Finite Element Simulation of High-Speed Blow Forming of an Automotive Component

Abstract

:1. Introduction

2. FE Simulation Procedure

3. Experiments

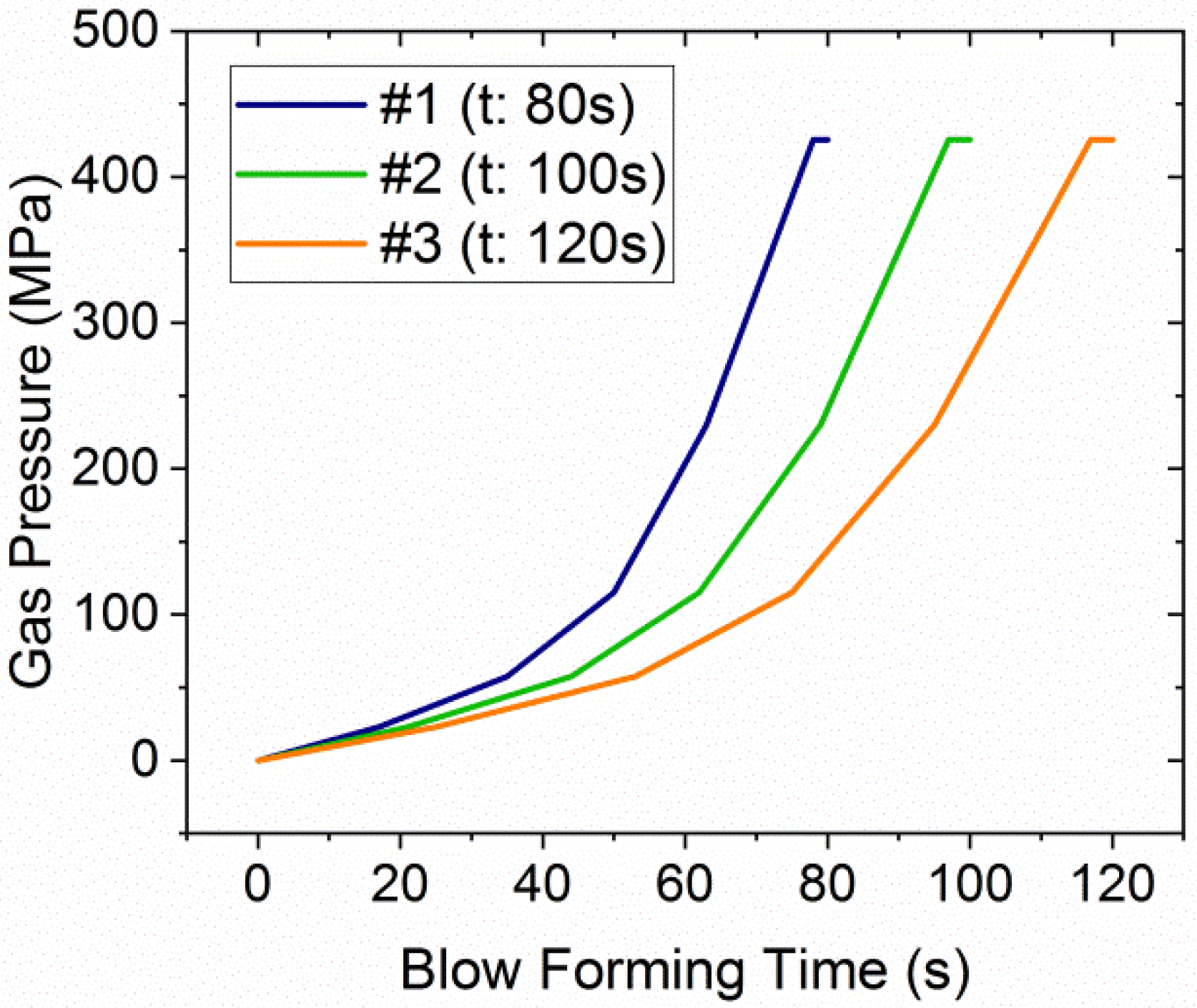

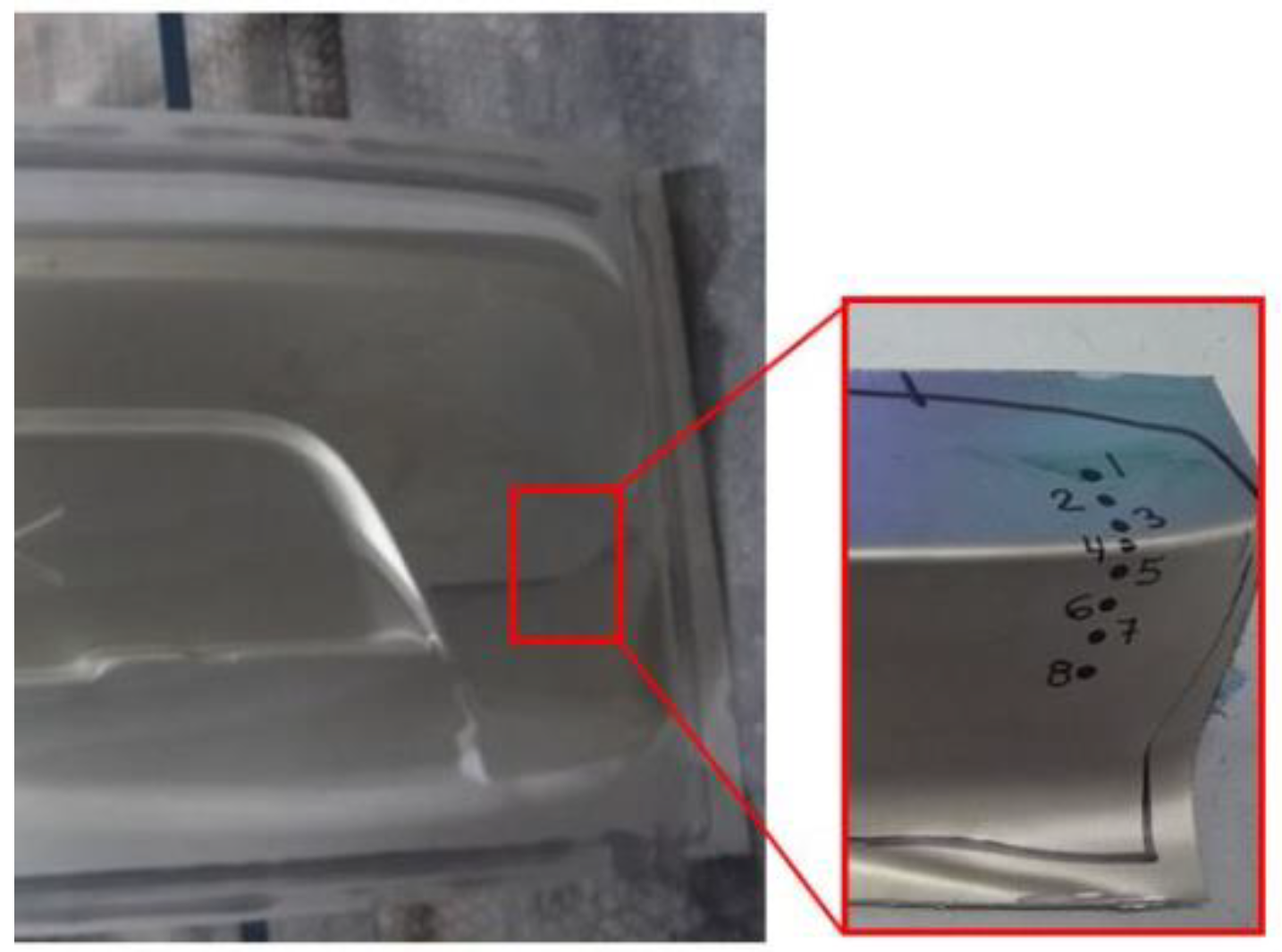

