Investigation of the Failure of Advanced High Strength Steels Heterogeneous Spot Welds

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Welding and Testing Procedure

2.3. Microstructure Investigations

3. Results

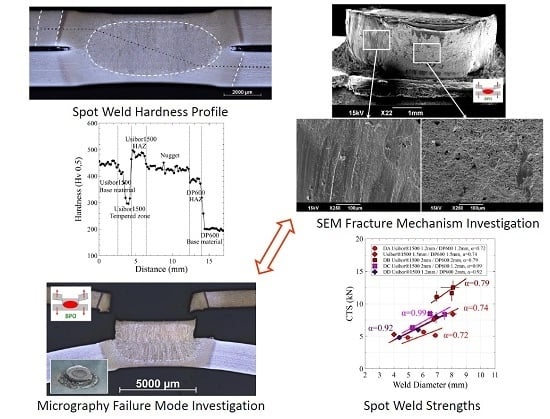

3.1. Spot Weld Microstructural Zones

- Usibor base metal

- Usibor tempered zone

- Usibor HAZ

- Fusion zone

- DP600 HAZ

- DP600 base metal

3.2. Cross Tension Tests

3.2.1. Failure Modes

- A zone full of small cavities due to debonding of the inclusions in the material (right zone).

- A zone exhibiting shear (left zone). The “pull-out” movement of the upper sheet in the final stage of fracture (vertical tangential motion of the fractured sheet with respect to the weld nugget) is indeed expected to produce such evidence of shearing.

3.2.2. Load Bearing Capacities

- Heterogeneous welding of Usibor®1500 1.5 mm with DP600 1.5 mm

- Homogeneous welding of DP600 1 mm

- Homogeneous welding of DP600 1.8 mm

- Homogeneous welding of Usibor®1500 1.5 mm

3.3. Tensile Shear Tests

3.3.1. Failure Modes

3.3.2. Load Bearing Capacities

4. Discussion

4.1. Liquid Metal Splash Influence on Cross Tension Performance

4.2. Positive Deviation of Cross Tension Failure Load with Dissimilar Thickness

4.3. Dissimilar Thickness Effect in Tensile Shear

5. Conclusions

- Positive deviation of the cross tension strength is observed in heterogeneous assemblies with dissimilar thicknesses.

- Such positive deviation is not as obvious in tensile shear. Namely, increasing the sheet thickness of the highest grade steel (Usibor in the present study) was ineffective in enhancing the tensile shear strength.

- Limited weld metal expulsion (splash) at the upper end of the welding range affects the cross tension behavior but has no significant effect on the tensile shear performance.

- Limited weld metal expulsion favors the occurrence of Partial Dome Failure in cross tension, where the crack first propagates close to the weld nugget boundary then forks up to form a button.

- Total Dome Failures, following the weld nugget-HAZ interface, were observed for low welding current in tensile shear in the DC configuration. This is in contrast to the usual Full Interfacial Failure often occurring for small welds in tensile shear.

- The failure load of heterogeneous AHSS spot welds increases with the nugget size and the sheet thickness regardless of the failure mode, as long no splash defects are encountered.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AHSS | Advanced High Strength Steel |

| RSW | Resistance Spot Welding |

| HAZ | Heat Affected Zone |

| FZ | Fusion Zone |

| CGHAZ | Coarse Grain Heat Affected Zone |

| CTS | Cross Tension failure load |

| TSS | Tensile Shear failure load |

| BPO | Button Pull-Out |

| PIF | Partial Interfacial Failure |

| FIF | Full Interfacial Failure |

Partial Dome Failure | |

| TDF | Total Dome Failure |

| UTS | Ultimate Tensile Strength |

References

- American Welding Society (AWS) D8 Committee on Automotive Welding. Specification for Automotive Weld Quality-Resistance Spot Welding of Steel, 1st ed.; American Welding Society: Miami, FL, USA, 2007. [Google Scholar]

- Resistance Welding-Weldability-Part 2: Alternative Procedures for the Assessment of Sheet Steels for Spot Welding; ISO Copyright Office: Geneva, Switzerland, 2004.

- Specimen Dimensions and Procedure for Cross Tension Testing Resistance Spot and Embossed Projection Welds; ISO Copyright Office: Geneva, Switzerland, 2001.

