Ti/Al Multi-Layered Sheets: Accumulative Roll Bonding (Part A)

Abstract

:1. Introduction

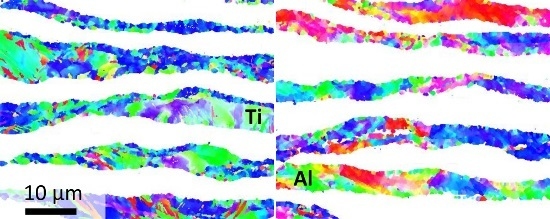

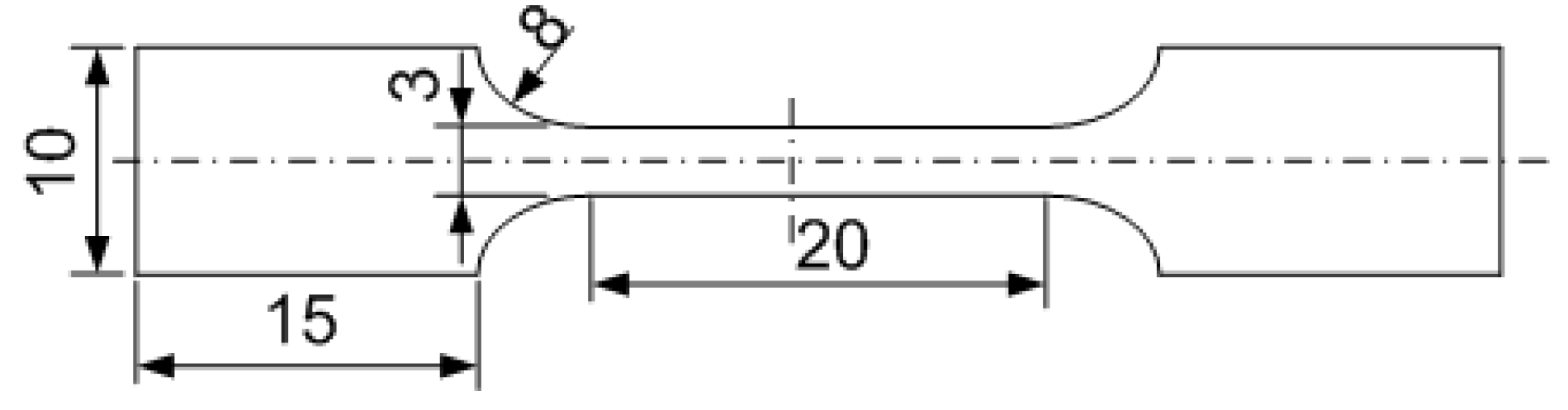

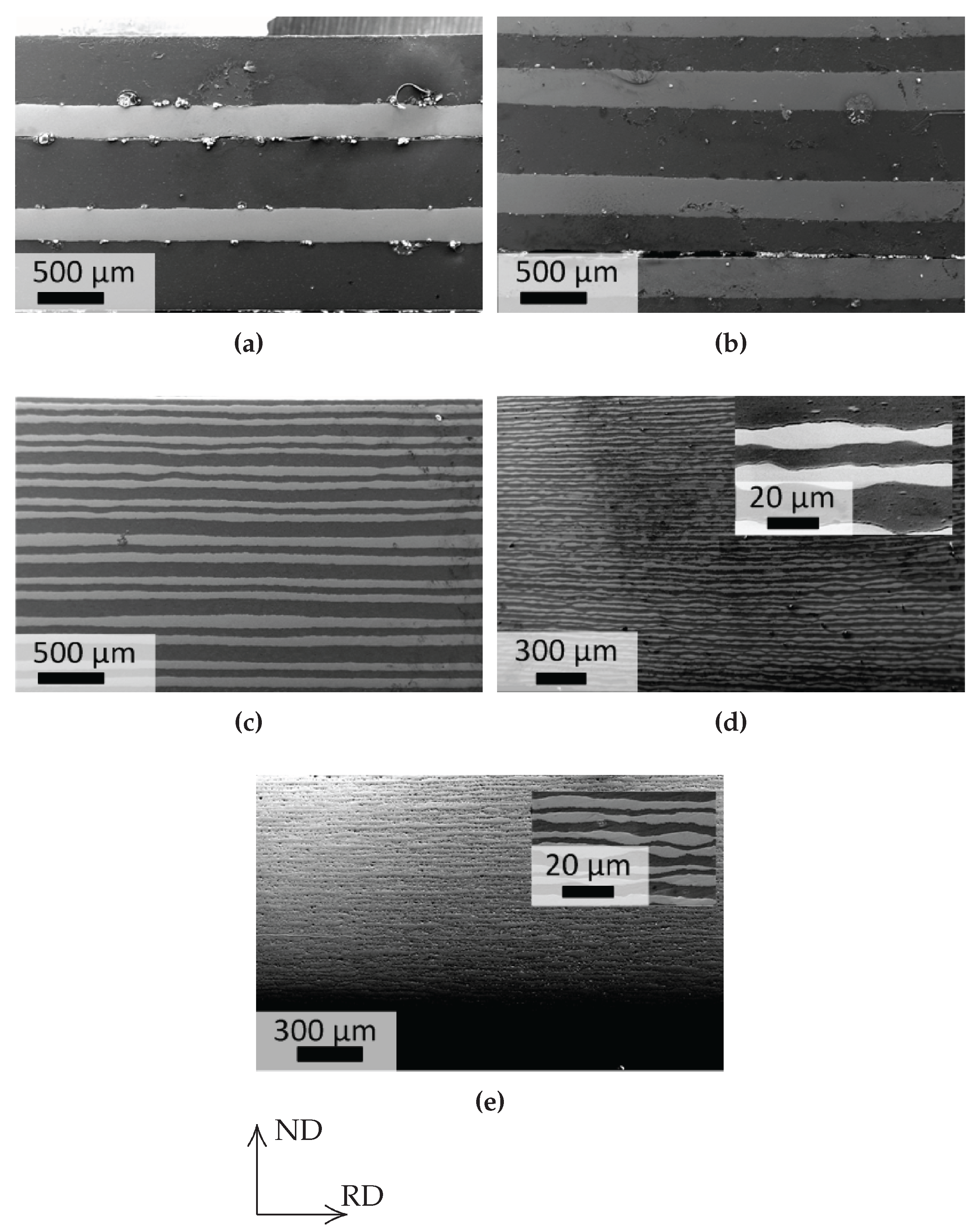

2. Experimental Section

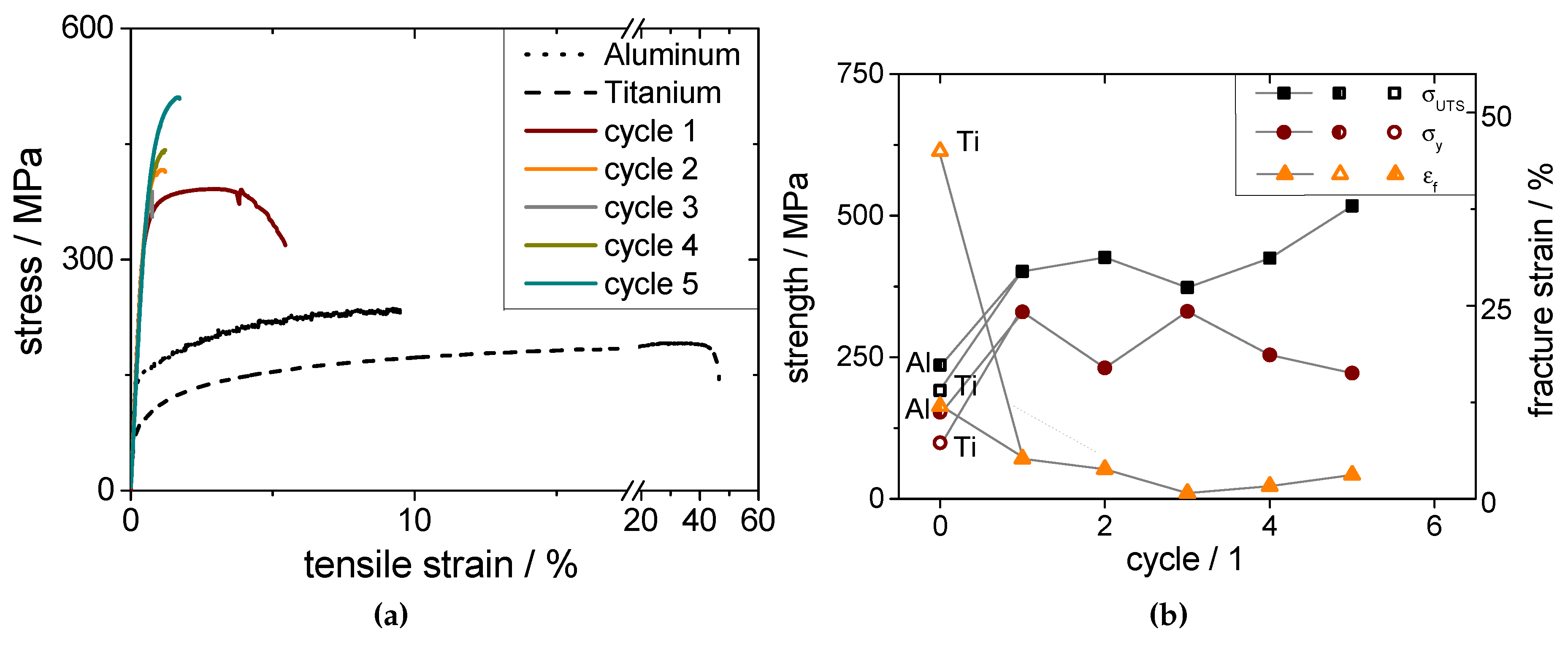

3. Results and Discussion

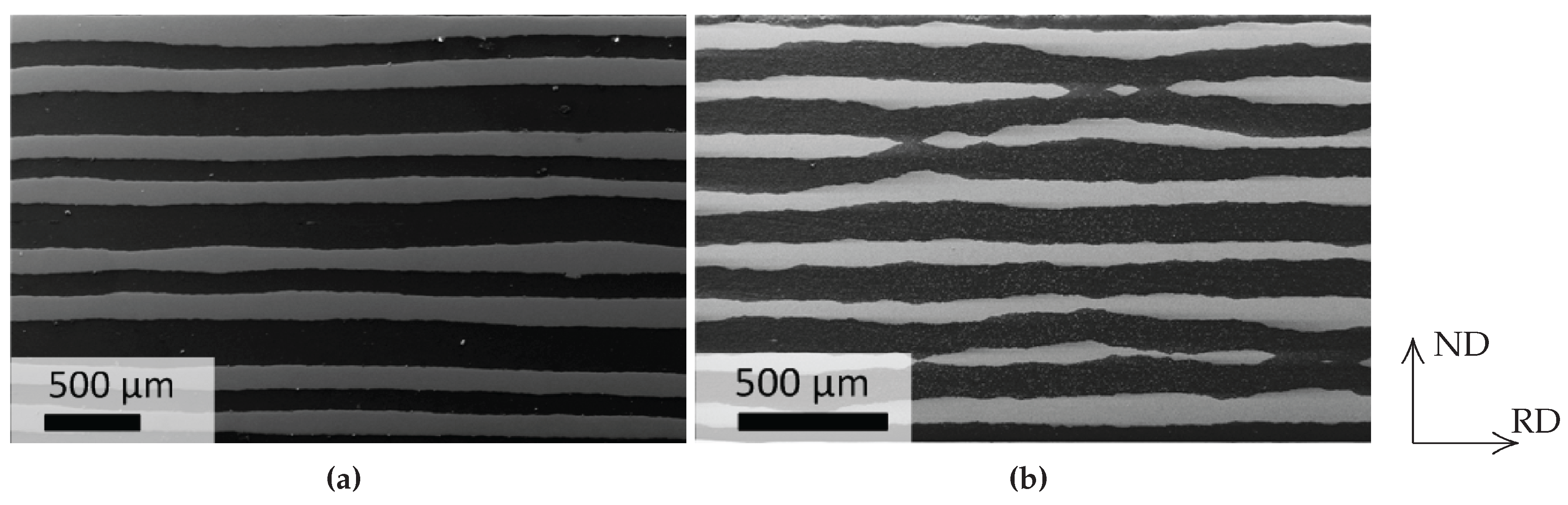

