Influence of Microstructure on Strength and Ductility in Fully Pearlitic Steels

Abstract

:1. Introduction

2. Experimental Method

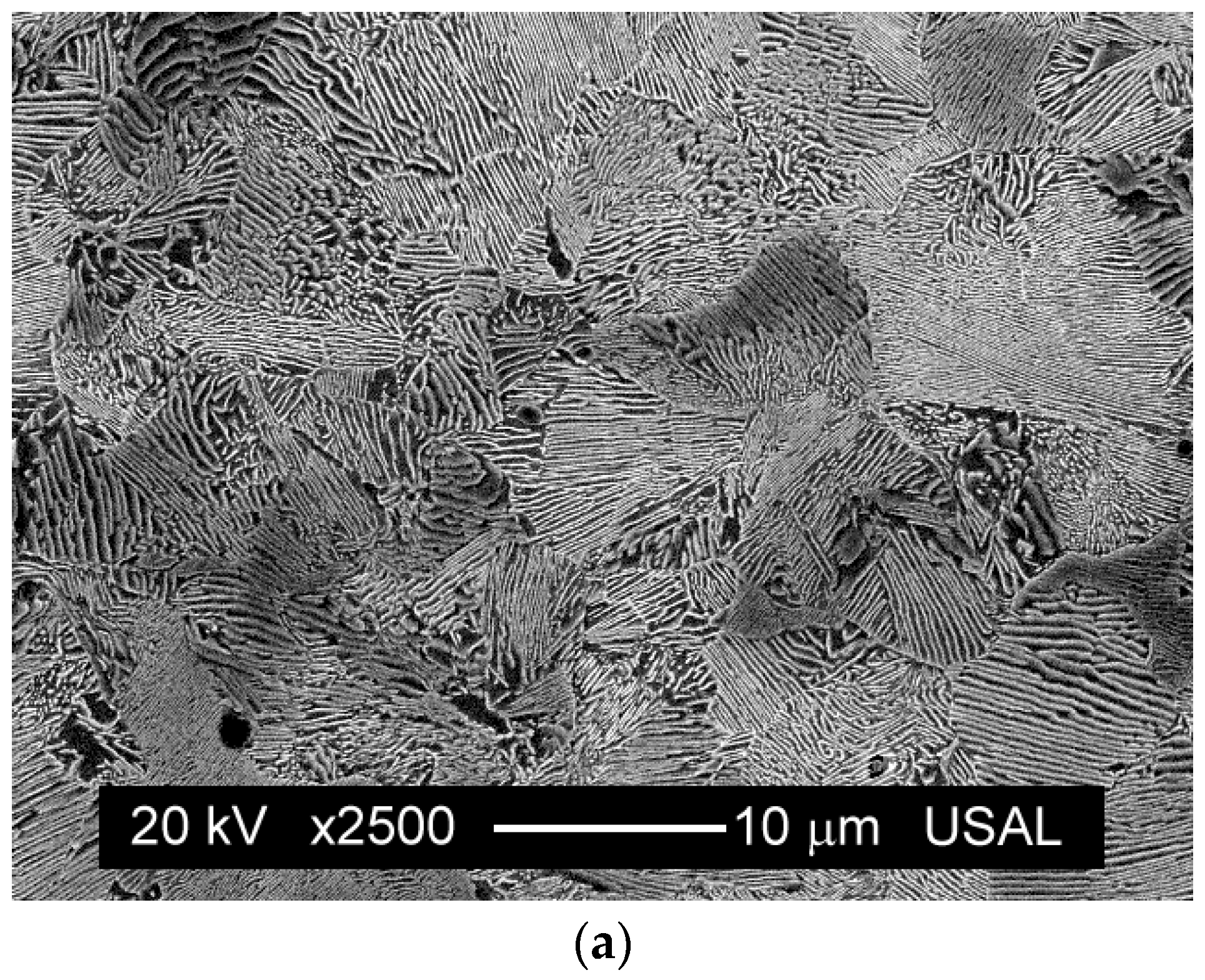

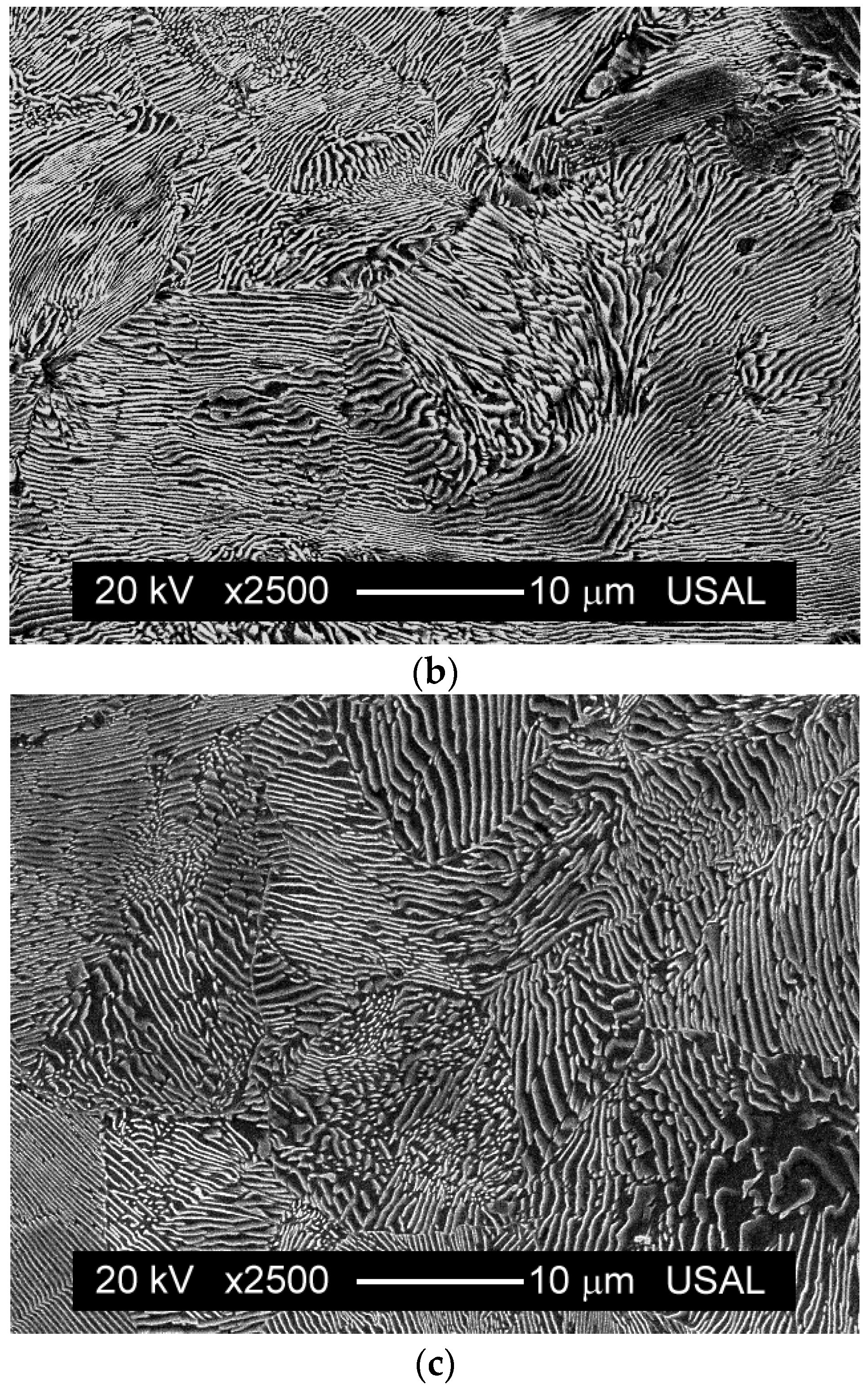

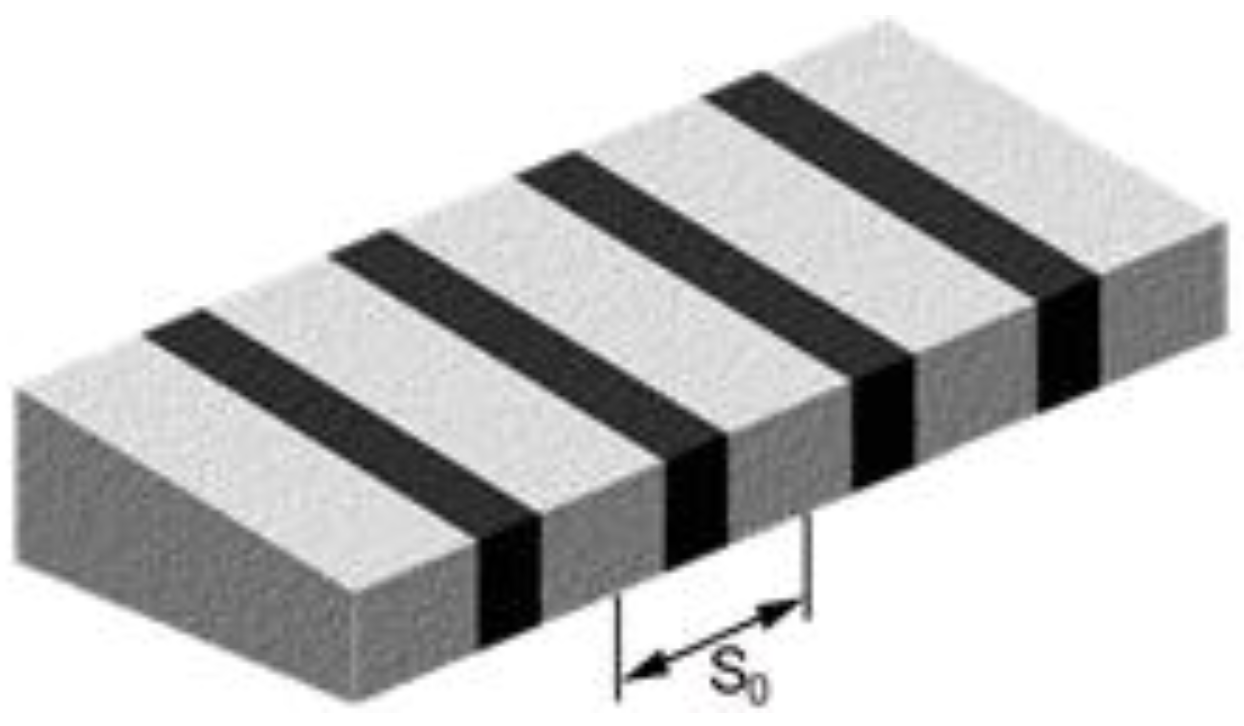

3. Microstructural Features