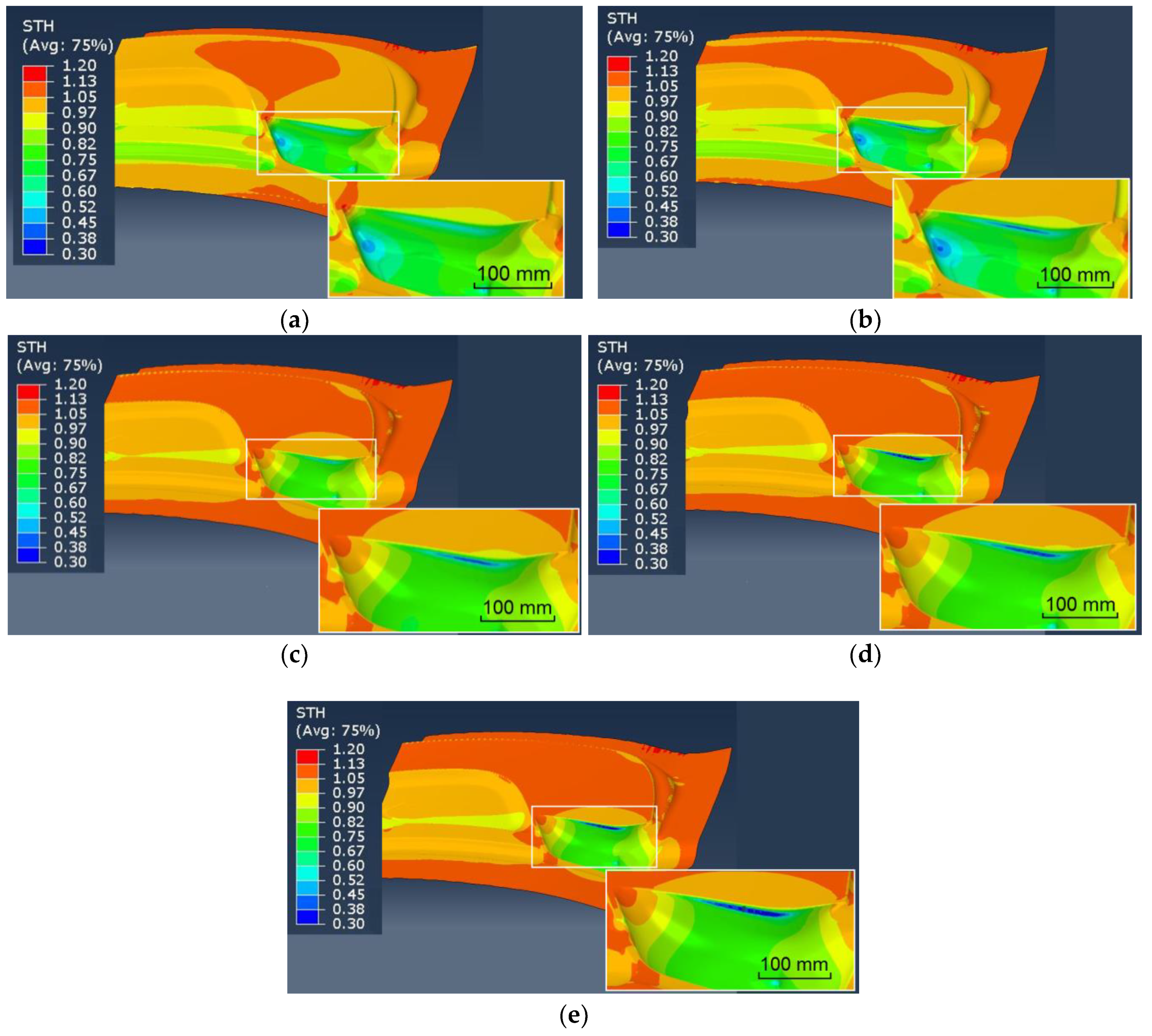

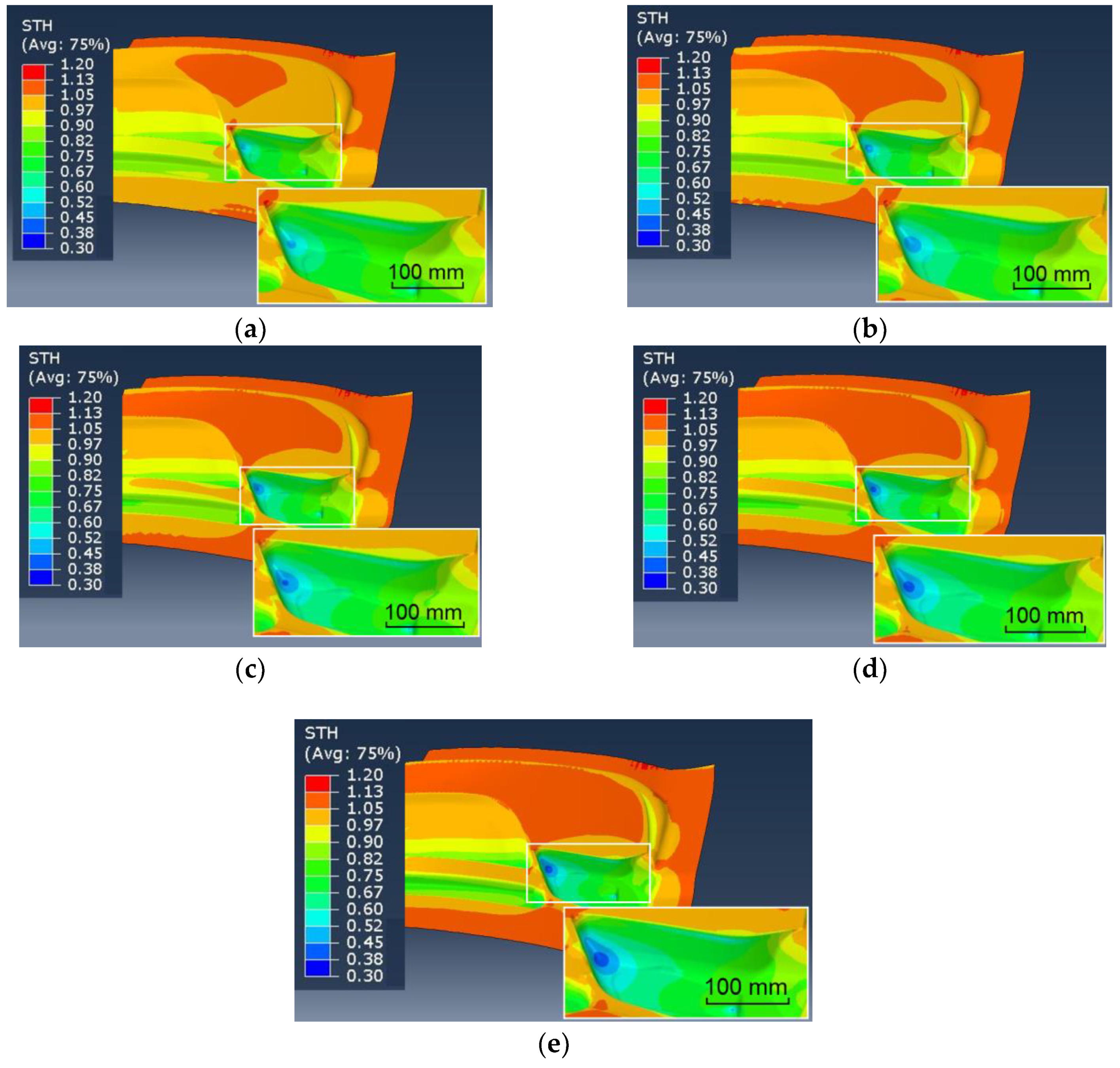

4. Results and Discussion

5. Conclusions

- (1)

- Good agreement was obtained between the numerical simulations using a variable m-value model and the experimental results.

- (2)

