High-Cycle Microscopic Severe Corrosion Fatigue Behavior and Life Prediction of 25CrMo Steel Used in Railway Axles

Abstract

:1. Introduction

2. Materials and Experimental Method

2.1. Material or Specimen

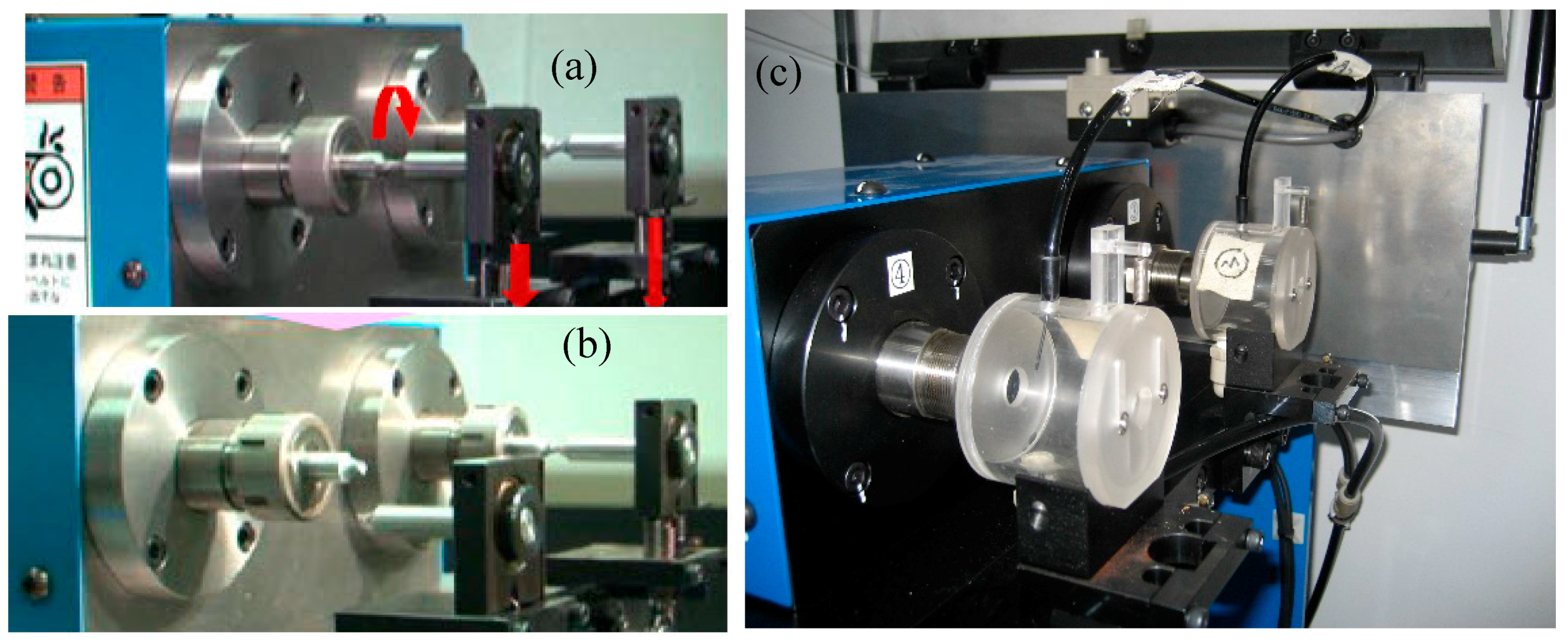

2.2. Mechanical Testing

2.3. Three-Parameter Weibull Distribution Function

3. Results

4. Discussion

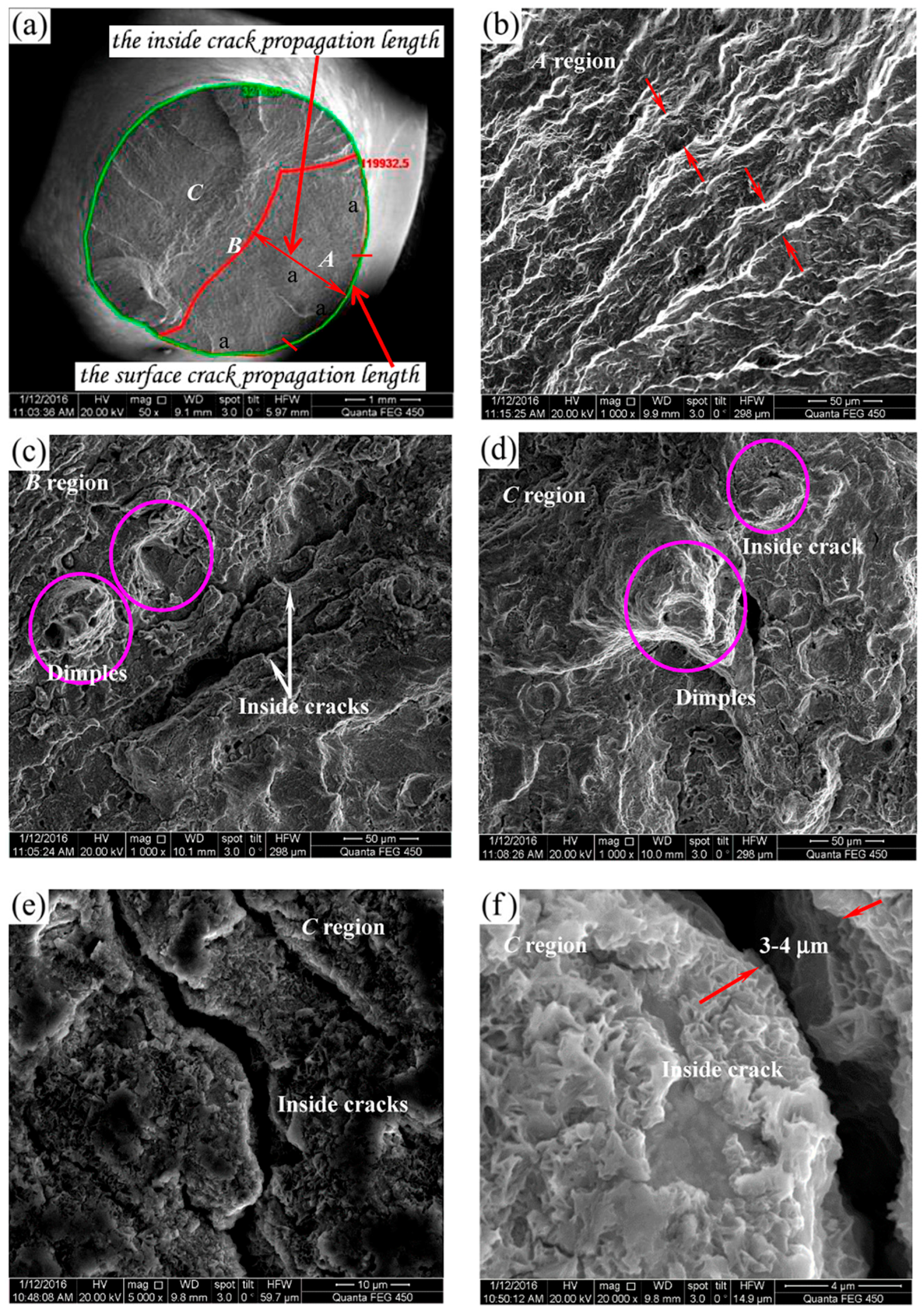

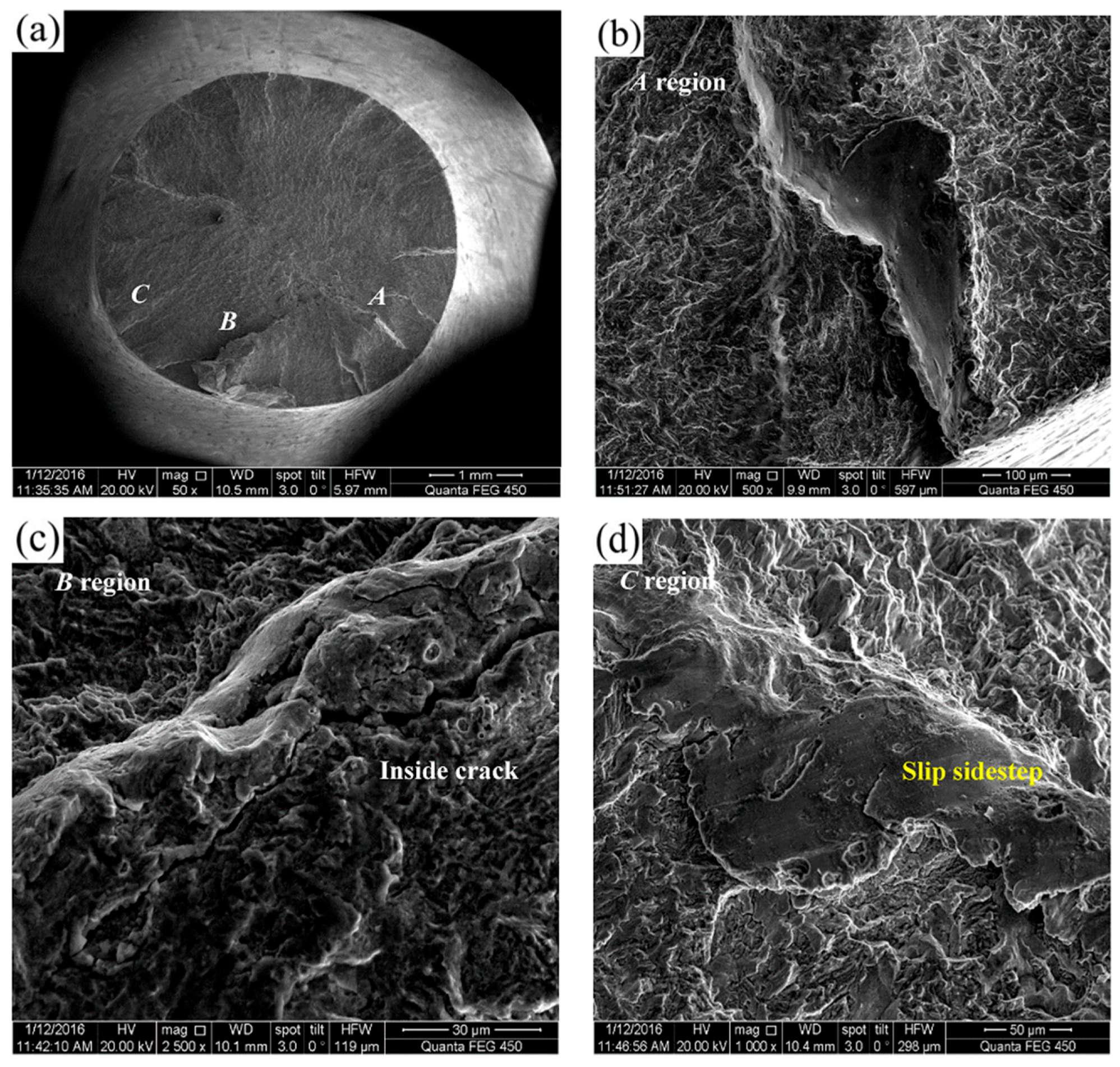

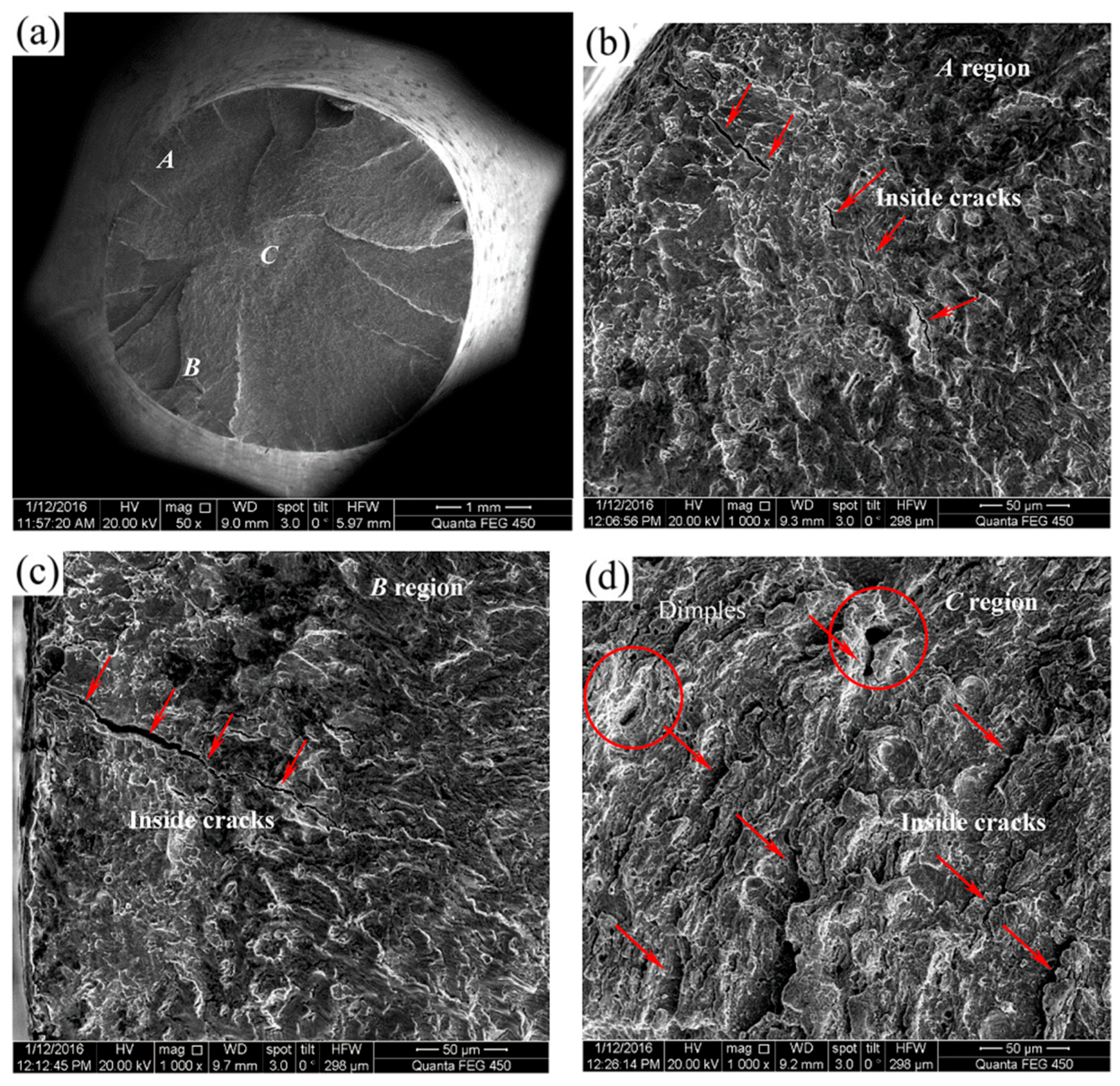

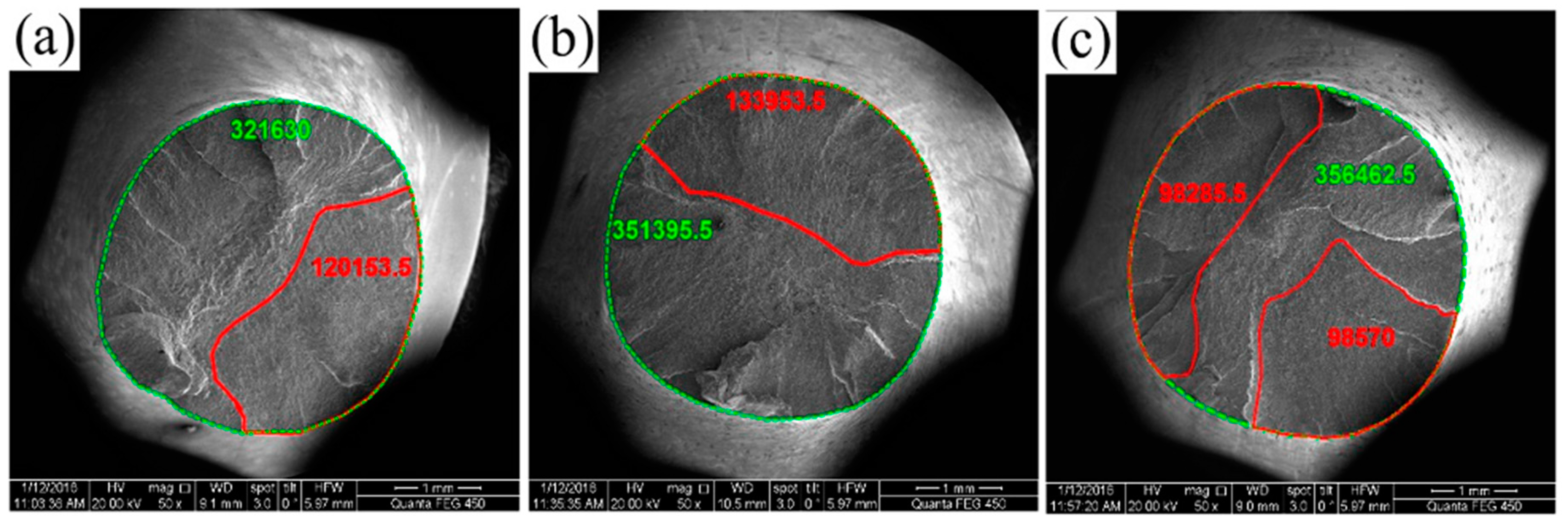

4.1. Fractography Analysis

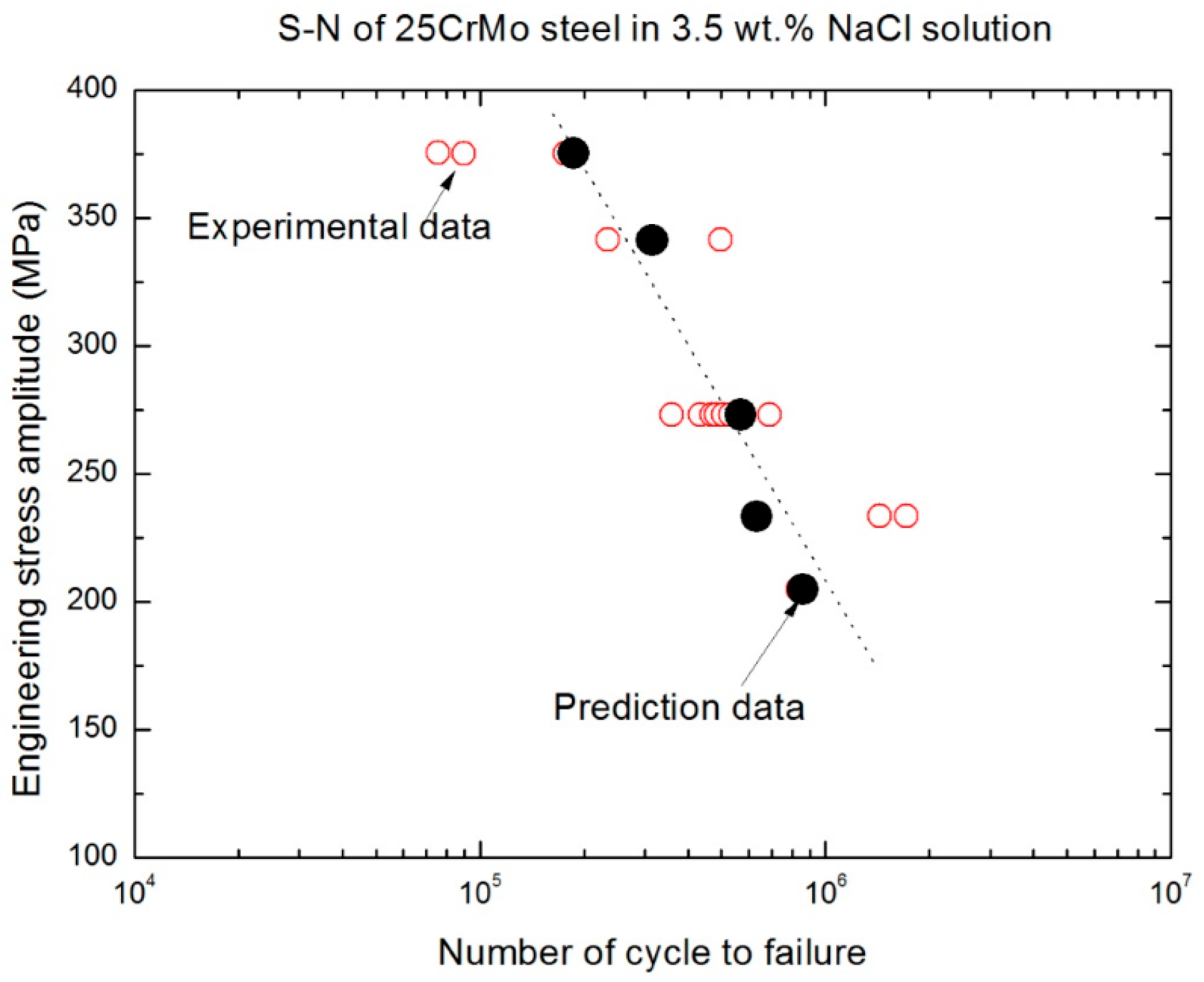

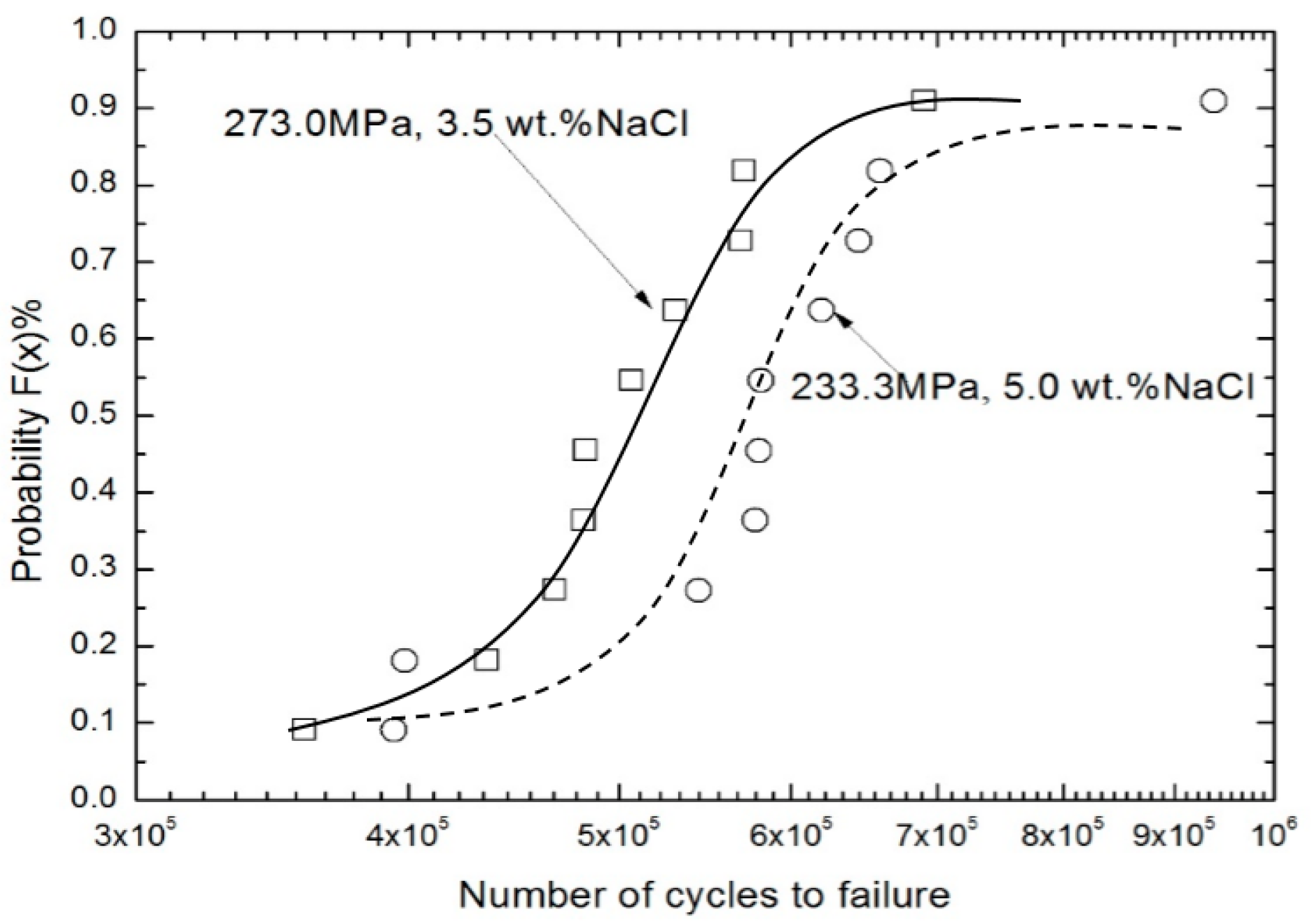

4.2. Fatigue Life Prediction and Reliability Analysis

5. Conclusions