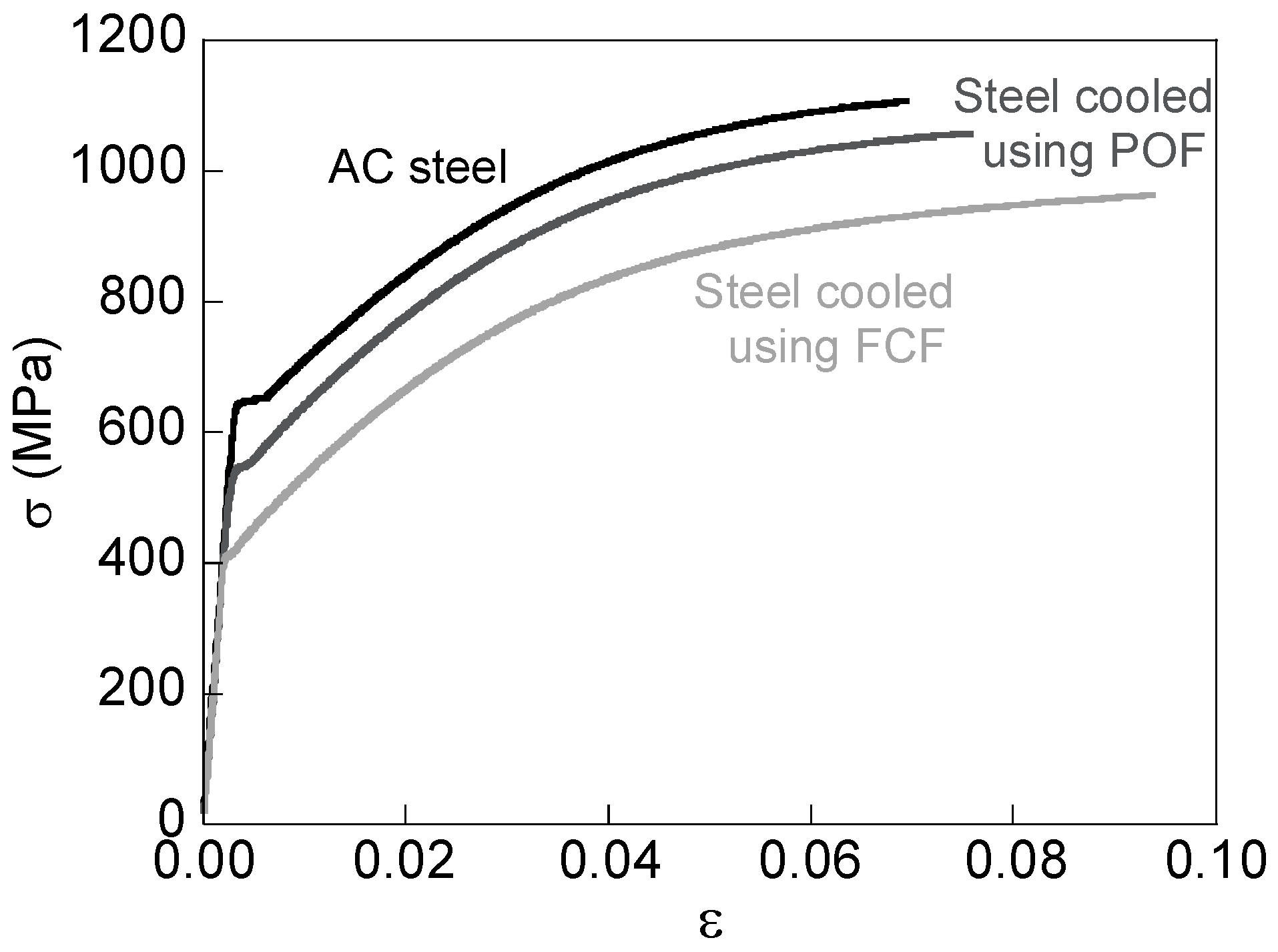

4. Mechanical Properties

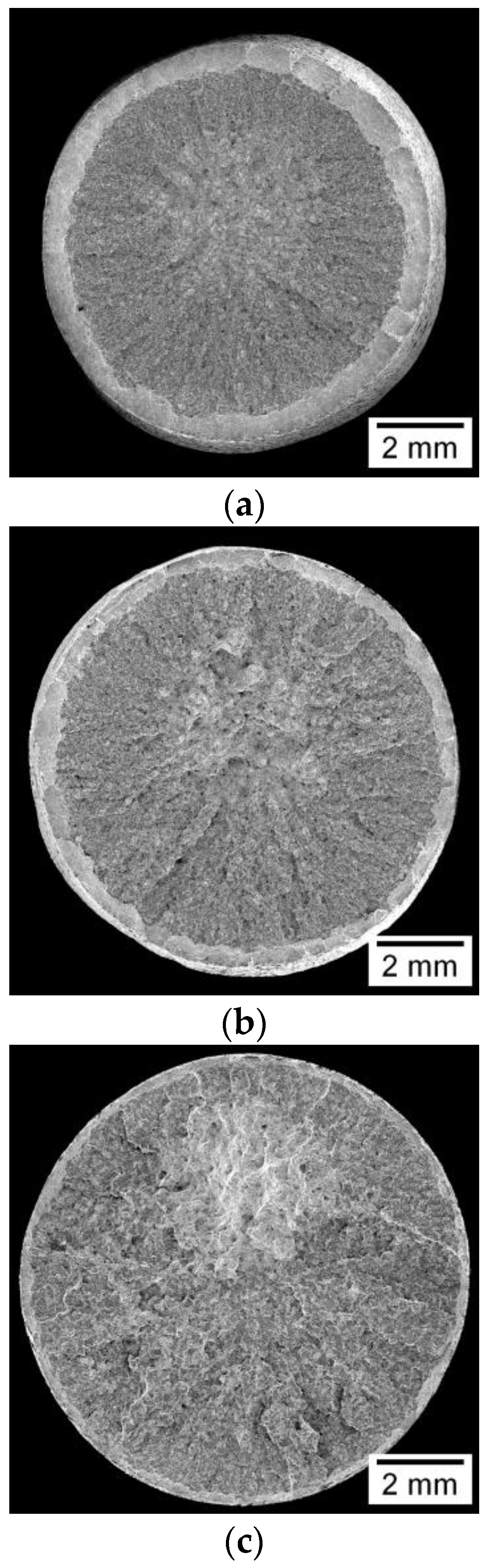

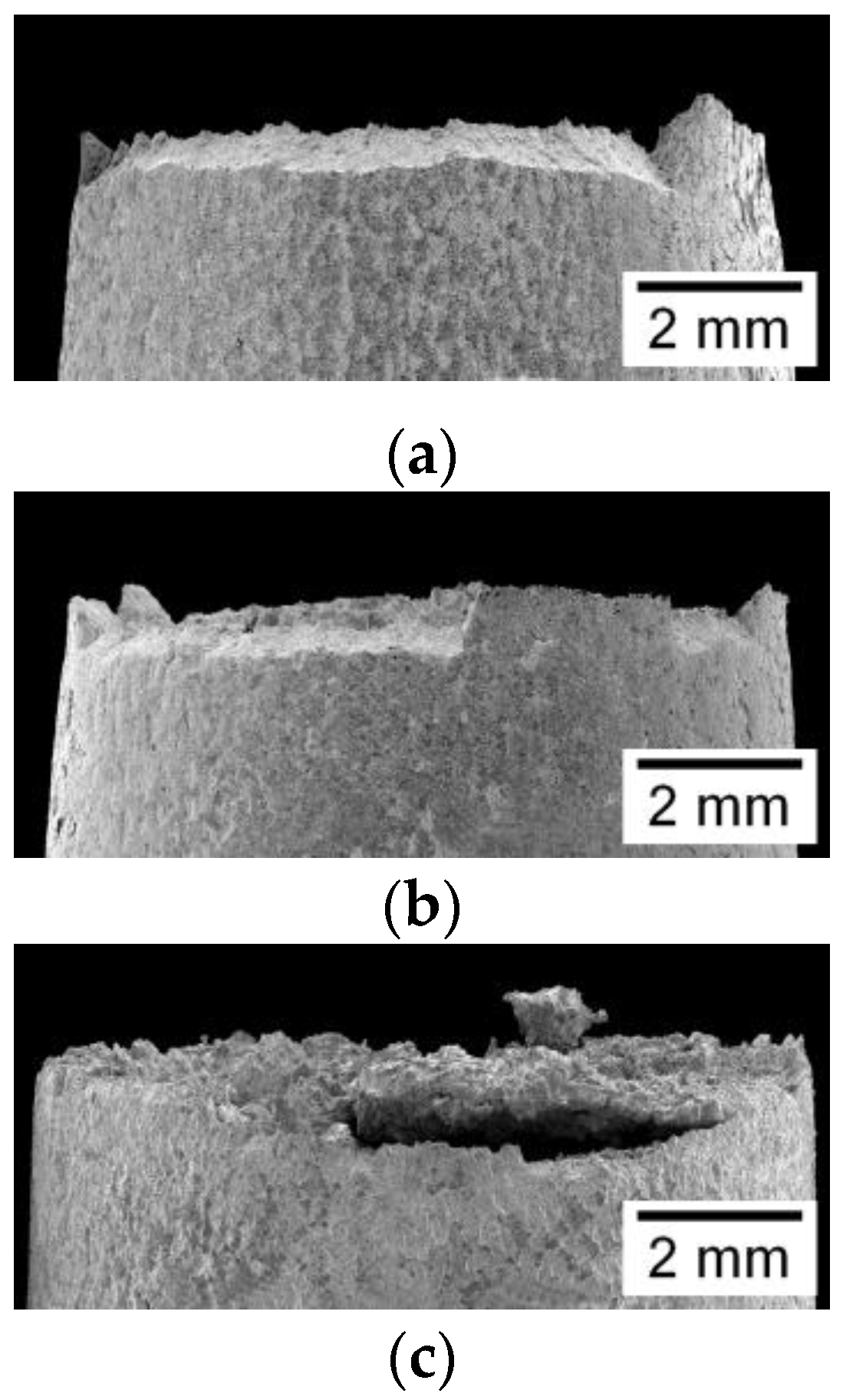