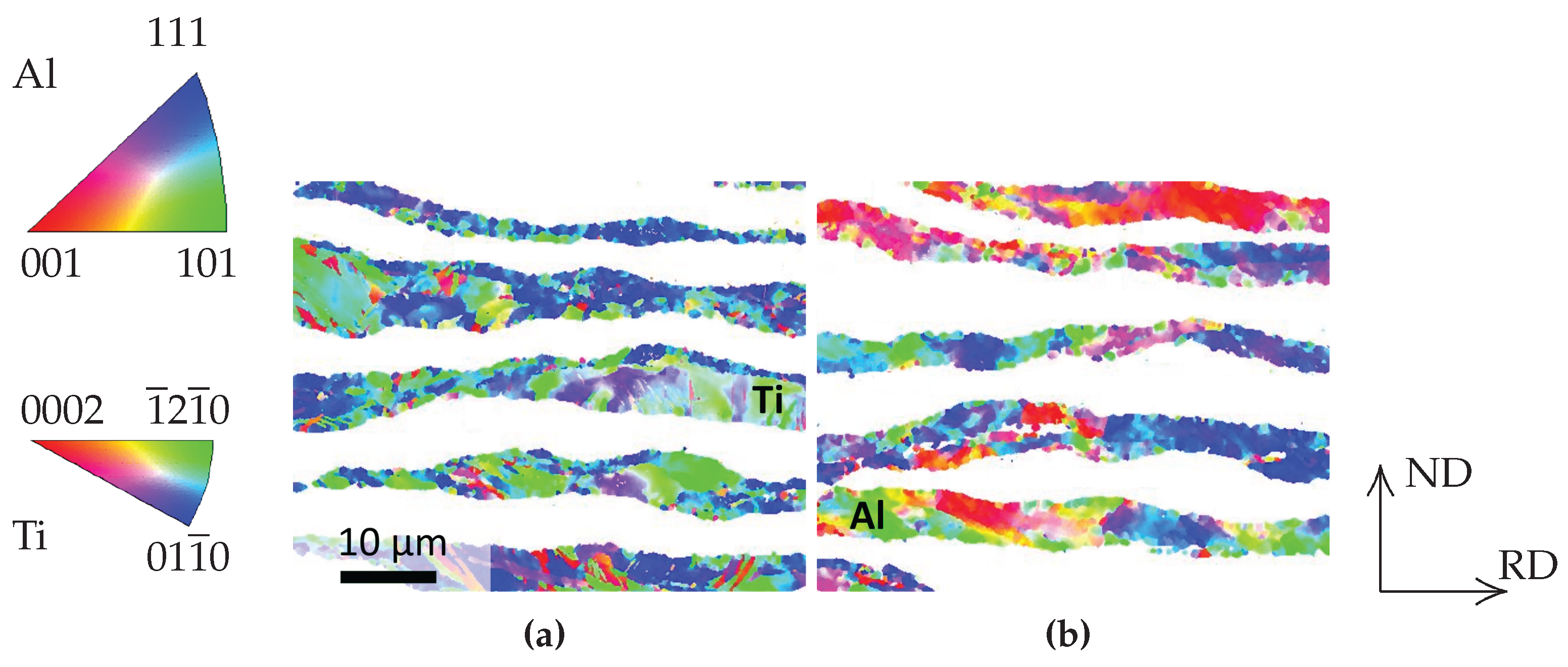

3.1. Intermediate Heat Treatment

3.2. Deformation Speed

3.3. ARB at Elevated Temperatures

| Temperature | Thickness Reduction | ||

|---|---|---|---|

| 30% | 40% | 50% | |

| RT | no bonding | weak bonding | strong bonding |

| laminar layers | necking of Ti | ||

| 473 K | no bonding | sufficient bonding | strong bonding |

| laminar layers | necking of Ti | ||

| 573 K | no bonding | sufficient bonding | sufficient bonding |

| laminar layers | necking of Ti | ||

3.4. Asymmetric ARB

4. Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kaufmann, H.; Sonsino, C.; Demofonti, G.; Riscifuli, S. High-strength steels in welded state for light-weight constructions under high and variable stress peaks. Steel Res. Int. 2008, 79, 382–389. [Google Scholar]

- Sonsino, C. Light-weight design chances using high-strength steels. Mater. Und Werkst. 2007, 38, 9–22. [Google Scholar] [CrossRef]

- Kwon, O.; Lee, K.; Kim, G.; Chin, K. New Trends in Advanced High Strength Steel Developments for Automotive Application. Mater. Sci. Forum 2010, 638–642, 136–141. [Google Scholar] [CrossRef]

