Study on Sintering Mechanism of Stainless Steel Fiber Felts by X-ray Computed Tomography

Abstract

:1. Introductions

2. Experimental Procedures

| Sintering Temperature(°C) | First Holding Time (min) | Test | Second Holding Time (min) | Test | Third Holding Time (min) | Test |

|---|---|---|---|---|---|---|

| 1000 | 10 | CT scan | 10 | CT scan | 20 | CT Scan |

| 1100 | 5 | 5 | 10 | |||

| 1200 | 5 | 5 | 10 |

3. Results and Discussions

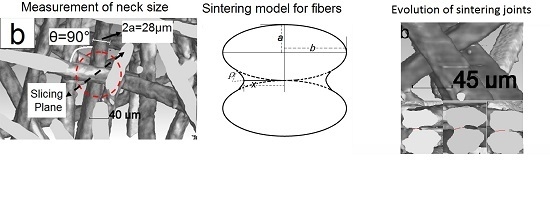

3.1. Dynamics Equation of Stable Neck Growth of Metal Fibers

3.2. Specific Evolutions of Sintering Joints

3.3. Determination of Sintering Mechanism of 316L SSFF

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix

References

- Lefebvre, L.P.; Banhart, J.; Dunand, D.C. Porous metals and metallic foams: Current status and recent developments. Adv. Eng. Mater. 2008, 10, 775–787. [Google Scholar] [CrossRef] [Green Version]

- Kostornov, A.G.; Galstyan, L.G. Sintering kinetics of porous fiber solids. Poroshkovaya Metall. 1984, 254, 41–45. [Google Scholar] [CrossRef]

- Balshin, M.Y.; Rybalchenko, M.K. Some problems of fiber metallurgy. Poroshkovaya Metall. 1964, 3, 16–22. [Google Scholar] [CrossRef]

- Kuczynski, G.C. Self-diffusion in sintering of metallic particles. Trans. Am. Inst. Min. Metall. Eng. 1949, 185, 169–178. [Google Scholar]

- Swinkels, F.B.; Ashby, M.F. A second report on sintering diagrams. Acta Metall. 1981, 29, 259–281. [Google Scholar] [CrossRef]

- Matsumara, G. Sintering of Iron Wires. Acta Metall. 1971, 19, 851–855. [Google Scholar] [CrossRef]

- Shyr, T.W.; Shie, J.W.; Huang, S.J.; Shun, T.Y.; Weng, S.H. Phase transformation of 316L stainless steel from wire to fiber. Mater. Chem. Phys. 2010, 122, 273–277. [Google Scholar] [CrossRef]

- Guo, S.J. Powder Sintering Theory; Metallurgical Industry Press: Beijing, China, 1998; pp. 185–187. [Google Scholar]

- Coble, R.L. Initial sintering of alumina and hematite. J. Am. Ceram. Soc. 1958, 41, 55–62. [Google Scholar] [CrossRef]

- Exner, H.E.; Bross, P. Material transport rate and stress distribution during grain boundary diffusion driven by surface tension. Acta Metall. 1979, 27, 1007–1012. [Google Scholar] [CrossRef]

- Exner, H.E.; Muller, C. Particle rearrangement and pore space coarsening during solid-state sintering. J. Am. Ceram. Soc. 2009, 92, 1384–1390. [Google Scholar] [CrossRef]

- Grupp, R.; Nothe, M.; Kieback, B.; Banhart, J. Cooperative material transport during the early stage of sintering. Nat. Commun. 2011. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Li, Y.; Hu, X.; Niu, Y.; Zhao, J.; Zhang, Z. In situ investigation of metal’s microwave sintering. Mater. Lett. 2012, 67, 162–164. [Google Scholar] [CrossRef]

- Guo, S.J. Powder Sintering Theory; Metallurgical Industry Press: Beijing, China, 1998; p. 189. [Google Scholar]

- Schatt, W.; Friedrich, E.; Joensson, D. Spannungsverteilung und versetzungsvervielfachung in der sinterkontaktregion. Acta Metall. 1983, 3, 121–128. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Li, A.; Tang, H. Study on Sintering Mechanism of Stainless Steel Fiber Felts by X-ray Computed Tomography. Metals 2016, 6, 18. https://doi.org/10.3390/met6010018

Ma J, Li A, Tang H. Study on Sintering Mechanism of Stainless Steel Fiber Felts by X-ray Computed Tomography. Metals. 2016; 6(1):18. https://doi.org/10.3390/met6010018

Chicago/Turabian StyleMa, Jun, Aijun Li, and Huiping Tang. 2016. "Study on Sintering Mechanism of Stainless Steel Fiber Felts by X-ray Computed Tomography" Metals 6, no. 1: 18. https://doi.org/10.3390/met6010018