Effect of Pulse Laser Welding Parameters and Filler Metal on Microstructure and Mechanical Properties of Al-4.7Mg-0.32Mn-0.21Sc-0.1Zr Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Laser Welding Parameters

3.2. Influence of Filler Metal on Weldability

3.3. Effect of Heat Treatment of Butt-Welded 1545 K Aluminum Alloy

4. Conclusions

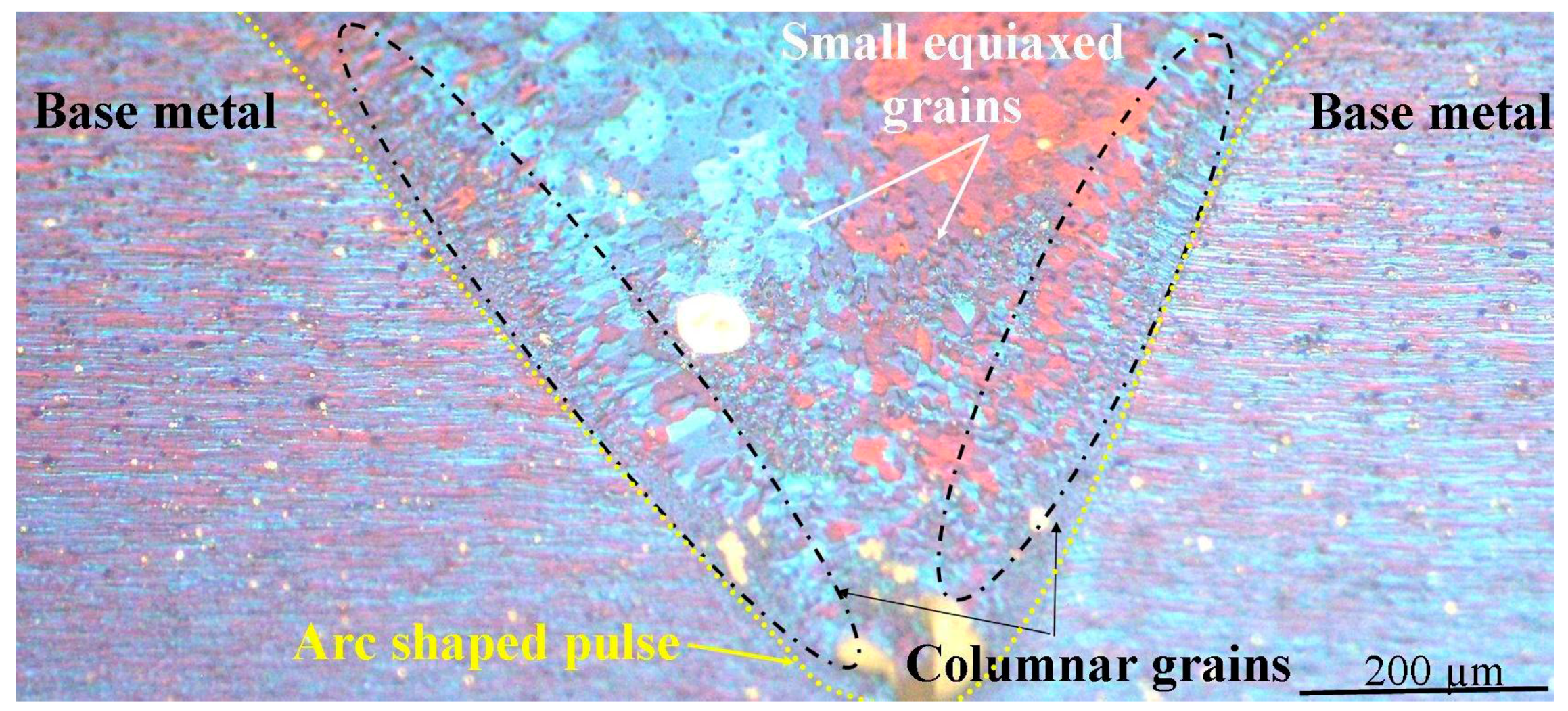

- The optimal parameters of pulsed laser welding of the Al-4.7Mg-0.32Mn-0.21Sc-0.1Zr alloy were determined. They were 330–340 V in voltage, 0.2–0.25 mm in pulse overlap with 12 ms duration, and 2 mm/s in welding speed with a ramp-down pulse shape.

