Characteristics of Resistance Spot Welded Ti6Al4V Titanium Alloy Sheets

Abstract

:1. Introduction

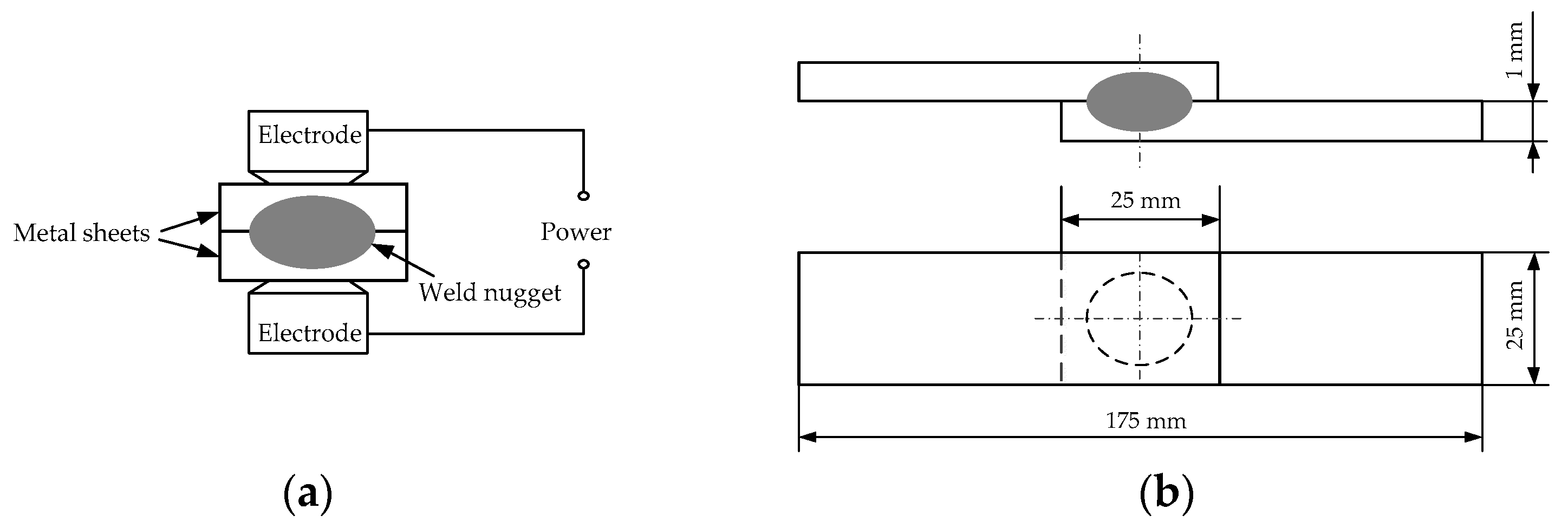