- The experimental results indicate that, the higher the number of cycles to failure, the stronger the effect of the corrosive media on the fatigue damage. In this HCF regime, the corrosion fatigue behavior of 25CrMo steel is not completely dependent on the corrosion time (exposure time). It is also dependent on the coupling action of the electrochemical reaction and the plastic deformation. When the number of cycles to failure is greater than 106, the corrosion fatigue data must be analyzed using a statistical analysis, such as the Weibull distribution model.

- For the same environmental media and applied load, the amount of scatter in the corrosion fatigue data is caused primarily by the number of fatigue crack initiation sites and the direction of the fatigue crack propagation in the early stage. A lower number of fatigue crack initiation sites indicates a shorter fatigue crack initiation life, and a faster corrosion fatigue crack growth rate indicates that the total life of the sample is shorter. Improving the surface quality of the sample by reducing the surface defects or the stress concentration sites helps reduce the dispersion in the corrosion fatigue data.

- The corrosion fatigue fracture characteristics indicate that there are fatigue crack propagation vestiges in the crack propagation regions, the second cracks, the plastic dimples, and the slip sidesteps near the interface region between the fatigue crack propagation region and the static fracture region.

- The results of the 3-P Weibull distribution analysis indicate that the corrosion fatigue data are more reliable as the value of the shape parameter (m) increases. At the same time, the characteristic corrosion fatigue life at any stress level for a small sample tested under the same environmental condition can be estimated simply and effectively using Equation (12).

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| a | crack length |

| b | scale parameter in Weibull distribution function |

| predication value of characteristic life | |

| c | location parameter in Weibull distribution function |

| α | the stress concentration factor (1.08) |

| d, L | the geometry size, respectively |

| g | the acceleration of gravity (9.8 m/s2) |

| F(x) | Weibull distribution function |

| m | shape parameter in Weibull distribution function |

| n | experimental number of corrosion fatigue life |

