Influence of Post Weld Heat Treatment on Strength of Three Aluminum Alloys Used in Light Poles

Abstract

:1. Introduction and Background

2. Specimen Preparation and Mechanical Testing

- As-Received (AR-6063, AR-6061 and AR-6005A).

- As-Received and artificially aged (AR+PHT-6063, AR+PHT-6061, AR+PHT-6005A).

- As-Welded (AW-6063, AW-6061, AW-6005A).

- Welded and subsequently heat treated (PWHT-6061, PWHT-6063, PWHT-6005A).

- As-Received and As-Welded subjected to re-solution heat treatment and aging (SHT+PHT-6005A).

3. Results and Discussion

3.1. Microstructure

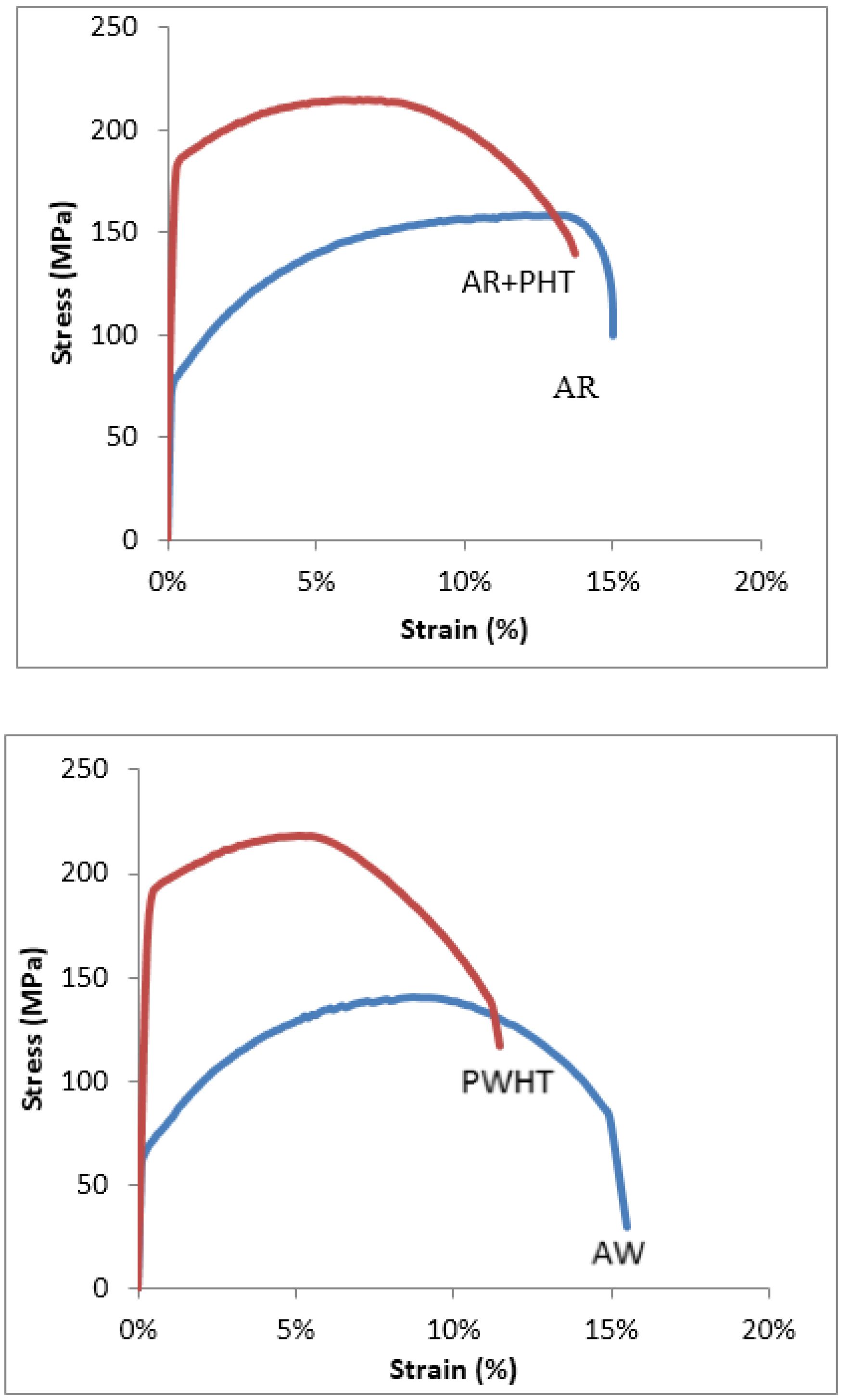

3.2. Typical Stress-Strain Response

3.3. Analysis of the Results

- σmin = calculated minimum stress for the PWHT specimens

- σavg = average tensile or yield strength for a given alloy in the PWHT condition

- k = statistical coefficient based on the number of tests, n

- Sσ = standard deviation of the test results for the particular alloy

- 6063-T4, PWHT up to 9.5 mm (3/8 in) thick and welded using AA4043.

