Study of the Influence of Intermix Conditions on Steel Cleanliness

Abstract

1. Introduction

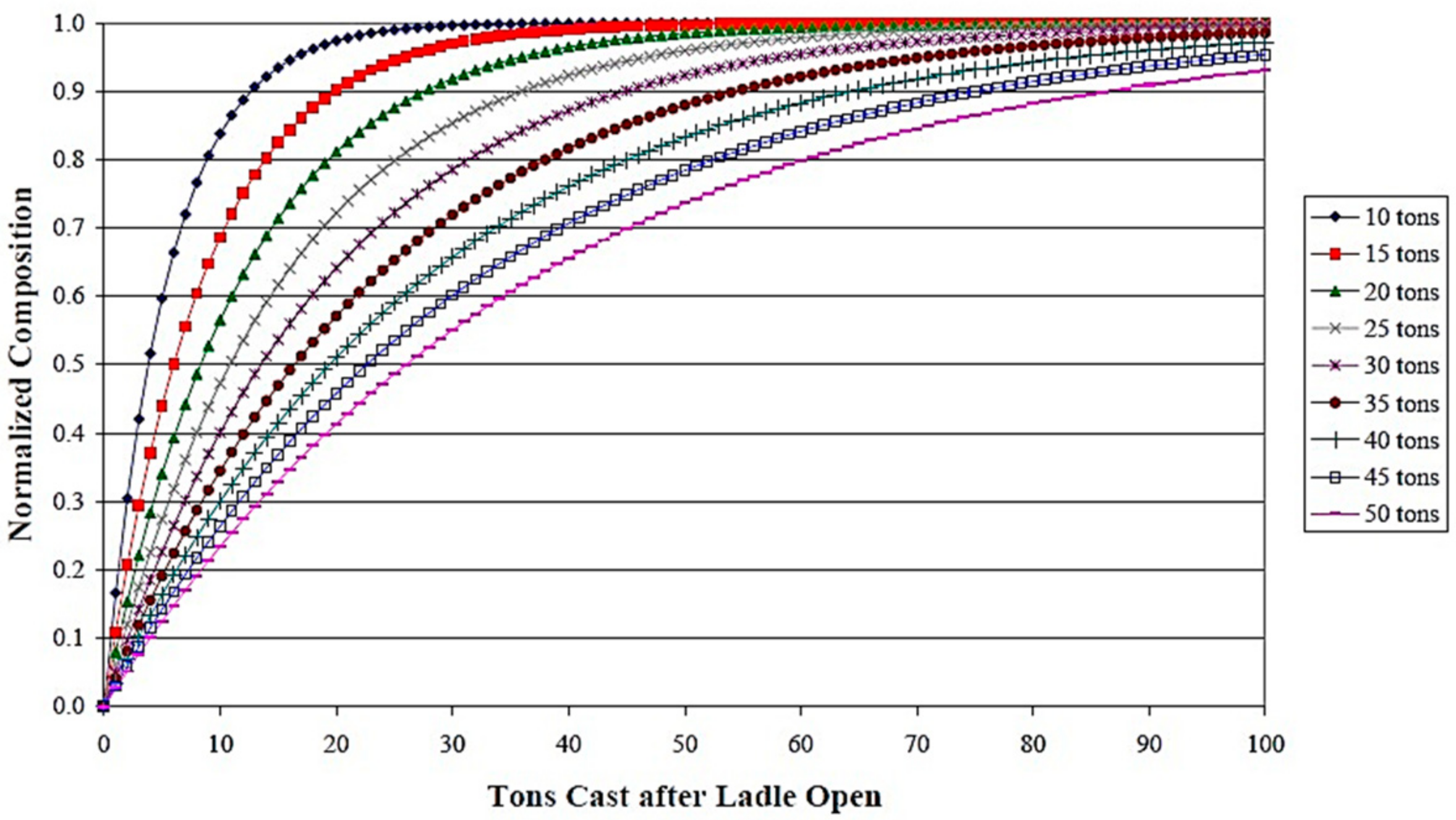

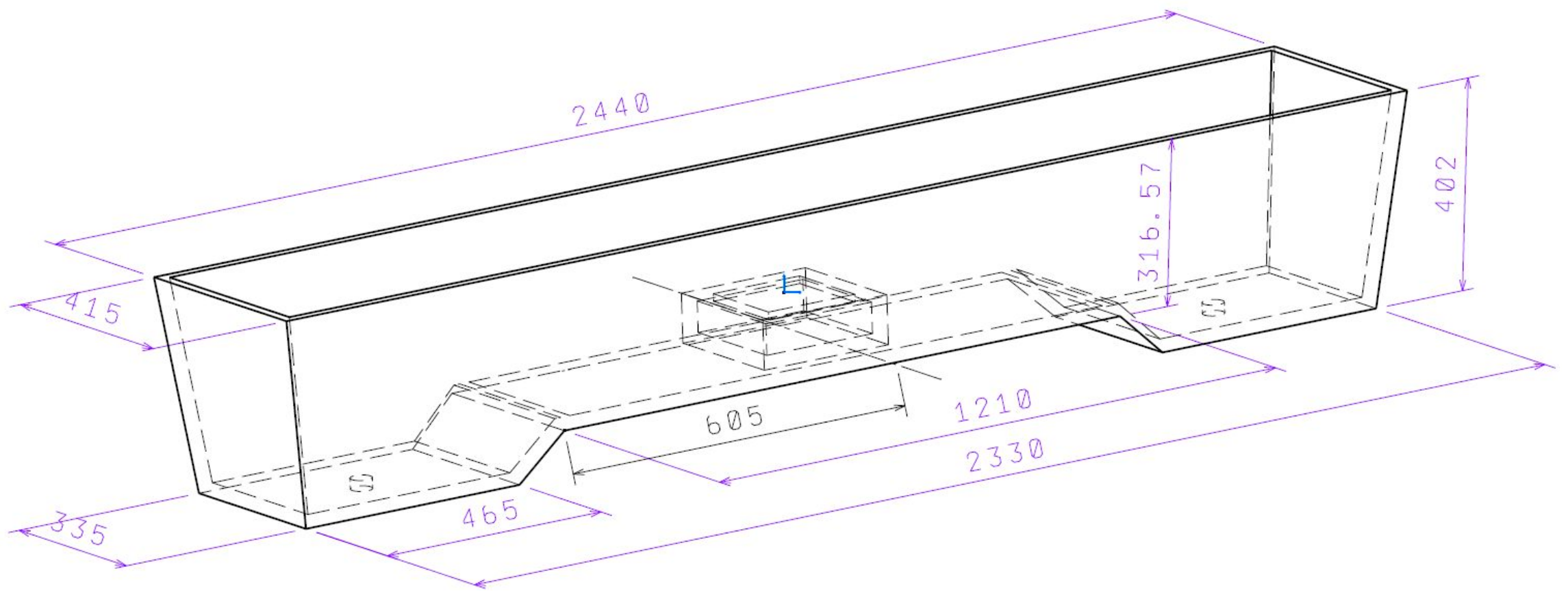