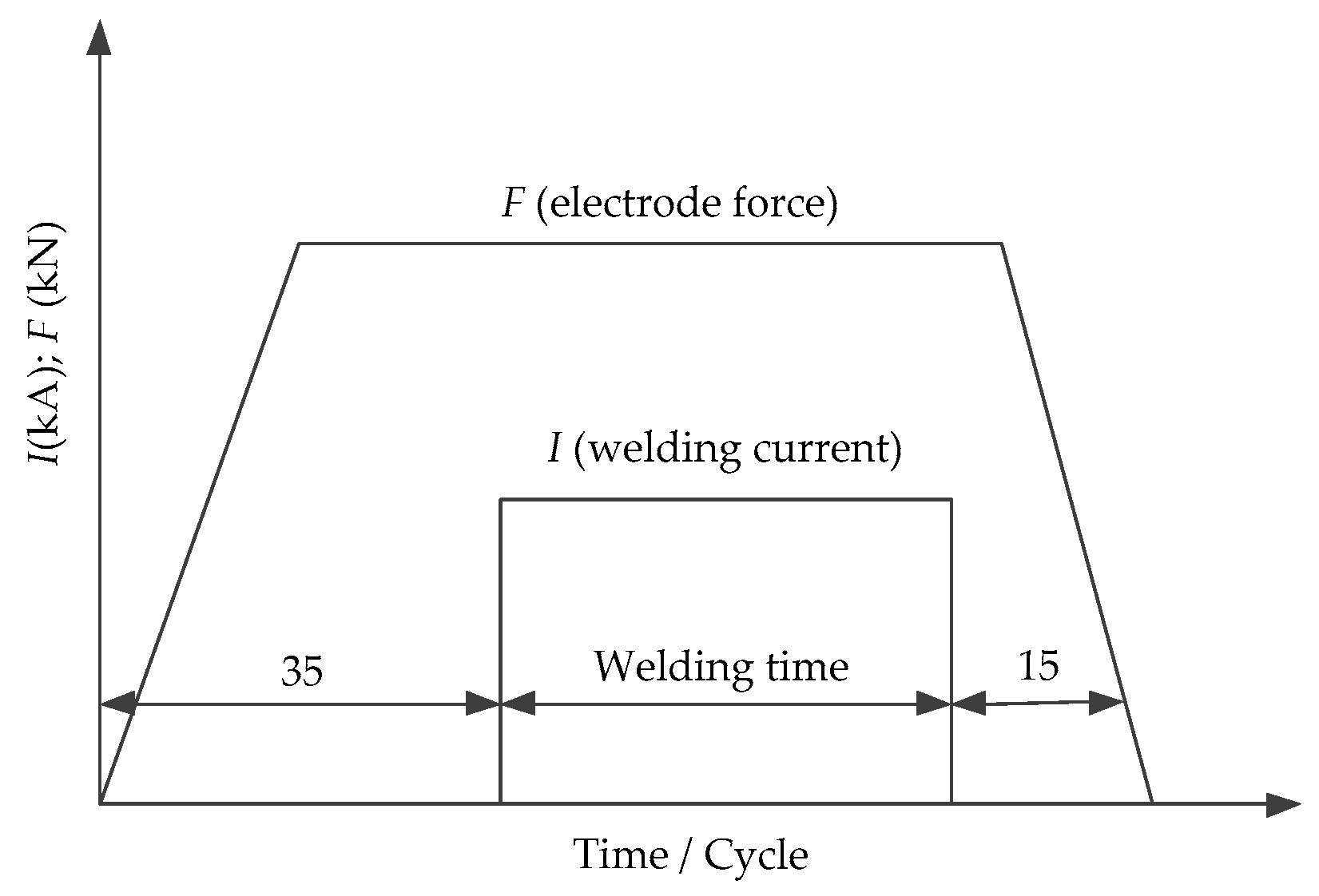

2. Materials and Methods

3. Results

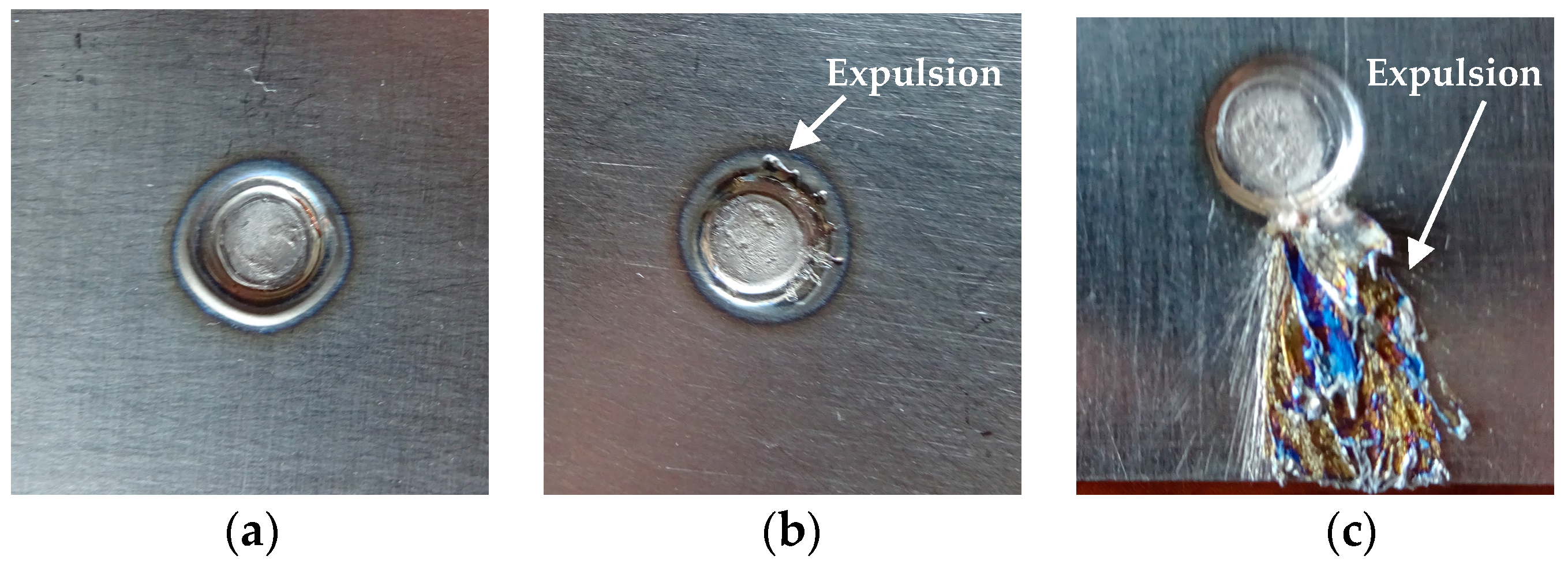