- Specimen Dimensions and Procedure for Shear Testing Resistance Spot, Seam and Embossed Projection Welds; ISO Copyright Office: Geneva, Switzerland, 2002.

- Sun, X.; Stephens, E.V.; Khaleel, M.A. Effects of fusion zone size and failure modes of Advanced High Strength Steel spot welds. In Proceedings of the Sheet Metal Welding Conference XII, Livonia, MI, USA, 10–12 May 2006.

- Sakuma, Y.; Oikawa, H. Factors to determine static strengths of spot weld for High Strength Steel sheets and developments of High Strength Steel sheets with strong and stable welding characteristics. Nippon Steel Tech. Rep. 2003, 88, 33–38. [Google Scholar]

- Pouranvari, M.; Asgari, H.; Mosavizadch, S.; Marashi, P.; Goodarzi, M. Effect of weld nugget size on overload failure mode of resistance spot welds. Sci. Technol. Weld. Join. 2007, 12, 217–225. [Google Scholar] [CrossRef]

- Hernandez, V.H.B.; Kuntz, M.L.; Khan, M.I.; Zhou, Y. Influence of microstructure and weld size on the mechanical behavior of dissimilar AHSS resistance spot welds. Sci. Technol. Weld. Join. 2008, 13, 769–776. [Google Scholar] [CrossRef]

- Chao, Y.J. Failure mode of spot welds: Interfacial versus pullout. Sci. Technol. Weld. Join. 2003, 8, 133–137. [Google Scholar]

- Khan, M.I.; Kuntz, M.L.; Zhou, Y. Effects of weld microstructure on static and impact performance of resistance spot welded joints in advanced high strength steels. Sci. Technol. Weld. Join. 2008, 13, 49–59. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P.H. Similar and dissimilar RSW of low carbon and austenitic stainless steels: Effect of weld microstructure and hardness profile on failure mode. Mater. Sci. Technol. 2009, 25, 1411–1416. [Google Scholar] [CrossRef]

- Alizadeh-Sh, M.; Marashi, S.P.H.; Pouranvari, M. Microstructure-properties relationships in martensitic stainless steel resistance spot welds. Sci. Technol. Weld. Join. 2014, 19, 595–602. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P.H.; Mousavizadeh, S.M. Failure mode transition and mechanical properties of similar and dissimilar resistance spot welds of DP600 and low carbon steels. Sci. Technol. Weld. Join. 2010, 15, 625–631. [Google Scholar] [CrossRef]

- Peterson, W.; Orth, F. Fracture transition behavior of spot welds in Advanced High-Strength Steels. In Proceedings of the Sheet Metal Welding Conference XII, Livonia, MI, USA, 10–12 May 2006.

- Safanama, D.S.; Marashi, S.P.H.; Pouranvari, M. Similar and dissimilar resistance spot welding of martensitic advanced high strength steel and low carbon steel: Metallurgical characteristics and failure mode transition. Sci. Technol. Weld. Join. 2012, 17, 288–294. [Google Scholar] [CrossRef]

- Abadi, M.M.H.; Pouranvari, M. Failure-Mode Transition in Resistance Spot Welded DP780. Mater. Technol. 2014, 48, 67–71. [Google Scholar]

- Pouranvari, M.; Marashi, S.P.H. Failure mode transition in AHSS resistance spot welds. Part I. Controlling factors and Part II: Experimental investigation and model validation. Mater. Sci. Eng. A 2011, 528, 8337–8343. [Google Scholar] [CrossRef]

- Jong, Y.S.; Lee, Y.K.; Kim, D.C.; Kang, M.J.; Hwang, I.S.; Lee, W.B. Microstructural evolution and mechanical properties of resistance spot welded ultra-high strength steel containing boron. Mater. Trans. 2011, 52, 1330–1333. [Google Scholar] [CrossRef]

- Bouzekri, M.; Dancette, S.; Dupuy, T.; Lens, A.; Oultit, B.N.; Massardier, V.; FabrEgue, D.; Klocker, H. An investigation of failure types in high-strength steel resistance spot welds. Weld. World 2010, 54, 3–14. [Google Scholar] [CrossRef]

- Choi, H.S.; Kim, B.M.; Park, G.H.; Lim, W.S. Optimization of resistance spot weld condition for single lap joint of hot stamped 22MnB5 by taking heating temperature and heating time into consideration. Trans. Korean Soc. Mech. Eng. 2010, 34, 1367–1375. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P.H. On failure mode of resistance spot welded DP980 advanced high strength steel. Can. Metall. Q. Can. J. Metall. Mater. Sci. 2012, 51, 447–455. [Google Scholar] [CrossRef]