2. Materials and Methods

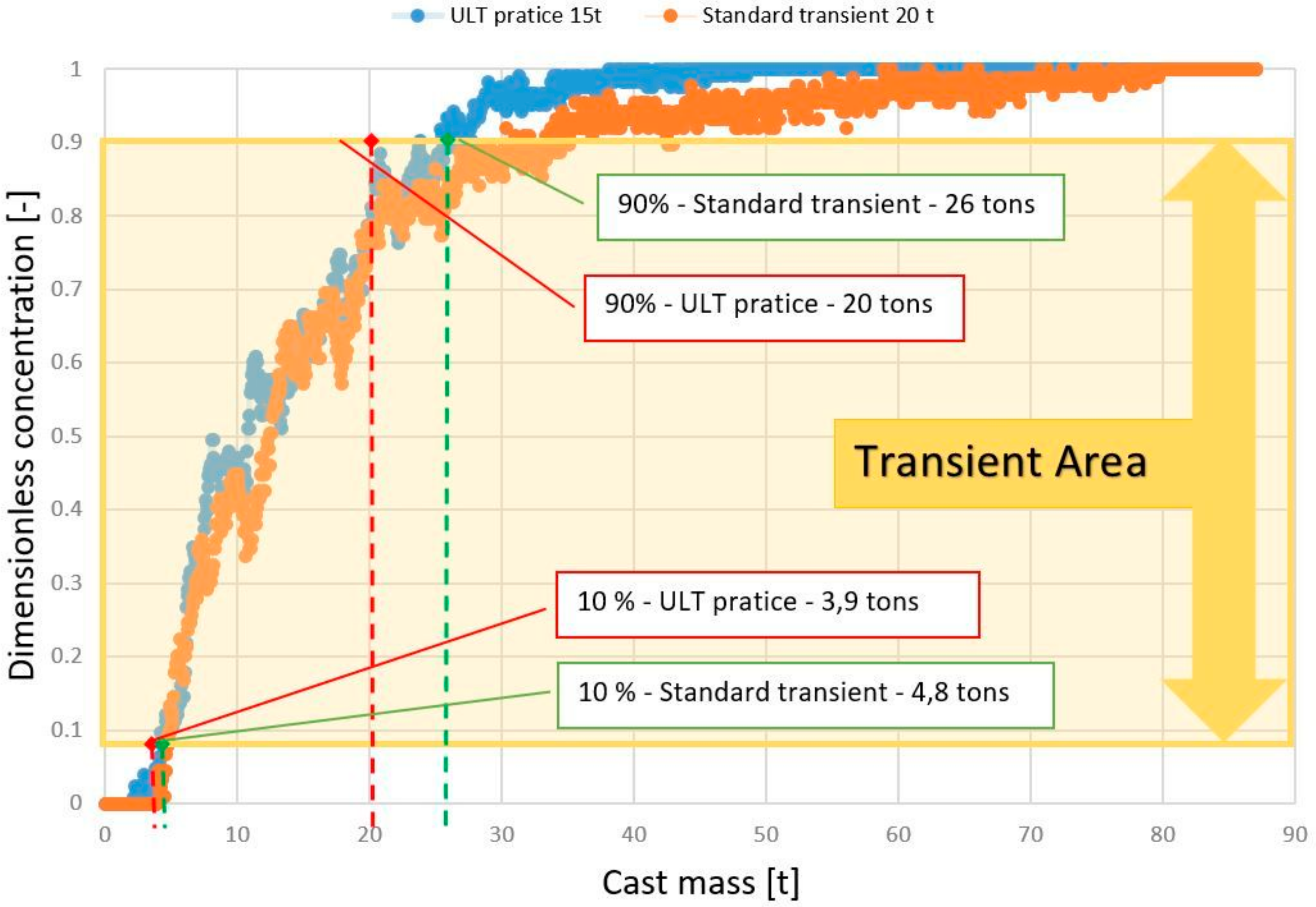

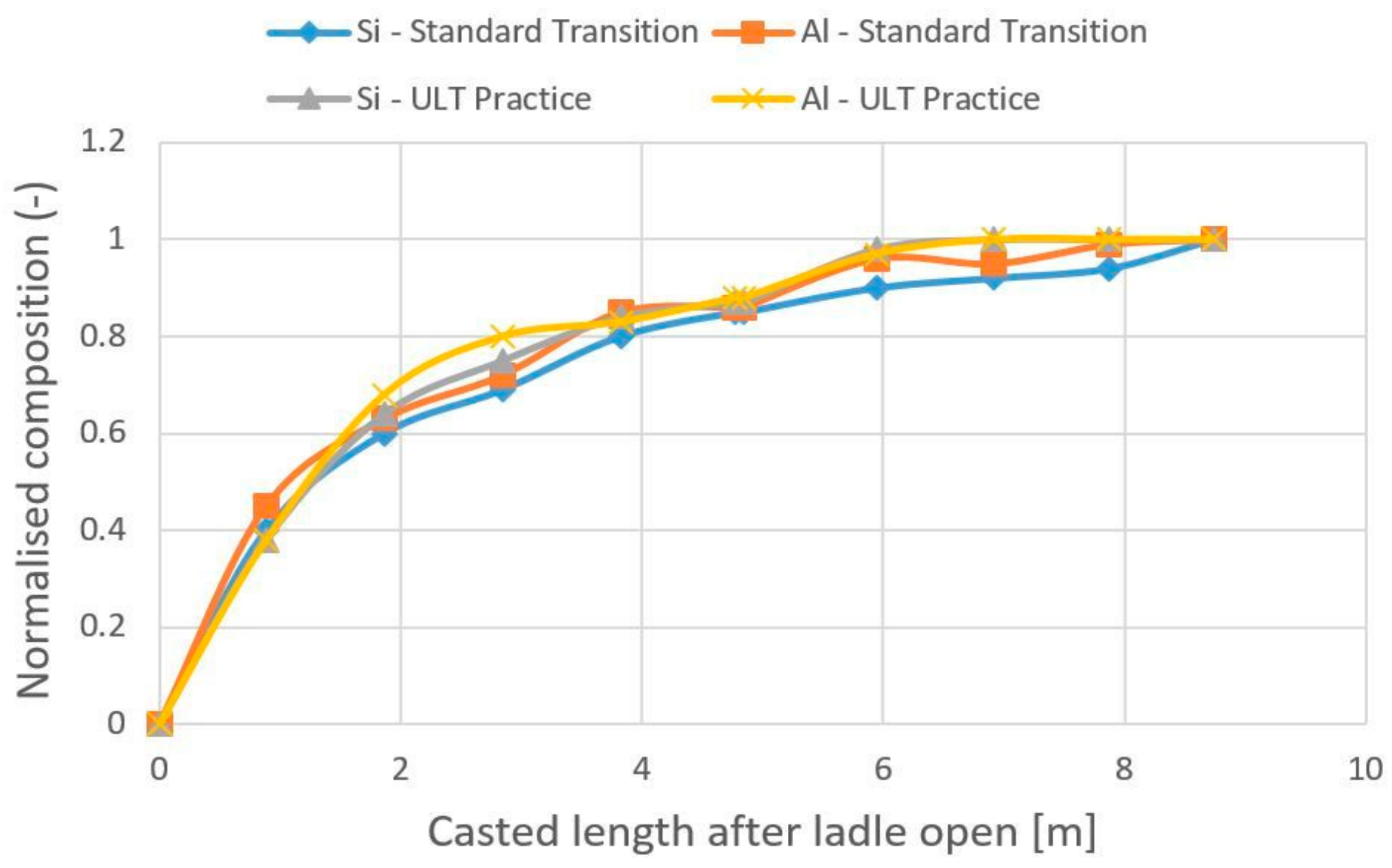

3. Results

4. Discussion

5. Conclusions

Authors Contributions

Funding

Conflicts of Interest

References

- Cho, M.J.; Kim, I.C. Simple Tundish Mixing Model of Continuous Casting during a Grade Transition. ISIJ Int. 2006, 46, 1416–1420. [Google Scholar] [CrossRef]

- Alizdeh, M.; Edris, H.; Pishevar, A.R. Behavior of Mixed Grade during the Grade Transition for Different Conditions in the Slab Continuous Casting. ISIJ Int. 2008, 48, 28–37. [Google Scholar] [CrossRef]