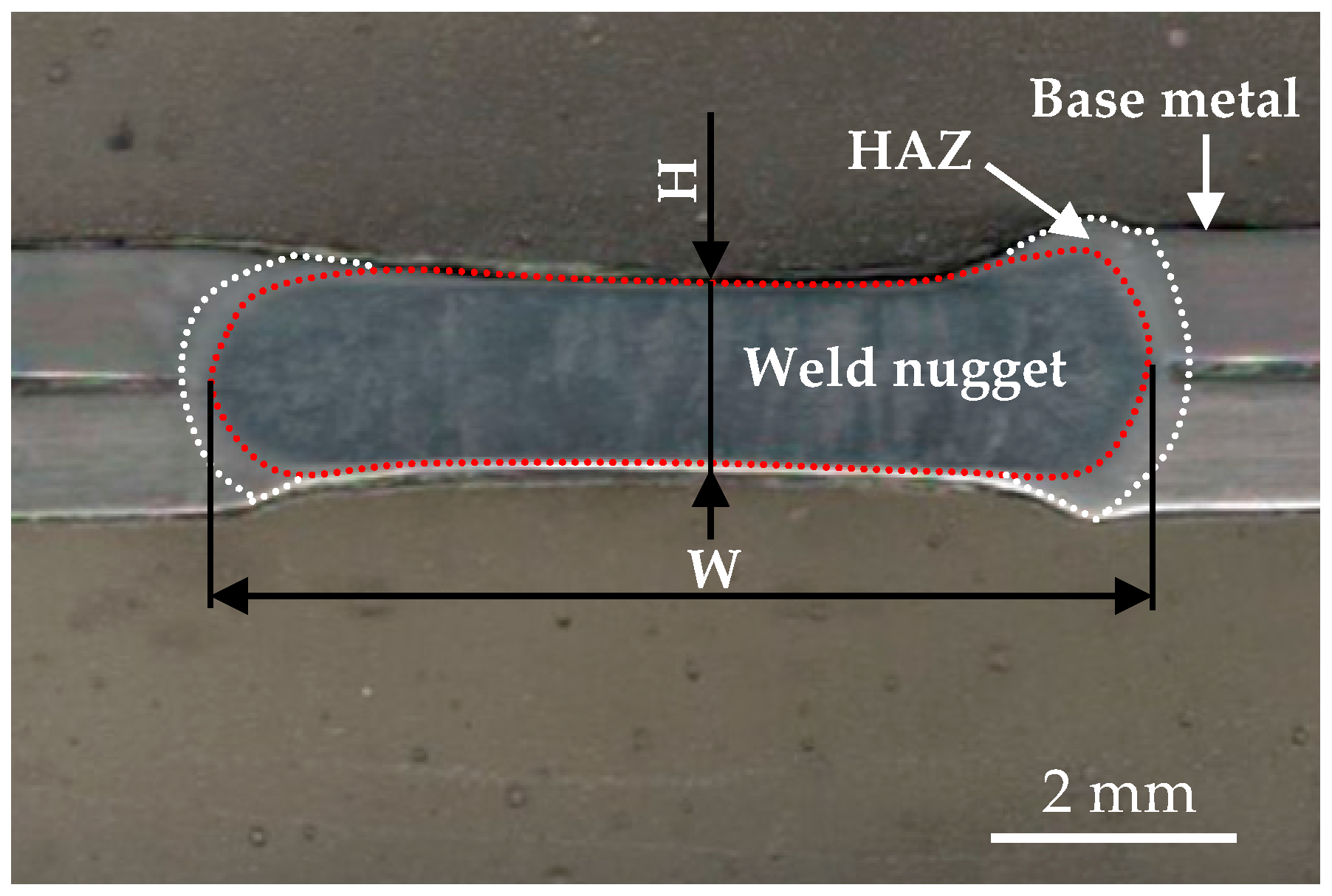

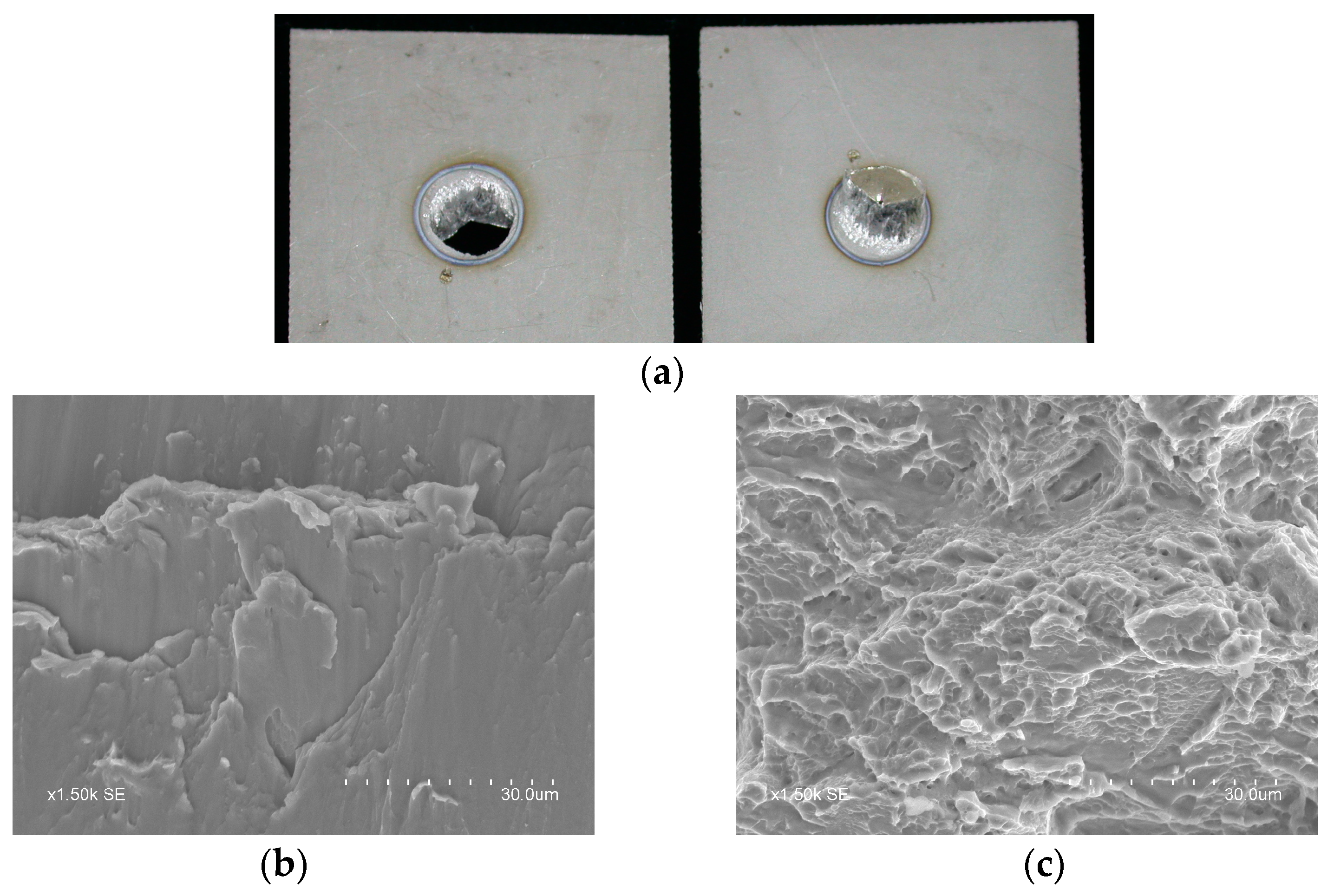

3.1. Weld Nugget Formation