| Ρ′ | corresponding correlation coefficient |

| E(x) | expected value of statistics |

| S(x) | standard deviation value |

| β | reliability index |

| Nf | number of cycles to failure |

| σ | stress amplitude (MPa) |

| R | stress ratio |

References

- Zhang, Y.T.; Bian, S.; Han, W.X. Effect of Mn on hardenability of 25CrMo axle steel by an improved end-quench test. China Foundry 2012, 9, 318–321. [Google Scholar]

- Beretta, S.; Carboni, M.; Fiore, G.; Conte, A.L. Corrosion-fatigue of A1N railway axle steel exposed to rainwater. Int. J. Fatigue 2010, 32, 952–961. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Yang, B.; Feng, M.F.; Wang, H. Probabilistic fatigue S-N curves including the super-long life regime of a railway axle steel. Int. J. Fatigue 2009, 31, 1550–1558. [Google Scholar] [CrossRef]

- Zhao, Y.X. A fatigue reliability analysis method including super long life regime. Int. J. Fatigue 2012, 35, 79–90. [Google Scholar] [CrossRef]

- Cervello, S. Fatigue properties of railway axles: New results of full-scale specimens from Euraxles project. Int. J. Fatigue 2016, 861, 2–12. [Google Scholar] [CrossRef]

- Miller, K.J.; O’Donnell, W.J. The fatigue limit and its elimination. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 545–557. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Berard, J.Y.; Dubarre, A.; Baudry, G.; Rathery, S.; Bathias, C. Gigacycle fatigue of ferrous alloys. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 667–672. [Google Scholar] [CrossRef]