- Braga, B.M.; Tavares, R. Additional Information on “Simple Tundish Mixing Model of Continuous Casting during a Grade Transition” by Cho and Kim. ISIJ Int. 2018, 58, 1178–1180. [Google Scholar] [CrossRef]

- Huang, X.; Thomas, B.G. Modeling of Steel Grade Transition in Continuous Slab Casting Process. Metall. Mater. Trans. B 1993, 24, 379–393. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L. Transient Fluid Flow Phenomena During Continuous Casting: Part II—Cast Speed Change, Temperature Fluctuation and Steel Grades Mixing. ISIJ Int. 2010, 50, 1783–1791. [Google Scholar] [CrossRef]

- Wang, Y.; Wen, X.; Qi, X.; Tang, X. Design of Bottom Height and Flow Control Device of Tundish for Slab Continuous Caster. J. Iron Steel Res. 2006, 13, 274–278. [Google Scholar]

- Morávka, J.; Mrajca, V.; Pindor, J. Possible ways of processing results of transition phenomena occuring in the tundish using approximation methods and their implementaion in field practice. In Proceedings of the 1st International Conference STEELSIM, Brno, Czech Republic, 25–27 October 2005. [Google Scholar]

- Mazumdar, K.D. Transient, Multiphase Simulation of Grade Intermixing in a Tundish under Constant Casting Rate and Validation Against Physical Modeling. JOM 2018, 70, 2139–2147. [Google Scholar] [CrossRef]

- Yeh, J.-L.; Hwang, W.-S.; Chou, C.-L. The Development of a Mathematical Model to Predict Composition Distribution in Casting Slab and Intermix Slab Length during Ladle Changeover Period and Its Verification by Physical Model. ISIJ Int. 1993, 33, 588–594. [Google Scholar] [CrossRef]

- Michalek, K. Využití Fyzikálního a Numerického Modelování pro Optimalizaci Metalurgických Procesů (Utilization of Physical and Numerical Simulation for Optimization of Metallurgical Processes); VŠB—Technical University of Ostrava: Ostrava, Czech Republic, 2001; ISBN 80-7078-861-5. (In Czech) [Google Scholar]

- Michalek, K.; Sawová, M.; Střasák, P. Modelling of transition phenomena in tundish during grade change of CC-Steel. In Proceedings of the 1st International Conference STEELSIM, Brno, Czech Republic, 25–27 October 2005. [Google Scholar]

- Buľko, B.; Kijac, J. Optimization of Tundish Equipment. Acta Metall. Slovaca 2010, 16, 76–83. [Google Scholar]

- Pieprzyca, J.; Merder, T.; Jowsa, J. Method for determining the time constants characterizing the intensity of steel mixing in continuous casting tundish. Arch. Metall. Mater. 2015, 60, 245–249. [Google Scholar] [CrossRef]

- Michalek, K.; Gryc, K.; Tkadlečková, M.; Bocek, D. Model study of tundish steel intermixing and operational verification. Arch. Metall. Mater. 2012, 57, 291–296. [Google Scholar] [CrossRef]

- Jha, P.K.; Kant, S.; Kumar, P.; Kumar, A. Time Zone Analysis of F-Curve for Intermixing during Ladle Change-Over; The Minerals, Metals, & Materials Society: Orlando, FL, USA, 2012. [Google Scholar] [CrossRef]

- Väyrynen, P.J.; Vapalahti, S.K.; Louhenkilpi, S. On Validation of Mathematical Fluid Flow Models for Simulation of Tundish Water Models and Industrial Examples. In Proceedings of the 2008 AISTech, Pittsburgh, PA, USA, 5–8 May 2008; Volume 2, pp. 41–50. [Google Scholar]

- Braun, A.; Pfeifer, H. Investigations of Non-isothermal Flow Conditions in a Two Strand Tundish Water Model using DPIV and PLIF-technique. In Proceedings of the SteelSim 2007—2nd International Conference of Simulation and Modeling of Metallurgical Processes in Steelmaking, Seggauberg, Austria, 12–14 September 2007; pp. 141–146. [Google Scholar]