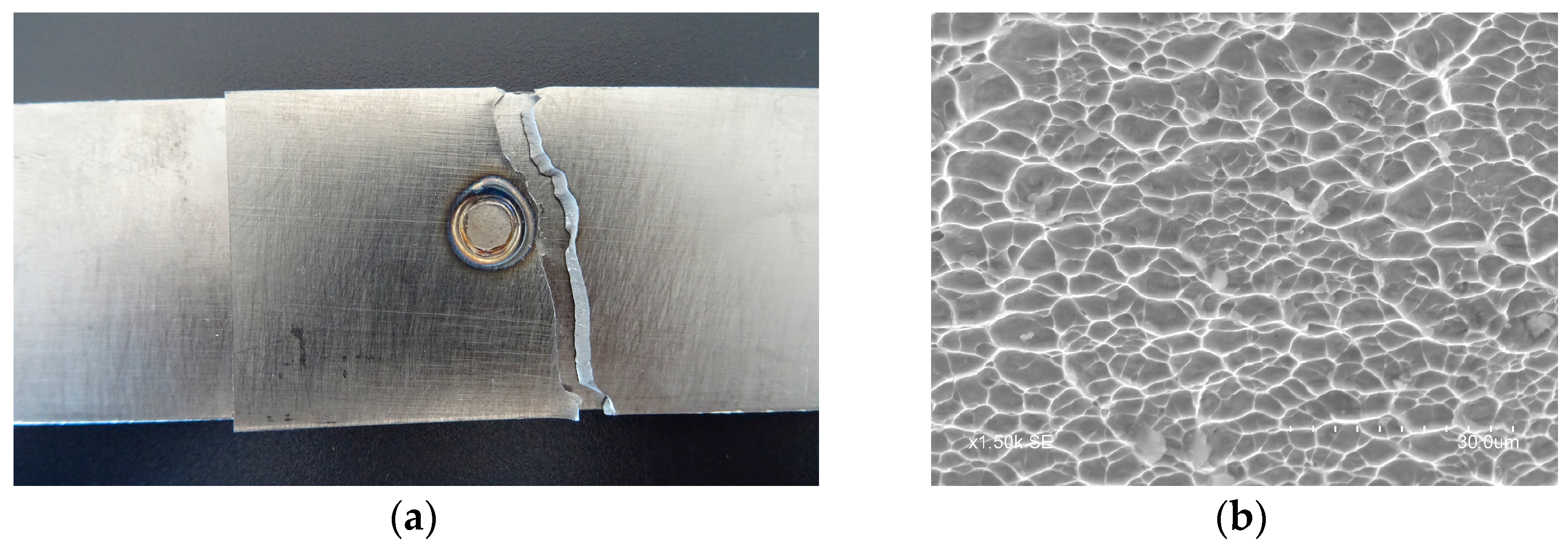

3.2. Tensile Strength

3.3. Microstructure

3.4. Hardness Distribution

4. Conclusions

- (1)