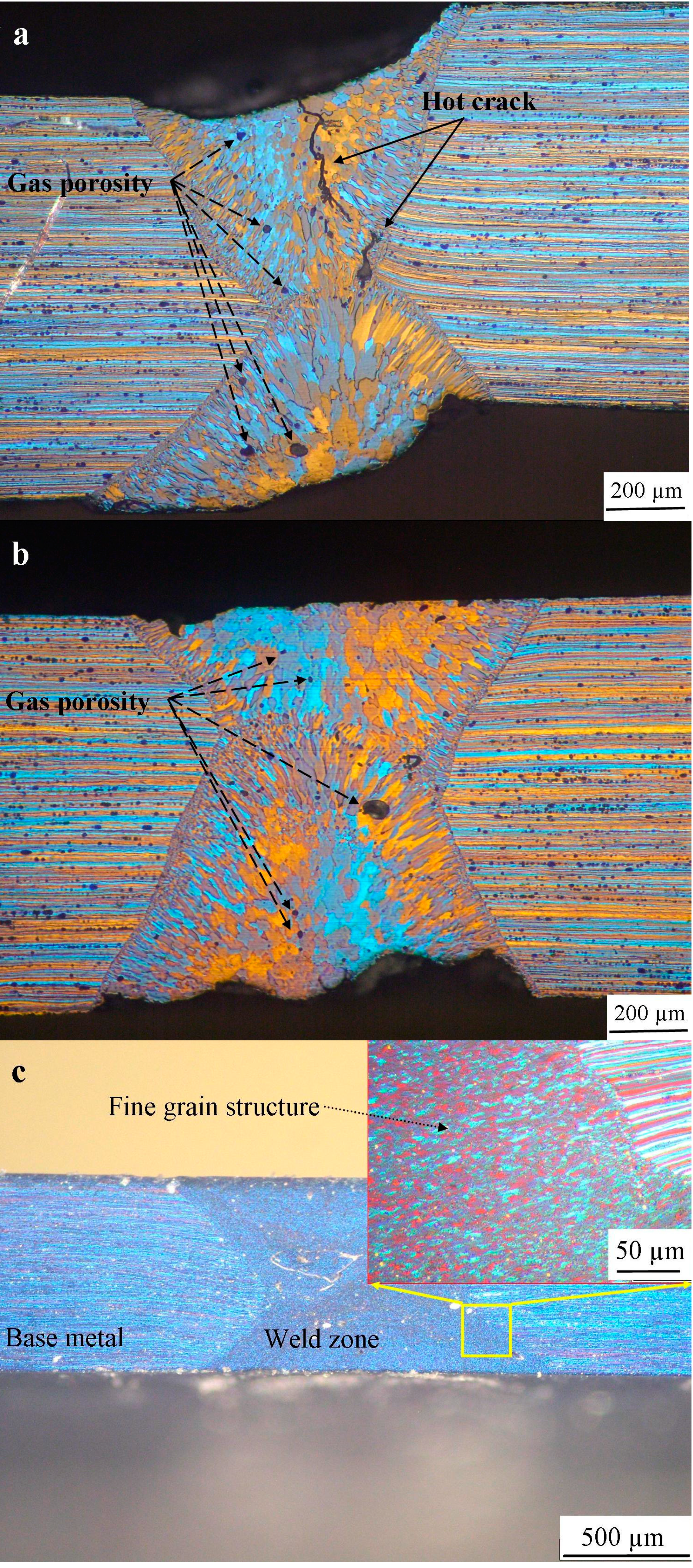

- It was found that pulsed laser welding of the alloy without and with AlMg filler metal led to the formation of a duplex as-cast structure with hot cracks and gas porosity as defects in the weld zone. The fine grain structure with an average grain size of 4 ± 0.2 µm and without any weld defects was formed in the weld zone after using AlTiB filler metal.

