Effect of Mo Content on Microstructure and Property of Low-Carbon Bainitic Steels

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

3.1. Characteristics of Microstructure

3.2. Quantitative Analysis

3.3. Mechanical Properties

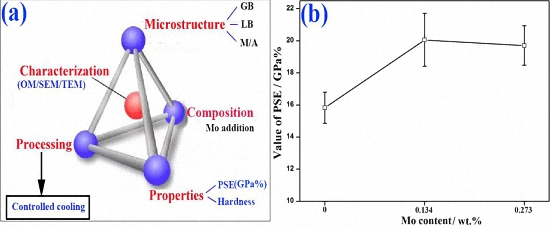

3.4. Design of Processing

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| PSE | product of strength and elongation |

| LSCM | high temperature laser scanning confocal microscopy |

| Bs | bainite starting temperature |

| Ms | martensite starting temperature |

| OM | optical microscopy |

| SEM | scanning electron microscopy |

| TEM | transmission electron microscope |

| XRD | X-ray diffractogram |

| M/A | martensite/austenite |

| GB | granular bainite |

| LB | lath bainite |

| RA | retained austenite |

| YS | yield strength |

| UTS | ultimate tensile strength |

| TE | total elongation |

| TTT | time-temperature-transformation |

References

- Soliman, M.; Palkowski, H. Development of the low temperature bainite. Arch. Civ. Mech. Eng. 2016, 16, 403–412. [Google Scholar] [CrossRef]

- Furuhara, T.; Tsuzumi, K.; Miyamoto, G.; Amino, T.; Shigesato, G. Characterization of Transformation Stasis in Low-Carbon Steels Microalloyed with B and Mo. Metall. Mater. Trans. A 2014, 45A, 5990–5996. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Computational design of advanced steels. Scr. Mater. 2014, 70, 12–17. [Google Scholar] [CrossRef]

- Hu, Z.W.; Xu, G.; Yang, H.L.; Zhang, C.; Yu, R. The Effects of Cooling Mode on Precipitation and Mechanical Properties of a Ti-Nb Microalloyed Steel. J. Mater. Eng. Perform. 2014, 23, 4216–4222. [Google Scholar] [CrossRef]

- Ivine, K.J.; Pickering, F.B. Low Carbon Bainitic Steels. J. Iron Steel Inst. 1957, 187, 292–309. [Google Scholar]

- Grange, R.A. Estimating the hardenability of carbon steels. Metall. Trans. B 1973, 4, 2231–2244. [Google Scholar] [CrossRef]

- Pickering, F.B. Physical Metallurgy and the Design of Steels; Applied Science Publishers Ltd.: London, UK, 1978. [Google Scholar]

- Khare, S.; Lee, K.; Bhadeshia, H.K.D.H. Relative effects of Mo and B on ferrite and bainite kinetics in strong steels. Int. J. Mater. Res. 2009, 100, 1513–1520. [Google Scholar] [CrossRef]

- Sourmail, T.; Smanio, V. Low temperature kinetics of bainite formation in high carbon steels. Acta Mater. 2013, 61, 2639–2648. [Google Scholar] [CrossRef]

- Kong, J.H.; Xie, C.S. Effect of molybdenum on continuous cooling bainite transformation of low-carbon microalloyed steel. Mater. Des. 2006, 27, 1169–1173. [Google Scholar] [CrossRef]

- Chen, X.W.; Qiao, G.Y.; Han, X.L.; Wang, X.; Xiao, F.R.; Liao, B. Effects of Mo, Cr, and Nb on microstructure and mechanical properties of heat affected zone for Nb-bearing X80 pipeline steels. Mater. Des. 2014, 53, 888–901. [Google Scholar] [CrossRef]

- Soliman, M.; Mostafa, H.; El-Sabbagh, A.S.; Palkowski, H. Low temperature bainite in steel with 0.26 wt. % C. Mater. Sci. Eng. A 2010, 527, 7706–7713. [Google Scholar] [CrossRef]

- Qian, L.; Zhou, Q.; Zhang, F.; Meng, J.; Zhang, M.; Tian, Y. Microstructure and mechanical properties of a low carbon carbide-free bainitic steel co-alloyed with Al and Si. Mater. Des. 2012, 39, 264–268. [Google Scholar] [CrossRef]

- Wang, Y.H.; Zhang, F.C.; Wang, T.S. A novel bainitic steel comparable to maraging steel in mechanical properties. Scr. Mater. 2013, 68, 763–766. [Google Scholar] [CrossRef]

- Long, X.Y.; Zhang, F.C.; Kang, J.; Lv, B.; Shi, X.B. Low-temperature bainite in low-carbon steel. Mater. Sci. Eng. A 2014, 594, 344–351. [Google Scholar] [CrossRef]