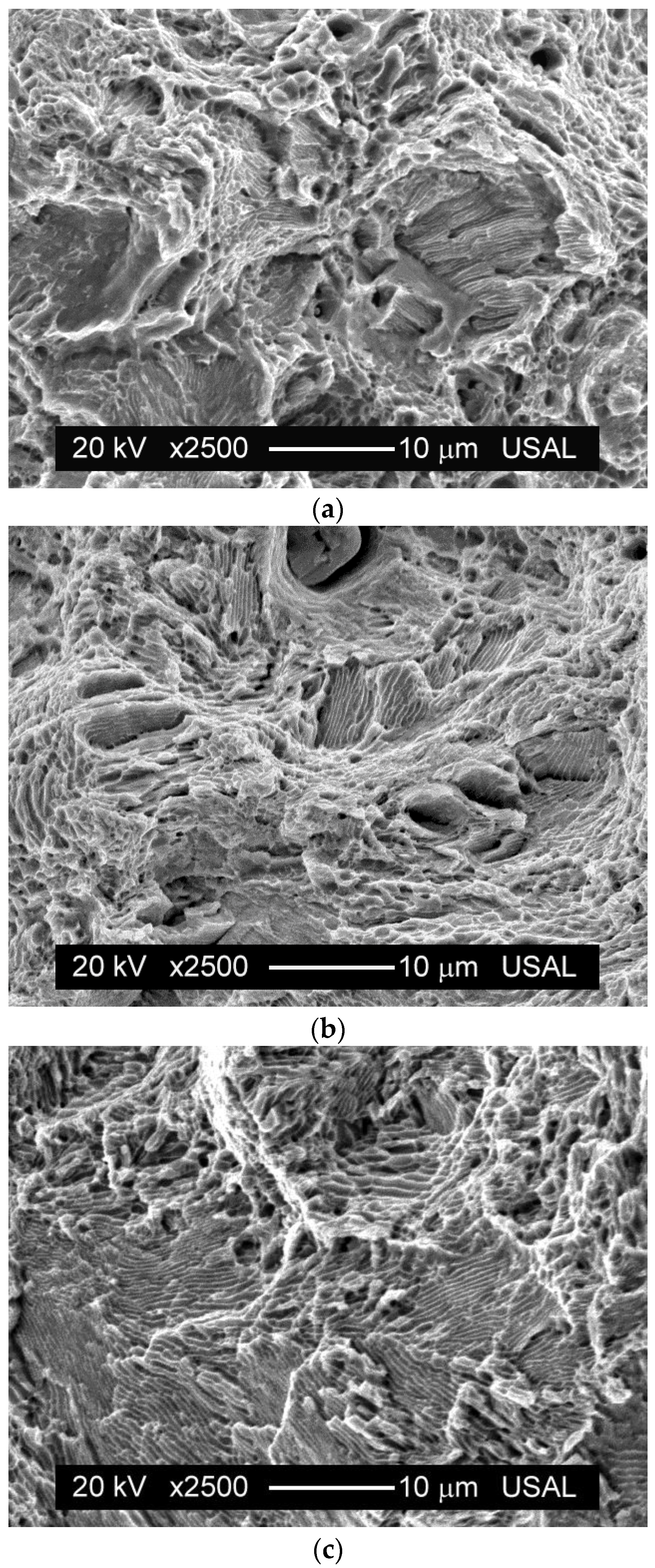

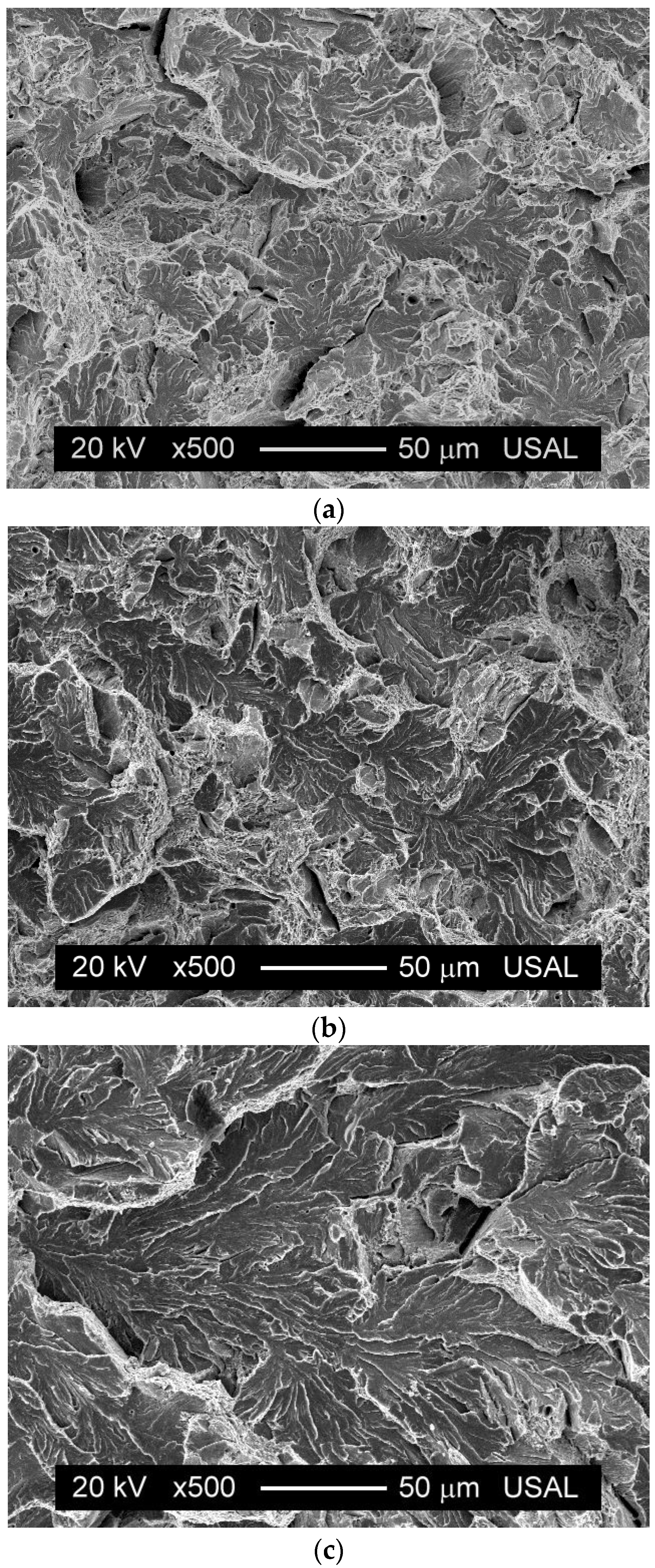

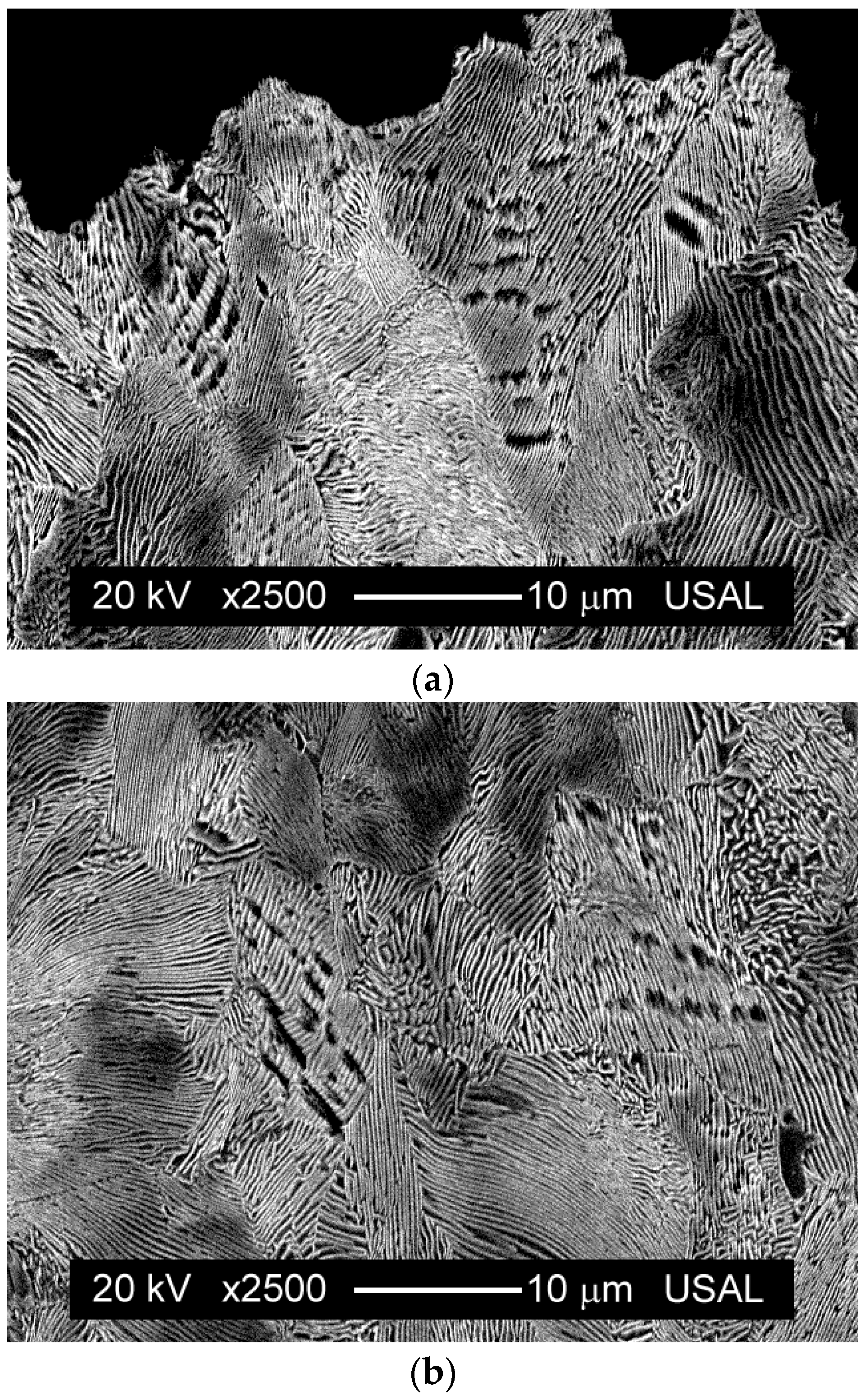