- Spena, P.R.; de Maddis, M.; Lombardi, F. Mechanical Strength and Fracture of Resistance Spot Welded Advanced High Strength Steels. Proced. Eng. 2015, 108, 450–456. [Google Scholar] [CrossRef]

- Dancette, S.; Massardier-Jourdan, V.; Merlin, J.; Fabrègue, D.; Dupuy, T. Investigations on the mechanical behavior of advanced high strength steels resistance spot welds in cross tension and tensile shear. Adv. Mater. Res. Trans. Tech. Publ. 2010, 89, 130–135. [Google Scholar] [CrossRef]

- Dancette, S.; Fabrègue, D.; Massardier, V.; Merlin, J.; Dupuy, T.; Bouzekri, M. Experimental and modeling investigation of the failure resistance of Advanced High Strength Steels spot welds. Eng. Fract. Mech. 2011, 78, 2259–2272. [Google Scholar] [CrossRef]

- Dancette, S.; Fabrègue, D.; Massardier, V.; Merlin, J.; Dupuy, T.; Bouzekri, M. Investigation of the Tensile Shear fracture of Advanced High Strength Steel spot welds. Eng. Fail. Anal. 2012, 25, 112–122. [Google Scholar] [CrossRef]

- Khan, M.S.; Bhole, S.D.; Chen, D.L.; Biro, E.; Boudreau, G.; van Deventer, J. Welding behavior, microstructure and mechanical properties of dissimilar resistance spot welds between galvannealed HSLA350 and DP600 steels. Sci. Technol. Weld. Join. 2009, 14, 616–625. [Google Scholar] [CrossRef]

- Choi, H.S.; Park, G.H.; Lim, W.S.; Kim, B.M. Evaluation of weldability for resistance spot welded single-lap joint between GA780DP and hot-stamped 22MnB5 steel sheets. J. Mech. Sci. Technol. 2011, 25, 1543–1550. [Google Scholar] [CrossRef]

- Spena, P.R.; de Maddis, M.; Lombardi, F.; Rossini, M. Dissimilar Resistance Spot Welding of Q&P and TWIP Steel Sheets. Mater. Manuf. Process. 2016, 31, 291–299. [Google Scholar]

- Marashi, S.P.H.; Pouranvari, M.; Salehi, M.; Abedi, A.; Kaviani, S. Overload failure behavior of dissimilar thickness resistance spot welds during tensile shear test. Mater. Sci. Technol. 2010, 26, 1220–1225. [Google Scholar] [CrossRef]

- Biro, E.; Cretteur, L.; Dupuy, T. Higher than expected strengths from dissimilar Configuration advanced high strength steel spot welds. In Proceedings of the Sheet Metal Welding Conference XV, Livonia, MI, USA, 2–5 October 2012.

- Pouranvari, M.; Marashi, P. Resistance Spot Welding of Unequal Thickness Low Carbon Steel Sheets. Adv. Mater. Res. 2010, 83, 1205–1211. [Google Scholar] [CrossRef]

- Dancette, S.; Massardier, V.; Fabrègue, D.; Merlin, J.; Dupuy, T.; Bouzekri, M. HAZ microstructures and local mechanical properties of high strength steels resistance spot welds. ISIJ Int. 2011, 51, 99–107. [Google Scholar] [CrossRef]

- Dancette, S.; Fabrègue, D.; Estevez, R.; Massardier, V.; Dupuy, T.; Bouzekri, M. A finite element model for the prediction of Advanced High Strength Steel spot welds fracture. Eng. Fract. Mech. 2012, 87, 48–61. [Google Scholar] [CrossRef]