- Wang, X.L.; Wu, K.M.; Hu, F.; Yu, L.; Wan, X.L. Multi-step isothermal bainitic transformation in medium-carbon steel. Scr. Mater. 2014, 74, 56–59. [Google Scholar] [CrossRef]

- Bohemen, S.M.C. Bainite and martensite start temperature calculated with exponential carbon dependence. Mater. Sci. Technol. 2012, 28, 487–495. [Google Scholar] [CrossRef]

- Aaronson, H.I.; Reynolds, W.T.; Purdy, G.R. The incomplete transformation phenomenon in steel. Metall. Mater. Trans. A 2006, 37A, 1731–1745. [Google Scholar] [CrossRef]

- Xia, Y.; Miyamoto, G.; Yang, Z.G.; Zhang, C.; Furuhara, T. Direct measurement of carbon enrichment in the incomplete bainite transformation in Mo added low carbon steels. Acta Mater. 2015, 91, 10–18. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Christian, J.W. Bainite in steels. Metall. Trans. 1990, 21A, 767–769. [Google Scholar] [CrossRef]

- Caballero, F.G.; Garcia-Mateo, C.; Santofimia, M.J.; Miller, M.K.; de Andrés, C.G. New experimental evidence on the incomplete transformation phenomenon in steel. Acta Mater. 2009, 57, 8–17. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.Y.; Shi, J.; Cao, W.Q.; Dong, H. Characterization of microstructure obtained by quenching and partitioning process in low alloy martenstic steel. Mater. Sci. Eng. A 2010, 527, 3442–3449. [Google Scholar] [CrossRef]

- Hu, H.J.; Xu, G.; Wang, L.; Xue, Z.L.; Zhang, Y.L.; Liu, G.H. The Effects of Nb and Mo Addition on Transformation and Properties in Low Carbon Bainitic Steels. Mater. Des. 2015, 84, 95–99. [Google Scholar] [CrossRef]

- Caballero, F.G.; Santofimia, M.J.; Capdevila, C.; García-Mateo, C.; de Andrés, C.G. Design of advanced bainitic steels by optimization of TTT diagrams and T0 curves. ISIJ Int. 2006, 46, 1479–1488. [Google Scholar] [CrossRef] [Green Version]

- Caballero, F.G.; Santofimia, M.J.; García-Mateo, C.; Chao, J.; de Andrés, C.G. Theoretical design and advanced microstructure in super high strength steels. Mater. Des. 2009, 30, 2077–2083. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. A thermodynamic analysis of isothermal transformation diagrams. Met. Sci. 1982, 16, 159–165. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Bainite in Steels; Institute of Materials: London, UK, 1992; pp. 1–450. [Google Scholar]

| Steel | C | Si | Mn | Mo | P | S | BS | MS |

|---|---|---|---|---|---|---|---|---|

| #1 | 0.223 | 1.523 | 2.187 | 0 | <0.01 | <0.003 | 546 | 357 |

| #2 | 0.219 | 1.504 | 2.095 | 0.134 | <0.01 | <0.003 | 543 | 360 |

| #3 | 0.225 | 1.519 | 2.034 | 0.273 | <0.01 | <0.003 | 538 | 358 |

| Sample | VGB | VLB | VM | Vγ |

|---|---|---|---|---|

| #1 (Mo-free) | 0.69 ± 0.04 | 0.05 ± 0.01 | 0.19 ± 0.02 | 0.07 ± 0.01 |

| #2 (0.134% Mo) | 0.39 ± 0.03 | 0.25 ± 0.02 | 0.25 ± 0.03 | 0.11 ± 0.01 |

| #3 (0.273% Mo) | 0.06 ± 0.01 | 0.47 ± 0.03 | 0.37 ± 0.03 | 0.10 ± 0.01 |

| Steel | YS (MPa) | UTS (MPa) | TE (%) | Z (%) | PSE (GPa %) |

|---|---|---|---|---|---|

| #1 | 561 | 1015 | 15.6 | 41 | 15.8 |

| #2 | 583 | 1127 | 18.3 | 37 | 20.6 |

| #3 | 610 | 1173 | 16.8 | 38 | 19.7 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.; Xu, G.; Zhou, M.; Yuan, Q. Effect of Mo Content on Microstructure and Property of Low-Carbon Bainitic Steels. Metals 2016, 6, 173. https://doi.org/10.3390/met6080173

Hu H, Xu G, Zhou M, Yuan Q. Effect of Mo Content on Microstructure and Property of Low-Carbon Bainitic Steels. Metals. 2016; 6(8):173. https://doi.org/10.3390/met6080173

Chicago/Turabian StyleHu, Haijiang, Guang Xu, Mingxing Zhou, and Qing Yuan. 2016. "Effect of Mo Content on Microstructure and Property of Low-Carbon Bainitic Steels" Metals 6, no. 8: 173. https://doi.org/10.3390/met6080173