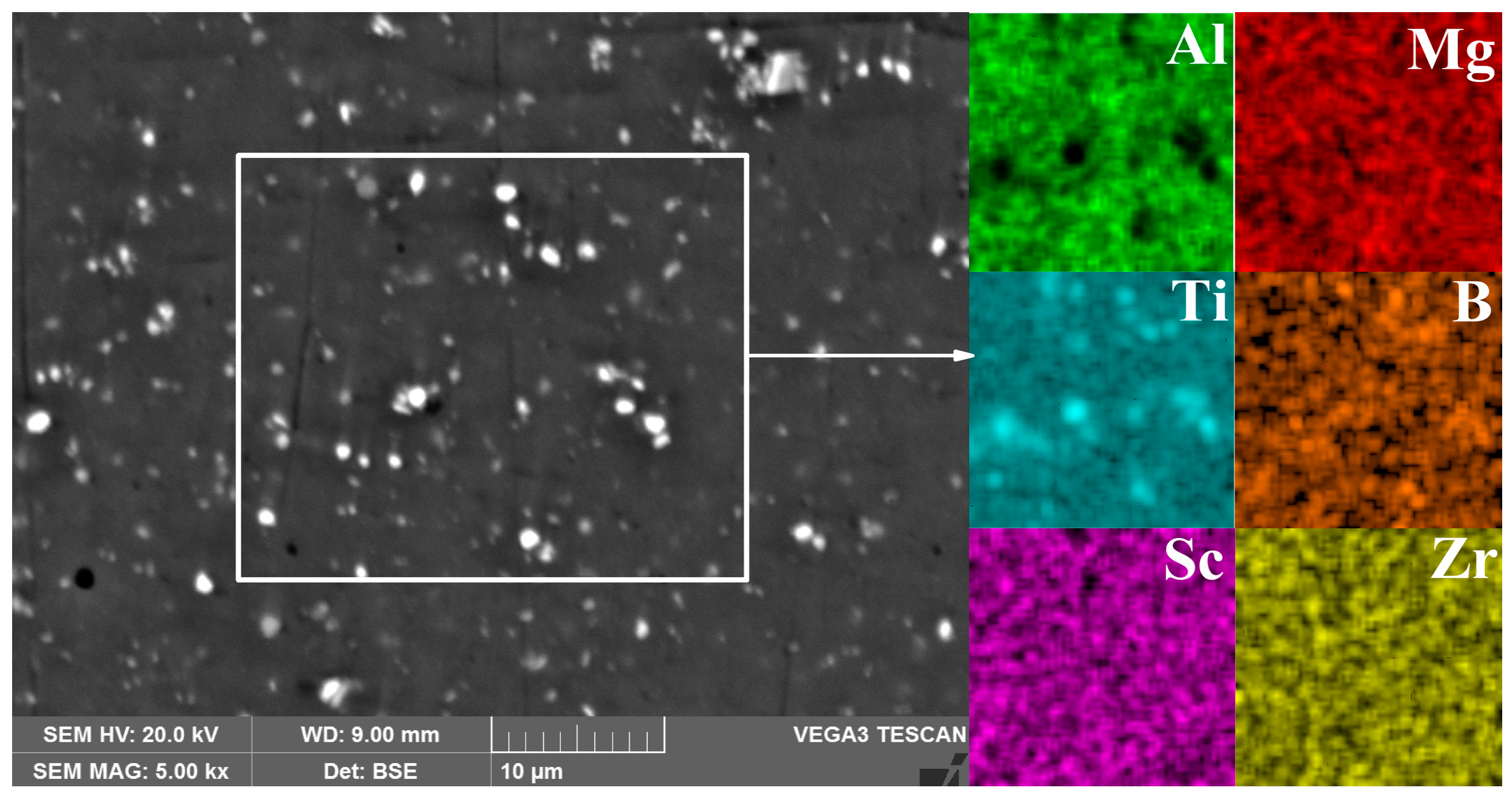

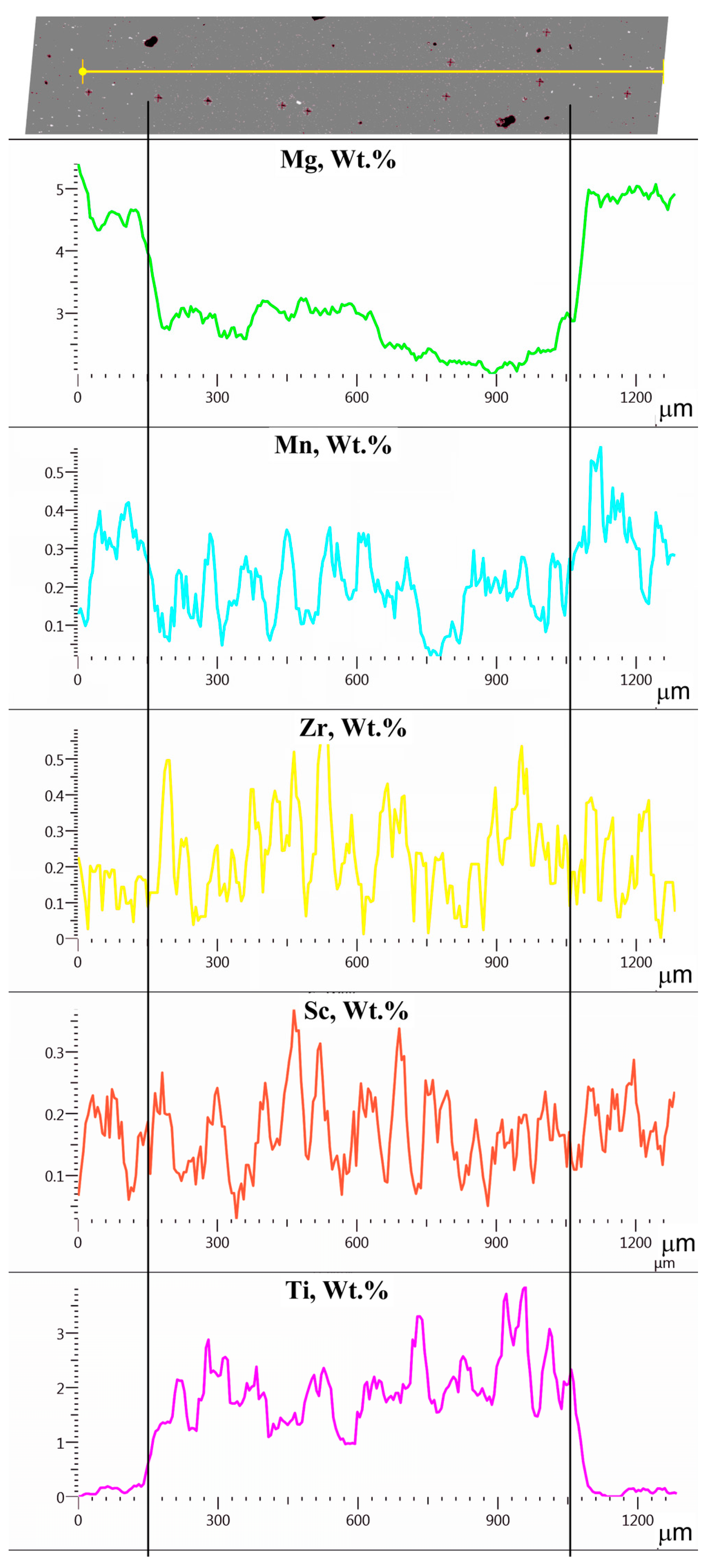

- The mixture of the base and filler metals was formed during laser welding with average concentrations of Mg, 2.8%; Mn, 0.2%; Zr, 0.1%; Sc, 0.15%; and Ti, 2.1%. The high density of the TiB2 phase was found in the weld. Zr and Sc were homogenously distributed in the solid solution.