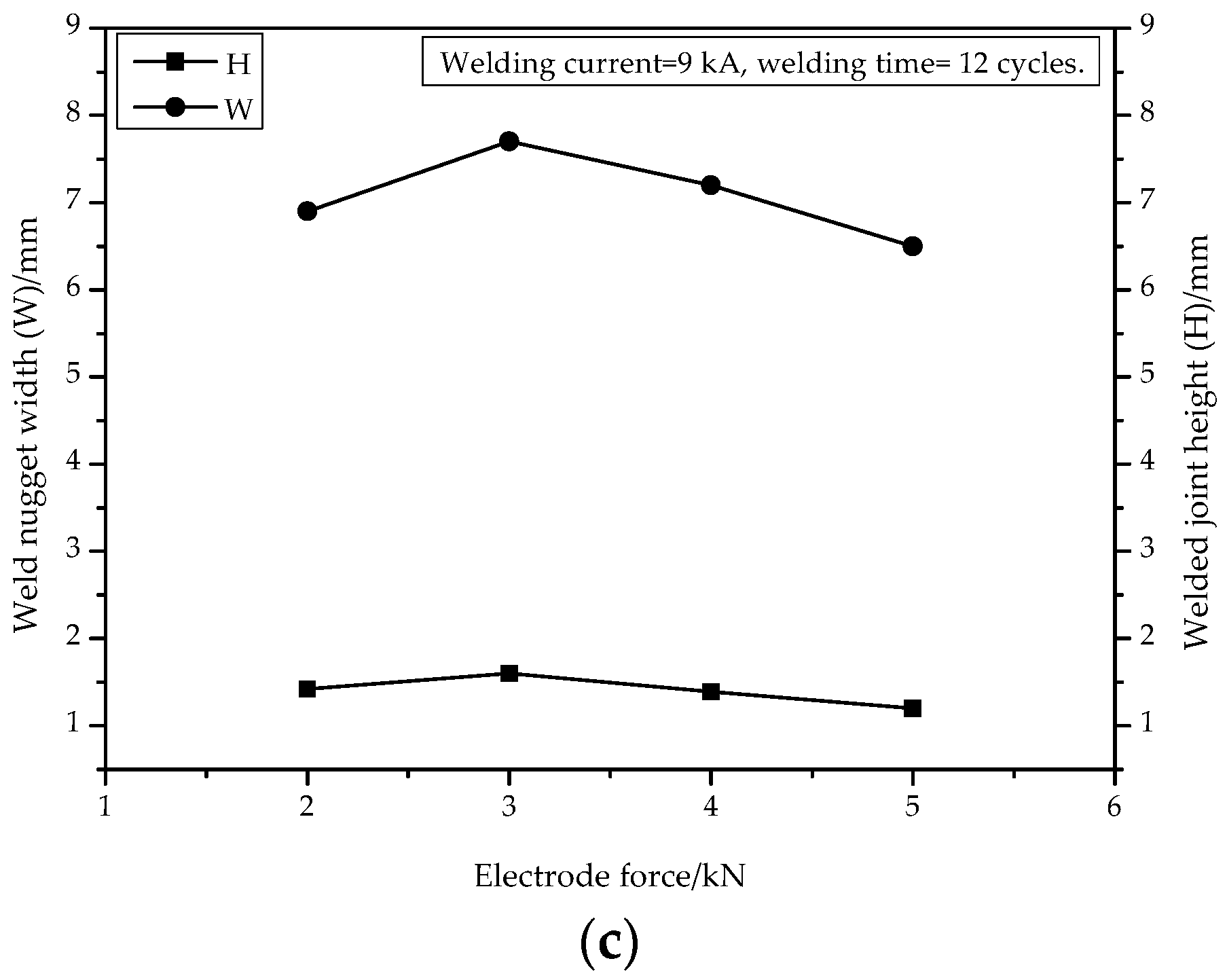

- The visible indentations resulting from a local plastic deformation on the sheets’ surface were caused by the electrode force at the faying surface between electrode and sheet. The expulsion on the weld nugget surface was mainly associated with the welding current. Although there was no expulsion on the weld nugget surface when the welding current was no more than 9 kA, with the welding current raised to 11 kA, the expulsion became very severe.

- (2)