- 6005A-T1, PWHT up to 6.4 mm (1/4 in)thick and welded using AA4043.

- 6061-T4, PWHT up to 6.4 mm (1/4 in) thick, and welded using AA4043.

4. Conclusions

- Heat treating (aging) the as-received (AR) material increased both the yield strength and ultimate tensile strength of all the alloys.

- Post weld heat treating increased both the yield strength and ultimate tensile strength of the three alloys studied.

- Re-solution heat treating the as-received material increased the yield strength and tensile strength of aluminum alloy 6005A.

- Re-solution heat treating subsequent to welding, followed by post weld heat treatment was observed to increase the tensile strength and yield strength of aluminum alloy 6005A.

- With the exception of aluminum alloy 6061 having a thickness of 9.5 mm (3/8 in), design provisions permitting use of 85% of the parent metal strengths (in T6 temper) for post weld heat treated (PWHT) light poles are confirmed. The alloys and thicknesses include: (i) 6063-T4 PWHT up to 9.5 mm thick; (ii) 6005A-T1 PWHT up to 6.4 mm thick; and (iii) 6061-T4 PWHT up to 6.4 mm thick.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sharp, M.L. Behavior and Design of Aluminum Structures; McGraw-Hill: New York, NY, USA, 1992. [Google Scholar]

- Kissell, R.; Ferry, R. Aluminum Structures—A Guide to Their Specifications and Design; John Wiley and Sons: London, UK; Washington, DC, USA, 1995. [Google Scholar]

- Elangovan, K.; Balasubramanian, V. Influence of post weld heat treatment on tensile properties of friction stir welded AA6061 aluminum alloy joints. Mater. Charact. 2008, 59, 1168–1177. [Google Scholar] [CrossRef]

- Demir, H.; Gunduiz, S. The effects of aging on the machinability of 6061 aluminum alloy. J. Mater. Des. 2009, 30, 1480–1483. [Google Scholar] [CrossRef]

- Xu, W.; Gittos, M.F. Materials and Structural Behavior of MIG Butt Welded in 6005-T6 Aluminum Alloy Extrusions under Quasi Static and Impact Loading; TWI Report Number 14054/1/04; The Welding Institute: Cambridge, UK, 2004. [Google Scholar]

- Groover, M.P. Fundamentals of Modern Manufacturing, Materials, Processes and Systems, 3rd ed.; John Wiley and Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Hatch, J.E. Aluminum: Properties and Physical Metallurgy, 10th ed.; American Society for Metals: Metals Park, OH, USA, 1983. [Google Scholar]

- The Aluminum Association. Aluminum Design Manual; Aluminum Association of America: Washington, DC, USA, 2010. [Google Scholar]

- Maedler, J.R. NEMA to Gordon Allison; The Aluminum Association: Washington, DC, USA, 12 February 1971. [Google Scholar]

- Wagoner, N. Reynolds Metals Company to R; Hartmann, Hapco: Abingdon, VA, USA, 5 August 1963. [Google Scholar]

- Hilty, E.; Menzemer, C.; Srivatsan, T. Influence of Welding and Heat Treatment on Microstructural Development and Properties of Aluminum Alloy 6005. In Proceedings of the 22nd PFAM Conference, Singapore, 18–20 December 2013.

- Hilty, E.; Menzemer, C.; Manigandan, K.; Srivatsan, T. Influence of welding and heat treatment on microstructure, properties and fracture behavior of a wrought aluminum alloy. Emerg. Mater. Res. 2014, 3, 230–242. [Google Scholar] [CrossRef]

- Leo, P.; D’Ostuni, S.; Casalino, G. Hybrid welding of AA5754 annealed alloy: Role of post weld heat treatment on microstructure and mechanical properties. Mater. Des. 2016, 90, 777–786. [Google Scholar] [CrossRef]

- The Aluminum Association. 2009 Aluminum Standards and Data; Aluminum Association of America: Washington, DC, USA, 2009. [Google Scholar]

- Hobart Filler Metals. Guide for Aluminum Welding; Illinois Tool Works: Chicago, IL, USA, 2013. [Google Scholar]

- ASTM B918-01. Standard Practice for Heat Treatment of Wrought Aluminum Alloys; ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar] [CrossRef]

- ASM Materials Handbook; ASM International: Materials Park, OH, USA, 1991; Volumes 4 and 6.