- Lee, S.; Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T. Role of shear strain in ultragrain refinement by accumulative roll-bonding ARB process. Scr. Mater. 2002, 46, 281–285. [Google Scholar] [CrossRef]

- Shi, M.; Takayama, Y.; Ma, C.; Watanabe, H.; Inoue, H. Microstructure and texture evolution in titanium subjected to friction roll surface processing and subsequent annealing. Trans. Nonferrous Met. Soc. China 2012, 22, 2616–2627. [Google Scholar] [CrossRef]

- Belov, N. Sparingly alloyed high-strength aluminum alloys: Principles of optimization of phase composition. Met. Sci. Heat Treat. 2012, 53, 420–427. [Google Scholar] [CrossRef]

- Sabirov, I.; Murashkin, M.; Valiev, R. Nanostructured aluminum alloys produced by severe plastic deformation: New horizons in development. Mater. Sci. Eng. A 2013, 560, 1–24. [Google Scholar] [CrossRef]

- Valiev, R.; Enikeev, N.; Murashkin, M.; Utyashev, F. Using intensive plastic deformations for manufacturing bulk nanostructure metallic materials. Mech. Solids 2012, 47, 463–474. [Google Scholar] [CrossRef]

- Latysh, V.; Semenova, I.; Salimgareeva, G.; Kandarov, I.; Zhu, Y.; Lowe, T.; Valiev, R. Nanomaterials by Severe Plastic Deformation; Trans Tech Publications Ltd.: Dürnten, Switzerland, 2006. [Google Scholar]

- Sabirov, I.; Perez-Prado, M.; Molina-Aldareguia, J.; Semenova, I.; Salimgareeva, G.; Valiev, R. Anisotropy of mechanical properties in high-strength ultra-fine-grained pure Ti processed via a complex severe plastic deformation route. Scr. Mater. 2011, 64, 69–72. [Google Scholar] [CrossRef]

- Bonarski, B.; Mikulowski, B.; Schafler, E.; Holzleithner, C.; Zehetbauer, M. Crystallographic textures of single and polycrystalline pure Mg and Cu subjected to HPT deformation. Arch. Metall. Mater. 2008, 53, 117–123. [Google Scholar]

- Lu, C.; Tieu, K.; Wexler, D. Significant enhancement of bond strength in the accumulative roll bonding process using nano-sized SiO2 particles. J. Mater. Process. Technol. 2009, 209, 4830–4834. [Google Scholar] [CrossRef]

- Peng, J.; Liu, Z.; Xia, P.; Lin, M.; Zeng, S. On the interface and mechanical property of Ti/Al-6%Cu-0.5%Mg-0.4%Ag bimetal composite produced by cold-roll bonding and subsequent annealing treatment. Mater. Lett. 2012, 74, 89–92. [Google Scholar] [CrossRef]

- Wang, J.; Hoagland, R.; Misra, A. Mechanics of nanoscale metallic multilayers: From atomic-scale to micro-scale. Scr. Mater. 2009, 60, 1067–1072. [Google Scholar] [CrossRef]

- Lapovok, R.; Ng, H.; Tomus, D.; Estrin, Y. Bimetallic Copper-Aluminium Tube by Severe Plastic Deformation. Scr. Mater. 2012, 66, 1081–1084. [Google Scholar] [CrossRef]

- Marr, T.; Freudenberger, J.; Kauffmann, A.; Romberg, J.; Okulov, I.; Petters, R.; Scharnweber, J.; Eschke, A.; Oertel, C.G.; Kühn, U.; et al. Processing of Intermetallic Titanium Aluminide Wires. Metals 2013, 3, 188–201. [Google Scholar] [CrossRef]

- Beausir, B.; Scharnweber, J.; Jaschinski, J.; Brokmeier, H.G.; Oertel, C.G.; Skrotzki, W. Plastic anisotropy of ultrafine grained aluminum alloys produced by accumulative roll bonding. Mater. Sci. Eng. A 2010, 527, 3271–3278. [Google Scholar] [CrossRef]

- Sauvage, X.; Wilde, G.; Divinski, S.; Horita, Z.; Valiev, R. Grain boundaries in ultrafine grained materials processed by severe plastic deformation and related phenomena. Mater. Sci. Eng. A 2012, 540, 1–12. [Google Scholar] [CrossRef]