- The UTS of the Al-4.7Mg-0.32Mn-0.21Sc-0.1Zr alloy welded with AlTiB was 320 MPa after annealing at 370 °C for 6 h and it was 85% of the UTS of the base alloy at the same condition.

Author Contributions

Conflicts of Interest

References

- Lathabai, S.; Lloyd, P.G. The effect of scandium on the microstructure, mechanical properties and weldability of a cast Al–Mg alloy. Acta Mater. 2002, 50, 4275–4292. [Google Scholar] [CrossRef]

- Filatov, Y.A.; Yelagin, V.I.; Zakharov, V.V. New Al–Mg–Sc alloys. Mater. Sci. Eng. A 2000, 280, 97–101. [Google Scholar] [CrossRef]

- Tao, Y.; Zhang, Z.; Ni, D.R.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Influence of welding parameter on mechanical properties and fracture behavior of friction stir welded Al–Mg–Sc joints. Mater. Sci. Eng. A 2014, 612, 236–245. [Google Scholar] [CrossRef]

- Leo, P.; Renna, G.; Casalino, G.; Olabi, A.G. Effect of power distribution on the weld quality during hybrid laser welding of an Al–Mg alloy. Opt. Laser Technol. 2015, 73, 118–126. [Google Scholar] [CrossRef]

- Kuo, T.Y.; Lin, H.C. Effects of pulse level of Nd–YAG laser on tensile properties and formability of laser weldments in automotive aluminum alloys. Mater. Sci. Eng. A 2006, 416, 281–289. [Google Scholar] [CrossRef]

- Novikov, I.I. Goryachelomkost Tsvetnykh Metallov i Splavov (Hot Shortness of Non-Ferrous Metals and Alloys); Nauka: Moscow, Russia, 1966; p. 300. [Google Scholar]

- Eskin, D.G.; Suyitno; Kargerman, L. Mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Prog. Mater. Sci. 2004, 49, 629–711. [Google Scholar] [CrossRef]

- Zolotorevskiy, V.S.; Pozdniakov, A.V.; Khvan, A.V. Thermodynamic calculations of the effective solidification range and its relation to hot cracking of aluminum-based ternary alloys. Russ. J. Non-Ferrous Met. 2011, 52, 50–55. [Google Scholar] [CrossRef]

- Lashko, N.F.; Lashko-Avakyan, S.V. Svarivaymie Legkie Splavy (Light-Weight Welded Alloys); Petrov, G.L., Ed.; Subpromgiz: St.-Petersburg, Russia, 1960; pp. 194–229.

- Argade, G.R.; Kumar, N.; Mishra, R.S. Stress corrosion cracking susceptibility of ultrafine grained Al–Mg–Sc alloy. Mater. Sci. Eng. A 2013, 565, 80–89. [Google Scholar] [CrossRef]

- Besel, Y.; Besel, M.; Alfaro, U.M.; Kakiuchi, T.; Hirata, T.; Uematsu, Y. Influence of local fatigue damage evolution on crack initiation behavior in a friction stir welded Al-Mg-Sc alloy. Int. J. Fatigue 2017, 99, 151–162. [Google Scholar] [CrossRef]

- Yang, D.; Li, X.; He, D.; Huang, H. Effect of minor Er and Zr on microstructure and mechanical properties of Al–Mg–Mn alloy (5083) welded joints. Mater. Sci. Eng. A 2013, 561, 226–231. [Google Scholar] [CrossRef]

- Fu, L.; Peng, Y.; Huang, J.; Deng, Y.; Yin, Z. Microstructures and mechanical properties of Gas Tungsten Arc Welded joints of new Al–Mg–Sc and Al–Mg–Er alloy plates. Mater. Sci. Eng. A 2015, 620, 149–154. [Google Scholar] [CrossRef]

- Urbikain, G.; Perez, J.M.; de Lacalle, L.N.L.; Andueza, A. Combination of friction drilling and form tapping processes on dissimilar materials for making nutless joints. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2016. [Google Scholar] [CrossRef]