- Li, S.X.; Zhang, P.Y.; Yu, S.R. Experimental study on very high cycle fatigue of martensitic steel of 2Cr13 under corrosive environment. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1146–1152. [Google Scholar] [CrossRef]

- Kang, D.H.; Kim, S.H.; Lee, C.H. Corrosion fatigue behaviors of HSB800 and its HAZs in air and seawater environments. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2013, 559, 751–758. [Google Scholar] [CrossRef]

- Jones, R.H.; Simonen, E.P. Early stages in the development of stress-corrosion cracks. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 1994, 176, 211–218. [Google Scholar] [CrossRef]

- Lai, C.L.; Tsay, L.W.; Chen, C. Effect of microstructure on hydrogen embrittlement of various stainless steels. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2013, 584, 14–20. [Google Scholar] [CrossRef]

- Bayraktar, E.; Garcias, I.M.; Bathias, C. Failure mechanisms of automotive alloys in very high cycle fatigue range. Int. J. Fatigue 2006, 28, 1590–1602. [Google Scholar] [CrossRef]

- Poting, S.; Zenner, H. Parameter C lifetime calculation for the high cycle regime. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 877–885. [Google Scholar] [CrossRef]

- Li, S.X.; Akid, R. Corrosion fatigue life prediction of a steel shaft material in seawater. Eng. Fail. Anal. 2013, 34, 324–334. [Google Scholar] [CrossRef]

- Pyttel, B.; Schwerdt, D.; Berger, C. Very high cycle fatigue—Is there a fatigue limit? Int. J. Fatigue 2011, 33, 49–58. [Google Scholar] [CrossRef]

- Qian, G.A.; Zhou, C.G.; Hong, Y.S. Experimental and theoretical investigation of environmental media on very-high-cycle fatigue behavior for a structural steel. Acta Mater. 2011, 59, 1321–1327. [Google Scholar] [CrossRef]

- Guo, Q.; Guo, X. Research on high-cycle fatigue behavior of FV520B stainless steel based on intrinsic dissipation. Mater. Des. 2016, 90, 248–255. [Google Scholar] [CrossRef]

- Sakai, T.; Lian, B.; Takeda, M.; Shiozawa, K.; Oguma, N.; Ochi, Y.; Nakajima, M.; Nakamura, T. Statistical duplex S-N characteristics of high carbon chromium bearing steel in rotating bending in very high cycle regime. Int. J. Fatigue 2010, 32, 497–504. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Wagner, D.; Wang, Q.Y.; Bathias, C. Effect of carburizing treatment on the “fish eye” crack growth for a low alloyed chromium steel in very high cycle fatigue. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2013, 559, 790–797. [Google Scholar] [CrossRef]

- Akita, M.; Uematsu, Y.; Kakiuchi, T.; Nakajima, M.; Tsuchiyama, T.; Bai, Y.; Isono, K. Effect of sensitization on corrosion fatigue behavior of type 304 stainless steel annealed in nitrogen gas. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2015, 640, 33–41. [Google Scholar] [CrossRef]

- Mohammad, M.; Abdullah, S.; Jamaludin, N.; Innayatullah, O. Predicting the fatigue life of the SAE 1045 steel using an empirical Weibull-based model associated to acoustic emission parameters. Mater. Des. 2014, 54, 1039–1048. [Google Scholar] [CrossRef]

- Ebara, R.C. Corrosion fatigue crack initiation in 12% chromium stainless steel. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2007, 468, 109–113. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Liu, H.B. Weibull modeling of the probabilistic S-N curves for rolling contact fatigue. Int. J. Fatigue 2014, 66, 47–54. [Google Scholar] [CrossRef]

- Weibull, W. A statistical distribution function of wide applicability. J. Appl. Mech. Trans. ASME 1951, 18, 293–297. [Google Scholar]

- Wang, X.S.; Guo, X.W.; Li, X.D.; Ge, D.Y. Improvement on the fatigue performance of 2024-T4 alloy by synergistic coating technology. Materials 2014, 7, 3533–3546. [Google Scholar] [CrossRef]

- Wang, X.S.; Li, X.D.; Yang, H.H.; Kawagoishi, N.; Pan, P. Environment-induced fatigue cracking behavior of aluminum alloys and modification methods. Corros. Rev. 2015, 33, 119–137. [Google Scholar] [CrossRef]

- Yang, H.H.; Wang, Y.L.; Wang, X.S.; Pan, P.; Jia, D.W. Synergistic effect of corrosion environment and stress on the fatigue damage behavior of Al alloys. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1309–1316. [Google Scholar] [CrossRef]

- ASTM. Standard Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials Annual Book of ASTM Standards (2004) USA; ASTM E468-90; ASTM: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Zheng, R.Y.; Yan, J.S. New estimation method of three-parameter Weibull distribution. J. Mech. Strength 2002, 24, 599–601. (In Chinese) [Google Scholar]