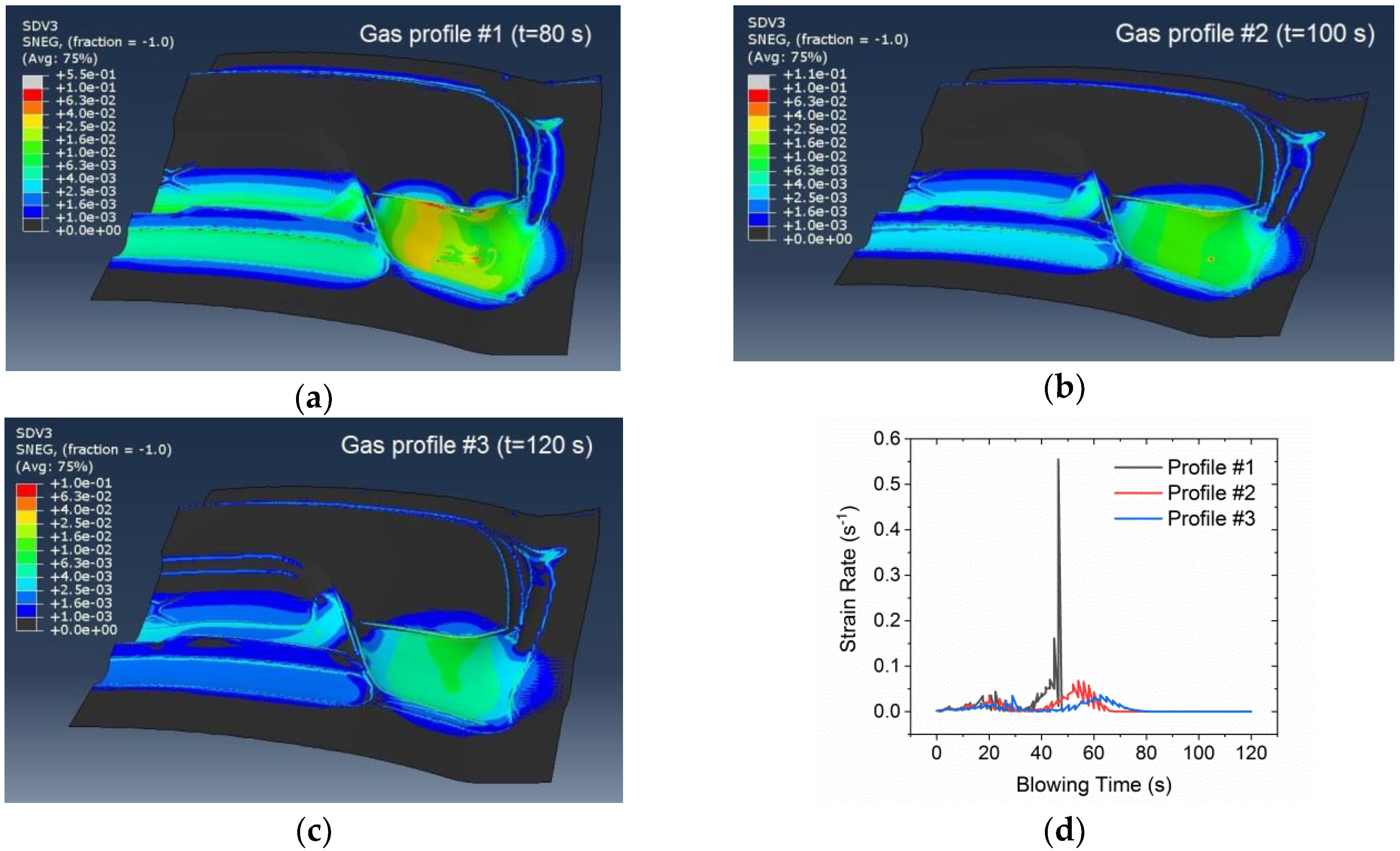

- An excessive thinning and fracture occurred when the forming cycle time was reduced from 120 s to 80 s, which was predicted by the VmV model but not by the power law.

- (3)

- It was shown that both the element size and friction coefficient had significant impacts on the predictions of the thinning. By reducing the element size, the thinning increases while the calculation cost also increases drastically. By increasing the friction coefficient, the amount of thinning was increased, significantly. The best agreement between the experimental observations and the FE simulation predictions was achieved when the friction coefficient was over 0.2.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hefti, L.D. Commercial airplane applications of superplastically formed AA5083 aluminum sheet. J. Mater. Eng. Perf. 2007, 16, 136–141. [Google Scholar] [CrossRef]

- Barnes, A.J. Industrial applications of superplastic forming: trends and prospects. Mater. Sci. Forum 2001, 357, 3–16. [Google Scholar] [CrossRef]

- Friedman, P.A.; Luckey, S.G. On the expanded usage of superplastic forming of aluminium sheet for automotive applications. Mater. Sci. Forum 2004, 447, 199–204. [Google Scholar] [CrossRef]

- Sherby, O.D.; Wadsworth, J. Superplasticity—recent advances and future directions. Prog. Mater. Sci. 1989, 33, 169–221. [Google Scholar] [CrossRef]

- Krajewski, P.E.; Schroth, J.G. Overview of quick plastic forming technology. Mater. Sci. Forum 2007, 551, 3–12. [Google Scholar] [CrossRef]

- Liu, J.; Tan, M.J.; Jarfors, A.E.; Fong, K.S.; Castagne, S. Superplastic-like forming of non-superplastic AA5083 combined with mechanical pre-forming. Int. J. Adv. Manuf Technol. 2011, 52, 123–129. [Google Scholar] [CrossRef]

- Luo, Y.; Luckey, S.G.; Friedman, P.A.; Peng, Y. Development of an advanced superplastic forming process utilizing a mechanical pre-forming operation. Int. J. Mach. Tools Manuf. 2008, 48, 1509–1518. [Google Scholar] [CrossRef]