- Boopathi, M.; Shankar, S.; Manikandakumar, S.; Ramesh, R. Experimental investigation of friction drilling on brass, aluminium and stainless steel. Procedia Eng. 2013, 64, 1219–1226. [Google Scholar] [CrossRef]

- Eliseev, A.A.; Fortuna, S.V.; Kolubaev, E.A.; Kalashnikova, T.A. Microstructure modification of 2024 aluminum alloy produced by friction drilling. Mater. Sci. Eng. A 2017, 691, 121–125. [Google Scholar] [CrossRef]

- De Lacalle, L.N.L.; Urbikain, G.; Azkona, I.; Zumalde, E.; Okariz, L. Friction drilling, form tapping and rotary broaching for fast joining technologies. Weld. Mater. Test. 2016, 4, 3–7. [Google Scholar]

- Spierings, A.B.; Dawson, K.; Kern, K.; Palm, F.; Wegener, K. SLM-processed Sc- and Zr-modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment. Mater. Sci. Eng. A 2017, 701, 264–273. [Google Scholar] [CrossRef]

- Li, R.; Wang, M.; Yuan, T.; Song, B.; Chen, C.; Zhou, K.; Cao, P. Selective laser melting of a novel Sc and Zr modified Al-6.2 Mg alloy: Processing, microstructure, and properties. Powder Technol. 2017, 319, 117–128. [Google Scholar] [CrossRef]

- Tabernero, I.; Lamikiz, A.; Martínez, S.; Ukar, E.; de Lacalle, L.N.L. Modelling of energy attenuation due to powder flow-laser beam interaction during laser cladding process. J. Mater. Process. Technol. 2012, 212, 516–522. [Google Scholar] [CrossRef]

- Zhen, H.; Yong, P.; Zhi, Y.; Xue, L. Comparison of FSW and TIG welded joints in Al-Mg-Mn-Sc-Zr alloy plates. Trans. Nonferrous Met. Soc. China 2011, 21, 1685–1691. [Google Scholar] [CrossRef]

- Zolotorevskiy, V.S.; Dobrozhinskaya, R.I.; Cheverikin, V.V.; Khamnagdaeva, E.A.; Pozdniakov, A.V.; Levchenko, V.S.; Besogonova, E.S. Strength and substructure of Al–4.7Mg–0.32Mn–0.21Sc–0.09Zr alloy sheets. Phys. Met. Metallogr. 2017, 118, 407–414. [Google Scholar] [CrossRef]

- Zolotorevskiy, V.S.; Dobrojinskaja, R.I.; Cheverikin, V.V.; Khamnagdaeva, E.A.; Pozdniakov, A.V.; Levchenko, V.S.; Besogonova, E.S. Evolution of the structure and mechanical properties of sheets of the of Al–4.7Mg–0.32Mn–0.21Sc–0.09Zr alloy due to deformation accumulated upon rolling. Phys. Met. Metallogr. 2016, 117, 1163–1169. [Google Scholar] [CrossRef]

- Filatov, Y.A.; Baidin, G.G.; Dobrozhinskaya, R.I.; Khamnagdaeva, E.A.; Ovsyannikov, B.V. A new 1545K Al–Mg–Sc system-based heat-treatable weldable cryogenic alloy. Tekhnol. Legk. Splavov. 2014, 1, 32–36. [Google Scholar]

- Martínez Krahmer, D.; Polvorosa, R.; de Lacalle, L.N.L.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for specimen manufacturing in tensile testing of steel plates. Exp. Tech. 2016, 40, 1555–1565. [Google Scholar] [CrossRef]

- Silva, C.M.A.; Rosa, P.A.R.; Martins, P.A.F. Innovative testing machines and methodologies for the mechanical characterization of materials. Exp. Tech. 2016, 40, 569–581. [Google Scholar] [CrossRef]

- Dixit, U.S.; Joshi, S.N.; Davim, J.P. Incorporation of material behavior in modeling of metal forming and machining processes: A review. Mater. Des. 2011, 32, 3655–3670. [Google Scholar] [CrossRef]