- Lu, Z.J.; Zhang, S.L.; Liu, X.F.; Liu, C.H. Some problems of Weibull distribution. Qual. Reliab. 2007, 32, 9–13. [Google Scholar]

- Cooper, K.R.; Kelly, R.G. Crack tip chemistry and electrochemistry of environmental cracks in AA 7075. Corros. Sci. 2007, 49, 2636–2662. [Google Scholar] [CrossRef]

- Li, X.D.; Wang, X.S.; Ren, H.H.; Chen, Y.L.; Mu, Z.T. Effect of prior corrosion state on the fatigue small cracking behavior of 6151-T6 aluminum alloy. Corros. Sci. 2012, 55, 26–33. [Google Scholar] [CrossRef]

- Wittke, P.; Klein, M.; Walther, F. Chemical-Mechanical Characterization of the Creep-Resistant Mg-Al-Ca Alloy DieMag422 Containing Barium-Quasistatic and Cyclic Deformation Behavior in Different Defined Corrosion Conditions. Mater. Test. 2014, 56, 16–23. [Google Scholar] [CrossRef]

- Goranson, U.G. Elements of structural integrity assurance. Int. J. Fatigue 1994, 16, 43–65. [Google Scholar] [CrossRef]

- Dhinakaran, S.; Prakash, R.V. Effect of low cyclic frequency on fatigue crack growth behavior of Mn-Ni-Cr steel in air and 3.5% NaCl solution. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2014, 609, 204–208. [Google Scholar] [CrossRef]

- Huang, X.; Liu, J.Z.; Ma, S.J.; Hu, B.R. Sensitivity analysis of the parameters in detail fatigue rating equation. Acta Aeronaut. ET Astronaut. Sin. 2012, 33, 863–870. (In Chinese) [Google Scholar]

- Sakin, R.; Ay, İ. Statistical analysis of bending fatigue life data using Weibull distribution in glass-fiber reinforced polyester composites. Mater. Des. 2008, 29, 1170–1181. [Google Scholar] [CrossRef]

- Sivapragash, M.; Lakshminarayanan, P.R.; Karthikeyan, R.; Raghukandan, K.; Hanumantha, M. Fatigue life prediction of ZE41A magnesium alloy using Weibull distribution. Mater. Des. 2008, 29, 1549–1553. [Google Scholar] [CrossRef]

| Material | Ultimate Tensile Strength | Offset Yield Strength | Elongation | Young’s Modulus |

|---|---|---|---|---|

| 25CrMo steel | 678 MPa | 520 MPa | 21.2% | 205 GPa |

| Condition | m | b (×105) | (×105) | c (×105) | Ρ′ | E(x) (×105) | S(x) (×105) | β |

|---|---|---|---|---|---|---|---|---|

| 273.0 MPa 3.5 wt % NaCl | 3.44 | 5.47 | 5.10 | 1.81 | 0.96 | 4.92 | 1.58 | 3.11 |

| 233.3 MPa 5.0 wt % NaCl | 2.08 | 6.51 | 6.00 | 2.42 | 0.84 | 5.77 | 2.91 | 1.98 |

| Testing Conditions | No. 1 ×105 | No. 2 ×105 | No. 3 ×105 | No. 4 ×105 | No. 5 ×105 | No. 6 ×105 | No. 7 ×105 | No. 8 ×105 | No. 9 ×105 | No. 10 ×105 |

|---|---|---|---|---|---|---|---|---|---|---|

| 273.0 MPa 3.5 wt % NaCl | 3.588 | 4.351 | 4.676 | 4.819 | 4.830 | 5.068 | 5.310 | 5.690 | 5.711 | 6.911 |

| 233.3 MPa 5.0 wt % NaCl | 3.942 | 3.987 | 5.440 | 5.779 | 5.799 | 5.811 | 6.200 | 6.446 | 6.590 | 9.386 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-L.; Wang, X.-S.; Wu, S.-C.; Yang, H.-H.; Zhang, Z.-H. High-Cycle Microscopic Severe Corrosion Fatigue Behavior and Life Prediction of 25CrMo Steel Used in Railway Axles. Metals 2017, 7, 134. https://doi.org/10.3390/met7040134

Wang Y-L, Wang X-S, Wu S-C, Yang H-H, Zhang Z-H. High-Cycle Microscopic Severe Corrosion Fatigue Behavior and Life Prediction of 25CrMo Steel Used in Railway Axles. Metals. 2017; 7(4):134. https://doi.org/10.3390/met7040134

Chicago/Turabian StyleWang, Yan-Ling, Xi-Shu Wang, Sheng-Chuan Wu, Hui-Hui Yang, and Zhi-Hao Zhang. 2017. "High-Cycle Microscopic Severe Corrosion Fatigue Behavior and Life Prediction of 25CrMo Steel Used in Railway Axles" Metals 7, no. 4: 134. https://doi.org/10.3390/met7040134