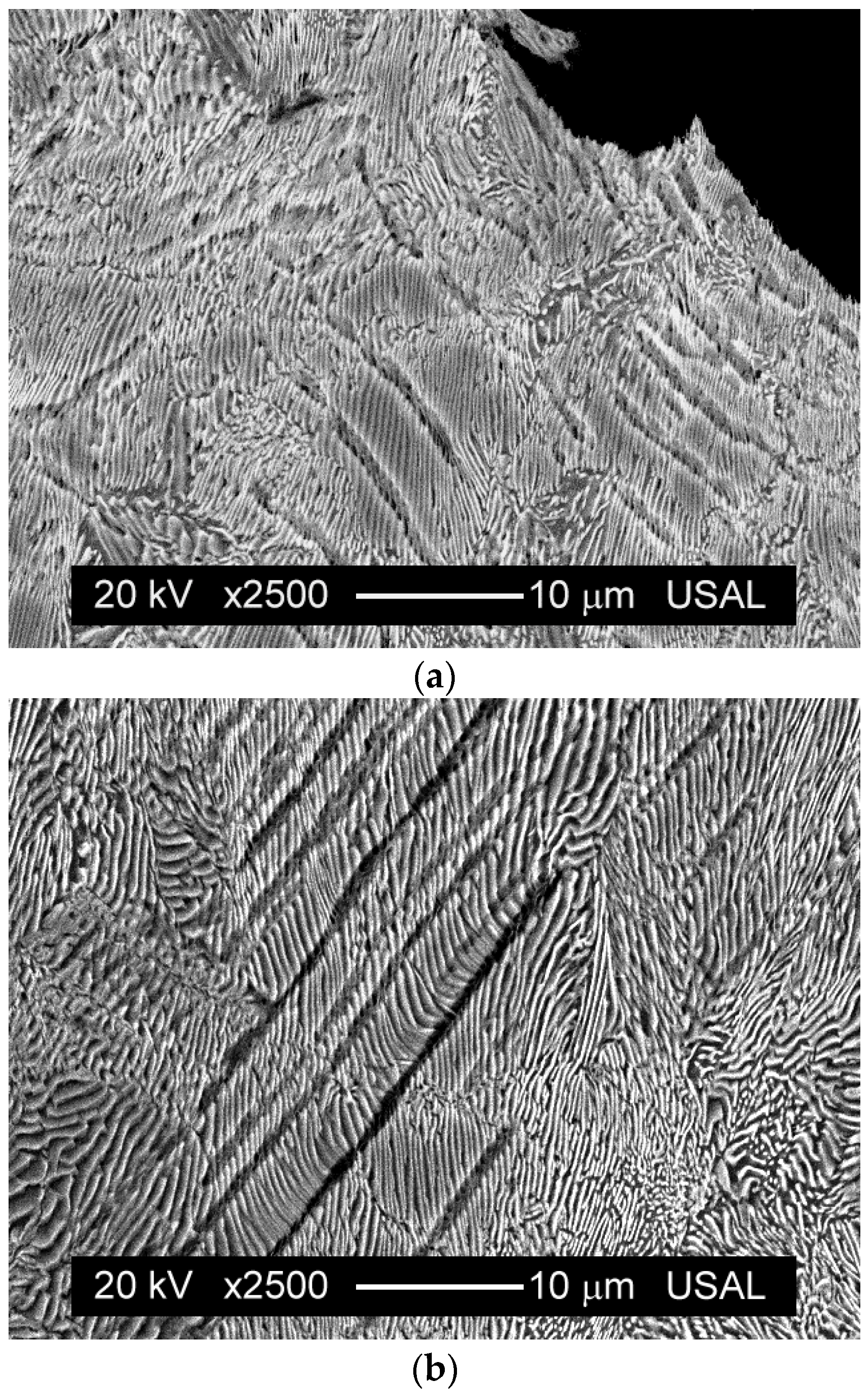

5. Fracture Surfaces

6. Fracto-Metallographic Analysis

7. Conclusions

- (1)

- The cooling rate clearly affects the steel microstructure, so that quick cooling produces finer pearlitic microstructures (smaller colonies and lower interlamellar spacing).