- Warmuzek, M.; Mrowkaand, G.; Sieniawski, J. Influence of Heat Treatment on Precipitation of Intermetallic Phases in Commercial AlMnFeSi Alloy. J. Mater. Process. Technol. 2004, 157–158, 624–632. [Google Scholar] [CrossRef]

- Gallais, C.; Simar, A.; Fabreque, D.; Denquin, A.; Lapasset, G.; de Meester, B.; Brechet, Y.; Pardoen, T. Multiscale Analysis of the Strength and Ductility of AA 6056 Aluminum Friction Stir Welds. Metall. Mater. Trans. 2007, 38, 964–981. [Google Scholar] [CrossRef]

- Starke, E.A., Jr. Fatigue and Microstructure; Meshii, M., Ed.; ASM International: Materials Park, OH, USA, 1979. [Google Scholar]

- Leo, P.; Renna, G.; Casalino, G.; Olabi, A.G. Effect of power distribution on weld quality during hybrid laser welding of an Al–Mg alloy. Opt. Laser Technol. 2015, 73, 118–126. [Google Scholar] [CrossRef]

| Element | Al | Cr | Cu | Fe | Mg | Mn | Si | Ti | Zn |

|---|---|---|---|---|---|---|---|---|---|

| 6063 | Balance | 0.1 | 0.1 | 0.35 | 0.9 | 0.1 | 0.6 | 0.1 | Max 0.1 |

| 6005A | Balance | 0.3 | 0.3 | 0.35 | 0.4 | 0.5 | 0.9 | 0.1 | 0.2 |

| 6061 | Balance | 0.04 | 0.15 | 0.7 | 1.2 | 0.15 | 0.8 | 0.15 | Max 0.05 |

| Alloy | Thick (mm) | Average Yield (MPa) | Average Ultimate (MPa) | Number of Tests | Standard Deviation Yield/Ultimate | Min. Yield (MPa) | Min. Ultimate (MPa) | Min. Yield/ADM | Min. Ult./ADM |

|---|---|---|---|---|---|---|---|---|---|

| 6063 | 6.4 | 190 | 219 | 10 | 0.92/0.95 | 165 | 193 | 0.96 | 0.93 |

| 6063 | 9.5 | 204 | 234 | 21 | 2.44/1.57 | 150 | 199 | 0.87 | 0.96 |

| 6005A | 3.2 | 227 | 272 | 12 | 1.0/1.05 | 201 | 245 | 0.83 | 0.93 |

| 6005A | 6.4 | 217 | 250 | 12 | 0.44/0.82 | 205 | 229 | 0.85 | 0.87 |

| 6061 | 6.4 | 261 | 281 | 15 | 0.93/0.98 | 239 | 258 | 0.99 | 0.98 |

| 6061 | 9.5 | 241 | 241 | 24 | 4.1/3.1 | 122 | 173 | 0.5 | 0.66 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Menzemer, C.C.; Hilty, E.; Morrison, S.; Minor, R.; Srivatsan, T.S. Influence of Post Weld Heat Treatment on Strength of Three Aluminum Alloys Used in Light Poles. Metals 2016, 6, 52. https://doi.org/10.3390/met6030052

Menzemer CC, Hilty E, Morrison S, Minor R, Srivatsan TS. Influence of Post Weld Heat Treatment on Strength of Three Aluminum Alloys Used in Light Poles. Metals. 2016; 6(3):52. https://doi.org/10.3390/met6030052

Chicago/Turabian StyleMenzemer, Craig C., Eric Hilty, Shane Morrison, Ray Minor, and Tirumalai S. Srivatsan. 2016. "Influence of Post Weld Heat Treatment on Strength of Three Aluminum Alloys Used in Light Poles" Metals 6, no. 3: 52. https://doi.org/10.3390/met6030052

APA StyleMenzemer, C. C., Hilty, E., Morrison, S., Minor, R., & Srivatsan, T. S. (2016). Influence of Post Weld Heat Treatment on Strength of Three Aluminum Alloys Used in Light Poles. Metals, 6(3), 52. https://doi.org/10.3390/met6030052