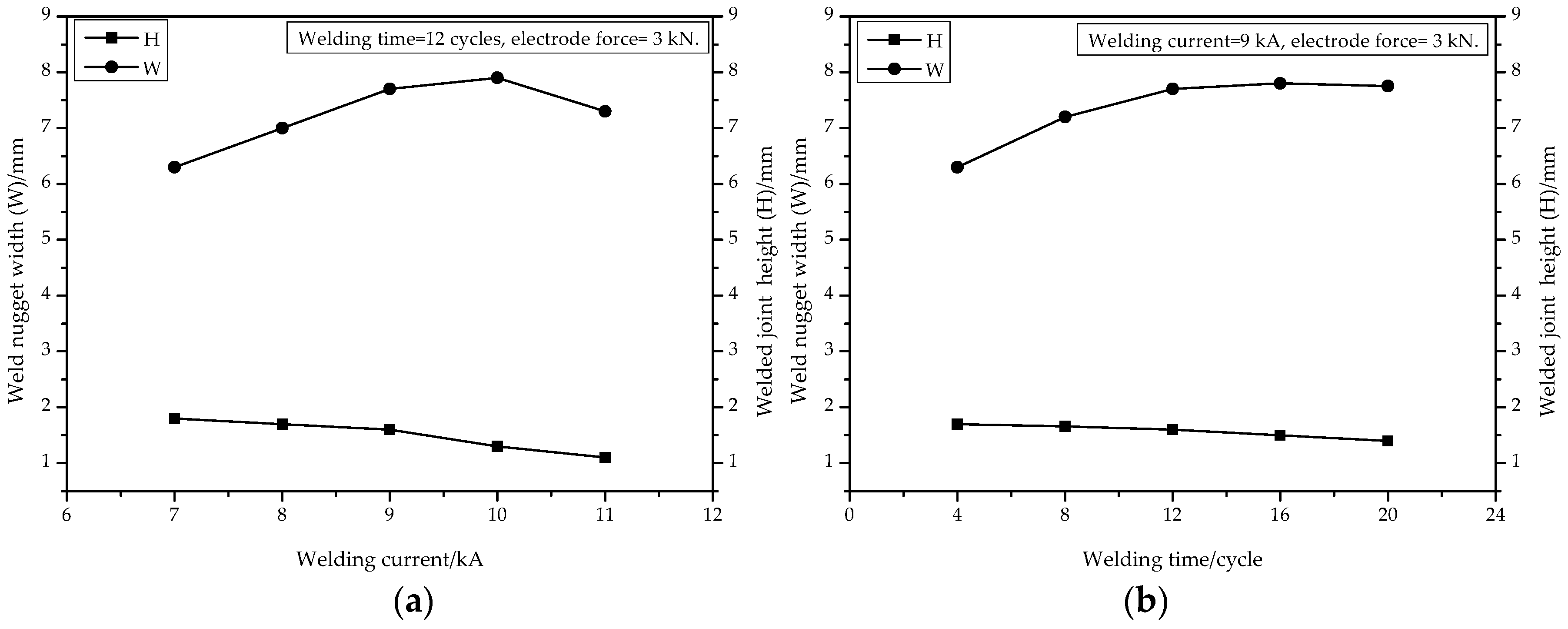

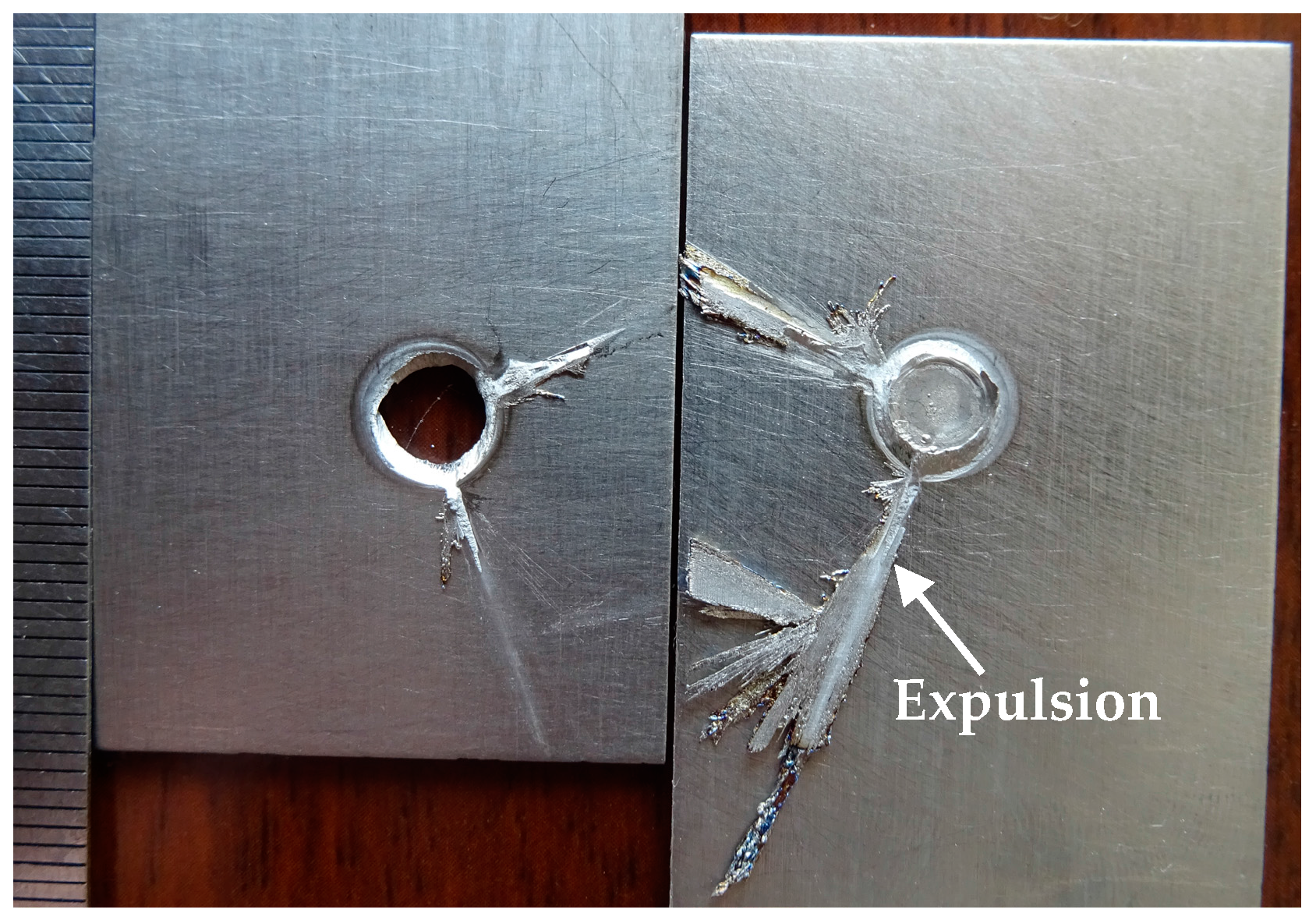

- With an increase in welding current, the weld nugget width (W) increased, and the welded joint height (H) at the weld nugget center decreased. When the welding time was increased from 4 cycles to 20 cycles, the weld nugget width (W) at first increased, and then changed less obviously. When the electrode force was increased from 2 kN to 5 kN, the weld nugget width (W) and welded joint height (H) all increased at first, and then evidently decreased.

- (3)

- The maximum tensile load of the welded joint was up to 14.3 kN. Two types of failure mode were observed: partial interfacial failure and pullout failure. In this investigation, the transition from PIF mode to PF mode was determined by the electrode indentation owing to enough weld nugget width (W) for all welded joints. The critical value of the welded joint height (H) was 1.55 mm.

- (4)

- The welded joint mainly consisted of three zones—weld nugget, HAZ and base metal—and there was an obvious notch in the edge of the weld nugget at the two metal sheets’ faying surface resulting from the insufficient heat input in this region. In the weld nugget zone, it could be seen that the β phase structure entirely transformed to a coarse acicular martensite α′ phase; therefore, the hardness of the weld nugget was the highest. The microstructure in HAZ was a mixture of primary α, primary β, and a transformation of the β phase to fine acicular α′ phase, resulting in the increase of hardness in the HAZ compared with the base metal.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heideberg, Germany, 2007; pp. 449–450. [Google Scholar]

- Cao, X.; Jahazi, M. Effect of welding speed on butt joint quality of Ti6Al4V alloy welded using a high-power Nd:YAG laser. Opt. Lasers Eng. 2009, 47, 1231–1241. [Google Scholar] [CrossRef]