- Schroth, J.G.; Brueggeman, H.M.; Grewal, N.P. Quick plastically formed aluminum doors: design and performance. J. Mater. Eng. Perf. 2007, 16, 339–348. [Google Scholar] [CrossRef]

- Boissiere, R.; Terzi, S.; Blandin, J.J.; Salvo, L. Quick-plastic forming: Similarities and differences with super-plastic forming. In Proceedings of the 6th EUROSPF Conference, Carcassonne, France, 3–5 September 2008. [Google Scholar]

- Prasannavenkatesan, R.; Parker, M.; Laplante, Y.; Bombardier, N.; Rush, B.; Shi, L.I. High speed blow forming processes. U.S. Patent Application No. 14/865,625, 30 March 2017. [Google Scholar]

- Verbom Inc. Available online: https://www.verbom.com/en/aluminium-spf/#5000-alloys-spf (accessed on 1 October 2018).

- Sorgente, D.; Tricarico, L. The role of the numerical simulation in superplastic forming process analysis and optimization. Key Eng. Mater. 2010, 433, 225–234. [Google Scholar] [CrossRef]

- Fereshteh-Saniee, F.; Fakhar, N.; Asgari, M.; Mahmudi, R. A new experimental-numerical approach for studying the effects of gas pressure profile on superplastic forming characteristics of Al-Mg5. 6 alloy. Int. J. Adv. Manuf. Technol. 2017, 91, 1771–1780. [Google Scholar] [CrossRef]

- Nazzal, M.A. Stability analysis and finite element simulations of superplastic forming in the presence of hydrostatic pressure. AIP Conf. Proceed. 2018, 1957, 050006. [Google Scholar] [CrossRef]

- Sorgente, D.; Tricarico, L. Characterization of a superplastic aluminium alloy ALNOVI-U through free inflation tests and inverse analysis. Int. J. Mater. Form. 2014, 7, 179–187. [Google Scholar] [CrossRef]

- Giuliano, G. Multiphase Gas Blow Forming of AA2017. J. Test. Eval. 2019, 47. [Google Scholar] [CrossRef]

- Khraisheh, M.; Zbib, H.; Hamilton, C.; Bayoumi, A. Constitutive modeling of superplastic deformation. Part I: Theory and experiments. Int. J. Plast. 1997, 13, 143–164. [Google Scholar] [CrossRef]

- Majidi, O.; Jahazi, M.; Bombardier, N. A Viscoplastic Model Based on a Variable Strain Rate Sensitivity Index for Superplastic Sheet Metals. Int. J. Mater. Form. 2018, 1–10. [Google Scholar] [CrossRef]

- Ridley, N. Metals for superplastic forming. In Superplastic Forming of Advanced Metallic Materials: Methods and Applications; Giuliano, G., Ed.; Woodhead Publishing: Cambridge, UK, 2011; pp. 3–33. ISBN 978-1-84569-753-2. [Google Scholar]

- Majidi, O.; Jahazi, M.; Bombardier, N.; Samuel, E. Variation of strain rate sensitivity index of a superplastic aluminum alloy in different testing methods. AIP Conf. Proceed. 2017, 1896, 020022. [Google Scholar] [CrossRef]

- Majidi, O.; Jahazi, M.; Bombardier, N. Characterization of mechanical properties and formability of a superplastic Al-Mg alloy. J. Phys. Conf. Series 2018, 1063, 012165. [Google Scholar] [CrossRef]

| m0 | m1 | g1 | g2 | h1 | h2 | h3 | h4 | f0 | φ |

|---|---|---|---|---|---|---|---|---|---|

| −0.667 | 3.97 | −0.074 | 0.043 | 0.59 | 0.71 | −0.44 | 0.28 | 0.0008 | 3.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Majidi, O.; Jahazi, M.; Bombardier, N. Finite Element Simulation of High-Speed Blow Forming of an Automotive Component. Metals 2018, 8, 901. https://doi.org/10.3390/met8110901

Majidi O, Jahazi M, Bombardier N. Finite Element Simulation of High-Speed Blow Forming of an Automotive Component. Metals. 2018; 8(11):901. https://doi.org/10.3390/met8110901

Chicago/Turabian StyleMajidi, Omid, Mohammad Jahazi, and Nicolas Bombardier. 2018. "Finite Element Simulation of High-Speed Blow Forming of an Automotive Component" Metals 8, no. 11: 901. https://doi.org/10.3390/met8110901