- Valiev, R.; Islamgaliev, R.; Alexandrov, I. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Zeipper, L.; Zehetbauer, M.; Holzleithner, C. Defect based micromechanical modelling and simulation of nanoSPD CP-Ti in post-deformation. Mater. Sci. Eng. A 2005, 410–411, 217–221. [Google Scholar] [CrossRef]

- Pippan, R.; Wetscher, F.; Hafok, M.; Vorhauer, A.; Sabirov, I. The Limits of Refinement by Severe Plastic Deformation. Adv. Eng. Mater. 2006, 8, 1046–1056. [Google Scholar] [CrossRef]

- Zehetbauer, M.; Grossinger, R.; Krenn, H.; Krystian, M.; Pippan, R.; Rogl, P.; Waitz, T.; Wurschum, R. Bulk Nanostructured Functional Materials By Severe Plastic Deformation. Adv. Eng. Mater. 2010, 12, 692–700. [Google Scholar] [CrossRef]

- Gottstein, G. Physikalische Grundlagen der Materialkunde; Springer: Berlin, Germany, 2001. [Google Scholar]

- Kang, D.H.; Kim, T. Mechanical behavior and microstructural evolution of commercially pure titanium in enhanced multi-pass equal channel angular pressing and cold extrusion. Mater. Des. 2010, 31, S54–S60. [Google Scholar] [CrossRef]

- Langdon, T. Processing of Aluminum Alloys by Severe Plastic Deformation; Trans Tech Publications Ltd.: Dürnten, Switzerland, 2006. [Google Scholar]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk material-development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Terada, D.; Inoue, S.; Tsuji, N. Microstructure and mechanical properties of commercial purity titanium severely deformed by ARB process. J. Mater. Sci. 2007, 42, 1673–1681. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Marr, T.; Freudenberger, J.; Kauffmann, A.; Scharnweber, J.; Oertel, C.G.; Skrotzki, W.; Siegel, U.; Kühn, U.; Eckert, J.; Martin, U.; et al. Damascene Light-Weight Metals. Adv. Eng. Mater. 2010, 12, 1191–1197. [Google Scholar] [CrossRef]

- Levi, F. Permanent Magnets Obtained by Drawing Compacts of Parallel Iron Wires. J. Appl. Phys. 1960, 31, 1469–1471. [Google Scholar] [CrossRef]

- Latypov, M.; Lee, D.; Jeong, H.; Lee, J.; Kim, H. Design of Hierarchical Cellular Metals Using Accumulative Bundle Extrusion. Metall. Mater. Trans. A 2013, 44A, 4031–4036. [Google Scholar] [CrossRef]

- Marr, T.; Freudenberger, J.; Seifert, D.; Klauß, H.; Romberg, J.; Okulov, I.; Scharnweber, J.; Eschke, A.; Oertel, C.G.; Skrotzki, W.; et al. Ti-Al Composite Wires with High Specific Strength. Metals 2011, 1, 79–97. [Google Scholar] [CrossRef]

- Nzoma, E.; Guillet, A.; Pareige, P. Nanostructured Multifilamentary Carbon-Copper Composites: Fabrication, Microstructural Characterization, and Properties. J. Nan. 2012, 2012, 360818. [Google Scholar] [CrossRef]

- Dundurs, J. Elastic Interaction of Dislocations with Inhomogeneities. In Mathematical Theory of Dislocations; Mura, T., Ed.; ASME: New York, NY, USA, 1969; pp. 70–115. [Google Scholar]

- Yang, D.; Hodgson, P.; Wen, C. The kinetics of two-stage formation of TiAl3 in multilayered Ti/Al foils prepared by accumulative roll bonding. Intermetallics 2009, 17, 727–732. [Google Scholar] [CrossRef]

- Maier, V.; Höppel, H.; Göken, M. Nanomechanical behavior of Al-Ti layered composites produced by accumulative roll bonding. J. Phys. Conf. Ser. 2010, 240, 012108. [Google Scholar] [CrossRef]

- Yang, D.; Cizek, P.; Hodgson, P.; Wen, C. Ultrafine equiaxed-grain Ti/Al composite produced by accumulative roll bonding. Scr. Mater. 2010, 62, 321–324. [Google Scholar] [CrossRef]