- (2)

- Material strength (represented by the yield stress and the ultimate tensile strength) increases when the heat treatment is applied by means of a rising cooling rate.

- (3)

- The increase of the cooling rate produces a decrease of the strain for maximum load (uniform elongation) and an increase of the reduction in area (non-uniform elongation).

- (4)

- From the macroscopic point of view, fracture surfaces resemble a more ductile appearance as the cooling rate rises.

- (5)

- The fractography of the process zone (that associated with fracture initiation) consists mainly of a mixture of two fracture micromechanisms: microvoid coalescence (MVC) and localized areas where the pearlite lamellae are easily observed.

- (6)

- For coarse pearlite microstructures (those associated with slow cooling that produces bigger colonies and higher interlamellar spacing), the fracture process is more brittle and more presence of ferrite/cementite lamellae can be observed in the fracture process zone (with the associated lower percentage of MVC areas).

- (7)

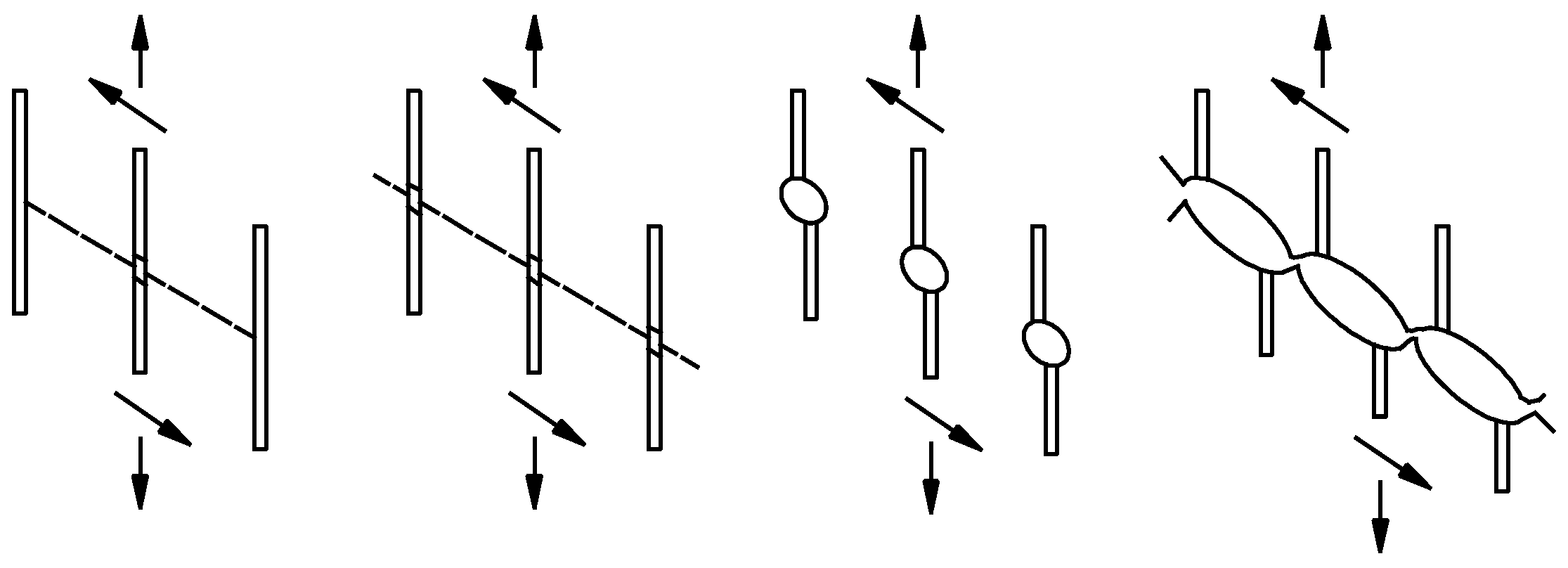

- The macroscopic fracture mode (brittle or ductile) can be explained on the basis of the microstructure of the pearlitic steel as a consequence of the heat treatment applied on it. In fine pearlitic microstructures, micro-damage during the standard tensile test takes place in the form of very small microcracks, thereby producing a ductile fracture behavior. On the other hand, in coarse pearlitic microstructures, micro-damage happens in the form of longer and aligned microcracks, thus generating a more brittle fracture behavior.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hall, E.O. The deformation and ageing of mild steel: III Discussion of results. Proc. Phys. Soc. Sect. 1951, B64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Karlsson, B.; Lindén, G. Plastic deformation of eutectoid steel with different cementite morphologies. Mater. Sci. Eng. 1975, 17, 153–164. [Google Scholar] [CrossRef]

- Marder, A.R.; Bramfitt, B.L. The effect of morphology on the strength of pearlite. Metall. Trans. 1976, 7A, 365–372. [Google Scholar] [CrossRef]

- Hyzak, J.M.; Bernstein, I.M. The role of microstructure on the strength and toughness of fully pearlitic steels. Metall. Trans. 1976, 7A, 1217–1224. [Google Scholar] [CrossRef]