- Witzendorff, P.; Kaierle, S.; Suttmann, O.; Overmeyer, L. Using pulse shaping to control temporal strain development and solidification cracking in pulsed laser welding of 6082 aluminum alloys. J. Mater. Process. Technol. 2015, 225, 162–169. [Google Scholar] [CrossRef]

- Dworak, J. Impact of Laser Beam Shape on YAG Pulsed Laser Welding; Biuletyn Instytutu Spawalnictwa: Gliwice, Poland, 2012; pp. 5–14. [Google Scholar]

- Lienert, T.J.; Lippold, J.C. Improved weldability diagram for pulsed laser welded austenitic stainless steel. Sci. Technol. Weld. Join. 2003, 8, 1–9. [Google Scholar] [CrossRef]

- Zhang, J.; Weckmann, D.C.; Zhou, Y. Effects of temporal pulse shaping on cracking susceptibility of 6061-T6 aluminum Nd:YAG laser welds. Weld. J. 2008, 87, 18–30. [Google Scholar] [CrossRef]

- Michaud, E.J.; Kerr, H.W.; Weckman, D.C. Temporal Pulse Shaping and Solidification Cracking in Laser Welded Al–Cu Alloys. In Proceedings of the 4th International Conference on Trends in Welding Research, Gatlinburg, TN, USA, 5–8 June 1995; pp. 153–158. [Google Scholar]

- Michaud, E.J.; Weckmann, D.C.; Kerr, H.W. Effect of Pulse Shape on Predicted Thermomechanical Strains in Nd:YAG Laser Welded Aluminum. In Proceedings of the International Congress on Applications of Lasers and Electro Optics, Orlando, FL, USA, 1994; pp. 461–470. [Google Scholar]

- Eskin, D.G.; Katgerman, L.; Suyitno; Mooney, J.F. Contraction of aluminum alloys during and after solidification. Metall. Mater. Trans. A 2004, 35, 1325–1335. [Google Scholar] [CrossRef]

| Al | Mg | Mn | Sc | Zr | Cu | Fe | Zn |

|---|---|---|---|---|---|---|---|

| bal. | 4.7 | 0.32 | 0.21 | 0.1 | <0.1 | <0.1 | <0.1 |

| Condition | UTS, MPa |

|---|---|

| As cast | 268 ± 8 |

| As cast and annealed at 370 °C for 6 h | 360 ± 10 |

| As cast, annealed and rolled | 490 ± 12 |

| Rolled and annealed at 370 °C for 6 h | 375 ± 8 |

| Welded without filler metal | 100 ± 9 |

| Welded with AlMg | 90 ± 7 |

| Welded with AlTiB | 260 ± 7 |

| Welded with AlTiB and annealed at 370 °C for 6 h | 320 ± 8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loginova, I.; Khalil, A.; Pozdniakov, A.; Solonin, A.; Zolotorevskiy, V. Effect of Pulse Laser Welding Parameters and Filler Metal on Microstructure and Mechanical Properties of Al-4.7Mg-0.32Mn-0.21Sc-0.1Zr Alloy. Metals 2017, 7, 564. https://doi.org/10.3390/met7120564

Loginova I, Khalil A, Pozdniakov A, Solonin A, Zolotorevskiy V. Effect of Pulse Laser Welding Parameters and Filler Metal on Microstructure and Mechanical Properties of Al-4.7Mg-0.32Mn-0.21Sc-0.1Zr Alloy. Metals. 2017; 7(12):564. https://doi.org/10.3390/met7120564

Chicago/Turabian StyleLoginova, Irina, Asmaa Khalil, Andrey Pozdniakov, Alexey Solonin, and Vadim Zolotorevskiy. 2017. "Effect of Pulse Laser Welding Parameters and Filler Metal on Microstructure and Mechanical Properties of Al-4.7Mg-0.32Mn-0.21Sc-0.1Zr Alloy" Metals 7, no. 12: 564. https://doi.org/10.3390/met7120564