- Köse, C.; Karaca, E. Robotic Nd:YAG Fiber laser welding of Ti-6Al-4V alloy. Metals 2017, 7, 221. [Google Scholar] [CrossRef]

- Attanasio, A.; Gelfi, M.; Pola, A.; Ceretti, E.; Giardini, C. Influence of material microstructures in micromilling of Ti6Al4V alloy. Materials 2013, 6, 4268–4283. [Google Scholar] [CrossRef] [PubMed]

- Akman, E.; Demir, A.; Canel, T.; Sınmazçelik, T. Laser welding of Ti6Al4V titanium alloys. J. Mater. Process. Technol. 2009, 209, 3705–3713. [Google Scholar] [CrossRef]

- Gao, X.L.; Zhang, L.J.; Liu, J.; Zhang, J.X. Comparison of tensile damage evolution in Ti6A14V joints between laser beam welding and gas tungsten arc welding. J. Mater. Eng. Perform. 2014, 23, 4316–4327. [Google Scholar] [CrossRef]

- Qi, Y.L.; Deng, J.; Hong, Q.; Zeng, L.Y. Electron beam welding, laser beam welding, gas tungsten arc welding of titanium sheet. Mater. Sci. Eng. A 2000, 280, 177–181. [Google Scholar]

- Caiazzo, F.; Curcio, F.; Daurelio, G.; Memola Capece Minutolo, F. Ti6Al4V sheets lap and butt joints carried out by CO2 laser: Mechanical and morphological characterization. J. Mater. Process. Technol. 2004, 149, 546–552. [Google Scholar] [CrossRef]

- Prasad Rao, K.; Angamuthu, K.; Bala Srinivasan, P. Fracture toughness of electron beam welded Ti6Al4V. J. Mater. Process. Technol. 2008, 199, 185–192. [Google Scholar]

- Chen, J.C.; Pan, C.X. Welding of Ti-6Al-4V alloy using dynamically controlled plasma arc welding process. Trans. Nonferr. Met. Soc. China 2011, 21, 1506–1512. [Google Scholar] [CrossRef]

- Wen, G.D.; Ma, T.J.; Li, W.Y.; Li, J.L.; Guo, H.Z.; Chen, D.L. Cyclic deformation behavior of linear friction welded Ti6Al4V joints. Mater. Sci. Eng. A 2014, 597, 408–414. [Google Scholar] [CrossRef]