- Kavishe, F.P.L.; Baker, T.J. Effect of prior austenite grain size and pearlite interlamellar spacing on strength and fracture toughness of a eutectoid rail steel. Mater. Sci. Technol. 1986, 2, 816–822. [Google Scholar] [CrossRef]

- Ray, K.K.; Mondal, D. The effect of interlamellar spacing on strength of pearlite in annealed eutectoid and hypoeutectoid plain carbon steels. Acta Metall. Mater. 1991, 39, 2201–2208. [Google Scholar] [CrossRef]

- Modi, O.P.; Deshmukh, N.; Mondal, D.P.; Jha, A.K.; Yegneswaran, A.H.; Khaira, H.K. Effect of interlamellar spacing on the mechanical properties of 0.65% C steel. Mater. Charact. 2001, 46, 347–352. [Google Scholar] [CrossRef]

- Elwazri, A.M.; Wanjara, P.; Yue, S. The effect of microstructural characteristics of pearlite on the mechanical properties of hypereutectoid steel. Mater. Sci. Eng. A 2005, 404, 91–98. [Google Scholar] [CrossRef]

- Yahyaoui, H.; Sidhom, H.; Braham, C.; Baczmanski, A. Effect of interlamellar spacing on the elastoplastic behavior of C70 pearlitic steel: Experimental results and self-consistent modeling. Mater. Des. 2014, 55, 888–897. [Google Scholar] [CrossRef] [Green Version]

- Dollar, M.; Bernstein, I.M.; Thompson, A.W. Influence of deformation substructure on flow and fracture of fully pearlitic steel. Acta Metall. 1988, 36, 311–320. [Google Scholar] [CrossRef]

- Toribio, J. Relationship between microstructure and strength in eutectoid steels. Mater. Sci. Eng. A 2004, 387–389, 227–230. [Google Scholar] [CrossRef]

- Toribio, J.; González, B.; Matos, J.C. Microstructure and mechanical properties in progressively drawn pearlitic steel. Mater. Trans. 2014, 55, 93–98. [Google Scholar] [CrossRef]

- Gomes, M.G.M.F.; de Almeida, L.H.; Gomes, L.C.F.C.; le May, I. Effects of microstructural parameters on the mechanical properties of eutectoid rail steels. Mater. Charact. 1997, 39, 1–14. [Google Scholar] [CrossRef]

- Bae, C.M.; Nam, W.J.; Lee, C.S. Effect of microstructural features on ductility in hypo-eutectoid steels. Scr. Mater. 1999, 41, 605–610. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Thompson, A.W. Effects of the prior austenite grain size on the ductility of fully pearlitic eutectoid steel. Metall. Trans. 1986, 17A, 461–472. [Google Scholar] [CrossRef]

- Izotov, V.I.; Pozdnyakov, V.A.; Luk′yanenko, E.V.; Usanova, O.Y.; Filippov, G.A. Influence of the pearlite fineness on the mechanical properties, deformation behavior, and fracture characteristics of carbon steel. Phys. Met. Metallogr. 2007, 103, 519–529. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E.; Smith, G.D.W. Dynamic studies of the tensile deformation and fracture of pearlite. Acta Metall. 1978, 26, 1405–1422. [Google Scholar] [CrossRef]

- Abrams, H. Grain size measurement by the intercept method. Metallography 1971, 4, 59–78. [Google Scholar] [CrossRef]

- Hu, X.; Houtte, P.V.; Liebeherr, M.; Walentek, A.; Seefeldt, M.; Vandekinderen, H. Modeling work hardening of pearlitic steels by phenomenological and Taylor-type micromechanical models. Acta Mater. 2006, 54, 1029–1040. [Google Scholar] [CrossRef]

- Li, J.; Sun, F.; Xu, W. On the evaluation of yield strength for microalloyed steels. Scr. Metall. Mater. 1990, 24, 1393–1398. [Google Scholar]

- Batte, A.D.; Honeycombe, R.W.K. Strengthening of ferrite by vanadium carbide precipitation. Met. Sci. J. 1973, 7, 160–168. [Google Scholar] [CrossRef]

- Izotov, B.I. Precipitation of disperse vanadium carbides at the interphase boundary upon the pearlitic transformation of a steel. Phys. Met. Metall. 2011, 111, 592–597. [Google Scholar] [CrossRef]

- Park, Y.J.; Bernstein, I.M. The process of crack initiation and effective grain size for cleavage fracture in pearlitic eutectoid steel. Metall. Trans. 1979, 10A, 1653–1664. [Google Scholar] [CrossRef]

- Miller, L.E.; Smith, G.C. Tensile fractures in carbon steels. J. Iron Steel Inst. 1970, 208, 998–1005. [Google Scholar]

| Cooling System | AC | POF | FCF |

|---|---|---|---|

| dC (μm) | 12 | 15 | 19 |

| s0 (μm) | 0.16 | 0.23 | 0.26 |

| Cooling System | AC | POF | FCF |

|---|---|---|---|

| E (GPa) | 202 | 200 | 203 |

| σY (MPa) | 650 | 560 | 441 |

| σR (MPa) | 1105 | 1055 | 965 |

| εR | 0.067 | 0.072 | 0.092 |

| RA (%) | 33 | 20 | 14 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toribio, J.; González, B.; Matos, J.-C.; Ayaso, F.-J. Influence of Microstructure on Strength and Ductility in Fully Pearlitic Steels. Metals 2016, 6, 318. https://doi.org/10.3390/met6120318

Toribio J, González B, Matos J-C, Ayaso F-J. Influence of Microstructure on Strength and Ductility in Fully Pearlitic Steels. Metals. 2016; 6(12):318. https://doi.org/10.3390/met6120318

Chicago/Turabian StyleToribio, Jesús, Beatriz González, Juan-Carlos Matos, and Francisco-Javier Ayaso. 2016. "Influence of Microstructure on Strength and Ductility in Fully Pearlitic Steels" Metals 6, no. 12: 318. https://doi.org/10.3390/met6120318