- Ng, H.; Przybilla, T.; Schmidt, C.; Lapovok, R.; Orlov, D.; Höppel, H.W.; Göken, M. Asymmetric accumulative roll bonding of aluminum-titanium composite sheets. Mater. Sci. Eng. A 2013, 576, 306–315. [Google Scholar] [CrossRef]

- Gu, S.; Fang, H.; Zhou, Z.; Du, J. The evolution of microstructure and mechanical properties of Ti/Al composite synthesized by accumulative roll-bonding. Acta Phys. Sin. 2012, 61, 186104. [Google Scholar]

- Hausöl, T.; Maier, V.; Schmidt, C.; Winkler, M.; Höppel, H.; Göken, M. Tailoring Materials Properties by Accumulative Roll Bonding. Adv. Eng. Mater. 2010, 12, 740–746. [Google Scholar] [CrossRef]

- Chaudhari, G.; Acoff, V.L. Titanium aluminide sheets made using roll bonding and reaction annealing. Intermetallics 2010, 18, 472–478. [Google Scholar] [CrossRef]

- Gurao, N.P.; Sethuraman, S.; Suwas, S. Evolution of Texture and Microstructure in Commercially Pure Titanium with Change in Strain Path During Rolling. Metall. Mater. Trans. A 2013, 44A, 1497–1507. [Google Scholar] [CrossRef]

- Romberg, J.; Freudenberger, J.; Scharnweber, J.; Gaitzsch, U.; Marr, T.; Eschke, A.; Kühn, U.; Oertel, C.G.; Okulov, I.; Petters, R.; et al. Metallographic Preparation of Aluminium-Titanium Composites. Pract. Metall. 2013, 50, 739–753. [Google Scholar] [CrossRef]

- Bouvier, S.; Benmhenni, N.; Tirry, W.; Gregory, F.; Nixon, M.; Cazacu, O.; Rabet, L. Hardening in relation with microstructure evolution of high purity titanium deformed under monotonic and cyclic simple shear loadings at room temperature. Mater. Sci. Eng. A 2012, 535, 12–21. [Google Scholar] [CrossRef]

- Chun, Y.; Yu, S.; Semiatin, S.; Hwang, S. Effect of deformation twinning on microstructure and texture evolution during cold rolling of CP-titanium. Mater. Sci. Eng. A 2005, 398, 209–219. [Google Scholar] [CrossRef]

- Valiev, R.; Ivanisenko, Y.; Rauch, E. Structure and deformation behavior of armco iron subjected to severe plastic deformation. Acta Mater. 1996, 44, 4705–4712. [Google Scholar] [CrossRef]

- Emmens, W. Formability: A Review of Parameters and Processes that Control, Limit or Enhance the Formability of Sheet Metal; Springer: Berlin, Germany, 2011; ISBN 9783642219047. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romberg, J.; Freudenberger, J.; Bauder, H.; Plattner, G.; Krug, H.; Holländer, F.; Scharnweber, J.; Eschke, A.; Kühn, U.; Klauß, H.; et al. Ti/Al Multi-Layered Sheets: Accumulative Roll Bonding (Part A). Metals 2016, 6, 30. https://doi.org/10.3390/met6020030

Romberg J, Freudenberger J, Bauder H, Plattner G, Krug H, Holländer F, Scharnweber J, Eschke A, Kühn U, Klauß H, et al. Ti/Al Multi-Layered Sheets: Accumulative Roll Bonding (Part A). Metals. 2016; 6(2):30. https://doi.org/10.3390/met6020030

Chicago/Turabian StyleRomberg, Jan, Jens Freudenberger, Hansjörg Bauder, Georg Plattner, Hans Krug, Frank Holländer, Juliane Scharnweber, Andy Eschke, Uta Kühn, Hansjörg Klauß, and et al. 2016. "Ti/Al Multi-Layered Sheets: Accumulative Roll Bonding (Part A)" Metals 6, no. 2: 30. https://doi.org/10.3390/met6020030

APA StyleRomberg, J., Freudenberger, J., Bauder, H., Plattner, G., Krug, H., Holländer, F., Scharnweber, J., Eschke, A., Kühn, U., Klauß, H., Oertel, C.-G., Skrotzki, W., Eckert, J., & Schultz, L. (2016). Ti/Al Multi-Layered Sheets: Accumulative Roll Bonding (Part A). Metals, 6(2), 30. https://doi.org/10.3390/met6020030