- Singh, S.; Koria, S.C. Model Study of the Dynamics of Flow of Steel Melt in the Tundish. ISIJ Int. 1993, 33, 1228–1237. [Google Scholar] [CrossRef]

| Mold Width (mm) | Casting Speed (m·min−1) | Theoretical Hourly Production of CCM (tons·h−1) | Tundish Width-to-Length Ratio | Operating Level of Water in Tundish (mm) | Initial Level of Water in Tundish for Simulation of 20-Ton Standard Transition | Initial Level of Water in Tundish for Simulation of 15-Ton ULT Practice |

|---|---|---|---|---|---|---|

| 1250 | 1 | 257.4 | 0.16 | 420 | 200 | 160 |

| Sample | C (%) | Mn (%) | Si (%) | P (%) | S (%) | Al (%) | N (%) |

|---|---|---|---|---|---|---|---|

| Steel grade A | Max. 0.0105 | 0.295–0.405 | 0.895–1.054 | 0.08–0.1 | Max. 0.01 | 0.095–0.165 | Max. 0.007 |

| Steel grade B | 0.003–0.0105 | 0.146–0.305 | 0.595–0.705 | 0.1–0.13 | Max. 0.009 | Max. 0.005 | Max. 0.005 |

| Standard Practice of Joining Steel Grades A and B (20 tons) | |||

|---|---|---|---|

| No. of Sample | Cast Mass during Intermix (tons) | Si Normalized | Al Normalized |

| 1 | 3.78 | 0.430 | 0.450 |

| 2 | 8.5 | 0.604 | 0.634 |

| 3 | 12.58 | 0.683 | 0.733 |

| 4 | 16.65 | 0.795 | 0.847 |

| 5 | 20.73 | 0.850 | 0.885 |

| 6 | 25.49 | 0.904 | 0.962 |

| 7 | 29.53 | 0.915 | 0.962 |

| 8 | 33.69 | 0.925 | 0.992 |

| 9 | 37.73 | 1 | 1 |

| ULT Practice of Joining Steel Grades A and B (15 tons) | |||

|---|---|---|---|

| No. of Sample | Cast Mass during Intermix (tons) | Si Normalized | Al Normalized |

| 1 | 3.45 | 0.372 | 0.372 |

| 2 | 8.15 | 0.661 | 0.669 |

| 3 | 12.44 | 0.775 | 0.804 |

| 4 | 16.27 | 0.846 | 0.831 |

| 5 | 19.95 | 0.913 | 0.908 |

| 6 | 23.44 | 0.966 | 0.953 |

| 7 | 27.76 | 1 | 1 |

| 8 | 31.59 | 1 | 1 |

| 9 | 35.47 | 1 | 1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bul’ko, B.; Molnár, M.; Demeter, P.; Baricová, D.; Pribulová, A.; Futáš, P. Study of the Influence of Intermix Conditions on Steel Cleanliness. Metals 2018, 8, 852. https://doi.org/10.3390/met8100852

Bul’ko B, Molnár M, Demeter P, Baricová D, Pribulová A, Futáš P. Study of the Influence of Intermix Conditions on Steel Cleanliness. Metals. 2018; 8(10):852. https://doi.org/10.3390/met8100852

Chicago/Turabian StyleBul’ko, Branislav, Marek Molnár, Peter Demeter, Dana Baricová, Alena Pribulová, and Peter Futáš. 2018. "Study of the Influence of Intermix Conditions on Steel Cleanliness" Metals 8, no. 10: 852. https://doi.org/10.3390/met8100852

APA StyleBul’ko, B., Molnár, M., Demeter, P., Baricová, D., Pribulová, A., & Futáš, P. (2018). Study of the Influence of Intermix Conditions on Steel Cleanliness. Metals, 8(10), 852. https://doi.org/10.3390/met8100852