit, I.; Potirniche, G.P.; Rink, K.K. Creep rupture behavior of Grade 91 steel. Mater. Sci. Eng. A 2013, 565, 382–391. [Google Scholar] [CrossRef]

- Ahn, J.C.; Sim, G.M.; Lee, K.S. Effect of aging treatment on high temperature strength of Nb added ferritic stainless steels. Mater. Sci. Forum 2005, 475, 191–194. [Google Scholar] [CrossRef]

- Ganesh, B.J.; Raju, S.; Rai, A.K.; Mohandas, E.; Vijayalakshmi, M.; Rao, K.B.S.; Raj, B. Differential scanning calorimetry study of diffusional and martensitic transformations in some 9 wt-% Cr low carbon ferritic steels. Mater. Sci. Technol. 2011, 27, 500–512. [Google Scholar] [CrossRef]

- Yoshino, M.; Mishima, Y.; Toda, Y.; Kushima, H.; Sawada, K.; Kimura, K. Influence of normalizing heat treatment on precipitation behavior in modified 9Cr-1Mo steel. Mater. High Temp. 2008, 25, 149–158. [Google Scholar] [CrossRef]

- Totemeier, T.C.; Tian, H.; Simpson, J.A. Effect of normalization temperature on the creep strength of modified 9Cr-1Mo steel. Metall. Mater. Trans. 2005, 37, 1519–1525. [Google Scholar] [CrossRef]

- Dudko, V.; Delyakov, A.; Kaibyshev, R. Effect of tempering on mechanical properties and microstructure of a 9% Cr heat resistant steel. Mater. Sci. Forum 2012, 706, 841–846. [Google Scholar] [CrossRef]

- Sawada, K.; Suzuki, K.; Kushima, H.; Tabuchi, M.; Kimura, K. Effect of tempering temperature on Z-phase formation and creep strength in 9Cr-1Mo-V-Nb-N steel. Mater. Sci. Eng. A 2008, 480, 558–563. [Google Scholar] [CrossRef]

- Masuyama, F.; Nishimura, N. Experience with creep-strength enhanced ferritic steels and new emerging computational methods. In Proceedings of the 2004 ASME/JSME Pressure Vessels and Piping Conference, San Diego, CA, USA, 25–29 July 2004; Volume 476, pp. 85–92.

- Shen, Y.Z.; Kim, S.H.; Cho, H.D.; Han, C.H.; Ryu, W.S. Identification of precipitate phases in a 11Cr ferritic/martensitic steel using electron microdiffraction. J. Nucl. Mater. 2010, 400, 64–68. [Google Scholar] [CrossRef]

- Anderson, P.; Bellgard, T.; Jones, F.L. Creep deformation in a modified 9Cr-1Mo steel. Mater. Sci. Technol. 2003, 19, 207–213. [Google Scholar] [CrossRef]

- Das, C.R.; Albert, S.K.; Bhaduri, A.K.; Srinivasan, G.; Murty, B.S. Effect of prior microstructure and mechanical properties of modified 9Cr-1Mo steel weld joints. Mater. Sci. Eng. A 2008, 477, 185–192. [Google Scholar] [CrossRef]

- Silwal, B.; Li, L.; Deceuster, A.; Griffiths, B. Effect of post-weld heat treatment on toughness of heat-affected zone of Grade 91 steel. Welding J. 2013, 92, 80s–87s. [Google Scholar]

- Shtansky, D.V.; Inden, G. Phase transformation in Fe-Mo-C and Fe-W-C steels—II. Eutectoid reaction of M23C6 carbide decomposition during austenitization. Acta Mater. 1997, 45, 2879–2895. [Google Scholar] [CrossRef]

- Ganesh, B.J.; Raju, S.; Mohandas, E.; Vijayalakshmi, M. Effect of thermal aging on the transformation temperatures and specific heat characteristics of 9Cr-1Mo ferritic steel. Defect Diffus. Forum 2008, 279, 85–90. [Google Scholar]

- Oono, N.; Nitta, H.; Iijima, Y. Diffusion of Nb in α-iron. Mater. Trans. 2003, 44, 2078–2083. [Google Scholar] [CrossRef]

- Raju, S.; Ganesh, B.J.; Rai, A.K.; Saroja, S.; Mohandas, E.; Vijayalakshmi, M.; Raj, B. Drop calorimetry studies on 9Cr-1W-0.23V-0.06Ta-0.09C reduced activation steel. Int. J. Thermophys. 2010, 31, 399–415. [Google Scholar] [CrossRef]

- Hald, J.; Korcakova, L.; Danielsen, H.K.; Dahl, K.V. Thermodynamics and kinetic modeling: Creep resistant materials. Mater. Sci. Technol. 2009, 24, 149–158. [Google Scholar] [CrossRef]

- Hong, S.G.; Jun, H.J.; Kang, K.B.; Park, C.G. Evolution of precipitates in the Nb-Ti-V microalloyed HSLA steels during reheating. Scr. Mater. 2003, 48, 1201–1206. [Google Scholar] [CrossRef]

- Taylor, K.A. Solubility products of titanium-, vanadium-, and niobium-carbide in ferrite. Scr. Mater. 1995, 32, 7–12. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shrestha, T.; Alsagabi, S.F.; Charit, I.; Potirniche, G.P.; Glazoff, M.V. Effect of Heat Treatment on Microstructure and Hardness of Grade 91 Steel. Metals 2015, 5, 131-149. https://doi.org/10.3390/met5010131

Shrestha T, Alsagabi SF, Charit I, Potirniche GP, Glazoff MV. Effect of Heat Treatment on Microstructure and Hardness of Grade 91 Steel. Metals. 2015; 5(1):131-149. https://doi.org/10.3390/met5010131

Chicago/Turabian StyleShrestha, Triratna, Sultan F. Alsagabi, Indrajit Charit, Gabriel P. Potirniche, and Michael V. Glazoff. 2015. "Effect of Heat Treatment on Microstructure and Hardness of Grade 91 Steel" Metals 5, no. 1: 131-149. https://doi.org/10.3390/met5010131

APA StyleShrestha, T., Alsagabi, S. F., Charit, I., Potirniche, G. P., & Glazoff, M. V. (2015). Effect of Heat Treatment on Microstructure and Hardness of Grade 91 Steel. Metals, 5(1), 131-149. https://doi.org/10.3390/met5010131