- Buffa, G.; Campanella, D.; Cammalleri, M.; Ducato, A.; Astarita, A.; Squillace, A.; Esposito, S.; Fratini, L. Experimental and numerical analysis of microstructure evolution during linear friction welding of Ti6Al4V. Procedia Manuf. 2015, 1, 429–441. [Google Scholar] [CrossRef]

- Maio, L.; Liberini, M.; Campanella, D.; Astarita, A.; Esposito, S.; Boccardi, S.; Meola, C. Infrared thermography for monitoring heat generation in a linear friction welding process of Ti6Al4V alloy. Infrared Phys. Technol. 2017, 81, 325–338. [Google Scholar] [CrossRef]

- Jiang, C.Y.; Wu, M.F.; Yu, C.; Liang, C. Morphology and strength of TC4/TC4 joint with 72Ag-28Cu filler metal. Rare Met. Mater. Eng. 2003, 32, 295–297. [Google Scholar]

- Wu, Z.; Mei, J.; Voice, W.; Beech, S.; Wu, X. Microstructure and properties of diffusion bonded Ti–6Al–4V parts using brazing-assisted hot isostatic pressing. Mater. Sci. Eng. A 2011, 528, 7388–7394. [Google Scholar] [CrossRef]

- Zhang, Y.; Sato, Y.S.; Kokawa, H.; Seung Park, S.H.C.; Hirano, S. Microstructural characteristics and mechanical properties of Ti–6Al–4V friction stir welds. Mater. Sci. Eng. A 2008, 485, 448–455. [Google Scholar] [CrossRef]

- Mironov, S.; Zhang, Y.; Sato, Y.S.; Kokawa, H. Development of grain structure in β-phase field during friction stir welding of Ti–6Al–4V alloy. Scr. Mater. 2008, 59, 27–30. [Google Scholar] [CrossRef]

- Buffa, G.; Ducato, A.; Fratini, L. FEM based prediction of phase transformations during friction stir welding of Ti6Al4V titanium alloy. Mater. Sci. Eng. A 2013, 581, 56–65. [Google Scholar] [CrossRef]

- Ertek Emre, H.; Kaçar, R. Resistance spot weldability of galvanize coated and uncoated TRIP steels. Metals 2016, 6, 299. [Google Scholar] [CrossRef]

- Aslanlar, S.; Ogur, A.; Ozsarac, U.; Ilhan, E. Welding time effect on mechanical properties of automotive sheets in electrical resistance spot welding. Mater. Des. 2008, 29, 1427–1431. [Google Scholar] [CrossRef]

- Kazdal Zeytin, H.; Ertek Emre, H.; Kaçar, R. Properties of resistance spot-welded TWIP steels. Metals 2017, 7, 14. [Google Scholar] [CrossRef]

- Wu, S.N.; Ghaffari, B.; Hetrick, E.; Li, M.; Liu, Q.; Jia, Z.H. Thermo-mechanically affected zone in AA6111 resistance spot welds. J. Mater. Process. Technol. 2017, 249, 463–470. [Google Scholar] [CrossRef]

- Kahraman, N. The influence of welding parameters on the joint strength of resistance spot-welded titanium sheets. Mater. Des. 2007, 28, 420–427. [Google Scholar] [CrossRef]

- Shi, H.X.; Qiu, R.F.; Zhu, J.H.; Zhang, K.K.; Yu, H.; Ding, G.J. Effects of welding parameters on the characteristics of magnesium alloy joint welded by resistance spot welding with cover plates. Mater. Des. 2010, 31, 4853–4857. [Google Scholar] [CrossRef]

- Chen, N.N.; Wang, H.P.; Carlson, B.E.; Sigler, D.R.; Wang, M. Fracture mechanisms of Al/steel resistance spot welds in lap shear test. J. Mater. Process. Technol. 2017, 243, 347–354. [Google Scholar] [CrossRef]

| Component | Al | V | Fe | Si | O | C | N | Ti |

|---|---|---|---|---|---|---|---|---|

| wt % | 6.15 | 3.96 | 0.3 | 0.15 | 0.2 | 0.02 | 0.01 | Balance |

| Condition | Welding Current (kA) | Welding Time (Cycle 1) | Electrode Force (kN) |

|---|---|---|---|

| Set 1 | 7, 8, 9, 10, 11 | 12 | 3 |

| Set 2 | 9 | 4, 8, 12, 16, 20 | 3 |

| Set 3 | 9 | 12 | 2, 3, 4, 5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhang, J.; Chen, F.; Yang, Z.; He, J. Characteristics of Resistance Spot Welded Ti6Al4V Titanium Alloy Sheets. Metals 2017, 7, 424. https://doi.org/10.3390/met7100424

Zhang X, Zhang J, Chen F, Yang Z, He J. Characteristics of Resistance Spot Welded Ti6Al4V Titanium Alloy Sheets. Metals. 2017; 7(10):424. https://doi.org/10.3390/met7100424

Chicago/Turabian StyleZhang, Xinge, Jiangshuai Zhang, Fei Chen, Zhaojun Yang, and Jialong He. 2017. "Characteristics of Resistance Spot Welded Ti6Al4V Titanium Alloy Sheets" Metals 7, no. 10: 424. https://doi.org/10.3390/met7100424