- Dancette, S. Comportement mécanique des soudures par points: mécanismes et stratégies de prédiction dans le cas des tôles en acier pour automobile. Ph.D. Thesis, Université de Lyon, Lyon, France, May 2009. [Google Scholar]

| Grade | Thickness (mm) | C | Mn | Si | B |

|---|---|---|---|---|---|

| DP600 | 1.2 | 0.088 | 1.870 | 0.150 | - |

| DP600 | 2 | 0.085 | 1.885 | 0.241 | - |

| Usibor®1500 | 1.2 | 0.221 | 1.184 | 0.256 | 0.003 |

| Usibor®1500 | 2 | 0.218 | 1.149 | 0.266 | 0.003 |

| Configuration | Usibor®1500 Sheet Thickness (mm) | DP600 Sheet Thickness (mm) |

|---|---|---|

| DA | 1.2 | 1.2 |

| DB | 2 | 2 |

| DC | 2 | 1.2 |

| DD | 1.2 | 2 |

| Configurations | Low Intensity Range | Middle Intensity Range | High Intensity Range |

|---|---|---|---|

| DA: Usibor 1.2 mm/DP600 1.2 mm | Usibor Failure (PIF) | Usibor Failure (BPO) | Usibor Failure (BPO + PDF) |

| DB: Usibor 2 mm/DP600 2 mm | Usibor Failure (PIF) | Usibor Failure (PIF) | Usibor Failure (BPO) |

| DC: Usibor 2 mm/DP600 1.2 mm | DP600 Failure (PIF) | DP600 Failure (BPO) | Usibor Failure (BPO + PDF) |

| DD: Usibor 1.2 mm/DP600 2 mm | Usibor Failure (BPO) | Usibor Failure (BPO) | Usibor Failure (BPO + PDF) |

| Configurations | Low Intensity Range | Middle Intensity Range | High Intensity Range |

|---|---|---|---|

| DA: Usibor 1.2 mm/DP600 1.2 mm | 4.82 ± 0.26 | 5.66 ± 0.15 | 5.13 ± 0.20 |

| DB: Usibor 2 mm/DP600 2 mm | 11.08 ± 0.88 | 11.64 ± 1.20 | 13.05 ± 1.14 |

| DC: Usibor 2 mm/DP600 1.2 mm | 6.33 ± 0.64 | 8.47 ± 0.77 | 8.37 ± 0.89 |

| DD: Usibor 1.2 mm/DP600 2 mm | 4.82 ± 0.11 | 6.00 ± 0.09 | 7.94 ± 0.94 |

| Configurations | Low Intensity Range | Middle Intensity Range | High Intensity Range |

|---|---|---|---|

| DA: Usibor 1.2 mm/DP600 1.2 mm | Usibor Failure (BPO) | Usibor Failure (BPO) | Usibor Failure (BPO) |

| DB: Usibor 2 mm/DP600 2 mm | FIF | Usibor Failure (BPO) | Usibor Failure (BPO) |

| DC: Usibor 2mm/DP600 1.2 mm | DP600 Failure (TDF) | DP600 Failure (BPO + lateral PDF) | DP600 Failure (BPO) |

| DD: Usibor 1.2 mm/DP600 2 mm | FIF | FIF | Usibor Failure (BPO) |

| Configurations | Low Intensity Range | Middle Intensity Range | High Intensity Range |

|---|---|---|---|

| DA: Usibor 1.2 mm/DP600 1.2 mm | 12.87 ± 0.55 | 14.11 ± 0.81 | 15.39 ± 0.05 |

| DB: Usibor 2 mm/DP600 2 mm | 25.95 ± 0.76 | 29.89 ± 0.31 | 33.13 ± 0.77 |

| DC: Usibor 2 mm/DP600 1.2 mm | 13.87 ± 0.64 | 15.85 ± 0.12 | 17.50 ± 0.05 |

| DD: Usibor 1.2 mm/DP600 2 mm | 12.55 ± 0.09 | 18.79 ± 0.31 | 20.00 ± 0.03 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huin, T.; Dancette, S.; Fabrègue, D.; Dupuy, T. Investigation of the Failure of Advanced High Strength Steels Heterogeneous Spot Welds. Metals 2016, 6, 111. https://doi.org/10.3390/met6050111

Huin T, Dancette S, Fabrègue D, Dupuy T. Investigation of the Failure of Advanced High Strength Steels Heterogeneous Spot Welds. Metals. 2016; 6(5):111. https://doi.org/10.3390/met6050111

Chicago/Turabian StyleHuin, Thibaut, Sylvain Dancette, Damien Fabrègue, and Thomas Dupuy. 2016. "Investigation of the Failure of Advanced High Strength Steels Heterogeneous Spot Welds" Metals 6, no. 5: 111. https://doi.org/10.3390/met6050111